Page 1

Portable Combustion

Analyzer (PCA)

INSTRUCTION 24-9351

Operation & Maintenance

Rev. 11 – May 2004

O 2 4 . 0 C O 1 2 H L D

C 2 9 . 5 C U 1 5 N G

T L 2 0 . 0 T A 1 9 0 P

q A 8 . 1 L A 1 . 2 4 S

M E N U

P C A

Product Leadership • Training • Service • Reliability

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects

in material and manufacture and will conform substantially to Bacharach Inc.’s applicable

specifications. Bacharach’s liability and Buyer’s remedy under this warranty are limited to the

repair or replacement, at Bacharach’s option, of this Product or parts thereof returned to Seller at

the factory of manufacture and shown to Bacharach Inc.’s reasonable satisfaction to have been

defective; provided that written notice of the defect shall have been given by Buyer to Bacharach

Inc. within one (1) year after the date of delivery of this Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach’s

liability and Buyer’s remedy under this warranty of title are limited to the removal of any title

defects or, at the election of Bacharach, to the replacement of this Product or parts thereof that

are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN

LIEU OF (I) ANY AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE: AND (II) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR

REMEDY IN CONTRACT OR TORT, WHETHER OR NOT ARISING FROM BACHARACH’S

NEGLIGENCE, ACTUAL OR IMPLIED. The remedies of the Buyer shall be limited to those

provided herein to the exclusion of any and all other remedies including, without limitation

incidental or consequential damages. No agreement varying or extending the foregoing

warranties, remedies or this limitation will be binding upon Bacharach, Inc. unless in writing,

signed by a duly authorized officer of Bacharach.

Register Your Warranty by Visiting

www.bacharach-inc.com

PCA

Notice:

Product improvements and enhancements are continuous, therefore the specifications and information

contained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Bacharach, Inc.

Copyright © 1999–2004, Bacharach, Inc., all rights reserved.

BACHARACH is a registered trademark of Bacharach, Inc. All other trademarks,

trade names, service marks and logos referenced herein belong to their respective companies.

A

Instruction 24-9351

Page 3

PCA

Contents

Contents

1.0 INTRODUCTION ............................................................................ 1-1

1.1 The Portable Combustion Analyzer........................................... 1-1

1.2 Displayed Data ........................................................................... 1-2

1.3 Sensor Configurations ................................................................ 1-3

2.0 TECHNICAL CHARACTERISTICS ............................................ 2-1

3.0 SETTING UP THE PCA................................................................. 3-1

3.1 Scope........................................................................................... 3-1

3.2 Power.......................................................................................... 3-1

3.2.1 Checking and Replacing the Batteries ........................... 3-1

3.2.2 Using the Optional Power Supply .................................. 3-2

3.3 Connecting the Probe ................................................................ 3-2

3.4 Configuring the PCA ................................................................. 3-4

4.0 OPERATION.................................................................................... 4-1

4.1 Key Pad Functions..................................................................... 4-1

4.2 Sampling Hole Location ............................................................ 4-2

4.3 Combustion Test ........................................................................ 4-3

4.3.1 Analyzer Turn On and Warm Up .................................. 4-3

4.3.2 Installing Probe in the Stack ......................................... 4-4

4.3.3 Performing a Combustion Test ...................................... 4-5

4.3.4 Ending a Combustion Test............................................. 4-5

4.3.5 Turning Off the Analyzer and Purging the CO Sensor.... 4-6

4.4 Differential Pressure Measurement ......................................... 4-7

4.5 Warm-up Screen ........................................................................ 4-8

4.6 Sensor Status Screen................................................................. 4-9

4.7 Combustion Test Screen.......................................................... 4-10

4.8 Fuel Selection Screen .............................................................. 4-11

4.9 Draft Screens ........................................................................... 4-12

4.10 Memory Directory Screen ..................................................... 4-13

4.11 Memory to PC Screen ............................................................ 4-14

4.12 ID Setup Screens ................................................................... 4-17

4.13 Temperature Setup Screen ................................................... 4-19

4.14 Draft Unit Setup Screen ....................................................... 4-20

4.15 Language Setup Screen......................................................... 4-21

4.16 Display Mode Setup Screen .................................................. 4-22

4.17 Time/Date Setup Screen........................................................ 4-23

4.18 Printer Setup Screen ............................................................. 4-24

4.19 Maintenance Password Screen ............................................. 4-25

4.20 Maintenance Screen .............................................................. 4-26

4.21 User Name Screens ............................................................... 4-27

Instruction 24-9351

i

Page 4

Contents

PCA

4.22 Saving Test Data ................................................................... 4-28

4.23 Printing Test Data................................................................. 4-29

4.24 Clear Memory Screen ............................................................ 4-31

4.25 Resetting the Microprocessor................................................ 4-31

5.0 CALIBRATION................................................................................ 5-1

5.1 Sensor Check ............................................................................. 5-1

5.2 Calibration Fixtures .................................................................. 5-2

5.3 Calibrate Menu Screen.............................................................. 5-3

5.4 Calibrate TA-Zero...................................................................... 5-4

5.5 Calibrate TA-Span..................................................................... 5-5

5.6 Calibrate TL-Zero ...................................................................... 5-6

5.7 Calibrate TL-Span ..................................................................... 5-7

5.8 Calibrate NX .............................................................................. 5-8

5.9 Calibrate CO .............................................................................. 5-9

5.10 Calibrate Draft....................................................................... 5-11

6.0 MAINTENANCE.............................................................................. 6-1

6.1 Routine Maintenance ................................................................ 6-1

6.2 Disassembly ............................................................................... 6-2

6.3 Cleaning the Probe .................................................................... 6-4

6.4 Water Trap/Filter Assembly Maintenance............................... 6-5

6.5 Replacing the Particulate Filter ............................................... 6-6

6.6 Replacing the Oxygen Sensor ................................................... 6-7

6.7 Replacing the Nitric Oxide Sensor ........................................... 6-8

6.7.1 Replacing the Nitric Oxide Sensor Filter ...................... 6-8

6.7.2 Replacing the Nitric Oxide Sensor Bias Battery .......... 6-9

6.8 Replacing the Carbon Monoxide Sensor................................. 6-10

6.8.1 Replacing the Carbon Monoxide Sensor Filter ........... 6-11

6.9 Replacing the Pump Assembly ............................................... 6-12

7.0 TROUBLESHOOTING.................................................................... 7-1

7.1 Analyzer Repair ......................................................................... 7-1

7.2 Error Codes ................................................................................ 7-2

7.3 Troubleshooting Guide .............................................................. 7-3

8.0 PARTS & SERVICE........................................................................ 8-1

8.1 Replacement Parts..................................................................... 8-1

8.2 Accessories ................................................................................. 8-2

8.3 Sales/Service Centers ................................................................ 8-6

APPENDIX A – Display Screen Translations...................................A-1

APPENDIX B – Printout Translations ..............................................B-1

ii

Instruction 24-9351

Page 5

PCA

Introduction

1.0 INTRODUCTION

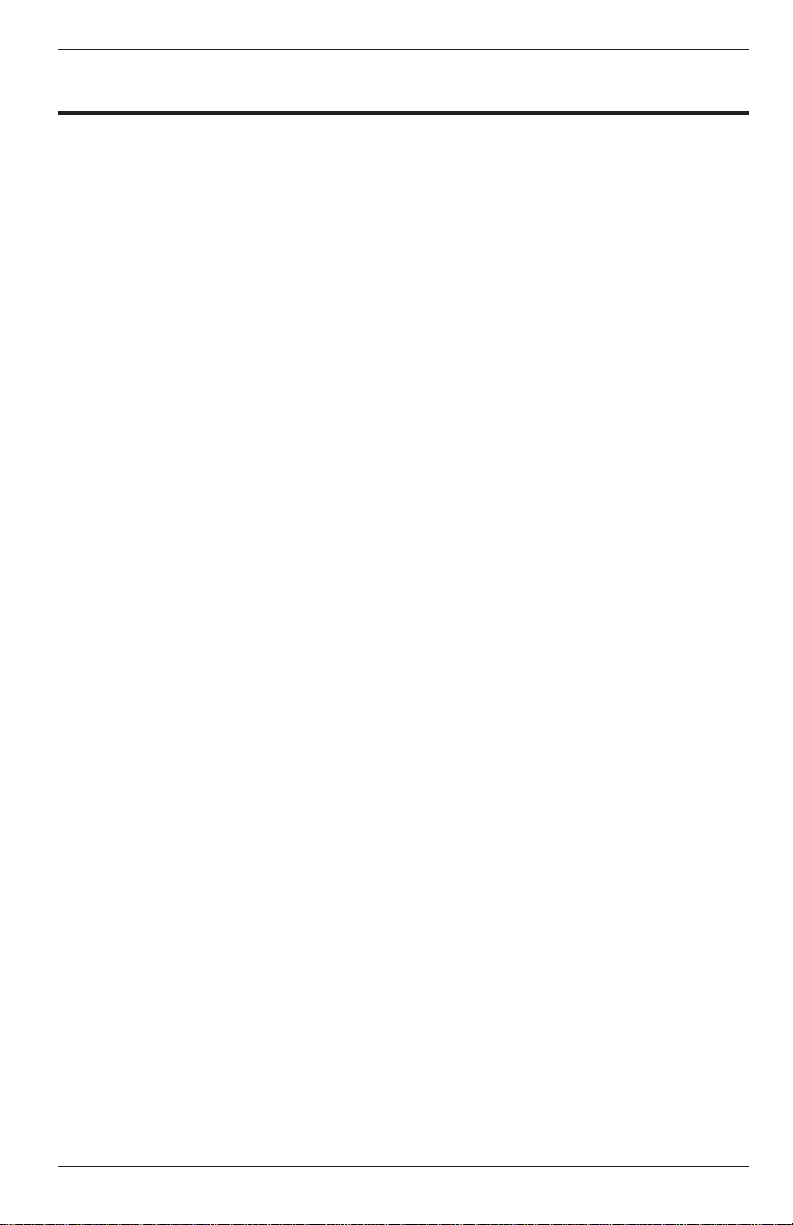

1.1 The Portable Combustion Analyzer

The Portable Combustion Analyzer (PCA) (Figure 1-1) is a commercial

grade, hand held, combustion efficiency analyzer that is designed for

continuous (on demand) sampling of light industrial and residential

furnaces, appliances, and boilers. The basic instrument is supplied with a

probe, instruction manual, batteries, and carrying case.

O 2 4 . 0 C O 1 2 H L D

C 2 9 . 5 C U 1 5 N G

T L 2 0 . 0 T A 1 9 0 P

q A 8 . 1 L A 1 . 2 4 S

Instruction 24-9351

M E N U

P C A

Figure 1-1. PCA

1-1

Page 6

Introduction

PCA

1.2 Displayed Data

The PCA directly measures, displays, and stores the following data:

• Room Temperature in °C or °F (Primary Air/Ambient Temperature)

• Flue Gas Oxygen Content in %

• Flue Gas Temperature in °C or °F

• Flue Gas Carbon Monoxide Content (H2 Compensated) in ppm

(For analyzers having a Carbon Monoxide sensor)

• Flue Gas Nitric Oxide content in ppm

(For analyzers having a Nitric Oxide sensor)

• Pressure/Draft in Millibars, Pascals, or Inches of Water Column

(For analyzers having a draft sensor)

• Differential Pressure in Millibars, Pascals, or Inches of Water Column

(For analyzers having a draft sensor)

The PCA will compute, display, and store the following data for any of the

standard fuels:

• Stack Loss in %

• Lambda

• Flue Gas Carbon Dioxide Content in %

• Flue Gas Carbon Monoxide Content referenced to 0% Oxygen in ppm

(For analyzers having a Carbon Monoxide sensor)

• Flue Gas Nitric Oxide Content referenced to 0% Oxygen in ppm

(For analyzers having a Nitric Oxide sensor)

The standard fuels are:

• Natural Gas

• Oil #2

• Oil #6

• LPG

• Koks

• Low Energy Gas

• P-Coal (available in English, German, Dutch, French, Italian,

Polish, and Spanish languages)

• Biofuel (available in Danish, Finnish, and Swedish languages)

The PCA continuously monitors flue-gas-exhaust conditions and updates

the above displayed values during a combustion test. If the analyzer is

equipped with an optional pressure sensor, draft measurements can be

made simultaneously with the combustion test, or made separately.

The analyzer has the ability to store data that was collected during a

combustion test or draft measurement. The stored data can then either be

viewed on the PCA’s display, printed using an optional printer, or downloaded to a computer.

1-2

Instruction 24-9351

Page 7

PCA

Introduction

1.3 Sensor Configurations

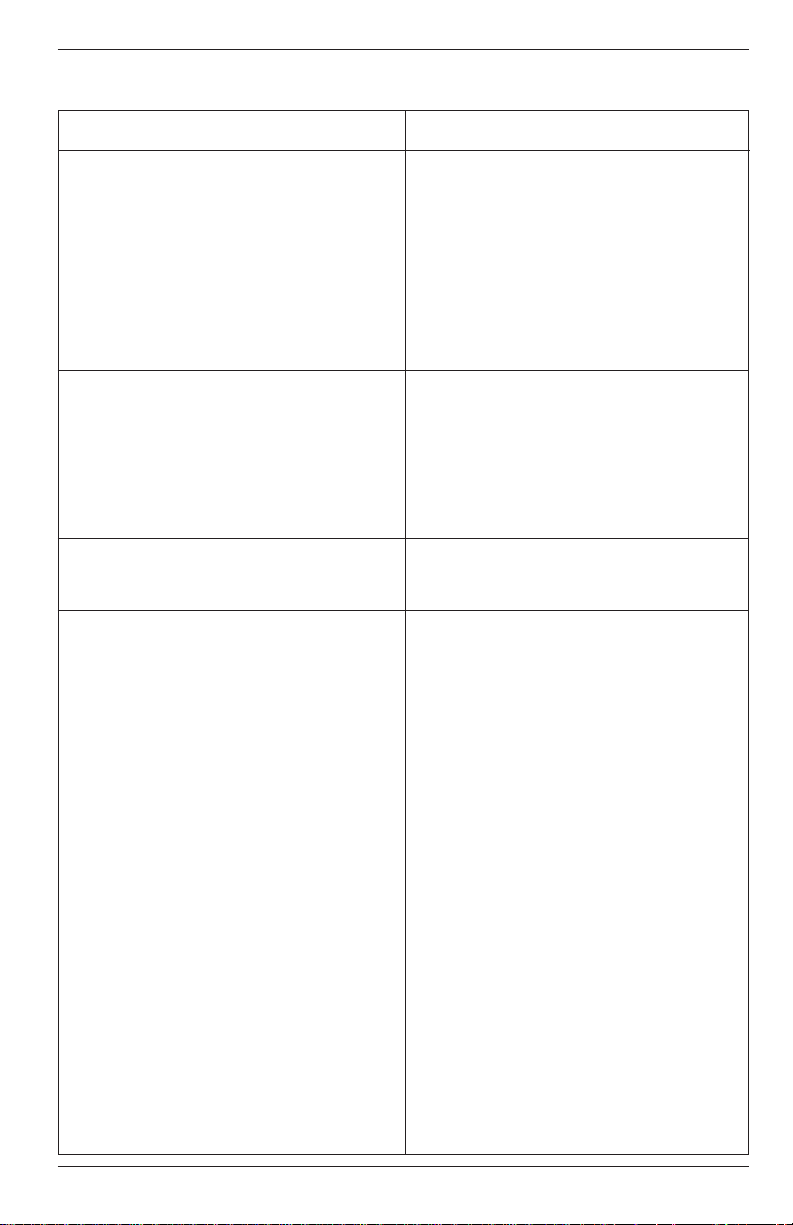

TABLE 1-1. PCA SENSOR CONFIGURATIONS

PCA Models Sensors Installed

Standard Advanced

PCA Part No.* Part No.** PCA Part No.* Part No.** Stack Temp., CO NX Draft

Model 24- 24- Model 24- 24- Air Temp. & O

10 7181 7281 40 7241 7251 X

15 7182 7282 45 7242 7252 X X

20 7183 7283 50 7243 7253 X X

25 7184 7284 55 7244 7254 X X X

30 7185 7285 60 7245 7255 X X X

35 7186 7286 65 7246 7256 X X X X

* English, Danish, Dutch, German, Finnish & Swedish languages

** English, French, German, Italian, Polish & Spanish languages

2

PCA 10 & 40

These basic instruments have the capability of measuring, displaying,

and storing combustion tests. They will also display flue gas Oxygen

content, flue gas Carbon Dioxide (CO2) content, air temperature, flue gas

temperature, stack loss, Lambda, and the current fuel selected. The

‘standard’ PCA 10 stores up to 10 combustion tests, while the ‘advanced’

PCA 40 can store up to 100 tests.

(

∆∆

∆P)

∆∆

PCA 15 & 45 with Draft

In addition to the features of the basic PCAs described above, these instruments have the added capability of measuring, displaying, and saving draft

or differential pressure in either Millibars, Pascals, or Inches-of-Water

Column.

PCA 20 & 50 with Carbon Monoxide Measurement

In addition to the features of the basic PCAs described above, these

instruments have the added capability of measuring, displaying, and

saving Carbon Monoxide (CO) content, as well as calculating CO referenced to 0% Oxygen.

PCA 25 & 55 with Draft and CO Measurement

These instruments combine the features of all the PCAs listed above.

PCA 30 & 60 with CO and Nitric Oxide Measurement

In addition to the features of the basic PCAs with CO measurement, these

instruments have the added capability of measuring, displaying, and

saving Nitric Oxide (NX) content, as well as calculating NX referenced to

0% Oxygen.

Instruction 24-9351

1-3

Page 8

Introduction

PCA

PCA 35 & 65 with Draft, CO & NX

These instruments are capable of measuring, displaying, and saving all

measurements as previously described.

Printout Capability

All PCAs have the ability to print the latest test data, or any of the saved

tests, to an optional printer using HP, IrDA or RS-232 protocol.

Advanced PCA Model Features

‘Advanced’ models of the PCA contain the following features that are in

addition to the features of their corresponding ‘standard’ PCAs:

• 100 memory locations

• RS232 output for transferring saved data to a Personal Computer

• Ability to enter three lines of user-identification information that is

printed at the top of each printout

• Ability to enter three lines of customer-identification information that

is printed with each test record.

• Automatic CO sensor purge on analyzers equipped with a CO sensor

Instruction 24-93511-4

Page 9

PCA

Technical Characteristics

2.0 TECHNICAL CHARACTERISTICS

The PCA Directly Measures and Displays:

• Oxygen content in flue gas in the range of 0.1 to 20.9 % O

• Flue gas temperature in the range of –18 to 1200 ºC (0 to 2192 ºF)

• Primary-air / ambient temperature is in the range of –18 to 999 ºC

(0 to 999 ºF)

Optional . . .

• Differential pressure/draft in the range of ±70.0 mb (±28" H2O)

• Carbon Monoxide* content in flue gas in the range of 0 to 4000 ppm

• Nitric Oxide* content in flue gas in the range of 0 to 1000 ppm

The PCA Computes and Displays:

(When the measured oxygen level is not above 18.8%, and the Stack (Flue

Gas) temperature is not above 1200 ºC (2192 °F)

• Stack loss in the range of 0.1 to 99.9%

• Carbon Dioxide content in flue gas from 0.1 to a fuel dependent

maximum value in percent

• Lambda in the range of 1 to 9.95

• Carbon Monoxide* content referenced to 0% Oxygen in the range of

0 to 9,999 ppm on analyzers equipped with a CO sensor.

• Nitrix Oxide* content referenced to 0% Oxygen in the range of 0 to

9,999 ppm on analyzers equipped with a NX sensor.

2

Standard Fuels** Available for

Combustion Calculations:

• Natural Gas

• Koks

• LEG

• LPG

• Oil #2

• Oil #6

• P-Coal (available in English, German, Dutch, French, Italian,

Polish, and Spanish languages)

• Biofuel (available in Danish, Finnish, and Swedish languages)

* For the PCA 30, 35, 60, & 65, the display can be set up to show either

measured values of Carbon Monoxide and Nitric Oxide (CO & NX), or

show the calculated values of these gases (CU & NU) referenced to

0% Oxygen. In either case, all values are listed on the printout of

analzyers equipped with a printer.

** Custom fuels available upon request. Contact factory for details.

Instruction 24-9351

2-1

Page 10

Technical Characteristics

Normal Operating Conditions:

Temperature:

Analyzer ...................0 to 40 ºC (32 to 104 ºF)

Probe.........................800 ºC (1472 ºF) Max.

Humidity:

Analyzer ...................15 to 90% Relative Humidity, Non-Condensing

Air Pressure:

Analyzer ...................Atmospheric

Probe.........................25 mb (10" H2O) draft max at probe tip

Performance:

Accuracy:

Oxygen*....................±0.3% O

Carbon Monoxide.....±5% of reading or ±10 ppm, whichever is greater

between 0 – 2000 ppm, and ±10% of reading

between 2001 – 4000 ppm.

Nitric Oxide..............±5% of reading or ±5 ppm, whichever is greater

Flue Gas Temp......... ±2 ºC between 0 and 124 ºC

±3 ºC between 125 and 249º C

±4 °C between 250 and 400 °C

Ambient Temp. ........±1 °C between 0 and 100° C

Pressure ...................±2% of reading or ±0.05 mb (±0.02 inches of

Water Column), whichever is greater

2

(±4 ºF between 32 and 255 ºF)

(±6 ºF between 256 and 480 ºF)

(±8 ºF between 481 and 752 ºF)

(±2 ºF between 32 and 212 ºF)

PCA

System Flow Rate:

With probe................200 cc/min minimum

Front Panel Controls:

Seven embossed push-button switches with tactile feedback (refer to

Section 4.1)

* Accuracy referenced in practical flue gas concentrations

(mixtures of O2, CO2 and N2)

2-2

Instruction 24-9351

Page 11

PCA

Technical Characteristics

Display:

20 character by 4 line alphanumeric LCD panel with a green backlight.

Power Requirements:

Four disposable AA alkaline batteries. Battery backup for the real-time

clock, RAM, and bias voltage for the Nitric Oxide sensor are provided by

internal lithium batteries. Optional AC Power Supplies (110 VAC &

230 VAC) are also available.

Operating Time:

A fresh set of four disposable AA alkaline batteries provides at least

8 hours of continuous operation with the pump running and the backlight

turned on.

Warm Up Time:

60 seconds.

Printer Interface:

Infrared & RS-232 Communications (refer to Section 4.23).

Materials:

• High impact ABS plastic case

• Polycarbonate window over the display

• Nickel plated, brass quick-connect hose fitting

• Stainless steel probe

Dimensions:

Height:.................. 215 mm (8.5 in.)

Width: ................... 96 mm (3.8 in.) at display (75 mm [3.0 in.] at controls)

Depth:................... 50 mm (2 in.)

Weight:

With Batteries:..... Approximately 0.7 Kg (1.5 lbs)

Instruction 24-9351

2-3

Page 12

Technical Characteristics

Agency Approvals:

_ TÜV Agency Approved (1.BImSchV - First Ordinance of the German

Federal Emissions Law)

Approval Number: TÜV By RgG 168

_ CE declaration of conformity

Manufacturer's name: Bacharach, Inc.

Manufacturer's address: 621 Hunt Valley Circle

New Kensignton, PA 15068

European operations: Bacharach Instruments

Sovereign House, Queensway

Royal Leamington Spa

Warwickshire CV31 3JR

United Kingdom

Product name: Portable Combustion Analyzer (PCA)

conforms to the following CE

requirements:

EN 50081-1, January 1992 (Emissions)

EN 50082-1, January 1992 (Immunity)

Equations

PCA

2

×=

max

COC2

()

TLTAqA

21

=

LA

2

−

O21

×=

COCU

×=

NONU

2-4

2

O21

−

21

21

2A

×−=

21

−

−

O21

O21

2

−

()

O21

2

2

Where:

= Measured Oxygen in percent

O

2

TA = Measured stack temperature in °C

TL = Measured primary air temperature in °C

CO = Measured Carbon Monoxide in ppm

+

B

NO = Measured Nitric Oxide in ppm

C2 = Calculated Carbon Dioxide in percent

qA = Calculated stack loss in percent

LA = Calculated Lambda

CU = Calculated Carbon Monoxide referenced

to 0% Oxygen

NU = Calculated Nitric Oxide referenced to 0%

Oxygen

CO2max, A2, and B are constants (see below)*:

Fuel CO2max A2 B

NG 11.8 0.66 0.009

KOKS 10.2 0.60 0.011

LEG 13.1 0.63 0.011

LPG 13.8 0.63 0.008

Oil#2 15.4 0.68 0.007

Oil#6 15.9 0.68 0.007

P-Coal 18.7 0.60 0.007

Biofuel 20.4 0.70 0.012

* Some constants vary for Danish, Italian, and Polish fuels

Instruction 24-9351

Page 13

PCA

Setup

3.0 SETTING UP THE PCA

3.1 Scope

Before using the PCA, you MUST:

• Check the batteries or plug in an optional Power Supply (Section 3.2)

• Connect the probe to the analyzer (Section 3.3)

• Check the analyzer’s configuration (Section 3.4)

3.2 Power

3.2.1 Checking and Replacing the Batteries

A fresh set of batteries is supplied with the PCA. Install the batteries as

described below. Check for a sufficient charge prior to each use. If a

LOWBATTERY message is displayed, replace the batteries.

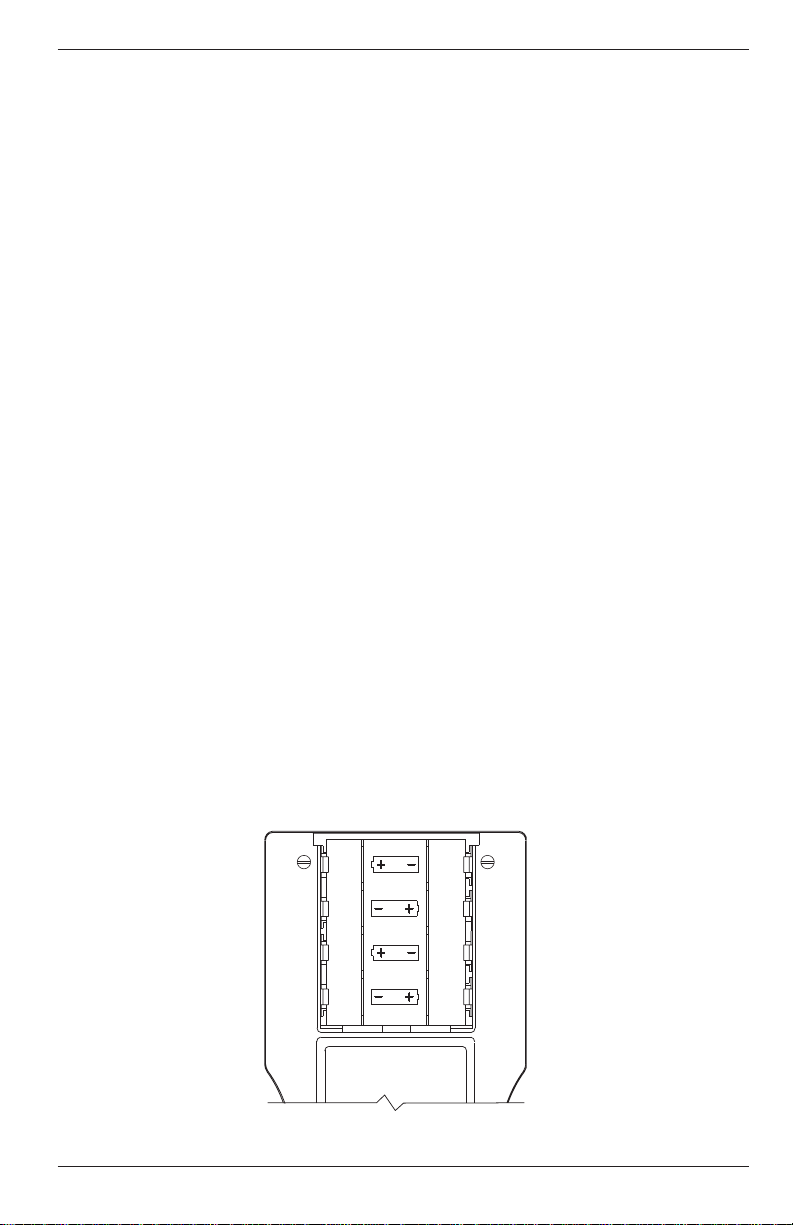

1. Remove the battery cover from the back of the PCA (Figure 3-1).

2. Remove (and properly dispose of) the old batteries.

3. Install a new set of four AA alkaline batteries, making sure to properly orient them as indicated by the “+” and “–” terminals in the

battery compartment.

4. Replace the battery cover.

Figure 3-1. Battery Replacement

Instruction 24-9351

3-1

Page 14

Setup

PCA

3.2.2 Using the Optional Power Supply

If an Optional Power Supply is to be used:

1. Connect the output plug of the Optional Power Supply to the

analyzer’s power supply jack (Figure 3-2).

2. Plug the Optional Power Supply into an appropriate AC wall outlet.

The analyzer will now operate and function normally.

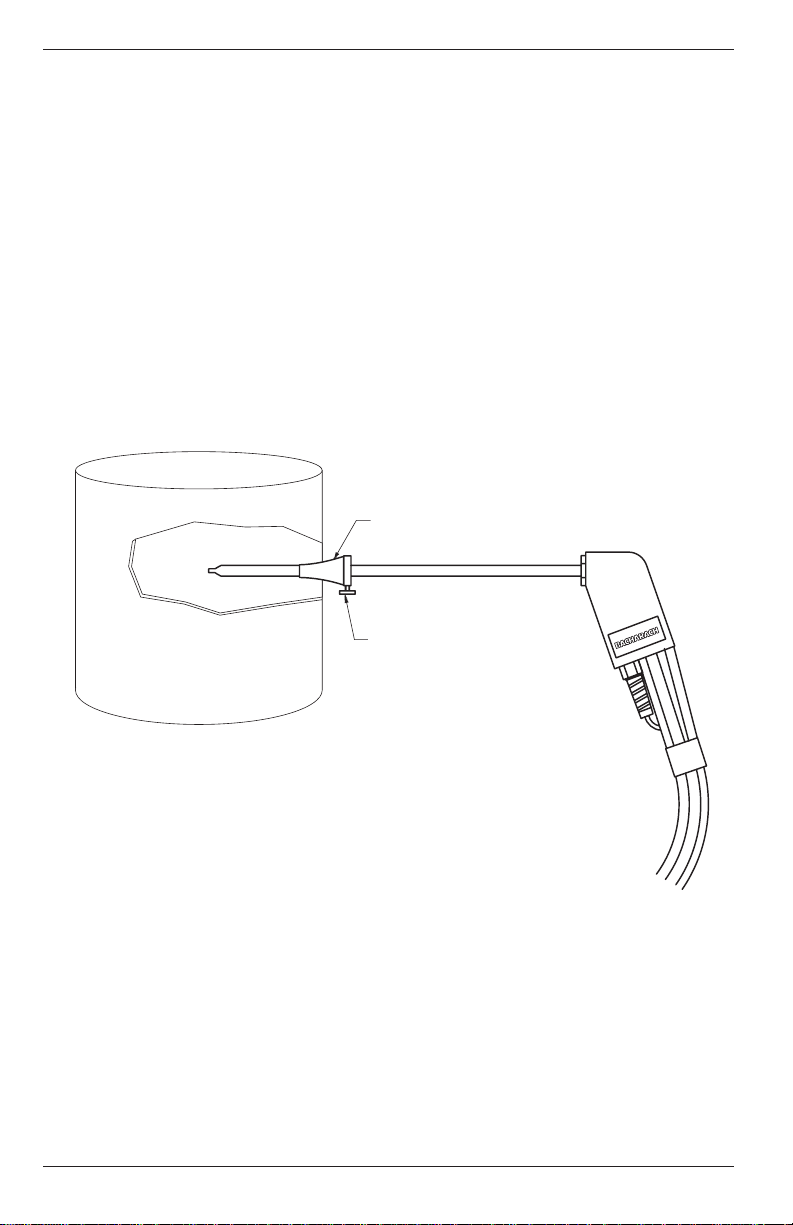

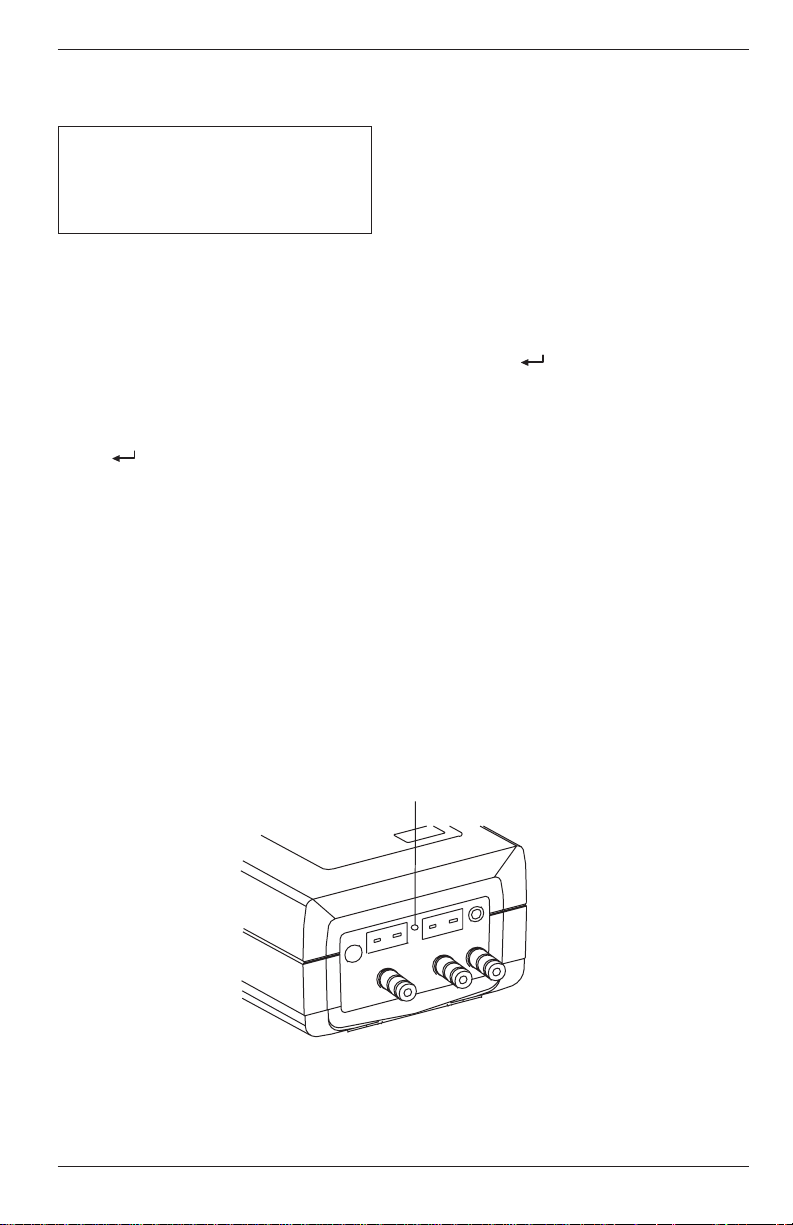

3.3 Connecting the Probe

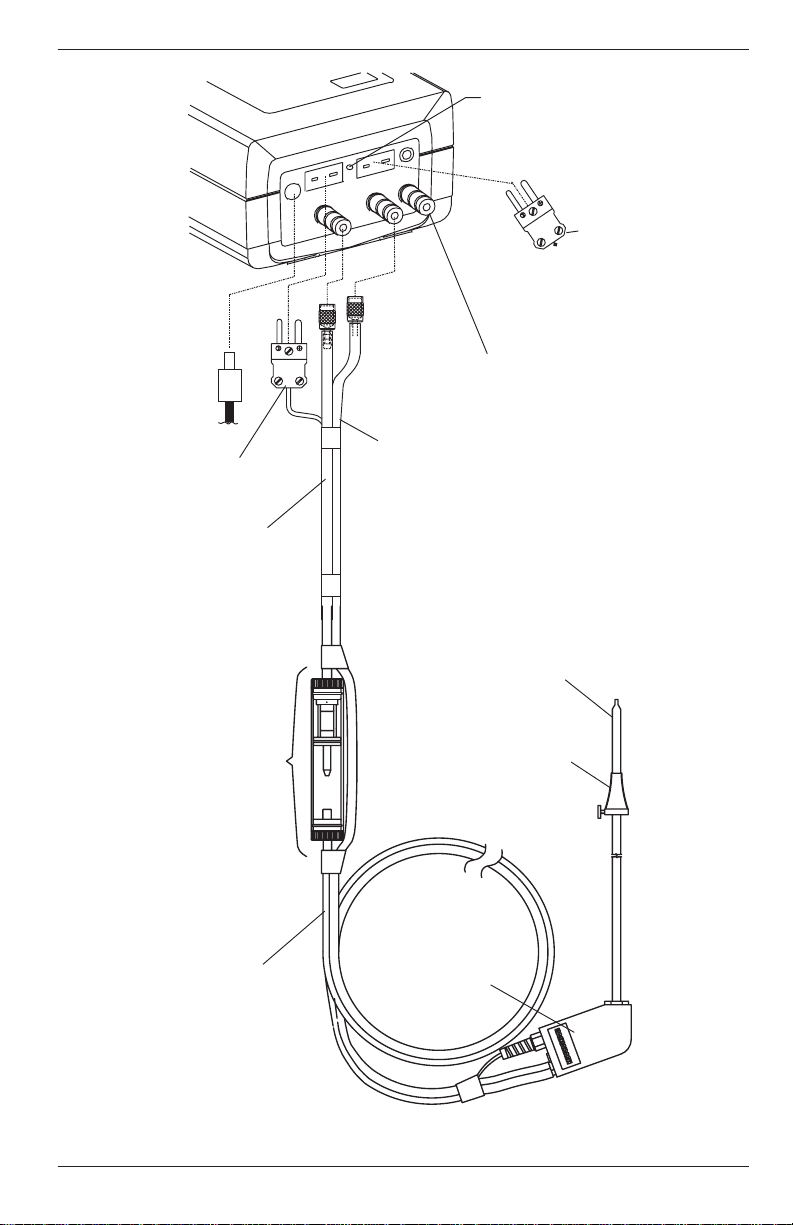

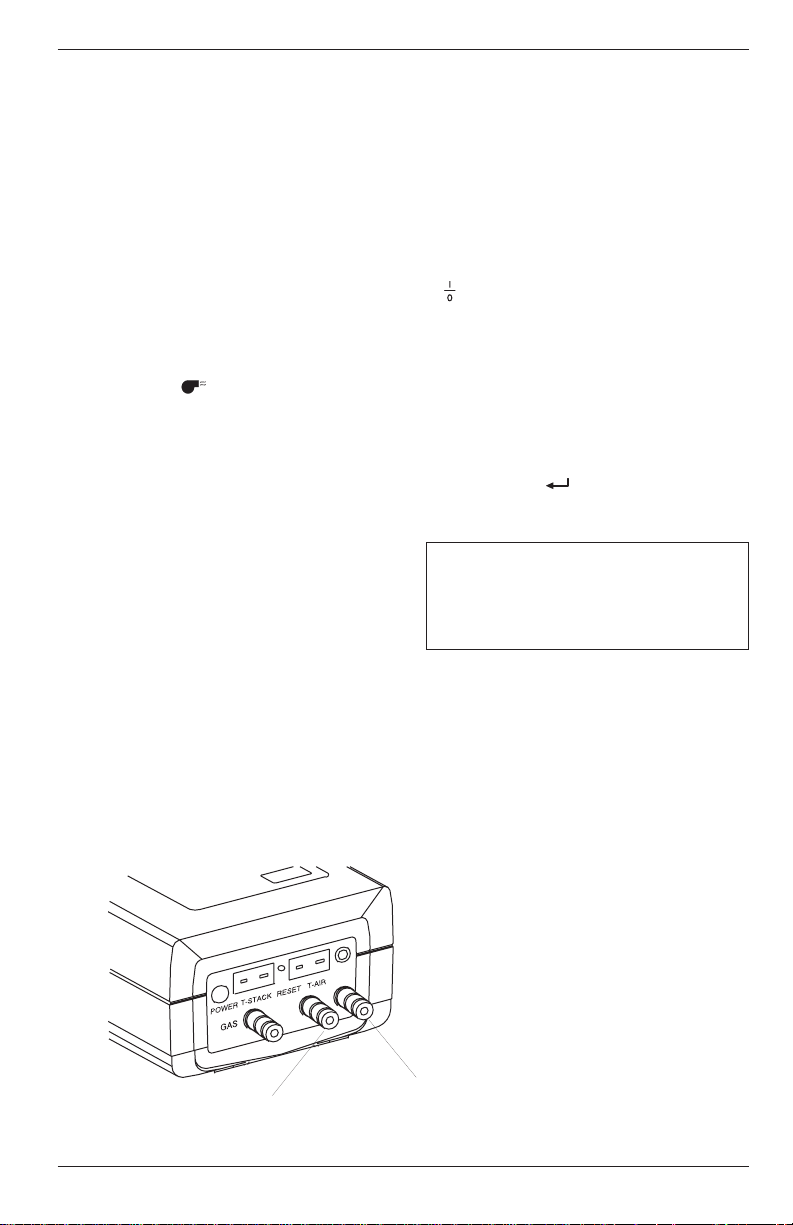

To attach the probe to the analyzer (Figure 3-2):

1. Push the yellow-banded, quick-connect Flue Gas Hose (giving a slight

twist) onto the analyzer’s GAS sample-inlet fitting.

2. Push the blue-banded, quick-connect Draft Hose (giving a slight twist)

onto the analyzer’s DRAFT sample-inlet fitting.

3. Push the Flue Gas Thermocouple into the T-STACK jack (connector

fits in only one way).

NOTE: The PCA has a built in room-air thermocouple.

Perform Step 4 only if the Optional Room Air/Primary Air

Thermocouple is used.

4. Push the Optional Room Air/Primary Air Thermocouple into the

T-AIR jack (connector fits in only one way).

NOTE: In order for the PCA to correctly calculate combustion efficiency when the burner’s primary-air temperature is

not the same as room temperature, the primary-air temperature should be measured using the optional Primary Air

Thermocouple.

Inspect all the hoses for cracks. If any hose is defective, replace the entire

probe assembly. Check that the water trap is dry and the filter is not

dirty or saturated with water.

3-2

Instruction 24-9351

Page 15

PCA

POWER

Setup

Reset Button

T-AIR

RESET

T-STACK

GAS

Room Air /

Primary Air

Thermocouple

(Optional)

Power Supply

110V/60Hz

230V/50Hz

(Optional)

Flue Gas

Thermocouple

Water

Trap / Filter

Assembly

Pressure Reference

Port (Used in the

Measurement of

Differential Pressure)

Draft Hose

Flue Gas

Hose

Probe Tube

Adjustable

Probe Stop

Figure 3-2. Connecting the Probe to the Analyzer

Instruction 24-9351

Flue

Gas

Hose

Probe

Handle

3-3

Page 16

Setup

PCA

3.4 Configuring the PCA

The PCA is configured at the factory for the parameters shown below, but

can be changed by following the instructions in the associated sections.

Function Parameters To Change,

Refer to . . .

Fuel Natural Gas Section 4.8

Temperature ºC Section 4.13

Optional Draft MB Section 4.14

Language English Section 4.15

Display Mode* CO & NX Section 4.16

Time HR:MIN:SEC Section 4.17

Date** DD.MM.YY Section 4.17

Printer IrDA Section 4.18

* Available only on the PCA 30, 35, 60, & 65

** The year displays as two digits on the instrument, and

four digits on the printout.

3-4

Instruction 24-9351

Page 17

PCA

Operation

4.0 OPERATION

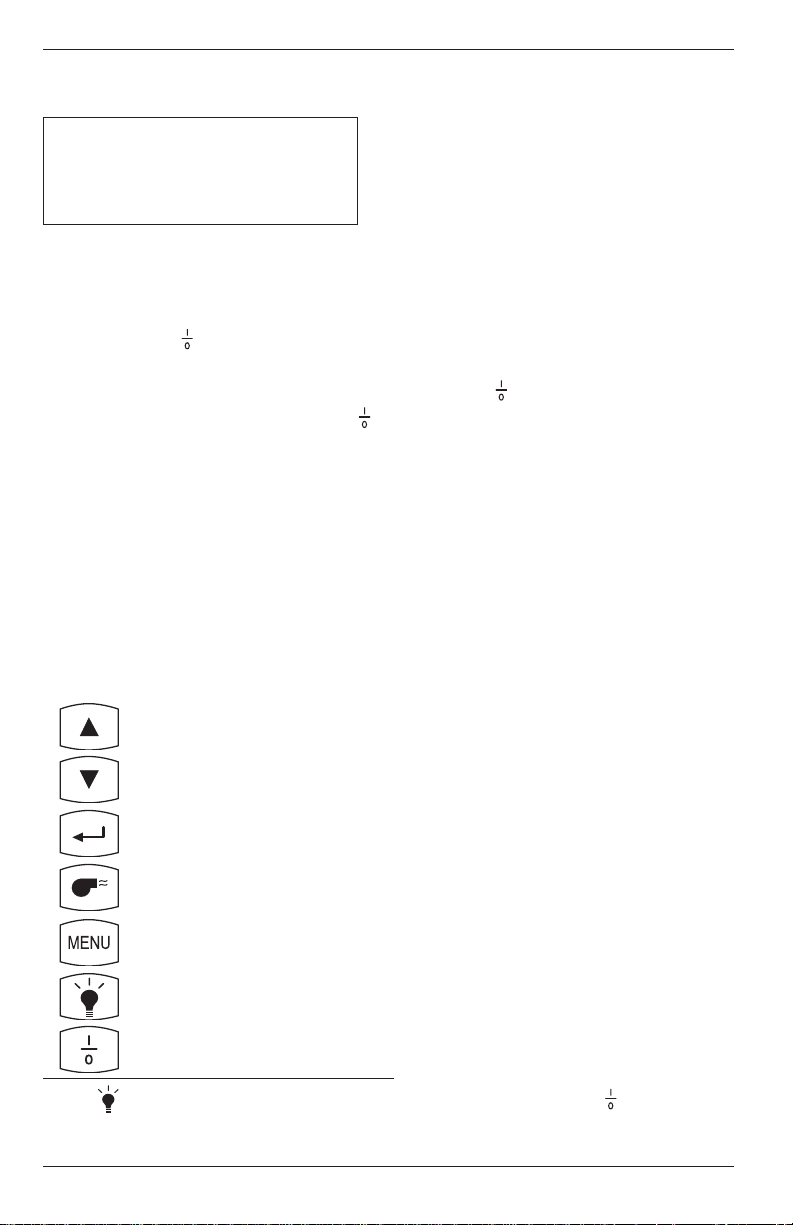

4.1 Key Pad Functions

Descriptions of the key pad functions are given below. Note that most of

the front panel key pad buttons perform multiple functions as determined

by what screen is being displayed at the time.

Turns the analyzer ON and OFF. Note that there is a 5 second

delay before the instrument actually turns OFF, thus allowing an

operator to turn the instrument back ON by pressing the key

to prevent the accidental loss of test data.

Moves the cursor [z] in front of a menu item up through the

displayed items. This key also increases alphanumeric values in

screens requiring a value change.

Moves the cursor [z] in front of a menu item down through the

displayed items. This key also decreases alphanumeric values in

screens requiring a value change.

Chooses the highlighted item (the item with the cursor [z] in front

of it) in all menus and screens. This key also causes the cursor to

enter the number field in the Maintenance Password Screen, and

causes the cursor to advance to the next field position in screens

requiring multiple alphanumeric entries.

Starts and stops a combustion test when the Combustion Test

Screen is displayed. Pressing this key in any other screen almost

always returns the instrument to the Combustion Test Screen.

However, there are four situations where this key behaves as an

enter key: 1) After entering a correct password in the Password

Screen, press the key to display the first calibration screen.

2) After entering an offset or span value in any of the Calibration

Edit Screens, press the key to store the new values. 3) After

entering a time or date value in the Time/Date Setup Screen,

press the key to store the new values and return the cursor to

the left side of the display. 4) After entering text in either the ID

Setup or User Name Screens, press the key to store the text.

Advances the display to the next menu screen.

Turns the backlight ON and OFF.

Instruction 24-9351

4-1

Page 18

Operation

PCA

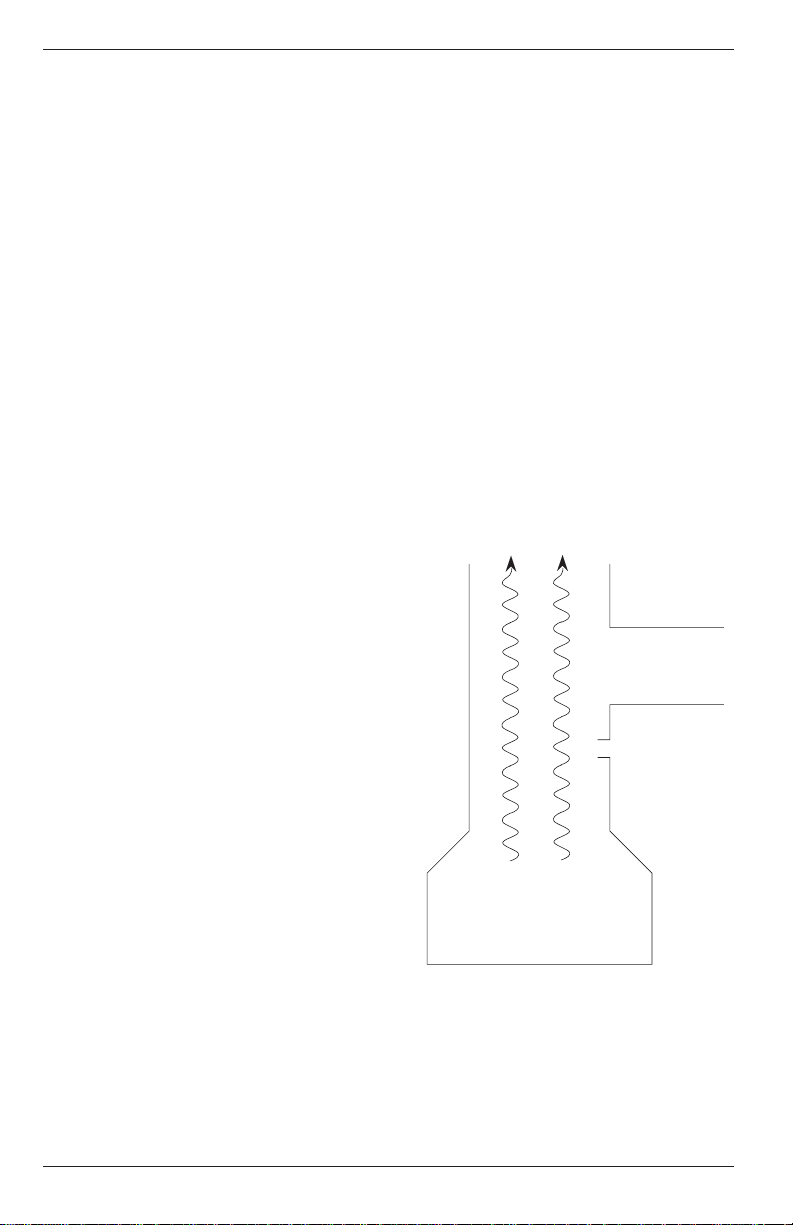

4.2 Sampling Hole Location

The analyzer requires that a 13 mm (½ in.) diameter sampling hole be

made in the furnace stack to accommodate the probe stop on the Probe

and Hose Assembly.

Locate the sampling hole downstream from the last heat exchanger,

and upstream from any source of dilution, such as a draft diverter

(Figure 4-1).

IMPORTANT! As the distance between the last heat exchanger and sampling point increases, stack loss will falsely

decrease due to heat loss by convection from the flue or stack.

For residential and light-commercial combustion-equipment applications,

the following recommendations are applicable:

• Oil Gun Burners – Locate sampling

hole at least 30 cm (12 in.) downstream from the furnace breaching,

and at least 15 cm (6 in.) upstream

from the furnace side of the draft

regulator.

• Gas Burners – Locate sampling hole

at least 15 cm (6 in.) upstream from

the furnace side of the draft diverter

on gas-converted units. For gasdesigned equipment, the probe may

be inserted down into the flue

through the draft diverter or hood.

FLUE GAS FLOW

(Downstream)

DRAFT

DIVERTER/

REGULATOR

SAMPLE

POINT

(Upstream)

FURNACE

BREECHING

Figure 4-1. Sampling Hole Location

4-2

Instruction 24-9351

Page 19

PCA

Operation

4.3 Combustion Test

IMPORTANT! Large rapid changes in the temperature of

the analyzer can affect its accuracy. This is important to

know if the analyzer is stored in a cold place (such as an

unheated vehicle in the winter) and then taken into a warm

furnace area. For the most accurate test results, allow the

analyzer to warm up to room temperature before use (about

10 minutes).

4.3.1 Analyzer Turn On and Warm Up

IMPORTANT! Be sure the probe is at room temperature

before performing the following steps.

1. Make sure that the analyzer is properly set up per Section 3.0.

2. Place probe in an area of fresh, ambient air; then press the analyzer’s

key.

3. Wait for the analyzer to countdown through its 60 second warmup

period; then perform one of the following:

• If no errors were detected during warmup, the Combustion

Test Screen will be displayed. Skip Step 4, and go to Section 4.3.2.

• If an error was detected during warmup, proceed with Step 4.

4. If one or more errors were detected by the microprocessor during

warmup, these errors will be displayed at the bottom of the Sensor

Status Screen. Address any problems now per Section 7.2; then repeat

this procedure starting with Step 1.

NOTE: If the error detected is not critical to your test, the

instrument can still perform any test not using the function

disabled by the error.

Instruction 24-9351

4-3

Page 20

Operation

4.3.2 Installing Probe in the Stack

1. After making a sampling hole in the stack (Section 4.2), and turning

on the analyzer (Section 4.3.1), screw the probe stop supplied with the

Probe and Hose Assembly into the sampling hole (Figure 4-2).

2. Insert the probe through the hole in the probe stop, then position the

probe tip inside the stack, near its center. Tighten the thumbscrew on

the probe stop to secure the probe.

PROBE STOP

PCA

4-4

THUMBSCREW

Figure 4-2. Installing the Probe

Instruction 24-9351

Page 21

PCA

Operation

4.3.3 Performing a Combustion Test

IMPORTANT: If the burner’s primary-air temperature is

not the same as the room temperature, then be sure the

Optional Room Air / Primary Air Thermocouple is installed

per Section 3.3.

1. With the Combustion Test Screen displayed and the probe installed in

the stack, press the key to start a combustion test (refer to Section 4.7).

2. Once all sensor readings are indicated on the screen: A) Loosen the

thumbscrew on the probe stop. B) Move the probe in and out of the

stack until the stack’s core temperature (hot spot) is located.

C) Tighten the thumbscrew to prevent further movement of the probe.

Locating the highest stack temperature is very important for accurate

combustion calculations.

3. You can now begin burner-service procedures. The readings on the

analyzer change quickly to show changes in burner performance.

CAUTION

With the Water Trap / Filter Assembly stood up on its Outlet

End, do not let water condensate build up beyond the tip of

the riser tube. The sensors could be damaged if water would

enter the analyzer. Drain the water condensate after every

combustion test (refer to Section 6.4).

4. Pressing the key will save the Combustion Test Screen readings

while a test is in progress. Moving the cursor (z) in front of the print

( P) function using the s key, and then pressing will print the test

information to an optional printer.

4.3.4 Ending a Combustion Test

1. Press the key to end a combustion test.

WARNING!

Burn hazard! Allow a hot probe to cool for about 5 minutes

before handling.

Instruction 24-9351

4-5

Page 22

Operation

CAUTION:

Do not place a hot probe inside the instrument’s carrying case.

Allow the probe to cool before storage.

2. Loosen the thumbscrew on the probe stop; then remove the probe and

probe stop from the stack.

3. If data was saved during the combustion test, you can turn off the

analyzer and review or print the stored data at a later time as described in Sections 4.10 and 4.23.

4.3.5 Turning Off the Analyzer and Purging the CO Sensor

Turn off the analyzer by pressing the key.

If the key is pressed while the CO reading is 100 ppm or higher, the

pump will automatically turn on (if not already running) to purge the

analyzer of CO.

IMPORTANT! The analyzer’s probe must be removed from

the stack during the purging process to allow fresh air to be

drawn through the analyzer.

PCA

The following message is displayed while the analyzer is being purged.

PURGING CO SENSOR

As soon as the CO level falls below 100 ppm, the pump turns off and the

analyzer starts its normal 5 second turn-off sequence.

To abort the purging process and immediately start the analyzer’s turn-off

sequence, press the key.

NOTE: Turning the analyzer off initiates a 5-second delay,

during which time the unit can be turned on again without

any warmup time. You can turn the analyzer back on during

this 5-second delay by pressing the key.

4-6

Instruction 24-9351

Page 23

PCA

Operation

4.4 Differential Pressure Measurement

The difference in pressure (∆P) between two areas can be measured by

using the PCA’s two pressure ports and DRAFT Screen. By using Pressure Port 2 (–) as the reference, the pressure applied to Port 1 (+) will be

displayed on the DRAFT Screen as the differential pressure between the

two ports.

1. Turn on the analyzer by pressing the key; wait for the warmup cycle

to complete; then press the MENU key until the first DRAFT Screen is

displayed (refer to Section 4.9). If a TA-SENSOR ERROR is displayed

because the probe’s thermocouple is not plugged into the analyzer, then

press the key to acknowledge the error before pressing the MENU

key.

2. While the first DRAFT Screen is displayed, remove any hoses connected to Pressure Ports 1 and 2; then press the key to zero these

ports at atmospheric pressure.

3. Connect two sampling hoses to

Pressure Ports 1 and 2

(Figure 4-3). Then place the open

end of each hose into the areas

DRAFT

DRAFT – 2.25 MB

HOT SPOT ---- °C P

«S

being measured.

4. The differential pressure between the two areas is now displayed on

the third DRAFT Screen. If the pressure at Port 1 is higher than

Port 2, then the pressure difference will be positive. But if the pressure at Port #1 is lower, then the pressure difference will be negative.

The reading shown in this example indicates that the pressure at

Port 1 is 2.25 mb lower than the pressure at Port 2.

Sampling Hoses with quickconnect fittings are available

as an optional accessory.

Refer to Section 8.2.

Pressure Port 2(–)

Pressure Port 1(+)

Reference

Figure 4-3. Differential Pressure Hose Connections

Instruction 24-9351

4-7

Page 24

Operation

PCA

4.5 Warmup Screen

BACHARACH, INC.

PCA xx

WARMUP yy

Where: xx = Instrument Model Number

yy = Counts down from 60 seconds

As soon as the key is pressed, the instrument’s serial number and

software version number are displayed for approximately 3 seconds. To

continuously display these items, hold down the key at start-up. The

warmup cycle continues after the key is released.

The Warmup Screen is displayed during the analyzer’s 60 second warmup

cycle, during which time the “Warmup” value (yy) counts down to zero.

After the warmup cycle is complete (and if the unit is working correctly)

the instrument will flash NO ERRORS DETECTED and go directly to

the Combustion Test Screen (Section 4.7). If there is a problem, however,

with one or more of the sensors, the Sensor Status Screen (Section 4.6) is

displayed with error message(s) appearing at the bottom of the screen.

Front Panel Key Functions:

– No Action

– No Action

– No Action

– No Action

– No Action

– Toggle Backlight ON/OFF*

– Turn analyzer OFF*

* The button will always turn the backlight on and off, and the key will

always turn the analyzer on and off. These two keys will not be mentioned

in the remainder of this section.

4-8

Instruction 24-9351

Page 25

PCA

Operation

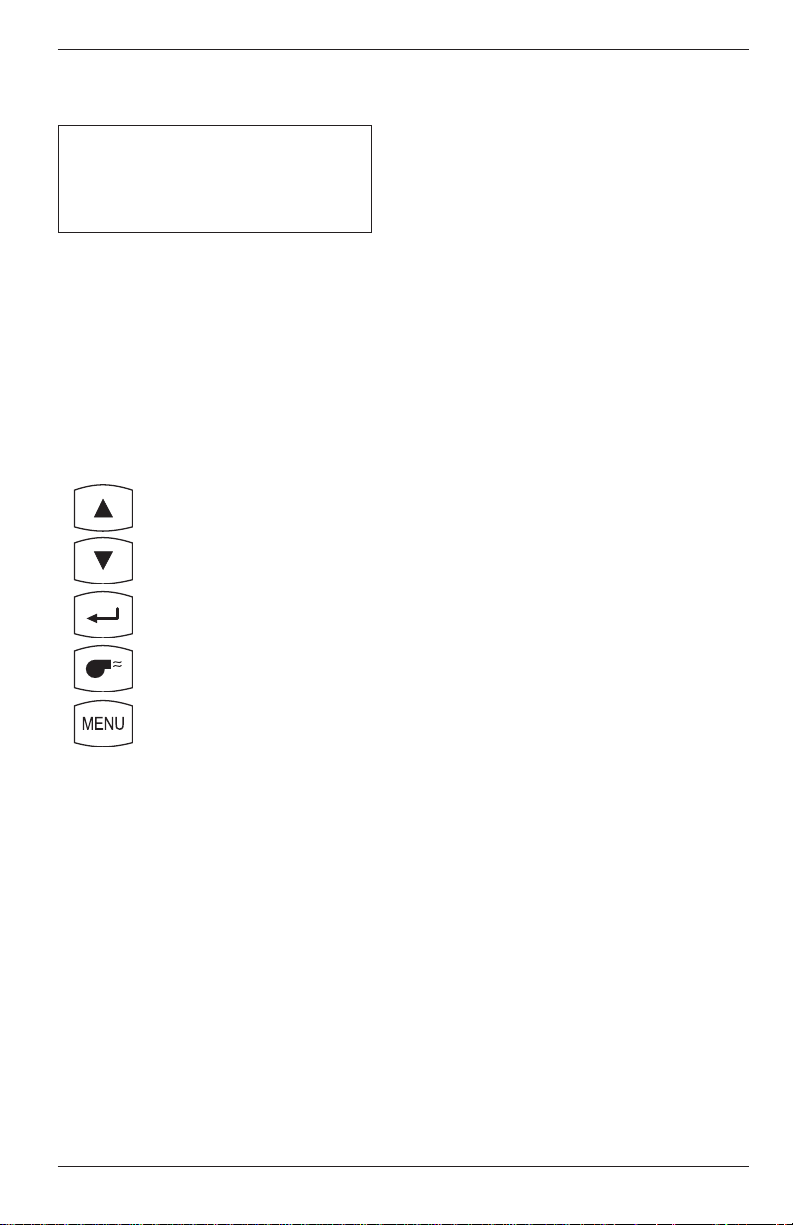

4.6 Sensor Status Screen

BACHARACH, INC.

PCA xx

WARMUP 0

z

Where: xx = Instrument Model Number

z = Sensor(s) in error

If there is problem with one or more of the sensors, the Sensor Status

Screen will be displayed after the analyzer has gone through its warmup

cycle (refer to Section 7.2 for a listing of the error codes).

Front Panel Key Functions:

– No Action

– No Action

– No Action

– Go to Combustion Test Screen

– No Action

Instruction 24-9351

4-9

Page 26

Operation

4.7 Combustion Test Screen

PCA models 10–25, 40–55 PCA models 30, 35, 60, & 65

O2 4.0 CO 12 HLD O2 4.0 CO 12 HLD

C2 9.5 CU 15 NG C2 9.5 NX 10 NG

TL 20.0 TA 190 P TL 20.0 TA 190 P

qA 8.1 LA 1.24

«S qA 8.1 LA 1.24 «S

PCA

This screen shows:

O2 ...............Oxygen content in flue gas (%)

C2 ...............Carbon Dioxide content

present in flue gas (%)

TL ...............Primary/Ambient air temp. (°F)

qA ...............Stack Loss

CO* .............Carbon Monoxide content in flue gas (ppm)

CU*............. Carbon Monoxide content referenced to 0% Oxygen (ppm)

TA ............... Stack (Flue gas) temperature (°F)

LA ............... LAMBDA

NX*.............Nitric Oxide content in flue gas (ppm)

NU* ............Nitric Oxide content referenced to 0% Oxygen (ppm)

HLD/RUN ..PCA on hold / PCA running test

NG .............. Fuel code for natural gas (see Section 4.8 for other codes)

P.................. Print Data

S..................Save Data

O2 4.0 CU 15 HLD

C2 9.5 NU 12 NG

TL 20.0 TA 190 P

qA 8.1 LA 1.24 «S

- OR -

* For PCA models 30, 35, 60 and 65, you have the option of displaying either

CO & NX, or CU & NU. Refer to Section 4.16 for setup instructions.

NOTE: Refer to Section 7.3 if stars (****) , dashes (----) , or

Xs (XXXX) appear in the display.

Front Panel Key Functions:

– Move cursor (z) up

4-10

– Move cursor (z) down

– Save or Print screen data

– Run test / Stop test

– Go to Fuel Selection Screen

Instruction 24-9351

Page 27

PCA

Operation

4.8 Fuel Selection Screen

«NATGAS FUEL

KOKS OIL NO.2

LEG OIL NO.6

LPG P-COAL

This screen is displayed by pressing the MENU key from the Combustion

Test Screen. This screen is used to select the fuel being burned.

To select a fuel, first use the st keys to move the cursor (z) in front of the

desired fuel, and then press the key.

NOTE: The fuel selected is saved as the default, and remains in memory after the PCA is turned off.

The fuel codes as displayed in the Combustion Test Screen:

NG = Natural Gas O#6 = Oil No. 6

KOK = Coal Gas PC = P-Coal (English, German, Dutch,

LPG = Propane French, Italian, Polish, and Spanish) or Biofuel

O#2 = Oil No. 2 (Danish, Finnish, and Swedish)

Front Panel Key Functions:

– Move cursor (z) up

– Move cursor (z) down

– Select Fuel

– Go to Combustion Test Screen

– Go to Draft Screens

Instruction 24-9351

4-11

Page 28

Operation

4.9 Draft Screens

PCA

The first Draft Screen is displayed by

repeatedly pressing the MENU key

from the Combustion Test Screen.

To measure draft, first zero the

analyzer’s pressure sensor to atmospheric pressure by disconnecting the

draft hose from the bottom of the

instrument, and then pressing the

key. Reconnect the draft hose after

the second Draft Screen appears

(shown for 3 seconds). The third

screen shows the current values of

draft and stack temperature as

measured by the analyzer.

When using the analyzer to make a

differential pressure measurement

(Section 4.4), the differential pressure

value will be displayed on the third

Draft Screen.

To save (S) or print (P) the screen

data, first use the st keys to move

the cursor (z) in front of the desired

function, and then press the key.

DRAFT

DISCONNECT DRAFT

HOSE

PRESS ±

DRAFT

RECONNECT DRAFT

HOSE

DRAFT

DRAFT – 0.25 XX

HOT SPOT 190 °C P

«S

Where: xx = Unit of measure.

Default is millibars (MB). See

Optional Draft SETUP Screen

(Section 4.14) for other choices.

Front Panel Key Functions:

– Move cursor (z) up

– Move cursor (z) down

– Save or Print screen data

– Go to Combustion Test Screen

– Go to Memory Directory Screen

4-12

Instruction 24-9351

Page 29

PCA

Operation

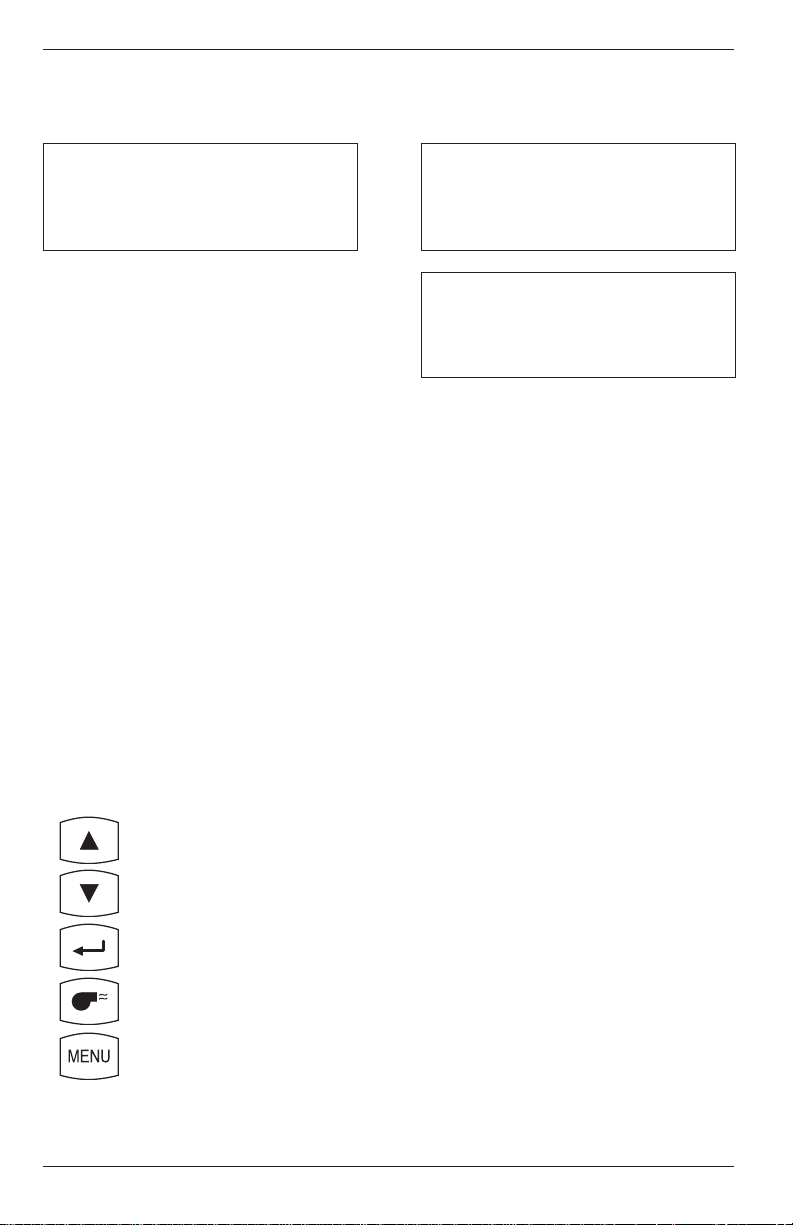

4.10 Memory Directory Screen

‘Standard’ PCA Screen ‘Advanced’ PCA Screen

MEMORY DIRECTORY MEMORY DIRECTORY

«M8 28.7.97 15:45 «98 28.7.97 15:45

M9 MEMORY EMPTY 99 MEMORY EMPTY

CLEAR MEMORY CLEAR MEMORY

The Memory Directory Screen is displayed by repeatedly pressing the

MENU key from the Combustion Test Screen. This screen is used to select

a memory location that contains saved data which an operator can review.

NOTE: A ‘standard’ PCA has 10 memory locations numbered M0 thru M9, while an ‘advanced’ PCA has 100 memory

locations numbered 0 thru 99.

To select a data-memory location, first use the st keys to move the

cursor (z) in front of the desired memory location; then press the key.

The saved data is now displayed in either the Combustion Test Screen or

Draft Screen, depending on whether the chosen memory location contains

combustion or draft information. To print the saved data, refer to Section 4.23.

After viewing or printing the saved data, use the st keys to move the

cursor (z) to the exit (E) function; then press . This will redisplay the

memory directory.

Selecting the CLEAR MEMORY function displays the Clear Memory

Screen from where all saved data can be erased (refer to Section 4.24).

Front Panel Key Functions:

– Move cursor (z) up

– Move cursor (z) down

– Display the data saved at the chosen memory location

– Go to Combustion Test Screen

– Go to Temperature Setup Screen, or the

Memory To PC Screen for Advanced units

Instruction 24-9351

4-13

Page 30

Operation

PCA

4.1 1 Memory to PC Screen

(For ‘Advanced’ PCA Models 40, 45, 50, 55, 60 & 65)

MEMORY TO PC

«TRANSMIT DATA

CLEAR MEMORY

The Memory To PC Screen is displayed by repeatedly pressing the MENU key

from the Combustion Test Screen. Use this screen to either transmit all

stored memory locations to a computer, or clear all memory locations.

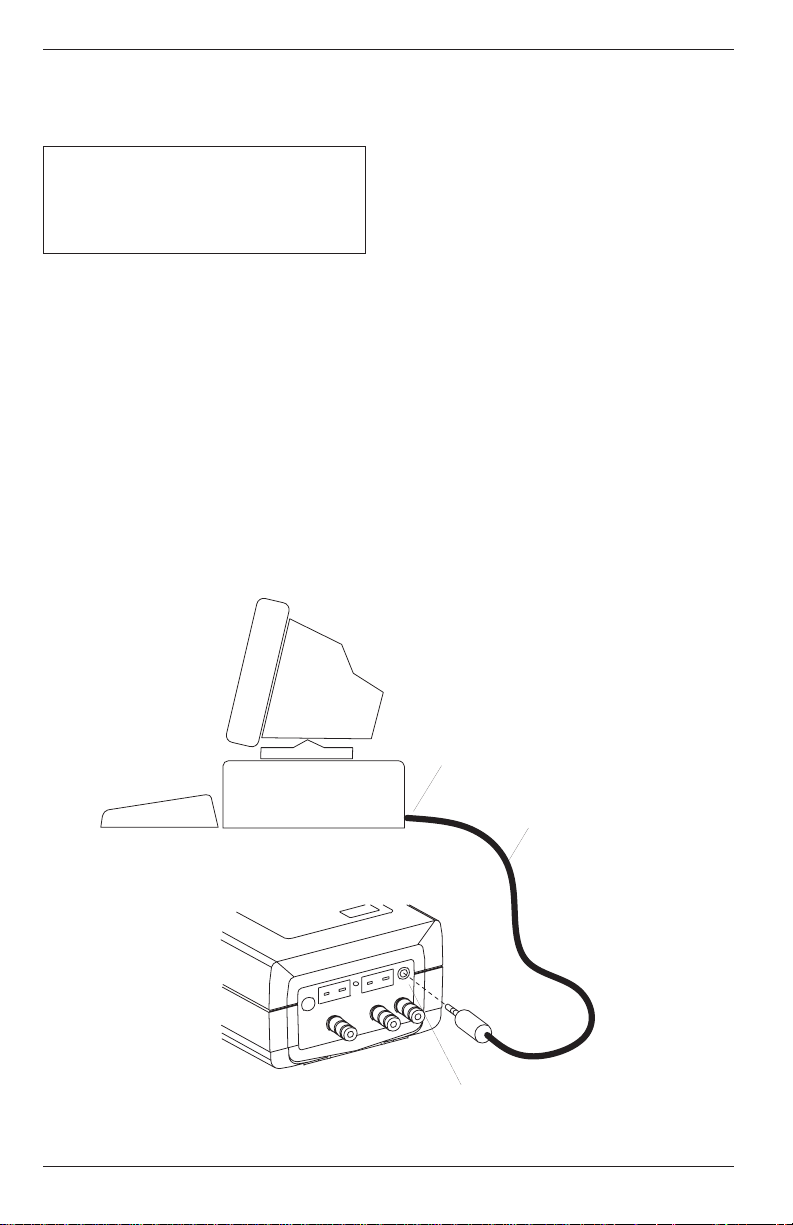

TRANSMIT DATA

Before data can be transmitted to a personal computer, the PCA’s RS-232

output must first be connected to an unused COM port on the computer

using serial data cable Part No. 24-1073 (see Figure 4-4). Also, a communications program (i.e., ProcommPlus®, Windows 3.x Terminal, or Windows 9x Hyper Terminal) must be installed, and its communications

parameters configured for: 9600 baud, 8 data bits, 1 stop bit, no parity,

and no handshaking.

4-14

A t t a c h D B 9 C o n n e c t o r t o c o m p u t e r ' s

C O M 1 o r C O M 2 p o r t . I f n e c e s s a r y ,

u s e a 2 5 - p i n t o 9 - p i n a d a p t e r .

S e r i a l D a t a C a b l e

P a r t N o . 2 4 - 1 0 7 3

T - A I R

R E S E T

T - S T A C K

P O W E R

G A S

R S - 2 3 2 C o n n e c t o r

Figure 4-4. Connecting the Serial Data Cable

Instruction 24-9351

Page 31

PCA

Operation

Data is transmitted to a computer in ASCII comma-delimited format,

which can be captured as a text file and then opened in most commercially available spreadsheet programs. Note that each data record consists of 20 fields, some of which may be blank for different tests and PCA

models as listed in Tables 4-1 & 4-2.

Use the communication software to capture and save the received data as

an ASCII text file. Consult the software’s documentation for detailed

instructions on how to perform this procedure.

To start transmitting data, first use the st keys to position the cursor (z)

in front of TRANSMIT DATA and then press the key. Observe that

as PCA downloads its data, the word TRANSMITTING appears on the

display.

CLEAR MEMORY

To clear all memory locations, first use the st keys to position the cursor

(z) in front of CLEAR MEMORY and then press the key. The Clear

Memory Screen will then appear from where all saved data can be erased

(refer to Section 4.24).

Front Panel Key Functions:

– Toggle cursor (z) position

– Toggle cursor (z) position

– Select function next to cursor

– Go to Combustion Test Screen

– Go to ID Setup Screen

Instruction 24-9351

4-15

Page 32

Operation

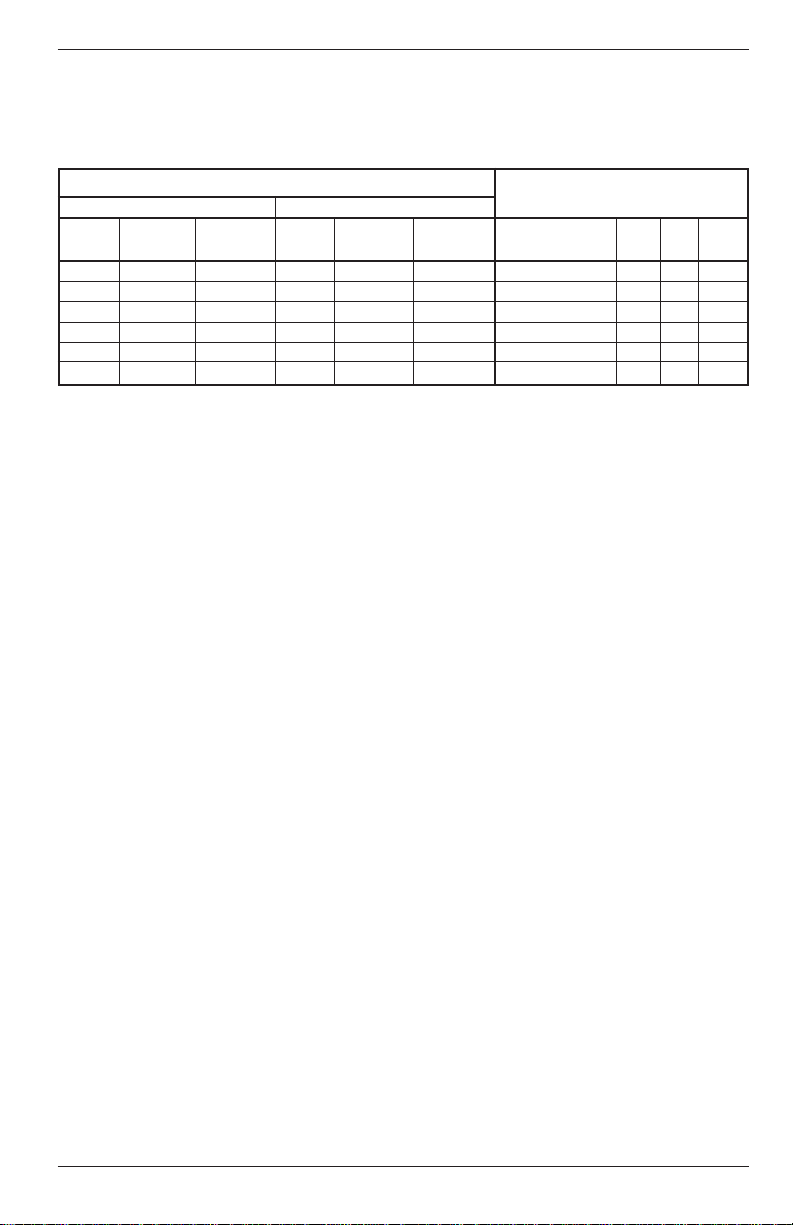

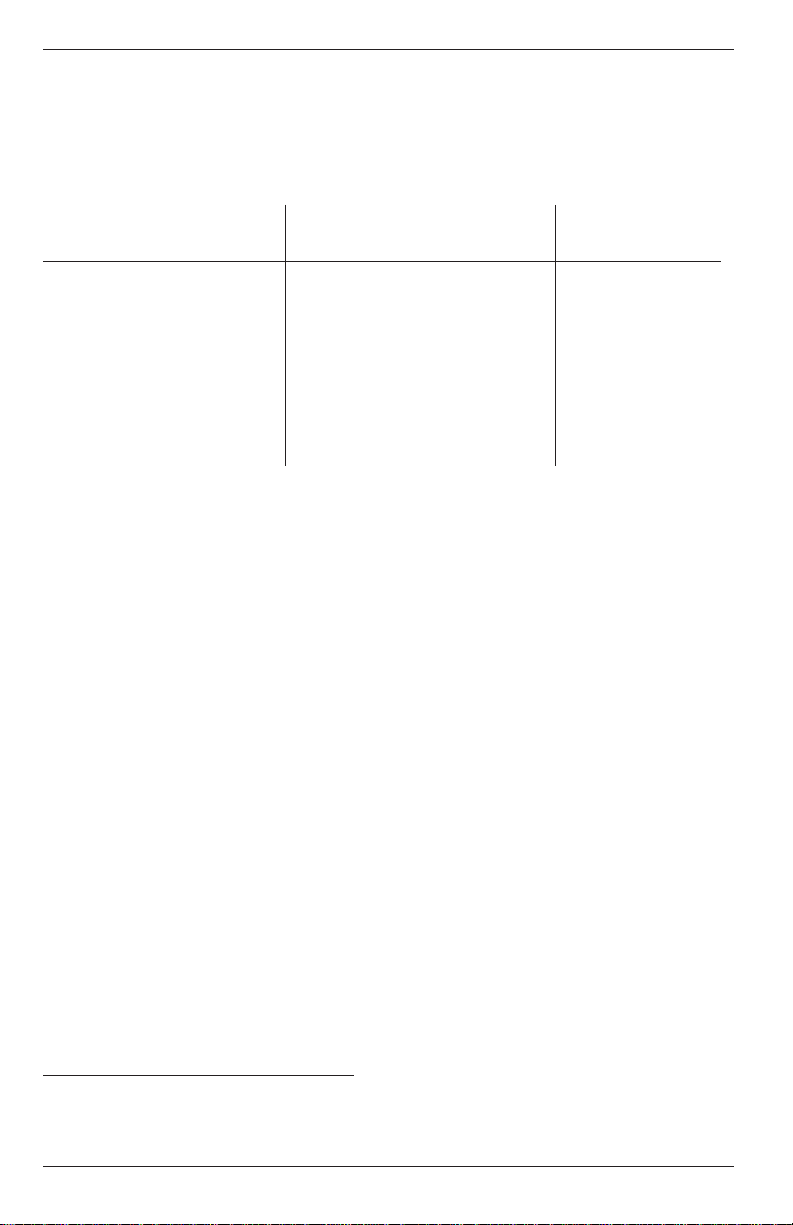

TABLE 4-1. COMMA-DELIMITED FIELDS

Field Data Name or Value Label in Column

Headings

1 Instrument serial number SN

2 ID line 1 (up to 16 characters) ID1

3 ID line 2 (up to 16 characters) ID2

4 ID line 3 (up to 16 characters) ID3

5 Time of test (hh:mm:ss) TIME

6 Date of test (dd.mm.yyyy) DATE

1

7

8

9

10

11

12

13

14

15

16

17

18

1

1

1

1

1

1,2

1,2

1,3

1,3

1

1

Name of fuel (up to 16 characters) FUEL

Flue gas temperature TA

Air temperature TL

Temperature unit of measure (F or C) C/F

O

concentration in % O2

2

CO2 concentration in % C2

CO concentration in ppm CO

CO referenced to 0% O2 in ppm CU

NO concentration in ppm NX

NO referenced to 0% O2 in ppm NU

qA in % qA

Lambda LA

19 Draft measurement DR

20 Draft unit of measure MB/PA/WC

1

Empty data field for draft tests

2

Empty data field for PCA Models 40 and 45

3

Empty data field for PCA Models 40, 45, 50, and 55

PCA

TABLE 4-2. TYPICAL SPREADSHEET FOR A PCA 65

SN ID1 ID2 ID3 TIME DATE FUEL TA TL C/F O2

AX1020 ID LINE 1 ID LINE 2 ID LINE 3 9:03:27 19.01.1999 NATGAS 190 20 C 4

AX1020 ID LINE 1 ID LINE 2 ID LINE 3 9:10:35 19.01.1999

C2 CO CU NX NU qA LA DR MB/PA/WC

9.5 12 15 10 12 8.1 1.24 -0.25 MB

-0.25 MB

Line 1: Column Headings

Line 2: Typical Combustion Readings

Line 3: Typical Draft Reading

4-16

Instruction 24-9351

Page 33

PCA

Operation

4.12 ID Setup Screens

(For ‘Advanced’ PCA Models 40, 45, 50, 55, 60 & 65)

SETUP

«ID #1

ID #2

ID #3

This initial ID Setup Screen is displayed by repeatedly pressing the MENU

key from the Combustion Test Screen. Use this screen to edit three lines

of customer information (i.e., the customer’s name, location, and burner

reference number).

Each ID line can be up to 16 alphanumerical characters in length. All

three lines will appear at the top of each test record for the purpose of

identifying individual tests.

Front Panel Key Functions for the Initial ID SETUP Screen:

– Move cursor (z) upward

– Move cursor (z) downward

– Select ID Number that is next to the cursor for editing

– Go to Combustion Test Screen

– Go to Temperature Setup Screen

To enter a line of text, first use the st keys to position the cursor (z) in

front of the desired ID line; then press . The selected ID Line Number

Screen will then appear.

SETUP

ID #1

«

Now press the st keys until the desired letter or number is displayed.

Available characters include:

“(space)ABCDEFGHIJKLMNOPQRSTUVWXYZüäöß0123456789”

Instruction 24-9351

4-17

Page 34

Operation

PCA

Press to save the selected character and advance to the next position.

If you make a mistake, press until the cursor is over the incorrect

character and make your correction by again using the st keys. After all

the desired characters have been selected, press the key to save the

text line and return to the initial ID SETUP Screen.

NOTE: The entered ID information will be saved with all

future memory records until it is modified or deleted.

Front Panel Key Functions for the Individual ID SETUP Screens:

– Increment character

– Decrement character

– Select the displayed character and advance to the next

character position

– Save the text line and return to the initial ID SETUP Screen

– Abort any changes to the text line and return to the initial

ID SETUP Screen

4-18

Instruction 24-9351

Page 35

PCA

Operation

4.13 Temperature Setup Screen

SETUP

TEMPERATURE UNIT «°C

°F

The Temperature Setup Screen is displayed by repeatedly pressing the

MENU key from the Combustion Test Screen. Use this screen to setup the

analyzer to display temperature in either °C or °F.

To select the instrument’s temperature unit-of-measure, first use the st

keys to move the cursor (z) in front of °C or °F, and then press the

key.

Front Panel Key Functions:

– Move cursor (z) up

– Move cursor (z) down

– Select temperature unit of measure next to cursor

– Go to Combustion Test Screen

– Go to Draft Unit Setup Screen

Instruction 24-9351

4-19

Page 36

Operation

PCA

4.14 Draft Unit Setup Screen

SETUP

DRAFT UNIT «MB

PA

WC

The Draft Unit Setup Screen is displayed by repeatedly pressing the

MENU key from the Combustion Test Screen. Use this screen to setup the

analyzer to display draft in either millibars (MB), Pascals (PA), or inchesof-water column (WC).

To select the draft unit-of-measure, first use the st keys to move the

cursor (z) in front of MB, PA or WC, and then press the key.

Front Panel Key Functions:

– Move cursor (z) up

– Move cursor (z) down

4-20

– Select draft unit of measure

– Go to Combustion Test Screen

– Go to Language Setup Screen

Instruction 24-9351

Page 37

PCA

Operation

4.15 Language Setup Screen

SETUP SETUP

LANGUAGE DAN NED LANGUAGE DEU FRA

DEU SVE «ENG ITA

«ENG FIN ESP POL

The Language Setup Screen is displayed by repeatedly pressing the MENU

key from the Combustion Test Screen. Use this screen to select the

language displayed on the analyzer. The languages available for selection

include: Danish, German, English, Dutch, Swedish and Finnish; or

German, English, Spanish, French, Italian and Polish. The languages

displayed depend on the model of the analyzer (refer to Table 1-1).

To select a language, first use the st keys to move the cursor (z) in front

of the desired language, and then press the key.

Front Panel Key Functions:

– Move cursor (z) up

- OR -

– Move cursor (z) down

– Select Language

– Go to Combustion Test Screen

– Go to Display Mode Setup Screen

Instruction 24-9351

4-21

Page 38

Operation

PCA

4.16 Display Mode Setup Screen

(For PCA Models 30, 35, 60 & 65)

SETUP

DISPLAY «CO NX

CU NU

The Display Setup Screen is displayed by repeatedly pressing the MENU

key from the Combustion Test Screen. Use this screen to select whether

the Combustion Test Screen will display the measured values of Carbon

Monoxide and Nitric Oxide (CO and NX), or the calculated values of these

gases (CU and NU) referenced to 0% Oxygen.

To setup the display, first use the st keys to move the cursor (z) in front

of either CO NX (measured values), or CU NU (calculated values), and

then press the key.

Front Panel Key Functions:

– Move cursor (z) up

4-22

– Move cursor (z) down

– Select Display Mode

– Go to Combustion Test Screen

– Go to Time/Date Setup Screen

Instruction 24-9351

Page 39

PCA

Operation

4.17 Time/Date Setup Screen

SETUP

«TIME 15:45:06

DATE 31.10.01

The Time/Date Setup Screen is displayed by repeatedly pressing the

MENU key from the Combustion Test Screen. Use this screen to enter the

current time and date.

To enter the correct time or date, first use the st keys to move the

cursor (z) in front of the function you wish to change. Each position in the

TIME or DATE number fields can then be changed by first pressing the

key to move the cursor into the desired position, then pressing the st

keys to increase or decrease the value. Pressing moves the cursor to

the next position in the number field. Each individual position can be

edited in the same manner. Once the time or date values have been

entered, press to save the values and return the cursor to the left side

of the screen.

Front Panel Key Functions:

– Move cursor (z) up, or Increase value in number fields

– Move cursor (z) down, or Decrease value in number fields

– Select Time or Date to be changed, or move cursor (z) to next

position in the number field

– Go to the Combustion Test Screen, or save the time and date

values and return the cursor to the left side of the display

– Go to Printer Setup Screen

Instruction 24-9351

4-23

Page 40

Operation

PCA

4.18 Printer Setup Screen

SETUP

«IR - HP PRINTER

IR - IRDA

RS232

The Printer Setup Screen is displayed by repeatedly pressing the MENU

key from the Combustion Test Screen. Use this screen to choose the type

of connection and printer being used.

IR-HP: Infrared connection to a printer manufactured by Hewlett

Packard, which uses their proprietary infrared communications protocol

IR-IRDA: Infrared connection to a printer that uses a standard IrDA

protocol

RS232: Cable connection between the PCA and any serial printer

capable of 9600 baud operation

Use the st keys to move the cursor (z) in front of the desired connection

and printer, and then press the key to make the selection and return

to the Combustion Test Screen.

Front Panel Key Functions:

– Move cursor (z) up

– Move cursor (z) down

– Select connection and printer next to cursor

– Go to Combustion Test Screen

– Go to Maintenance Password Screen

4-24

Instruction 24-9351

Page 41

PCA

Operation

4.19 Maintenance Password Screen

MAINTENANCE

«PASSWORD XXX

Where: xxx = Password number

The Maintenance Password Screen is displayed by repeatedly pressing

the MENU key from the Combustion Test Screen. From here a three-digit

password must be entered to access the instrument’s Maintenance

Screens. The password number is provided on the Portable Combustion

Analyzer Calibration Password card that was supplied with the analyzer.

To enter the password, first press the key to move the cursor (z) into

the first number field, and then press the st keys until the first digit of

the password is displayed. Press to advance to the next number field

and enter the second digit. Perform the same sequence a third time to

complete the password. Press the key after the correct password is

entered to display the Maintenance Screen.

Front Panel Key Functions:

– No action, or increase value in password number field

– No action, or decrease value in password number field

– Move cursor (z) to next position in password number field

– Go to Combustion Test Screen (if cursor is on left side of

screen), or go to Maintenance Screen (if the proper password

was entered), or return cursor to left side of screen (if the

wrong password was entered)

– Go to Combustion Test Screen (if cursor is on left side of

screen), or return cursor to left side of screen (if cursor is in

the password number field)

Instruction 24-9351

4-25

Page 42

Operation

PCA

4.20 Maintenance Screen

MAINTENANCE

«CALIBRATION

USER NAME

The Maintenance Screen is displayed after entering the correct password

in the Maintenance Password Screen (Section 4.19). Use this screen to

enter either the analyzer’s Calibration Screen or User Name Screen.

To enter the Calibration Screen, first use the st keys to position the

cursor (z) in front of CALIBRATION, and then press the key.

NOTE: Section 5.0 contains detailed calibration procedures.

To enter the User Name Screen, first use the st keys to position the

cursor (z) in front of USER NAME, and then press the key.

Front Panel Key Functions:

– Toggle cursor (z) position

4-26

– Toggle cursor (z) position

– Select function next to cursor

– Go to Combustion Test Screen

– No action

Instruction 24-9351

Page 43

PCA

Operation

4.21 User Name Screens

USER NAME

«LINE 1

LINE 2

LINE 3

This initial User Name Screen is displayed after selecting USER NAME

from the Maintenance Screen (Section 4.20). Use this screen to either

enter or edit three lines of user-name information.

Each user-name line can be up to 20 alphanumerical characters in length.

All three lines will appear at the top of each printout for the purpose of

identifying the user or owner of the instrument (i.e., your company’s

name and address).

Front Panel Key Functions for Initial User Name Screen:

– Move cursor (z) upward

– Move cursor (z) downward

– Select Line Number that is next to the cursor for editing

– Go to Combustion Test Screen

– Return to Maintenance Screen

To enter text, first use the st keys to position the cursor (z) in front of

the desired line number; then press . The selected User Name Line

Number Screen will then appear.

USER NAME

LINE 1

«

Now press the st keys until the desired letter or number is displayed.

Available characters include:

“(space)ABCDEFGHIJKLMNOPQRSTUVWXYZüäöß0123456789”

Instruction 24-9351

4-27

Page 44

Operation

Press to save the selected character and advance to the next position.

If you make a mistake, press until the cursor is over the wrong character and make your correction by again using the st keys.

After all the desired characters have been selected, press to save the

text line and return to the initial User Name Screen.

Front Panel Key Functions for Individual User Name Screens:

– Increment character

– Decrement character

– Select the displayed character and advance to the next

character position

– Save the text line and return to the initial User Name Screen

– Abort any changes to the text line and return to the initial

User Name Screen

PCA

4.22 Saving Test Data

O2 4.0 CO 12 HLD DRAFT

C2 9.5 CU 15 NG DRAFT – 0.25 MB

TL 20.0 TA 190 P HOT SPOT 190 °C P

qA 8.1 LA 1.24 «S «S

To save the data displayed in either the Combustion Test or Draft

Screens, first use the st keys to move the cursor (z) in front of the save

(S) function and then press the key. The data will be saved in

memory, and can be recalled at any time from the Memory Directory

Screen (Section 4.10).

NOTE: Data will be automatically stored in the next free

memory location. After all memory locations are filled, any

additional data that is saved will start overwriting previously saved data starting at the first memory location.

4-28

Instruction 24-9351

Page 45

PCA

0

0 I

Operation

4.23 Printing Test Data

O2 4.0 CO 12 HLD DRAFT

C2 9.5 CU 15 NG DRAFT – 0.25 MB

TL 20.0 TA 190 «P HOT SPOT 190 °C «P

qA 8.1 LA 1.24 S S

Before printing, ensure that the correct

connection and printer has been selected per

Section 4.18.

The Print function is available in either the

Combustion Test Screen or the Draft Screen*.

NOTE: The data which is stored in

memory can also be printed. First go to

the Memory Directory Screen (Section

4.10) and display the data to be printed;

then print the data as described below.

When using an infrared printer:

1. Place analyzer in-line with the printer’s

IR input (see Figure 4-5).

6 0 °

m a x .

4 5 c m

( 1 8 i n . )

m a x .

2. Use the st keys to move the cursor (z) in

front of the print (P) function.

3. Press the key to start printing.

* The HOT SPOT line shown in the Draft

Screen does not appear on the printout.

Instruction 24-9351

M E N U

P C A

Figure 4-5. Aligning the Printer

4-29

Page 46

Operation

When using a serial printer:

1. First connect the analyzer to the printer using the optional RS-232

cable (see Figure 4-6).

2. Set the printer’s communication parameters to 9600 baud, 8 data bits,

1 stop bit, no parity, and no handshaking.

3. Use the st keys to move the cursor (z) in front of the print (P)

function.

4. Press the key to start printing.

A t t a c h D B 9 C o n n e c t o r t o p r i n t e r ' s

s e r i a l i n p u t p o r t . I f n e c e s s a r y ,

u s e a 2 5 - p i n t o 9 - p i n a d a p t e r .

PCA

4-30

S e r i a l D a t a C a b l e

P a r t N o . 2 4 - 1 0 7 3

T - A I R

R E S E T

T - S T A C K

P O W E R

G A S

R S - 2 3 2 C o n n e c t o r

Figure 4-6. Connecting a Serial Printer to the Analyzer

Instruction 24-9351

Page 47

PCA

Operation

4.24 Clear Memory Screen

CLEAR MEMORY

C

«E

The Clear Memory Screen is accessed from either the Memory Directory

Screen (Section 4.10) or the Memory to PC Screen (Section 4.11).

To clear all memory locations, use the st keys to place the cursor (z) in

front of the clear (C) function, and then press the key.

To return to the previous screen without clearing any memory locations, use

the st keys to place the cursor (z) in front of the exit (E) function; then

press .

4.25 Resetting the Microprocessor

If the analyzer “locks-up” and cannot be turned OFF, reset the microprocessor by pressing the RESET button (Figure 4-7). The button can be

activated using the end of a paper clip.

Instruction 24-9351

RESET

BUTTON

T - A I R

R E S E T

T - S T A C K

P O W E R

G A S

Figure 4-7. Reset Button

4-31

Page 48

Operation

PCA

NOTES:

4-32

Instruction 24-9351

Page 49

PCA

Calibration

5.0 CALIBRATION

NOTE: Bacharach recommends that the PCA be calibrated

by your nearest Bacharach Service Center. Calibration,

however, can be performed in the field if your facility has the

necessary equipment and qualified personnel to perform the

procedures described in the sections that follow.

IMPORTANT! To prevent the loss of data during calibration, perform the following procedures with fresh batteries, or

using an optional Power Supply (see Section 3.2).

5.1 Sensor Check

IMPORTANT! Before turning on the analyzer or performing any of the calibration procedures, ensure that the analyzer will be sampling fresh air, and that the probe is at

room temperature.

When the analyzer is first turned on and allowed to cycle through its

60 second warmup period, and while sampling fresh air, the sensors are

checked (read) and calibrated (set) to the following ambient conditions:

• Oxygen sensor is spanned to 20.9%

• Carbon Monoxide sensor (if installed) is zeroed

• Nitric Oxide sensor (if installed) is zeroed

• Pressure sensor (if installed) is zeroed

Instruction 24-9351

5-1

Page 50

Calibration

PCA

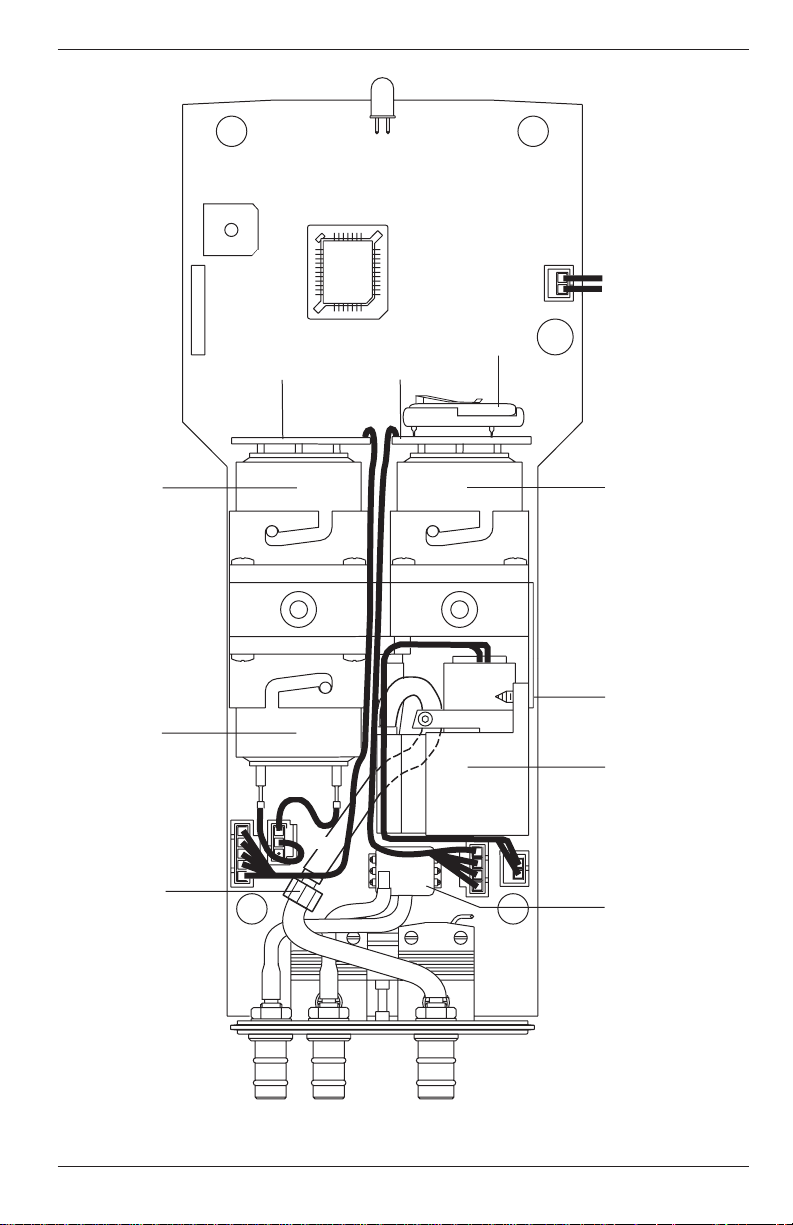

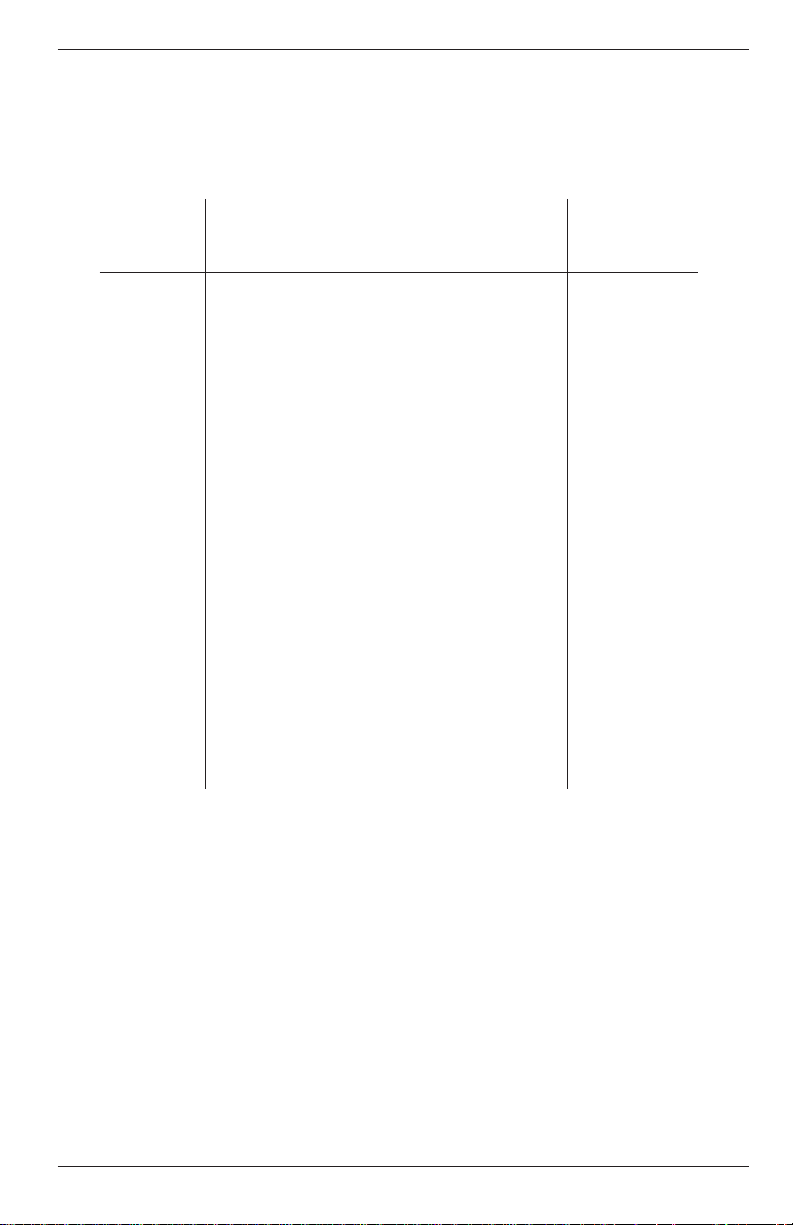

5.2 Calibration Fixtures

A gas and a draft fixture will be required to perform the various calibration procedures described in this manual.

Material Required:

• Calibration Kit (Refer to Section 8.2)

• Calibration Gas Cylinder (Refer to Section 8.2)

• Bellows

• Micromanometer

Procedure:

Assemble the appropriate fixture, shown in Figure 5-1, as required by the

calibration procedure being performed.

GAS

FIXTURE

DRAFT

FIXTURE

Leave Top

Port Open

23 4 5

1

3

Parts Shown:

1. Gas Cylinder

2. Regulator*

3. Tubing*

4. Tee*

5. Flowmeter*

6. Fitting, Gas*

7. Fitting, Draft*

* Contained in Calibration Kit

M E N U

P C A

7

Micromanometer

3

3

M E N U

P C A

6

4

3

Bellows

5-2

Figure 5-1. Calibration Fixtures

Instruction 24-9351

Page 51

PCA

Calibration

5.3 Calibrate Menu Screen

«TA-ZERO CALIBRATE

TA-SPAN NX

TL-ZERO CO

TL-SPAN DRAFT

The Calibrate Menu Screen is displayed after entering the correct password in the Maintenance Password Screen (Section 4.19) and selecting

CALIBRATION from the Maintenance Screen (Section 4.20). Use this

screen to select the sensor to be calibrated.

Press the st keys until the cursor (z) is in front of the desired function,

and then press the key.

NOTE: TA is the stack temperature sensor, while TL is the

optional Room Air/Primary Air temperature sensor.

NOTE: If a sensor is not installed (i.e., the instrument does

not have a Nitric Oxide sensor or thermocouple simulator

installed), the corresponding calibration screen will not be

displayed.

Front Panel Key Functions:

– Move cursor (z) up

– Move cursor (z) down

– Select sensor to be calibrated

– Go to Combustion Test Screen

– Return to Maintenance Screen

Instruction 24-9351

5-3

Page 52

Calibration

5.4 Calibrate TA-Zero

Material Required:

• Thermocouple Simulator (K-type) Range: 0 to 300°C

Accuracy: ±0.3°C

Procedure:

1. With the analyzer turned off, first plug the simulator's K-type connector into the T-STACK jack (Figure 3-2); then turn on the analyzer and

wait for its warmup cycle to complete.

2. Enter the Calibration Menu Screen per Section 5.3; then choose

TA-ZERO to zero the analyzer’s stack temperature channel.

3. Adjust the simulator to 0° C (32° F).*

4. Wait until the MEASURED reading on the screen stabilizes. Then use

the st and keys to enter an APPLIED value that equals 0 °C

(32 °F).

PCA

Typical Calibrate TA-Zero Screen During Calibration Procedure:

CALIBRATE TA-ZERO

MEASURED 3.0°C

APPLIED 0000.0°C

4. Press the key to calibrate the analyzer’s MEASURED value to

that of the APPLIED value. At this time the Calibrate Menu Screen is

redisplayed.

* The calibration range for this screen is 0 – 5 °C (32 – 41°F). Any

attempt to calibrate outside this range will cause the analyzer to

display an error message.

5-4

Instruction 24-9351

Page 53

PCA

Calibration

5.5 Calibrate TA-Span

Material Required:

• Thermocouple Simulator (K-type) Range: 0 to 300°C

Accuracy: ±0.3°C

Procedure:

1. With the analyzer turned off, first plug the simulator's K-type connector into the T-STACK jack (Figure 3-2); then turn on the analyzer and

wait for its warmup cycle to complete.

2. Enter the Calibration Menu Screen per Section 5.3; then choose

TA-SPAN to span the analyzer’s stack temperature channel.

3. Set the simulator to 300° C (572° F).*

4. Wait until the MEASURED reading on the screen stabilizes. Then use

the st and keys to enter an APPLIED value that equals 300 °C

(572 °F).

Typical Calibrate TA-Span Screen During Calibration Procedure:

CALIBRATE TA-SPAN

MEASURED 295.0°C

APPLIED 0300.0°C

4. Press the key to calibrate the analyzer’s MEASURED value to

that of the APPLIED value. At this time the Calibrate Menu Screen is

redisplayed.

* The calibration range for this screen is 270 – 330 °C (518 – 626 °F).

Any attempt to calibrate outside this range will cause the analyzer to

display an error message.

Instruction 24-9351

5-5

Page 54

Calibration

5.6 Calibrate TL-Zero

Material Required:

• Thermocouple Simulator (K-type) Range: 0 to 300°C

Accuracy: ±0.3°C

Procedure:

1. With the analyzer turned off, first plug the simulator’s K-type connector into the T-AIR jack (Figure 3-2); then turn on the analyzer and

wait for its warmup cycle to complete.

2. Enter the Calibration Menu Screen per Section 5.3; then choose

TL-ZERO to zero the analyzer’s room-air/primary-air temperature

channel.

3. Set the simulator to 0 °C (32 °F).*

4. Wait until the MEASURED reading on the screen stabilizes. Then use

the st and keys to enter an APPLIED value that equals 0 °C

(32 °F).

PCA

Typical Calibrate TL-Zero Screen During Calibration Procedure:

CALIBRATE TL-ZERO

MEASURED 3.0°C

APPLIED 0000.0°C

4. Press the key to calibrate the analyzer’s MEASURED value to

that of the APPLIED value. At this time the Calibrate Menu Screen is

redisplayed.

* The calibration range for this screen is 0 – 5 °C (32 – 41 °F). Any

attempt to calibrate outside this range will cause the analyzer to

display an error message.

5-6

Instruction 24-9351

Page 55

PCA

Calibration

5.7 Calibrate TL-Span

Material Required:

• Thermocouple Simulator (K-type) Range: 0 to 300°C

Accuracy: ±0.3°C

Procedure:

1. With the analyzer turned off, first plug the simulator’s K-type connector into the T-AIR jack (Figure 3-2); then turn on the analyzer and

wait for its warmup cycle to complete.

2. Enter the Calibration Menu Screen per Section 5.3; then choose

TL-SPAN to span the analyzer’s room-air/primary-air temperature

channel.

3. Set the simulator to 100 °C (212 °F).*

4. Wait until the MEASURED reading on the screen stabilizes. Then use

the st and keys to enter an APPLIED value that equals 100 °C

(212 °F).

Typical Calibrate TL-Span Screen During Calibration Procedure:

CALIBRATE TL-SPAN

MEASURED 102.0°C

APPLIED 0100.0°C

4. Press the key to calibrate the analyzer’s MEASURED value to

that of the APPLIED value. At this time the Calibrate Menu Screen is

redisplayed.

* The calibration range for this screen is 90 – 110 °C (194 – 230 °F).

Any attempt to calibrate outside this range will cause the analyzer to

display an error message.

Instruction 24-9351

5-7

Page 56

Calibration

PCA

5.8 Calibrate NX

(For PCA Models 30, 35, 60 & 65)

The Nitric Oxide sensor needs to be spanned at regular intervals to

determine that it still meets its accuracy specification. Because of the

toxicity of Nitric Oxide gas, however, unless your facility has the necessary gas cylinders and personnel trained in the handling of toxic gases,

we recommend that the Nitric Oxide sensor be spanned by an authorized

Bacharach Service Center.

Material Required:

• Calibration Gas Fixture (Section 5.2)

• Gas Cylinder, 50 to 150 ppm Nitric Oxide with an analytical accuracy of

±1% (customer supplied)

Procedure:

1. Enter the Calibrate Menu Screen per Section 5.3. Then choose to

calibrate the NX sensor.

2. At the conclusion of Step 1 the pump should start running.

3. Using the Gas Fixture shown in Figure 5-1, attach the Nitric Oxide

calibration-gas cylinder to the analyzer’s GAS inlet.

4. Adjust the regulator of the calibration fixture for a flowmeter indication of approximately 2 SCFH.

5. Wait until the MEASURED reading on the screen stabilizes (approximately 3 minutes). Then use the st and keys to enter an

APPLIED value* that equals the concentration that is stamped on the

NX calibration-gas cylinder.

Typical Calibrate NX Screen During Calibration,

Using 100 ppm Nitric Oxide Calibration Gas:

CALIBRATE NX

MEASURED 092 PPM

APPLIED 0100 PPM

6. Press the key to calibrate the analyzer’s MEASURED value to

that of the APPLIED value. At this time the Calibrate Menu Screen is

redisplayed.

* The calibration range for this screen is 50 – 150 ppm. Any attempt to

calibrate outside range will cause the analyzer to display an error

message.

5-8

Instruction 24-9351

Page 57

PCA

Calibration

5.9 Calibrate CO

(For PCA Models 20, 25, 30, 35, 50, 55, 60 & 65)

Material Required:

• Calibration Gas Fixture (Section 5.2)

• Gas Cylinder, 500 ppm CO in air (Refer to Section 8.2)

• Gas Cylinder, CO (1000 ppm) and H2 (1000 ppm) in Nitrogen

(Refer to Section 8.2)

Procedure:

1. Enter the Calibrate Menu Screen per Section 5.3. Then choose to

calibrate the CO sensor.

2. At the conclusion of Step 1 the pump should start running.

3. Using the Gas Fixture shown in Figure 5-1, attach the CO calibrationgas cylinder to the analyzer’s GAS inlet.

4. Adjust the regulator of the calibration fixture for a flowmeter indication of approximately 2 SCFH.

5. Wait until the MEASURED reading on the screen stabilizes (approximately 3 minutes). Then use the st and keys to enter an

APPLIED value* that equals the concentration which is stamped on

the CO calibration-gas cylinder.

Typical CALIBRATE CO Screen During Calibration Procedure,

Using 500 ppm CO Calibration Gas: