Page 1

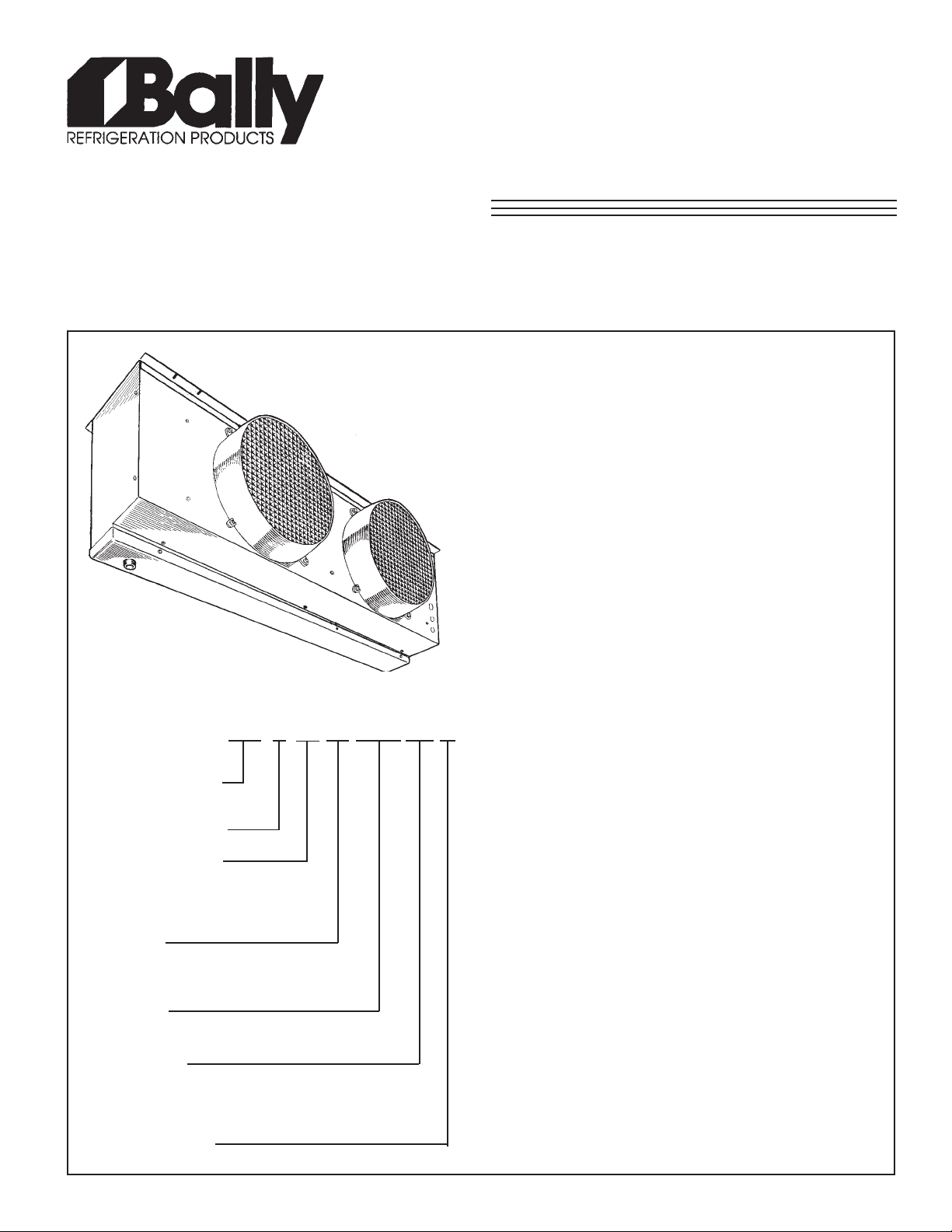

PRODUCT DA T A &

Electric Defrost

Medium Profile

BB Unit Coolers

INSTALLATION

Bulletin: B30-BBE-PDI-15

1048680

Medium and low Temp Applications

°F Room Temp. or Higher)

(-30

Electrical Power: Three Phase

* Heavy gauge textured aluminum cabinet

construction resists scratches/corrosion and

minimizes weight for shipment, installation and

service.

* Attractive and durable high density polyethylene

fan guards with built-in throw boosters.

* 3/8 Tubing coil construction (reduces operating

charge).

* VENTURI-FLO Distributor eliminates need for

distributor nozzle selections.

* Adjustable Defrost Termination Thermostat with

dual Fan Delay function.

NOMENCLATURE

BB

BALLY

MEDIUM PROFILE

UNIT COOLER

NUMBER OF FANS

MBH CAPACITY AT

o

10

F T .D. (60Hz)

SIZE 24 = 24,000 BTUH

OF COOLING

OPTIONS

P = PRE ASSEMBLED REMOTE

S = STANDARD UNIT

DEFROST

ED = ELECTRIC DEFROST

ELECTRICAL

T3 = 208-230/3/60 T4 = 460/3/60

T5 = 575/3/60 T7 = 200-220/3/50

T8 = 380/3/60 T9 = 380-400/3/50

REVISION LEVEL

24

1

* Stainless-Steel Defrost Heaters mounted on the

-ED-

P

T4 B

coil for service accessibility

* Refrigerants R12, R22, R502, R134a, R404A,

R407A, R407B, R407C, R507.

CONTENTS PAGE

Nomenclature.....................................

Capacity Data.....................................

Electrical Data....................................

Wiring Diagrams................................

Dimensional Data...............................

Alco TXV Selections...........................

Sporlan TXV Selections.....................

Pictorial Views....................................

Application..........................................

Installation..........................................

Inspection...........................................

Location..............................................

Mounting.............................................

Drain Line...........................................

Piping..................................................

Wiring.................................................

System Check....................................

Maintenance.......................................

Service Parts List...............................

Project Information............................

Cover

2,3

2,3

4,5

6

7

8

9

9

9

9

9

10

10

10

10

10

10

11

Back

Page 2

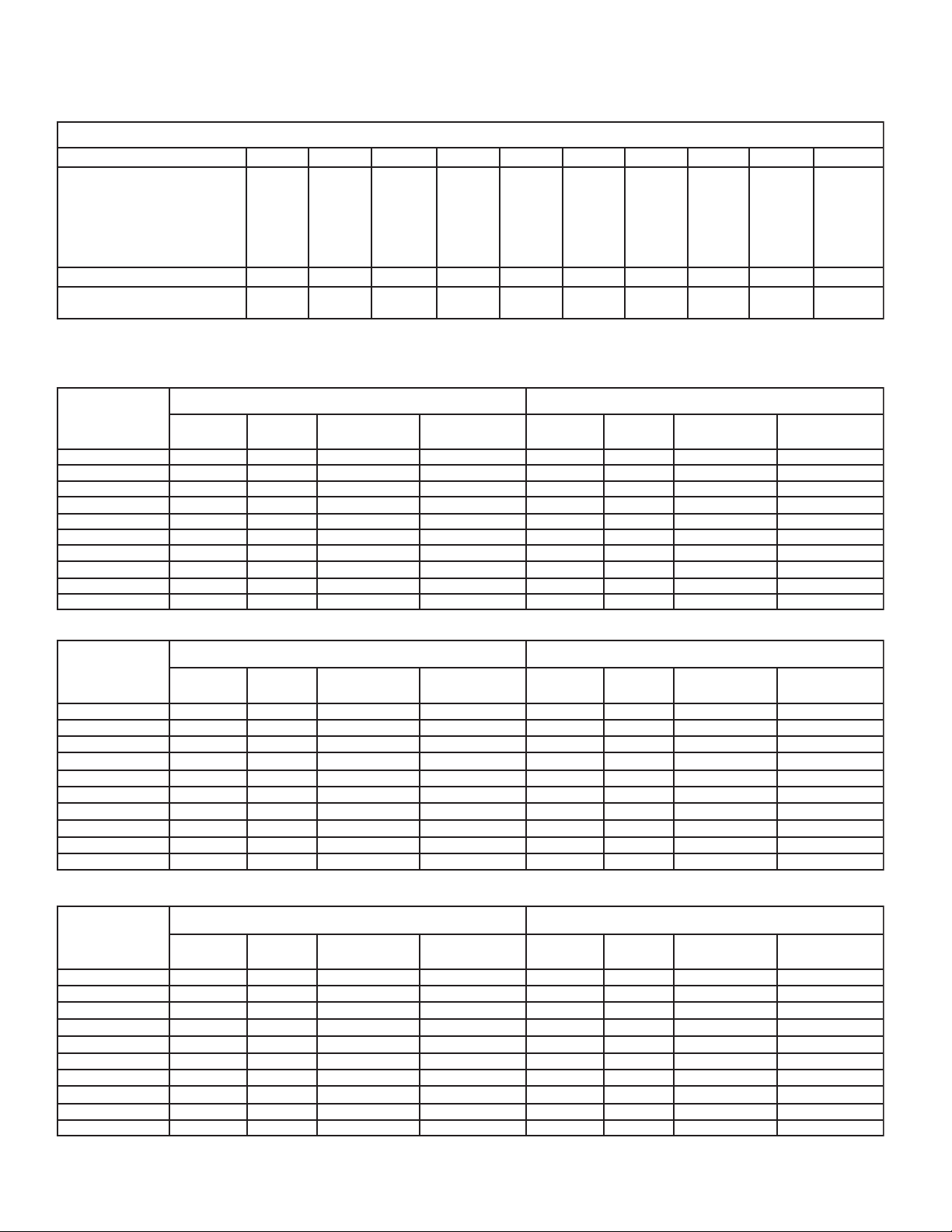

60Hz SPECIFICATIONS

Capacity Data - (BTUH) @ 10oF TD 60Hz

BBLEDOM

o

ERUTAREPMETPAVE

FDE-P611DE-P911DE-P421DE-P232DE-P832DE-P542DE-P152DE-P063DE-P863DE-P573

52+/02+

01+

0

01020304-

MFC

TNAREGIRFER

*EGRAHC

* R404A at -20oF S.S.T . with coil 30% full

LBS

KG

00091

02681

05081

09

271

05161

01051

08631

0013007405540049004900290019056310563105631

8.5

7.2

00032

04522

05812

03902

05591

07181

06561

4.5

4.2

00092

02482

05572

09362

05642

01922

08802

2.8

7

.3

00083

04273

63

001

08543

00323

02003

06372

5.8

9.3

00064

08054

00734

06814

00193

04363

02133

8.01

9.4

00035

04915

05305

03284

05054

07814

06183

6.21

7.5

00006

0088

5

00075

00645

00015

00474

00234

1.61

3.7

00007

00686

00566

00736

00595

00355

00405

6.91

9.8

00008

00487

00067

00827

00086

00236

00675

4.22

2.01

00088

04268

00638

08008

00847

02596

06336

5.42

2.11

208-230/3/60

LEDOM

B3T-DE-P611BB10.25.25102342.114102

B3T-DE-P911BB10.25.25100168.518.9152

B3T-DE-P421BB10.25.25100168.518.9152

BB20.45.451086112.038.7354

B3T-DE-P232

B3T-DE-P832BB20.45.451086112.038.7354

B3T-DE-P542BB20.45.451086112.038.7354

B3T-DE-P152BB20.45.451086112.038

B3T-DE-P063BB30.65.651052717.449.5506

B3T-DE-P863BB30.65.651052717.449.5506

B3T-DE-P573BB30.65.651052717.449.5506

YTQ

ELECTRICAL DATA 60HZ

SROTOMNAF SRETAEHTSORFED

LATOT

ALF

.CRIC.NIM

YTICAPMA

ESUF.XAM

)SPMA(

STTAWSPMA

.CRIC.NIM

YTICAPMA

.7354

460/3/60

SROTOMNAF SRETAEHTSORFED

LEDOM

YTQ

B4T-DE-P611BB10.152.15102346.57 51

B4T-DE-P911BB10.152.15100169.79.951

B4T-DE-P421BB10.152.15100169.79.951

B4T-DE-P232BB20.

B4T-DE-P832BB20.252.251086111.519.8152

B4T-DE-P542BB20.252.251086111.519.8152

B4T-DE-P152BB20.252.251086111.5

B4T-DE-P063BB30.352.351052713.229.7203

B4T-DE-P863BB30.352.351052713.229.7203

B4T-DE-P573BB30.352.351052713.229.7203

LATOT

ALF

252.251086111.519.8152

.CRIC.NIM

YTICAPMA

ESUF.XAM

)SPMA(

STTAWSPMA

19.8152

.CRIC.NIM

YTICAPMA

AM

AM

ESUF.X

)SPMA(

ESUF.X

)SPMA(

575/3/60

LEDOM

B5T-DE-P611BB18.01 5102345.46.551

B5T-DE-P911BB18.01 5100163.69.751

B5T-DE-P421BB18.01 5100163.69.751

B5T-DE-P232BB26.18.1510861

B5T-DE-P832BB26.18.151086111.211.5102

B5T-DE-P542BB26.18.151086111.211.5102

B5T-DE-P152BB26.18.151086111.211.5102

-P063BB34.26.251052719.714.2252

B5T-DE

B5T-DE-P863BB34.26.251052719.714.2252

B5T-DE-P573BB34.26.251052719.714.2252

All Fan Motors are 3/4 H.P .

SROTOMNAF SRETAEHTSORFED

YTQ

LATOT

ALF

.CRIC.NIM

YTICAPMA

ESUF.XAM

)SPMA(

STTAWSPMA

11.211.5102

.CRIC.NIM

YTICAPMA

AM

ESUF.X

)SPMA(

- 2-

Page 3

50Hz SPECIFICATIONS

Capacity Data - (BTUH) @ 10oF TD 50Hz

BBLEDOM

o

ERUTAREPMETPAVE

FDE-P611DE-P911DE-P421DE-P232DE-P232DE-P542DE-P152DE-P063DE-P863DE-P573

52+/02+

01+

0

01020304-

MFC

TNAREGIRFER

*EGRAHC

* R404A at -20oF S.S.T . with coil 30% full

LBS

KG

08471

03171

60661

70

951

85841

90831

68521

0752009308730087008700870557033110563105631

8.5

7.2

06112

73702

20102

65291

68971

61761

53251

4.5

4.2

08662

64162

64352

97242

87622

77012

01291

2.8

7

.3

06943

16243

33

212

41813

61792

81672

17152

5.8

9.3

02324

47414

40204

11583

27953

33433

07403

8.01

9.4

06784

58774

22364

27344

64414

02583

70153

6.21

7.5

00255

6904

5

04425

23205

02964

80634

44793

1.61

3.7

00446

21136

08116

40685

04745

67805

86364

6.91

9.8

00637

82127

02996

67966

06526

44185

29925

4.22

2.01

06908

14397

21967

47637

61886

85936

19285

5.42

2.11

200-220/3/50

LEDOM

-P232BB24.338.351586017.726.4304

380-400/3/50

LEDOM

T-DE-P063BB34.26.25105271728.3304

ELECTRICAL DATA 50HZ

SROTOMNAF SRETAEHTSORFED

YTQ

B7T-DE-P611BB17.131.25105937.014.3151

B7T-DE-P911BB17.131.25108555.411.8102

B7T-DE-P421BB17.131.25108555.411.8102

B7T-DE

B7T-DE-P832BB24.338.351586017.726.4304

B7T-DE-P542BB24.338.351586017.726.4304

B7T-DE-P152BB24.338.

B7T-DE-P063BB31.535.551587519.041.1555

B7T-DE-P863BB31.535.551587519.041.1555

B7T-DE-P573BB31.535.551587519.041.1

YTQ

B9T-DE-P611BB18.00.15102348.65.851

B9T-DE-P911BB18.00.15100166.92151

B9T-DE-P421BB18.00.15100166.92151

B9T-DE-P232BB26.18.15

B9T-DE-P832BB26.18.151086113.819.2252

B9T-DE-P542BB26.18.151086113.819.2252

B9T-DE-P152BB26.18.151086113.819.2252

B9

B9T-DE-P863BB34.26.25105271728.3304

B9T-DE-P573BB34.26.25105271728.3304

LATOT

ALF

LATOT

ALF

.CRIC.NIM

YTICAPMA

351586017.726.4304

SROTOMNAF SRETAEHTSORFED

.CRIC.NIM

YTICAPMA

ESUF.XAM

)SPMA(

ESUF.XAM

)SPMA(

1086113.819.2252

STTAWSPMA

STTAWSPMA

.CRIC.NIM

YTICAPMA

555

.CRIC.NIM

YTICAPMA

AM

AM

ESUF.X

)SPMA(

ESUF.X

)SPMA(

All Fan Motors are 3/4 H.P .

- 3 -

Page 4

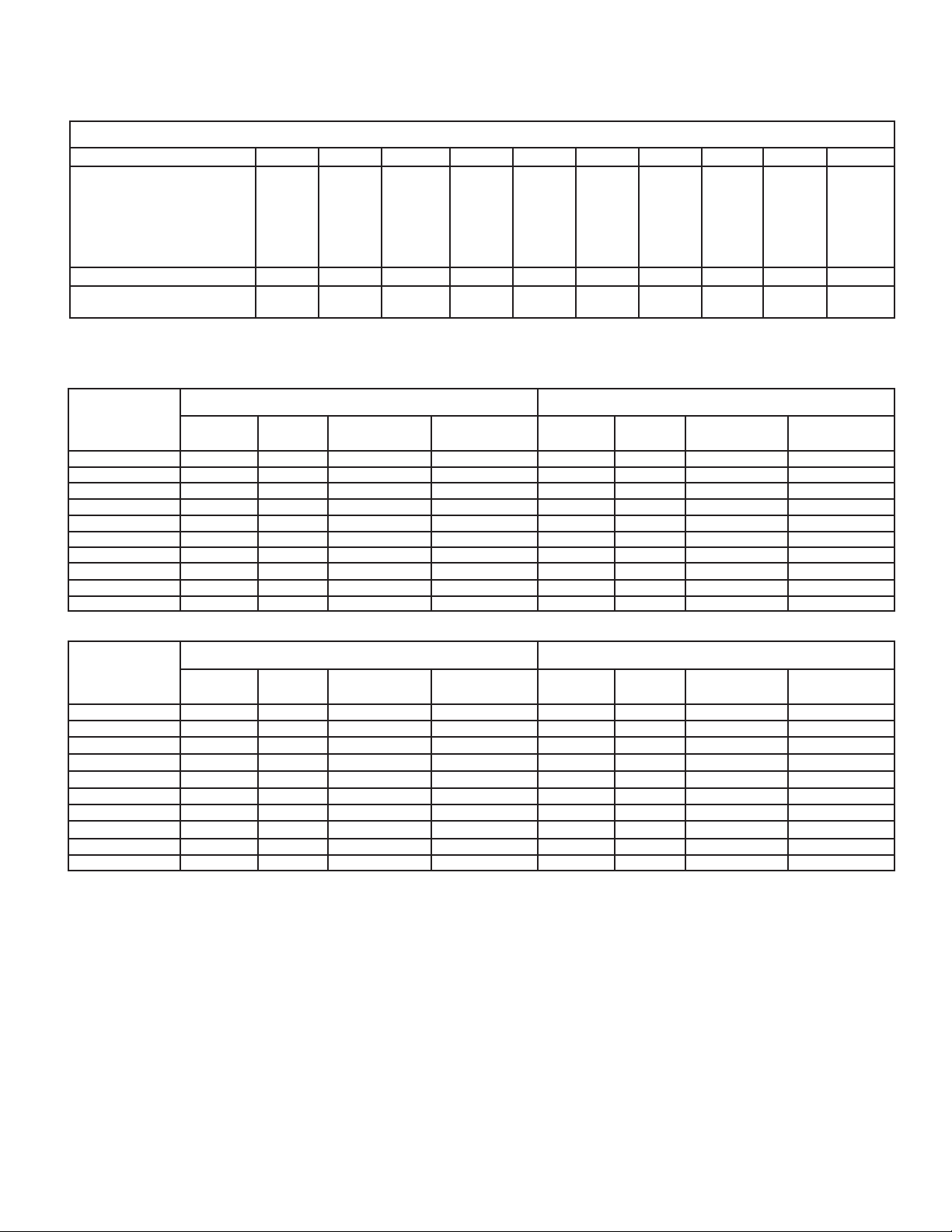

WIRING DIAGRAM

- 4 -

Page 5

WIRING DIAGRAM

- 5 -

Page 6

116

DIMENSIONAL DATA

119

124

232 238

245 251

360

368

375

DIMENSIONAL DATA

INCHES (MILLIMETERS)

Electric Defrost Model 116 119 124 232 238 245 251 360 368 375

Number of Fans

Liquid Connection (O.D. Sweat)

Suction Connection (O.D. Sweat)

Approx. Shipping Weight

Lbs.

Kg

1 1 1 2 2 2 2 3 3 3

5/8

(16)

7/8

(22)

160 190 205 350 370 380 390 540 560 580

73 86 93 159 168 173 177 245 227 264

7/8

(22)

1 1/8

(29)

7/8

(22)

1 3/8

(35)

7/8

(22)

1 3/8

(35)

7/8

(22)

1 5/8

(41)

7/8

(22)

1 5/8

(41)

7/8

(22)

1 5/8

(41)

7/8

(22)

1 5/8

(41)

1 1/8

(29)

2 1/8

(54)

1 1/8

(29)

2 1/8

(54)

- 6 -

Page 7

ALCO TXV SELECTIONS

R404A - R507

EVAP TEMP

+20/+25oF

+10oF

0oF

-10oF

-20oF

-30oF

-40oF

EVAP TEMP

+20/+25oF

+10oF

0oF

-10oF

-20oF

-30oF

-40oF

BTUH VALVE # BTUH VALVE# BTUH VALVE # BTUH VALVE # BTUH VALVE #

19000

18620

18050

17290

16150

15010

13680 HFES 2-RZ

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

53000

51940

50350

48230

45050

41870

38160 HFES 7-RZ 43200 HFES 7-RZ 50400 HFES 10-RZ

R22

EVAP

TEMP

+20/+25oF

+10oF

0oF

-10oF

-20oF

-30oF

-40oF

EVAP

TEMP

+20/+25oF

+10oF

0oF

-10oF

-20oF

-30oF

-40oF

116P-ED 119P-ED 124P-ED 232P-ED 238P-ED

BTUH VALVE # BTUH VALVE# BTUH VALVE # BTUH VALVE # BTUH VALVE #

19000

18620

18050

17290

16150

15010

13680

245P-ED 251P-ED 360P-ED 368P-ED 375P-ED

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

53000

51940

50350

48230

45050

41870

38160

MODEL BB

116P-ED 119P-ED 124P-ED 232P-ED 238P-ED

HFES

1 1/2-RC

HFES

1 1/2-RZ

23000

22540

21850

20930

19550

18170

16560

HFES

1 1/2-RC

HFES

2-RZ

29000

28420

27550

26390

24650

22910

20880

HFES

2-RC

HFES

3 1/2-RZ

38000

37240

36100

34580

32300

30020

27360

HFES

3 1/2-RC

HFES

3 1/2-RZ

46000

45080

43700

41860

39100

36340

33120

3 1/2-RC

245P-ED 251P-ED 360P-ED 368P-ED 375P-ED

HFES

3 1/2-RC

HFES

5-RZ

60000

58800

57000

54600

51000

47400

HFES

3 1/2-RC

HFES

5-RZ

70000

68600

66500

63700

59500

55300

HFES

5-RC

HFES

7-RZ

80000

78400

76000

72800

68000

63200

57600

HFES

5-RC

HFES

7-RZ

HFES 10-RZ

88000

86240

83600

80080

74800

69520

63360

MODEL BB

HFES

1 1/2-HC

HFES

2-HZ

HFES

2 1/2-HZ

HFES

3-HC

HFES

5 1/2-HZ

23000

22540

21850

20930

19550

18170

16560

60000

58800

57000

54600

51000

47400

43200 HFES 8-HZ 57600 HFES 10-HZ

HFES

1 1/2-HC

HFES

2 1/2-HZ

HFES

5 1/2-HC

HFES

5 1/2-HZ

29000

28420

27550

26390

24650

22910

20880

70000

68600

66500

63700

59500

55300

50400

HFES

2-HC

HFES

2 1/2-HZ

HFES

3-HZ

HFES

5 1/2-RC

HFES

8-RZ

38000

37240

36100

34580

32300

30020

27360

80000

78400

76000

72800

68000

63200

HFES

2 1/2-HC

HFES

3-HZ

HFES

5 1/2-HZ

HFES

5 1/2-HC

HFES

8-HZ

46000

45080

43700

41860

39100

36340

33120

88000

86240

83600

80080

74800

69520

63360

HFES

3-HC

HFES

5 1/2-HZ

HFES

5 1/2-HC

HFES

8-HZ

HFES 10-HZ

HFES

HFES

5-RZ

HFES

7-RC

HFES

10-RZ

MODEL BB R134a

EVAP TEMP

+20/+25oF

+10oF

0oF

EVAP TEMP

+20/+25oF

+10oF

0oF

Where available use the HFESC series valve which includes sweat fittings with a removable/cleanable inlet screen.

Note: Above Selections are based on 100 oF Entering Liquid Temperature.

VENTURI - FLO distributor does not require the selection or use of distributor nozzles.

116P-ED 119P-ED 124P-ED 232P-ED 238P-ED

BTUH VALVE # BTUH VALVE# BTUH VALVE # BTUH VALVE # BTUH VALVE #

19000

18620

18050

HFES

1 1/2-MC

23000

22540

21850

HFES

1 3/4-MC

29000

28420

27550

HFES

1 3/4-MC

38000

37240

36100

HFES

2 1/2-MC

46000

45080

43700

245P-ED 251P-ED 360P-ED 368P-ED 375P-ED

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

53000

51940

50350

HFES

4-MC

60000

58800

57000

HFES

4-MC

70000

68600

66500

HFES

6-MC

80000

78400

76000

HFES

6-MC

88000

86240

83600

- 7 -

HFES

4-MC

HFES

6-MC

Page 8

SPORLAN TXV SELECTIONS

R502* - 404A - R507

EVAP

TEMP

+20/25 oF

+10 oF

0 oF

-10 oF

-20 oF

-30 oF

-40 oF

EVAP

TEMP

+20/25 oF

+10 oF

0 oF

-10 oF

-20 oF

-30 oF

-40 oF

116P-ED 119P-ED 124P-ED 232P-ED 238P-ED

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

19000

18620

18050

17290

16150

15010

13680

EGSE

1 1/2-C

EGSE

1 1/2-ZP

245P-ED 251P-ED 360P-ED 368P-ED 375P-ED

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

53000

51940

50350

48230 SSE 4-ZP

45050

41870

38160

SSE 4-C

SSE 6-ZP

R22

EVAP

TEMP

+20/25 oF

+10 oF

0 oF

-10 oF

-20 oF

-30 oF

-40 oF

EVAP

TEMP

+20/25 oF

+10 oF

0 oF

-10 oF

-20 oF

-30 oF

-40 oF

116P-ED 119P-ED 124P-ED 232P-ED 238P-ED

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

19000

18620

18050

17290

16150

15010

13680

EGVE

1 1/2-C

EGVE

2-ZP40

245P-ED 251P-ED 360P-ED 368P-ED 375P-ED

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

53000

51940

50350

48230

45050

41870

38160 SVE 8-ZP40 50400 SVE 10-ZP40

SVE 4-C

SVE 5-ZP40

MODEL BB

23000

22540

21850 EGSE 2-C

20930

19550

18170

16560

60000

58800

57000 SSE 6-C 66500 SSE 7-C 83600 EBSSE 7 1/2-C

54600

51000

47400

43200 SSE 7-ZP

EGSE

1 1/2-C

EGSE 2-ZP

SSE 4-C

SSE 6-ZP

29000

28420

27550

26390 EGSE 2-ZP 34580 SSE 3-ZP 41860

24650

22910

20880

70000

68600

63700 SSE 6-ZP

59500

55300

50400

EGSE 2-C

SSE 3-ZP

SSE 6-C

SSE 7-ZP

38000

37240

36100

32300

30020

27360

80000

78400

76000

72800

68000

63200

57600

SSE 3-C

SSE 4-ZP

SSE 7-C

SSE 7-ZP

OSE 9-ZP

46000

45080

43700

39100

36340

33120

88000

86240

80080 SSE 7-ZP

74800

69520

63360

SSE 4-C

SSE 4-ZP

SSE 7-C

OSE 9-ZP

MODEL BB

23000

22540

21850 EGVE 2-C 27550 EGVE 3-C

20930

19550

18170

16560

60000

58800

57000

54600 SVE 5-ZP40 63700

51000

47400

43200

EGVE

1 1/2-C

EGVE

2-ZP40

SVE 4-C

SVE 8-ZP40

29000

28420

26390

24650

22910

20880

70000

68600

66500

59500

55300

EGVE 2-C

EGVE

3-ZP40

SVE 5-C

SVE 8-ZP40

38000

37240

36100

34580

32300

30020

27360

80000

78400

76000

72800 SVE 8-ZP40

63200

57600

68000

EGVE 3-C

SVE

4-ZP40

SVE 8-C

SVE

10-ZP40

46000

45080

43700

41860

39100

36340

33120

88000

86240

83600

80080

74800

69520

63360

EGVE 3-C

SVE 4-ZP40

SVE 5-ZP40

SVE 8-C

SVE

10-ZP40

R12* - R134a

EVAP

TEMP

+20/25 oF

+10 oF

0 oF

EVAP

TEMP

+20/25 oF

+10 oF

0 oF

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

19000

18620

18050

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

53000

51940

50350

116P-ED 119P-ED 124P-ED 232P-ED 238P-ED

EGJE

1 1/2-C

23000

22540

21850 EGJE 2-C

EGJE

1 1/2-C

245P-ED 251P-ED 360P-ED 368P-ED 375P-ED

60000

SJE 5-C

58800

57000

SJE 5-C

MODEL BB

29000

28420

27550

70000 SJE 5-C

68600 SJE 6-C

66500 SJE 5-C 76000 EBSJE 7-C

EGJE 2-C

38000

37240

36100

80000

78400

SJE

2 1/2-C

SJE 6-C

46000

45080

43700

88000

86240

83600

* Valve part numbers are coded for R404A (also may be used on R502 or R507) and R134a (also may be used on R12)

Note: Above Selections are based on 100 oF Entering Liquid Temperature.

VENTURI - FLO distributor does not require the selection or use of distributor nozzles.

- 8 -

SJE 3-C

EBSJE 7-C

Page 9

ELECTRICAL VIEW

DEFROST

ADJUSTABLE DEFROST

TERMINATION

CONTROL

ENTERING

SERVICE

KNOCK-OUTS

TERMINAL BLOCKS

DEFROST CONTROL (TOP)

HEATERS (MIDDLE)

FAN MOTORS (BOTTOM)

THERMOSTAT

BULB

FRONT HEATER

SLOT COVER PLATE

(REMOVE 5 SCREWS)

REAR HEATER SLOT

COVER PLATE

(REMOVE 5 SCREWS)

DEFROST HEATER

(4 0N AIR-ENTERING SIDE,

2 ON LEAVING AIR-SIDE)

ELEMENTS (6)

HEATER

SPRING

CLIPS

DRAIN PAN

HEATER

ELEMENT(1)

APPLICATION

These Unit Coolers are designed for use with R12,

R22, R134a, R404A, R407A/B/C, R507 or R502

refrigerants.

At room temperatures above 34°F and evaporating

temps no lower than 27°F the air flowing through the

coil will accomplish the defrost. Temperatures of 34°F

and below (to -40°F) require positive defrosting.

(either Electric or Hot Gas).These models require the

use of (1) Time Clock (to initiate and terminate the

defrost cycle). (2) Fan-Delay thermostat (to prevent

evaporator fans from starting up right after defrost and

blowing water on to fan blades, guards and floor) (3)

Defrost Termination Control (to prevent unnecessary

prolonged heating and steaming of the coil once all

the ice and frost has melted).

The coil must not be exposed to any abnormal atmospheric or acidic environments. This may result in

corrosion to the cabinet and possible coil failure

(leaks). (Consult manufacturer for optional baked on

phenolic protective coatings).

INSTALLATION

The installation and start-up of Unit Coolers should

only be performed by qualified refrigeration mechanics.

This equipment should be installed in accordance

with all applicable codes, ordinances and local bylaws.

INSPECTION

Inspect all equipment before unpacking for visible

signs of damage or loss. Check shipping list against

material received to ensure shipment is complete.

PIPING VIEW

SUCTION

CONNECTION

EXTERNAL

EQUALIZER

CONNECTION

IMPORTANT: Remember, you, the consignee, must

make any claim necessary against the transportation

company. Shipping damage or missing parts, when

discovered at the outset, will prevent later unnecessary and costly delays.

If damage or loss during transport is evident,

make claim to carrier, as this will be their responsibility, not the manufacturer’s.

Should carton be damaged, but damage to equipment is not obvious, a claim should be filed for “concealed damage” with the carrier.

IMPORTANT: The electrical characteristics of the unit

should be checked at this time to make sure they

correspond to those ordered and to electrical power

available at the job site.

Save all shipping papers, tags and instruction sheets

for reference by installer and owner.

LOCATION

The unit location in the room should be selected to

ensure uniform air distribution throughout the entire

space to be refrigerated. Be sure that the unit does

not draw air in, or blow directly out, through an

opened door and that the product does not obstruct

the free circulation of air. Allow a minimum of 24”

clearance at each end and behind the unit.

The Unit Coolers draw air through the coil and discharge air from the fan side.

Consideration should be given to the coil location in

order to minimize the piping run length to the condensing unit and floor drain.

TX VALVE

CONNECTION

- 9 -

Page 10

MOUNTING

Mounting brackets with 7/16” dia holes are provided

for flush mounting to the ceiling. For details refer to

dimensional data on page 6. Ensure adequate clearance (at least 24”) is provided behind the coil as well

as each side (to enable access to the electrical and

refrig. compartments).

Ensure that the ceiling is level since the drain pan

has been sloped for drainage during the defrost

cycle.

DRAIN LINE

The drain line should be run from the drain connection, sloping at least 4” per foot. A trap outside the

room will prevent warm air from entering through the

tubing. Connection should be made to proper drainage

facilities that comply with local regulations.

To prevent freeze-up when the temperature of the

refrigerated space is 32 oF or lower, the drain line

should be heated along its run inside the cold room.

The heated drain line should be insulated. It is recommended that the heater be energized at all times. A

heat input of 20 watts per foot in a 0 oF room and 30

watts per foot in a -20 oF room is usually satisfactory.

The drain pan may be mounted with the drain fitting at

either end (remove pan heater and relocate pan). See

page 6 for drain fitting details.

Ensure that the drain pan has sufficient slope for

proper drainage (prevention of ice build up/blockage in pan).

PIPING

Refrigerant line sizes are important and may not be

the same size as the coil connections. (depends on

the length of run) If in doubt, consult “Recommended

refrigerant line sizes” charts. (Engineering Manuals or

other recognized sources of information).

WIRING

Wire system in accordance with governing standards

and local codes. See data and wiring diagrams on

pages 2, 3, 4 and 5 for wiring arrangement. Electrical

wiring is to be sized in accordance with minimum

circuit ampacity rating.

For ease of identifying the proper wiring terminals, unit

wiring is colour coded and terminal block connections

are identified. When fan delay thermostats (combination fan delay and defrost termination) are installed,

on start-up, the fans do not operate until the coil

temperature is reduced to approximately

20 oF. It is normal for the fans to cycle a few times

until the room temperature is brought down. At higher

evaporating temperatures this control may not close

and therefore should be by-passed or replaced with an

adjustable type.

The defrost termination control is adjustable and

may be set at a minimumof 40 oF (fully CW) to a

maximum of 75 oF (fully CCW). Normal setting is

55 oF. This can be increased if the defrost heaters are terminated too soon (frost still left) or

decreased if terminated too long (steaming of

coil). Time clock should be set for a fail-safe time

termination of 30 minutes.

SYSTEM CHECK

Before Start-Up:

1. All wiring should be in accordance with local

codes.

2. Refrigerant lines should be properly sized.

3. Electric defrost systems should include a

liquid line solenoid valve.

4. Thorough evacuation and, dehydration has

been performed.

5. The suction, discharge, and receiver service

valves must be open.

6. The system should include a liquid line drier

mois ture indicator and suction filter.

7. Pour enough water into the drain pan to allow

a good check on drainage and seal the trap.

After Start-Up:

1. If necessary, temporarily by-pass fan delay

control to run fans until room temp is lowered.

(Run jumper wire from terminal N to F on

control circuit terminal block).

2. Check the compressor oil level to ensure the

correct oil charge.

3. Be sure that the expansion valve is properly

set to provide the correct amount of superheat.

(should be around 5 to 6 oF for 10 oF T.D.

operation).

4. Heavy moisture loads are usually encountered

when starting the system for the first time. If

the coil temperature is below freezing, this will

cause a rapid build-up of frost on the coil.

During the initial pull-down frost build-up

should be watched and the coil defrosted

manually, as required.

5. Check for proper evaporator fan blade rotation.

MAINTENANCE

The unit should be periodically inspected for any

dirt or build-up on the fin surface and cleaned if

necessary with a soft whisk or brush.

Also ensure coil and pan does not have any

excessive ice build-up from improper defrost

operation. When replacing heater elements first

remove heater slot covers and heater clips. (See

page 9 for detailed view).

10

Page 11

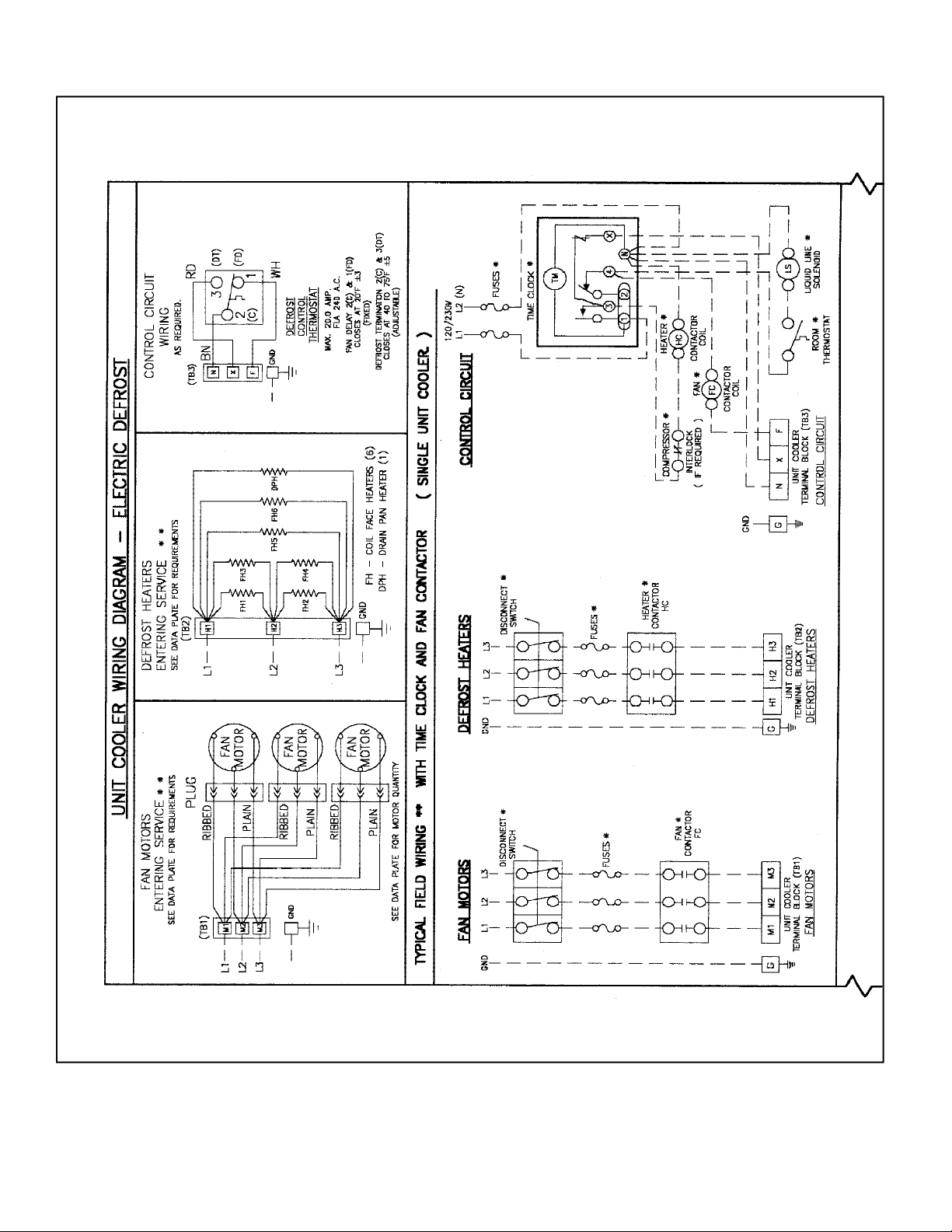

SERVICE PARTS LIST

FAN MOTORS - 60Hz

208-230/1/60

208-230/3/60

460/3/60

575/3/60

FAN MOTORS - 50Hz

200-220/1/50

200-220/3/50

380-400/3/50

FAN BLADES

20" 18o Pitch 4-Blade

20" 23o Pitch 4-Blade

FAN GUARDS

Moulded Throw Booster (standard)

Metal Wire (optional)

Acorn Nut

Motor Mount

Terminal Block - Fan Motor(s)

Terminal Block-Defrost Heaters

Terminal Block-Control

Defrost Control Thermostat

Face Heater Clip

MODELS

ALL

ALL

ALL

ALL

MODELS

ALL

ALL

ALL

MODELS

116P-ED

ALL (EXCEPT 116P-ED)

MODELS

ALL

ALL

ALL

MODELS

ALL

MODELS

ALL

ALL

ALL

ALL

ALL

PART #

1045032

1045033

1045034

1045035

PART #

1045032

1045033

1045034

PART #

1048568

1045115

PART #

1045089

1045091

1045138

PART #

1045031

PART #

1045017

1045018

1045017

1048610

1048609

COIL FACE HEATERS (6 REQUIRED) DRAIN PAN HEATER (1 REQUIRED)

MODEL 230V 380V 460V 575V 230V 380V 460V 575V

116

119, 124

232, 238, 245, 251

360, 368, 375

1045039-001

1045039-005

1045039-009

1045039-013

1045039-002

1045039-006

1045039-010

1045039-014

1045039-003

1045039-007

1045039-011

1045039-015

1045039-004

1045039-008

1045039-012

1045039-016

1045039-017

1045039-021

1045039-025

1045039-029

1045039-018

1045039-022

1045039-026

1045039-030

1045039-019

1045039-023

1045039-027

1045039-031

1045039-020

1045039-024

1045039-028

1045039-032

11

Page 12

SERVICE LOG

09/07/05

ETADSTNEMMOC

PROJECT INFORMATION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

DISTRIBUTED BY:

General Sales, PGeneral Sales, P

General Sales, P

General Sales, PGeneral Sales, P

135 Little Nine Drive, Morehead City135 Little Nine Drive, Morehead City

135 Little Nine Drive, Morehead City

135 Little Nine Drive, Morehead City135 Little Nine Drive, Morehead City

252-240-2829 • 1-800-24-BALL252-240-2829 • 1-800-24-BALL

252-240-2829 • 1-800-24-BALL

252-240-2829 • 1-800-24-BALL252-240-2829 • 1-800-24-BALL

e-mail: ballysales@ballyrefboe-mail: ballysales@ballyrefbo

e-mail: ballysales@ballyrefbo

e-mail: ballysales@ballyrefboe-mail: ballysales@ballyrefbo

Due to Manufacturer’s policy of continuous product improvement, the Manufacturer reserves the right to make changes without notice.

arar

ts & Serts & Ser

ar

ts & Ser

arar

ts & Serts & Ser

vice Manufacturing & Engineeringvice Manufacturing & Engineering

vice Manufacturing & Engineering

vice Manufacturing & Engineeringvice Manufacturing & Engineering

xx

x

xx

, NC 28557, NC 28557

, NC 28557

, NC 28557, NC 28557

Y • FY • F

AX: 252-240-0384AX: 252-240-0384

Y • F

AX: 252-240-0384

Y • FY • F

es.com • wwwes.com • www

es.com • www

es.com • wwwes.com • www

AX: 252-240-0384AX: 252-240-0384

.ballyrefbo.ballyrefbo

.ballyrefbo

.ballyrefbo.ballyrefbo

xx

es.comes.com

x

es.com

xx

es.comes.com

C

US

Loading...

Loading...