Page 1

BQZ-Line

01/15/11

CondensingUnits

PRODUCTDATA&

SPECIFICATIONS

BulletinB40-BQZ-PDS-1

1090652

Outdoor Air-Cooled

Scroll Condensing Units

1 to 6 HP -

Medium and Low

Temperature Refrigeration

CONTENTS

Page

Nomenclature.....................................................................................................................

Features and Options ........................................................................................................

Capacity Data (Imperial and Metric)...................................................................................

Electrical Data....................................................................................................................

Dimensional Data...............................................................................................................

Specications.....................................................................................................................

Sound Data........................................................................................................................

Wiring Diagrams ...............................................................................................................

EC Motor Application.........................................................................................................

Generic Service Parts List..................................................................................................

Warranty.............................................................................................................................

Project Information.............................................................................................................

“As Built” Service Parts List................................................................................................

For the latest product updates and further information, visit www.ballyrefboxes.com

11 - 13

14 - 16

2

2 - 3

4 - 7

8

9

10

10

17

19

19

BACK

Page 2

ModelName

B40-BQZ-PDS-1

- 2 -

01/15/11

B = Bally

NOMENCLATURE

BQZA030H8-HT3A

Series

A = Latest Catalog Series

ModelSeries

QZ = Quiet Scroll Air Cooled Condensing Unit Line

CompressorManufacturer

A = Copeland

NominalHP

010 - 060 = 1 - 6 HP

ApplicationRange

H = High and Med Temp

M = Med Temp

E = Extended Medium Temperature

L = Low Temp

• Heavy duty weatherproof construction

• High efciency enhanced tube and n condenser design

• High efciency EC variable speed motor as head pressure control

• Receiver with fusible plug and liquid shut-off valve

• Liquid injection (low temperature models)

• Adjustable low pressure control and xed high pressure control

• Discharge thermostat on applicable models only

Voltage*

S2 = 208/230-1-60* S3 = 230-1-60

S6 = 200/220-1-50 S7 = 200-1-50*

T3 = 208/230-3-60 T4 = 460-3-60

T7 = 200/220-3-50 T9 = 380/400-3-50

STANDARDFEATURES

• Copeland Scroll compressors

• Painted cabinet

TM

• Gold Coat

• Crankcase heater

• Time delay relay

ns

Enclosure

H = Outdoor

Refrigerant*

6 = R404A / R507*

7 = R407C

8 = R404A / R507 / R22 / R407C

*subjecttocompressoravailability

OPTIONALACCESSORIES

• Sealed liquid line lter drier and sight glass

• Suction accumulator

• Sealed suction lter

• Heated and insulated receiver - required in ambients below 10°F

• Non-fused disconnect switch

• Pump down toggle switch

• Mechanical time clock

• Sound insulated compressor compartment *

• Wall mount kit

• Oil seperator (2 fan models only)

* see sound data table on page 10

Page 3

OPTIONALFEATUREPACKAGES

B40-BQZ-PDS-1

- 3 -

01/15/11

(FactoryMounted)

Package A:

• Standard Features (see pg. 2)

Package B:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

Package C:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Suction Accumulator

• Plus Mechanical Time Clock

Package D:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Heated and Insulated Receiver

(required in ambients below 10°F)

Package E:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Heated and Insulated Receiver

(required in ambients below 10°F)

• Plus Suction Accumulator

• Plus Mechanical Time Clock

Package F:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Mechanical Time Clock

Package G:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Heated and Insulated Receiver

(required in ambients below 10°F)

• Plus Mechanical Time Clock

Package H:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Suction Accumulator

• Plus Heated and Insulated Receiver

(required in ambients below 10°F)

Package J:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Compressor Compartment Sound Insulation

Package K:

• Standard Features (see pg. 2)

• Plus Sealed Liquid Line Filter Drier & Sight Glass

• Plus Compressor Compartment Sound Insulation

• Plus Mechanical Time Clock

Page 4

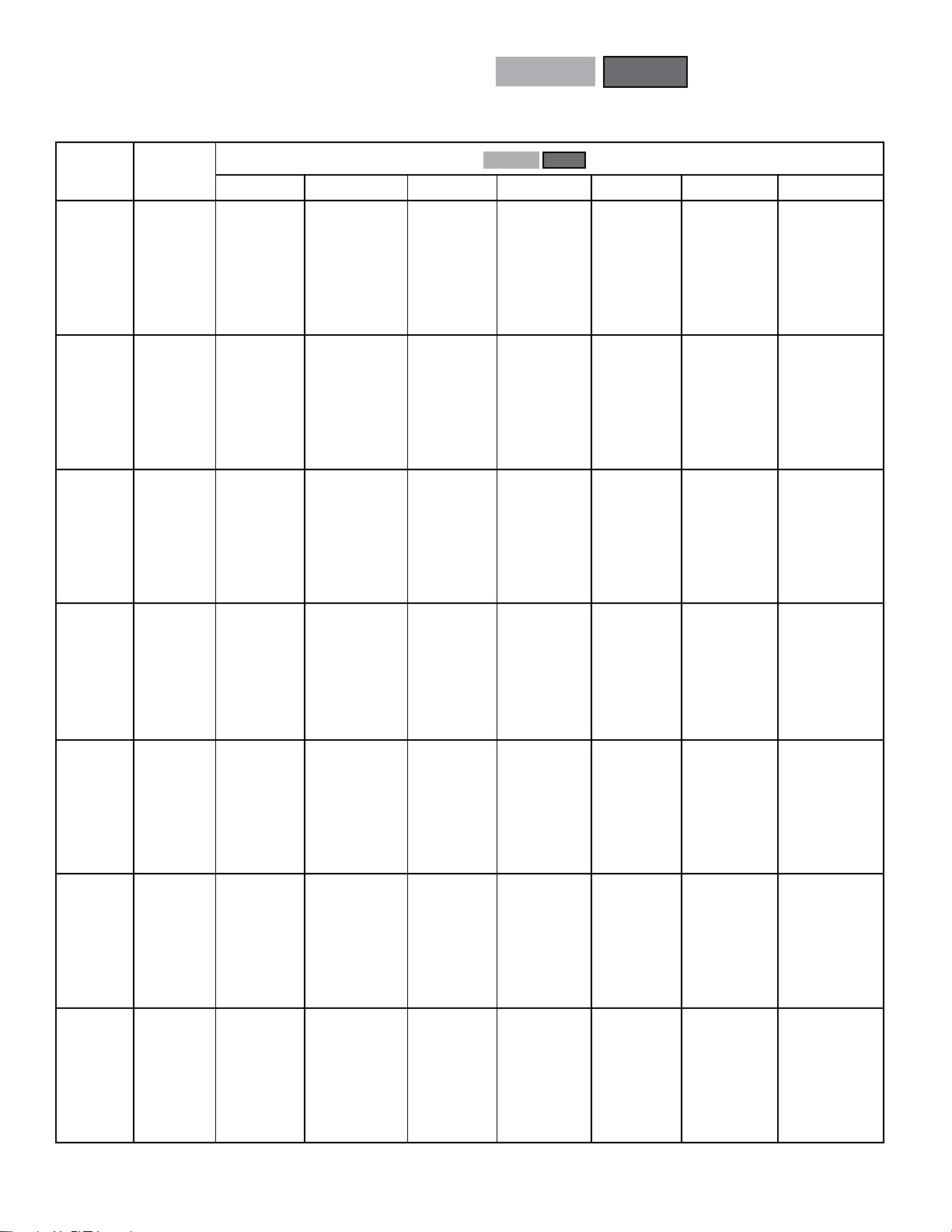

BQZA

B40-BQZ-PDS-1

- 4 -

01/15/11

COPELAND

CAPACITYDATA-

R404A

R507

HIGH/MEDIUMTEMPERATURE

60Hz

SATURATED

MODEL

BQZA020H8 30 (-1.1) 22770 (6672) 21870 (6408) 20960 (6141) 20030 (5869) 19090 (5593) 18120 (5309) 17150 (5025)

Compressor 15 (-9.4) 17540 (5139) 16840 (4934) 16150 (4732) 15440 (4524) 14700 (4307) 13950 (4087) 13190 (3865)

Model 10 (-12.2) 15960 (4676) 15340 (4495) 14700 (4307) 14050 (4117) 13390 (3923) 12710 (3724) 12000 (3516)

ZB15KCE 5 (-15) 14480 (4243) 13910 (4076) 13340 (3909) 12750 (3736) 12150 (3560) 11520 (3375) 10880 (3188)

BQZA025H8 30 (-1.1) 27280 (7993) 26160 (7665) 25020 (7331) 23870 (6994) 22680 (6645) 21480 (6294) 20250 (5933)

Compressor 15 (-9.4) 21170 (6203) 20310 (5951) 19440 (5696) 18530 (5429) 17610 (5160) 16660 (4881) 15700 (4600)

Model 10 (-12.2) 19320 (5661) 18540 (5432) 17730 (5195) 16920 (4958) 16080 (4711) 15210 (4457) 14320 (4196)

ZB19KCE 5 (-15) 17570 (5148) 16860 (4940) 16130 (4726) 15380 (4506) 14620 (4284) 13830 (4052) 13010 (3812)

BQZA030H8 30 (-1.1) 32430 (9502) 31090 (9109) 29730 (8711) 28340 (8304) 26930 (7890) 25490 (7469) 24020 (7038)

Compressor 15 (-9.4) 25200 (7384) 24170 (7082) 23110 (6771) 22040 (6458) 20940 (6135) 19800 (5801) 18640 (5462)

Model 10 (-12.2) 23010 (6742) 22070 (6467) 21

ZB21KCE 5 (-15) 20930 (6132) 20080 (5883) 19200 (5626) 18310 (5365) 17390 (5095) 16440 (4817) 15470 (4533)

BQZA035H8 30 (-1.1) 40390 (11840) 38820 (11380) 37230 (10910) 35610 (10440) 33960 (9950) 32290 (9460) 30580 (8960)

Compressor 15 (-9.4) 31000 (9090) 29800 (8730) 28580 (8380) 27330 (8010) 26060 (7640) 24770 (7260) 23440 (6870)

Model 10 (-12.2) 28180 (8260) 27100 (7940) 26000 (7620) 24860 (7290) 23710 (6950) 22520 (6600) 21300 (6240)

ZB26KCE 5 (-15) 25550 (7490) 24570 (7200) 23570 (6910) 22540 (6610) 21490 (6300) 20410 (5980) 19300 (5660)

BQZA040H8 30 (-1.1) 46520 (13630) 44700 (13100) 42850 (12560) 40960 (12000) 39040 (11440) 37080 (10870) 35080 (10280)

Compressor 15 (-9.4) 35460 (10390) 34080 (9990) 32670 (9570) 31230 (9150) 29740 (8720) 28220 (8270) 26660 (7810)

Model 10 (-12.2) 32140 (9420) 30890 (9050) 29600 (8670) 28290 (8290) 26930 (7890) 25540 (7490) 24110 (7070)

ZB30KCE 5 (-15) 29010 (8500) 27870 (8170) 26700

BQZA050H8 30 (-1.1) 55670 (16320) 53460 (15670) 51200 (15010) 48910 (14330) 46570 (13650) 44190 (12950) 41770 (12240)

Compressor 15 (-9.4) 43000 (12600) 41300 (12100) 39560 (11590) 37790 (11080) 35980 (10540) 34130 (10000) 32220 (9440)

Model 10 (-12.2) 39190 (11490) 37640 (11030) 36070 (10570) 34450 (10100) 32790 (9610) 31100 (9110) 29350 (8600)

ZB38KCE 5 (-15) 35570 (10420) 34190 (10020) 32750 (9600) 31290 (9170) 29780 (8730) 28230 (8270) 26640 (7810)

BQZA060H8 30 (-1.1) 65430 (19180) 62800 (18400) 60120 (17620) 57410 (16830) 54640 (16010) 51830 (15190) 48950 (14350)

Compressor 15 (-9.4) 50640 (14840) 48630 (14250) 46570 (13650) 44460 (13030) 42300 (12400) 40100 (11750) 37830 (11090)

Model 10 (-12.2) 46180 (13530) 44340 (12990) 42470 (12450) 40550 (11880) 38580 (11310) 36560 (10710) 34480 (10110)

ZB45KCE 5 (-15) 41950 (12290) 40290 (11810) 38590 (11310) 36840 (10800) 35060 (10280) 33210 (9730) 31310 (9180)

SUCTION

TEMP.

F° (C°)

40 (4.4) 26690 (7820) 25640 (7513) 24570 (7199) 23490 (6883) 22390 (6560) 21270 (6232) 20130 (5898)

35 (1.7) 24700 (7237) 23720 (6950) 22730 (6660) 21720 (6364) 20710 (6068) 19670 (5763) 18610 (5453)

25 (-3.9) 20940 (6135) 20120 (5895) 19280 (5649) 18420 (5397) 17560 (5145) 16660 (4881) 15760 (4618)

20 (-6.7) 19190 (5623) 18440 (5403) 17670 (5177) 16880 (4946) 16090 (4714) 15280 (4477) 14440 (4231)

0 (-17.8) 13080 (3832) 12580 (3686) 12050 (3531) 11530 (3378) 10970 (3214) 10410 (3050) 9830 (2880)

-5 (-20.6)

40 (4.4) 31790 (9314) 30480 (8931) 29160 (8544) 27810 (8148) 26450 (7750) 25050 (7340) 23650 (6929)

35 (1.7) 29490 (8641) 28280 (8286) 27050 (7926) 25800 (7559) 24530 (7187) 23240 (6809) 21910 (6420)

25 (-3.9) 25150 (7369) 24120 (7067) 23070 (6760) 22010 (6449) 20920 (6130) 19800 (5801) 18670 (5470)

20 (-6.7) 23110 (6771) 22180 (6499) 21210 (6215) 20220 (5924) 19230 (5634) 18200 (5333) 17150 (5025)

0 (-17.8) 15910 (4662) 15280 (4477) 14620 (4284) 13930 (4081) 13240 (3879) 12520 (3668) 11770 (3449)

-5 (-20.6)

40 (4.4) 37770 (11067) 36200 (10607) 34620 (10144) 33010 (9672) 31370 (9191) 29720 (8708) 28020 (8210)

35 (1.7) 35050 (10270) 33600 (9845) 32130 (9414) 30630 (8975) 29110 (8529) 27560 (8075) 25980 (7612)

25 (-3.9)

20 (-6.7) 27500 (8058) 26380 (7729) 25220 (7389) 24050 (7047) 22850 (6695) 21610 (6332) 20350 (5963)

0 (-17.8) 18960 (5555) 18200 (5333) 17400 (5098) 16590 (4861) 15750 (4615) 14890 (4363) 14000 (4102)

-5 (-20.6)

40 (4.4) 47470 (13910) 45620 (13370) 43750 (12820) 41850 (12260) 39930 (11700) 37970 (11130) 35980 (10540)

35 (1.7) 43850 (12850) 42150 (12350) 40410 (11840) 38660 (11330) 36880 (10810) 35060 (10280) 33210 (9730)

25 (-3.9) 37100 (10870) 35660 (10450) 34200 (10020) 32710 (9590) 31200 (9140) 29640 (8690) 28070 (8230)

20 (-6.7) 33960 (9950) 32640 (9570) 31310 (9180) 29950 (8780) 28560 (8370) 27140 (7950) 25680 (7530)

0 (-17.8) 23070 (6760) 22190 (6500) 21280 (6240) 20360 (5970) 19400 (5690) 18430 (5400) 17410 (5100)

-5 (-20.6)

40 (4.4) 54770 (16050) 52630 (15420) 50440 (14780) 48230 (14130) 45970 (13470) 43670 (12800) 41330 (12110)

35 (1.7) 50560 (14820) 48580 (14240) 46570 (13650) 44520 (13050) 42430 (12430) 40310 (11810) 38140 (11180)

25 (-3.9) 42650 (12500) 40990 (12010) 39290 (11510) 37560 (11010) 35790 (10490) 33990 (9960) 32140 (9420)

20 (-6.7) 38970 (11420) 37450 (10980) 35900 (10520) 34310 (10060) 32700 (9580) 31040 (9100) 29340 (8600)

0 (-17.8) 26060 (7640) 25020 (7330) 23950 (7020) 22860 (6700) 21720 (6370) 20560 (6030) 19360 (5670)

-5 (-20.6)

40 (4.4) 651

35 (1.7) 60290 (17670) 57890 (16970) 55450 (16250) 52960 (15520) 50440 (14780) 47880 (14030) 45270 (13270)

25 (-3.9) 51250 (15020) 49200 (14420) 47130 (13810) 45020 (13190) 42870 (12560) 40680 (11920) 38430 (11260)

20 (-6.7) 47020 (13780) 45150 (13230) 43250 (12680) 41320 (12110) 39330 (11530) 37320 (10940) 35250 (10330)

0 (-17.8) 32180 (9430) 30920 (9060) 29630 (8680) 28310 (8300) 26940 (7900) 25530 (7480) 24070 (7050)

-5 (-20.6)

40 (4.4) 76400 (22390) 73320 (21490) 70200 (20570) 67040 (19650) 63830 (18710) 60560 (17750) 57250 (16780)

35 (1.7) 70810 (20750) 67960 (19920) 65070 (19070) 62130 (18210) 59150 (17340) 56100 (16440) 53010 (15540)

25 (-3.9) 60270 (17660) 57860 (16960) 55400 (16240) 52890 (15500) 50340 (14750) 47730 (13990) 45070 (13210)

20 (-6.7) 55350 (16220) 53130 (15570) 50870 (14910) 48570 (14230) 46220 (13550) 43820 (12840) 41360 (12120)

0 (-17.8) 37970 (11130) 36470 (10690) 34930 (10240) 33360 (9780) 31730 (9300) 30050 (8810) 28320 (8300)

-5 (-20.6)

80 (26.6) 85 (29.4) 90 (32.2) 95 (35.0) 100 (37.8) 105 (40.6) 110 (43.3)

11780 (3452) 11320 (3317) 10860 (3182) 10370 (3038) 9880 (2895) 9370 (2745) 8830 (2587)

14350 (4205) 13780 (4038) 13190 (3865) 12570 (3683) 11940 (3498) 11290 (3308) 10610 (3109)

29910 (8764) 28690 (8406) 27430 (8037) 26150 (7662) 24840 (7278) 23510 (6888) 22140 (6487)

17100 (5010) 16410 (4808) 15710 (4603) 14970 (4386) 14210 (4164) 13420 (3932) 12610 (3695)

20750 (6080) 19960 (5850) 19140 (5610) 18310 (5370) 17450 (5110) 16560 (4850) 15630 (4580)

23290 (6830) 22330 (6540) 21370 (6260) 20360 (5970) 19320 (5660) 18260 (5350) 17160 (5030)

10 (19080) 62510 (18320) 59870 (17550) 57200 (16760) 54480 (15970) 51720 (15160) 48920 (14340)

28990 (8500) 27870 (8170) 26700 (7820) 25500 (7470) 24270 (7110) 22980 (6730) 21650 (6340)

34220 (10030) 32880 (9640) 31490 (9230) 30060 (8810) 28590 (8380) 27070 (7930) 25480 (7470)

CAPACITYBTU/H(WATTS)

110 (6185) 20130 (5898) 19110 (5599) 18080 (5297) 17010 (4984)

(7820) 25490 (7470) 24260 (7110) 22980 (6730) 21670 (6350)

R404AR507

AMBIENTTEMPERATURE°F(°C)

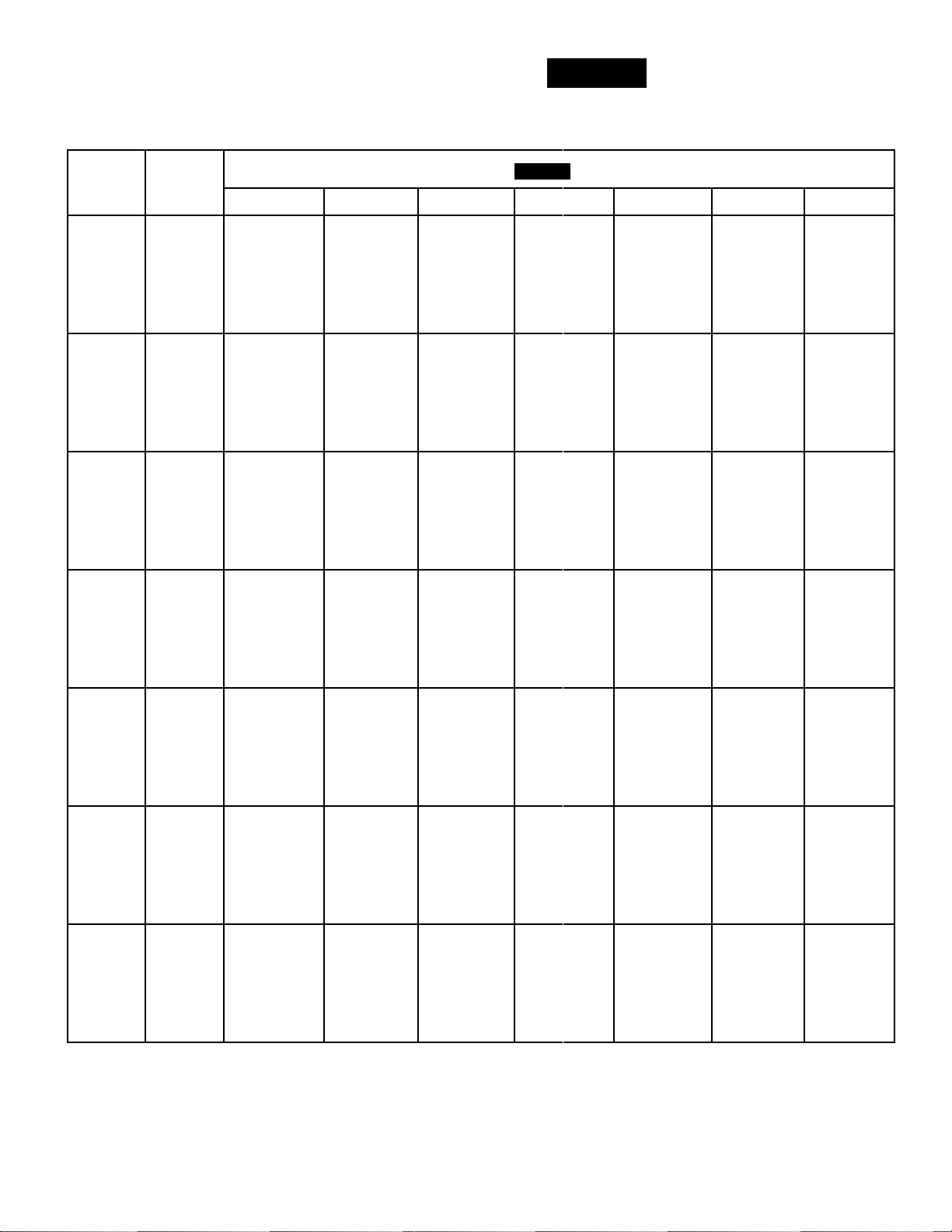

Page 5

BQZA

B40-BQZ-PDS-1

- 5 -

01/15/11

COPELAND

CAPACITYDATA-

R407C

HIGH/MEDIUMTEMPERATURE

60Hz

MODEL

BQZA020H8

Compressor

Model

ZB15KCE

BQZA025H8

Compressor

Model

ZB19KCE

BQZA030H8

Compressor

Model

ZB21KCE

BQZA035H8

Compressor

Model

ZB26KCE

BQZA040H8

Compressor

Model

ZB30KCE

BQZA050H8

Compressor

Model

ZB38KCE

BQZA060H8

Compressor

Model

ZB45KCE

SATURATED

SUCTION

TEMP.

°F ° C

45 (7.2) 27500 (8060) 26700 (7820) 25900 (7590) 25000 (7330) 24200 (7090) 23300 (6830) 22400 (6560)

40 (4.4) 25200 (7390) 24400 (7150) 23700 (6950) 22900 (6710) 22100 (6480) 21300 (6240) 20400 (5980)

35 (1.7) 23000 (6740) 22300 (6540) 21600 (6330) 20900 (6130) 20100 (5890) 19300 (5660) 18500 (5420)

30 (-1.1) 20900 (6130) 20200 (5920) 19600 (5740) 18900 (5540) 18200 (5330) 17500 (5130) 16800 (4920)

25 (-3.9) 18900 (5540) 18300 (5360) 17700 (5190) 17100 (5010) 16500 (4840) 15800 (4630) 15100 (4430)

20 (-6.7) 17100 (5010) 16500 (4840) 16000 (4690) 15400 (4510) 14800 (4340) 14200 (4160) 13500 (3960)

15 (-9.4) 15400 (4510) 14900 (4370) 14400 (4220) 13800 (4040) 13300 (3900) 12700 (3720) 12100 (3550)

10 (-12.2) 13800 (4040) 13300 (3900) 12800 (3750) 12300 (3600) 11800 (3460) 11300 (3310) 10700 (3140)

45 (7.2) 30100 (8820) 29200 (8560) 28200 (8260) 27200 (7970) 26100 (7650) 25000 (7330) 23900 (7000)

40 (4.4) 27400 (8030) 26600 (7800) 25700 (7530) 24700 (7240) 23800 (6980) 22800 (6680) 21700 (6360)

35 (1.7) 24800 (7270) 24100 (7060) 23200 (6800) 22400 (6560) 21500 (6300) 20600 (6040) 19700 (5770)

30 (-1.1) 22400 (6560) 21700 (6360) 21000 (6150) 20200 (5920) 19400 (5690) 18600 (5450) 17800 (5220)

25 (-3.9) 20100 (5890) 19500 (5710) 18800 (5510) 18100 (5300) 17500 (5130) 16700 (4890) 16000 (4690)

20 (-6.7) 18000 (5280) 17400 (5100) 16800 (4920) 16200 (4750) 15600 (4570) 15000 (4400) 14400 (4220)

15 (-9.4) 16000 (4690) 15500 (4540) 15000 (4400) 14400 (4220) 13900 (4070) 13400 (3930) 12800 (3750)

10 (-12.2) 14200 (4160) 13700 (4020) 13300 (3900) 12800 (3750) 12400 (3630) 11900 (3490) 11400 (3340)

45 (7.2) 37800 (11080) 36600 (10730) 35400 (10370) 34100 (9990) 32800 (9610) 31400 (9200) 30100 (8820)

40 (4.4) 34600 (10140) 33500 (9820) 32400 (9500) 31200 (9140) 30000 (8790) 28800 (8440) 27500 (8060)

35 (1.7) 31600 (9260) 30600 (8970) 29500 (8650) 28500 (8350) 27400 (8030) 26300 (7710) 25100 (7360)

30 (-1.1) 28700 (8410) 27800 (8150) 26800 (7850) 25900 (7590) 24900 (7300) 23900 (7000) 22800 (6680)

25 (-3.9) 26000 (7620) 25200 (7390) 24300 (7120) 23400 (6860) 22500 (6590) 21600 (6330) 20700 (6070)

20 (-6.7) 23400 (6860) 22700 (6650) 21900 (6420) 21100 (6180) 20300 (5950) 19500 (5710) 18700 (5480)

15 (-9.4) 21100 (6180) 20400 (5980) 19700 (5770) 19000 (5570) 18300 (5360) 17500 (5130) 16800 (4920)

10 (-12.2) 18800 (5510) 18200 (5330) 17600 (5160) 17000 (4980) 16300 (4780) 15700 (4600) 15000 (4400)

45 (7.2) 47100 (13800) 45800 (13420) 44400 (13010) 43100 (12630) 41600 (12190) 40100 (11750) 38500 (1

40 (4.4) 43300 (12690) 42100 (12340) 40800 (11960) 39500 (11580) 38100 (11170) 36600 (10730) 35100 (10290)

35 (1.7) 39500 (11580) 38400 (11250) 37200 (10900) 35900 (10520) 34600 (10140) 33200 (9730) 31800 (9320)

30 (-1.1) 35800 (10490) 34700 (10170) 33600 (9850) 32500 (9520) 31200 (9140) 30000 (8790) 28600 (8380)

25 (-3.9) 32300 (9470) 31300 (9170) 30300 (8880) 29200 (8560) 28000 (8210) 26800 (7850) 25600 (7500)

20 (-6.7) 29000 (8500) 28100 (8240) 27100 (7940) 26100 (7650) 25100 (7360) 24000 (7030) 22900 (6710)

15 (-9.4) 26100 (7650) 25200 (7390) 24400 (7150) 23500 (6890) 22500 (6590) 21500 (6300) 20500 (6010)

10 (-12.2) 23500 (6890) 22800 (6680) 22000 (6450) 21200 (6210) 20400 (5980) 19500 (5710) 18600 (5450)

45 (7.2) 53300 (15620) 51900 (15210) 50500 (14800) 49000 (14360) 47400 (13890) 45800 (13420) 44200 (12950)

40 (4.4) 48600 (14240) 47300 (13860) 46000 (13480) 44600 (13070) 43100 (12630) 41700 (12220) 40200 (11780)

35 (1.7) 44200 (12950) 43000 (12600) 41700 (12220) 40400 (11840) 39100 (11460) 37800 (11080) 36400 (10670)

30 (-1.1) 40000 (11720) 38900 (11400) 37700 (11050) 36600 (10730) 35400 (10370) 34100 (9990) 32900 (9640)

25 (-3.9) 36100 (10580) 35100 (10290) 34000 (9960) 33000 (9670) 31900 (9350) 30700 (9000) 29600 (8670)

20 (-6.7) 32500 (9520) 31600 (9260) 30600 (8970) 29600 (8670) 28600 (8380) 27600 (8090) 26500 (7770)

15 (-9.4) 29100 (8530) 28300 (8290) 27400 (8030) 26500 (7770) 25600 (7500) 24600 (7210) 23700 (6950)

10 (-12.2) 26100 (7650) 25300 (7410) 24400 (7150) 23600 (6920) 22800 (6680) 21900 (6420) 21100 (6180)

45 (7.2) 65700 (19250) 64100 (18790) 62300 (18260) 60400 (17700) 58500 (17140) 56400 (16530) 54300 (15910)

40 (4.4) 60300 (17670) 58700 (17200) 57100 (16730) 55300 (16210) 53500 (15680) 51600 (15120) 49700 (14570)

35 (1.7) 55100 (16150) 53600 (15710) 52100 (15270) 50500 (14800) 48800 (14300) 47000 (13770) 45200 (13250)

30 (-1.1) 50100 (14680) 48800 (14300) 47300 (13860) 45800 (13420) 44300 (12980) 42700 (12510) 41000 (12020)

25 (-3.9) 45500 (13330) 44200 (12950) 42900 (12570) 41500 (12160) 40100 (11750) 38600 (11310) 37100 (10870)

20 (-6.7) 41100 (12050) 39900 (11690) 38700 (11340) 37400 (10960) 36100 (10580) 34800 (10200) 33500 (9820)

15 (-9.4) 36900 (10810) 35900 (10520) 34800 (10200) 33600 (9850) 32500 (9520) 31300 (9170) 30100 (8820)

10 (-12.2) 33100 (9700) 32200 (9440) 31200 (9140) 30100 (8820) 29100 (8530) 28100 (8240) 27000 (7910)

45 (7.2) 75600 (22160) 73600 (21570) 71500 (20950) 69300 (20310) 67100 (19660) 64800 (18990) 62400 (18290)

40 (4.4) 69100 (20250) 67300 (19720) 65400 (19170) 63400 (18580) 61300 (17970) 59200 (17350) 57000 (16700)

35 (1.7) 63000 (18460) 61300 (17970) 59600 (17470) 57800 (16940) 55900 (16380) 53900 (15800) 51900 (15210)

30 (-1.1) 57300 (16790) 55800 (16350) 54200 (15880) 52500 (15390) 50800 (14890) 49000 (14360) 47100 (13800)

25 (-3.9) 52000 (15240) 50600 (14830) 49100 (14390) 47600 (13950) 45900 (13450) 44300 (12980) 42600 (12480)

20 (-6.7) 47000 (13770) 45700 (13390) 44300 (12980) 42900 (12570) 41400 (12130) 39900 (11690) 38300 (11220)

15 (-9.4) 42400 (12430) 41100 (12050) 39800 (11660) 38500 (11280) 37100 (10870) 35700 (10460) 34200 (10020)

10 (-12.2) 38000 (11140) 36800 (10780) 35600 (10430) 34400 (10080) 33100 (9700) 31800 (9320) 30400 (8910)

80 (26.6) 85 (29.4) 90 (32.2) 95 (35.0) 100 (37.8) 105 (40.6) 110 (43.3)

CAPACITYBTU/H(WATTS)

R407C

AMBIENTTEMPERATURE°F(°C)

1280)

NOTE: The capacities shown above are rated at dew point. The dew point is a saturation point and is the condition (pressure and temperature) at

which a gas begins to condense. Since R407C has signicant glide, the saturated gas and saturated liquid temperatures are not the same.

It is important that all components of a system are selected correctly

Page 6

CAPACITYDATA-

B40-BQZ-PDS-1

- 6 -

01/15/11

BQZA

R404A

R507

60Hz

MEDIUMTEMPERATURE

COPELAND

SATURATED

MODEL

BQZA010M6 30 (-1.1) 15730 (4609) 15110 (4427) 14470 (4240) 13830 (4052) 13160 (3856) 12470 (3654) 11770 (3449)

Compressor 15 (-9.4) 11900 (3487) 11430 (3349) 10960 (3211) 10480 (3071) 9980 (2924) 9450 (2769) 8900 (2608)

Model 10 (-12.2) 10770 (3156) 10360 (3035) 9930 (2909) 9490 (2781) 9040 (2649) 8560 (2508) 8060 (2362)

ZB10KCE 5 (-15) 9710 (2845) 9350 (2740) 8970 (2628) 8570 (2511) 8160 (2391) 7720 (2262) 7270 (2130)

BQZA011M6 30 (-1.1) 17580 (5151) 16910 (4955) 16220 (4752) 15520 (4547) 14810 (4339) 14070 (4123) 13300 (3897)

Compressor 15 (-9.4) 13280 (3891) 12790 (3747) 12270 (3595) 11740 (3440) 11180 (3276) 10610 (3109) 10010 (2933)

Model 10 (-12.2) 12020 (3522) 11570 (3390) 11100 (3252) 10620 (3112) 10100 (2959) 9570 (2804) 9010 (2640)

ZB11KCE 5 (-15) 10840 (3176) 10430 (3056) 10000 (2930) 9540 (2795) 9070 (2658) 8580 (2514) 8050 (2359)

BQZA015M6 30 (-1.1) 21030 (6162) 20180 (5913) 19300 (5655) 18380 (5385) 17420 (5104) 16410 (4808) 15360 (4500)

Compressor 15 (-9.4) 15920 (4665) 15250 (4468) 14540 (4260) 13790 (4040) 12990 (3806) 12150 (3560) 11250 (3296)

Model 10 (-12.2) 14390 (4216) 13770 (4035) 13100 (3838) 12390 (3630) 1

ZB13KCE 5 (-15) 12940 (3791) 12350 (3619) 11730 (3437) 11060 (3241) 10340 (3030) 9570 (2804) 8740 (2561)

SUCTION

TEMP.

F° (C°)

40 (4.4) 18670 (5470) 17930 (5253) 17180 (5034) 16400 (4805) 15610 (4574) 14810 (4339) 13980 (4096)

35 (1.7) 17160 (5028) 16470 (4826) 15790 (4626) 15080 (4418) 14350 (4205) 13610 (3988) 12840 (3762)

25 (-3.9) 14370 (4210) 13810 (4046) 13230 (3876) 12640 (3704) 12030 (3525) 11410 (3343) 10760 (3153)

20 (-6.7) 13090 (3835) 12590 (3689) 12060 (3534) 11530 (3378) 10970 (3214) 10410 (3050) 9810 (2874)

0 (-17.8) 8740 (2561) 8400 (2461) 8060 (2362) 7700 (2256) 7330 (2148) 6930 (2030) 6510 (1907)

-5 (-20.6)

40 (4.4) 20880 (6118) 20080 (5883) 19260 (5643) 18430 (5400) 17580 (5151) 16710 (4896) 15810 (4632)

35 (1.7) 19180 (5620) 18450 (5406) 17690 (5183) 16940 (4963) 16150 (4732) 15350 (4498) 14530 (4257)

25 (-3.9) 16050 (4703) 15450 (4527) 14830 (4345) 14190 (4158) 13530 (3964) 12850 (3765) 12150 (3560)

20 (-6.7) 14630 (4287) 14080 (4125) 13510 (3958) 12930 (3788) 12330 (3613) 11700 (3428) 11050 (3238)

0 (-17.8) 9710 (2845) 9350 (2740) 8950 (2622) 8540 (2502) 8100 (2373) 7630 (2236) 7140 (2092)

-5 (-20.6)

40 (4.4) 24910 (7299) 23910 (7006) 22890 (6707) 21830 (6396) 20730 (6074) 19590 (5740) 18410 (5394)

35 (1.7) 22920 (6716) 22000 (6446) 21050 (6168) 20060 (5878) 19040 (5579) 17970 (5265) 16850 (4937)

25 (-3.9)

20 (-6.7) 17540 (5139) 16810 (4925) 16040 (4700) 15250 (4468) 14400 (4219) 13500 (3956) 12560 (3680)

0 (-17.8) 11560 (3387) 11000 (3223) 10420 (3053) 9780 (2866) 9080 (2660) 8340 (2444) 7530 (2206)

-5 (-20.6)

80 (26.6) 85 (29.4) 90 (32.2) 95 (35.0) 100 (37.8) 105 (40.6) 110 (43.3)

7810 (2288) 7520 (2203) 7210 (2113) 6890 (2019) 6540 (1916) 6180 (1811) 5800 (1699)

8670 (2540) 8330 (2441) 7960 (2332) 7570 (2218) 7160 (2098) 6720 (1969) 6250 (1831)

19240 (5637) 18450 (5406) 17630 (5166) 16770 (4914) 15880 (4653) 14930 (4374) 13930 (4081)

10240 (3000) 9710 (2845) 9150 (2681) 8530 (2499) 7860 (2303) 7140 (2092) 6350 (1861)

CAPACITYBTU/H(WATTS)

R404AR507

AMBIENTTEMPERATURE°F(°C)

1630 (3408) 10840 (3176) 9980 (2924)

Page 7

BQZA

B40-BQZ-PDS-1

- 7 -

01/15/11

COPELAND

CAPACITYDATA-

LOWTEMPERATURE

R404A

R507

60Hz

SATURATED

MODEL

BQZA020L6 -10 (-23.3) 10640 (3118) 10260 (3006) 9860 (2889) 9470 (2775) 9070 (2658) 8670 (2540) 8280 (2426)

Compressor -20 (-28.9) 8640 (2532) 8340 (2444) 8030 (2353) 7720 (2262) 7400 (2168) 7090 (2077) 6790 (1989)

Model -25 (-31.7) 7740 (2268) 7470 (2189) 7180 (2104) 6910 (2025) 6630 (1943) 6350 (1861) 6090 (1784)

ZF06K4E -30 (-34.4) 6880 (2016) 6640 (1946) 6390 (1872) 6140 (1799) 5890 (1726) 5650 (1655) 5420 (1588)

BQZA025L6 -10 (-23.3) 13480 (3950) 13010 (3812) 12530 (3671) 12010 (3519) 11490 (3367) 10940 (3205) 10370 (3038)

Compressor -20 (-28.9) 10910 (3197) 10540 (3088) 10160 (2977) 9770 (2863) 9350 (2740) 8910 (2611) 8460 (2479)

Model -25 (-31.7) 9770 (2863) 9440 (2766) 9100 (2666) 8750 (2564) 8380 (2455) 7990 (2341) 7590 (2224)

ZF08K4E -30 (-34.4) 8690 (2546) 8410 (2464) 8110 (2376) 7800 (2285) 7480 (2192) 7130 (2089) 6770 (1984)

BQZA030L6 -10 (-23.3) 14780 (4331) 14260 (4178) 13720 (4020) 13170 (3859) 12600 (3692) 12000 (3516) 11380 (3334)

Compressor -20 (-28.9) 11980 (3510) 11570 (3390) 11150 (3267) 10720 (3141) 10270 (3009) 9800 (2871) 9300 (2725)

Model

ZF09K4E -30 (-34.4) 9570 (2804) 9250 (2710) 8910 (2611) 8580 (2514) 8220 (2408) 7840 (2297) 7470 (2189)

BQZA035L6

Compressor -20 (-28.9) 14450 (4234) 13920 (4079) 13390 (3923) 12820 (3756) 12240 (3586) 11660 (3416) 11040 (3235)

Model -25 (-31.7) 12960 (3797) 12500 (3663) 12010 (3519) 11520 (3375) 11010 (3226) 10480 (3071) 9930 (2909)

ZF11K4E -30 (-34.4) 11590 (3396) 11170 (3273) 10740 (3147) 10310 (3021) 9860 (2889) 9400 (2754) 8910 (2611)

BQZA045L6 -10 (-23.3) 22440 (6580) 21570 (6320) 20630 (6050) 19660 (5760) 18660 (5470) 17640 (5170) 16620 (4870)

Compressor -20 (-28.9) 18040 (5290) 17290 (5070) 16520 (4840) 15720 (4610) 14910 (4370) 14110 (4140) 13350 (3910)

Model -25 (-31.7) 16020 (4690) 15350 (4500) 14640 (4290) 13920 (4080) 13220 (3870) 12530 (3670) 11890 (3480)

ZF13K4E -30 (-34.4) 14130 (4140) 13520 (3960) 12880 (3770) 12250 (3590) 11640 (3410) 11070 (3240) 10540 (3090)

BQZA055L6 -10 (-23.3) 26520 (7770) 25580 (7500)

Compressor -20 (-28.9) 21440 (6280) 20690 (6060) 19900 (5830) 19080 (5590) 18250 (5350) 17390 (5100) 16520 (4840)

Model -25 (-31.7) 19160 (5620) 18480 (5420) 17780 (5210) 17050 (5000) 16320 (4780) 15560 (4560) 14790 (4330)

ZF15K4E -30 (-34.4) 17050 (5000) 16440 (4820) 15810 (4630) 15160 (4440) 14510 (4250) 13850 (4060) 13190 (3870)

BQZA060L6 -10 (-23.3) 31360 (9190) 30270 (8870) 29170 (8550) 28040 (8220) 26860 (7870) 25650 (7520) 24390 (7150)

Compressor -20 (-28.9) 25260 (7400) 24410 (7150) 23560 (6900) 22690 (6650) 21800 (6390) 20880 (6120) 19940 (5840)

Model -25 (-31.7) 22530 (6600) 21790 (6390) 21030 (6160) 20280 (5940) 19510 (5720) 18720 (5490) 17900 (5250)

ZF18K4E -30 (-34.4) 20010 (5860) 19340 (5670) 18690 (5480) 18040 (5290) 17380 (5090) 16710 (4900) 16000 (4690)

SUCTION

TEMP.

F° (C°)

0 (-17.8)

-5 (-20.6) 11740 (3440) 11310 (3314) 10870 (3185) 10420 (3053) 9980 (2924) 9520 (2789) 9080 (2660)

-15 (-26.1) 9610 (2816) 9270 (2716) 8910 (2611) 8570 (2511) 8210 (2406) 7860 (2303) 7520 (2203)

-35 (-37.2) 6080 (1781) 5860 (1717) 5630 (1650) 5410 (1585) 5180 (1518) 4960 (1453) 4760 (1395)

-40 (-40.0)

0 (-17.8)

-5 (-20.6) 14910 (4369) 14370 (4210) 13830 (4052) 13260 (3885) 12660 (3709) 12050 (3531) 11420 (3346)

-15 (-26.1) 12150 (3560) 11740 (3440) 11310 (3314) 10860 (3182) 10380 (3041) 9900 (2901) 9390 (2751)

-35 (-37.2) 7720 (2262) 7460 (2186) 7190 (2107) 6910 (2025) 6630 (1943) 6320 (1852) 6000 (1758)

-40 (-40.0)

0 (-17.8)

-5 (-20.6) 16330 (4785) 15740 (4612) 15140 (4436) 14520 (4254) 13870 (4064) 13210 (3871) 12520 (3668)

-15 (-26.1) 13340 (3909) 12870 (3771) 12400 (3633) 11910 (3490) 11390 (3337) 10870 (3185) 10310 (3021)

-25 (-31.7) 10720 (3141) 10360 (3035) 10000 (2930) 9610 (2816) 9210 (2699) 8790 (2575) 8360 (2449)

-35 (-37.2) 8490 (2488) 8210 (2406) 7920 (2321) 7610 (2230) 7290 (2136) 6960 (2039) 6620 (1940)

-40 (-40.0)

0 (-17.8)

-5 (-20.6) 19580 (5737) 18840 (5520) 18070 (5295) 17270 (5060) 16450 (4820) 15610 (4574) 14740 (4319)

-10 (-23.3) 17760 (5204) 17090 (5007) 16410 (4808) 15700 (4600) 14970 (4386) 14220 (4166) 13430 (3935)

-15 (-26.1) 16040 (4700) 15460 (4530) 14850 (4351) 14220 (4166) 13570 (3976) 12890 (3777) 12200 (3575)

-35 (-37.2) 10320 (3024) 9950 (2915) 9580 (2807) 9190 (2693) 8790 (2575) 8380 (2455) 7950 (2329)

-40 (-40.0)

0 (-17.8)

-5 (-20.6) 24840 (7280) 23900 (7000) 22880 (6710) 21810 (6390) 20710 (6070) 19580 (5740) 18450 (5410)

-15 (-26.1) 20170 (5910) 19370 (5680) 18510 (5420) 17630 (5170) 16730 (4900) 15810 (4630) 14930 (4380)

-35 (-37.2) 12370 (3630) 11810 (3460) 11250 (3300) 10700 (3140) 10170 (2980) 9710 (2850) 9310 (2730)

-40 (-40.0)

0 (-17.8)

-5 (-20.6) 29340 (8600) 28280 (8290) 27170 (7960) 26030 (7630) 24840 (7280) 23610 (6920) 22370 (6560)

-15 (-26.1) 23900 (7000) 23050 (6760) 22170 (6500) 21250 (6230) 20310 (5950) 19340 (5670) 18340 (5370)

-35 (-37.2) 15100 (4430) 14540 (4260) 13980 (4100) 13400 (3930) 12820 (3760) 12240 (3590) 11670 (3420)

-40 (-40.0)

0 (-17.8)

-5 (-20.6) 34740 (10180) 33520 (9820) 32260 (9450) 30960 (9070) 29640 (8690) 28270 (8290) 26840 (7870)

-15 (-26.1) 28200 (8260) 27250 (7990) 26270 (7700) 25270 (7410) 24240 (7100) 23190 (6800) 22090 (6470)

-35 (-37.2) 17680 (5180) 17090 (5010) 16520 (4840) 15950 (4670) 15380 (4510) 14810 (4340) 14220 (4170)

-40 (-40.0)

80 (26.6) 85 (29.4) 90 (32.2) 95 (35.0) 100 (37.8) 105 (40.6) 110 (43.3)

12900 (3780) 12420 (3639) 11930 (3495) 11420 (3346) 10930 (3202) 10430 (3056) 9930 (2909)

5320 (1559) 5110 (1497) 4900 (1436) 4690 (1374) 4480 (1313) 4290 (1257) 4110 (1204)

16420 (4811) 15820 (4635) 15210 (4457) 14570 (4269) 13910 (4076) 13230 (3876) 12530 (3671)

6810 (1995) 6570 (1925) 6330 (1855) 6080 (1781) 5820 (1705) 5540 (1623) 5260 (1541)

17980 (5268) 17330 (5078) 16640 (4876) 15950 (4673) 15230 (4462) 14480 (4243) 13710 (4017)

7510 (2200) 7250 (2124) 6980 (2045) 6710 (1966) 6420 (1881) 6120 (1793) 5820 (1705)

21500 (6300) 20670 (6056) 19810 (5804) 18930 (5546) 18020 (5280) 17080 (5004) 16120 (4723)

9180 (2690) 8840 (2590) 8490 (2488) 8150 (2388) 7790 (2282) 7430 (2177) 7060 (2069)

27370 (8020) 26360 (7730) 25250 (7400) 24100 (7060) 22890 (6710) 21640 (6340) 20390 (5980)

10720 (3140) 10220 (3000) 9720 (2850) 9250 (2710) 8830 (2590) 8470 (2480) 8190 (2400)

32330 (9470) 31140 (9130) 29910 (8770) 28640 (8390) 27320 (8010) 25960 (7610) 24560 (7200)

13300 (3900) 12790 (3750) 12270 (3600) 11760 (3450) 11250 (3300) 10740 (3150) 10240 (3000)

38340 (11240) 36950 (10830) 35540 (10420) 34080 (9990) 32590 (9550) 31040 (9100) 29430 (8630)

15550 (4560) 15030 (4400) 14510 (4250) 14020 (4110) 13520 (3960) 13040 (3820) 12550 (3680)

CAPACITYBTU/H(WATTS)

24590 (7210) 23560 (6900) 22500 (6590) 21410 (6270) 20300 (5950)

R404AR507

AMBIENTTEMPERATURE°F(°C)

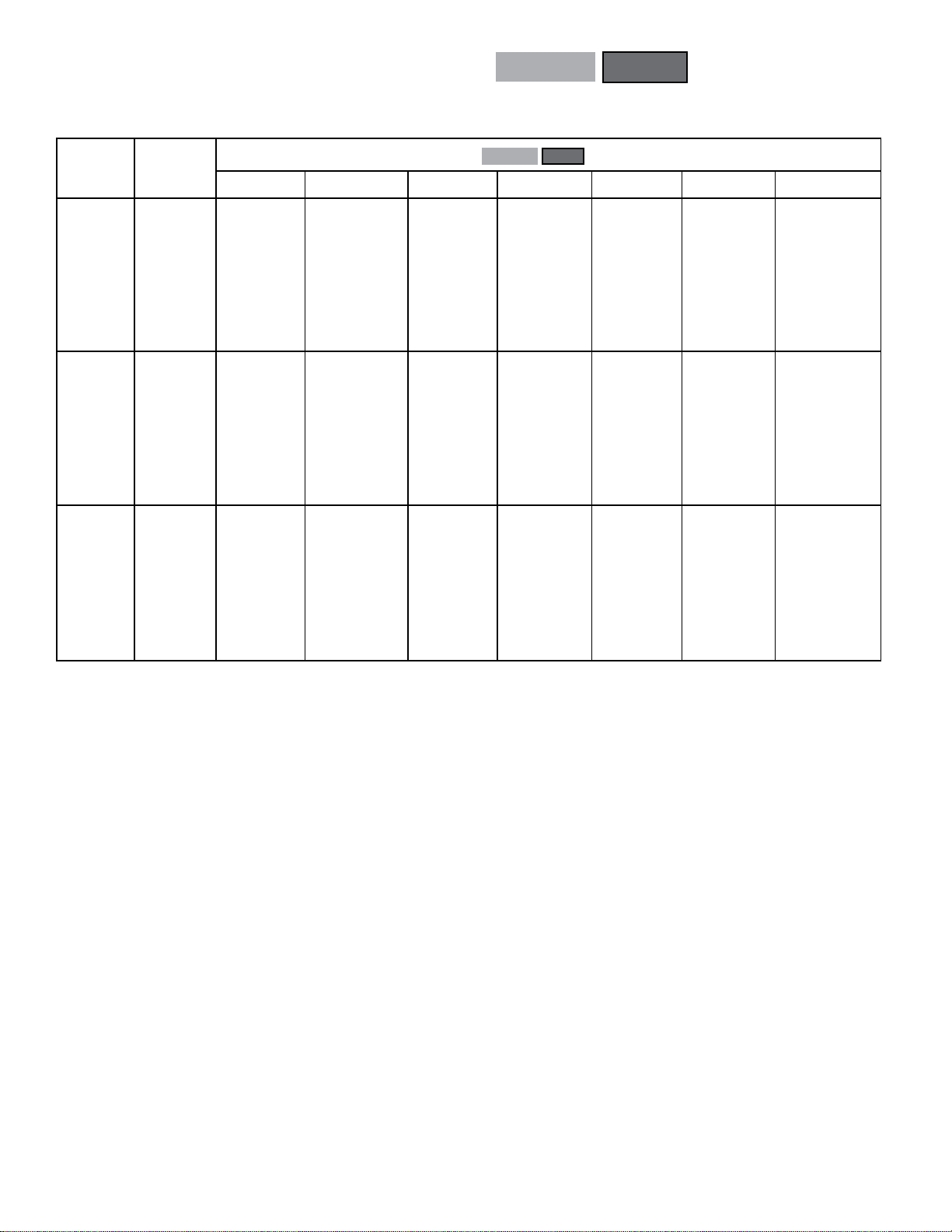

Page 8

BQZA

B40-BQZ-PDS-1

- 8 -

01/15/11

COPELAND

ELECTRICALDATA

COPELANDMODELS

WITHSTANDARDECFANMOTOR

60Hz

CONDENSING

UNIT

MODEL

BQZA010M6-H S2 ZB10KCE-PFV 208-230/1/60 10.0 41 1 165 1.7 14.2 20

BQZA011M6-H S2 ZB11KCE-PFV 208-230/1/60 10.0 45 1 165 1.7 14.2 20

BQZA015M6-H

BQZA020H8-H

BQZA025H8-H

BQZA030H8-H

BQZA035H8-H

BQZA040H8-H

BQZA050H8-H

BQZA060H8-H

BQZA020L6-H

BQZA025L6-H

BQZA030L6-H

BQZA035L6-H

BQZA045L6-H

BQZA055L6-H

BQZA060L6-H

S2 ZB13KCE-PFV 208-230/1/60 12.9 54 1 165 1.7 17.8 30

S2 ZB15KCE-PFV 208-230/1/60 15.7 61 1 165 1.7 21.3 35

T3 ZB15KCE-TF5 208-230/3/60 8.9 55 1 165 1.7 12.8 20

T4 ZB15KCE-TFD 460/3/60 5.0 27 1 165 0.9 7.2 15

S2 ZB19KCE-PFV 208-230/1/60 17.9 73 1 165 1.7 24.1 40

T3 ZB19KCE-TF5 208-230/3/60 10.0 63 1 165 1.7 14.2 20

T4 ZB19KCE-TFD 460/3/60 5.0 31 1 165 0.9 7.2 15

S2 ZB21KCE-PFV 208-230/1/60 20.7 95 1 165 1.7 27.6 45

T3 ZB21KCE-TF5 208-230/3/60 12.1 77 1 165 1.7 16.8 25

T4 ZB21KCE-TFD 460/3/60 7.4 39 1 165 0.9 10.2 15

S2 ZB26KCE-PFV 208-230/1/60 23.6 127 2 330 3.4 32.9 50

T3 ZB26KCE-TF5 208-230/3/60 13.9 88 2 330 3.4 20.8 30

T4 ZB26KCE-TFD 460/3/60 7.1 44 2 330 1.8 10.7 15

S2 ZB30KCE-PFV 208-230/1/60 26.8 132 2 330 3.4 36.9 60

T3 ZB30KCE-TF5 208-230/3/60 15.7 115 2 330 3.4 23.0 35

T4 ZB30KCE-TFD 460/3/60 7.5 47.5 2 330 1.8 11.2 15

S2 ZB38KCE-PFV 208-230/1/60 31.1 175 2 330 3.4 42.3 70

T3 ZB38KCE-TF5 208-230/3/60 22.1 115 2 330 3.4 31.0 50

T4 ZB38KCE-TFD 460/3/60 9.6 63 2 330 1.8 13.8 20

T3 ZB45KCE-TF5 208-230/3/60 22.5 156 2 330 3.4 31.5 50

T4 ZB45KCE-TFD 460/3/60 11.5 70 2 330 1.8 16.2 25

S2 ZF06K4E-PFV 208-230/1/60 13.6 61 1 165 1.7 18.7 30

T3 ZF06K4E-TF5 208-230/3/60 9.3 55 1 165 1.7 13.3 20

T4 ZF06K4E-TFD 460/3/60 4.3 27 1 165 0.9 6.3 15

S2 ZF08K4E-PFV 208-230/1/60 16.4 73 1 165 1.7 22.2 35

T3 ZF08K4E-TF5 208-230/3/60 9.7 63 1 165 1.7 13.8 20

T4 ZF08K4E-TFD 460/3/60 5.0 31 1 165 0.9 7.2 15

S2 ZF09K4E-PFV 208-230/1/60 16.4 88 1 165 1.7 22.2 35

T3 ZF09K4E-TF5 208-230/3/60 9.6 77 1 165 1.7 13.7 20

T4 ZF09K4E-TFD 460/3/60 5.7 39 1 165 0.9 8.0 15

S2 ZF11K4E-PFV 208-230/1/60 20.7 109 1 165 1.7 27.6 45

T3 ZF11K4E-TF5 208-230/3/60 12.1 88 1 165 1.7 16.8 25

T4 ZF11K4E-TFD 460/3/60 7.1 44 1 165 0.9 9.8 15

S2 ZF13K4E-PFV 208-230/1/60 26.8 129 2 330 3.4 36.9 60

T3 ZF13K4E-TF5 208-230/3/60 15.0 99 2 330

T4 ZF13K4E-TFD 460/3/60 8.2 49.5 2 330 1.8 12.1 20

S2 ZF15K4E-PFV 208-230/1/60 31.8 169 2 330 3.4 43.2 70

T3 ZF15K4E-TF5 208-230/3/60 21.4 123 2 330 3.4 30.2 50

T4 ZF15K4E-TFD 460/3/60 9.6 62 2 330 1.8 13.8 20

T3 ZF18K4E-TF5 208-230/3/60 23.9 156 2 330 3.4 33.3 50

T4 ZF18K4E-TFD 460/3/60 9.3 70 2 330 1.8 13.4 20

COMPRESSOR

MODELNO.

POWER

SUPPLY

COMPRESSOR

RLA LRA QTY WATTS FLA MCA MOP

WITH STANDARD EC

CONDENSER FAN MOTOR

3.4 22.2 35

UNIT

Page 9

BQZA

B40-BQZ-PDS-1

- 9 -

01/15/11

COPELAND

DIMENSIONALDATA

60Hz

Page 10

COPELAND

B40-BQZ-PDS-1

- 10 -

01/15/11

SPECIFICATIONS

COPELANDMODELS

60HzBQZA

CONDENSING

UNIT

MODEL

BQZA010M6 5/8 16 3/8 10 11 5.0 300 136

BQZA011M6 5/8 16 3/8 10 11 5.0 305 139

BQZA015M6 7/8 22 3/8 10 14 6.4 305 139

BQZA020H8 7/8 22 3/8 10 14 6.4 325 148

BQZA025H8 7/8 22 1/2 13 19.5 8.9 325 148

BQZA030H8 7/8 22 1/2 13 19.5 8.9 325 148

BQZA035H8 7/8 22 1/2 13 21.5 9.8 TBA

BQZA040H8 1 1/8 29 1/2 13 21.5 9.8 TBA

BQZA050H8 1 1/8 29 1/2 13 21.5 9.8 TBA

BQZA060H8 1 1/8 29 1/2 13 30.0 13.6 TBA

BQZA020L6 7/8 22 3/8 10 11.0 5.0 320 145

BQZA025L6 7/8 22 3/8 10 14.0 6.4 325 148

BQZA030L6 7/8 22 3/8 10 14.0 6.4 325 148

BQZA035L6 7/8 22 1/2 13 19.5 8.9 325 148

BQZA045L6 1 1/8 29 1/2 13 21.5 9.8 TBA

BQZA055L6 1 1/8 29 1/2 13 21.5 9.8 TBA

BQZA060L6 1 1/8 29 1/2 13 21.5 9.8 TBA

SUCTION(OD) LIQUID(OD)

Inches mm Inches mm Lbs. Kgs Lbs. Kgs

UNITCONNECTIONS

RECEIVERCAPACITY

90%FULL

APPROX.SHIPPINGWEIGHT

SOUNDPRESSURELEVELS

(dBA-60Hz)

CONDENSINGUNIT

MODEL

BQZA010M6 ZB10KCE 55 71

BQZA011M6 ZB11KCE 56 72

BQZA015M6 ZB13KCE 58 74

BQZA020H8 ZB15KCE 55 71

BQZA025H8 ZB19KCE 57 71

BQZA030H8 ZB21KCE 53 72

BQZA035H8 ZB26KCE TBA TBA

BQZA040H8 ZB30KCE TBA TBA

BQZA050H8 ZB38KCE TBA TBA

BQZA060H8 ZB45KCE TBA TBA

BQZA020L6 ZF06K4E 54 71

BQZA025L6 ZF08K4E 53 72

BQZA030L6 ZF09K4E 55 73

BQZA035L6 ZF11K4E 55 73

BQZA045L6 ZF13K4E TBA TBA

BQZA055L6 ZF15K4E TBA TBA

BQZA060L6 ZF18K4E TBA TBA

- Data is typical of “free eld” conditions. Factors such as reecting wall, background noise and

installation may have signicant inuence on data

- Testing performed according to AHRI Standard 270

COMPRESSOR

MODEL

dBA@10ft.

withSoundInsulated

CompressorCompartment

dBA@10ft.

withoutSoundInsulated

CompressorCompartment

- For more accurate ratings refer to AHRI Standard 275 for correction factors due to reecting planes

- Data is for 100% fan speed. Further sound reductions of approx. 4-6 dBA can be expected at ambients

below 70°F

Page 11

BQZA

B40-BQZ-PDS-1

- 11 -

01/15/11

COPELAND

TYPICALUNITWIRINGDIAGRAM-

230/1/60-STANDARDECFANMOTOR

60Hz

Page 12

BQZA

B40-BQZ-PDS-1

- 12 -

01/15/11

COPELAND

TYPICALUNITWIRINGDIAGRAM-

230/3/60-STANDARDECFANMOTOR

60Hz

Page 13

BQZA

B40-BQZ-PDS-1

- 13 -

01/15/11

COPELAND

TYPICALUNITWIRINGDIAGRAM-

60Hz

460/3/60-STANDARDECFANMOTOR

Page 14

BQZA

B40-BQZ-PDS-1

- 14 -

01/15/11

COPELAND

ECMOTORAPPLICATION

EC MOTORS

60Hz

ECMotors-FeaturesandBenets

Air cooled condensing units utilizing electrically commutated motor (EC motor) technology offer many benets;

Improved Efciency, Reduced Sound Levels, Speed Control, Simplicity and Reliability

Efciency

EC motors are more energy efcient than conventional

AC (PSC and shaded pole) motors. Unlike AC motors that

see efciency decrease as the motor speed is decreased,

an EC motor efciency remains consistent throughout its

range of operation.

Head Pressure Control

EC motors make it easier to maintain stable head pressures when motor speeds are varied according to operating conditions. When compared to a conventional ooded

valve system, EC motors do a much better job maintaining

stable head pressures. System performance is further

enhanced with consistent liquid temperatures that ensure

optimized operation of the nozzle and TX valve in the

evaporator.

Reduced Refrigerant Charge

System charges can be reduced by 30 – 40% by utilizing

variable speed EC motors to control head pressures. The

elimination of the head pressure control valve also eliminates the need for extra refrigerant required to ood the

condenser

Reduced Energy Consumption

When a system’s head pressure is controlled using a

ooded head pressure control valve, the condenser fan

motor runs at 100% fan speed all of the time. When head

pressure is controlled using an EC motor and the motor

speed is varied according to operating conditions, this

results in lower energy consumption of the motor.

There are also potential energy savings available from the

compressor by running with lower head pressure setting

controlled by a simple EC motor controller.

The amount of energy to be saved depends on; ambient

conditions, system operation conditions and head pressure set point.

Sound

As EC motor speeds vary for different operating conditions

they also offer reduced sound levels when compared to

conventional motor running full speed. Sound levels are

reduced on cooler days and in evenings.

Simplicity and Reliability

The installation and control of EC motors is very simple

compared to other methods of speed control used on

conventional AC motors. Lower running operating temperatures and smooth transitional speed changes make EC

motors durable and reliable.

Page 15

BQZA

B40-BQZ-PDS-1

- 15 -

01/15/11

COPELAND

ECMOTORAPPLICATION

(cont’d)

EC MOTORS

60Hz

VariableSpeedECCondenserFanMotors

ECM fan/motor combinations using DC motors with integral AC to DC conversion allow direct connection to the AC

mains with all the energy saving and control benets of a

DC motor. Ideally, with multiple motors on the condenser,

all should simultaneously slow down /speed up together.

This provides for maximum energy savings and smoothest

head pressure control.

Important Warnings:

(Please read before handling motors)

!

1. When connecting the unit to the power supply,

dangerous voltages occur. Due to motor

capacitor discharge time, do not open the motor

within 5 minutes after disconnection of all phases.

2. With a Control voltage fed in or a set speed value

being saved, the motor will restart automatically

after a power failure.

3. Dangerous external voltages can be present at the

motor terminals even when the unit is turned off.

4. The Electronics housing can get hot.

5. The cycling on and off of EC motors should be

controlled by the DC control voltage (i.e. 0V DC

will turn motor off). Excessive cycling of the motor

by line voltage contactors may cause stress on

the motors and reduce the motor life.

Speed Adjustment Characteristics

The EC motor varies its speed linearly based on a 1-10V

input signal. At 10 VDC, the motor runs at full speed. At 0

to approx. 1 VDC, the motor turns off. A chart of the speed

control curve is shown below. The motor can be controlled

at any speed below its nominal RPM.

Control Signal

The input control signal is supplied by an external control

signal from a factory installed proportional pressure control. Units with factory installed proportional pressure controls are adjusted with initial factory settings. These may

require further adjustments to suit local eld conditions.

Proportional Pressure Control (Factory Installed)

Units equipped with factory installed P352 controls use a

proportional/integral pressure controller to vary and maintain the motor speed at the desired head pressure. The

controller has two main user adjustable features:

• Head Pressure Set point

• Throttling range

Leave the minimum Output setting at 0% and Jumpers

should be set for Direct Acting (do not re-adjust)

Mod ule

User Adjust

Setpoint

Potentiometer

User Adjust

Throttling Range

Potentiom eter

0%

Minimum

Output

Potentio meter

LED Indicat or

(Percent of Output)

THROT

RANGE

OUTPU

Connec tor

MIN

T

Operation Mode

Jumper Positions

3 4

2

1

N

O

Integration DIP Switch

Direct

Acting

Full RPM

RPM

1

Control voltage [V dc]

Head Pressure Set Point

The head pressure set point potentiometer is adjustable

from 90-250 psig. This maintains a minimum condensing temp at the corresponding pressure set point. Typical

R404A set points are from 170-200 psig. (i.e. 78oF - 89oF

Condensing Temperature).

Note: Very low set points may cause the fan motors to run

full speed continually even if the condenser is properly

sized. The fans will turn off if the system pressure falls

below the desired set point.

10

Page 16

BQZA

B40-BQZ-PDS-1

- 16 -

01/15/11

COPELAND

ECMOTORAPPLICATION

(cont’d)

EC MOTORS

60Hz

Minimum Output

The minimum output potentiometer controls the minimum

signal sent to the motor and is factory set at 0%. It is adjustable between 0 and 60% of the output range. If this is

adjusted to 50%, the motors will not start running until 5V

is applied to the motor. The motor will start running at 50%

of full speed. To maximize sound reduction and energy

savings and to provide the most stable control, it is recommended this setting be left at 0%.

Throttling range

The throttling range potentiometer controls how far the

system pressure deviates from the control set point to

generate a 100% output signal from the control and is adjustable from 10 -100 psig. The throttling range determines

how quickly the motor will reach full speed when detecting

a change in head pressure. For example, if the set point

is 190 psig and the throttling range is 50 psig, when the

system pressure is below 190 psig, the fans will be off.

When the system pressure reaches 240 psig (190+50)

the fans will be at full speed. To make the fans ramp more

slowly the throttling range should be increased. To maximize sound reduction and energy efciency and to provide

for the most stable control, it is recommended this setting

be left at 100 psig.

Direct Acting (DA) mode. Failure to ensure J1 jumper is

in direct acting mode will cause the system to trip on high

head pressure.

Integration constant

The integration constant switch provides ability to change

controller from a proportional only control to a proportional plus integral control. To provide the most responsive system and to maintain a stable head pressure, it is

recommended the integration setting be left on “fast” with

the Mode switch set to OFF (Proportional AND Integral

activated)

FAST (on)

3 4

2

1

O

N

MEDIUM (off)

SLOW (off)

OFF (set for PROPORTIONAL /

INTEGRAL MODE)

Reverse acting or direct acting mode of operation

The reverse acting/direct acting jumper is used to ensure the controller responds correctly to the desired head

pressure. In Direct Acting (DA) mode, the motor speed

increases as the pressure rises above desired set point.

For proper condenser operation, this jumper MUST be in

Transducer Wiring

The P352PN controls use a P266 (P399,or P499) pressure transducer to generate a 0.5 to 4.5 VDC input signal.

The transducer is wired to the terminal block at the bottom

of the control as shown in the diagram below.

InteriorViewandTypicalWiringofP352PNControl

Page 17

BQZA

B40-BQZ-PDS-1

- 17 -

01/15/11

GENERICSERVICEPARTSLIST

60Hz

COPELAND

PARTDESCRIPTION MODELS PARTNUMBER

ECFanMotor- 1/3 HP ALL 1089880

Transformer(req’d for EC Motor on 460V models) 460V Models 1086000-0207

FanBlade ALL 1090668

MotorMount ALL 1089899

FanGuard ALL 1089892

PressureControl, P352PN-3C, Fan Motor Speed Control ALL 1087946

Transformer, 24V, for pressure control ALL 170110

PressureTransducer ALL 1073355

WallMountingKit ALL 1089895

Page 18

NOTES

B40-BQZ-PDS-1

- 18 -

01/15/11

Page 19

Finished Goods Warranty

B40-BQZ-PDS-1

- 19 -

01/15/11

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GeneraL Warranty PoLiCy

Subject to the terms and conditions hereof, the Company warrants all Products, including Service

Parts, manufactured by the Company to be free of defects in material or workmanship, under normal use and application for a period of one (1) year from the original date of installation, or eighteen

(18) months from the date of shipment from the Company, whichever occurs rst. Any replacement

part(s) so supplied will be warranted for the balance of the product’s original warranty. The part(s) to

be replaced must be made available in exchange for the replacement part(s) and reasonable proof

of the original installation date of the product must be presented in order to establish the effective

date of the warranty, failing which, the effective date will be based upon the date of manufacture plus

thirty (30) days. Any labour, material, refrigerant, transportation, freight or other charges incurred in

connection with the performance of this warranty will be the responsibility of the owner at the current rates and prices then in effect. This warranty may be transferred to a subsequent owner of the

product.

this Warranty does not CoVer

(a) Damages caused by accident, abuse, negligence, misuse, riot, re, ood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized

alteration or repair of the system affecting the product’s reliability or performance (d) damages caused

by improper matching or application of the product or the product’s components (e) damages caused by

failing to provide routine and proper maintenance or service to the product (f) expenses incurred for the

erecting, disconnecting, or dismantling the product (g) parts used in connection with normal maintenance,

such as lters or belts (h) products no longer at the site of the original installation (i) products installed

or operated other than in accordance with the printed instructions, with the local installation or building

codes and with good trade practices (j) products lost or stolen.

NooneisauthorizedtochangethisWARRANTY or to create for or on behalf of the Company any

other obligation or liability in connection with the Product(s). There is no other representation, warranty

or condition in any respect, expressed or implied, made by or binding upon the Company other than

the above or as provided by provincial or state law and which cannot be limited or excluded by such

law, nor will we be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modication of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State laws.

PROJECTINFORMATION

Sy stem

Mo del Numbe r Da te o f Sta rt-Up

Se rial Numb er Se rvic e Con tract or

Re frig erant Ph one

El ectr ical Suppl y Fa x

Page 20

“ASBUILT”SERVICEPARTSLIST

01/15/11

Service Parts List

Label

To Be Attached

HERE

DISTRIBUTEDBY:

General Sales, Parts & Service Manufacturing & Engineering

135 Little Nine Drive, Morehead City, NC 28557

252-240-2829 • 1-800-24-BALLY • FAX: 252-240-0384

e-mail: ballysales@ballyrefboxes.com • www.ballyrefboxes.com

Due to Manufacturer’s policy of continuous product improvement,

the Manufacturer reserves the right to make changes without notice.

Loading...

Loading...