Page 1

Magnetoflow

Mag Meter

®

Sanitary Meter

with Model Primo

®

3.1

Installation &

Operation Manual

IOM-104-02

BadgerMeter,Inc.

®

53400-104

3-09

Page 2

SCOPE OF THIS MANUAL

This manual contains information concerning the installation, operation and maintenance of Badger’s Magnetoflow

meter models with Primo® Amplifier.

To ensure proper meter performance, the instructions given in this

manual should be thoroughly understood. Keep a copy of this manual

in a readily accessible location for future reference.

®

electromagnetic flow

TABLE OF CONTENTS

System Description ........................................................................ 2

Unpacking and Inspection ............................................................. 2

Transportation and Handling ......................................................... 2

Meter Installation ............................................................................ 3

Specifications - Detector ............................................................... 5

Grounding ....................................................................................... 6

Specifications - Amplifier ................................................................ 6

Wiring .............................................................................................. 7

Programming ................................................................................... 9

Unit of Measure .......................................................................... 9

Full Scale Setting (Maximum Flow) ......................................... 10

Low Flow Cutoff ........................................................................ 10

Empty Pipe Detection ............................................................... 11

Flow Direction ........................................................................... 11

Filter Dampening ...................................................................... 12

Error List (Messages) .............................................................. 12

Resetting of Totalizers ............................................................. 12

Analog Outputs ......................................................................... 13

Pulse Outputs ........................................................................... 14

Wiring of AMR unit to Mag ....................................................... 14

Frequency Output .................................................................... 15

Flow Alarms .............................................................................. 15

Detector Factor Field Calibration ............................................ 15

Accuracy Test .......................................................................... 16

Meter/Pipe Size ........................................................................ 16

Password Protection ................................................................ 16

Language Selection ...................................................................... 16

Troubleshooting ............................................................................ 17

Error Message Explanation ......................................................... 18

Board Assembly Replacement .................................................... 19

Fuse Replacement ....................................................................... 19

All Badger’s Magnetoflow mag flow meters are factory tested and

calibrated. A calibration certificate is included in the shipment of each

meter.

UNPACKING AND INSPECTION

Magnetoflow mag flowmeters are shipped in special shipping containers. Upon receipt of the meter, perform the following unpacking

and inspection procedures. If damage to the shipping container is

evident, be present when the meter is unpacked.

A) Carefully open the shipping container following any instruc-

tions that may be marked on the exterior. Remove all

cushioning material surrounding the meter.

B) Retain the shipping box and all packing materials for possible

use in reshipment or storage.

C) Visually inspect the meter for any physical damage such as

scratches, loose or broken parts, or any other sign of damage

that may have occurred during shipment.

NOTE: If damage is found, request an inspection report by

the carrier’s agent within 48 hours of delivery. Then file a

claim with the carrier. A formal claim for equipment

damaged in transit is the responsibility of the customer.

D) Verify that the meter received is consistent with the product

ordered. The detail on the product labels on the detector and

the amplifier should help this verification.

E) All detectors with PTFE liner are shipped from the factory with

a liner protector. This protector maintains the proper form of the

PTFE material and protects it during shipping and storage. Do

not remove this protector until you are ready to install the unit.

F) Storage: If the meter is not to be immediately installed, store

it in its original container in a dry, sheltered location. Storage

temperature: -4 to 158 °F (-20 to 70 °C)

METER INSTALLATION

METER LOCATION GUIDELINES

The following are several guidelines for determination of a good

location for meter installation:

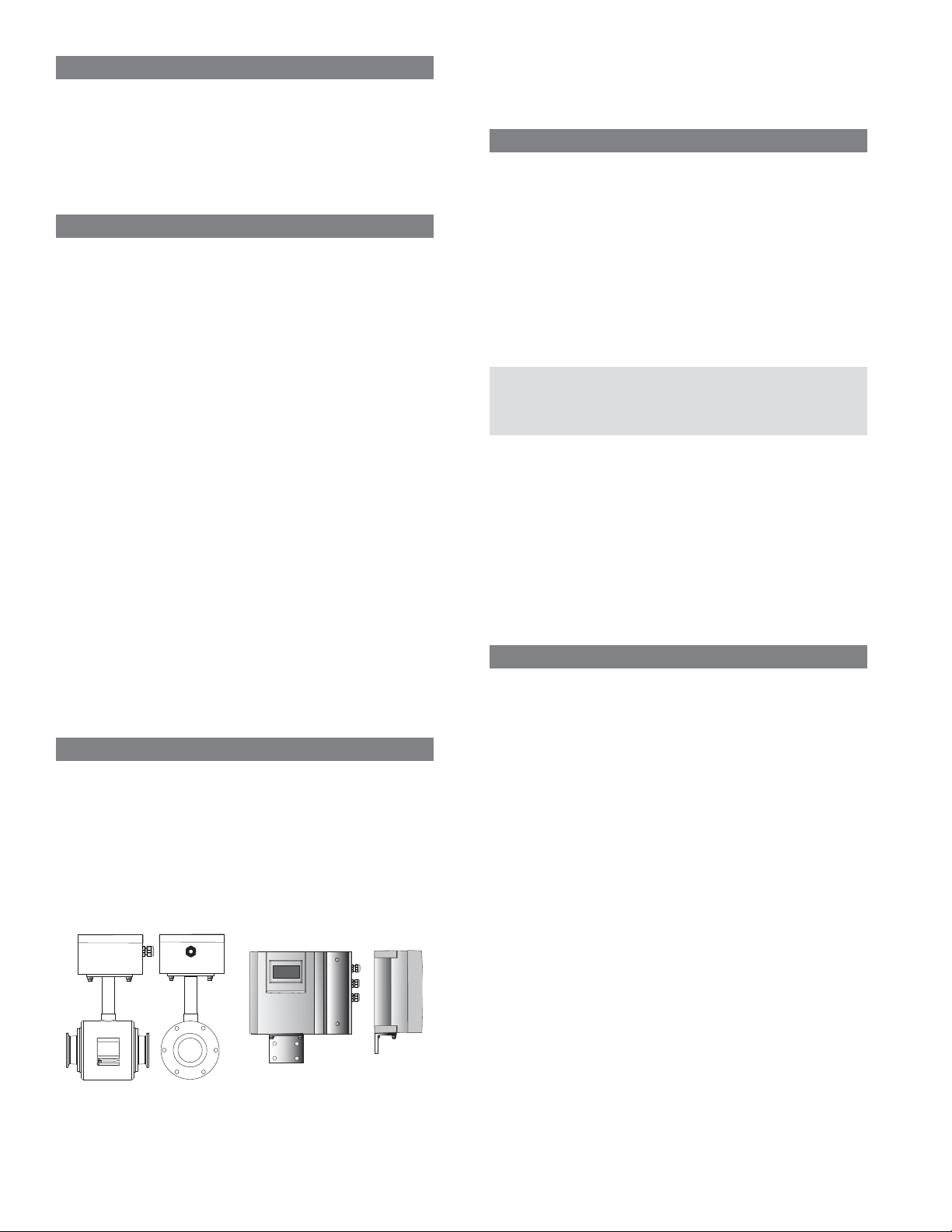

SYSTEM DESCRIPTION

Magnetoflow® electromagnetic flow meters are intended for fluid

metering in most industries including water, wastewater, food and

beverage, pharmaceutical and chemical.

The basic components of an electromagnetic flow meter are two: 1)

The Detector; which includes the flow tube, isolating liner and

measuring electrodes, and 2) the Amplifier, which is the electronic

device responsible for the signal processing, flow calculation, display

and output signals.

Detector

The materials of construction of the wetted parts (liner and electrodes) should be appropriate for the specifications on the intended

type of service. Review of the compatibilities consistent with the

specifications is recommended.

Primo

Temperature Ranges

In order to prevent damage to the meter, the maximum temperature

ranges must be observed.

Primo® Amplifier

Ambient temperature: -4 to 140°F (-20 up to +60°C)

Detector

Fluid temperature: -40 to 311°F (-40 up to +155°C)

Outdoor Installations - Primo Amplifier

The Primo Amplifier can be installed outdoors but with a few

requirements:

1. The ambient environment must not be out of the temperature

ratings for the unit. (-4 to 140 degrees F)

2. The Primo must be protected to some degree from the outside

elements. At a minimum, a roof or shield of sorts should be

fabricated over the unit to protect the LCD display from the

sunlight. It will also keep the unit out of the possibility of a hard

sustained rain which could cause moisture to get into the unit. An

alternative approach would be to simply mount the unit in a

“Hoffman style” outdoor enclosure, eliminating the potential of

either issue arising.

If an indoor environment is within 250 feet of the Mag meter

installation, consideration should be given to increase the cable

length and mount the Primo indoors.

2

Page 3

Chemical Injection Applications

For water line applications with a chemical injection point, the meter

should be installed upstream of the chemical injection point to

eliminate any issues with the meter performance. If an upstream

location is not possible for the meter, consider moving the injection

point downstream of the meter location. If the meter must be installed

downstream of the chemical injection point, the distance between

these (2) locations must be significant; frequently 50 - 100 feet.

When the solution made up of the water and the injected chemical

reach the Mag meter, it must be a complete homogeneous mixture.

If too close, the Mag meter will sense (2) different liquids (conductivity

different for each) and will be confused as to how to process the

information. Many other factors such as the type of injection method,

(spaced bursts versus continuous stream of drops), or whether the

chemical is injected in a liquid or gas form, can cause a wide variation

in the distance required from one application to another.

Due to this wide range of factors, it is difficult to specify a distance that

will always work for any application without establishing a value far in

excess of what would usually be required. Please contact Badger

Meter's Technical Support at 1-800-616-3837 with your application

detail and they can assist in determining if the Mag meter should

properly perform. As noted, the meter may require 50 - 100 feet from

the injection point to assure the complete homogeneous state.

Submersible Option

If the meter is to be installed in a meter vault, it should be installed to

be sure the amplifier is not inside the vault.

Other Considerations

Avoid all pipe locations where the flow is pulsating, such as in the outlet

side of piston or diaphragm pumps.

Avoid locations near equipment producing electrical interference

such as electric motors, transformers, variable frequency, etc.

Install the meter with enough room for future access for maintenance

purposes.

The mag meter isolating liner is not intended to be used as gasket

material. Standard gaskets (not provided) should be installed to ensure

a proper hydraulic seal. When installing the gaskets, make sure they are

properly centered to avoid flow restriction or turbulence. Do not use

graphite or any electrically conductive sealing compound to hold the

gaskets in place during installation. This could affect the reading

accuracy of the measuring signal.

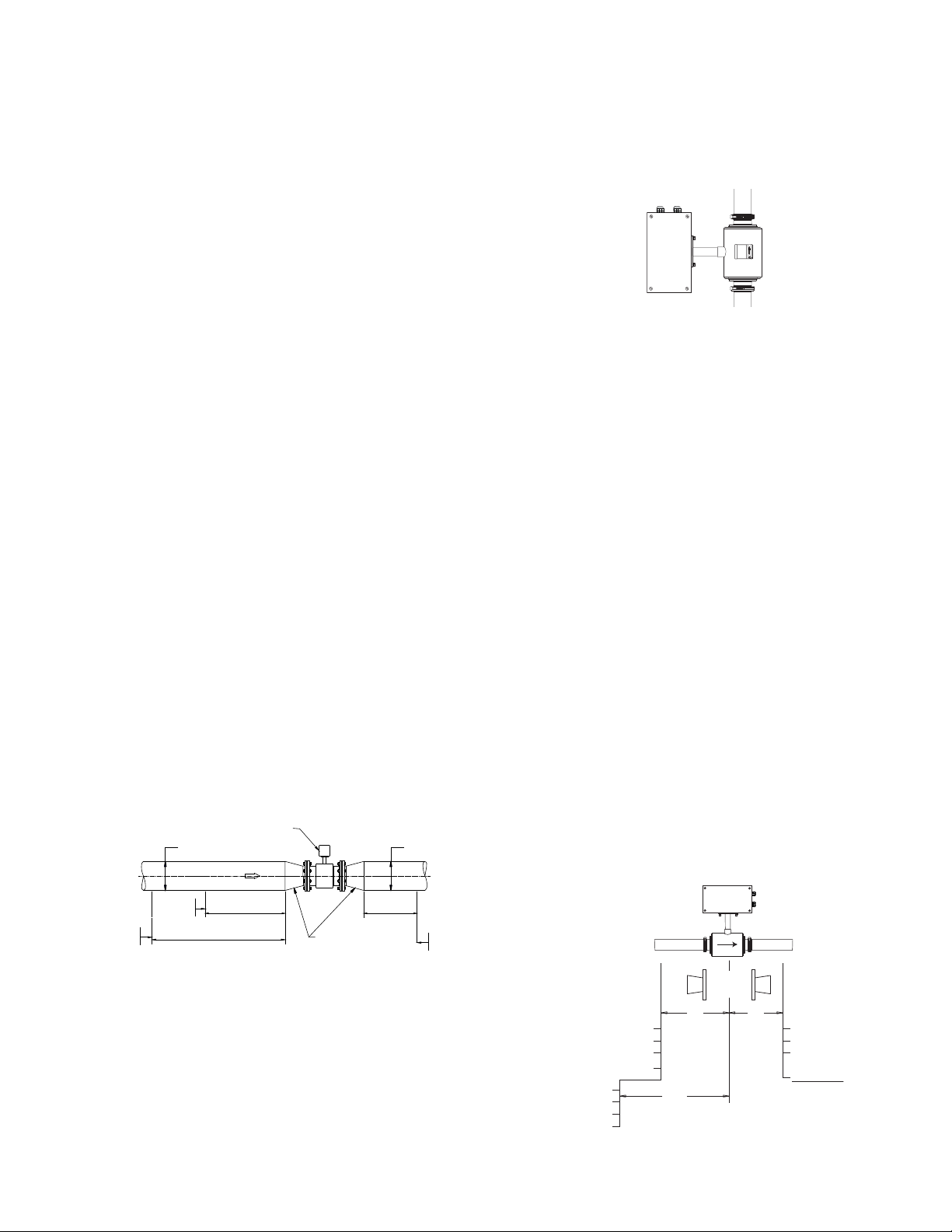

STRAIGHT PIPE REQUIREMENTS

For optimum accuracy performance, it is required to provide sufficient inlet and outlet straight pipe runs. An equivalent to 3 diameters

of straight pipe is required on the inlet side, and 2 diameters on the

outlet side. There are no special requirements for standard concentric pipe reducers.

MAGNETOFLOW MAG FLOWMETER

D (Pipe Size)D (Pipe Size)

FORWARD FLOW

chines, etc. Be sure both ends of signal cable are securely fastened.

Run power and signal cables in separate conduit.

METER ORIENTATION

Magnetoflow Mag Meters can operate accurately in any pipe line

orientation.

However, the most recommended installation position is vertical

piping, with the the liquid flowing upward.

FIG. 1 VERTICAL PIPE MOUNTING

HIGHLY RECOMMENDED

This installation practice ensures two objectives:

· The pipe remains completely full of liquid, even at low flow, low

pressure applications with a discharge to the atmosphere.

· Solid build-ups or sediments that could be part of the process

fluid will not deposit or accumulate on the liner and/or electrodes.

The model Magnetoflow® Sanitary meter is designed to measure flow

in bi-direction only. Carefully observe the "forward flow" label

attached to the meter body and install the meter accordingly.

PIPING CONFIGURATION

Appropriate piping arrangements should be provided to ensure

the meter is not exposed to extreme pipe vibrations. The piping

arrangements should include appropriate pipe supports.

For optimum accuracy performance, it is required to provide

sufficient inlet and outlet straight pipe runs. An equivalent of 3

diameters of straight pipe is required on the inlet side of the

meter, and 2 diameters on the outlet side, measured from the

center of the meter body.

Avoid installing the detector close to flow disturbance generating

valves and fittings.

Do not install the detector in the outlet side of Piston or

Diaphragm type pumps. Avoid all pipe locations where the flow is

pulsating. Avoid installing the detector in the suction side of any

pumps; possible creation of vacuum can affect meter

performance or cause damage to the PTFE liner.

TEMPERATURE

Note: Environmental temperature of installation is not to exceed

maximum specification of 122°F (50°) for the Primo amplifier.

ELBOW

CHECK VALVE

GLOBE VALVE

BUTTERFLY VALVE

PUMP

TEE

GATE VALVE

(FULLY OPEN)

MINIMUM STRAIGHT PIPE

3 x D

MINIMUM STRAIGHT PIPE

7 x D

MINIMUM STRAIGHT PIPE

STANDARD CONCENTRIC

REDUCERS

(NO DISTANCE REQUIRED)

2 x D

ELBOW

TEE

ANY VALVE

By using pipe reducers, a smaller meter size can be mounted in larger

pipeline sizes. This may also increase low flow accuracy performace.

In order to minimize flow disturbances and excessive loss of head,

custom fabricated pipe reducers must have a minimum slope angle

of 15 degrees. If this is not possible, install the custom pipe reducers

as if they were fittings, leaving the minimum straight pipe required.

Mounting Location

The detector should never be installed on the suction side of a pump

where a vaccuum exists to eliminate the possibility of damage to the liner.

If vibration exits on the pipeline, secure the piping before and after

the meter. If a strong vibration exists, the amplifier should be mounted

remotely. Do not install cables near power cables, electrical ma-

GLOBE VALVE

NEEDLE VALVE

CHECK VALVE

PUMP

ELBOW

GATE VALVE

(FULLY OPENED)

BALL VALVE

UPSTREAM

TEE

5-7 D

STRAIGHT PIPE RUN

(ANY POSITION)

PIPE REDUCERS

NO REQUIREMENT

DOWN STREAM

2 D3 D

ELBOW

TEE

ANY VALVE

NO PUMPS

3

Page 4

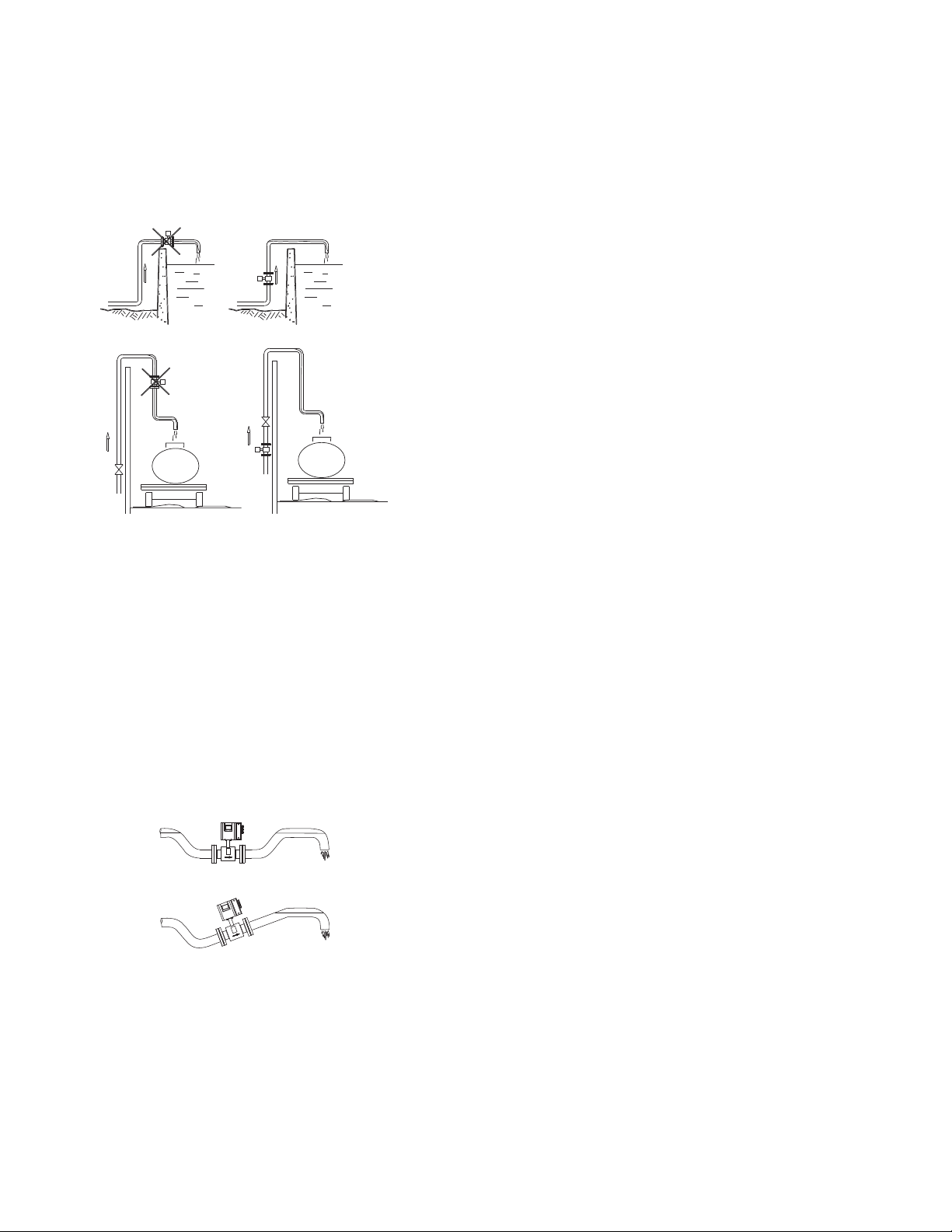

PARTIALLY FILLED PIPE SITUATIONS

FLOW

FLOW

FLOW

FLOW

Magnetoflow® mag meters are designed to operate in closed, full

pipes.

It is relatively common to encounter situations where the process

pipe will remain momentarily partially filled due to certain hydraulic

conditions. Examples of this include discharge to the atmosphere

(lack of back pressure), insufficient line pressure, gravity flow

applications, etc.

WRONG

FLOW

WRONG

FLOW

RIGHT

FLOW

RIGHT

FLOW

To eliminate the negative effect of these situations on the

performance of the mag meter, observe the following guidelines:

· Avoid installing the detector in the highest point of the pipe line

· Do not install the detector in vertical, downward flow sections

of the pipe

· ON/OFF valves should ALWAYS be located on the downstream

side of the meter

· Select the recommended vertical orientation with flow upwards

whenever possible

· Make sure that the flow range of the meter size selected is

consistent with the application flow range

To minimize the possibility of partially full pipe flows in horizontal,

gravity or low pressure applications, it is recommended to create a

pipe arrangement as shown in the figure below. This arrangement

ensures the detector remains full of liquid at all times.

Open Discharge

Horizontal Installation

Open Discharge

Horizontal

4

Page 5

3.94"

3.94"

Meter with junction box for

®

D

remote Primo

converter

B

A

C

Flow RangeEst. Weight

ABC Dwith Primo GPM LPM

inches mm inch mm inch mm inch mm inch mm Lbs Kg Min Max Min Max

3/8”10 7.1 180 .992 25.2 2.8 70 8.3 210 12 5.5 0.034 11.4 0.13 43

1/2”15 7.1 180 .992 25.2 2.8 70 8.3 210 12 5.5 0.06 20 0.23 76

3/4”20 7.1 180 .992 25.2 2.8 70 8.3 210 12 5.5 0.13 45.4 0.52 171

1” 25 7.1 180 1.984 50.4 2.8 70 8.3 210 13 6 0.24 80 0.92 305

1 1/2” 40 7.9 200 1.984 50.4 3.5 89 9.3 235 15 7 0.6 181 2.1 687

2” 50 7.9 200 2.516 63.9 4.1 104 9.8 250 17 7.5 1.0 323 3.7 1223

2 1/2” 65 10.6 270 3.047 77.4 5.1 129 10.6 270 20 9 1.5 504 5.8 1910

3” 80 10.6 270 3.579 90.9 5.5 140 11.0 280 23 10.5 2.2 727 8.3 2751

4” 100 10.6 270 4.682 118.9 6.3 160 11.8 300 24 11 4.0 1292 14.8 4892

SPECIFICATIONS

Flow Range: 0.1 - 33 fps (0.03-10 m/s)

Sizes: 3/8" to 4" (10 to 100 mm)

Min. Conductivity:

Accuracy:

≥ 0.5% accuracy of rate from .1-1 fps.

≥ 0.25% accuracy of rate from 1-33 fps.

≥ 0.5 micromhos/cm

Electrode Material: Alloy C

Liner Material: PTFE

Max. Fluid Temperature: 311°F, (155°C)

Pressure Limits: 150 psi (10Bar)

Coil Power: Pulsed DC

Ambient Temperature: -4°F to 122°F, (-20°C to 50°C)

Meter Enclosure Material: Stainless Steel 316

End Connections: Tri-clamp (sizes 1"-4" per ISO 2852)

Junction Box Enclosure Protection: Stainless Steel, Nema 4X

Cable Entries: 1/2" NPT Cord Grip

Remote Amplifier Enclosure: NEMA 4

PRIMO® AMPLIFIER (3.1 ELECTRONICS)

11.7"

7.75"

298mm

197mm

SPECIFICATIONS

Power Supply: 85-265 VAC, 45-65 Hz

Power Consumption: 20W

Accuracy: ± 0.25% accuracy of rate from 1-39.4 fps.

Repeatability: 0.1%

Minimum Fluid Conductivity: 5.0 micromhos/cm

Flow Direction: Unidirectional or bidirectional, 2 separate

totalizers (programmable)

Analog Outputs: 0/4-20mA, 800ohms Max Load

Ouput Frequency: Scaled Pulse output, (open collector) Max

5Khz

Digital Outputs:

Voltage sourcing transistor, 24VDC, 100mA max

(3) AC electro-mechanical relays, 48VAC, 0.5 amp max

± 0.5% accuracy of rate from 0.1-1.0 fps.

9.68"

246mm

25mm

1"

4.96"

126mm

Mounting Bracket for

Remote Configuration

Outputs: All ouputs are short circuit safe

Noise Dampening: Programmable from 1 to 6

Pulse Width: Programmable up to 500ms

Galvanic Isolation: ≤ 500V

Zero-point Stability: Automatic correction

LCD Display: 4 lines x 16 character back-lit alphanumeric

Displays (2) Totalizers, Flow Rate, Alarm conditions

Housing: Cast aluminum, powder coated paint

Housing Rating: NEMA 4X

Mounting: Detector mount or remote mount (bracket supplied)

Cable Connection: 1/2" NPT Cord Grip

Ambient Temperature: -4 to 140° F (-20 to 60° C)

Serial Communication: RS232

5

Page 6

WIRING

At installation, be sure to comply with the following requirements:

IMPORTANT!

• Disconnect power to the unit before attempting any

connection or service to the unit

• Do not bundle or route signal lines with power lines

• Keep all lines as short as possible

• Use twisted pair shielded wire for all output wiring

• Observe all applicable local electrical codes

For the AC power connections use three wire sheathed cable with

overall cable diameter of 0.2" to 0.45" (5mm to 12mm). For signal

output use 18 to 22 gauge (0.25 mm

Overall cable diameter between 0.12" to 0.35" (3mm to 9mm).

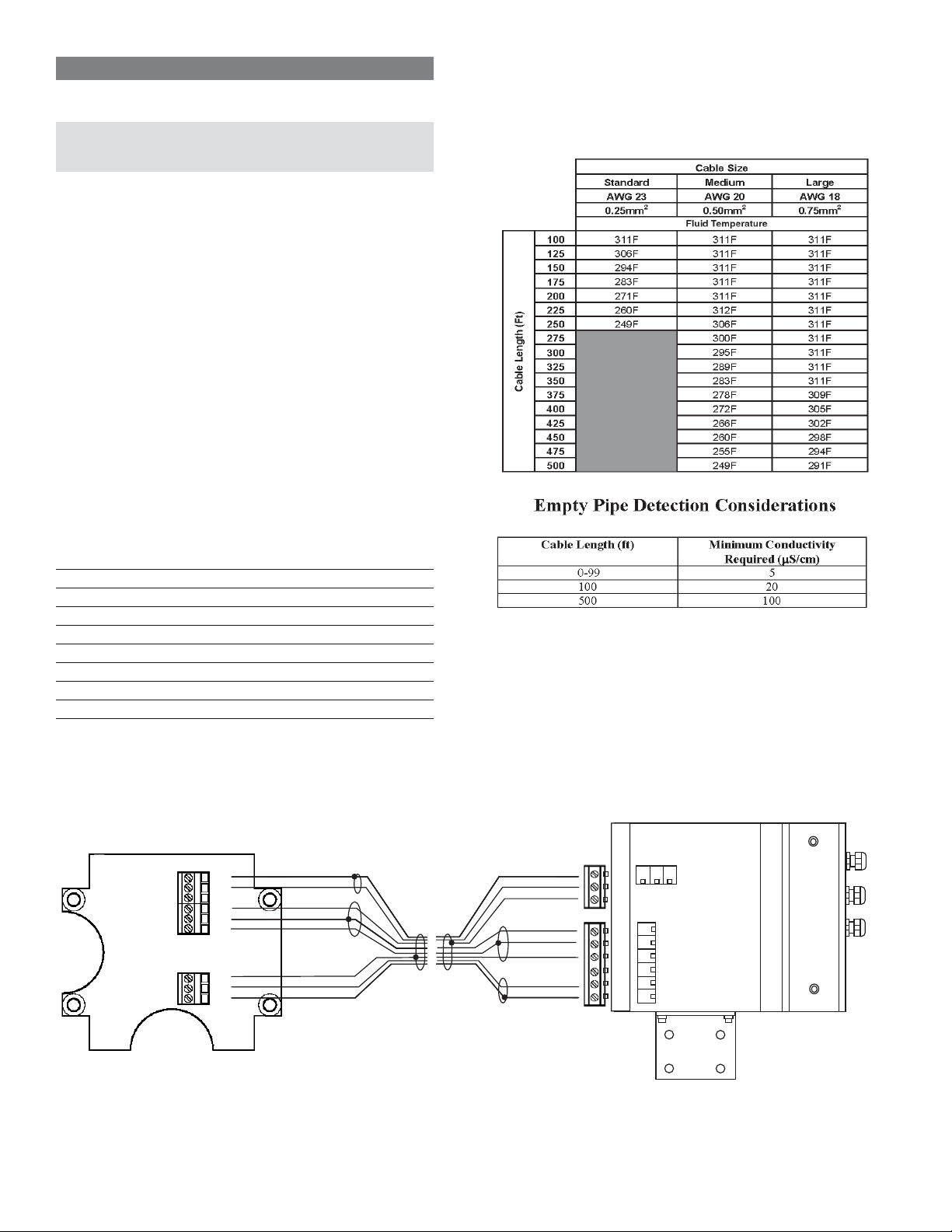

WIRING FOR REMOTE PRIMO® CONFIGURATION

Wiring between the detector and the Primo amplifier comes complete

from the factory. If your installation requires the use of conduit, the

following are recommended steps for wiring of the detector to the

amplifier.

1. Remove the junction box lid. Carefully remove the wires connected

to the terminal blocks that run to the Primo amplifier. Note which

wire goes into which terminal. The chart below may be of assistance for reference of wire color and terminal connection.

2. Run cable through conduit from Primo amplifier location, retaining

the wiring of the cable to the amplifier as supplied.

2

to 0.75mm2) shielded wire.

Remote style Primo Amplifier models can be ordered with longer

cable than our standard stock lengths of the standard cable; 15, 30,

50 and 100 feet. The following chart shows the cable style options

and the maximum flow medium temperature that can exist in the

application environment at a given length of that cable.

3. Complete conduit assembly on both ends and rewire cable into

junction box as wired when received. See wiring diagram below.

Connection No. Description Wire color

11 Coil Green

12 Coil Yellow

13 Main Shield Yellow/green

45 Electrode White

44* Electrode Shield Black

46 Electrode Brown

40 Empty Pipe Pink

44* Empty Pipe Shield Black

*Connections with the No. 44 are lying on the same potential

Wiring for Remote Primo Configuration

shield (black)

pink

brown

shield (black)

white

yellow/green

yellow

green

44

40

44

46

44

45

13

12

11

green

yellow

yellow/green

white

shield (black)

brown

pink

shield (black)

13 12 11

45

44

46

44

40

44

6

Page 7

WIRING INPUTS AND OUTPUTS TO THE PRIMO

®

AMPLIFIER

Once the wiring between the sensor and the amplifier is done proceed

to wire any inputs and outputs to the Primo amplifier.

IMPORTANT! For safety reasons leave AC power connections to the unit as the last step. Follow all the safety

precautions and local code to prevent electrical shock and/

or damaging of the electronic components.

1. Loosen the two bolts on the red amplifier cover. Remove the cover.

Inside the amplifier you will see a terminal strip similar to the one

depicted in the figure to the right.

POWER

To prevent accidents, power connection should be made only

after all other connections have been completed.

The PRIMO amplifier is a microprocessor based device. It is

important that the power supply be as "clean" as possible.

Avoid using power lines that feed heavy loads such as pumps,

motors, etc. If dedicated lines are not available, a filtering or isolation

system might be required.

It is recommended that the internal fuse protection be maintained.

Use a 2 amp slow blow fuse.

Board Accessible with Red Cover Removed

Line

How to connect the amplifier to remote digital indicators/

totalizers that do not require external power supply

This connection is intended for use with indicators that do not require

an external power supply such as the ER series indicators from

Badger Meter. For the ER-6, ER-8 or ER-9, connect terminal 15 of

the Amplifier to terminal 2 of the ER series and terminal 16 to ground

or terminal 1 of the ER indicator.

For connection to the PC 100 Controller, connect terminal 15 of the

amplifier to terminal 14 of the PC 100 and terminal 16 of the amplifier

to terminal 12 of the PC 100.

Pulse Output Passive (+)

Pulse Output Active

(+24vdc)

Flow Direction Common

Error Out

(Open if error occurs)

Flow Alarm (Open between

min. and max. values)

Frequency Output

Emitter (-)

Active Analog Output (+)

Analog Common (-)

15

13

11

9

7

5

3

1

16

14

12

10

8

6

4

2

Pulse Output Common (-)

Reset (-)

Reset (+) (open to reset)

Forward Flow Direction

Reverse Flow Direction

Error Out Common

Flow Alarm Common

Frequency Output

Collector (+)

RS 232 TxD

RS 232 RxD

RS 232 Ground

7

Page 8

PROGRAMMING (3.1 Electronics)

The Primo® amplifier comes preprogrammed from the factory and in

most instances will not require any additional manipulation. However,

if you will be using the flow signal outputs or need to reprogram the

meter to suit your particular needs, it will be necessary to familiarize

yourself with the programming procedures.

Programming of the Primo amplifier is very simple

This section gives step by step instruction on how to program each

of the functions of the amplifier and an explanation of the choices that

are available for each one.

First, using a small flat screwdriver, remove the red cover from the

main amplifier housing. At the lower right corner of the unit you will

see three square buttons. These buttons are used to perform all

programming procedures.

Programming Keys

NOTE: The programming buttons have been placed inside

the amplifier enclosure to prevent tampering or accidental

reprogramming of the unit. After programming, be sure to

reassemble the red cover on the enclosure.

The four line 16 digit LCD display of the Primo amplifier will guide you

through each of the programming options/steps. The main screen will

display:

1st Line: Flow Rate

2nd Line: Totalizer (TOT+ or TOT1)

3rd Line: Totalizer (TOT- or TOT2)

4th Line: Displays revision of software to assist

in troubleshooting. This line is also

used to display any error messages

that may occur during operation of the meter.

The main display screen will be in one of the following modes. (See

Flow Direction on page 11 for additional detail.)

the programming parameters, the program returns automatically to

the main screen. Even during the parameter setting mode, the meter

will be measuring and totalizing any flow that occurs.

There are three main submenus: factors, outputs/totals and measurement. Each submenu gives access to the following appropriate

functions:

Factors:

1) Detector factor

2) Pipe diameter

3) Password protection

Outputs/Totals:

1) Reset totals

2) Analog outputs

3) Pulse outputs

4) Frequency

5) Flow alarm

Measurement:

1) Unit

2) Full scale

3) Low flow cutoff

4) Empty pipe detection

5) Flow direction

6) Filter

7) Error list

PROGRAMMING OF MEASUREMENT

PARAMETERS

When the programming submenu screen appears, notice the right

arrow on the far left side. Using the up arrow key, you can position

the arrow in front of the submenu that you wish to interrogate. We

recommend starting with the "measurement" submenu followed by

the "outputs/totals" submenu and finally the "factors" submenu.

Uni-Directional Mode

Bi-Directional Mode

By pressing the Enter or E key (bottom key), you will be at the main

submenu screen. If no entry is done within 5 minutes while in any of

Use the key to position the > arrow next to "measurement" and

press the key. The following screen will appear:

UNIT OF MEASURE

This is where you will select the unit of measurement for the flow rate

indication and the totalizers. Use the key to place the arrow next

8

Page 9

to "change" and press key. The first unit of measurement screen

will appear:

applications requirements, making sure that it falls within the suggested flow range of the meter.

Using the or keys,select the desired unit of measure for flow rate

indication.

Choices are:

L/h Liters/hour

L/m Liters/minute

l/s Liters/second

m³/h Cubic meters/hour

m³/m Cubic meters/minute

m³/s Cubic meters/second

GPM US gallons/minute

MGD US million gallons/day

LbM US liquid pounds/minute

oz US fluid ounces/minute

IGM Imperial gallons/minute

The existing totalizer values are automatically converted into the

selected unit of measure.

After selecting unit of measure for flow rate, press Enter. You will see

the following screen for selecting unit of measure for the totalizer.

When done, press enter and then the key and the next parameter

will appear.

This is the same full scale parameter as previously visited. It is

positioned here to provide ability to change full scale setting if no unit

of measure change is necessary.

The full scale can be chosen in a range of 0.4 up to 39.4 ft/sec. A flow

value is assigned to the analog output as well as the frequency output

by the full scale scaling. The scaling is valid for both flow directions.

NOTE: If the flow rate is exceeding the full scale setting by more

than 5%, an error is indicated that the selected full scale range

is exceeded. (Terminals 7 and 8)

Once this is done, press E and then the key and the next parameter

will appear:

LOW FLOW CUTOFF

This is the low flow cutoff function. It is used to assign a low flow rate

at which measurement will stop, preventing measurement and thus

totalization errors. This parameter can be programmed from 0 % up

to 10% of selected full scale flow rate.

Choices are as follow; any existing values on the totalizers will

automatically be converted into the new selected unit of measure

L Liter

m³ Cubic meter

G US gallons

MG US million gallons

Lb US liquid pounds

oz US fluid ounces

IG Imperial gallons

aft Acre feet

ft³ Cubic feet

After the totalizer unit of measure selection, press the E key the

following screen will appear:

FULL SCALE (MAXIMUM FLOW)

If you changed the unit of measure, the full scale or maximum flow

may also need to be changed to reflect the maximum flow rate with

the new unit of measure. This is a very important parameter as it

relates to other parameters including frequency output, lowflow cut-off, alarm outputs and analog signal outputs. Adjust

the desired new full scale setting based on your meter size and your

Place the > arrow next to "change" and then press the key. The

following screen will appear:

The factory setting is 0.2%. Increasing this value will help prevent

false readings during "no flow" conditions due to fluid movement in

the pipe caused by vibrations or piping arrangements.

Using the and keys select a value and then press ENTER.

Press key and you will see the next parameter:

9

Page 10

EMPTY PIPE DETECTION

The empty pipe detection parameter when programmed to be ON will

provide an error relay indication if the meter is partially filled with liquid.

This will also show an empty pipe error message on the display.

Position the > next to "change" and press the key. The following

screen will appear:

NOTE: The empty pipe detection can be calibrated if required

if the fluid conductivity is different than water or the remote

cable length is significantly changed.

When calibration is complete, hit ENTER.

The switching threshold for the empty pipe detection is when the

measuring signal “full pipe” plus hysteresis value is exceeded (i.e.

= 360 mV+ 1000 mV). The maximum value for the switching threshold

is at 4000 mV.

If full pipe calibration value is higher than 3000mV, please contact

customer service for assistance.

Hit key for next parameter screen:

FLOW DIRECTION

The flow direction can be programmed to uni- or bi-directional modes.

Use the and keys to turn the feature ON or OFF as desired.

If off is selected, hit ENTER and then the key to go to the next

parameter. If ON is selected, hit ENTER and the following screen

will appear:

To proceed with calibration, leave "YES" selected and hit ENTER

for the next screen.

The pipe has to be filled with the media that will be measured by the

meter. A value between 0 and 5000 mV will be measured and

displayed. The value increases with decreasing conductivity,

increasing cable length or size. For normal water, the value should

be between 10mV and 500mV. Afterwards the signal difference

between full and empty pipe is determined by the hysteresis value.

Place the > next to "change" and press the key. One of the

following (2) screens will appear:

Uni-directional totalizes the flow only in one direction (flow direction

on the detector label). If the fluid is flowing in the opposite direction,

the counter will indicate zero on the display and no outputs. Both

totalizers can be used as resettable counters in this mode. The

totalizers are indicated as "TOT1" and "TOT2".

The bi-directional setting measures the flow in both directions. The

first totalizer (TOT+) is measuring in the forward flow direction and

the second totalizer (TOT-), the reverse direction. A change of flow

direction is indicated via the flow direction relay.

Make sure your pipe is full of fluid and when ready, hit ENTER. This

new screen is the hysteresis value entered. This value is set at the

factory at 1000 mV to allow some variation in empty pipe detection

to eliminate the potential for false "empty pipe signals." It is not

necessary for this value to be changed.

10

Page 11

Relay Wiring Terminals

Using the and key select which flow direction mode you want

and press ENTER. Hit the key to go to the next parameter.

FILTER DAMPENING

This feature is for dampening of all output signals and flow rate

display. This function has no effect on the totalizers.

The factory setting is 1. If you notice too much back and forth

oscillation of the flow rate indication, increase this value incrementally until the display is more stable. Your choices are 1 though 6 or

"Inactive." To change the filter value, place the arrow next to "change"

and press the key. The following screen will show:

Any error is indicated via the error relay as well as displayed on

line 4 of the LCD display. The relay is normally closed during

normal operation and is opened when an error occurs.

Error Relay

Now hit the key again and you will be at the screen for clearing

all the error list information.

Hit Enter to clear and the following screen will appear with "Done"

indication.

Using the and keys select the desired filter value and then

press ENTER. Hit key to go to last parameter of this submenu.

ERROR LIST (MESSAGES)

The error list in the program menu indicates the last 8 error types

that have occurred and the frequency of each. The sum of all

switching on processes can be read on the "Power Up Counter." This can assist in checking possible power failures.

Line up the > with "change" and hit the key. This will bring up

the 1st error. Continue hitting the key to toggle through the last

8 errors that occured, with #1 being the most recent error and the

power-up indication screens.

An overview of the possible errors and causes can be found in

the Troubleshooting section.

Now hit enter twice and you will be back at the submenu screen.

PROGRAMMING OF OUTPUTS/TOTALS

PARAMETERS

The next submenu is outputs/totals.

From the main submenu screen, position the > next to the "outputs/

totals" submenu and press the key.

The following screen will appear:

RESETTING OF TOTALIZERS

This parameter is used to reset either of the totalizers to zero.

11

Page 12

Line up the > with change and hit key.

Now line up the > next to the totalizer you wish to reset. Hit key and

that totalizer will now indicate "DONE."

If desired to reset the other totalizer, repeat the same steps.

Press or keys until you find the type of analog output that you

desire among the following screens:

The "TOT2" totalizer in the uni-directional flow mode, can be reset

externally.

The following is the wiring connections diagram for external reset.

When finished, hit Enter. Hit key to go to the next parameter.

ANALOG OUTPUTS

This parameter is for selection of the desired analog output and

also calibration if required.

The following are the options available for the analog output ranges.

NOTE: The flow value is limited to 105% of the programmed full

scale value. If this value is exceeded, an overflow error will appear

on the LCD display. In bi-direction operation, the flow direction is

indicated via the flow direction relay. The following diagram illustrates wire connections for the analog ouput signal.

Once you have selected the output, press the ENTER key to select

that particular output. You will then be at the calibration screen. You

should calibrate the analog output after you have it connected to your

PLC or chart recorder.

4 to 20 mA

0 to 20 mA

2 to 10 mA

0 to 10 mA

Press the key at the "change" line the following screen will appear:

12

Page 13

If calibration is in fact desired, hit ENTER again to get to the following

screen:

This is an important reminder to make sure that if the meter

is part of a closed loop system, you must put the system in

manual operation while performing the calibration process.

Hit the key to continue and this screen will apprear:

Hooking up an amp meter in series with the connected chart recorder

(Terminals 1 and 3), you may use the and keys to calibrate the

4mA signal for "0" flow. Hit ENTER to continue.

Use the and keys to change the value to the desired pulse rate.

This value may be set from .001 to 10,000 pulses/unit of measure.

Maximum frequency of 10kHz can not be exceeded. Based on

maximum flow rate setting, the program will not permit a value that

exceeds this frequency.

Press ENTER when you have programmed the desired number.

This parameter is pulse width, or the time duration that each pulse

will be "ON". The 50% setting means 50% on 50% off. You can set

the width in increments of 5 ms from 5-500 ms. The factory setting

is 20 ms. Program this parameter to match the required pulse width

of the remote accessory that will receive the pulse output. For output

to any AMR device, see steps below.

Now the 20 mA signal may be calibrated for 100% flow based on

maximum flow rate set in programming.

NOTE: When you use a different analog output setting than 420mA, (i.e. 0-20mA) that the output calibration will still be

performed with 4-20mA and applied to the selected setting (i.e.

0-20mA).

Hit ENTER to complete calibration and the key for next parameter.

PULSE OUTPUTS

The pulse output parameter will determine how many pulses per

gallon, liter, etc. will be sent out to remote counters, controllers, etc.

It will also set how many decimal digits will be displayed on the

totalizers. If, for example, you choose 100 pulses per gallon, then the

display totalizers will have two digits after the decimal point.

Move the > arrow next to "change", then press the key and the

following screen will appear:

Hit enter and the next screen is:

This parameter permits changing of the factory setting of "Normally

Open" for the pulse output to "Normally Closed." After complete, hit

enter and the key for the next parameter.

WIRING OF AMR UNIT TO MAG METER

AMR Wiring Diagram

Pulse Output

Passive

Pulse Output

Common

Primo Terminal

15

Primo Terminal

16

Step 1: Check to make sure your pulse output settings are correct

per chart.

Maximum Flow Rate Pulse Output Setting

Less than 5500 gpm 1 pulse per 100 or 1000 gallons

Greater than 5500 gpm 1 pulse per 1000 gallons

Less than 5500 Cu. Ft./min. 1 pulse per 100 or 1000 Cu. Ft.

Greater than 5500 Cu. Ft./min. 1 pulse per 1000 Cu. Ft.

Step 2: Set pulse width to "50 ms (AMR)"

Step 3: Set pulse type to "normally open"

Red (+)

Black (-)

AMR

Device

13

Page 14

The following diagram is for other wiring connections for pulse

outputs.

FREQUENCY OUTPUT

This is the Frequency Output parameter. The setting can range from

500 Hz up to 5000 Hz for the Full Scale Value. (Example: If 1600 Hz

is selected, then when meter display indicates full scale value, this

output is equal to 1600 Hz).

Use the and keys to select the minimum flow percentage and

press ENTER; the following screen will appear:

Use the and arrows to change the maximum flow percentage

and press ENTER.

NOTE: On the signal output, the relays will remain energized until the flow rate returns to within the flow limits.

Flow Alarm Relay

If a change is desired, line up > cursor with change and hit key.

When complete, hit Enter.

Hit key for next parameter.

FLOW ALARMS

This parameter allows the setting of a minimum and maximum

percentage (%) of the Full Scale flow rate value. Settings can be made

in 1% increments from 0 to 100%. The minimum value must be smaller

than the maximum value.

Press ENTER again to return to submenu screen.

PROGRAMMING OF FACTORS

PARAMETERS

The third and last submenu "Factors" contains parameters that

usually do not require changes.

Press ENTER until you reach the submenu screen if not already there.

Position the > next to the "factors" submenu and press the key.

The following screen will appear:

DETECTOR FACTOR (FIELD CALIBRATION)

This is the Detector factor setting. When the meter was calibrated,

this value was programmed in this parameter as a result of that

calibration. Each detector has its individual factor. This detector

factor is also included on the label of the meter body.

Move the > next to "change" and press the key. The following

screen will appear:

Line up the > with "change" and hit key. This is the detector factor setting.

14

Page 15

With this parameter, you can fine tune your calibration to meet your

applications needs. If you find that the meter is off by a certain percentage,

you can modify the detector factor to achieve the desired accuracy.

Even though all meters are calibrated at the factory, sometimes your

specific installation and fluid parameters make it necessary to

recalibrate a meter under actual operating conditions with the liquid

being metered.

The following instructions are provided to assist in performing an onsite calibration check and adjustment. This procedure may require

either a test tank or vessel of known capacity or a second flow meter

installed in the same line.

ACCURACY TEST

1. Place a test tank of calibrated volume at the output of the meter.

2. Operate meter until test tank is filled to the appropriate calibrated

level. Since meter accuracy can vary somewhat with flow rate,

we recommend making test run at the same flow rate used in

actual operation.

3. Record quantity indicated on display totalizer.

4. Repeat run three times and calculate an average for the (4) tests.

5. Perform the following calculation to determine the percent of

accuracy of the meter.

When complete, press Enter.

Hit key to go to the next parameter.

PASSWORD PROTECTION

This is the password protection parameter. The unit will be set at "0"

(no password required) from the factory. If activated, whenever you

want to go into any of the submenus, the unit will ask for the password number.

To activate the password, line up the > with "change" and hit key.

Qty. Delivered in vessel Old Detector New Detector

Average Meter Reading

Example 1.

In this example, the meter accuracy is low and must be increased

by a calibration correction.

Example 2.

In this example, the meter accuracy is high by 4% and must be

reduced by a calibration correction.

When finished with detector factor parameter, hit ENTER and then

hit key to go to the next parameter.

100 Gallons x

95 Gallons

100 Gallons

104 Gallons

x

Factor

68.85 = 72.47

x 68.85 = 66.20

=

Factor

METER/PIPE SIZE

Change "0" to any desired number from 1 to 999. Hit enter and after

returning to the main screen, you will always have to enter the new

password to get into the submenus. If the password is lost or forgotten, a factory "333" password value can also be used to satisfy the

password entry. If later no password is desired, change the value

back to "0", hit Enter and a password will no longer be required to

enter any of the submenus.

Hit ENTER twice and you will be back at the main screen.

LANGUAGE SELECTION

The software permits the selection of English or Spanish languages.

To change the language, switch off power to Primo Amplifier. While

holding the ENTER key down, re-power the unit. Hit ENTER to get

to the following screen:

Place the arrow next to "change" and press the key. The

following screen will show:

This parameter will come preprogrammed from the factory matching the line size of the detector. However, if you replace the entire

amplifier in the field, you may need to reprogram this parameter.

Select the pipe diameter of your flow meter by using the and

keys to match your meter size.

Select desired language and hit ENTER several times until main

menu screen appears.

15

Page 16

TROUBLESHOOTING

The Magnetoflow® mag meter should give you many years of maintenance free operation. However, should it malfunction, there are certain things

that we recommend you check before contacting our technical support department or your local Badger® Representative.

Note: If the fluid measured has a high concentration of conductive solids, deposits may accumulate on the internal liner walls and electrodes. These

deposits will cause a reduction of the measuring output. Thus, it is recommended to remove the meter and inspect the liner and electrodes after

6 months. If deposits are found, remove them with a soft brush. Repeat inspection process every 6 months or until an appropriate inspection cycle,

(likely longer) can be established for the specific application. Some general conditions as follows:

DESCRIPTION POSSIBLE CAUSE RECOMMENDED ACTION

Flow is present but display is "0" Signal cable not connected. Check signal cable.

Detector mounted opposite of the main Turn detector by 180° or switch terminal 45 and 46 or

flow direction (see arrow on the nameplate). reprogram to biodirectional mode.

Coil or electrode cables exchanged. Check cable connections for cross wiring.

Inaccurate measuring Parameter wrong. Check the parameters (transmitter, detector factor and

Pipe not fully filled. Check if meter is fully filled.

No display No power. Apply power.

Incorrect power. Check power value.

Wiring connections. Check power input/output connections.

Fuse blown. Replace fuse. (2 Amp slow blow 5 x 20 mm)

Flow rate value known to be wrong Maximum flow rate setting. Change setting.

Detector Factor. Check value on label.

Deposits on electrodes and/or liner. Check and remove deposits.

Incorrect pipe size programmed. Check size if necessary.

Flow rate indication unstable Filter value too low. Increase filter value setting.

Cable issue. Make sure cable is shielded and not vibrating.

Grounding issue. Make sure meter is properly grounded to a good

Partially full pipe. Make sure pipe is full of fluid.

size) according to attached data sheet.

earth ground.

Air. Make sure fluid does not contain air bubbles.

Amplifier location - outside electrical Make sure amplifier is not too close to sources of

interference. electrical interference.

Chemical injections. Check location of injection in relation to location of

meter.

16

Page 17

ERROR MESSAGE EXPLANATION

Some general conditions to keep in mind: When certain connections are sensed by the electronics, the following error messages can be indicated

on the display (line 4) as well as on relay 3. The relay is closed during normal operation and is opened by an error appearing.

The following error messages can appear:

ERROR MESSAGE POSSIBLE CAUSE RECOMMENDED ACTION

Err: Detector No detector connection with amplifier. Check detector and cable connections in accordance with

Connection between amplifier and detector Contact Technical Support.

interrupted.

Supply voltage too low. Contact Technical Support.

Grounded coils in meter. Contact Technical Support.

Water in detector. Contact Technical Support.

Err: Output Micro processor output control defective. Contact Technical Support.

Err: unknown Program error. Contact Technical Support.

Err: empty pipe Pipe may not be full. Make sure all trapped air is out of system.

Err: full scale Actual flow rate is exceeding the programmed Reduce flow rate or increase the programmed full scale

full scale value by more than 5%. value.

Err: AD-Range AD-Converter is exceeding signal limits. Check the grounding scheme of the meter installation.

Err: AD-Init Initialization of AD-Converter unsuccessful. Contact Technical Support.

Instruction Manual.

If fluid or fluid conductivity recalibrate the parameter.

See grounding section in manual.

If additional assistance is required, please contact our TECHNICAL SUPPORT department at 1-800-456-5023 or contact your local Badger

Representative.

®

17

Page 18

COMPLETE BOARD ASSEMBLY REPLACEMENT

Make sure power to Primo® amplifier is

off before proceeding.

1. Pull the electrode, coil and display wiring

plugs. Loosen the screws S1 to S5 and

remove the existing board assembly.

2. Put in new board assembly and reassemble

screws to S1 and S5. Reinstall the (3) wiring

plugs.

3. Program the new board assembly with the

previous detector factor and meter size.

FUSE REPLACEMENT

Make sure power to Primo amplifier is off before proceeding.

Fuse type: 250 V, 2 A (time-lag)

18

Page 19

(This page intentionally left blank.)

19

Page 20

Please see our website at

www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

Due to continuous research, product improvements and enhancements,

Badger Meter reserves the right to change product or system specifications

without notice, except to the extent an outstanding bid obligation exists.

BadgerMeter,Inc.

P.O. Box 245036, Milwaukee, WI 53224-9536

Telephone: (414) 355-0400 / (800) 456-5023

Fax: (414) 355-7499 / (866) 613-9305

®

www.badgermeter.com

Loading...

Loading...