Page 1

HR | E LCD Encoder

IMPORTARI

For proper handling of the higher reading resolution and the extended status indicator

capabilities of the HR-E LCD encoder, the following software versions are required for your

reading system:

Reading Data Management Software

• ReadCenter Data: Version 1.11.12.27 or higher (does not include extended status

indicator capabilities

• ReadCenter Analytics and ReadCenter Analytics Mobile: Version 2.12.7.6 or later

Mobile Reading Systems

• ORS: Version 2.2.1 or later

Handheld Reading Systems

• Badger Field Application Suite: Version 2.2.3 or later

• ORION Field Application route reading software: Version 2.2.3 or later

• ORION Endpoint Utility programming & quick read software: Version 2.2.2 or later

Please contact Badger Meter Technical Support at 1-800-456-5023 or the appropriate endpoint

provider if you need assistance.

LCD-IOM-01-EN (December 2012)

62014-159 Rev. 1

Installation and

Programming Manual

Page 2

HR | E LCD Encoder

Page ii December 2012

Page 3

Installation and Programming Manual

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

License Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Audience and Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

LCD Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Visual Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Units of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

9-Digit Totalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6-Digit Totalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Rate of Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Meter Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Visual Measurement Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INSTALLING THE HRE LCD ENCODER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bayonet Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wire Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

308 In-Line Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

HRE LCD ENCODER PROGRAMMING SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Launching the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CONNECTING THE HRE LCD ENCODER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page iii December 2012

Page 4

HR | E LCD Encoder

PROGRAMMING THE HRE LCD ENCODER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Select the COM Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Perform a Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Read Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Change Current Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Apply Current Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

HRE LCD PROGRAMMER PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Serial # Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Meter Type Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Meter Model/Size Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unit of Measure Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Billing Units Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Reading Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rate of Flow Units Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rate of Flow Time Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

View Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Clear Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

UPDATING THE FIRMWARE VERSION OF ADE TYPE ME/SE ENDPOINTS . . . . . . . . . . . . . . . . . . . . 23

Page iv December 2012

Page 5

Installation and Programming Manual

INTRODUCTION

Product Unpacking and Inspection

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

License Requirements

This device complies with Part 15 of the FCC Rules. Operation of this device is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including interference

that may cause undesired operation. Any changes made by the user not approved by Badger Meter can void the user’s

authority to operate the equipment.

Audience and Purpose

This manual is intended to be used by utilities for installing and programming the HR-E LCD Encoder.

PRODUCT OVERVIEW

Description

The HR-E LCD Encoder is a fully electronic, solid-state encoder with no moving parts.

Compatibility

The HR-E LCD Encoder is designed for use with all current Badger Meter Recordall® Disc, Turbo Series, Compound Series,

Combo Series and Fire Service meters and assemblies. The HR-E LCD Encoder provides connectivity with Badger Meter ORION®

and GALAXY® AMR/AMI endpoints and other AMR/AMI technology solutions approved by Badger Meter.

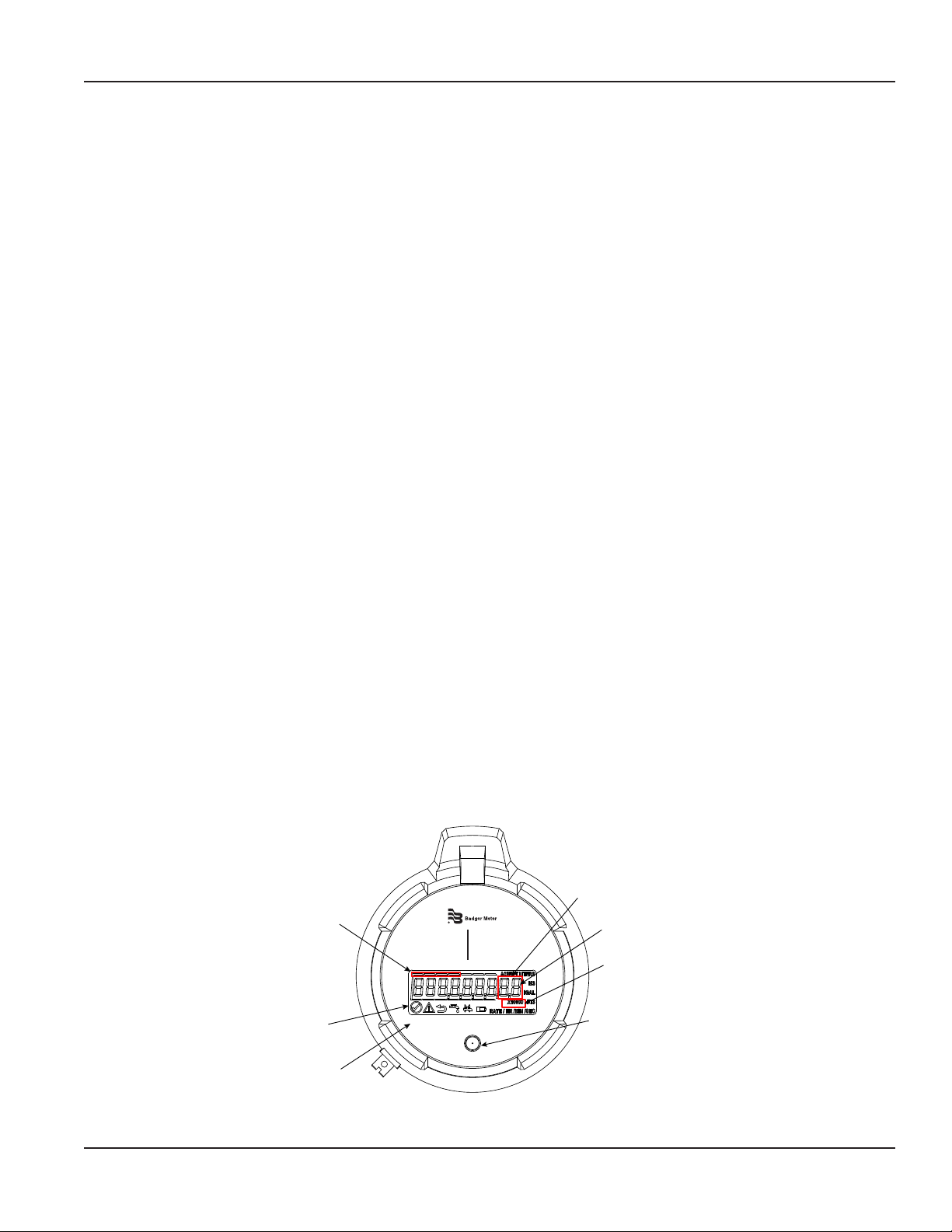

LCD Display

The HR-E LCD Encoder has a nine-digit Liquid Crystal Display (LCD) to show consumption, flow and alarm information.

There is no need to activate the display. The display automatically toggles between 9-digit and 6-digit consumption

(segmented leak detector in this mode), rate of flow and meter model.

Extended Visual

Reading Resolution

Typical Billing

Segments

HR

E LCD

In 6-digit mode, the

last digit is a dashed

line that becomes a

ow nder

Multiplier Value

(x10, x100, x1000, x10,000)

Status

Indicators

4-Digit

Date Code

1212

Figure 1: HR-E LCD Encoder Face

IR Programming

Port

Page 5 December 2012

Page 6

HR | E LCD Encoder

Visual Display

Units of Measure

The units of measure are factory-programmed and user-programmable. Options include U.S. gallons, Imperial gallons, cubic

feet, cubic meters, and liters.

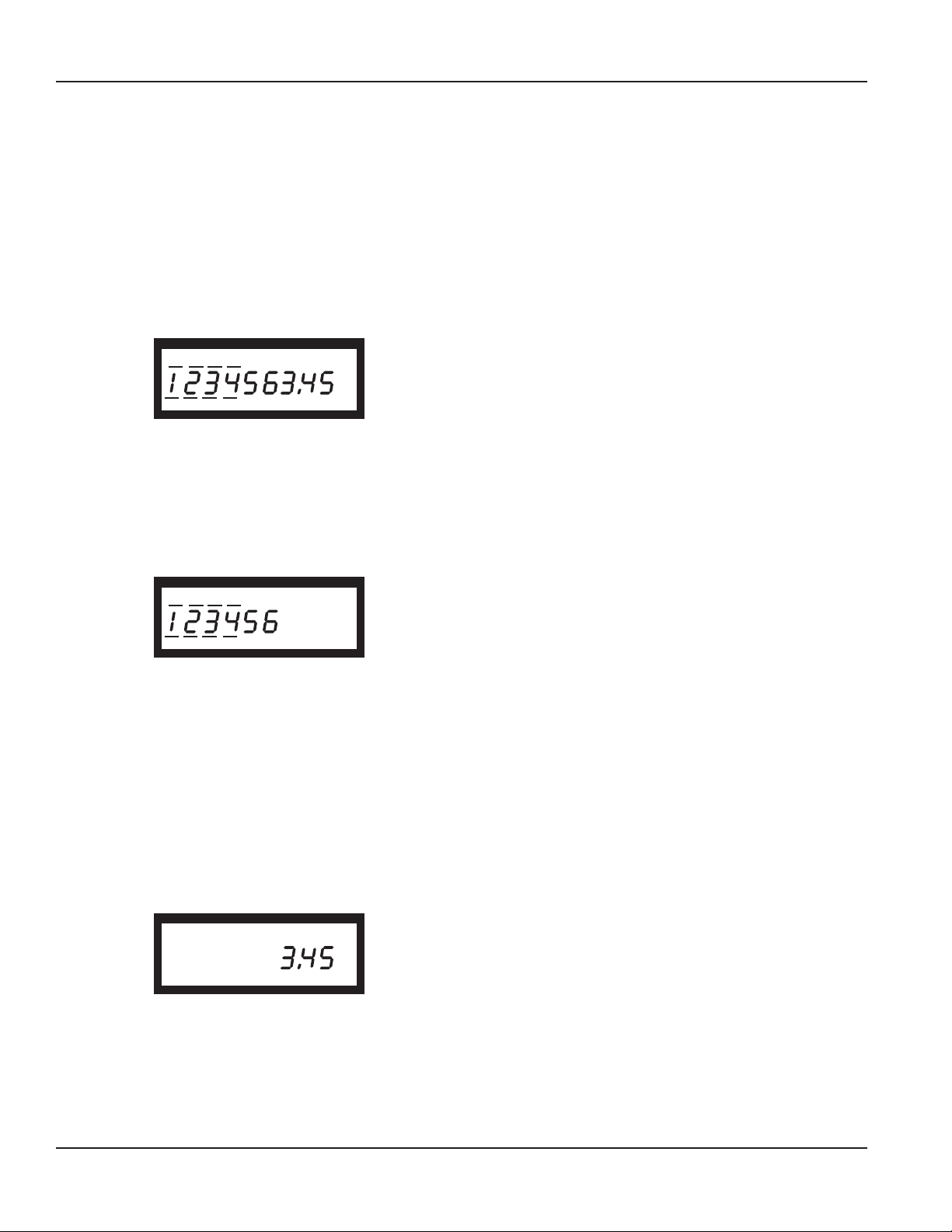

9-Digit Totalization

The consumption display includes all nine digits and a decimal point (based on meter model, size and unit of measure). The

displayed value is the sum of the forward flow minus any reverse flow. This screen displays for 30 seconds.

Model 25 Disc Series Meter Calibrated in Gallons

4

GAL

6-Digit Totalization

This mode is used to represent the typical 6 wheel odometer registration as seen on a mechanical encoder. In 6-digit totalizer

mode, depending on the meter model, size and unit of measure, one of the multiplier values will also be shown (X1, X10,

X100, X1000, X10,000). When water is flowing through the meter, this display will include a series of moving segments to

represent a flow finder. This screen displays for 20 seconds.

Model 25 Disc Series Meter Calibrated in Gallons

4

GAL

X10

In 9 and 6 digit totalizer mode, the display also includes indicator lines above and below the digits to provide the electronic

equivalent of the white and black number wheels seen on a mechanical encoder. The segmented lines above and below the

numbers represent what the white number wheels do for the mechanical encoders—typical utility standard billing units.

For more detailed information on the visual totalizer displays, see “How to Read and Encoder” document LCD-A-01.

Rate of Flow

The rate of flow is factory programmed for gallons per minute. The encoder displays both the unit of measure and rate of flow.

The rate of flow display is shown without leading zeros. A reverse flow is indicated by a minus sign before the flow rate. The

displayed rate will be based on the average flow rate for the prior minute (since the last time the flow rate was displayed). This

screen displays for 5 seconds.

Model 25 Disc Series Meter Calibrated in Gallons

4

RATE /MIN

Page 6 December 2012

GAL

Page 7

Installation and Programming Manual

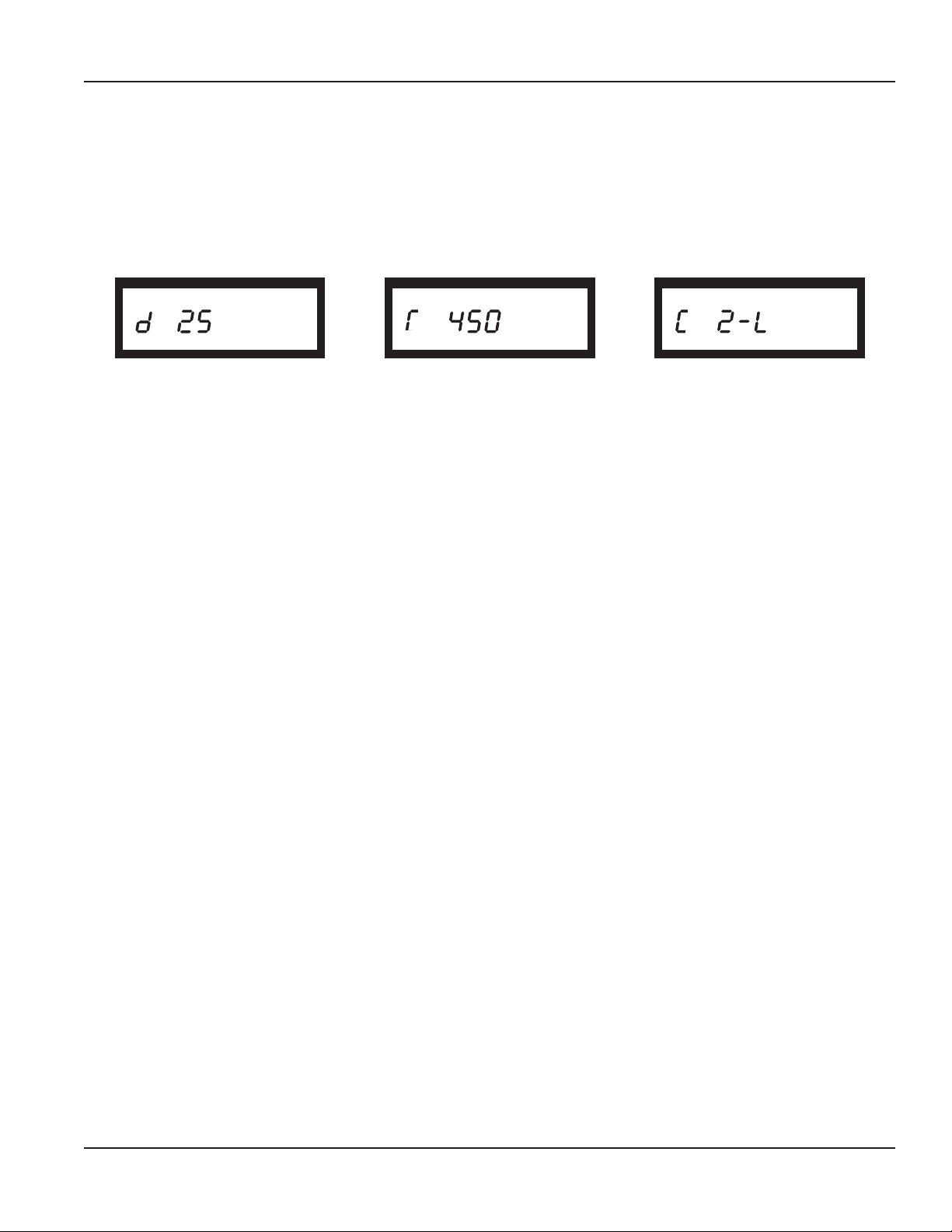

Meter Model Information

This screen identifies the meter for which the encoder was programmed and displays for 5 seconds. The display shows

the meter type (turbo, disc, compound), the meter model, and the unit of measure (gal, ft3, m3, imp, liter). Disc meters are

indicated by a d, Turbo meters are indicated by a stylized T (only the right half of the horizontal line appears) and Compound

meters are indicated by a C. See samples below:

Model 25 Disc Series Meter

Calibrated in Gallons

GAL GAL

Model 450 Turbo Series Meter

Calibrated in Gallons

2" Low Side Compound Series Meter

Calibrated in Cubic Feet

FT3

Page 7 December 2012

Page 8

HR | E LCD Encoder

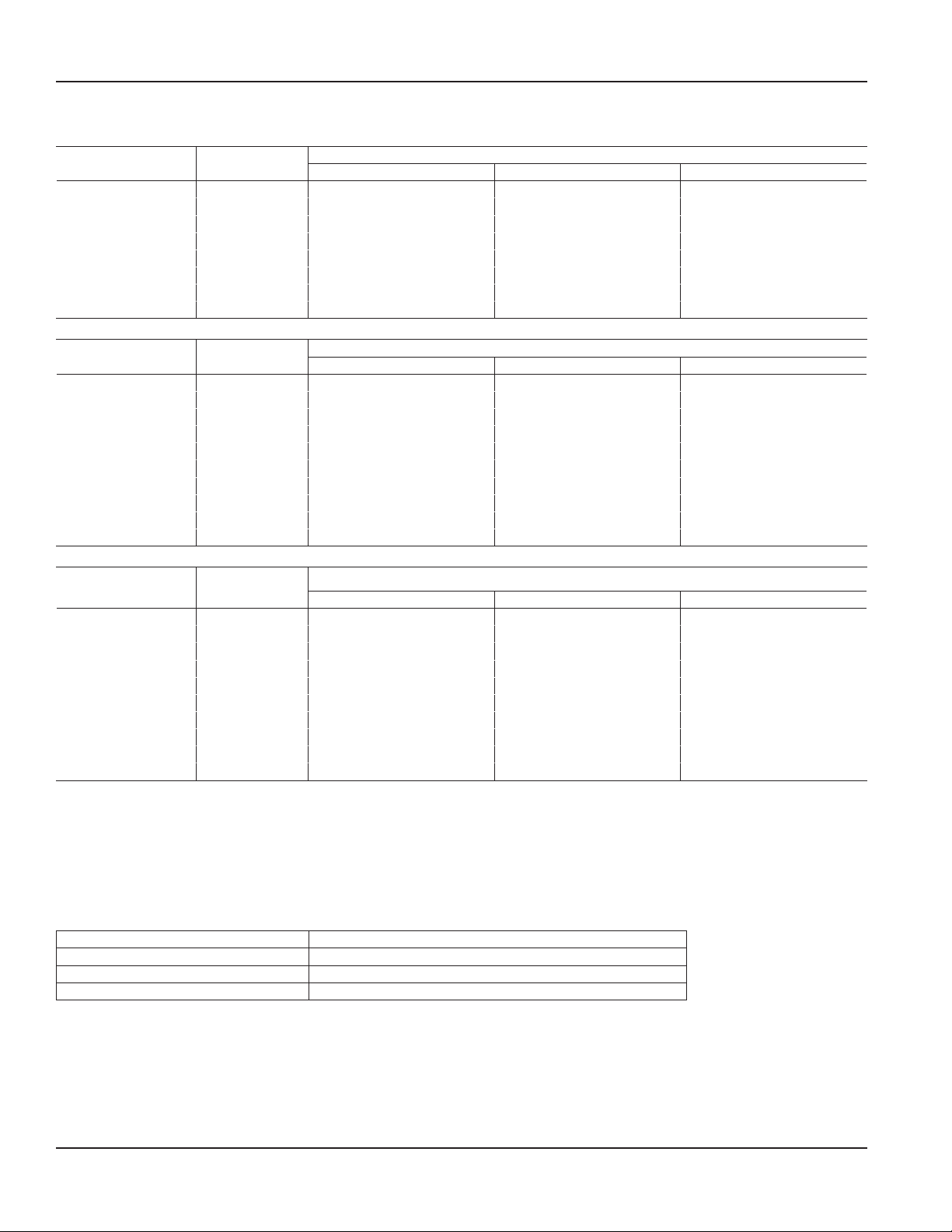

Visual Measurement Resolution

Recordall

Disc Series

LP 5/8", 5/8" x 3/4" 0.01 0.001 0.0001

M25 5/8", 5/8" x 3/4" 0.01 0.001 0.0001

M35 3/4" 0.01 0.001 0.0001

M40 1" 0.01 0.001 0.0001

M55 1" 0.01 0.001 0.0001

M70 1" 0.01 0.001 0.0001

M120 1-1/2" 0.1 0.01 0.001

M170 2" 0.1 0.01 0.001

Recordall

Turbo Series

T160 1-1/2" 0.1 0.01 0.001

T200 2" 0.1 0.01 0.001

T450 3" 0.1 0.01 0.001

T1000 4" 0.1 0.01 0.001

T2000 6" 1 0.1 0.01

T3500 8" 1 0.1 0.01

T5500 10" 1 0.1 0.01

T6200 12" 10 1 0.01

T6600 16" 10 1 0.01

T10000 20" 10 1 0.01

Recordall Compound

Series

High Side T200 2" 0.1 0.01 0.001

Low Side M25 2" 0.01 0.001 0.0001

High Side T450 3" 0.1 0.01 0.001

Low Side M25 3" 0.01 0.001 0.0001

High Side T1000 4" 0.1 0.01 0.001

Low side M35 4" 0.01 0.001 0.0001

High Side T2000 6" 1 0.1 0.01

Low Side M35 6" 0.01 0.001 0.0001

High Side T3500 8" 1 0.1 0.01

Low side M120 8" 0.1 0.01 0.001

Size

Size

Size

Gallons Cubic Feet Cubic Meters

Gallons Cubic Feet Cubic Meters

Gallons Cubic Feet Cubic Meters

9-Digit Encoder Output

9-Digit Encoder Output

9-Digit Encoder Output

MPORTANTI

Endpoint Reading Resolution

The electronic encoder output resolution of the HR-E LCD Encoder is 9 digits. Though the encoder output is 9-digit resolution, the

reading resolution sent to the reading software is dependent on the endpoint that the HR-E LCD is connected to.

Readings reported from the endpoints are the left-most significant digits of the encoder reading.

Endpoint Technology Reading Resolution Reported to Reading Software

ORION ME/SE 8-digit reading, plus the extended message capability

ORION CE 7-digit reading

GALAXY 6-digit reading

See LCD-A-03-EN for appropriate test circle code/reading resolutions for the HR-E LCD encoder with ORION or GALAXY endpoints.

Page 8 December 2012

Page 9

Installation and Programming Manual

Status Indicators

Status indicators are sent as part of the encoder message to AMR/AMI systems that are capable of receiving an extended

message, such as ORION ME and SE endpoints. The details can also be read through an IR interface.

Status indicators appear in the display as symbols that illuminate when the condition is active and dim when the condition

is eliminated.

All HR-E LCD Encoders are delivered in a storage mode so that a meter alarm is not triggered. During storage mode, the meter

model displays on the encoder. As water begins to flow through the meter, the encoder switches from storage mode to

normal operation.

The following chart indicates the HR-E LCD Encoder conditions when connected to a Badger Meter ORION ME/SE endpoint.

The chart does not apply to ORION CE or GALAXY endpoints. The HR-E LCD displays the indicators and sends information, but

the ORION CE and GALAXY endpoints ignore the extra information and do not report it.

Status Indicator Icon Status Description HR-E LCD Display HR-E LCD with ORION ME/

SE *Version 1.8 or higher

firmware required

Meter

functioning

correctly

Encoder alarm Several potential conditions

Reverse flow Encoder detects reverse flow. Reverse flow alarm remains

Suspected leak Encoder detects 24 hours

Encoder operating correctly. Continuous display on

encoder as long as no other

status indicators are triggered.

Encoder alarm remains

may exist, including:

• Encoder removal

• Temperature limit

exceeded (34…140° F)

• Magnetic tamper

without one 15-minute

interval of no flow.

active for 35 days. The alarm

automatically clears after 35

days if any of the 3 conditions

has not recurred.

active for 35 days. The alarm

automatically clears after 35

days if reverse flow condition

has not recurred.

The alarm clears automatically

when a 15-minute no-flow

interval occurs

Indicator Status not sent to

the endpoint.

Encoder alarm sent to ORION

ME/SE endpoint.

Encoder detects reverse flow

and sends alarm message to

ORION ME/SE endpoint.

Encoder detects suspected

leak and sends alarm message

to ORION ME/SE endpoint.

30 day no usage No measured flow in past 30

days.

End of life

battery indicator

Indicated battery life based on

pre-calculated consumption.

The alarm is automatically

cleared once flow occurs.

Alarm activated at 19 years

and does not clear.

If condition clears before

message is sent to the

endpoint, it is not reported.

Encoder detects 30 days no

usage and sends alarm to

ORION ME/SE endpoint.

Encoder sends alarm to ORION

ME/SE endpoint.

Page 9 December 2012

Page 10

HR | E LCD Encoder

INSTALLING THE HRE LCD ENCODER

Bayonet Mount

The fully potted encoder assembly has a bayonet mount compatible with all Recordall Disc, Turbo Series, Compound Series,

Combo Series and Fire Series meters and assemblies. The bayonet mount positions the encoder in any of four orientations for

visual reading convenience. The HR-E LCD Encoder can be removed from the meter without disrupting water service.

The HR-E LCD Encoder is available factory pre-wired to Badger Meter AMR/AMI products. The HR-E LCD Encoder is

permanently sealed to eliminate the intrusion of moisture, dirt, or other contaminants, and is suitable for installation in all

environments, including meter pits subject to continuous submergence.

Install the encoder on the water meter and secure it using the tamper-proof screw provided.

Wire Connections

The HR-E LCD is provided as either a factory-wired assembly or as an encoder with pre-sized wire harness available for

connection in the field. Standardized lead lengths are 3, 10, 25, and 75 feet. See ADE-I-01 for instructions.

308 In-Line Connector

The Badger Meter 308 In-line connector is an optional feature that allows connectivity to a AMR/AMI devices without the

need for a field splice kit. See ORI-I-69 for instructions.

Page 10 December 2012

Page 11

HRE LCD ENCODER PROGRAMMING SOFTWARE

Installing the Program

This section describes how to install the HR-E LCD Encoder programming software.

1. Double-click the setup.exe le to begin installation. The Welcome screen displays.

Installation and Programming Manual

2. Click Next to select the destination folder for the program.

Page 11 December 2012

Page 12

HR | E LCD Encoder

3. Select a folder and click Next. An installation conrmation screen displays.

4. Click Next to conrm the installation. The program begins installing.

5. When the installation is complete, click Close to exit the installation program.

Page 12 December 2012

Page 13

Installation and Programming Manual

Launching the Program

1. Double-click the HR-E LCD Encoder desktop icon.

2. Read the License Agreement. If you agree, click Accept License. If you select Decline License, the program will

not start.

3. Once you accept the license agreement, the Splash screen displays. From this screen, you can view the license

agreement, view trademarks, and sign in. Your sign-in initials are used in the product’s log file to record any changes

you make to the HR-E LCD Encoder. To sign in, enter your initials using between 3 and 5 characters. After you enter

the third character, the Next button becomes active. Any characters after the 5th are ignored. When you have entered

your initials, click Next to display the Programmer screen.

Page 13 December 2012

Page 14

HR | E LCD Encoder

View License Option

The View License button displays a pop-up of the license agreement. The only option is to click Close to return to the

Splash Screen.

View Trademarks Option

The View Trademarks button displays a trademark pop-up specified by the Legal department. The only option is to click

Close to return to the Splash Screen.

Page 14 December 2012

Page 15

Installation and Programming Manual

CONNECTING THE HRE LCD ENCODER

To read and program the encoder using the Infrared Remote (IR) head, you must connect the IR head to a serial port on

your computer:

1. Plug the serial connector of the IR head into the serial port of your computer, or plug the serial connector of the IR

head into the serial-to-USB adapter, then plug the USB adapter into a USB port.

2. Open the lid on the encoder.

3. Mount the IR head bracket onto the encoder, aligning the hole in the holder with the IR port on the encoder.

4. Rest the IR head in the bracket with the nubs on the back of the head seated in the slots of the bracket.

Parts List

The 67660-001 kit includes:

67451-001 IR head bracket

67572-009 HR-E LCD Programming Software (not shown)

These optional parts are also available:

64436-023 IR programming and data profile cable

64436-029 Serial-to-USB Adapter

Page 15 December 2012

Page 16

HR | E LCD Encoder

PROGRAMMING THE HRE LCD ENCODER

From the Programmer screen, you can view and change the parameters that are currently programmed into the HR-E LCD

Encoder, as well as load new parameters into the HR-E LCD Encoder. You can also clear the encoder's reading.

Select the COM Port

The software communicates to the HR-E LCD Encoder via the selected COM Port. From the IR Port drop-down menu, select the

COM port connected to the encoder.

Perform a Read

Click on the Read option.

If the correct COM port is selected and a good response is received, the software delays a short time then populates the

Programmer screen data fields with the information from the encoder.

If the encoder is programmed the way you want, just disconnect it from the IR bracket. If not, see "Change Current Settings"

on page 17.

Page 16 December 2012

Page 17

Installation and Programming Manual

Read Errors

If no COM port is selected, this error message displays. In this case, click OK, select the correct COM port, and try the

Read again.

If the wrong COM port is selected, this error message displays. In this case, click Cancel, select the correct COM port, and try

the Read again.

Change Current Settings

If you need to change the settings for the current encoder, follow this procedure.

To set a default value for any of the data fields:

1. Click the down arrow to the right of the eld to display a drop-down list of values.

2. Click on the value you want to set as the default for that eld.

OTE:N You must set the default value for the Meter Type field before you set the Meter Model / Size field.

The Rate of Flow Units do not have to be the same as the Unit of Measure (even in a cubic foot meter, the

flow rate can be gallons per minute).

Apply Current Settings

When you click Apply Current Settings, the displayed settings are programmed into the encoder and the encoder goes into

storage mode. In storage mode, the encoder displays the meter type and unit of measure. In this example, a Model 25 Disc

Meter measured in gallons:

GAL

The software retains the current settings until you perform another Read.

If you have multiple encoders to program with the same parameters, just attach the IR head bracket to them, one at a time,

and click Apply Current Settings.

Page 17 December 2012

Page 18

HR | E LCD Encoder

HRE LCD PROGRAMMER PARAMETERS

Serial # Field

The Serial number field is a read-only field that displays the HR-E LCD Encoder factory-assigned serial number. You cannot

change this number.

12345

Meter Type Field

The Meter Type field displays the type of meter to which the encoder will connect.

Select the drop-down menu to the right of the data field to select the meter type. Available options are Disc, Compound

(CSM), Turbo (TSM).

Page 18 December 2012

Page 19

Installation and Programming Manual

Meter Model/Size Field

The Meter Model/Size field auto-populates based on the Meter Type selected.

Select the drop-down menu to the right of the data field to select a different meter model. The Meter Sizes corresponding to

the Meter Models in the drop-down menu are described in the table below.

For Recordall Combination Fire Service meters and assemblies, refer to the appropriate Disc and TSM columns of the table.

Disc Model CSM Model TSM Model

5/8", 5/8"x3/4" LP 2" High Side 1-1/2" T160

5/8", 5/8"x3/4" M25 2" Low Side 2" T200

3/4" M35 3" High Side 3" T450

1" M40 3" Low Side 4" T1000

1" M55 4" High Side 6" T2000

1" M70 4" Low Side 8" T3500

1-1/2" M120 6" High Side 10" T5500

2" M170 6" Low Side 12" T6200

16" T6600

20" T10000

Unit of Measure Field

The Unit of Measure field displays the unit selected to measure the flow.

Select the drop-down menu to the right of the data field to select a different unit of measure. The options are gallons, cubic

meter, liter, cubic feet, and Imperial gallons.

Page 19 December 2012

Page 20

HR | E LCD Encoder

Billing Units Field

The Billing Units field displays the default usage units for which the customer is billed. The defaults are based on the Unit of

Measure selected:

Unit of Measure Default Billing Unit

Gallons, liters, imperial gallons 1000

Cubic feet 100

Cubic meters 10

Select the drop-down menu to the right of the data field to select a billing unit.

Reading Field

The Reading field is a read-only field that displays the current meter reading as a real number. The number of decimal places is

determined by the units and meter size.

You cannot change this number.

Page 20 December 2012

Page 21

Installation and Programming Manual

Rate of Flow Units Field

The Rate of Flow Units field displays the unit by which the rate of flow is measured.

The factory-programmed default is Gallons.

Select the drop-down menu to the right of the data field to select a different rate of flow units. The options are gallons, cubic

meter, liter, cubic feet, and Imperial gallons.

Rate of Flow Time Field

The Rate of Flow Time field displays the time unit set for the rate of flow.

The factory-programmed default is Per Minute.

Select the drop-down menu to the right of the data field to select a different rate of flow time. The options are minutes, hours,

or seconds.

Page 21 December 2012

Page 22

HR | E LCD Encoder

View Indicators

The View Indicators button displays the current status of the selected meter.

The status indicators are Encoder Removal, 30 Day No Usage, Suspected Leak, Programmed, End of Battery Life, Reverse Flow,

Magnetic Tamper and Temperature Limit Exceeded. For descriptions of these indicators, see "Status Indicators" on page 9.

1. To clear the indicators, click the Clear Indicators button.

OTE:N The Clear Indicators button does NOT clear the Programmed indicator.

2. Click Close to exit the window.

Clear Reading

Be very careful with the Clear Reading feature! It deletes all readings for the selected meter. If you select this option, a pop-up

messages displays, asking you to enter a password to confirm the deletion.

Contact Badger Meter Technical Support to get the password.

Page 22 December 2012

Page 23

Installation and Programming Manual

TROUBLESHOOTING

Issue Probable Cause Solution

Programmer screen is blank after a

Read.

Error message displayed after clicking

an option on the programmer screen.

Bad connection. Check for damaged or broken wires.

COM Port not specied. Select a COM Port from the IR Port

drop-down menu.

IR head not aligned with encoder. Align the IR head with the IR port on

the encoder.

UPDATING THE FIRMWARE VERSION OF ADE TYPE ME/SE ENDPOINTS

For the HR-E LCD, ME/SE endpoints need to be high resolution version endpoints.

This procedure should be used only for updating the rmware version of in-stock stand-alone encoder type “ADE” ME/

SE endpoints.

Firmware version 1.9 or higher is required in these endpoints to use the HR-E LCD encoder. The Attach Endpoints feature

updates the rmware version of the endpoint.

To update the rmware version of an ADE type ME/SE endpoint:

1. Align and hold the IR head over the antenna at the bottom of the endpoint.

2. Click the Attach Endpoint button.

If the endpoint is properly aligned to the IR head, the programmer queries the endpoint, then updates its rmware version.

If the programmer cannot find the endpoint, it displays this message:

In this case, reposition the IR head so it contacts the antenna on the

endpoint, then click OK.

Page 23 December 2012

Page 24

ADE, GALAXY, ORION, RECORDALL, and RTR are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities.

Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2012 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuffen | Germany | +49-7025-9208-0

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacific | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | Rm 501, N° 11 Longyue Apartment | N° 180 Longjin Rd, Jiuting Songjiang District | Shanghai, China | 201615 | +86-21-5763 5412

Loading...

Loading...