Page 1

PRODUCT DATA &

INSTALLATION

Bulletin B30-BB-PDI-13

1047753

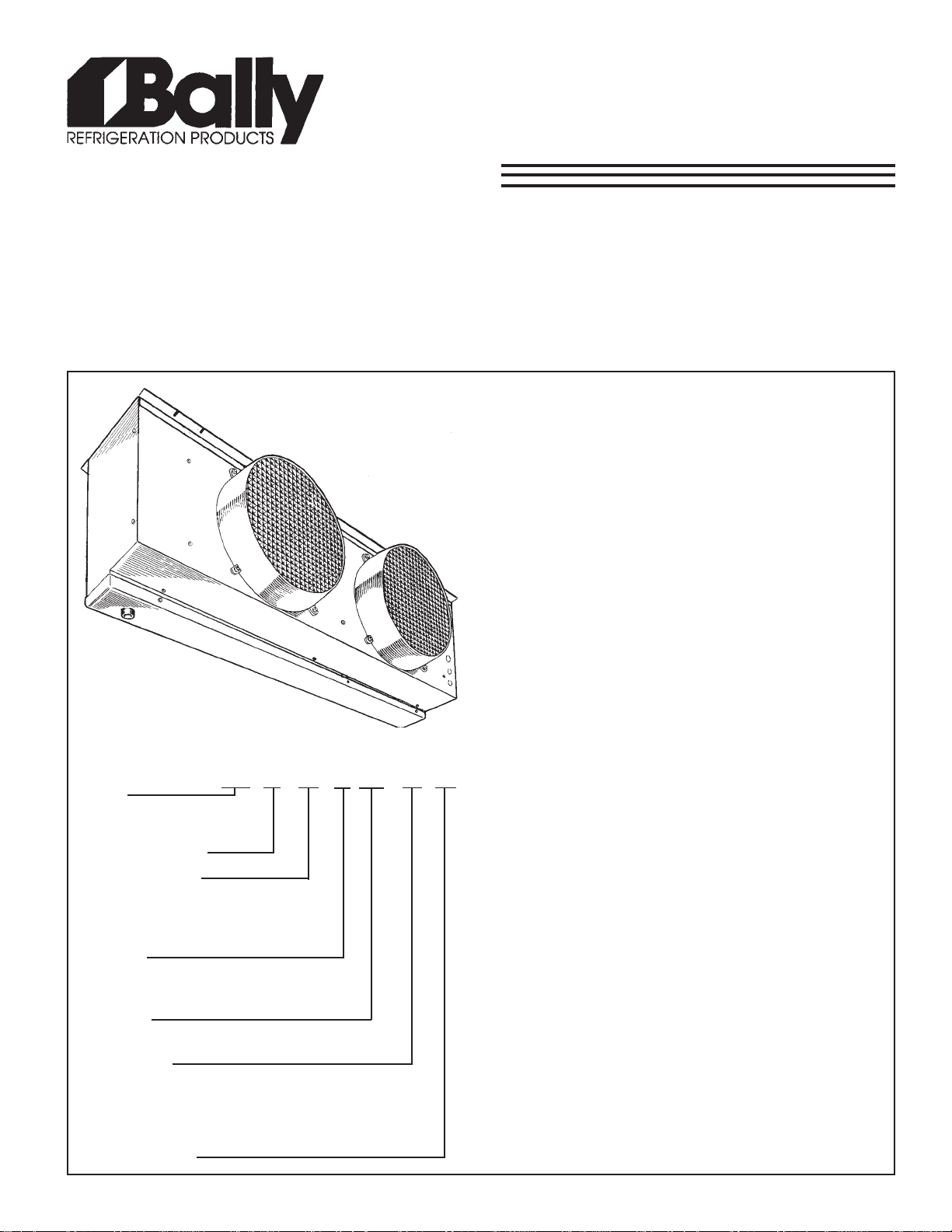

Medium Profile

BB Unit Coolers

High Temp Applications

°F Room Temp. or Higher)

(+35

Air Defrost

Electrical Power:

Single & Three Phase

* Heavy gauge textured aluminum cabinet

construction resists scratches/corrosion and

minimizes weight for shipment, installation and

service.

* Attractive and durable high density polyethylene

fan guards with built-in throw boosters.

NOMENCLATURE

BB 1 31 P -A- T4 B

BALLY

MEDIUM PROFILE

UNIT COOLER

NUMBER OF FANS

MBH CAP ACITY A T

°F T .D. (60Hz)

10

SIZE 31 = 31,000 BTUH

OF COOLING

OPTIONS

P = PRE ASSEMBLED REMOTE

S = STANDARD UNIT

DEFROST

A = AIR DEFROST

ELECTRICAL

S2 = 208-230/1/60 S6 = 200-220/1/50

T3 = 208-230/3/60 T4 = 460/3/60

T5 = 575/3/60 T7 = 200-220/3/50

T8 = 380/3/60 T9 = 380-400/3/50

REVISION LEVEL

* 3/8 Tubing coil construction (reduces operating

charge).

* VENTURI-FLO Distributor eliminates need for

distributor nozzle selections.

* Refrigerants R12, R22, R502, R134a, R404A,

R407A, R407B, R407C, R507.

CONTENTS

Nomenclature....................................

Capacity Data.....................................

Electrical Data...................................

Wiring Diagram..................................

Dimensional Data..............................

Pictorial Views...................................

Expansion Valve Selection..............

Application.........................................

Installation.........................................

Inspection..........................................

Location.............................................

Mounting............................................

Drain Line...........................................

Wiring.................................................

System Check....................................

Maintenance.......................................

Service Parts List..............................

Project Information............................

PAGE

Cover

2

2,3

4

5

6

6

7

7

7

7

7

7

7

7

7

Back

Back

Page 2

SPECIFICATIONS

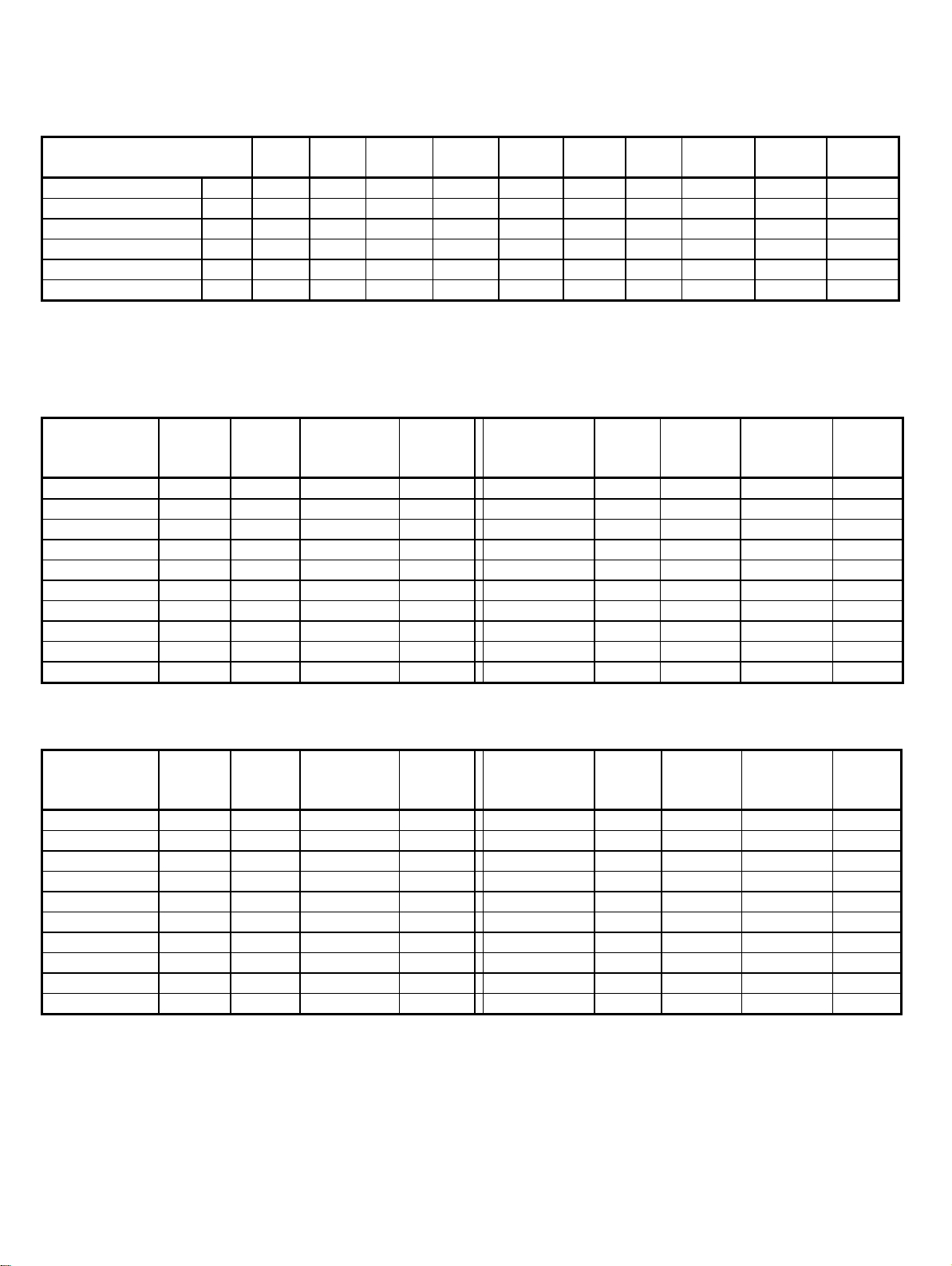

CAPACITY DATA (BTUH)

High Temperature

Model BB

Capacity 1°F T.D. BTUH 2,000 2,500 3,100 3,900 4,700 5,400 6,300 7,400 8,300 9,300

Capacity 10°F T.D. BTUH 20,000 25,000 31,000 39,000 47,000 54,000 63,000 74,000 83,000 93,000

Capacity 15°F T.D. BTUH 30,000 37,500 46,500 58,500 70,500 81,000 94,500 111,000 124,500 139,500

CFM cfm 3,000 4,700 4,550 9,400 9,400 9,100 9,100 13,650 13,650 13,150

Refrigerant Charge* Lbs. 3.4 6.1 9 8.9 11.8 14.9 17.9 17.7 23 26.5

Approx. Shipping Wt Lbs. 160 190 205 350 370 380 390 540 560 580

* R22 at +20°F S.S.T. with coil 30% full

120P-A 125P-A 131P-A 239P-A 247P-A 254P-A 263P-A 374P-A 383P-A 393P-A

ELECTRICAL DATA FAN MOTORS 60HZ

208-230/1/60 208-230/3/60

MODEL

BB120P-A-S2B

BB125P-A-S2B

BB131P-A-S2B

BB239P-A-S2B

BB247P-A-S2B

BB254P-A-S2B

BB263P-A-S2B

BB374P-A-S2B

BB383P-A-S2B

BB393P-A-S2B

FAN

MOTOR

QTY

1 3.3 4.13 15

1 3.3 4.13 15

1 3.3 4.13 15

2 6.6 7.43 15

2 6.6 7.43 15

2 6.6 7.43 15

2 6.6 7.43 15

3 9.9 10.73 15

3 9.9 10.73 15

3 9.9 10.73 15

FAN

FLA

TOTAL

MIN. CIRC.

AMPACITY

(A)

MAX.

FUSE

(AMPS)

MODEL

BB120P-A-T3B

BB125P-A-T3B

BB131P-A-T3B

BB239P-A-T3B

BB247P-A-T3B

BB254P-A-T3B

BB263P-A-T3B

BB374P-A-T3B

BB383P-A-T3B

BB393P-A-T3B

FAN

MOTOR

QTY

FAN FLA

TOTAL

MIN. CIRC.

AMPACITY

(A)

1 2.0 2.5 15

1 2.0 2.5 15

1 2.0 2.5 15

2 4.0 4.5 15

2 4.0 4.5 15

2 4.0 4.5 15

2 4.0 4.5 15

3 6.0 6.5 15

3 6.0 6.5 15

3 6.0 6.5 15

MAX.

FUSE

(AMPS)

460/3/60 575/3/60

FAN

MODEL

MOTOR

QTY

BB120P-A-T4B

BB125P-A-T4B

BB131P-A-T4B

BB239P-A-T4B

BB247P-A-T4B

BB254P-A-T4B

BB263P-A-T4B

BB374P-A-T4B

BB383P-A-T4B

BB393P-A-T4B

1 1.0 1.25 15

1 1.0 1.25 15

1 1.0 1.25 15

2 2.0 2.25 15

2 2.0 2.25 15

2 2.0 2.25 15

2 2.0 2.25 15

3 3.0 3.25 15

3 3.0 3.25 15

3 3.0 3.25 15

All fan motors are 3/4 H.P.

FAN

FLA

TOTAL

MIN. CIRC.

AMPACITY

(A)

MAX.

FUSE

(AMPS)

MODEL

BB120P-A-T5B

BB125P-A-T5B

BB131P-A-T5B

BB239P-A-T5B

BB247P-A-T5B

BB254P-A-T5B

BB263P-A-T5B

BB374P-A-T5B

BB383P-A-T5B

BB393P-A-T5B

- 2 -

FAN

MOTOR

QTY

FAN FLA

TOTAL

MIN. CIRC.

AMPACITY

(A)

1 0.8 1 15

1 0.8 1 15

1 0.8 1 15

2 1.6 1.8 15

2 1.6 1.8 15

2 1.6 1.8 15

2 1.6 1.8 15

3 2.4 2.6 15

3 2.4 2.6 15

3 2.4 2.6 15

MAX.

FUSE

(AMPS)

Page 3

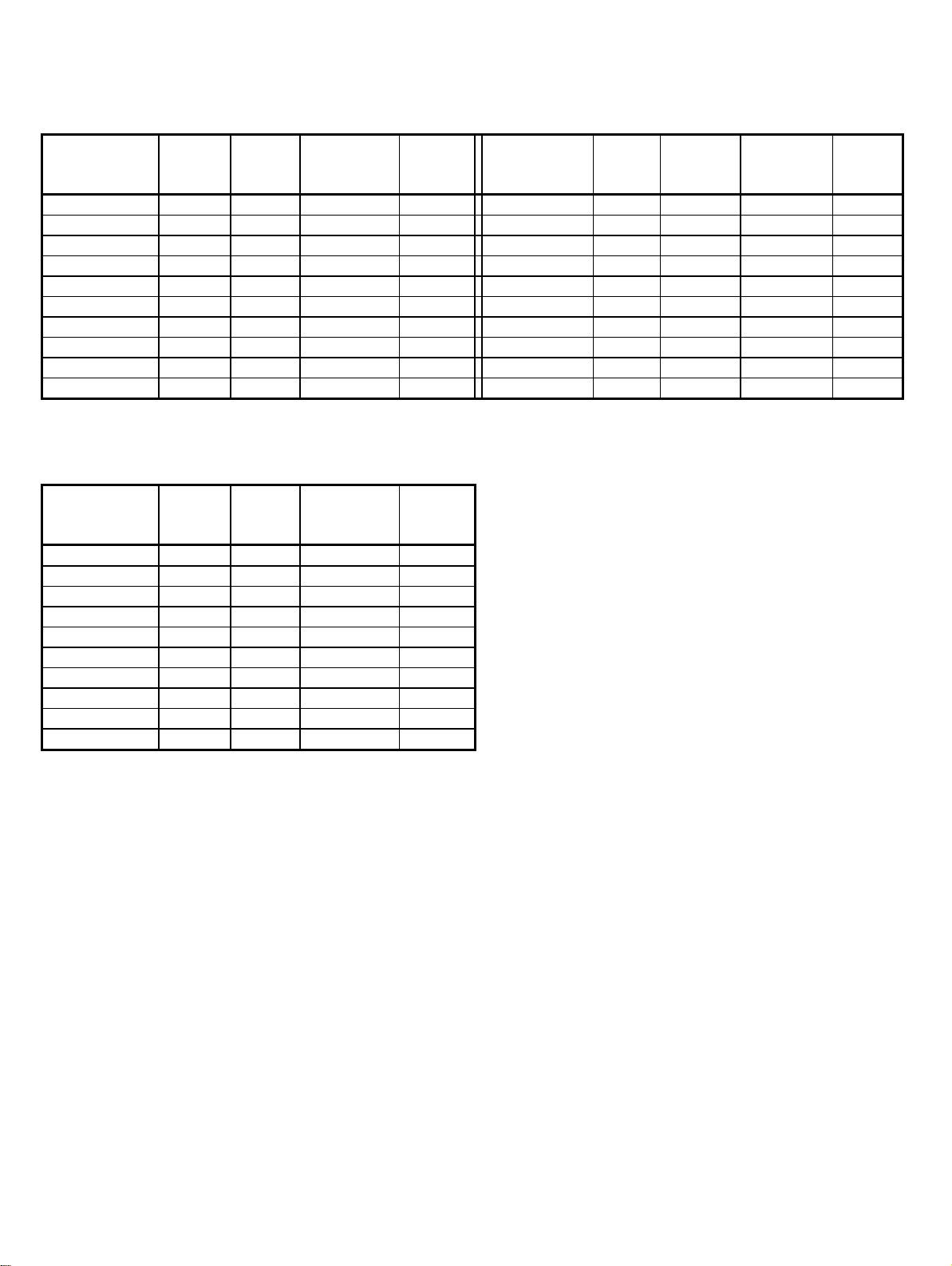

ELECTRICAL DATA FAN MOTORS 50HZ

200-220/1/50 200-220/3/50

MODEL

BB120P-A-S6B

BB125P-A-S6B

BB131P-A-S6B

BB239P-A-S6B

BB247P-A-S6B

BB254P-A-S6B

BB263P-A-S6B

BB374P-A-S6B

BB383P-A-S6B

BB393P-A-S6B

380-400/3/50

MODEL

BB120P-A-T9B

BB125P-A-T9B

BB131P-A-T9B

BB239P-A-T9B

BB247P-A-T9B

BB254P-A-T9B

BB263P-A-T9B

BB374P-A-T9B

BB383P-A-T9B

BB393P-A-T9B

FAN

MOTOR

QTY

1 3.1 3.88 15

1 3.1 3.88 15

1 3.1 3.88 15

2 6.2 6.98 15

2 6.2 6.98 15

2 6.2 6.98 15

2 6.2 6.98 15

3 9.3 10.08 15

3 9.3 10.08 15

3 9.3 10.08 15

FAN

MOTOR

QTY

1 0.8 1.0 15

1 0.8 1.0 15

1 0.8 1.0 15

2 1.6 1.8 15

2 1.6 1.8 15

2 1.6 1.8 15

2 1.6 1.8 15

3 2.4 2.6 15

3 2.4 2.6 15

3 2.4 2.6 15

FAN

FLA

TOTAL

FAN

FLA

TOTAL

MIN. CIRC.

AMPACITY

(A)

MIN. CIRC.

AMPACITY

(A)

MAX.

FUSE

(AMPS)

MAX.

FUSE

(AMPS)

MODEL

BB120P-A-T7B

BB125P-A-T7B

BB131P-A-T7B

BB239P-A-T7B

BB247P-A-T7B

BB254P-A-T7B

BB263P-A-T7B

BB374P-A-T7B

BB383P-A-T7B

BB393P-A-T7B

FAN

MOTOR

QTY

FAN FLA

TOTAL

MIN. CIRC.

AMPACITY

(A)

1 1.7 2.13 15

1 1.7 2.13 15

1 1.7 2.13 15

2 3.4 3.83 15

2 3.4 3.83 15

2 3.4 3.83 15

2 3.4 3.83 15

3 5.1 5.53 15

3 5.1 5.53 15

3 5.1 5.53 15

MAX.

FUSE

(AMPS)

All fan motors are 3/4 H.P.

- 3 -

Page 4

WIRING DIAGRAM

- 4 -

Page 5

DIMENSIONAL DATA

DIMENSIONAL DATA

INCHES (MILLIMETRES)

High Temp Air Defrost Model: 120 125 131 239 247 254 263 374 383 393

Number of Fans 1 1 1 2 2 2 2 3 3 3

Liquid Connection (O.D. Sweat) 5/8

(16)

Suction Connection (O.D. Sweat) 7/8

(22)

5/8

(16)

1 1/8

(29)

5/8

(16)

1 1/8

(29)

- 5 -

5/8

(16)

1 3/8

(35)

7/8

(22)

1 3/8

(35)

7/8

(22)

1 5/8

(41)

7/8

(22)

1 5/8

(41)

7/8

(22)

1 5/8

(41)

7/8

(22)

1 5/8

(41)

7/8

(22)

2 1/8

(54)

Page 6

ELECTRICAL VIEW PIPING VIEW

SUCTION EXTERNAL TX VALVE

TERMINAL BLOCK CONN. EQUALIZER CONN. CONN.

THERMOSTATIC EXPANSION VALVE

SELECTION CHART FOR +35°°F ROOMS AND UP

ALCO VALVE MODEL* SPORLAN VALVE MODEL

MODEL T.D. CAPACITY

MBH

120A 10

15

125A 10

15

131A 10

15

239A 10

15

247A 10

15

254A 10

15

263A 10

15

374A 10

15

383A 10

1583124.5

393A 10

1593139.5

20

30

25

37.5

31

46.5

39

58.5

47

70.5

54

81

63

94.5

74

111

* Where available use the HFESC series valve which includes sweat fittings with a removable/cleanable inlet screen.

Note: Above Selections are based on 100°F Entering Liquid Temperature.

VENTURI - FLO distributor does not require the selection or use of distributor nozzles,

REFRIGERANT

R22

HFES-2-HC

HFES-2 1/2-HC

HFES-2-HC

HFES-3-HC

HFES-2 1/2-HC

HFES-5 1/2-HC

HFES-3-HC

HFES-5 1/2-HC

HFES-5 1/2-HC

HFES-5 1/2-HC

HFES-5 1/2-HC

HFES-8-HC

HFES-5 1/2-HC

HFES-8-HC

HFES-5 1/2-HC

HFES-10-HC

HFES-8-HC

HFES-10-HC

HFES-8-HC

HFES-10-HC

REFRIGERANT

R502/404A/507

HFES-1 1/2-RC

HFES-2-RC

HFES-2-RC

HFES-3 1/2-RC

HFES-3 1/2-RC

HFES-3 1/2-RC

HFES-3 1/2-RC

HFES-5-RC

HFES-3 1/2-RC

HFES-5-RC

HFES-5-RC

HFES-7-RC

HFES-5-RC

HFES-10-RC

HFES-7-RC

HFES-10-RC

HFES-7-RC

HFES-10-RC

HFES-10-RC

TRAE-12-RC

REFRIGERANT

R134a

HFES-1 1/2-MC

HFES-2 1/2-MC

HFES-1 3/4-MC

HFES-4-MC

HFES-2 1/2-MC

HFES-4-MC

HFES-4-MC

HFES-4-MC

HFES-4-MC

HFES-6-MC

HFES-4-MC

HFES-6-MC

HFES-4-MC

HFES-7 1/2-MC

HFES-6-MC

HFES-7 1/2-MC

HFES-6-MC

HFES-11-MC

HFES-7 1/2-MC

HFES-11-MC

REFRIGERANT

R22

EGVE-1 1/2-C

EGVE-3-C

EGVE-2-C

EGVE-3-C

EGVE-3-C

EGVE-3-C

EGVE-3-C

SVE-4-C

EGVE-3-C

SVE-5-C

SVE-4-C

SVE-8-C

SVE-4-C

SVE-8-C

SVE-5-C

SVE-8-C

SVE-8-C

SVE-10-C

SVE-8-C

SVE-10-C

REFRIGERANT

R502/404A/507

EGSE-1 1/2-C

EGSE-2-C

EGSE-2-C

SSE-3-C

EGSE-2-C

SSE-4-C

SSE-3-C

SSE-4-C

SSE-4-C

SSE-6-C

SSE-4-C

SSE-7-C

SSE-4-C

SSE-7-C

SSE-6-C

OSE-9-C

SSE-7-C

OSE-9-C

OSE-7-C

OSE-12-C

REFRIGERANT

R12/R134a

EGJE-1 1/2-C

EGJE-2-C

EGJE-1 1/2-C

SJE-2 1/2-C

EGJE-2-C

SJE-3-C

SJE-2 1/2-C

SJE-5-C

SJE-3-C

SJE-6-C

SJE-5-C

SJE-6-C

SJE-5-C

OJE-6-C

OJE-9-C

OJE-12-C

SJE-6-C

OJE-9-C

OJE-6-C

OJE-9-C

- 6 -

Page 7

APPLICATION

High Temp Unit Coolers are designed for use with R12, R22,

R134a, R404A, R407A/B/C, R507 or R502 refrigerants.

At room temperatures above 34°F and evaporating temps no

lower than 27°F the air flowing through the coil will accomplish

the defrost. Temperatures of 34°F and below (to -40°F) require

positive defrosting. (either Electric or Hot Gas).

The coil must not be exposed to any abnormal atmospheric or

acidic environments. This may result in corrosion to the cabinet

and possible coil failure (leaks). (Consult manufacturer for

optional baked on phenolic protective coatings).

INSTALLATION

The installation and start-up of Unit Coolers should only be

performed by qualified refrigeration mechanics.

This equipment should be installed in accordance with all

applicable codes, ordinances and local by-laws.

MOUNTING

Mounting brackets with 7/16” dia holes are provided for flush

mounting to the ceiling. For details refer to dimensional data on

page 5. Ensure adequate clearance (at least 24”) is provided

behind the coil as well as each side (to enable access to the

electrical and refrig. compartments).

Ensure that the ceiling is level since the drain pan has been

sloped for drainage during the defrost cycle.

DRAIN LINE

The drain line should be run from the drain connection, sloping

at least 4” per foot. A trap outside the room will prevent warm air

from entering through the tubing. Connection should be made

to proper drainage facilities that comply with local regulations.

Ensure that the drain pan has sufficient slope for proper

drainage (prevention of ice build up/blockage in pan).

INSPECTION

Inspect all equipment before unpacking for visible signs of

damage or loss. Check shipping list against material received

to ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must make any

claim necessary against the transportation company. Shipping

damage or missing parts, when discovered at the outset, will

prevent later unnecessary and costly delays.

If damage or loss during transport is evident, make claim to

carrier, as this will be their responsibility, not the

manufacturer’s.

Should carton be damaged, but damage to equipment is not

obvious, a claim should be filed for “concealed damage” with

the carrier.

IMPORTANT: The electrical characteristics of the unit should be

checked at this time to make sure they correspond to those

ordered and to electrical power available at the job site.

Save all shipping papers, tags and instruction sheets for

reference by installer and owner.

LOCATION

The unit location in the room should be selected to ensure

uniform air distribution throughout the entire space to be

refrigerated. Be sure that the unit does not draw air in, or blow

directly out, through an opened door and that the product does

not obstruct the free circulation of air. Allow a minimum of 24”

clearance at each end and behind the unit.

The Unit Coolers draw air through the coil and discharge air

from the fan side.

PIPING

Refrigerant line sizes are important and may not be the same

size as the coil connections. (depends on the length of run) If in

doubt, consult “Recommended refrigerant line sizes” charts.

(Engineering Manuals or other recognized sources of

information).

WIRING

Wire system in accordance with governing standards and local

codes. See data and wiring diagrams on pages 2 and 3 for

wiring arrangement. Electrical wiring is to be sized in

accordance with minimum ampacity rating.

SYSTEM CHECK

Before Start-Up:

1. All wiring should be in accordance with local codes.

2. Refrigerant lines should be properly sized.

3. Off-cycle defrost systems should include a liquid line

solenoid valve.

4. Thorough evacuation and, dehydration has been performed.

5. The suction, discharge, and receiver service valves must be

open.

6. The system should include a liquid line drier moisture

indicator and suction filter.

7. Pour enough water into the drain pan to allow a good check

on drainage and seal the trap.

After Start-Up:

1. Check the compressor oil level to ensure the correct oil

charge.

2. Be sure that the expansion valve is properly set to provide

the correct amount of superheat.

3. Heavy moisture loads are usually encountered when starting

the system for the first time.

4. Check for proper evaporator fan blade rotation.

Consideration should be given to the coil location in order to

minimize the piping run length to the condensing unit and floor

drain.

MAINTENANCE

The unit should be periodically inspected for any dirt or build-up

on the fin surface and cleaned if necessary with a soft whisk or

brush.

- 7 -

Page 8

SERVICE PARTS LIST

01/10/05

06/1/032-802

06/3/032-802

06/3/064

06/3/575

05/1/022-002

05/3/022-002

05/3/004-083

NAF

SEDALB

O

81"02

O

32"02

SDRAUGNAF

po(eriWlateM

tuNnrocA

ZHO6-SROTOMNAF

ZH05-SROTOMNAF

edalB-4hctiP

edalB-4hctiP

)dradnats(retsooBworhTdedluoM

)lanoit

TNUOMROTOM

KCOLBLANIMRET

SLEDOM

LLA

LLA

LLA

LLA

SLEDOM

LLA

LLA

LLA

SLEDOM

A021

LLA

LLA

LLA

LLA1305401

LLA710540

)A021TPECXE(LLA

SLEDOM

1

#TRAP

2305401

3305401

4305401

5401

530

#TRAP

2305401

3305401

4305401

#TRAP

8658401

5115401

#TRAP

9805401

1905401

8315401

SERVICE LOG

ETADSTNEMMOC

PROJECT INFORMATION

metsyS

rebmuNledoM pU-tratSfoetaD

rebmuNlaireS rotcartnoCecivreS

tnaregirfeRenohP

ylppuSlacirtcelExaF

DISTRIBUTED BY:

General Sales, PGeneral Sales, P

General Sales, P

General Sales, PGeneral Sales, P

135 Little Nine Drive, Morehead City135 Little Nine Drive, Morehead City

135 Little Nine Drive, Morehead City

135 Little Nine Drive, Morehead City135 Little Nine Drive, Morehead City

252-240-2829 • 1-800-24-BALL252-240-2829 • 1-800-24-BALL

252-240-2829 • 1-800-24-BALL

252-240-2829 • 1-800-24-BALL252-240-2829 • 1-800-24-BALL

e-mail: ballysales@ballyrefboe-mail: ballysales@ballyrefbo

e-mail: ballysales@ballyrefbo

e-mail: ballysales@ballyrefboe-mail: ballysales@ballyrefbo

Due to Manufacturer’s policy of continuous product improvement, the Manufacturer reserves the right to make changes without notice.

arar

ts & Serts & Ser

ar

ts & Ser

arar

ts & Serts & Ser

vice Manufacturing & Engineeringvice Manufacturing & Engineering

vice Manufacturing & Engineering

vice Manufacturing & Engineeringvice Manufacturing & Engineering

xx

x

xx

, NC 28557, NC 28557

, NC 28557

, NC 28557, NC 28557

Y • FY • F

AX: 252-240-0384AX: 252-240-0384

Y • F

AX: 252-240-0384

Y • FY • F

es.com • wwwes.com • www

es.com • www

es.com • wwwes.com • www

AX: 252-240-0384AX: 252-240-0384

.ballyrefbo.ballyrefbo

.ballyrefbo

.ballyrefbo.ballyrefbo

xx

es.comes.com

x

es.com

xx

es.comes.com

C

US

Loading...

Loading...