Page 1

M-Series® M7600

Electromagnetic Flow Meter

MAG-UM-00507-EN-02 (February 2018)

User Manual

Page 2

M-Series® M7600 Electromagnetic Flow Meter

Page ii February 2018MAG-UM-00507-EN-02

Page 3

User Manual

CONTENTS

Scope of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Precautions and Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rigging, Lifting and Moving Large Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Meter Location, Orientation and Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Meter Mount Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Temperature Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pipelines and Fluid Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Meter Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Straight Pipe Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pipe Reducer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chemical Injection Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Partially-Filled Pipe Situations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Meter Gaskets and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Meter/Pipeline Connection Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Meter Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Conductive Pipe Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pipelines with Cathodic Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wiring Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Opening the Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Conguring Input/Output (I/O). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring to a PC-200 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring to an ER-10 Industrial Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Menu Programming Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Screen Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Function Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

M7600 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning the Flow Tube and Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Errors & Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page iii February 2018 MAG-UM-00507-EN-02

Page 4

M-Series® M7600 Electromagnetic Flow Meter

Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Materials of Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page iv February 2018MAG-UM-00507-EN-02

Page 5

Detector

Scope of This Manual

SCOPE OF THIS MANUAL

This manual contains information concerning the installation, operation and maintenance of the Badger Meter®

M-Series M7600 electromagnetic flow meter. Read and understand the instructions given in this manual. Retain this

manual in a readily accessible location for future reference.

SAFETY PRECAUTIONS AND INSTRUCTIONS

Some procedures in this manual require special safety considerations. In such cases, the text is emphasized with the

following symbols:

Symbol Explanation

Warning indicates the potential for severe personal injury, death or substantial property damage.

Comply with the instructions and proceed with care.

Caution indicates the potential for minor personal injury or property damage. Comply with the

instructions and proceed with care.

SYSTEM DESCRIPTION

The Badger Meter M7600 electromagnetic flow meter successfully combines the most advanced electromagnetic

flow metering technology with the simplicity and ruggedness of the Badger Meter proven Batching Systems for

Industrial Applications.

The M7600 meter is intended for fluid metering in most industries including water, wastewater, food and beverage,

pharmaceutical, chemical and concrete.

The basic components of an electromagnetic flow meter are:

• The detector, which includes the flow tube, isolating liner and measuring electrodes.

• The amplifier, which is the electronic device responsible for the signal processing, flow calculation, display and

output signals.

The construction materials of the wetted parts (liner and electrodes) should be appropriate for the specifications on the

intended type of service. We recommend that you review all of the compatibilities consistent with the specifications.

Each meter is factory tested and calibrated. A calibration certificate is included with each meter.

Amplifier

®

Figure 1: Amplifier and Detector

Page 5 February 2018 MAG-UM-00507-EN-02

Page 6

Unpacking and Inspection

UNPACKING AND INSPECTION

Follow these guidelines when unpacking the M-Series equipment.

• If a shipping container shows any sign of damage, have the shipper present when you unpack the meter.

• Follow all unpacking, lifting and moving instructions associated with the shipping container.

• Open the container and remove all packing materials. Store the shipping container and packing materials in the event the

unit needs to be shipped for service.

• Verify that the shipment matches the packing list and your order form.

• Inspect the meter for any signs of shipping damage, scratches, or loose or broken parts.

OTE:N If the unit was damaged in transit, it is your responsibility to request an inspection report from the carrier within 48

hours. You must then file a claim with the carrier and contact Badger Meter for appropriate repairs or replacement.

• All detectors are shipped with a liner protector on each end to maintain proper form of the polytetrafluoroethylene (PTFE)

material during shipping and storage.

OTE:N Do not remove the liner protectors until you are ready to install.

• Storage: If the meter is to be stored, place it in its original container in a dry, sheltered location. Storage temperature ranges

are: – 22…158° F (– 30…70° C).

Rigging, Lifting and Moving Large Units

WHEN RIGGING, LIFTING OR MOVING LARGE UNITS, FOLLOW THESE GUIDELINES:

• DO NOT lift or move a meter by its amplifier, junction box, detector neck, or cables.

• Use a crane rigged with soft straps to lift and move meters with flow tubes that are between two inches and four inches

(50 mm and 100 mm). Place the straps around the detector body, between the flanges, on each side of the detector.

®

Place straps between flanges.

Figure 2: Rigging Large Units Figure 3: Sling-Rigged Lifting Methods

• Use the sling-rigged method to lift large detectors into a vertical position while they are still crated. Use this method to

position while they are still crated. Use this method to position large detectors vertically into pipelines.

• Do not lift a detector with a forklift by positioning the detector body on the forks, with the flanges extending beyond the

lift. This could dent the housing or damage the internal coil assemblies.

• Never place forklift forks, rigging chains, straps, slings, hooks or other lifting devices inside or through the detector's flow

tube to hoist the unit. This could damage the isolating liner.

Do not lift detector with forklift. Do not lift or rig lifting devices through detector.

Page 6 February 2018MAG-UM-00507-EN-02

Figure 4: Lifting and Rigging Cautions

Page 7

Meter Location, Orientation and Applications

METER LOCATION, ORIENTATION AND APPLICATIONS

Meter Mount Conguration

The meter mount configuration has the amplifier mounted directly on the detector. This compact, self-contained

configuration minimizes installation wiring.

Temperature Ranges

TO PREVENT DAMAGE TO THE METER, STRICTLY OBSERVE THE AMPLIFIER’S AND DETECTOR’S MAXIMUM

TEMPERATURE RANGES.

In regions with extremely high ambient temperatures, protect the detector.

Amplifier Ambient temperature – 4…140° F (–20…60° C)

Detector (PTFE) Fluid temperature – 40…212° F (– 40…100° C)

Pipelines and Fluid Flow

Take the following precautions during installation:

• Do not install the meter on pipes with extreme pipe vibrations. If pipes are vibrating, secure the piping with appropriate

pipe supports in front of and behind the meter.

• Do not install the meter close to pipeline valves, fittings or impediments that can cause flow disturbances.

• Do not install the meter on suction sides of pumps.

• Do not install the meter on outlet sides of piston or diaphragm pumps. Pulsating flow can affect meter performance.

• Avoid installing the meter near equipment that produces electrical interference such as electric motors, transformers, variable

frequency, and power cables.

• Verify that both ends of the signal cables are securely fastened.

• Place power cables and signal cables in separate conduits.

• Place the meter where there is enough access for installation and maintenance tasks.

Page 7 February 2018 MAG-UM-00507-EN-02

Page 8

RIGHT

Electrode

WRONG

BUTTERFL

VE

FLOWMETER

Meter Location, Orientation and Applications

Meter Orientation

Mag meters can operate accurately in any pipeline orientation and can measure volumetric flow in forward and reverse

directions.

OTE:N A "Forward Flow" direction arrow is printed on the detector label.

Vertical Placement

Mag meters perform best when placed vertically, with liquid flowing upward and meter electrodes in a closed, full pipe.

Vertical placement allows the pipe to remain completely full, even in low flow, low pressure applications, and it prevents

solids build-up, sediment deposit and accumulation on the liner and electrodes.

Figure 5: Vertical placement

Horizontal Placement

The M7600 meters are equipped with an Empty Pipe Detection feature. If an electrode mounted in the pipe is not covered by

fluid for five seconds, the meter will display an Empty Pipe Detection condition. The meter will send out an error message

and stop measuring flow. When the electrode is again covered with fluid, the error message disappears and the meter will

begin measuring.

Plane

Electrode

Plane

Figure 6: Horizontal placement

When installing the meter on a horizontal pipe, mount the detector to the pipe with the flow-measuring electrode axis in a

horizontal plane (three and nine o’clock). This placement helps prevent solids build-up, sediment deposit and accumulation

on the electrodes.

Straight Pipe Requirements

Sufficient straight-pipe runs are required at the detector inlet and outlet for optimum meter accuracy and performance. An

equivalent of three diameters of straight pipe is required on the inlet (upstream) side. Two diameters are required on the outlet

(downstream) side.

D (Pipe Size) D (Pipe Size)

FORWARD FLOW

CHECK VALVE

GLOBE VALVE

Y VALVE

PUMP

Page 8 February 2018MAG-UM-00507-EN-02

ELBOW

TEE

GATE VALVE

(FULLY OPEN)

MINIMUM STRAIGHT PIPE

3 x D

MINIMUM STRAIGHT PIPE

7 x D

MINIMUM PIPING REQUIREMENT

STANDARD CONCENTRIC

REDUCERS

(NO DISTANCE REQUIRED)

Figure 7: Straight pipe requirements

2 x D

MINIMUM STRAIGHT PIPE

ELBOW

TEE

ANY VAL

Page 9

Meter Location, Orientation and Applications

Pipe Reducer Requirements

With pipe reducers, a smaller meter can be mounted in larger pipelines. This arrangement may increase low-flow accuracy.

There are no special requirements for standard, concentric, pipe reducers.

Custom fabricated pipe reducers must have an approximate slope angle of 15 degrees to minimize flow disturbances and

excessive loss of head. If this is not possible, install the custom pipe reducers as if they were fittings and install the required

amount of straight pipe

Figure 8: Pipe reducer requirements

Chemical Injection Applications

For water line applications with a chemical injection point, install the meter upstream of the injection point. This eliminates

any meter performance issues.

Figure 9: Chemical injection point upstream of meter

If a meter must be installed downstream of a chemical injection connection, the distance between the meter and the

injection point should be between 50 and 100 feet (15 and 30 meters). The distance must be long enough to allow the water

or chemical solution to reach the meter in a complete, homogeneous mixture.

If the injection point is too close, the meter senses the two different conductivities for each liquid. This will likely result in

inaccurate measurements. The injection method—spaced bursts, continuous stream of drips or liquid or gas—can also affect

downstream readings by the meter.

Page 9 February 2018 MAG-UM-00507-EN-02

Page 10

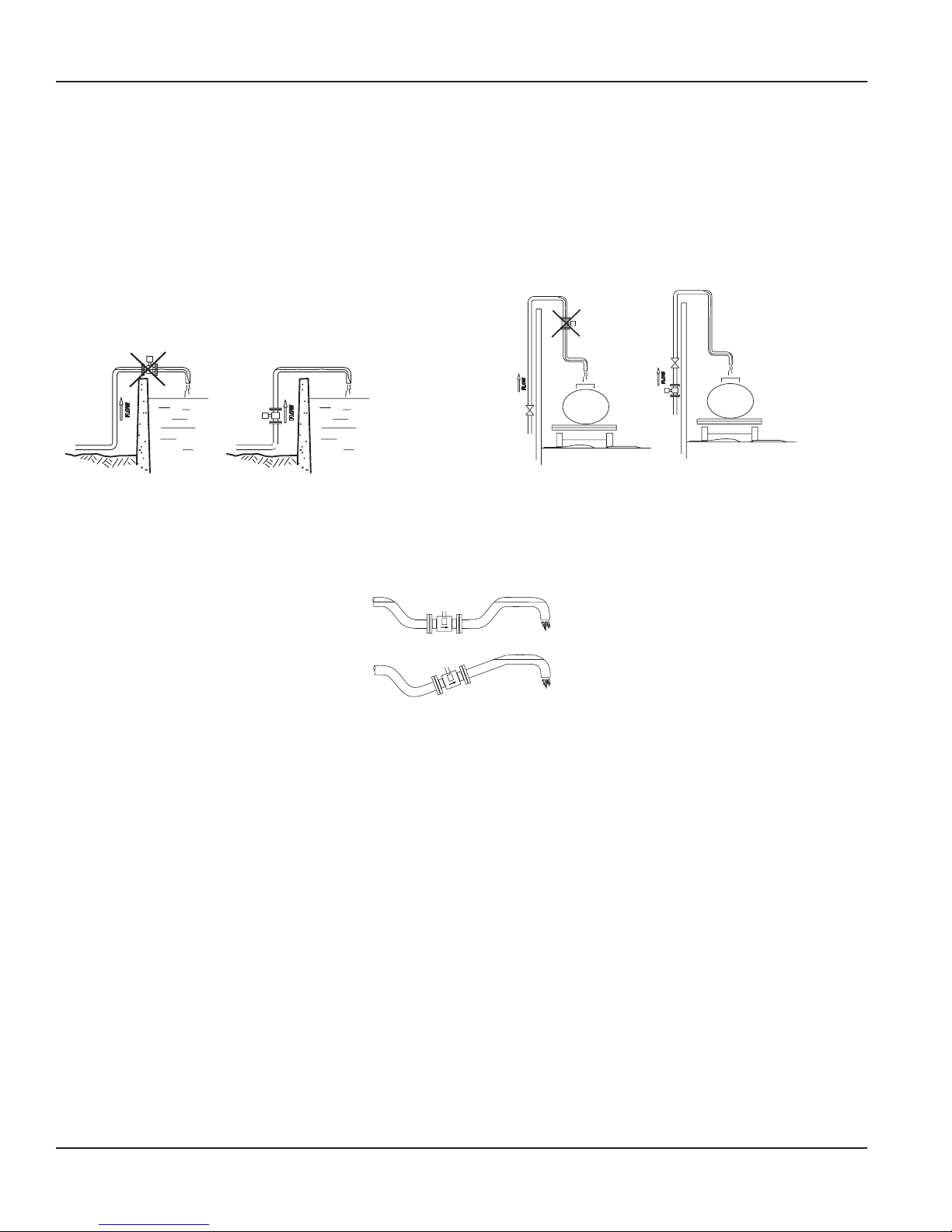

WRONG

RIGHT

Meter Location, Orientation and Applications

Partially-Filled Pipe Situations

In some locations, the process pipe may be momentarily only partially filled. Examples include: lack of back pressure,

insufficient line pressure and gravity flow applications.

To eliminate these situations:

• Do not install the meter at the highest point of the pipeline.

• Do not install the meter in a vertical, downward flow section of pipe.

• Always position the ON/OFF valves on the downstream side of the meter.

RIGHT

FLOW

Figure 10: Incorrect meter placement

WRONG

FLOW

FLOW

Do not install in a vertical, downward position. Position "On/Off" valves on downstream side.

Figure 11: Position valves on downstream side

FLOW

To minimize the possibility of partially-full pipe flows in horizontal, gravity or low pressure applications, create a pipe

arrangement that ensures the detector remains full of liquid at all times.

Figure 12: Pipe positioned to keep water in detector

Page 10 February 2018MAG-UM-00507-EN-02

Page 11

GASKETS RECOMMENDED

Meter Gaskets and Grounding

METER GASKETS AND GROUNDING

Gasket and grounding requirements must be considered when determining the meter location, orientation and application.

Grounding rings are provided with the M7600 meter.

Meter/Pipeline Connection Gaskets

You must install gaskets (provided) between the detector's isolating liner and the pipeline flange to ensure a proper

and secure hydraulic seal. Use gaskets that are compatible with the fluid. Center each gasket on the flange to avoid flow

restrictions or turbulence in the line.

During installation, do not use graphite or any electrically conductive sealing compound to hold the gaskets. This could

compromise the accuracy of the measuring signal.

Figure 13: Meter/pipeline connection gaskets

Meter Grounding

Process pipeline material can be either electrically conductive (metal) or not electrically conductive (made of or lined with

PVC, fiberglass or concrete).

It is essential that the mag meter amplifier’s input ground (zero voltage reference) be electrically connected to the liquid media and

to a good, solid earth ground reference.

Conductive Pipe Grounding

To achieve an adequate ground, the meter body MUST be electrically connected to the liquid media. The mag meter flanges

are provided with grounding bolts for this purpose.

If the pipe material is electrically conductive, simply install grounding straps between these grounding bolts and the

mating flanges.

To ensure a good electrical connection at the mating flanges, we recommend that you drill and tap the flanges and install a

grounding screw (not provided).

These grounding straps must be copper wire, at least 12 AWG size. They must be connected on both sides (inlet and outlet) of

the detector and to a local, earth ground.

Pipelines with Cathodic Protection

As for pipelines with cathodic protection, install meter potential-free. No electric connection from the meter to the pipeline

system may exist and power supply is to be provided via isolating transformer.

GROUNDING RINGS ALSO NEED TO BE INSTALLED ISOLATED FROM THE PIPELINE SYSTEM.

Observe national rules for potential-free installations.

Electrically isolated

"X"

6 mm² Cu

Figure 14: Cathodic protection

Electrically isolated

M4:1

"X"

Page 11 February 2018 MAG-UM-00507-EN-02

Page 12

Power Connections

POWER CONNECTIONS

Wiring Safety

AT INSTALLATION, BE SURE TO COMPLY WITH THE FOLLOWING REQUIREMENTS:

• Disconnect power to the unit before attempting any connection or service to the unit.

• Do not bundle or route signal lines with power lines.

• Keep all lines as short as possible.

• Use twisted pair shielded wire for all output wiring.

• Observe all applicable local electrical codes.

Opening the Cover

The M7600 amplifier's design lets you open the cover

without completely removing it.

Follow these steps:

1. Completely remove the top two screws from the

amplier using a blade/slotted screwdriver.

2. Loosen both of the bottom screws so that the round

head of each screw clears the top face of the cover.

3. Pull down the cover to the open position.

• For the 2 x M20 cable inlets, use only flexible electric

cables.

• Use separate cable inlets to separate power from signal

and input/output cables.

Figure 15: Remove two screws

Figure 16: Open the cover

Page 12 February 2018MAG-UM-00507-EN-02

Page 13

Power Connections

Power Supply Connections

External Disconnect

• Install an external disconnect switch or circuit breaker that meets local standards.

• Position the M7600 meter in an accessible location.

• Position and identify the disconnect device so as to provide safe and easy operation.

• Label the disconnect device as being for the mag meter.

AC Power Wiring

For the AC power connections, use three wire-sheathed cable with an overall cable diameter of 0.2…0.45 inch (5…12 mm).

For signal output, use 18…22 gauge (0.25…0.75 mm2) shielded wire. Overall cable diameter between 0.12…0.35 inch

(3…9 mm).

TO PREVENT ACCIDENTS, CONNECT MAIN POWER ONLY AFTER ALL OTHER WIRING HAS BEEN COMPLETED.

The amplifier is a microprocessor device. It is important that the power supply be as “clean” as possible. Avoid using power

lines that feed heavy loads: pumps, motors, etc. If dedicated lines are not available, a filtering or isolation system may

be required.

Take national applicable rules into account.

• Observe type plate (mains voltage and frequency)

• Equipment shall be provided with a external means for disconnecting it from each operating energy supply source. The

disconnecting means shall disconnect all current-carrying conductors.

1. Open the cover (see "Opening the Cover" on page 12).

2. Push the power cable through the upper cable inlet.

3. Connect as shown in Figure 17.

4. Close the cover and tighten the screws.

Power supply 92…275V AC (50/60 Hz)

Recommended cable size min. 0.75 mm²

Power supply 9…36V DC (max. 9 W)

Recommended cable size min. 0.75 mm²

Figure 17: Power connections

Page 13 February 2018 MAG-UM-00507-EN-02

Page 14

Power Connections

Conguring Input/Output (I/O)

Display

Push-buttons

Output Description Terminal

Open collector max. 10 kHz

Pulse Output

Passive max. 32V DC, <100 Hz 100 mA, >100 Hz 20 mA

Solid-state relays max. 230V AC, 500 mA, max. 1 Hz S1 and S2

Alarm Output

Open collector

Passive max. 32V DC, 100 mA

Exit

Save

Coil connector

Figure 18: Configuring I/O

Table 1: Input/output descriptions

Power supply

Pulse output, solid-state relays (S1, S2)

S1

S2

1

2

3

4

5

6

7

8

9

A

B

C

Y

G

Pulse output, open collector (1, 2)

Alarm output (3, 4)

1 and 2

3 and 4

• USE SEPARATE CABLE INLETS FOR CABLES CONNECTED TO THE SOLID-STATE RELAY OUTPUT AND CABLES CONNECTED

TO THE OTHER INPUT/OUTPUTS.

• IN MULTIPHASE NETWORKS, SOLID-STATE RELAY SHOULD HANDLE ONLY THE SAME PHASE THAT IS USED FOR

POWERING THEMETER.

Connecting the M7600 Meter to 110V AC from Batch Control Panel Power Supply

Typical concrete batch panel.

Meter

Batch Panel

Ground

Neutral

Hot

Meter Pulse Input

Solid-State

Relay Output

Limit 230V AC

*

Neutral

Hot

S1

S2

Figure 19: Batch panel power connections

• The connection shown in Figure 19 is for batch panels that require a 115V AC hot pulse for meter signals.

• Consult the batch panel manufacturer to confirm the required pulse signal.

• For a 115V AC neutral pulse signal to the batch panel, take the S2 jumper to the 115 neutral power supply.

DO NOT PASS MORE THAN 230V AC THROUGH THE SOLIDSTATE RELAY.

Page 14 February 2018MAG-UM-00507-EN-02

Page 15

Common

Power Connections

Wiring to a PC-200 Controller

To connect the open collector scaled pulse output from the Model M7600 meter to the PC-200 controller, follow Figure 20.

Open Collector

Transistor Output

1

DC-Switched

2

3

4

5

6

Figure 20: Wiring to a PC-200 controller

Wiring to an ER-10 Industrial Register

Common

Open Collector

Transistor Output

Terminal Function Operation

1 Ground —

2 Input B

Count input

3 — Not used

4 Reset Connect to ground to reset totalizer. This is a maintained or level-sensitive reset.

5 Program enable Connect to ground to enter program mode.

6 Backlight common —

7 Backlight power Connect to power to light display.

1

DC-Switched

2

3

4

5

6

7 +10-30VDC7 +10-30VDC

6 DC Common

5 Enable/R

5 Enable/R

Figure 21: Wiring to an ER-10 register

Count input

Contact closure of NPN 100 Hz max

Table 2: ER-10 wiring terminals

Rear View

RST 4

IN B 2

GND 1

Reset

Count Input

GroundProgram enable

Page 15 February 2018 MAG-UM-00507-EN-02

Page 16

Menu Programming Options

MENU PROGRAMMING OPTIONS

Screen Layout

The following M7600 meter programming options are available from the M7600 Menu:

• Scale factor

• Pulse/unit

• Flow unit

• Totalizer unit

Function Buttons

All M7600 programming is accomplished using the three function buttons located on the front of the amplifier. Screen

navigation, digit, and parameter selection is performed by pressing a combination of these three buttons.

Display

Push-buttons

Figure 22: Function buttons

Exit

Save

Press the Exit/Save button to access the M7600 programming options.

Press the left button to scroll through the programming options.

Press the center button to edit a programmable option.

For selection list options (for instance, Totalizer Unit or Flow Unit), press the left button to change the value. Press the right

button to confirm the new value.

For numerical options (for instance, Scale Factor or Pulse/Unit), press the left button to change the numerical digit value.

Press the center button to move to the next numerical digit. When all digits are entered, press the right button to confirm

the new value.

Status Icons

Communication interface is activated

Meter is unlocked

Error message

Empty pipe detection

Page 16 February 2018MAG-UM-00507-EN-02

Page 17

Menu Programming Options

M7600 Menu

Scale Factor Changing the scale factor lets you adjust the meter’s accuracy without disturbing parameters set

by the factory. You can tune the meter to meet changing application requirements in a range of

±10% (0.90 to 1.10).

If it is necessary to recalibrate the meter, follow these steps:

1. Determine the exact quantity of uid that actually passed through the meter by using a

calibrated volumetric container or by weighing the container.

2. Note the volume of uid indicated by meter.

3. Note the current scale factor on the meter LCD (scale factor menu).

4. Use the following formula to calculate the new scale factor for recalibration:

Qty delivered

Qty on meter

X

Old scale

factor

New scale

factor

5. Use the meter push-buttons to enter the new scale factor.

6. Rerun test to verify that the recalibration is correct.

Example:

You have a 3" size meter in your installation. You run a test batch quantity of 210 gallons. The

totalizer on the meter indicates 203 gallons. Your present scale factor on the meter is 1.00.

Using the formula:

210

1.0=1.03

X

203

Your new scale factor is 1.03.

Pulse/Unit The Pulses/Unit parameter lets you set how many pulses per unit of measure will be transmitted.

The maximum output frequency of 10,000 pulses/sec.

10 kHz must not be exceeded for the Open Collector.

1 Hz must not be exceeded for the Solid-State Relay.

If both are used, 1 Hz must not be exceeded.

For example, assuming the unit of measure is gallons:

• Setting the Pulses/Unit to 1 will transmit 1 pulse every gallon

• Setting the Pulses/Unit to 0.01 will transmit 1 pulse every 100 gallons

You must configure pulses/unit if the function of the selected output is to be open collector or

solid-state.

Flow Unit Flow Units let you select among the Flow Units listed below. Flow units are automatically

converted into the selected unit.

Display Flow Unit Display Flow Unit

L/s Liters/Second gal/s Gallons/Second

L/min Liters/Minute gal/min Gallons/Minute

L/h Liters/Hour gal/h Gallons/Hour

m3/s Cubic Meters/Second MG/D MillionGallons/Day

m3/min Cubic Meters/Minute IG/s ImperialGallons/Second

m3/h Cubic Meters/Hour IG/min ImperialGallons/Minute

ft3/s Cubic Feet/Second IG/h ImperialGallons/Hour

ft3/m Cubic Feet/Minute Oz/min Ounce/Minute

ft3/h Cubic Feet/Hour bbl/min Barrel/Minute

Totalizer Unit This parameter establishes the units of measure for the totalizers.

Display Totalizer Unit Display Totalizer Unit

L Liters MG Million Gallons

hL Hectoliter IG Imperial Gallons

3

m

3

ft

gal U.S. Gallons Aft Acre Foot

Cubic Meters bbl Barrel

Cubic Feet Oz Fluid Ounces

Page 17 February 2018 MAG-UM-00507-EN-02

Page 18

Maintenance

MAINTENANCE

Mandatory, routine or scheduled maintenance should not be required for the M7600 Mag Meter electronics or flow tube after

proper installation. However, some occurrences may require personnel to perform the following:

• Flow tube and electrode cleaning

• Circuit board replacement

DO NOT CLEAN COMPONENTS INSIDE THE AMPLIFIER OR JUNCTION BOX.

Cleaning the Flow Tube and Electrode

At times flow tube, electrodes, amplifier/junction box housings and the amplifier window may need periodic cleaning,

depending on process fluid properties, fluid flow rate and surrounding environment.

Clean the flow tube and electrodes by following the material handling and cleaning procedures documented in the

Material Safety Data Sheet (MSDS) guidelines for the products(s) that were in contact with the flow tube and electrodes.

Should flow tube and/or electrode cleaning become necessary:

1. Disconnect detector from pipeline.

2. Clean electrodes according to MSDS guidelines.

3. Reconnect detector to pipeline.

Page 18 February 2018MAG-UM-00507-EN-02

Page 19

Troubleshooting

TROUBLESHOOTING

The M7600 mag meter is designed for many years of optimal performance. However, should it malfunction, there are certain

things that we recommend you check before contacting our Technical Support department or your local Badger Meter

Representative.

Errors & Warnings

OTE:N The M7600 display flashes whenever an error is detected.

Description Possible Cause Recommended Action

Coil disconnected • Meter is not connected.

• Connection to meter is interrupted.

Coil shorted Coil cables shorted. Check coil cables.

Empty pipe Pipe may not be full. Make sure that pipe is always filled at the

Medium with low conductivity. Calibrate meter, see "M7600 Menu" on page 17.

Cable is broken or disconnected. Check the cable for the empty pipe signal.

Range Actual flow rate is exceeding the programmed full

scale by more than 100%.

Pulse output Pulse rate exceeds the maximum Reduce pulse scale (pulse/unit) and/or reduce

AD error Input signal from detector is too high. Check the grounding scheme of the meter

Excitation

frequency

EEPROM Configuration file is missing. Contact Badger Meter Technical Support.

Configuration Configuration file is corrupted. Contact Badger Meter Technical Support.

Measure Timeout Measurement was not completed within

The excitation frequency is too high for

this detector.

specific time.

Check if meter is connected and make sure that

cable connection is not interrupted. You can also

contact Badger Meter Technical Support.

measuring point.

Reduce the flow rate or increase the programmed

full scale.

pulse width configuration.

installation. See "Meter Grounding" on page 11.

Decrease the excitation frequency in the Menu.

Contact Badger Meter Technical Support.

Page 19 February 2018 MAG-UM-00507-EN-02

Page 20

M-Series® M7600 Electromagnetic Flow Meter

SPECIFICATIONS

Performance

Sizes Sizes 1/2…4 in. (15…100 mm)

Flow Range 0.14…1320 gpm (0.53…5000 lpm)

±0.5% of rate for velocities greater than 1.64 ft/s, ±0.008 ft/s less than 1.64 ft/s

Accuracy

Repeatability ±0.1%

Fluid Temperature Maximum fluid temperature: 212° F (100° C)

Storage Temperature –40…140° F (–40…60° C)

Ambient Temperature –4…140° F (–20…60° C)

Fluid Conductivity Minimum liquid conductivity: 5 micromhos/cm

Flow Direction Unidirectional

Pressure Limits Working pressure: 232 psi (16 bar)

Materials of Construction

Flow Tube AISI 316 stainless steel

Detector Housing Flange material: carbon steel, enamel paint finishing

Liner Material PTFE

End Connection ANSI 150# carbon steel flanges

Electrodes Materials Hastelloy C22

Amplifier Housing

Cable Entries Two 1/2 in. NPT cord grip

Grounding Rings Standard (pre-installed)

Optional Grounding Electrodes 2

Inputs

Power Supply 92…275 VAC

Coil Excitation Pulsed DC

Programming PC user interface

Outputs

Digital Output

Frequency Output Maximum output frequency: 10 kHz

Pulse Width 50% duty cycle

Approvals

Meter Enclosure NEMA 4

NIST Handbook B44 Complies for batching applications

±0.5% of rate for velocities greater than 0.50 m/s, ±2.5 mm/s less than 0.50 m/s

Note: The maximum measuring error depends on the installation conditions.

Powder-coated cast aluminum, NEMA 4

Meter mounted only

Output 1: solid-state relay up to 230V, 500 mA

Output 2: Opto-isolated open collector, 50 mA at 24V DC

Control. Manage. Optimize.

M-Series is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, B elarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, O ce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | R acianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: IOM-193-02-EN 53400-193

Loading...

Loading...