Page 1

Refrigerant / Combustibles

Leak Detector

Instruction 0019-9211

Operation and Maintenance

Rev. 9 – November 2012

Pat. 6,362,741, D447,071

Product Leadership • Training • Service • Reliability

Page 2

The Informant™ 2

ii 0019-9211 Rev 9

Page 3

COMBUSTIBLE REFRIGERANT GAS WARNING: For your safety, DO

NOT use the Informant 2 with the refrigerant sensor to detect refrigerants

which are rated as combustible/flammable gases (e.g. ASHRAE - A2 or A3

rated refrigerants). Use with combustible/flammable refrigerant gases can

cause an explosion resulting in death or severe injury.

Register Your Warranty by Visiting

www.mybacharach.com

WARRANTY

The Informant™ 2

Bacharach, Inc. wa rrants to Buyer that at th e time of delivery this Product will be free from defects in

material and m anufacture and will conform substan tially to Bacharach Inc.’s applic able specifications.

Bacharach’s liabil ity and B uyer’s r emed y under thi s warrant y are limi ted to th e repair or replac ement, at

Bacharach’s opt ion, of t his Prod uct or parts t hereof returned to Sell er at the fact ory of m anufact ure and

shown to Bacharac h Inc.’ s r eas ona bl e sati sf ac tio n to have been defectiv e; pr ovided that written n otice of

the defect shall have bee n given by Buyer to Bacharac h Inc. wit hin one (1) year after the date of deliv ery

of this Product by Bacharach, Inc.

Bacharach, Inc. w arrants t o Buyer t hat it will c onve y good titl e to this P roduct . Bachar ach’s liabil ity an d

Buyer’s remedy under this warranty of title are limited to the removal of any title defects or, at the

election of Bacharach, to the replacement of this Product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF

(I) ANY AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT

LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE: A ND (II) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN

CONTRACT OR TORT, WHETHER OR NOT ARISING FROM BACHARACH’S NEGLIGENCE,

ACTUAL OR IMPLIED. The remedies of the Buyer shall be limited to those provided herein to the

exclusion of any and all other remedies including, without limitation incidental or consequential

damages. No agreem ent varying o r extending th e foregoing warranties, rem edies or this li mitation will

be binding upon Bacharach , Inc. unl es s in writi ng , sig ne d b y a duly auth orized officer of Bacharach.

Product improvements and enhancements are continuous, therefore the specifications and information

contained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages

in connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the

prior written consent of Bac h ar ach, Inc .

Copyright © 2000-2012, Bacharach, Inc., all rig hts res erv ed.

BACHARACH

Informant™ is a trademark of Bacharach, Inc. All other trademarks, trade names,

service marks and logos referenced herein belong to their respective companies.

®

is a registered trademark of Bacharach, Inc.

NOTICE

0019-9211 Rev 9 iii

Page 4

The Informant™ 2

TABLE OF CONTENTS

1. OVERVIEW ................................................................................................................ 1

1.1. Introduction ..................................................................................................... 1

1.2. Features ......................................................................................................... 2

1.3. Technical Characteristics ................................................................................ 3

2. OPERATION .............................................................................................................. 5

2.1. Battery Installation .......................................................................................... 5

2.2. Sensor Installation Overview........................................................................... 5

2.3. Refrigerant Sensor Installation ........................................................................ 6

2.4. Combustibles Sensor Installation .................................................................... 7

2.5. Turning the Detector On and Off ..................................................................... 7

2.6. Low Battery Indication .................................................................................... 8

2.7. Audible Indicator Mute .................................................................................... 8

2.8. Locating a Gas Leak ....................................................................................... 9

2.9. Sensor Failure Indication ...............................................................................10

2.10. False Refrigerant Indication ...........................................................................10

2.11. Refrigerant Sensor Flooding Indication ..........................................................11

2.12. SAE Refrigerant Leak Detection Tips .............................................................11

3. MAINTENANCE ....................................................................................................... 13

3.1. Introduction ....................................................................................................13

3.2. Routine Maintenance .....................................................................................13

3.3. Probe Filter Replacement ..............................................................................13

3.4. Sensor Replacement .....................................................................................14

3.5. Probe Assembly or Fan Replacement ............................................................15

4. TROUBLESHOOTING ............................................................................................. 19

5. PARTS AND SERVICE ............................................................................................ 21

5.1. Complete Kits ................................................................................................21

5.2. Optional Accessories .....................................................................................22

5.3. Replacement Parts ........................................................................................22

5.4. Sales/Service Centers ...................................................................................23

6. Declaration of Conformity ...................................................................................... 24

iv 0019-9211 Rev 9

Page 5

1. OVERVIEW

The Informant™ 2

1.1. Introduction

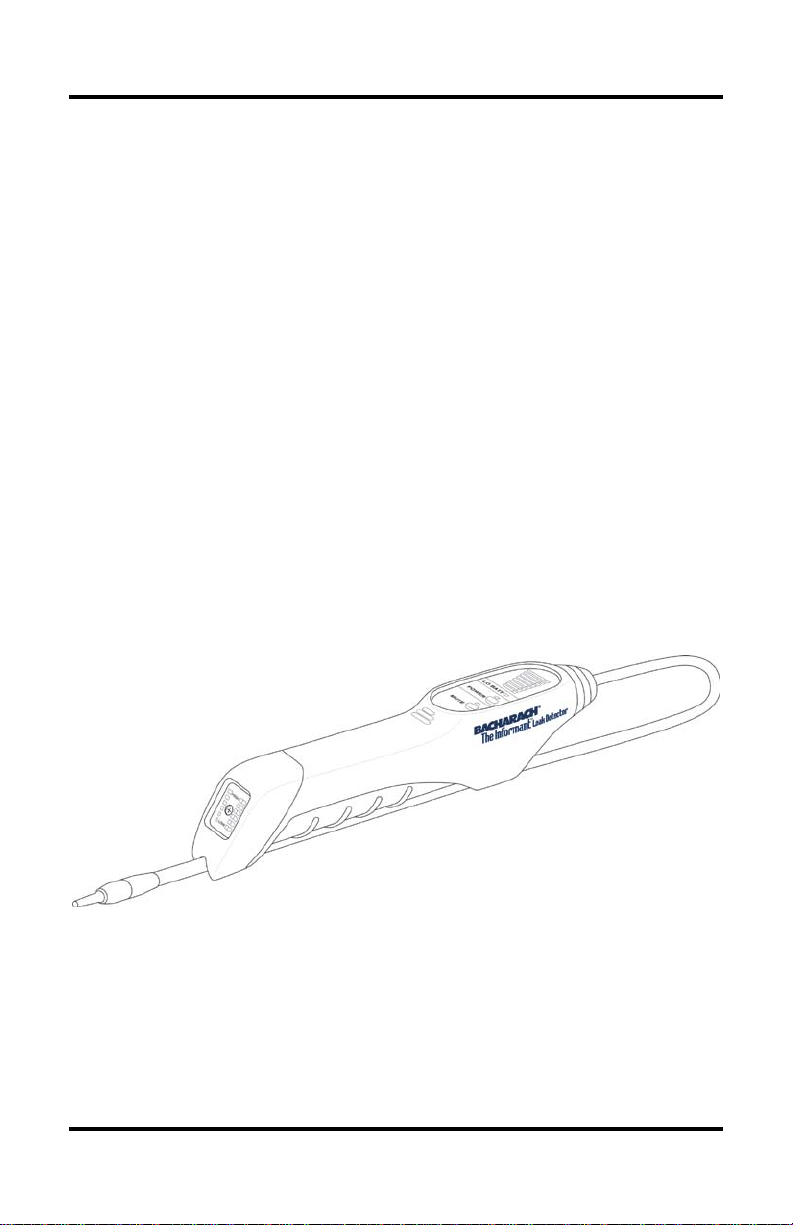

The Informant 2 Dual Refrigerant / Combustibles Leak Detector

(Figure 1) is a portable, battery power ed instrument design ed to pinpoint

the location of either ref r ige rant or c ombustible-gas leak s us ing s ep arate,

interchangeable sensors. The type of gas detected depends on the

sensor installed.

The detector is design ed to be qu ickly responsive, even when high levels

of background vapors or gases are present. No manual sensitivity

adjustments are necessary during the inspection process.

The Informant 2 is suitable for HVAC Service Technicians, Gas Utility

Personnel, Automotive Service Facilities, and Plant Maintenance

Departments who are in need of a small, lightweight and rugged

instrument that is ca pable of pinpointing sm all to large refrigerant leaks

as those found in air-conditioning units, and automobile engine

compartments, as well as locating combustible gas leaks in residential

appliances and furnaces, industrial heating units, and gas distribution

equipment.’

Figure 1. The Inform an t 2 Leak Detector

0019-9211 Rev 9 1

Page 6

The Informant™ 2

1.2. Features

Detects the presence of either refrigerants or combustible gases

•

(with appropriate sensor installed)

Sensors that represent the latest advancements in sensor

•

technology

Microprocessor-controlled circuitry that guarantees accuracy and

•

reliability

Dual bar-graph LEDs provide visual indication of the

•

refrigerant/combustibles level from a wide variety of viewing angles

Audible refrigerant/combustibles level indicator with mute feature

•

Flashing probe tip whose flash rate varies in accordance with

•

changes in the detected refrigerant/c ombustibles level

Automatic zero and background compensation that allows a leak to

•

be quickly found in contaminated atmospheres without requiring

manual sensitivity adjustments

Flexible probe that allow it to be either “docked” in its storage

•

position for close-up leak testing, or unfolded to its maximum length

of 20 inches (508 mm) for locating leaks in hard-to-reach areas

Long-life fan provides positive airflow past sensor resulting in a faster

•

response time

Filter in probe tip prevents water from reaching sensor

•

One-handed operation

•

No calibration required

•

Batteries included

•

Optional protective rubber boot, includes a cavity that

•

accommodates a Maglite

One year warranty

•

Extended warranty available

•

Made in U.S.A.

•

2 0019-9211 Rev 9

®

flashlight

Page 7

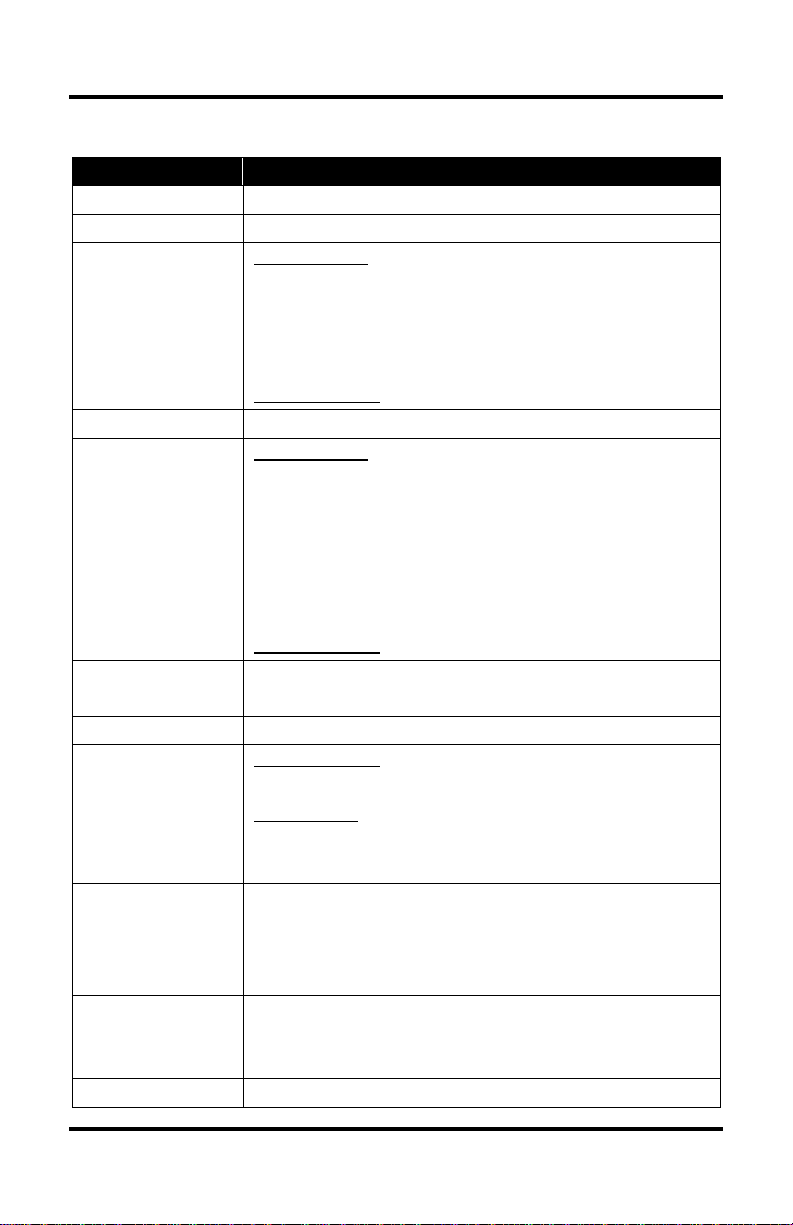

Specification

Description

Power

Four ‘AA’ Alkaline Batteries

Warm-Up Time

10 seconds

Gases

Refrigerants: All CFC, HCFC and HFC refrigerants

Response Time

0.2 seconds

Sensitivity

Refrigerants: 0.5 oz/year (14 g/yr) of R-134a

Sensitivity

Automatic

Battery Life

4–5 hours, under typical intermittent operation

Sensors

Combustibles: Semiconductor type with a typical

Probe

Flexible gooseneck, 20 inch (508 mm) maximum

Sampling

40 to 50 cc/min with sensor installed

Weight

0.86 lb (0.39 kg) w/ batteries

1.3. Technical Characteristics

The Informant™ 2

Detected

Adjustment

including: R-12, R-22, R-123, R-134a and blends

R-404A, R-408A, R-409A, and R-410A (i.e., any

refrigerant containing Chlorine, Fluorine or Bromine

gas).

Combustibles:

All combustible gases and vapors.

(hardest to detect refrigerant) as detected by

moving probe tip at 2" (50 mm) per second,

0.1" (3 mm) above leak source. A leak rate of less

than 0.25 oz/year (7 g/yr) can be detected when

probe tip is held steady over leak source for at

least 5 seconds.

Combustibles:

50 ppm Methane, minimum.

5 year life span, plug-in replacement.

Refrigerant:

Heated Diode type with a typical life

span of 150 hours or 1 year of normal use, plug-in

replacement.

length [reduces to 3 inches (76 mm) when wrapped

around instrument], includes integral sensor, filter,

and LED

System Flow

Rate

0019-9211 Rev 9 3

Page 8

The Informant™ 2

Specification

Description

Switches

Power ............................ Toggles detector ON/OFF

Size W×L×H

1.75 x 9.62 x 2.25 inches

Operating

Position ............................................................. Any

Visual and

Power On .............................................. Green LED

Approvals

CE Mark

Independently tested in accordance with EMC

Mute.................. Toggles audible indicator ON/OFF

(Excludes

44.50 x 244.30 x 57.20 mm

Probe)

Environment

Temperature .................... 32 to 122 °F (0 to 50 °C)

Humidity ............... 15 to 90% RH, non-condensing

Audible

Indicators

Low Battery .............................................. Red LED

Mute...................................................... Amber LED

Relative Gas Level:

The detector responds to increasing gas

levels by activating its visual and audib le

indicators as follows:

– Dual LED bar-graphs (located on

Visual

the top and rear of the detector) begin to

progressively glow in series. In addition,

an LED located in the probe tip begins to

increase its blink rate from an idle rate of

once-per-second.

Audible

– The audible indicator’s tick rate

begins to increase from its idle rate of

one-tick-per-second.

Sensor Failure ....................... The middle gas-level

LED glows steadily

Refrigerant: Listed in accordance to SAE J1627

Combustibles:

Lab certified to UL913, intrinsically

safe for use in Class I, Division 1, Group D

hazardous areas

Directive 2004/108/EC

4 0019-9211 Rev 9

Page 9

2. OPERATION

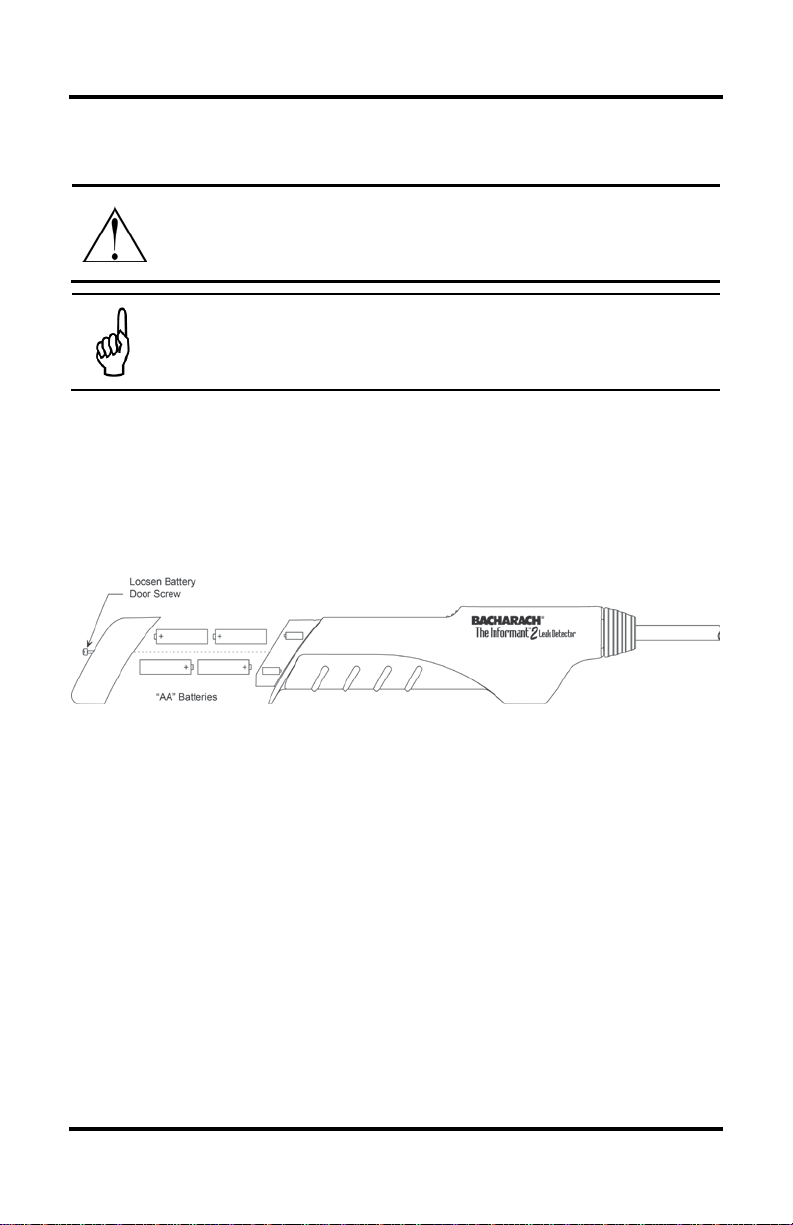

2.1. Battery Installation

The Informant™ 2

WARNING: Explosion hazard. To reduce the risk of igniting

a flammable atmosphere, batteries must only be changed in

an area known to be non-flammable.

NOTE: To maintain agency approval, use only the following

types of ‘AA’ batteries: Energizer E91; Duracell MN1500;

Rayovac 815; and Panasonic AM-3PI.

1. See Figure 2. Using a #1 Phillips screwdriver, first loosen the battery

door screw located at the rear of the detector; then remove the door.

2. Install four ‘AA’ alkaline batteries into the detector, observing the

polarity markings that are molded on the side of the case.

3. Reinstall the battery door and tighten its screw.

Figure 2. Battery Installation

2.2. Sensor Installation Overview

Before leak testing can begin, the appropriate sensor must be installed. If

you have a combustibles-only or refrigerant-only detector, then simply

install the sensor that was supplied with the detector. If, however, you

have a dual detector, then install the sensor that corresponds to the gas

that will be detected during the inspect ion proc es s.

For the detector to maintain agency approval, the blue probe tip must be

used with refrigerant sensor 0019-0510, while the red probe tip must be

used with combustibles sensor 0019-0499.

The color-coded probe tips allow an operator to easily identif y which

sensor is installed — “blue” for refrigerants, and “red” for combustibles.

0019-9211 Rev 9 5

Page 10

The Informant™ 2

NOTE: For dual detectors, the red probe tip will not screw onto a

probe that has a refrigerant sensor installed. This feature

safeguards against the possibility of an operator mistakenly thinking

that a detector with a refrigerant sensor is configured to detect

combustibles. See the WARNING below.

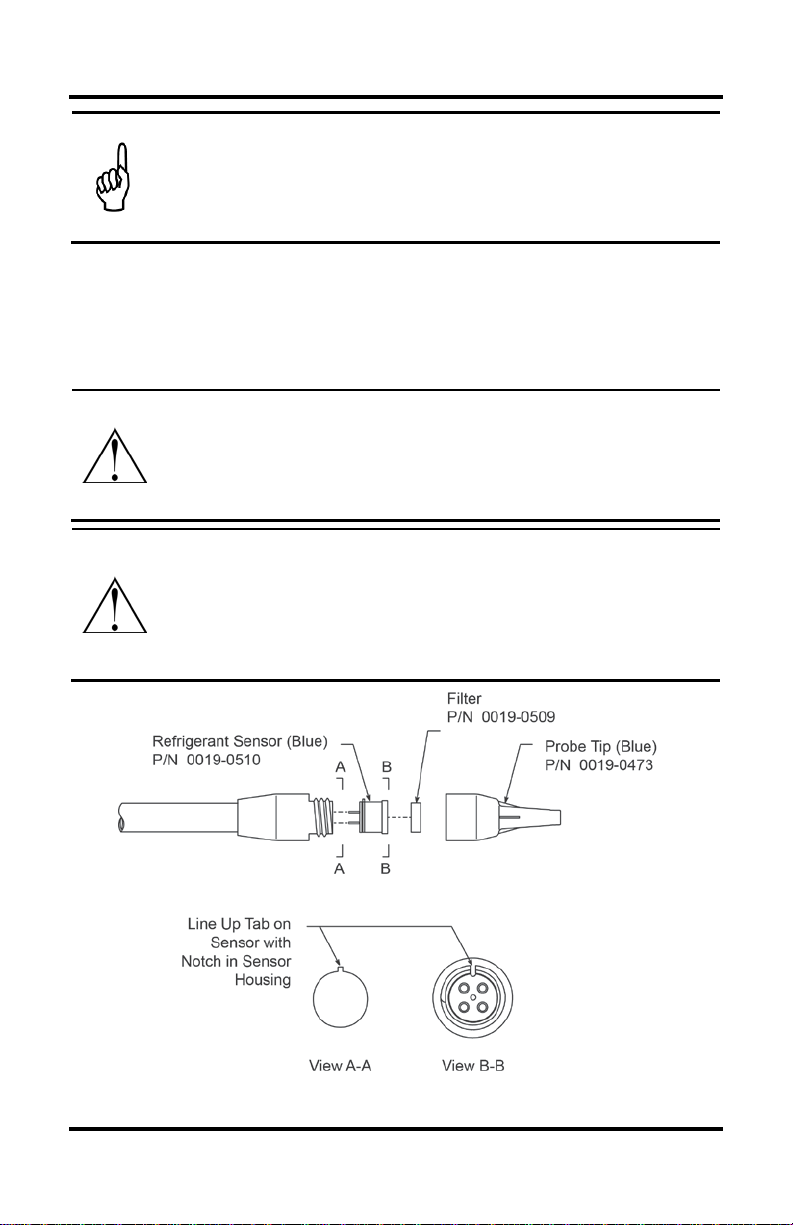

2.3. Refrigerant Sensor Installation

Install the refrigerant sensor, filter, and “blue” probe tip onto the end of

the detector’s flexible probe as shown in Figure 3a. Observe the blue

color coding on both the sensor and probe tip.

WARNING: Explosion hazard. DO NOT use the Informant 2 with

its refrigerant sensor installed in an area that is classified by the

National Electrical Code as being a hazardous location where a

potential for explosion or fire exist because of flammable gases or

vapors in the atmosphere.

COMBUSTIBLE REFRIGERANT GAS WARNING: For your

safety, DO NOT use the Informant 2 with the refrigerant sensor to

detect refrigerants which are rated as combustible/flammable

gases (e.g. ASHRAE - A2 or A3 rated refrigerants). Use with

combustible/flammable refrigerant gases can cause an explosion

resulting in death or severe injury.

Figure 3a. Sensor Inst allation (Refrigerant Sensor)

6 0019-9211 Rev 9

Page 11

2.4. Combustibles Sensor Installation

Install the combustibles sensor, filter, and “red” probe tip onto the end of

the detector’s flexible probe as shown in Figure 3b. Observe the red

color coding on both the sensor and probe tip.

The Informant™ 2

NOTE: The Informant 2 is intrinsically safe only when its

combustibles sensor is installed.

Figure 3b. Sensor Installation (Combustibles Sensor)

2.5. Turning the Detector On and Off

See Figure 4. The detector is toggled ON and OFF by pressing the

POWER

button.

When first turned on, observe that the Power LED glows and that all

other LEDs are tested by being turned on for 1 second.

The detector requires 10 seconds to warm up. After which time all LEDs

should be off except for the Power LED, along with the probe tip blinking

and audible indicator ticking at approximately once-per-second.

0019-9211 Rev 9 7

Page 12

The Informant™ 2

NOTE: During the warm-up period, the detector has zeroed

out any background concentration of vapors or gases that

were present in the area.

After the detector is turned on and allowed to warm up, it is ready to

perform leak testing as described in Section Procedure for Locating a

Gas Leak.

Figure 4. Controls and Indicators

2.6. Low Battery Indication

A low-battery condition is indicated when the

LO BATT

LED glows.

There will be approximately 20 minutes of full operation time remaining

from the time this LED first turns on; after which, the intensity of all LEDs

and audible output will graduall y dim inish.

When a low-battery indication occurs, replace the batteries as described

under the previous Section Battery Installation.

2.7. Audible Indicator Mute

The audible indicator’s ticking sound is toggled on and off by pressing

the

button. Observe that the

MUTE

button’s amber LED glows

MUTE

when the audible indicator is turned of f .

8 0019-9211 Rev 9

Page 13

2.8. Locating a Gas Leak

After the detector is turned on and allowed to warm up, observe that

none of the gas-level LEDs should be glowing. Also note that both the

probe tip should be blinking and the audible indicator ticking once per

second. All of these indicators show that the detector is currently not

detecting a change in gas concentration.

The Informant™ 2

IMPORTANT: The detector’s function is to detect a change

in gas levels, and not to make a quantitative measurement of

the level. The technique of locating a leak by detecting a

change in level allows an operator to quickly locate the

source of a leak without making manual sensitivity

adjustments, or being concerned about the background

vapor or gas level in the surrounding area.

Leak testing can be performed with the probe either “docked” in its

storage position for close-up leak testing, or unfolded to its maximum

length of 20 inches (508 mm) for locating leaks in hard-to-reach areas.

Begin leak testing by slowly moving the probe toward the area to be

tested. If surfaces are dirty or wet, wipe them off with a clean shop towel

to prevent the filter from clogging. Avoid allowing water to enter the

probe tip.

When the detector first “sees” an increased gas level, all gas-level LEDs

immediately glow along with the probe tip blinking and audible indicator

ticking at a very rapid rate. If movement of the probe is stopped for more

than 10 seconds, the detector’s automatic self-zero feature will cause all

gas-level LEDs to turn off, along with decreasing the blinking and tick ing

rate of the probe tip and audible indicator, respectively.

Once the presence of gas has been determined and the detector allowed

to self zero, moving the probe toward the source of the leak will once

again cause the detector to respond in a positive manner. After which, if

the probe is moved away from the leak source, the detector will respond

with a lower gas-level indication.

0019-9211 Rev 9 9

Page 14

The Informant™ 2

CAUTION:

When using the refrigerant sensor, note

Use the following general procedure to pinpoint the source of a leak:

1. Move the probe tip along the lines that are carrying gas and around

2. Continue moving in the same direction as long as the detector’s gas-

3. Once the source of the leak has been passed, the detector’s gas

2.9. Sensor Failure Indication

A sensor failure is indicated by the middle gas-level LED on both

displays glowing steady. Refer to the Troub les ho oti ng Guide Section of

this manual for information on how to clear this condition.

2.10. False Refrigerant Indication

False refrigerant indications are usually caused by abnormal changes in

sensor temperature. These temperature changes are typically due to a

sudden change in air flow past the sensor, or the sensor being heated by

an outside source. To avoid false refrigerant indications, DO NOT . . .

10 0019-9211 Rev 9

that exposing this sensor to a steady stream of highly

concentrated refrigerant will severely reduce sensor

life or damage the sensor. Sensor life is directly

proportional to the amount of refrigerant that passes

through the sensor.

As for the combustible sensor, exposing it to a high

concentration of combustible gas may temporarily make the

detector less responsive to lower gas levels. If this occurs,

move the detector to an area of fresh air for several minutes

to purge the sensor of gas.

the fittings until the detector responds in a positive manner.

level LEDs remain at full scale. This indicates that the gas

concentration is increasing.

level indicators will all begin to decrease. At this point, reverse the

direction of probing. As the probe tip is moved back and forth across

the leak, the detector will autom atically adjust its sensitivity to allow

the user to pinpoint its source.

allow the probe tip to become clogged with dirt,

•

allow the probe’s filter to become covered with water,

•

Page 15

use the detector in windy areas,

•

move the probe tip back and forth faster than 2" per second,

•

allow the probe tip to contact a hot surface.

•

2.11. Refrigerant Sensor Flooding Indication

When the refrigerant sensor becomes flooded with a high concentration

of gas, observe that t he ga s -level LEDs quickly light full scale and then

all turn off, leaving both the audible tick rate and probe tip blink rate at

elevated levels. When this condition occurs, move the detector to an

area of fresh air until all indicators return to their idle state.

The Informant™ 2

2.12. SAE Refrigerant Leak Detection Tips

The following was derived from SAE Surface Vehicle Standard J1628,

Technician Procedure for Using Electronic Refrigerant Leak Detectors for

Service of Mobile Air-Conditioning Systems:

• The electronic leak detector shall be operated in accordance with the

equipment manufacturer’s operating instructions.

• Leak test with the engine not in operation.

• The air conditioning system shall be charged with sufficient refrigerant

to have a gauge pressure of at least 340 kPa (49 psi) when not in

operation. At temperatures below 15 °C (59 °F), leaks may not be

measurable, since this pressure may not be reached.

• Take care not to contaminate the detector probe tip if the part being

tested is contaminated. If the part is particularly dirty, it should be

wiped off with a dry shop towel or blown off with shop air. No cleaners

or solvents shall be used, since many electronic detectors are sensitive

to their ingredients.

• Visually trace the entire refrigerant system, and look for signs of air-

conditioning lubricant leakage, damage, and corrosion on all lines,

hoses, and components. Each questionable area shall be carefully

checked with the detector probe, as well as all fittings, hose-to-line

couplings, refrigerant controls, service ports with caps in place, brazed

or welded areas, and areas around attachment points and hold-downs

on lines and components.

0019-9211 Rev 9 11

Page 16

The Informant™ 2

• Always follow the refrigerant system around in a continuous path so

that no areas of potential leaks are missed. If a leak is found, always

continue to test the remainder of the system.

• At each area checked, the probe shall be moved around the location,

at a rate no more than 25 to 50 mm/sec (1 to 2 in./sec), and no more

than 5 mm (0.2 inch) from the surface completely around the position.

Slower and closer movement of the probe greatly improves the

likelihood of finding a leak.

• An apparent leak shall be verified at least once by blowing shop air into

the area of the suspected leak, if necessary, and repeating the check

of the area. In cases of very large leaks, blowing out the area with

shop air often helps locate the exact position of the leak.

• Leak testing of the evaporator core while in the air conditioning module

shall be accomplished by turning the air conditioning blower on high for

a period of 15 seconds minimum, shutting it off, then waiting an

additional 15 seconds minimum for the refrigerant to accumulate in the

case, then inserting the leak detector probe into the blower resistor

block or condensate drain hole if no water is present, or into the

closest opening in the heating/ventilation/air conditioning case to the

evaporator, such as the heater duct or a vent duct. If the detector

activates, a leak apparently has been found.

• Following any service to the refrigerant system of the vehicle, and any

other service which disturbs the refrigerant system, a leak test of the

repair and of the service ports of the refrigerant system shall be done.

12 0019-9211 Rev 9

Page 17

3. MAINTENANCE

3.1. Introduction

The Informant™ 2

By following the procedures outlined below, The Informant 2 Leak

Detector will provide many years of trouble-free and dependable

operation.

3.2. Routine Maintenance

• Replace the batteries per Section Battery Installation when the

LO BATT

LED glows.

• Periodically check the detector’s sensitivity by exposing the sensor to a

source of its corresponding gas (either a refrigerant or combustible

gas). DO NOT, however, check the sensitivity of the refrigerant sensor

by cracking open a bottle of refrigerant or Schrader valve and exposing

the sensor to a stream of pure refrigerant. This will severely reduce

sensor life or damage the sensor.

• Routinely check the probe filter. A dirty filter will lengthen the detector’s

response time, or prevent the detection of gas if the filter has become

clogged with dirt or covered with water. A dirty filter will also short en

the life of a refrigerant sensor, as the result of not allowing enough air

to pass over the sensor to keep it cool. Replace a dirty or clogged filter

per Section Probe Filter Replacement.

• Keep the detector case and probe clean by wiping them with a shop

towel. If necessary, moisten the towel with a mild detergent solution.

Avoid using any type of solvents that may either attack the detector’s

ABS plastic case, or leave behind a hydrocarbon residue that may

desensitize the sensor.

3.3. Probe Filter Replacement

The probe filter is designed to keep dust, dirt, and water from entering

into the sensor area.

Replace the filter whenever it becomes clogged as evidenced by the

detector not responding in a positive manner to a known source of gas. If

the filter is covered with water, simply remove the filter and dry it off.

Replace the probe filter as follows (refer back to Figures 3a and 3b).

0019-9211 Rev 9 13

Page 18

The Informant™ 2

Material Required:

• Probe Filter (refer to Section Replacement Parts)

Procedure:

1. Turn OFF detector.

2. Unscrew probe tip.

3. Remove filter following the appropriate procedure below:

a. Refrigerant Sensor — Remove filter from top of sensor.

b. Combustibles Sensor — Remove filter from probe tip (use a

straightened paper clip to poke out filter).

4. Insert replacement filter.

5. Reinstall probe tip.

3.4. Sensor Replacement

Over time a sensor will become less response to gas as it nears the end

of its useful life. (The combustibles sensor has a life expectancy of

approximately 5 years. The refrigerant sensor’s life expectancy is

approximately 150 hours or 1 year of normal use, but will var y dependin g

on the amount of refrigerant that passes through the sensor.)

Replace the sensor as follows (refer back to Figures 3a and 3b).

Material Required:

• Sensor (refer to Section Replacement Parts)

Procedure:

1. Turn OFF detector.

2. Unscrew probe tip.

3. Pull out sensor from its socket and discard.

4. Plug in new sensor, making sure its tab lines up with notch in sensor

housing.

5. If necessary, install a new filter per Section Probe Filter

Replacement); then reinstall probe tip.

6. Turn ON the detector and check that it responds in a positive manner

to a source of its corresponding gas.

14 0019-9211 Rev 9

Page 19

3.5. Probe Assembly or Fan Replacement

Replace the probe assembly or fan as follows (see Figures 5 thru 8):

The Informant™ 2

Material Required:

• Probe Assembly or Fan (refer to Section Replacement Parts )

• #1 Phillips screwdriver

• Medium flat blade screwdriver

Procedure:

1. Turn OFF detector; then remove the battery door and batteries.

2. Unscrew probe tip and lay aside.

3. Using a medium flat-blade screwdriver, first pry off the front retaining

collar as shown in Figure 6. Then, remove the two case screws and

pull the case halves apart.

4. Unplug both the probe and fan connectors from the printed circuit

board,

connector

being very careful not to damage the pins on the

; then remove the probe assembly from the detector.

5. Remove fan from probe assembly by removing its three screws as

shown in Figure 7.

6. Depending on whether the fan or probe assembly is being replaced,

perform one of the following:

a. If the fan is being replaced — Discard the old fan and install a

new one using the screws removed in Step 5.

b. If the probe assembly is being replaced — Install the old fan onto

the new probe using the screws removed in Step 5. Also, install

the sensor from the old probe assembly into the replacement

probe assembly per the previous Section Sensor Replacement.

7. Plug both the probe and fan connectors onto their respective header

holes on the printed circuit board as shown in Figure 8.

8. Position the probe assembly between the two case halves, routing

the fan wires through the notches in the case as shown in Figure 8.

Then reassemble the case; push on the front retaining collar; screw

on the probe tip; and reinstall the batteries.

0019-9211 Rev 9 15

Page 20

The Informant™ 2

See Figure 6 for

See Figure 7 for

See

9. Turn ON the detector and check that it responds in a positive manner

to a source of its corresponding gas.

instructions on how to

remove the Front

Retaining Collar.

instructions on how to

replace the fan.

Figure 8

for electrical

connector

details.

16 0019-9211 Rev 9

Figure 5. Assembly of the Informant 2

Page 21

The Informant™ 2

Figure 6. Front Retaining Collar Installation

Figure 7. Fan Installation

0019-9211 Rev 9 17

Page 22

The Informant™ 2

Figure 8. Connector Locations on Printed Circuit Board

18 0019-9211 Rev 9

Page 23

Symptom

Probably Cause and Remedy

Instrument does not

a. Batteries are dead or installed

the printed circuit board. See Figure 8.

The middle gas-level

Sensor depleted or faulty. Replace per

All gas-level LEDs

Refrigerant sensor “flooded” with

4. TROUBLESHOOTING

The following table lists the causes and remedies for the most common

problems that may occur with the detector.

The Informant™ 2

If the information in Table 1 does not solve the problem, or for help with

any problem that is not listed, please contact one of the Bacharach

Sales/Service Centers listed in Section Parts & Service.

Table 1. Troubleshooting Guide

turn on.

LED on both displays

glows steady.

momentarily light full

scale and then turn

off, leaving both the

audible tick rate and

probe tip blink rate at

-elevated levels.

backward. Install four fresh ‘AA’

alkaline batteries per Section Battery

Installation.

b. Possible faulty refrigerant sensor.

-Remove refrigerant sensor and turn on

detector. If detector now turns on, and

after warm-up shows a bad sensor (see

sensor failure indication below), replace

sensor per Section Sensor

Replacement.

c. Loose printed circuit board connector.

Disassemble detector and ensure that

all connectors are securely attached to

Section Sensor Replace me nt.

refrigerant. Move the detector to an area

of fresh air for about 1 minute, or until all

indicators return to their idle state.

0019-9211 Rev 9 19

Page 24

The Informant™ 2

Symptom

Probably Cause and Remedy

Short refrigerant

a. Probe filter dirty, thus not allowing

periods of time.

Slow gas response

a. Probe filter clogged. Replace filter per

Replacement.

Erratic gas indication.

a. Sensor faulty. Replace sensor per

the printed circuit board. See Figure 8.

sensor life.

time.

enough air to flow over the sensor to

keep it cool. Replace filter often per

Section Probe Filter Replacement.

b. Sensor has often been exposed to high

concentrations of refrigerant. Avoid

sampling pure refrigerant for long

Section Probe Filter Replacement.

b. Sensor nearly depleted or faulty.

Replace sensor per Section Sensor

Replacement.

c. Crack in rubber sheathing that covers

the probe’s flexible tube, allowing air to

enter through the crack. Replace probe

assembly per Section Probe Assembly

or Fan Replacement.

d. Internal fan defective. Replace fan per

Section Probe Assembly or Fan

Section Sensor Replace me nt.

b. Loose sensor. Unscrew probe tip and

ensure that sensor is being held firmly

in socket.

c. Loose printed circuit board connector.

Disassemble detector and ensure that

all connectors are securely attached to

20 0019-9211 Rev 9

Page 25

Contents

and a soft carrying case

carrying case

Detector, refrigerant sensor, color-

and a soft carrying case

in a hard carrying case

Detector, combustibles sensor,

batteries, and a soft carrying case

packaged in a hard carrying case

5. PAR TS AND SERVICE

5.1. Complete Kits

P/N Informant 2 Kit

0019-8042

Dual Refrigerant/

Combustibles

Dual Deluxe

0019-8045

Refrigerant/

Combustibles

The Informant™ 2

Detector, refrigerant and

combustible gas sensors, colorcoded probe tips, 5 probe filters,

instruction manual, 4 ‘AA’ batteries,

Detector, refrigerant and

combustible gas sensors,

color-coded probe tips, 5 probe

filters, instruction manual,

6 ‘AA’ batteries, soft carrying case,

protective rubber boot, and a

MagLite

®

, all packaged in a hard

0019-8040 Refrigerant Only

0019-8043

0019-8041

Deluxe

Refrigerant Only

Combustible Gas

Only

Deluxe

0019-8044

Combustible Gas

Only

0019-9211 Rev 9 21

coded probe tip, 5 probe filters,

instruction manual, 4 ‘AA’ batteries,

Detector, refrigerant sensor, colorcoded probe tip, 5 probe filters,

instruction manual, 6 ‘AA’ batteries,

soft carrying case, protective rubber

boot, and a MagLite

®

, all packaged

color-coded probe tip, 5 probe

filters, instruction manual, 4 ‘AA’

Detector, combustibles sensor,

color-coded probe tip, 5 probe

filters, instruction manual, 6 ‘AA’

batteries, soft carrying case,

protective rubber boot, MagLite

®

, all

Page 26

The Informant™ 2

5.2. Optional Accessories

P/N Informant 2 Kit Contents

®

0019-8037

Deluxe Upgrade

Kit

Protective rubber boot, MagLite

‘AA’ batteries, and a hard carrying

case

Upgrades a refrigerant-only

Informant 2 to a dual sensing

instrument. Includes a combustible

gas sensor, color-coded probe tip,

0019-8047

Combustible Gas

Upgrade Kit

and 5 probe filters

Upgrades a combustible-gas-only

Informant 2 to a dual sensing

instrument. Includes a refrigerant

gas sensor, color-coded probe tip,

0019-8046

Refrigerant

Upgrade Kit

and 5 probe filters

Provides a protective cover for the

0019-0497

0019-0501

5.3. Replacement Parts

Protective

Rubber Boot

Hard Carrying

Case

Informant 2 that includes a

MagLite

(MagLite

®

flashlight cavity

®

not included)

Provides storage for all Informant 2

components

P/N Contents

0019-0502 Fan

0019-0509 Filter (pack of 5)

0019-0488 Front Retaining Collar

0019-0481 Probe Assembly (excludes fan, probe tip, sensor & filter)

0019-0473 Probe Tip: Refrigerant, Blue

0019-0507 Probe Tip: Combustibles, Red

0102-1043 Screw, Battery Door

0002-7727 Screw, Case

0002-2143 Screw, Fan

0019-0510 Sensor: Refrigerant

, 2

22 0019-9211 Rev 9

Page 27

P/N Contents

0019-0499 Sensor: Combustibles

0019-0491 Soft Carrying Case

0019-0591 Battery Door Assembly

The Informant™ 2

5.4. Sales/Service Centers

Replacement parts and service can be obtained by contacting one of the

following Bacharach Sales/Service Centers:

United States

Bacharach, Inc.

621 Hunt Valley Circle

New Kensington, PA 15068

Phone: 1-800-736-4666

Fax: 724-334-5723

Email: help@mybacharach.com

Canada

Bacharach of Canada, Inc.

20 Amber St. Unit #7

Markham, Ontario L3R SP4

Canada

Phone: 905-470-8985

Fax: 905-470-8963

Email: bachcan@idirect.com

0019-9211 Rev 9 23

Page 28

The Informant™ 2

6. Declaration of Conformity

24 0019-9211 Rev 9

Page 29

NOTES

The Informant™ 2

0019-9211 Rev 9 25

Page 30

The Informant™ 2

NOTES

26 0019-9211 Rev 9

Page 31

The Informant™ 2

NOTES

0019-9211 Rev 9 27

Page 32

The Informant™ 2

World Headquarters

621 Hunt Valley Circle, New Kensington, Pennsylvania 15068

Phone: 724-334-5000 • Toll Free: 1-800-736-4666 • Fax: 724-334-5001

Website: www.MyBacharach.com • E-mail: help@MyBacharach.com

28 0019-9211 Rev 9

Loading...

Loading...