Page 1

Installation and Maintenance

Instructions

for

Air-Cooled, Remote and Water-Cooled

Condensing Units

Bally Refrigerated Boxes Inc.,

General Sales, Manufacturing and Engineering

135 Little Nine Drive, Morehead City, NC 28557

Phone: 800-24BALLY, 252-240-2829 Fax: 252-240-0384

Service and Warranty

Phone: 800-344-9302, 610-337-8600 Fax: 610-337-0431

Visit our web site at www.ballyrefboxes.com

B40-CU-IM-13

1068157

Page 2

Table of Contents

Pages

General Safety, Inspection & General Warranty Policy 3

Handling, Placement & Installation 4 – 6

Electrical Information & Wiring Diagrams 7 – 14

Refrigerant Piping 15 – 16

Water-Cooled Condensers, Piping & Flow Rates 17 – 18

System Accessories 19

Leak Testing, Evacuation & Dehydration 20

Line Insulation 21

Refrigerant Charging 21 – 23

Compressor Oils 24 – 25

System Start-up Check List 26 – 27

Low Temperature Room Pull-Down 27

Checking Compressor & Evaporator Superheat 28

System Operational Check List 29

System Troubleshooting 30 – 32

Customer Instructions 33

Maintenance Program 33

Service Parts Availability 33

Finished Goods Warranty & Service Log 34

Warranty Activation Certificate 35

Service Parts List Back Cover

2

Page 3

General Safety

IMPORTANT SAFETY NOTE

Only a qualified refrigeration mechanic who is familiar with refrigeration systems and components, including all

controls should perform the installation and start-up of the system. To avoid potential injury, use care when

working around coil

should be installed in accordance with all applicable codes, ordinances and local by-laws.

surfaces (if applicable) or sharp edges of metal cabinets. All piping and electrical wiring

WARNING

Always disconnect and lock off the main power supply on any system that will be worked on to avoid

accidental start up of the equipment.

Inspection

Inspect all equipment before unpacking for visible signs of damage or loss. Check shipping list against material

received to ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must make any claim necessary against the transportation

company. Shipping damage or missing parts, when discovered at the outset, will prevent later unnecessary and

costly delays. If damage or loss during transport is evident, make claim to carrier, as this will be their

responsibility, not that of the manufacturer.

Should carton be damaged, but damage to equipment is not obvious, a claim should be filed for “concealed

damage” with the carrier.

IMPORTANT: Check the electrical ratings on the unit to make sure they correspond to those ordered and to

electrical power available at the job site. Save all shipping papers, tags, and instruction sheets for reference by

installer and owner.

General Warranty Policy

Please refer to the “Finished Goods Warranty” on page 34.

3

Page 4

g

g

Handling, Placement and Installation

IMPORTANT: When selecting a location for the condensing unit, consideration should be given to some of the

following:

(a) Loading capacity of the floor or roof. Check building codes for weight distribution requirements.

(b) Distance to suitable electrical supply.

(c) Distance to the evaporator.

(d) Adequate air circulation and ventilation.

(e) Close proximity to water source and floor drains (water-cooled units)

(f) Accessibility for maintenance.

(g) Local building codes.

(h) Adjacent buildings relative to noise levels.

(i) Wishes of the end user / owner.

When all of the above points have been considered and a specific location chosen, it is advisable to obtain

written approval of this location from the building and/or condensing unit owner. This may be a means of

avoiding disagreement and expense at a later date.

A fully qualified and properly equipped crew with the necessary tackle and rigging should be engaged to

locate the condensing unit in position. When lifting the unit, spreader bars and chafing gear should be used to

prevent damage.

The unit should be placed on a base, which is level and even. Units should be lagged to sleepers or support

base. Place unit where it will not be subject to damage by traffic or flooding. On critical installations where noise

is liable to be transmitted through the floor structure, vibration isolators should be installed. Isolators should be

installed under mounting base and may be rubber or cork or equal.

DO NOT

The condensing unit should be positioned to allow adequate space for performing service work.

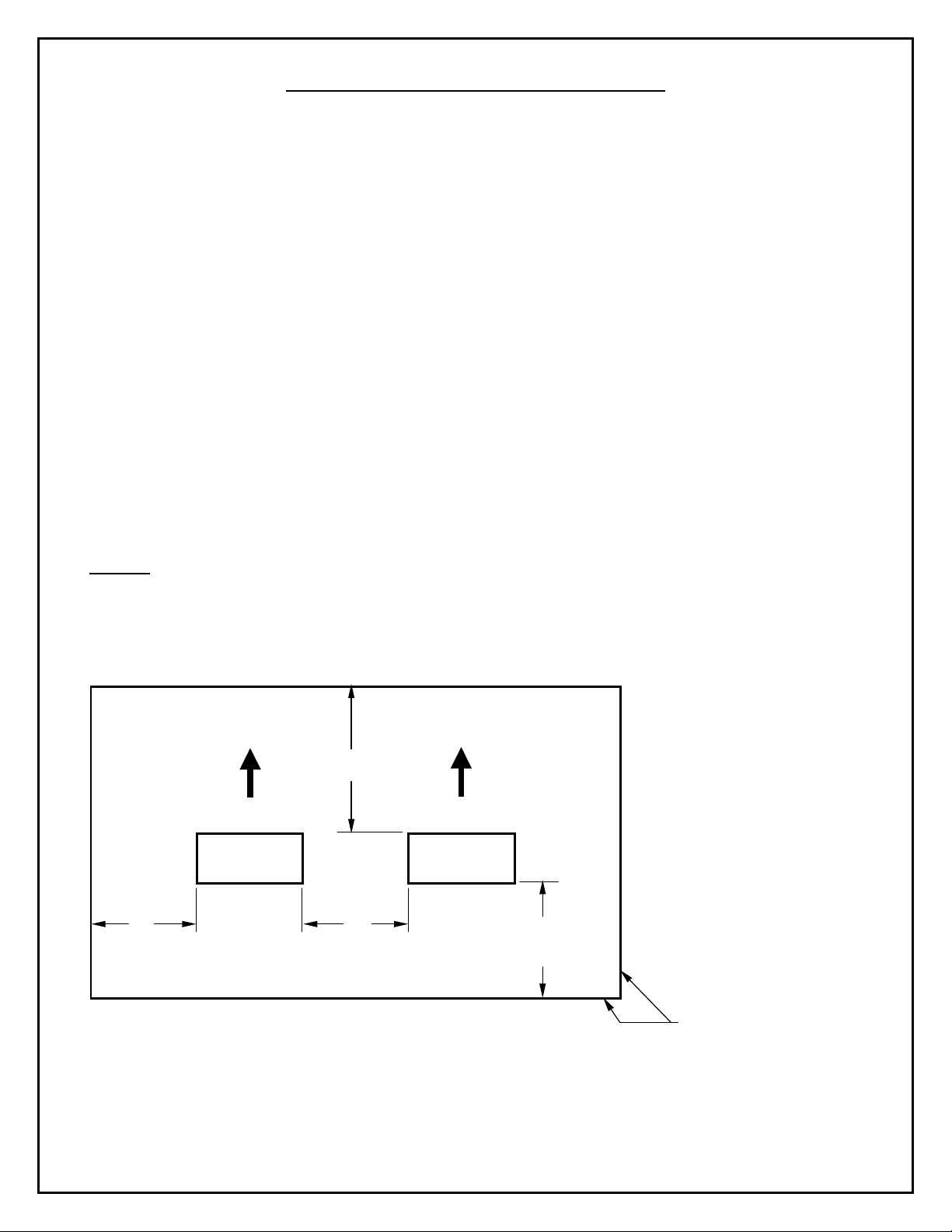

Indoor and outdoor air-cooled condensing units should be positioned using the guidelines shown below.

USE THE SHIPPING SKID AS A PERMANENT BASE.

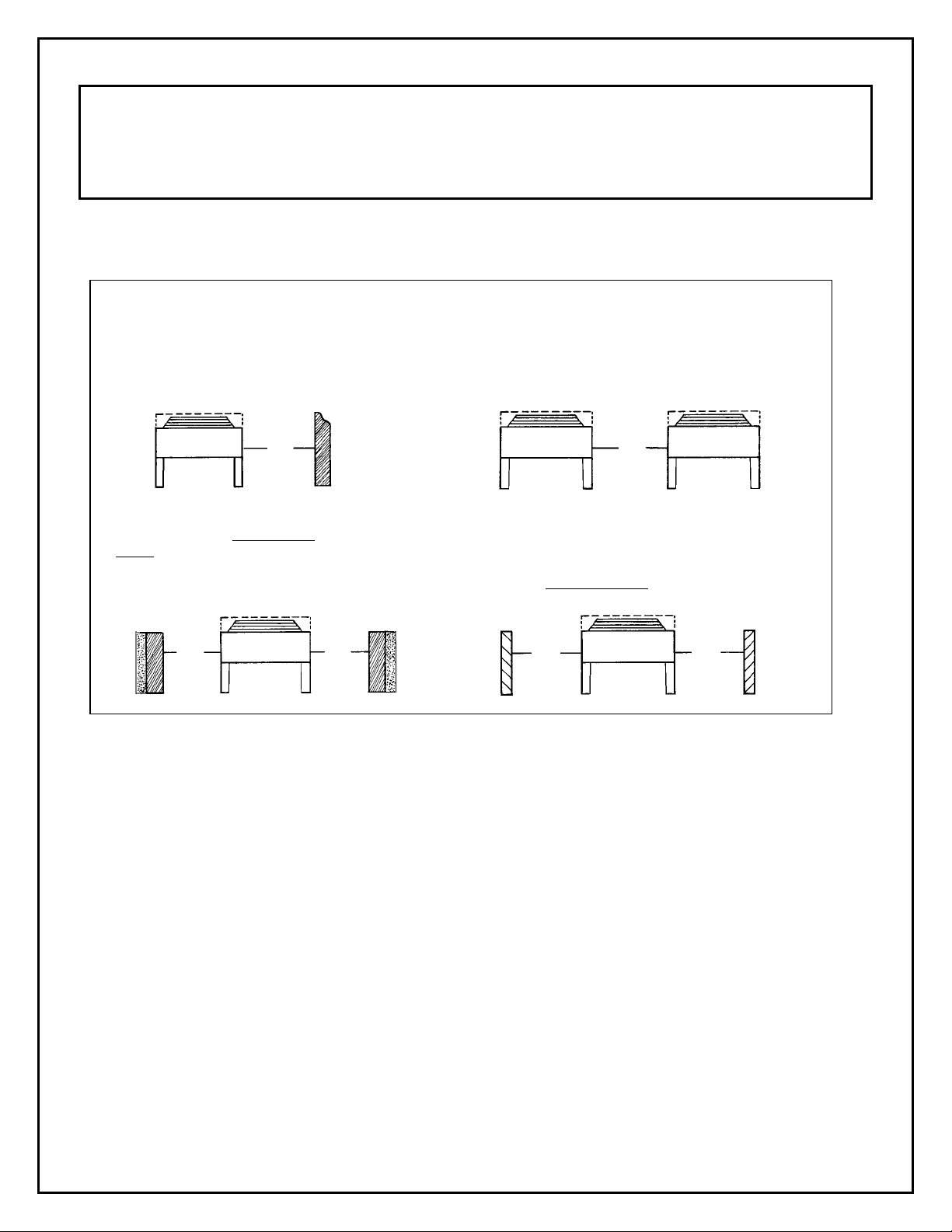

Air Cooled Condensing Unit Minimum Clearance (for Horizontal Air Flow Units)

48" (1.2 m)

Minimum

Air FlowAir Flow

Condensing UnitCondensing Unit

*

Width of

Condensin

Minimum

* No closer than 24" (.62 m)

Unit

*

Width of

Condensin

Minimum

Unit

* Height of

Condensing Unit

Minimum

Walls

4

Page 5

p

SPECIAL NOTE FOR LARGE AIR COOLED CONDENSING UNITS: Vertical flow air cooled condensing units

are large and heavy pieces of mechanical equipment and must be handled as such. A fully qualified and

properly equipped crew with the necessary tackle and rigging should be engaged to locate the condensing unit

into location. The unit can be lifted by means of lifting holes located in the base frame of the unit. Spreader

bars should be used to prevent damage to the sides of the unit. Do not sling directly around the base of unit.

The unit should be placed on a base which is level and even.

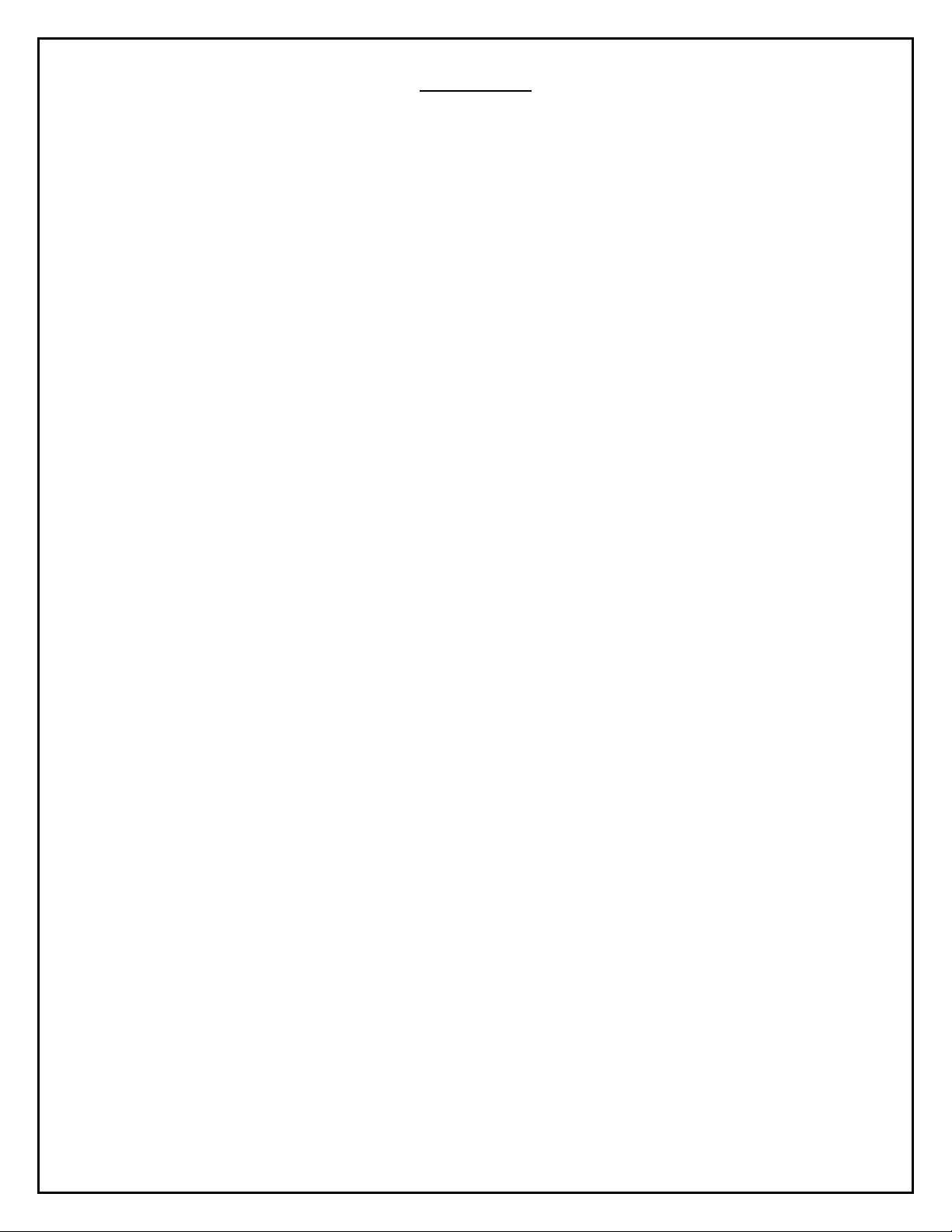

Air Cooled Condensing Unit Minimum Clearance (For Vertical Air Flow Units)

WALLS OR OBSTRUCTIONS

All sides of the unit must be a minimum of 4 feet

(1.25 m) away from the wall or obstruction.

Overhead obstructions are not permitted. If

enclosed by three walls, the unit must be installed as

indicated for units in a

it.

MULTIPLE UNITS

A minimum of 8 feet (2.5 m) is required between

multiple units placed side by side. If placed end to

end, the minimum distance between units is 4 feet

(1.25 m)

4 ft

(1.25 m)

min.

8 ft

(2.5 m)

min.

UNITS IN PITS:

The top of the unit must be level

the top of the pit. In addition, a

above

with, or

minimum of 8 feet (2.5 m) is required between

the unit and the pit walls.

LOUVERS / FENCES:

Louvers/fences must have a minimum of 80% free

area and 4 feet (1.25 m) minimum clearance

between the unit and the louver/fence. Height of

louver/fence must not exceed

top of unit.

8 ft

(2.5 m)

min.

8 ft

(2.5 m)

min.

4 ft

(1.25 m)

min.

4 ft

(1.25 m)

min.

Units equipped with spring-mounted compressors have shipping spacers that are designed to hold the

compressor rigidly during transit to prevent possible damage. Before operating the unit, it is necessary to

remove these spacers. To remove the shipping spacers, follow these steps:

(a) Remove the upper nuts / washers.

(b) Discard the shipping spacers.

(c) Install the rubber cone washers (located in the electrical box).

(d) Replace the upper mounting nuts / washers.

(e) Allow 1/16 inch space between the mounting nuts / washers and the compressor foot.

On units equipped with rigid mounted compressors, check the compressor mounting bolts to insure they have

not vibrated loose during shipping.

5

Page 6

Ventilation

If the compressors or condensing units are to be located in machine rooms, adequate ventilation air must be

provided in order to avoid an excessive temperature rise in the room. Air requirements vary with ambient air

temperatures and the refrigeration load, however the following rule of thumb may be used to approximate

ventilating air quantities:

Model Type Air Quantity

Air-cooled condensing units (for horizontal air flow units) 1,000 cfm (472 L/s) per Hp

Air-cooled compressors (with remote condensers) 250 cfm (118 L/s) per Hp

Suction cooled or water-cooled compressors 200 cfm (94 L/s) per Hp

(with remote or water cooled condensers)

All of the above mentioned air quantities are based on relatively short discharge line runs within the machine

rooms. If using long uninsulated discharge line runs are unavoidable in the machine room, additional ventilation

air is required to offset the heat added to the room by the discharge gas.

6

Page 7

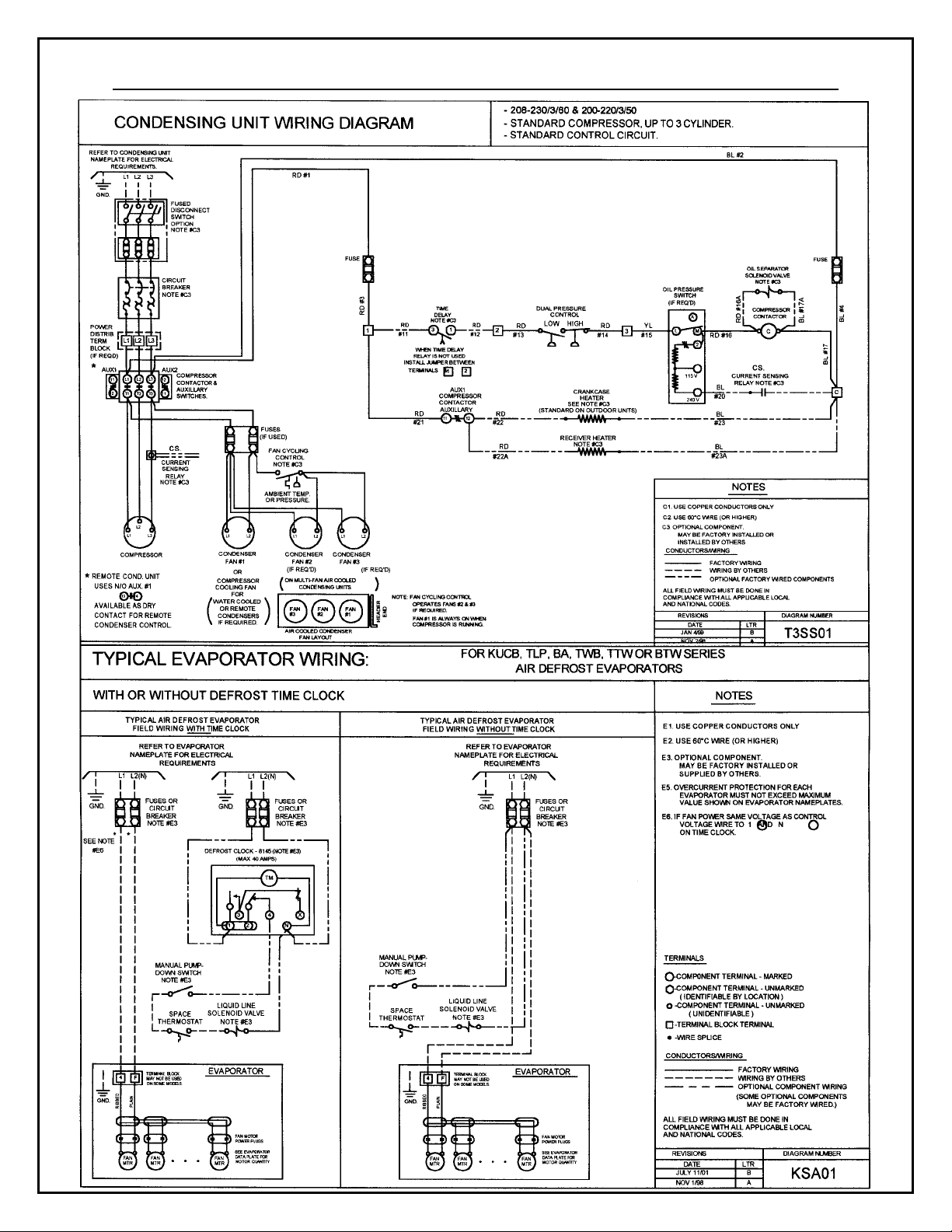

Electrical Information

WARNING

All wiring and connections to the unit must be made in accordance with national as well as local electrical codes

and by-laws.

Electrical wiring should be sized in accordance with the minimum circuit ampacities shown on the unit

nameplate and applicable electrical codes. The unit power connections are approved for copper wire only.

Connect the field power supply through a fused branch circuit disconnect switch. The entering service fuse must

not exceed the maximum overcurrent protection (MOP) value on the unit data plate.

Field connected control circuit wires are terminated directly at the control circuit terminal block in accordance

with the appropriate wiring diagram.

Voltage at the unit terminals must not vary more than the allowable variation during start-up and while under full

load. If the voltage is normal at the supply with the compressor not running and drops considerably when the

switch is closed and the motor is trying to start, there is a high resistance due to undersized wires or faulty

connections. Voltage drop between inoperative and full load must not exceed 3% of line voltage. In addition, the

phase imbalance at the motor terminals should be within 2% on three phase units.

60 Hz Supply 50 Hz Supply

Power Allowable Variation Power Allowable Variation

115-1-60 103-127 V 100-1-50 90-110 V

208/230-1-60 197-254 V 200/220-1-50 190-242 V

208/230-3-60 187-254 V 200/220-3-50 180-242 V

460-3-60 414-506 V 380/400-3-50 342-440 V

575-3-60 518-632 V

All systems should use a liquid line solenoid valve (installed at the evaporator) and should be energized by the

room or fixture thermostat. For systems with a defrost time clock, the liquid line solenoid and thermostat should

be energized by the time clock. Initially set the defrost time clock (model 8145) as follows:

Air defrost evaporators; 3 per day (every 8 hours) with the time termination at 45 minutes.

Electric defrost evaporators; 4 per day (every 6 hours) with time termination set (Fail Safe) at 30 minutes.

Check that the wiring from the defrost termination thermostat is wired to terminal “X” on the clock and terminates

the defrost cycle when the evaporator coil reaches approximately 55

also be checked for proper operation. This ensures that all water droplets have been refrozen to the coil before

the evaporator fan starts back up.

Note: The above settings are guidelines only and must be re-adjusted to suit local field conditions and actual

evaporator equipment specifications.

Refer to the evaporator installation manual for further information.

An evaporator airflow interlock is recommended on some installations so that the compressor will pump down

and shut off in the event that the evaporator fan is off for any reason. This is wired into the control circuit in

series with the thermostat and solenoid valve.

Refer to the following wiring diagrams for typical air defrost and electric defrost wiring arrangements.

o

F. The fan delay thermostat wiring should

WARNING

Any deviation or change to the electrical components or wiring as supplied on the original equipment, or

noncompliance with the voltage and phase balance requirements without written authorization will void the

warranty.

7

Page 8

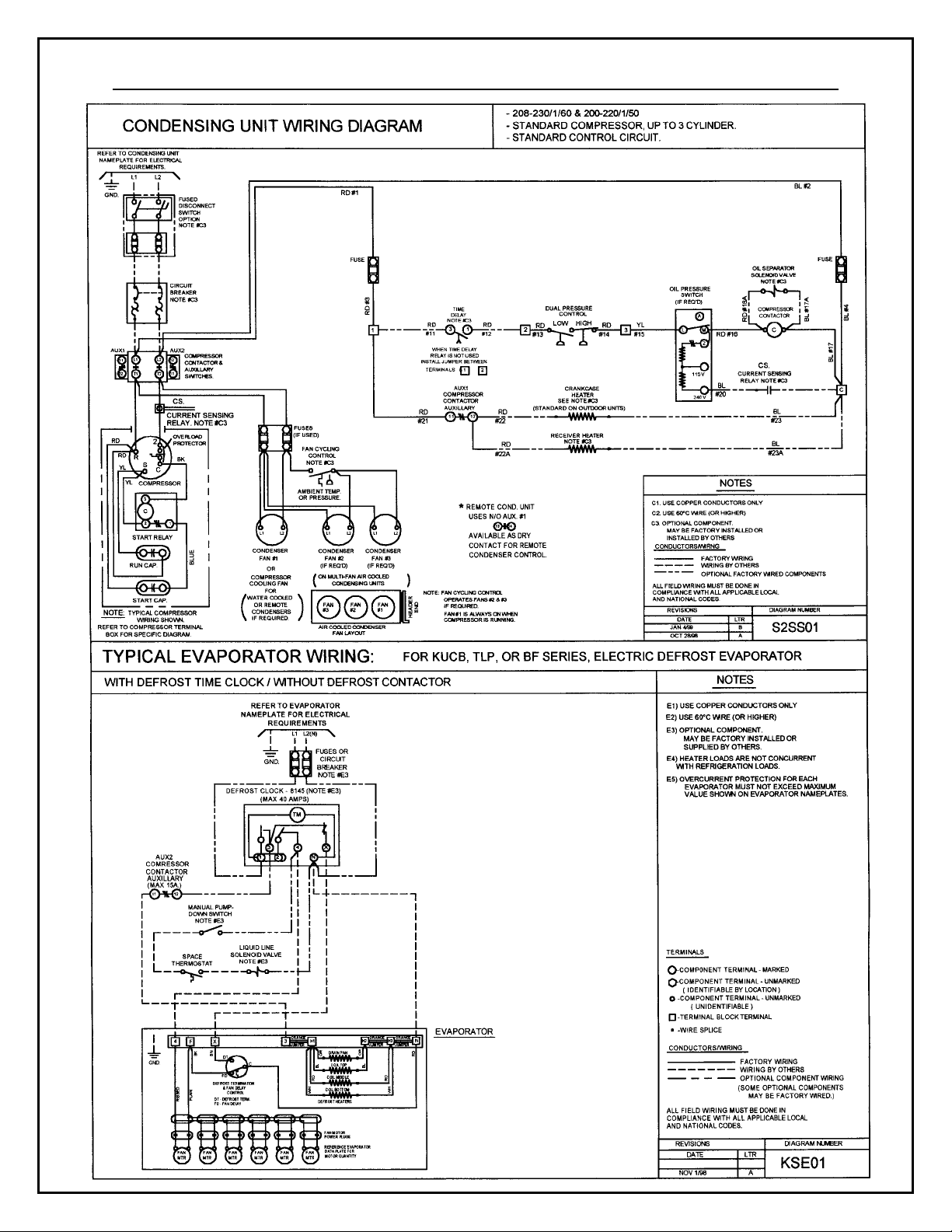

Electrical Wiring Diagram – Horizontal Air Flow Condensing Units (RP-Line)

8

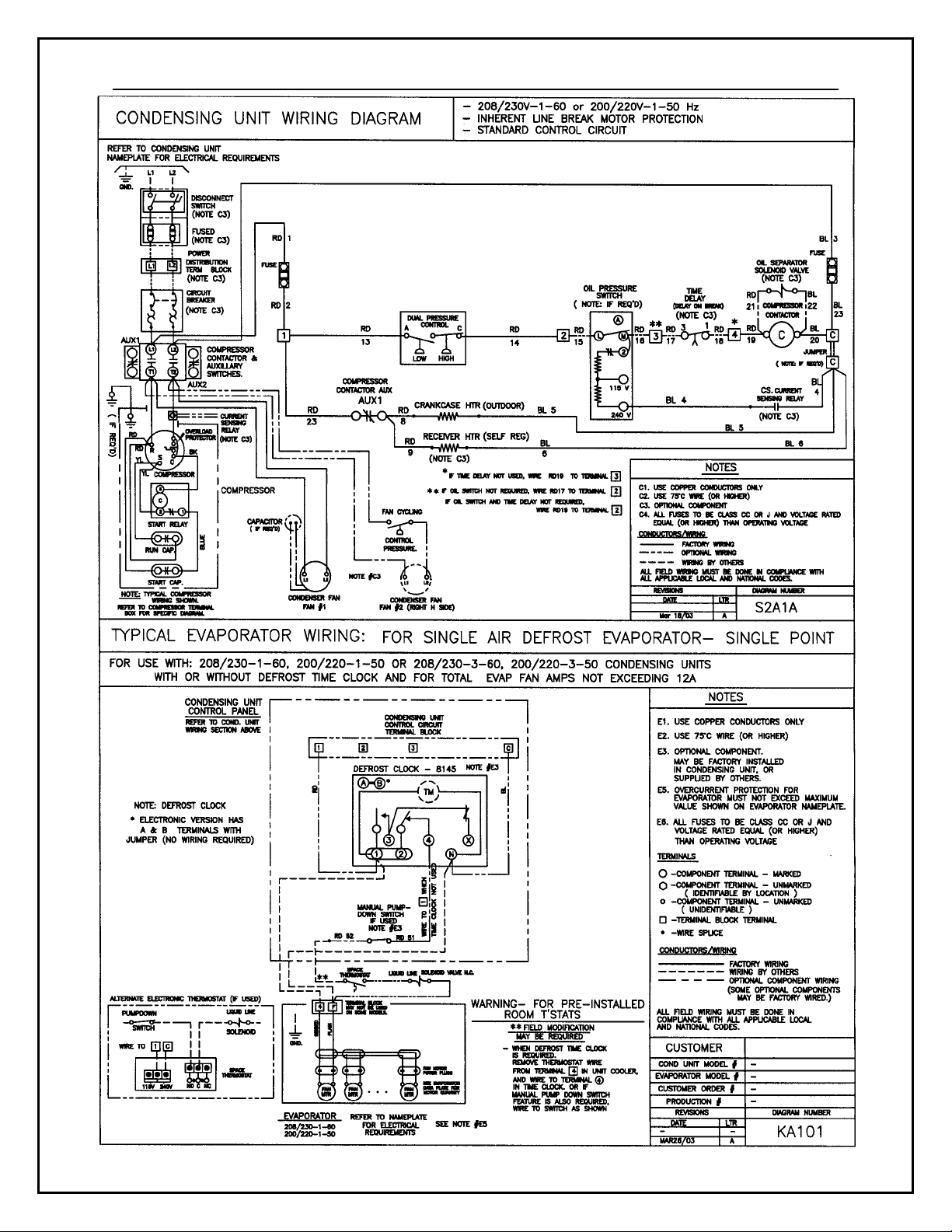

Page 9

Electrical Wiring Diagram – Horizontal Air Flow Condensing Units (RP-Line)

9

Page 10

Electrical Wiring Diagram – Horizontal Air Flow Condensing Units (BE-Line)

10

Page 11

Electrical Wiring Diagram – Horizontal Air Flow Condensing Units (BE-Line)

11

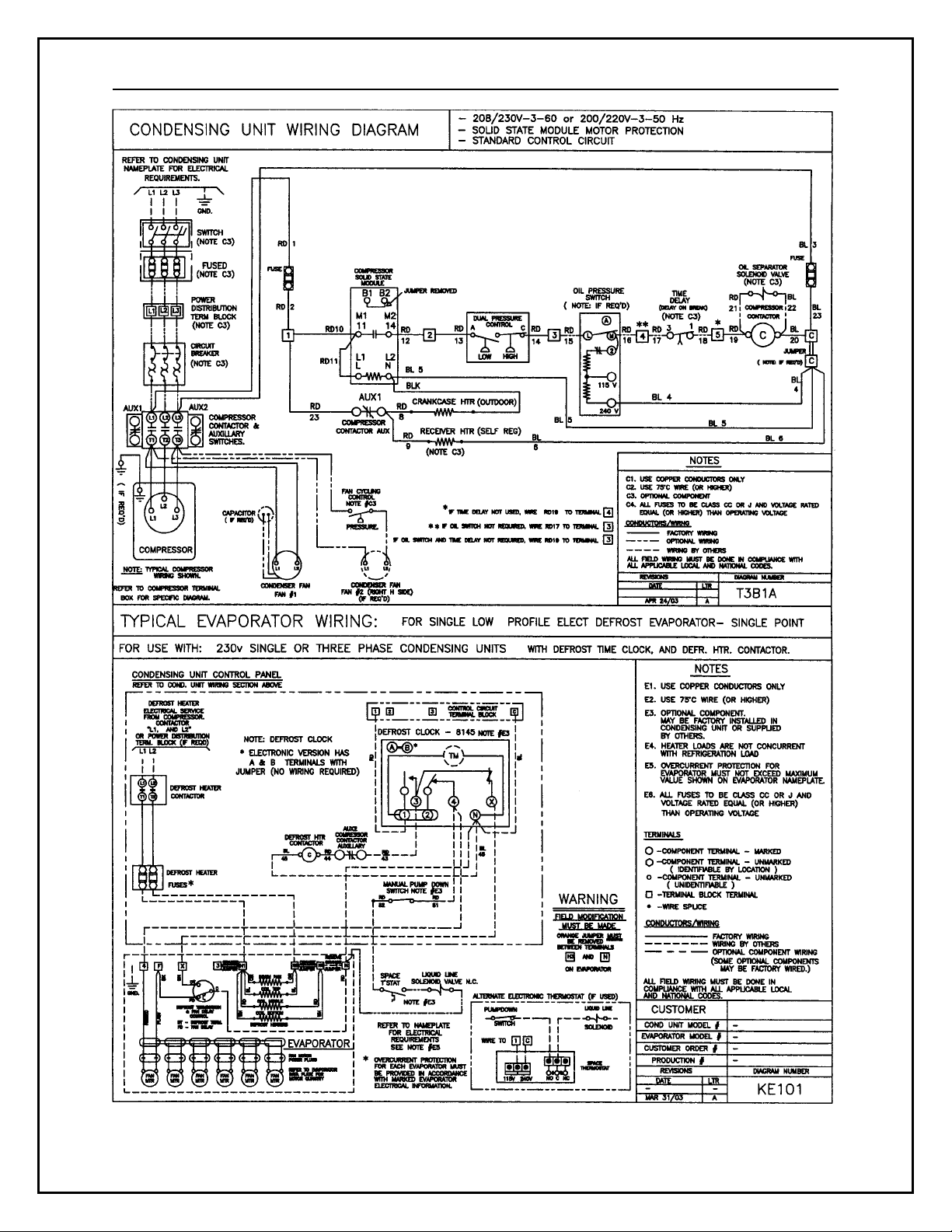

Page 12

Electrical Wiring Diagram – Horizontal Air Flow Condensing Units (BE-Line)

12

Page 13

Electrical Wiring Diagram – Horizontal Air Flow Condensing Units

13

Page 14

Electrical Wiring Diagram – Vertical Air Flow Condensing Units

14

Page 15

Refrigerant Piping

WARNING

All local codes must be observed in the installation of refrigerant piping.

IMPORTANT PIPING NOTE

Appropriate line sizing practices must be used throughout the installation of the refrigeration system. Special

consideration must be taken when the condensing unit is installed above the evaporator. REFRIGERATION

GRADE COPPER TUBING MUST BE USED FOR PIPING SYSTEMS.

Piping practice and line sizing charts as recommended by A.S.H.R.A.E. or other reputable refrigeration

standards must be followed to ensure minimum pressure drop and correct oil return. An inert gas such as dry

nitrogen should be passed through the piping during welding or brazing operations. This reduces or eliminates

oxidation of the copper and formation of scale inside the piping. For specific piping requirements refer to your

local distributor or sales representative.

Correct line sizing is most critical because of the several factors involved:

(a) Minimum pressure drop to ensure efficient compressor performance.

(b) Sufficient gas velocity to maintain proper oil return to the compressor under all load conditions.

(c) Elimination of conditions on multiple evaporators whereby oil may log in an idle evaporator.

Suction lines should be sized on the basis of a maximum total pressure drop equivalent to a 2

in saturated temperature. At 40

o

At -20

F (-28.9oC) suction temperature, this is approximately 1.3 psig (9.0 kPa) for R-404A.

o

F (4.4oC) suction temperature, this is approximately 3 psig (20.7 kPa) for R-22.

Horizontal liquid lines should be sized on a basis of a maximum pressure drop equivalent to a 2

in the sub-cooling temperature. If the lines must travel up vertically then adequate sub-cooling must be provided

to overcome the vertical liquid head pressures. A head of two feet of liquid refrigerant is approximately

equivalent to 1 psig (6.9 kPa). Liquid line velocities should not exceed 300 fpm (1.52 m/s). This will prevent

possible liquid hammering when the solenoid valve closes.

o

F (1.1oC) change

o

F (1.1oC) drop

Pressure Loss of Liquid Refrigerant in Liquid Line Risers

(Expressed in Pressure Drop PSIG and Subcooling Loss oF)

Liquid Line Rise in Feet

Refrigerant

PSIG

R-134a

R-22

R-404A, R-507

Refrigerant

4.9 2.0 7.4 2.9 9.8 4.1 12.3 5.2 14.7

4.8 1.6 7.3 2.3 9.7 3.1 12.1 3.8 14.5

4.1 1.1 6.1 1.6 8.2 2.1 10.2 2.7 12.2

40' 50' 75' 100'

PSIG

R-134a

R-22

R-404A, R-507

Based on 110 oF liquid temperature at bot tom of riser .

19.7 8.8 24.6 11.0 36.8 17.0 49.1 23.7

19.4 6.2 24.2 8.0 36.3 12.1 48.4 16.5

16.3 14.1 20.4 5.6 30.6 8.3 40.8 11.8

o

PSIG

F

Liquid Line Rise in Feet

o

PSIG

F

o

PSIG

F

o

PSIG

F

o

PSIG

F

o

PSIG

F

o

F

6.3

4.7

3.3

30'10' 15' 20' 25'

o

PSIG

F

o

F

15

Page 16

At the temperatures encountered in the condenser, receiver and liquid line a certain amount of oil is always

being circulated with the refrigerant through the system by the compressor. However, at the evaporator

temperature, and with the refrigerant in a vapor state, the oil and refrigerant separate. This oil can only be

returned to the compressor by gravity or by entrainment in the suction gas. Roof installations leave no

alternative but by entrainment for oil return, so suction gas velocity and correct line sizing to maintain this

velocity are imperative. Care must be taken not to oversize the suction line in the desire for maximum

performance.

Gas velocity in vertical suction lines must not be less than 1,000 fpm (5 m/s) and preferably 1,250 to

1,500 fpm (6 to 8 m/s).

Important: A suction trap must be installed at the base of all suction risers of four (4) feet or more in order to

trap oil and allow entrainment in the suction gas.

IMPORTANT PIPING NOTE

If steps of capacity control are supplied on a compressor, provisions must be made for oil return by sizing

suction risers to maintain adequate gas velocities at reduced refrigerant flow.

During the lower capacity running mode (compressor capacity control energized) oil will collect in the elbow or at

U-bend below pipe “B”. This will divert the gas and oil to flow up the smaller pipe “A” at a higher velocity.

IMPORTANT: When welding service valves or any components that may be damaged by heat, manufacturer’s

installation instructions must be adhered to. Wrapping components with a wet cloth will help to prevent damage

from heat.

IMPORTANT: All suction lines outside of the refrigerated space must be insulated.

16

Page 17

Water-Cooled Condensers

WARNING

All water and drain connections to the unit must be made in accordance with national as well as local plumbing

codes and by-laws.

Cooling water circuits in some shell and tube water-cooled condensers may be either series or parallel as

required by the particular application. The “series” flow is usually for city water where lower entering water

temperatures exist and higher-pressure drops can be tolerated (such as city water supplies). The “parallel”

circuit flows are usually required when the water temperatures enter at 85

water pressure drops (such as closed loop cooling tower supplies).

On some condensers, the

water circuiting may be

entirely internal with only an

inlet and outlet water fitting.

The water inlet is always at

the bottom connection.

All water-cooled condensers

require a water regulating

valve that must be installed

upstream of the condenser.

The water-regulating valve is

adjustable and is set to

provide the desired condensing pressure. As the condensing pressure rises, the valve will open and allow more

water to flow. As the condensing pressure lowers the valve will start to close to reduce the amount of water flow

into the condenser. If water supply pressure is excessive, a pressure-reducing valve must be used since the

allowable working pressure of water valves and condensers is normally 150 psig (1136 kPa). Typical

condensing temperatures normally range between 90 to 110

supply flow capacity available at the site determines the suitable condensing temperature. Lower inlet water

temperatures (below 70

o

F) allow the condensing unit to run at a lower condensing temperature without resulting

o

F. The actual water inlet temperature and water

in a high water flow rate (consumption). Higher water inlet temperatures (above 85

temperature to be higher to avoid excessive water flow rates. Refer to the water flow rate chart to estimate the

flow rate (GPM-US gallon per minute) at given water temperatures and loads. The TD (temperature difference)

is the difference between the condensing temperature and the water inlet temperature.

Example: Given 80

evaporator load. The results are:

o

20

F TD = 100 oF Cond.Temp., series flow is .148 x 12 = 1.78 GPM, parallel flow = .185 x 12 = 2.22 GPM

o

30

F TD = 110 oF Cond.Temp., series flow is .103 x 12 = 1.24 GPM, parallel flow = .128 x 12 = 1.54 GPM

o

F inlet water available, +25 oF evaporating temperature application and 1 ton (12,000Btuh)

Knowing the GPM you can estimate the pressure drop through the condenser (and compressor, if with body

coil). Refer to the Typical Pressure Drop tables and use the appropriate flow to estimate the resulting pressure

drop. If using a condenser that has only ONE water circuit (two connections) use the “parallel” column on the

GPM flow rate chart.

Care should be exercised in locating the condensing unit so that the condenser will never be exposed to

temperatures below freezing.

Excessive water velocities or cavitation on the waterside of the condenser tubes may damage a water-cooled

condenser. In order to prevent operating difficulties, care should be taken to follow the instructions outlined

below:

(a) Water velocities through the condenser should not exceed 7 fps (2.13 m/s). Higher velocities can result

in “impingement corrosion”. In order to maintain water velocities at an acceptable level, parallel circuiting

of the condenser may be necessary when high water flow is required.

(b) If a water-circulating pump is used, it should be installed so that the condenser is fed from the discharge

side of the pump.

o

F (29.4oC) or higher requiring lower

o

F) require the condensing

17

Page 18

(c) If the condenser is installed more than 5 ft (1.52 m) higher than the outlet drain point of the condenser, a

)

vacuum breaker or open vent line should be provided to prevent the outlet line from creating a partial

vacuum condition.

CONSULT THE FACTORY OR LOCAL SALES REPRESENTIVE FOR FURTHER INFORMATION.

WATER FLOW REQUIREMENTS

(Gallon Per Minute Per 1 MBH Evaporator Load)

HIGHER WATER FLOW RATES

20 o TD

Evaporating

Temperature

45

25

15

-10

-30

LOWER WATER FLOW RATES

30 o TD

Evaporating

Temperature

45

25

15

-10

-30

Typical Pressure Drops (PSIG) Condensers

Model (HP)

1,1 1/2 , 2

3, 3 1/2, 4

5, 6

7 1/2, 9

10

15

20, 25

30, 35, 40

Flow

(GPM)

10.6

22

34.2

22.40.3

48.71.2

6 18.6 2.5

22.70.4

49.91.4

6212.9

32.70.4

57.2 1

9212.9

5 2.6 0.35

10 9 1.25

15 18 2.7

10 0.7

15 1.4

25 3.4

10 0.4

20 1.3

40 4.6

Pressure Drop

Series Parallel

Consult factory for Data

(Condensing Temperature - Entering Water Temperature)

SERIES

Condensing Temperature

90 oF 100 oF 110 oF 90 oF 100 oF 110 oF

0.135 0.137 0.142 0.168 0.172 0.175

0.144 0.148 0.153 0.179 0.185 0.189

0.148 0.153 0.158 0.185 0.192 0.197

0.167 0.173 0.182 0.208 0.217 0.225

0.183 0.190 0.200 0.227 0.237 0.250

(Condensing Temperature - Entering Water Temperature)

SERIES PARALLEL

o

F 100 oF 110 oF 90 oF 100 oF 110 oF

90

0.092 0.093 0.095 0.113 0.115 0.118

0.097 0.100 0.103 0.121 0.125 0.128

0.100 0.103 0.107 0.125 0.130 0.133

0.113 0.118 0.123 0.142 0.147 0.153

0.123 0.128 0.135 0.153 0.160 0.168

Water

Valve

Size

1/2

Condensing Temperature

PARALLEL

Typical Pressure Drops (PSIG

3/4

1

1

1 1/4

1 1/4

1 1/2

Compressor Coil (smaller models only)

Compressor

Model Family

KW

EW / 3W

Larger compressor models use fans in plac e of water cooling coils.

Flow (GPM) Pressure Drop

11.7

26.2

3 13.5

10.5

21.3

32.8

45.9

18

Page 19

System Accessories

In order to ensure trouble free operation of the refrigeration system it is important that the following system

accessories be reviewed and installed.

(a) A moisture indicating LIQUID SIGHT GLASS should be installed in the liquid line between the

receiver and as close as possible to the expansion valve on the evaporator. If it is mounted on the

condensing unit, it will be mounted downstream of the receiver outlet service valve and immediately

after the liquid line drier. It will change color if there is moisture present in the system. It also allows the

contractor to detect a shortage of refrigerant or flash gas in the liquid line. Bubbles are not normally

visible in the sight glass of a properly charged system, however it is normal to see bubbles appear in the

sight glass for a few minutes when the compressor starts. Bubbles in a sight glass installed on the

condensing unit must never be used as the final indicator for shortage of refrigerant in the

system.

(b) A LIQUID LINE FILTER DRIER (sealed or replaceable core) should be installed in the system to

remove foreign matter and moisture that may have entered the system during installation. Liquid line

driers should be installed downstream of the receiver outlet valve and upstream of the liquid line

solenoid valve (if supplied). Liquid line driers may or may not have access valves, depending on the

size and application. They should be replaced whenever there is excessive pressure drop across the

filter, or when the system becomes contaminated due to system leaks, compressor burn-outs, acid

formation, or moisture accumulation as indicated by the moisture indicating sight glass. Refer to the

specific manufacturer’s recommendation for servicing.

(c) A DISCHARGE MUFFLER may be used to help minimize the noise created in the discharge line of the

compressor. This noise my be the result of variations in piping configuration, the pattern of the gas flow,

line sizes, operating pressures or compressor and unit mounting. A particular combination of gas flow

and piping will result in a resonant frequency, which may amplify the sound and vibration to an

undesirable level. Gas pulsations from the compressor discharge may also be amplified in a similar

manner.

(d) A DISCHARGE OIL SEPARATOR may be used with flooded systems, low temperature systems and

systems with long runs of piping or other factors that tend to cause oil return problems. They help

maintain oil volume levels in the compressor oil sump.

(e) A LIQUID LINE SOLENOID VALVE must be installed at the evaporator. Installing a solenoid valve will

allow all of the refrigerant to be pumped out of the low side (evaporator and suction line) when the

thermostat has been satisfied. This reduces the risk of refrigerant migrating or flooding back to the

compressor. Locating the solenoid at the evaporator (instead of the condensing unit) will minimize the

pump-down time and refrigerant capacity required by the receiver.

(f) A SUCTION LINE FILTER (sealed or replaceable core) when used are always installed upstream of the

compressor suction service valve and any accumulators or other options that may be installed. Suction

filters are equipped with “Schrader” type access valves that allow plugged filters and elements to be

identified quickly when the pressure drops get too high. Refer to the specific manufacturer’s

recommendation for servicing.

(g) Units equipped with spring-mounted compressors should have VIBRATION ELIMINATORS in both the

suction and discharge lines. They minimize noise transmission and provide flexibility if it is ever

necessary to remove a compressor. Vibration eliminators should be installed at ninety degrees to the

vibration for best results and whenever possible, in a horizontal position, parallel to the compressor

crankshaft. Suction vibration eliminators MUST

refreezing of condensate, causing expansion damage to the bellows inside the eliminator. This

expansion can eventually fatigue the copper bellows causing rupture and loss of refrigerant.

(h) A SUCTION LINE ACCUMULATOR is used to prevent liquid refrigerant from reaching the compressor.

Liquid flood back can occur for various reasons such as a malfunctioning expansion valve, refrigerant

overcharge, hot gas defrost cycle or extremely low load on the evaporator. An accumulator should be

used if frost or dirt collect on the evaporator coil(s). This can reduce the heat transfer. Some suction line

accumulators are equipped with a built in suction to liquid line heat exchangers. All hot gas defrost

systems must use an accumulator.

(i) A SUCTION TO LIQUID HEAT EXCHANGER should be used if a system requires long liquid lines from

the receiver to the evaporator or if the liquid has to rise vertically upward any distance. It can help

prevent excessive frosting on the compressor body and increase superheat in the suction line reducing

the possibility of liquid refrigerant from returning to the compressor.

(j) A PHASE / VOLTAGE MONITOR protects the system against phase loss (single phasing), phase

reversal (improper sequence), high voltage and low voltage (brownouts).

be insulated on low temperature systems to prevent

19

Page 20

Leak Testing

IMPORTANT: All system piping, including the condensing unit and accessories should be thoroughly tested for

leaks prior to start up and charging. The system should be initially pressurized to a maximum of 150 psig (1136

kPa) with dry nitrogen to ensure that the system is free of major leaks. With the system free of major leaks, a

more detailed leak check should be performed. Discharge the initial dry nitrogen charge and add enough

refrigerant to raise the system pressure up to 10 psig (170 kPa) (tracer amount). Add dry nitrogen to increase

the system pressure to a maximum of 150 psig (1136 kPa). It is recommended that an electronic leak detector

be used when checking for leaks because of its greater sensitivity to small leaks. As a further check it is

recommended that this pressure be held for a minimum of 12 hours and then rechecked. The system must be

leak free for satisfactory operation.

WARNING

HFC-134a has been shown to be combustible at pressures as low as 5.5 psig (140 kPa) at 350 oF (176.7 oC)

when mixed with air at concentrations more than 60% air by volume. At lower temperature, higher pressures

are required to support combustion. Therefore, air should never be mixed with HFC-134a for leak detection.

IMPORTANT ENVIRONMENTAL NOTE

When conventional leak detection methods are employed using HCFC or CFC tracer gas, all of the tracer gas

must be reclaimed and disposed of in a proper manner.

Evacuation and Dehydration

When the system is completely free of refrigerant leaks, an evacuation of the entire system should be completed

by using a “high vacuum” pump. This evacuation, if completed correctly, will ensure long life for the system as

well as elimination of moisture and non-condensable gas problems. Moisture problems causing compressor

failure will void warranty. Follow the recommended procedure carefully.

CAUTION

Do not use the refrigeration compressor to evacuate the system. Never start the compressor or perform a

megger insulation test while the system is in a vacuum.

Dehydration Procedure

Use only a “high vacuum” pump capable of drawing a vacuum of 100 microns. Change the vacuum pump oil

frequently. Gauges or vacuum measuring instruments should be suitable to measure conditions at any stage of

the process in order to give the operator indications of progress. For specific recommendations, refer to the

vacuum pump supplier for these instruments.

Copper jumper lines should be used to interconnect both high and low-pressure sides of the system. These

lines should be at least 3/8” O.D. in order to handle the light density vapor at high vacuum obtained at

completion of operation. Lines smaller than 3/8” O.D. will slow down the process considerably as well as making

final system vacuum questionable. The entire system temperature should be over 60

be effective. If the temperature is less than 60

evacuation with a “sweeping “ of dry nitrogen is recommended. First evacuation should be to at least 750-micron

depth. When this point is reached, break the vacuum with refrigerant or dry nitrogen to melt any moisture, which

may have frozen during the first vacuum stage.

o

F (16 oC) the final vacuum should be 50 microns. Double

o

F (16 oC) for evacuation to

IMPORTANT ENVIRONMENTAL NOTE

When conventional leak detection methods are employed using HCFC or CFC tracer gas, all of the tracer gas

must be reclaimed and disposed of in the proper manner.

Reclaim any tracer gas from the system and re-evacuate to a final vacuum of at least 100 microns at a minimum

o

60

F (16 oC) system temperature. With this degree of evacuation, all moisture and non-condensables will be

removed from the entire system.

20

Page 21

Line Insulation

After the final system leak test is complete, it is important that all refrigerant lines exposed to high ambient

conditions must be insulated to reduce the heat pick-up and prevent the formation of flash gas in the liquid lines.

Suction lines should be insulated with 3/4 inch wall insulation, Armstrong “Armaflex” or equal. To prevent rupture

due to condensate re-freezing, all suction vibration eliminators on low temperature systems must be

completely insulated. Liquid lines exposed to high ambient temperatures should be insulated with 1/2 inch wall

insulation or better. Any insulation that is to be located in an outdoor environment should be protected from UV

exposure to prevent deterioration of the insulating value.

Refrigerant Charging

Condensing units must be charged only with the refrigerant for which they were designed. The type of

refrigerant to be used is specified on the name plate of the unit. Installing a liquid line drier between the service

gauge and the liquid service port when charging a unit will ensure the refrigerant supplied to the system is clean

and dry. This is especially important when charging a low temperature system. Blend type refrigerants (400

series, i.e. R404A) must not be vapor charged unless the cylinder is completely emptied into the system.

Weigh the refrigerant drum before and after charging in order to keep an accurate record of the weight

of refrigerant put into the system.

IMPORTANT REFRIGERANT CHARGING NOTE

Overcharging a system can result in poor system performance, personal injury and / or compressor damage.

DO NOT

when located at the condensing unit, indicates the system is undercharged.

Note: To estimate the total system requirement, refer to the manufacturer’s evaporator and condensing unit

specifications on typical operating charges and include the amount for the liquid lines (see tables below). Allow

an extra 10% to 15% safety factor. Ensure the receiver can handle the required charge during the pump down

mode. (Refer to the condensing unit brochure pump down specifications).

Break the vacuum by charging liquid refrigerant into the receiver side only (charge through the receiver outlet

valve gauge port with the valve in the open position). Close the valve and then continue to charge through the

gauge port feeding the liquid line and evaporator. Start the compressor and continue to charge.

Refrigerant may be added at the compressor through the compressor suction service valve in gas form only.

When liquid charging is used, a liquid charging valve must be installed. While charging the system, special

attention should be paid to the oil level in the compressor.

If charging to the “bubble” method (observing liquid line sight glass), always use a sight glass located directly

before the TXV (thermostatic expansion valve) for the final indicator.

On units that use an adjustable flooded condenser pressure-regulating valve (Sporlan ORI-6 or ORI-10) the

proper adjustment must be set. Sporlan set their controls at 120 psig (929 kPa). These controls should be readjusted to the following pressures:

Refer to Sporlan’s installation instructions (bulletins 90-30-1 and 90-31) for further details.

charge strictly by the holding capacity of the receiver. DO NOT assume that bubbles in a sight glass,

185 psig (1377 kPa) for R-22 (2 1/2 turns in clockwise for ORI-6, 4 turns in for ORI-10)

200 psig (1480 kPa) for R-404A (3 turns in clockwise for ORI-6, 5 turns in for ORI-10)

21

Page 22

p

)

Typical Air-Cooled Condensing Unit (with Horizontal Airflow Condensers)

Refrigerant Operating Charges (LBS) (Less Evaporator and Liquid Lines)

Warm Ambients * (above 50

application

o

F) ambient

Cold Ambients ** (below 50

winter operation with flooded head

ressure control

Model HP R-22 R-404A / R-507 Model HP R-22 R-404A / R-507

1/2 H, M

1/2 L

3/4 H, M

3/4 L

1 H, M & L

1 1/2 H, L

1 1/2 M

2 H, M, L

3 H, M, L

3 1/2 M

3 1/2 L

4 H, M

4 L

5 H

5 M

6 L

7 1/2 M †

7 1/2+M †

7 1/2 L †

9 L

10 M, L

15 M, L

20 M

20 L

25 M, L

30 M, L

* Above conditions are with condenser 40 % full and receiver 10 % full.

** Above conditions are with condenser flooded at between 60 - 80 % full with fan cycling where

available and receiver 10 % full.

H = High temperature M = Medium temperature L = Low temperature

† = on BE 7.5 HP machines, use refrigerant charge indicated for 6 HP

2.0 1.7

2.0 1.7

2.4 2.1

2.0 1.7

3.2 2.8

4.2 3.7

5.1 4.4

5.1 4.4

6.5 5.7

6.1 5.3

8.3 7.2

7.7 6.7

8.5 7.4

7.7 6.7

13.4 11.7

11.5 10.0

19.6 17.1

25.5 22.2

16.3 14.2

19.6 17.1

23.5 20.4

32.6 28.3

47.9 41.7

36.7 31.9

47.9 41.7

47.9 41.7

1/2 H, M

1/2 L

3/4 H, M

3/4 L

1 H, M & L

1 1/2 H, L

1 1/2 M

2 H, M, L

3 H, M, L

3 1/2 M

3 1/2 L

4 H, M

4 L

5 H

5 M

6 L

7 1/2 M †

7 1/2+M †

7 1/2 L †

9 L

10 M, L

15 M, L

20 M

20 L

25 M, L

30 M, L

3.3 2.9

3.3 2.9

4.2 3.6

3.3 2.9

4.9 4.3

6.1 5.3

7.6 6.6

7.6 6.6

10.2 8.9

9.8 8.5

13.5 11.8

13.1 11.4

13.7 11.9

13.1 11.4

22.8 19.8

19.3 16.8

28.5 24.8

38.9 33.0

22.8 19.8

28.5 24.8

38.0 33.0

54.3 47.2

65.3 56.8

54.3 47.2

72.2 62.8

72.2 62.8

For R-134a charges consult factory.

o

F) (outdoor

Refrigerant Charge (LBS) for

Liquid Lines (per 10 Feet)

Line Size (inches) R-134a, R-22 R-404A, R-507

3/8 0.4 0.34

1/2 0.74 0.64

5/8 1.19 1.03

7/8 2.47 2.12

1 1/8 4.22 3.61

1 3/8 6.42 5.5

1 5/8 9.1 7.8

22

Page 23

Typical Air-Cooled Condensing Unit (with Vertical Airflow Condensers)

Refrigerant Operating Charges (LBS) (Less Evaporator and Liquid Lines)

WARM AMBIENTS*

TYPE HP +40F -40F +40F -40F

15 H 25.7 --- 30.0 47.7 --- --20 H 25.7 --- 30.0 47.7 --- --25 H 31.2 --- 36.3 57.9 --- --30 H 39.6 --- 46.2 74.1 --- --35 H 46.8 --- 46.8 83.7 --- --40 H 49.7 --- 49.7 94.6 --- --50 H 64.4 --- 64.4 117.8 --- --15 M 31.2 29.5 35.4 53.1 33.1 48.5

20 M 31.2 29.5 35.4 53.1 33.1 48.5

25 M 38.2 36.0 43.3 64.9 40.5 59.2

30 M 48.3 45.6 54.9 82.8 51.3 75.6

35 M 56.8 53.7 56.8 93.8 53.7 85.9

40 M 62.6 58.7 62.6 107.4 58.7 97.7

SINGLE CIRCUIT UNITS

DUAL CIRCUIT UNITS

These figures are guidelines only

--- Not Applicable

* Based on condenser summer charge +receiver 15% full +

sub-cooling circuit 100% full (where applicable)

** Based on condenser summer charge +condensers flooded

(between 60-80% full with fan cycling-- where applicable)

+receiver 15% full + sub-cooling circuit 100% full (where applicable)

50 M 80.1 75.4 80.1 133.5 75.4 121.9

10L 19.1 18.5 28.9 32.0 26.9 29.7

15L 27.7 26.8 43.1 48.0 40.1 44.4

22L 28.2 27.2 40.3 53.3 37.7 49.0

27L 34.4 33.2 49.2 65.0 46.0 59.7

30L 37.5 36.0 54.9 73.5 51.1 67.3

40L 51.0 49.1 73.5 97.4 68.6 89.5

30 H 51.5 --- 59.9 95.3 --- --40 H 51.5 --- 59.9 95.3 --- --50 H 62.4 --- 72.7 115.8 --- --60 H 79.2 --- 92.4 148.2 --- --70 H 93.6 --- 93.6 167.5 --- --80 H 99.5 --- 99.5 189.2 --- ---

100 H 128.8 --- 128.8 235.7 --- ---

30 M 62.4 58.9 70.8 106.2 66.2 97.0

40 M 62.4 58.9 70.8 106.2 66.2 97.0

50 M 76.4 72.1 86.6 129.7 81.0 118.5

60 M 96.6 91.1 109.9 165.6 102.6 151.1

70 M 113.6 107.4 113.6 187.6 107.4 171.7

80 M 125.1 117.4 125.1 214.8 117.4 195.4

100 M 160.2 150.9 160.2 267.1 150.9 243.9

20L 38.3 36.9 57.8 64.0 53.9 59.3

30L 55.4 53.5 86.1 95.9 80.2 88.7

44L 56.5 54.4 80.7 106.6 75.5 98.0

54L 68.9 66.4 98.3 129.9 92.0 119.5

60L 75.0 72.0 109.7 146.9 102.2 134.6

80L 102.1 98.3 146.9 194.9 137.3 179.0

AMBIENT TEMP>50F

R22 R404A

COLD AMBIENTS**

AMBIENT TEMP.

R22 R404A

23

Page 24

Compressor Oils

-

-

Check to see that the oil level is 1/8 to 1/3 up on the compressor sight glass on compressors so equipped

before starting the compressor and after 15 to 20 minutes of operation.

CAUTION: Oil levels should not be allowed to go above the centre or 1/2 of the sight glass. Excessive oil levels

in the compressor can result in excessive compressor noise, higher power consumption or internal compressor

damage.

Welded hermetic compressors normally do not have sight glasses or means of determining their oil level. This

type of compressor is usually installed in packaged systems or in close proximity to the fixture.

All welded hermetic compressors are factory charged with enough oil to compensate for any piping losses up to

about 35 ft (10.7 m) (one way) remote location. In the event of any substantial oil loss due to a leak or excessive

line run, recharge as per the table below.

Add approximately 1/3 fl oz per foot (32 ml per meter) for any remote location over 35 ft (10.7 m). If in doubt of

an actual oil level, the only positive check is to remove the compressor and drain the oil (through the suction

connection) and recharge with the correct factory charge (refer to unit specifications). DO NOT

oil that has been exposed to the atmosphere. DO NOT re-fill, at any one time more than a total of 110 % of the

compressor’s factory specified charge. Allow time for some of the oil to circulate into the system.

Refrigeration Oils - Copeland Semi-Hermetic Reciprocating Compressors

Interims

56)

A

POE's

Mineral

Oils

Lubricant Type

Copeland Ultra 22CC

Mobil EAL ARTIC 22 CC

ICI (Virginia KMP)

Emkarate RL 32CF

Thermal Zone 22CC

Witco Suniso 3GS

Texaco Capella WF32

Calumet RO15 (Witco)

Witco LP-200*

Penreco*

Sontex 200-LT

Traditional Refrigerants

R-12 R-22, R-502

NOT

ACCEPTABLE

PP PM

PP PM

PP PM

PP

PP

A

AA P

AA P

AA P

R-401A, R-401B, R402A,

R-408A, R409A (MP-39,

MP-66, HP-80, FX-10, FX

Shritene

Copeland Ultra 200

A/B

Shreve Zerol 200 TD

Soltex AB200A

Thermal Zone 200

A/B M/O

Mix

Legend P = Preferred Lubricant Choice M = Mixture of Mineral Oil and AlkylBenzene

* BR, QR and Scroll A/C applications

Shell 22-12

Witco R-195-0

A = Acceptable Alternative

AA PM

AA PM

AA PM

AA PM

AA P

AA P

(AB) with 50 % AB.

re-use drained

HFC's

R-134a, R-404A, R

507, R-407C, R-

410A

P

NOT

ACCEPTABLE

NOT

ACCEPTABLE

NOT

ACCEPTABLE

24

Page 25

Refrigeration Oils--Bitzer Semi-Hermetic Reciprocating Compressors:

,

,

2KC-05.2(Y) to 6F-50.2(Y)

Interim Blends

R-401A, R-401B, R-402A,

R-408A, R-409A,

(MP-39, MP-66, HP-80,

FX-10, FX56)

R-134a, R-404A,

R-507, R-407C

Lubricant Type

(H)CFC

R-22

HFC's

ICI (Virgina KMP)

Polyol Ester

Mineral Oils

Alkyl Benzene

A/B M/O

Mix

Legend: P = Preferred A= Acceptable Alternative

- Compressor with "Y" designation are factory charged with polyolester oil

* NOTE: When operating (H)CFC with ester oils the quantity of refrigerant dissolved in the oil is

more than doubled as compared with conventional lubricants. Special care should be

taken. Refer to Bitzer Technical Bulletin KT-510-2, section 5 for additional information.

Emkarate RL32S

Mobil EAL Arctic 32 A* A* P

Castrol Icematic SW32 A* A* P

Suniso 3GS A A

Suniso 4GS A A

Capella Oil WF32 A A

Capella Oil WF68 A A

Esso Zerice R68 A A

Zerol 150 P P

Zerol 300 P P

Icematic 2284 P P

Esso Zerice S46 P P

Esso Zerice S68 P P

Shell Clavus SD 2212 P P

Esso Zerice R46 A A

A* A* P

Not

Acceptable

Not

Acceptable

Not

Acceptable

Refrigeration Oils--Carlyle Semi-Hermetic Reciprocating Compressors:

06D/E and 06CC

HFC's

Lubricant Type

(H)CFC

R-22

R-134a

R-404A

R-507, R-407C

Totaline P903-1001,1701 A

Castrol E68 A

Polyol Ester

ICI Emkerarate RL68H A

CPI CP-2916S A

Not Approved

CPI Solest 68 A

BP Marine Enersyn MP-S68

A

Witco Suniso 3GS A

Mineral/Alkyl

Benzene

Totaline P903-2001 A

Texaco Capella Oil WFI-32-150 A

IGI Cryol -150 A

Not Approved

Shrieve Zerol-150 A

A = Approved

Some restrictions may apply.For further information consult Carlyle factory or Carlyle web site.

Due to the extreme hygroscopic (moisture absorbing) characteristics of Polyol Ester (POE) oils,

systems MUST NEVER

be left open to the atmosphere for any extended period of time. Simply pulling a

deep vacuum on the system during the evacuation and dehydration procedure WILL NOT remove

moisture that is absorbed into POE oils.

25

Page 26

System Start-up Check List

IMPORTANT START-UP NOTE

Only a qualified refrigeration mechanic who is familiar with compressor performance and the function and

adjustment of all controls and components should start up the compressor. Finishing up work on the

installations should be planned so that a qualified mechanic is on the job for at least the first full day that the

unit is in operation.

Before any refrigeration system is started, the following items should be checked:

(1) Check that all electrical and refrigeration connections are tight.

(2) Check compressor crankcase oil level (if equipped with sight glass). It should be from 1/8 to 1/2 full in

the sight glass.

(3) Insure that compressor shipping spacers (spring mounted compressors) or hold down nut (solid

mounted compressors are properly in place.

(4) Check that the compressor discharge and suction shut-off valves are open.

(5) Ensure that the high and low pressure controls (see table below) pressure regulating valves, oil

pressure safety controls and any other safety controls are adjusted properly.

(6) Check that the room thermostat is set for normal operation and adjust if required.

(7) Check all motors, fans and pump bearings in the condenser and evaporator. If they are the type that

require oil or grease, make sure that this is attended to in accordance with the tag, which will be

attached. Fan blades and pumps should be checked for correct rotation, tightness and alignment. Air

should draw air through the condenser (air cooled condensing unit models).

(8) Electric and hot gas evaporator fan motors should be temporarily wired for continuous operation until

the room temperature has stabilized.

(9) Observe the system pressures during the charging and initial operation process. DO NOT

the system is low on refrigerant charge unless the oil level is dangerously low.

(10) Continue to charge the system until it has enough charge for proper operation. DO NOT

OVERCHARGE THE SYSTEM.

shortage of refrigerant. It could be caused by a restriction.

(11) DO NOT

the oil charge has properly adjusted itself to maintain the proper level in the sight glass.

(12) Compressor performance, and that of all of the moving components, should be watched carefully

throughout the first operating cycle and then checked periodically during the first day of operation.

Careful attention to details at this time will pay dividends in trouble-free performance of the

entire system.

(13) Check that the wiring diagrams, instructions bulletins etc. are read and attached to the unit for future

reference. Ensure that the Warranty Activation Certificate is filled in and either faxed or mailed back to

the number or address provided.

leave the system unattended until the system has reached its normal operating condition and

Note that bubbles in the sight glass may not necessarily mean a

add oil while

CAUTION

Extreme care must be used when starting a compressor for the first time after the system has been charged.

During this time liquid refrigerant may have migrated to the compressor crankcase, creating a condition that

could cause the compressor damage due to slugging. Energizing a crankcase heater (if so equipped) 24 hours

prior to start-up is recommended. If the compressor is not equipped with a crankcase heater, directing a 500

watt heat lamp or other safe heat source on the lower shell or crankcase of the compressor for approximately

thirty minutes is recommended.

WARNING

Three phase scroll compressors must be checked for correct rotation. During the initial start up, observe the

suction and discharge gauges to ensure the suction pressure drops and the discharge pressure rises.

26

Page 27

(

)

(

)

(

)

(

)

(

)

(

)

Pressure Control Settings

Minimum

Temperature oF *

50

40

30

20

10

0

-10

-20

-30

* The coldest T emperature of either the fixture or outdoor ambient.

R-134a

Cut-in

PSIG

35 5 70208530

25 5 55207030

17 5 40205030

12 0 30104020

75" Hg20 0 30 10

55" Hg15 0 20 5

--150150

--100100

- - 10 0 6 3" Hg

Cut-out

PSIG

R-22 R-404A, R-507

Cut-in

PSIG

Cut-out

PSIG

Cut-in

PSIG

Cut-out

PSIG

High Pressure Control Settings

Refrigerant

R-134a

R-22

R-404A

Air-Cooled Units Water Cooled Units

Maximum Cut-out (PSIG)

250 200

370 315

400 315

Low Temperature Room Pull-Down

It can take up to two weeks to properly start-up and pull-down a large freezer. Large freezers should be pulldown to temperature in stages. Too fast a pull-down can cause structural problems in pre-fabricated rooms and

will damage (crack) concrete floors. Reduce room temperature by 10 to 15

temperature for 24 to 48 hours at 35

during this pull down stage.

Once the room is pulled down to temperature, expect frost on the compressor end bell and any exposed suction

line. A lack of frost in these areas probably indicates too high of suction superheat. Reduce defrost frequency to

30 minutes every 6 hours if possible. Adjust the defrost termination (and time clock) so that the coil and drain

pan are COMPLETELY free of frost / ice at termination. Too short of a defrost cycle will allow residual ice to

grow. Too long of a defrost will allow the coil(s) to steam at the end of the cycle. The steam will condense and

freeze fans, fan guards and create frosting on the ceiling of the room. The evaporator fan delay must allow any

condensate left on the coil surface to refreeze before the fans start.

o

F (1.7 oC) and again at 25 oF (-3.9 oC). Monitor the amount of defrost water

o

F (5.6 to 8.4 oC) per day. Hold this

27

Page 28

Checking Superheat

IMPORTANT SYSTEM BALANCING NOTE

To obtain maximum system capacity and insure trouble free operation it is necessary to check both the

compressor and evaporator superheat.

Compressor Superheat

Compressor suction superheat must be checked. To check the superheat at the compressor the following steps

should be followed:

(1) Measure the suction pressure at the suction service valve of the compressor. Determine the saturated

temperature corresponding to this pressure from a “Pressure- Temperature” chart.

(2) Measure the suction temperature of the suction line about 6 inches (15 cm) back from the compressor

suction valve using an accurate thermometer.

(3) Subtract the saturated temperature (from step 1) from the actual suction line temperature (from step 2).

This difference is the actual superheat at the compressor.

System capacity decreases as the suction superheat increases. For maximum system capacity, the suction

superheat should be kept as low as is practical. The superheat at the compressor should range within

20 to 45

NOTE: Too low of a suction superheat can result in liquid being returned to the compressor. This can cause

dilution of the oil and eventually cause failure of the bearings and rings through wash out as well as liquid

slugging.

NOTE: Too high of a suction superheat will cause excessive discharge temperatures which cause a break down

of the oil and will result in piston ring wear, piston and cylinder wall damage.

If adjustment to the suction superheat is required, it should be done either by adjusting the thermostatic

expansion valve at the evaporator, the use of liquid to suction heat exchanger or suitable use of suction line

insulation.

o

F (11.2 to 25.2 oC) Superheat.

Evaporator Superheat

Once the refrigerated space is at its design temperature or close to design temperature, the evaporator

superheat must be checked. To check the suction superheat at the evaporator the following steps should be

followed:

(1) Measure the suction pressure in the suction line at the bulb location by either,

(a) A gauge in the external equalizer line will indicate the pressure directly and accurately.

(b) A gauge directly in the suction line near the evaporator or directly in the suction header will suffice.

(2) Measure the temperature of the suction line at the point where the thermostatic expansion valve bulb is

clamped to the suction line.

(3) Convert the pressure obtained in step 1 above to a saturated evaporator temperature from a “Pressure-

Temperature” chart.

(4) Subtract the saturated temperature (from step 1) from the actual suction line temperature (from step 2).

This difference is the actual superheat at the evaporator.

The superheat at the evaporator should be a minimum of 6 to 10

o

C) design TD (temperature difference) to a maximum of 12 to 15 oF (6.7 to 8.4 oC) for systems with a higher

operating TD.

Low temperature applications (freezers) should be set at superheats of 4 to 6

TD = Box temperature – evaporating temperature.

o

F (3.4 to 5.6 oC) for systems with a 10 oF (5.6

o

F (2.2 to 3.4 oC).

28

Page 29

System Operational Check List

When the system has been running trouble free for an extended time (two weeks or more) and design

conditions are satisfied, the following check list should be followed:

(1) Check that compressor discharge and suction pressures are operating within the allowable design

limits for the compressor. If not, take the necessary corrective action.

(2) Check the liquid line sight glass and expansion valve operation. If there is an indication that the system

is low on refrigerant, thoroughly check the system for leaks before adding refrigerant.

(3) Check the level of the oil in the compressor sight glass (if so equipped). Add oil as necessary.

(4) The thermostatic expansion valve must be checked for proper superheat settings. The sensing bulb

must have positive contact with the suction line and should be insulated. Valves operating at a high

superheat setting results in low refrigeration capacity. Low superheat settings can cause liquid slugging

and compressor bearing washout. (Refer to the section on compressor and evaporator superheats)

(5) Check the voltage and amperage readings at the compressor terminals. Voltage reading must be

within the recommended guidelines. Normal operating amperages can be much lower than the

compressor nameplate values.

(6) To check the high pressure control setting it is necessary to build up the head pressure to the cut-out

point of the control. This can be done by stopping the condenser fan(s) (air cooled condensing units) or

pump and watching the pressure rise on a high pressure gauge to make sure the high pressure control

is operating at the setting.

(7) Check the low pressure settings by throttling the compressor shut-off valve and allowing the

compressor to pump down. This operation must be done with extreme caution to avoid too sudden a

reduction in crankcase pressure, which will cause oil slugging and possible damage to the compressor

valves. Close the valve a turn at a time while watching the compound gauge for change and allowing

time for the crankcase pressure to equalize with the pressure control bellows pressure. The slower the

pressure is reduced, the more accurate will be the check on the pressure control setting.

(8) Recheck all safety and operating controls for proper operation and adjust as necessary.

(9) Check defrost controls for initiation and termination settings, and the length of defrost period. Set

the fail safe on the time clock at the length of defrost plus 25 %.

(10) If the system is equipped with winter head pressure controls (fan cycling or flooded valves), check for

operation.

(11) Fill in the Service Log in the back of this Installation Manual.

29

Page 30

System Troubleshooting

The following System Troubleshooting Guide lists the most common types of malfunctions encountered with

refrigeration systems. These simple troubleshooting techniques can save time and money minimizing

unnecessary downtime and end-user dissatisfaction.

Contact the factory or your local sales representative for further information or assistance.

System Troubleshooting Guide

Condensing Unit Problem Possible Causes

Compressor will not run. Does not try to start.

Compressor hums, but will not start. 1. Improperly wired.

Compressor starts, but trips on overload

protector.

Compressor short cycles. 1. Low pressure control differential set too low.

Start relay burns out. 1. Improperly wired.

Contact welded stuck on start relay 1. Short cycling.

Start capacitor burns out 1. Improperly wired.

1. Main power switch open.

2. Fuse blown or tripped circuit breaker.

3. Thermal overloads tripped.

4. Defective contactor or coil.

5. System shut down by safety devices.

6. Open thermostat or control. No cooling required.

7. Liquid line solenoid will not open.

8. Loose wiring.

2. Low line voltage.

3. Loose wiring.

4. Defective start or run capacitor.

5. Defective start relay.

6. Motor windings damaged.

7. Internal compressor mechanical damage.

1. Improperly wired.

2. Low line voltage.

3. Loose wiring.

4. Defective start or run capacitor.

5. Defective start relay.

6. Excessive suction or discharge pressure.

7. Tight bearings or mechanical damage in compressor.

8. Defective overload protector.

9. Motor windings damaged.

10. Overcharged system.

11. Shortage of refrigerant.

12. Suction or discharge pressure too high.

13. Inadequate ventilation.

14. Operating system beyond design conditions.

2. Shortage of refrigerant.

3. Low airflow at evaporator(s).

4. Discharge pressure too high.

5. Compressor internal discharge valves leaking.

6. Incorrect unit selection (oversized).

2. Low or high line voltage.

3. Short cycling.

4. Improper mounting of relay.

5. Incorrect start or run capacitor.

6. Incorrect relay.

2. No bleed resistor on start capacitor.

2. Short cycling.

3. Low line voltage.

4. Relay contacts sticking.

5. Incorrect capacitor.

6. Start winding remaining in circuit for prolonged period.

30

Page 31

Condensing Unit Problem Possible Causes

Compressor noisy or vibrating. 1. Flood back of refrigerant.

2. Improper piping support on the suction or discharge lines.

3. Broken or worn internal compressor parts.

4. Incorrect oil level.

5. Scroll compressor rotating in reverse (three phase).

6. Improper mounting on unit base.

Discharge pressure too high. 1. Non-condensables in the system.

2. System overcharged with refrigerant.

3. Discharge service valve partially closed.

4. Condenser fan not running.

5. Dirty condenser coil.(air-cooled condensers)

6. Dirty tubes. .(water-cooled condensers)

7. Defective or improperly set water regulating valve.

(water-cooled condensers)

8. Defective or improperly set flooded head pressure control.

Discharge pressure too low. 1. Low suction pressure.

2. Cold ambient air.

3. Suction service valve partially closed.

4. Shortage of refrigerant.

5. Defective or improperly set water regulating valve.

(water-cooled condensers)

6. Defective or improperly set flooded head pressure control.

Suction pressure too high. 1. Excessive load.

2. Compressor internal valves broken.

3. Incorrect unit selection (undersized).

4. Improper TXV bulb charge.

Suction pressure too low. 1. Shortage of refrigerant.

2. Evaporator dirty or iced up.

3. Clogged liquid line filter drier.

4. Clogged suction line filter or compressor suction strainers.

5. Expansion valve malfunctioning.

6. Condensing temperature too low.

7. Improper TX valve selection.

8. Evaporator distributor feed problems.

Low or no oil pressure. 1. Low oil level. (trapped oil in evaporator or suction line)

2. Clogged suction oil strainer.

3. Excessive liquid refrigerant in the crankcase.

4. Worn oil pump.

5. Oil pump reversing gear sticking in the wrong position.

6. Worn bearings.

7. Loose fitting on oil line.

8. Pump housing gasket leaking.

Compressor loses oil. 1. Refrigerant leak.

2. Short cycling.

3. Excessive compressor ring blowby.

4. Refrigerant flood back.

5. Improper piping or traps.

6. Trapped oil in evaporator.

Compressor runs continuously 1. Excessive load.

2. Too low of a system thermostat setting or defective

thermostat.

3. Shortage of refrigerant.

4. Leaking compressor internal valves.

5. Malfunctioning liquid line solenoid.

6. Incorrect unit selection (undersized).

31

Page 32

System Troubleshooting Guide

Fixture Problem Possible Causes

Room temperature too high.

Room temperature too low. 1. Defective room thermostat or improper differential / setting.

Ice accumulating on ceiling. 1. Defrost on too long (improper setting / defective termination

Evaporator coil not clear of ice after defrost. 1. Defrost on too short (improper setting / defective

Ice building up in drain pan. 1. Improper slope in pan.

Evaporator fans will not operate. 1. Main power switch open.

1. Defective room thermostat or improper differential / setting.

2. Malfunctioning liquid line solenoid valve.

3. Insufficient air across evaporator coil (iced up coil, product

blocking evaporator, fan blade / motor problem).

4. Improper evaporator superheat (low refrigerant charge,

plugged TXV strainer, poor TXV bulb contact, incorrect

TXV setting).

5. Malfunctioning condensing unit.

2. Malfunctioning liquid line solenoid valve.

thermostat, improper setting / defective time clock).

2. Too many defrosts per day.

3. Fans not delayed after defrost (improper setting / defective

fan delay thermostat).

termination thermostat, improper setting / defective time

clock).

2. Electric heaters defective / miswired / low voltage.

3. Not enough defrosts per day.

4. Air defrost evaporator operating at too low of temperature

(require electric defrost).

5. Defective / miswired interlock at compressor contactor.

6. Defective defrost contactor or coil.

2. Blocked drain line (unheated , not insulated).

3. Electric heater in drain pan defective / miswired / low

voltage).

4. Not enough defrosts per day.

5. Lack of or improper P-trap in drain line.

2. Fuse blown or tripped circuit breaker.

3. Defective contactor or coil.

4. Room temperature too high (fan delay thermostat open).

5. Fan delay thermostat improper setting / defective.

6. Defective fan motor (low voltage / tripped on thermal

overload).

7. Defective time clock.

8. Normal mode during defrost cycle (electric defrost type

evaporator).

IMPORTANT TROUBLESHOOTING NOTE

Before any components are changed on the refrigeration system, the cause of the failure must be identified.

Further problems will exist unless the true cause or problem is identified and corrected.

32

Page 33

Customer Instructions

Completely fill in Warranty Activation Certificate located inside of the back cover of this Installation and

Maintenance Manual. The top (white) copy should be faxed or mailed per the instructions on this form. The

(pink) copy is for the installing contractor’s files and the (yellow) copy is to be left attached inside of the

Installation and Maintenance Manual for the owner / end user’s future reference.

Give the owner / end user instructions on normal operation of the system. Explain electrical characteristics,

location of disconnect switches as well as other safety precautions. Advise on keeping equipment area clean

and free of debris. If system has operational features, point these out to the operator.

Maintenance Program

In order to ensure that the refrigeration system runs trouble free for many years, a follow-up maintenance

program (consisting of a minimum of two inspections per year) should be set up. A qualified refrigeration service

mechanic should carry out this semi-annual inspection. The main power supply must be disconnected and

locked off to avoid accidental start up of the equipment.

(1) Check electrical components and tighten any loose connections.

(2) Check all wiring and electrical insulators.

(3) Check contactors to ensure proper operation and contact point for wear.

(4) Check that fan motors (if applicable) are operational, ensure fan blades are tight and all mounting bolts

are tight.

(5) Check oil and refrigerant levels in the system.

(6) Ensure that the condenser surface (if applicable) is cleaned and free of dirt and debris.

(7) Check the operation of the control system. Make certain that all of the safety controls are operational

and functioning properly.

(8) Check all refrigeration piping. Make sure that all mechanical joints and flare nuts are tight.

Service Parts Availability

Genuine replacement service parts should be used whenever possible. Refer to the Service Parts List on the

back cover of this Installation and Maintenance Manual or attached to the unit. Parts may be obtained by

contacting your local sales representative or authorized distributor.

33

Page 34

FINISHED GOODS WARRANTY

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GENERAL WARRANTY POLICY

Subject to the terms and conditions hereof, the Company warrants all Products, including Service Parts,

manufactured by the Company to be free of defects in material or workmanship, under normal use and

application for a period of one (1) year from the original date of installation, or eighteen (18) months from

the date of shipment from the Company, whichever occurs first. Any replacement part(s) so supplied will be

warranted for the balance of the product’s original warranty. The part(s) to be replaced must be made

available in exchange for the replacement part(s) and reasonable proof of the original installation date of the

product must be presented in order to establish the effective date of the warranty, failing wh ich, the effective

date will be based upon the date of manufacture plus thirty (30) days. Any labour, material, refrigerant,

transportation, freight or other charges incurred in connection with the p erformance of this warranty will be

the responsibility of the owner at the current rates and prices then in effect. This warranty may be tran sferred

to a subsequent owner of the product.

THIS WARRANTY DOES NOT COVER

(a) Damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized alteration

or repair of the system affecting the product’s reliability or performance (d) damages caused by improper

matching or application of the product or the product’s components (e) damages caused by failing to provide

routine and proper maintenance or service to the product (f) expenses incurred for the erecting,

disconnecting, or dismantling the product (g) parts used in connection with normal maintenance, such as

filters or belts (h) products no longer at the site of the original installation (i) products installed or operated

other than in accordance with the printed instructions, with the local installation o r building codes and with

good trade practices (j) products lost or stolen.

No one is authorized to change this WARRANTY or to create for or on behalf of the Company any other

obligation or liability in connection with the Product(s). There is no other representation, warranty or

condition in any respect, expressed or implied, made by or binding upon the Company other than the above

or as provided by provincial or state law and which cannot be limited or excluded by such law, nor will we

be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modification of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State laws.

Service Log

Date Comments

34

Page 35

Start-up Information

Important: This start-up information should be completely filled in on each installation and remain with the unit

as a permanent record for future reference. Future service work may be logged on the proceeding page. Service

parts list are attached to the back cover. PLEASE PRINT LEGIBLY

Name & address of installation______________________________________________________

__________________________________________________________________________

Name, address, phone & fax # of Installing contractor _______________________________________

__________________________________________________________________________

__________________________________________________________________________

Type of System (Cooler, Freezer, etc…) ___________ Design Box Temperature _____

Condensing Unit System start-up date ______________________

Unit model # _________________________________ Unit serial #

Compressor model #___________________________ Compressor serial #_______________________

____________________________

Evaporator(s) QTY ______

Unit model #

Unit model #____________________________ Unit serial #____________________________

Evaporator(s) unit electrical rating: Volts__________Phase__________Hz __________

Voltage at evaporator terminals: L1/L2___________ L2/L3 ____________ L1/L3__________

Amperage at evaporator: L1___________ L2____________ L3______________

Expansion valve - Manufacturer________________________________ Model #

Evaporator drain line trapped outside of box____Yes _____No

____________________________ Unit serial #____________________________

____________________

System Conditions (Record just before desired box temperature is reached)

Refrigerant Type________Total Charge________System evacuation # of times______Final micron

Ambient at start-up ______oF Operating box temperature______oF

Thermostat setting ______

Condensing unit electrical rating: Volts__________Phase__________Hz __________

Voltage at compressor terminals: L1/L2___________ L2/L3 ____________ L1/L3__________

Amperage at compressor: L1___________ L2 ____________ L3 ___________

Compressor discharge pressure__________psig Compressor suction pressure__________psig

Discharge line temperature at compressor______

Superheat at compressor ___

Suction line temperature at evaporator TX valve bulb______ oF Superheat at evaporator______

o

F Defrost settings ______ / day Minutes fail safe ______

o

o

F

F Suction line temperature at compressor______ oF

_______

o

F

Comments:________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

o

F

35

Page 36

Service Parts List

08/08/2007

Due to Bally Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

Bally Refrigerated Boxes Inc.,

General Sales, Manufacturing and Engineering

135 Little Nine Drive, Morehead City, NC 28557

Phone: 800-24BALLY, 252-240-2829 Fax: 252-240-0384

Service and Warranty

Phone: 800-344-9302, 610-337-8600 Fax: 610-337-0431

Visit our web site at www.ballyrefboxes.com

Loading...

Loading...