Page 1

HI FLOW® Sampler

Natural Gas

Leak Rate Measurement

Instruction 0055-9017

Operation & Maintenance

Rev. 5 – June 2010

Product Leadership • Training • Service • Reliability

Page 2

A

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects in

material and manufacture and will conform substantially to Bacharach Inc.’s applicable specifications.

Bacharach’s liability and Buyer’s remedy under this warranty are limited to the repair or replacement, at

Bacharach’s option, of this Product or parts thereof returned to Seller at the factory of manufacture and

shown to Bacharach Inc.’s reasonable satisfaction to have been defective; provided that written notice of

the defect shall have been given by Buyer to Bacharach Inc. within one (1) year after the date of delivery

of this Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach’s liability and

Buyer’s remedy under this warranty of title are limited to the removal of any title defects or, at the

election of Bacharach, to the replacement of this Product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY

AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE: AND (II)

ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACT OR TORT, WHETHER OR NOT

ARISING FROM BACHARACH’S NEGLIGENCE, ACTUAL OR IMPLIED. The remedies of the Buyer shall be

limited to those provided herein to the exclusion of any and all other remedies including, without limitation incidental or consequential damages. No agreement varying or extending the foregoing warranties,

remedies or this limitation will be binding upon Bacharach, Inc. unless in writing, signed by a duly

authorized officer of Bacharach.

Register Your Warranty by Visiting

www.mybacharach.com

Declaration of Conformity

Manufacturer’s name: Bacharach, Inc.

Manufacturer’s address: 621 Hunt Valley Circle

New Kensington, PA 15068-7074

European operations: Bacharach Europe

Sovereign House, Queensway

Leamington Spa

Warwickshire CV31 3JR

United Kingdom

Product name: Hi Flow Sampler

conforms to the following specifications:

EMC Directive 61326:1998

IEC 61000-4-3: Radiated Immunity

IEC 61000-4-2

Notice:

Product improvements and enhancements are continuous; therefore the specifications and

information contained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language

without the prior written consent of Bacharach, Inc.

Copyright © 2010, Bacharach, Inc., all rights reserved.

BACHARACH

trade names, service marks and logos referenced herein belong to their respective owners.

®

and HI FLOW® are registered trademarks of Bacharach, Inc. All other trademarks,

Instruction 0055-9017

Page 3

Hi Flow Sampler Contents

Table of Contents

1 Introduction........................................................................................ 1

1.1 General Description................................................................................................. 1

1.2 Material Supplied .................................................................................................... 2

1.3 Why Use the Hi Flow Sampler?................................................................................ 2

1.4 Control Unit Description .........................................................................................3

1.5 Top Panel Connections & Controls .......................................................................... 3

2 Technical Data .................................................................................... 5

3 Operation............................................................................................ 7

3.1 Operating Precautions (Please Read)....................................................................... 7

3.2 Battery Connection ................................................................................................. 7

3.3 Sampling Hose & Attachment Connections.............................................................. 8

3.4 Grounding...............................................................................................................9

3.5 Attachments.......................................................................................................... 10

3.5.1 Flange Strap (34", 80" & 137") ................................................................. 10

3.5.2 Beveled Nozzle Tool (6.5" & 24")............................................................... 10

3.5.3 Capture Bag............................................................................................ 11

3.5.4 Disposable Bags with Nozzle ................................................................... 11

3.5.5 Bellows Tool ............................................................................................ 11

3.5.6 Claw Tool ................................................................................................ 12

3.5.7 3-Port Background Gas Sampler ............................................................. 12

3.6 Turning ON the Hi Flow Sampler ........................................................................... 12

3.7 Turning OFF the Hi Flow Sampler ......................................................................... 13

3.8 Selecting the Basic or Expanded Menu Mode......................................................... 13

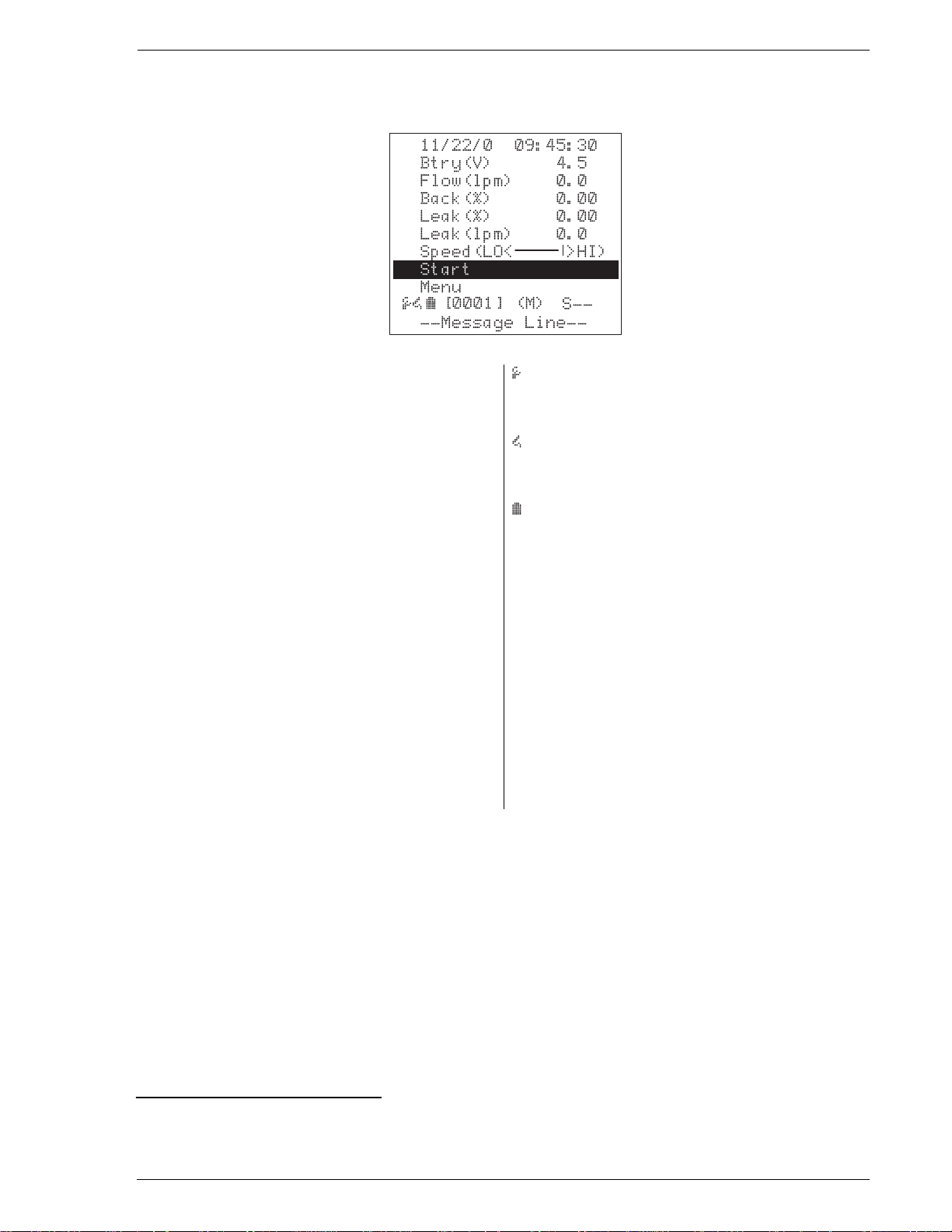

3.8.1 Basic Main Screen................................................................................... 15

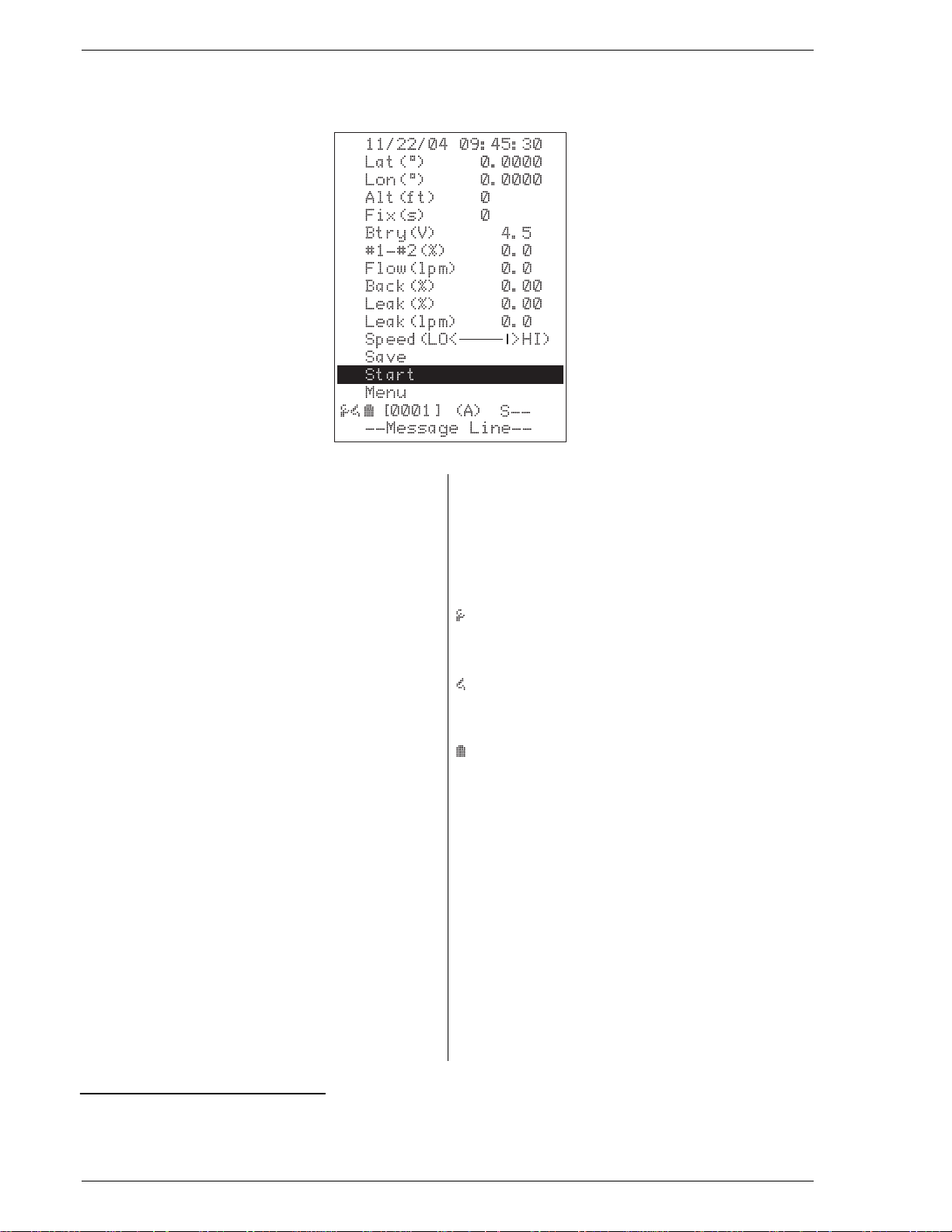

3.8.2 Expanded Main Screen ........................................................................... 16

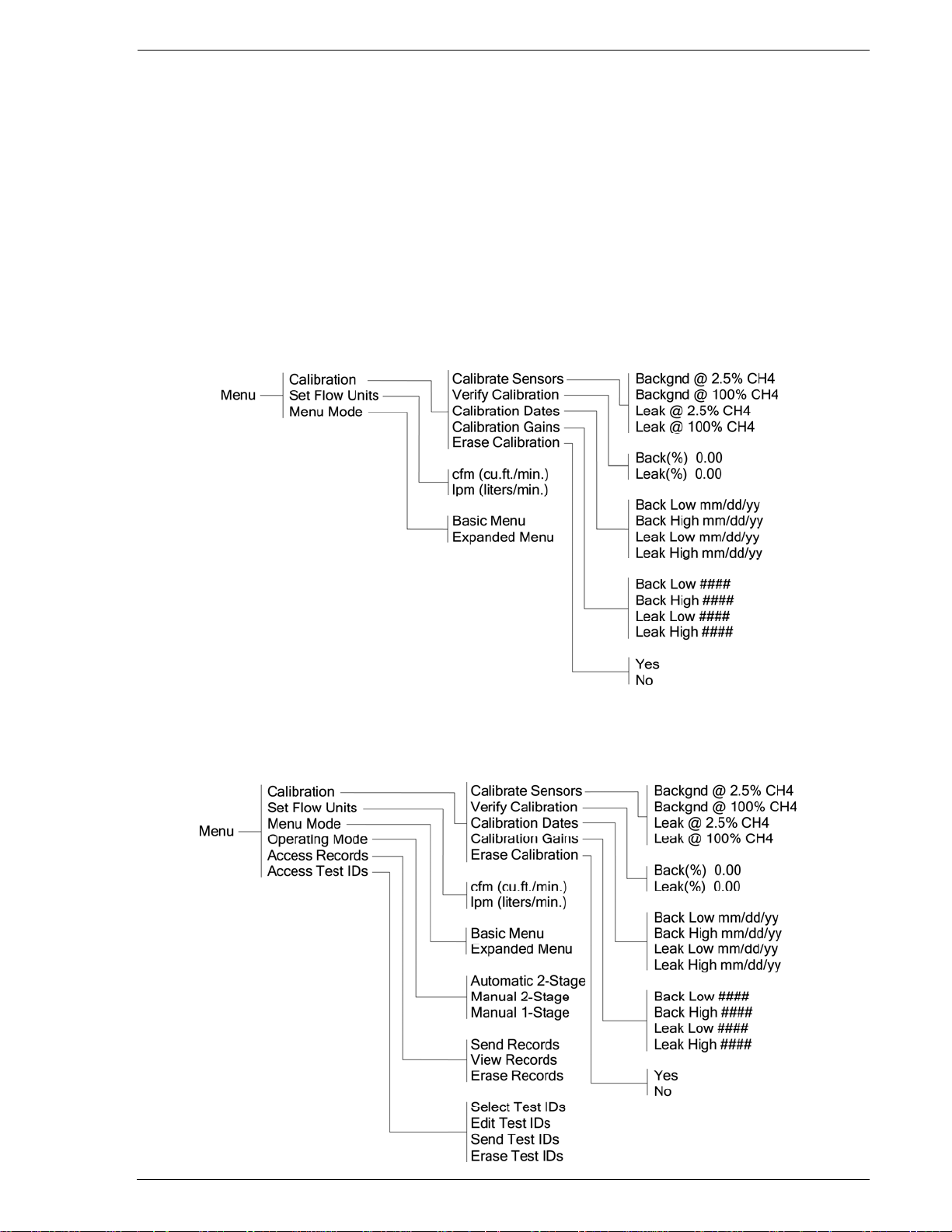

3.9 Menu System ........................................................................................................17

3.10 Battery Status .......................................................................................................18

3.11 Calibration Menu ..................................................................................................18

3.12 Set Flow Units – lpm or cfm................................................................................... 18

3.13 Menu Mode – Basic or Expanded........................................................................... 19

3.14 Operating Mode – Automatic or Manual................................................................. 19

3.14.1 Automatic 2-Stage Measurement Mode ................................................... 19

3.14.2 Manual Measurement Mode .................................................................... 20

3.14.2.1 Manual 2-Stage Mode ........................................................... 20

3.14.2.2 Manual 1-Stage Mode ........................................................... 21

3.15 Access Records...................................................................................................... 22

3.15.1 Send Records .......................................................................................... 22

3.15.2 View Records........................................................................................... 24

3.15.3 Erase Records ......................................................................................... 24

3.16 Importing Saved Data into a Spreadsheet .............................................................. 25

3.17 Access Test IDs ..................................................................................................... 27

3.17.1 Select Test IDs ........................................................................................27

3.17.2 Edit Test IDs ........................................................................................... 28

3.17.3 Send Test IDs.......................................................................................... 29

3.17.4 Erase Test IDs......................................................................................... 30

3.18 Making a Leak Rate Measurement......................................................................... 32

3.18.1 Leak Rate Measurement – Basic Menu Mode ........................................... 32

3.18.2 Leak Rate Measurement – Automatic 2-Stage Mode................................. 33

3.18.3 Leak Rate Measurement – Manual 2-Stage Mode..................................... 36

3.18.4 Leak Rate Measurement – Manual 1-Stage Mode..................................... 38

3.19 Message Line......................................................................................................... 40

3.20 GPS Data ..............................................................................................................41

3.21 Barcode Scanner Data........................................................................................... 42

4 Calibration ........................................................................................ 43

Instruction 0055-9017

i

Page 4

Contents Hi Flow Sampler

4.1 View Calibration Dates ..........................................................................................43

4.2 Gas Calibration Equipment Setup .........................................................................43

4.3 Check Calibration Procedure .................................................................................44

4.4 Gas Calibration Procedure .....................................................................................45

4.5 Calibration Amplifier Gain Check ..........................................................................47

4.6 Erase Calibration Procedure ..................................................................................47

5 Maintenance ......................................................................................49

5.1 Electrostatic Discharge Precautions .......................................................................49

5.2 Charging the Battery Pack .....................................................................................50

5.3 Removing the Cover ...............................................................................................51

5.4 Replacing the Internal Filters.................................................................................52

5.4.1 Leak-Gas Filter........................................................................................52

5.4.2 Leak-Gas Sensor Filter ............................................................................53

5.4.3 Background-Gas Sensor Filter .................................................................53

5.5 Gas Sensor Replacement .......................................................................................54

5.6 Pump Replacement ................................................................................................55

5.7 Flow Rate Verification ............................................................................................56

5.8 Setting Date and Time ...........................................................................................59

5.9 Resetting the Microprocessor .................................................................................60

6 Troubleshooting .................................................................................61

6.1 Instrument Repair .................................................................................................61

6.2 Troubleshooting Guide ..........................................................................................61

6.3 Error Codes in Saved Test Records ........................................................................63

7 Parts & Service ..................................................................................65

7.1 Replacement Parts .................................................................................................65

7.2 Optional Accessories..............................................................................................65

7.3 Service Centers......................................................................................................66

ii

Instruction 0055-9017

Page 5

Hi Flow Sampler Introduction

1 Introduction

1.1 General Description

The Hi Flow Sampler is portable, intrinsically safe, battery-powered

instrument designed to determine the rate of gas leakage around various

pipefittings, valve packings, and compressor seals found in natural gas

transmission, storage, and compressor facilities.

A component’s leak rate is measured by sampling at a high flow rate so

as to capture all the gas leaking from the component along with a certain

amount of surrounding air. By accurately measuring the flow rate of the

sampling stream and the natural gas concentration within that stream,

the gas leak rate can be calculated using Equation 1. The instrument

automatically compensates for the different specific gravity values of air

and natural gas, thus assuring accurate flow rate calculations.

Instruction 0055-9017

Leak = Flow x (Gas

sample

– Gas

background

where:

Leak = rate of gas leakage from source (cfm)

Flow = sample flow rate (cfm)

Gas

Gas

= concentration of gas from leak source (%)

sample

background

= background gas concentration (%)

To ensure that the instrument is capturing all the gas that is escaping

from the component, two measurements are performed at two different

flow rates. The first measurement is taken at the highest possible flow

rate, followed by a second measurement at a flow rate that is

approximately 70–80% of the first. If the two calculated leak rates are

within 10% of each other, then it can be assumed that all gas has been

captured during the test.

For those mathematicians who are wondering how both calculations can

be the same with different flow rates, note that the measured CH

the lower flow rate will be higher due to less air being drawn in with the

sample, thus balancing out the lower flow rate.

The instrument is packaged inside a backpack, thus leaving the

operator’s hands free for climbing ladders or descending into manholes.

The instrument is controlled by a handheld unit consisting of an LCD

and a 4-key control pad, which is attached to the main unit via a 6 foot

coiled cord.

The gas sample is drawn into the unit through a flexible 1.5 inch I.D.

hose. Various attachments connected to the end of the sampling hose

provide the means of capturing all the gas that is leaking from the

component under test.

The main unit consists of an intrinsically safe, high-flow blower that

pulls air from around the component being tested through a flexible hose

and into a gas manifold located inside the unit. The sample is first

passed through a venturi restrictor where the measured pressure

differential is used to calculate the sample’s actual flow rate. Next, a

portion of the sample is drawn from the manifold and directed to a

combustibles sensor that measures the sample’s CH

) x 10–2 Eq. 1

level at

4

concentration in

4

1

Page 6

Introduction Hi Flow Sampler

the range of 0.05 to 100% gas by volume. A second identical

combustibles sensor channel measures the background CH

level within

4

the vicinity of the leaking component. The final element in the sampling

system is a blower that exhausts the gas sample back into the

atmosphere away from the sampling area.

The measured flow rate and the measured CH

levels (both leak and

4

background levels) are used to calculate the leak rate of the component

being tested, with all measured and calculated values being displayed on

the hand-held control unit.

1.2 Material Supplied

High Flow Sampler Unit

Backpack

6 Foot, 1.5 Inch Hose Assembly

Battery Pack (Qty. 2)

Battery Charger w/ Power Supply

Control Unit with LCD and 4-button keypad

Assortment of Attachments (for complete capture of the gas leak)

Flange Strap 34", 80", and 137"

Capture Bag 36" x 36"

Beveled Nozzle 6.5" and 24"

Bag Nozzle w/ box of disposable bags

Bellows Tool

Claw Tool

3-Port Background Gas Sampler

1.3 Why Use the Hi Flow Sampler?

Allows ranking of gas leaks in leak-rate order

Allows users to determine if the potential savings in lost gas by

repairing a leak

Allows users to determine payback periods for particularly

expensive repairs

Allows more cost-effective use of your maintenance budget

Identifies problem areas

Determines baseline leakage conditions

Provides permanent record of leakage and repair

Greenhouse gas credits

Pays for itself in recovered gas

2

Instruction 0055-9017

Page 7

Hi Flow Sampler Introduction

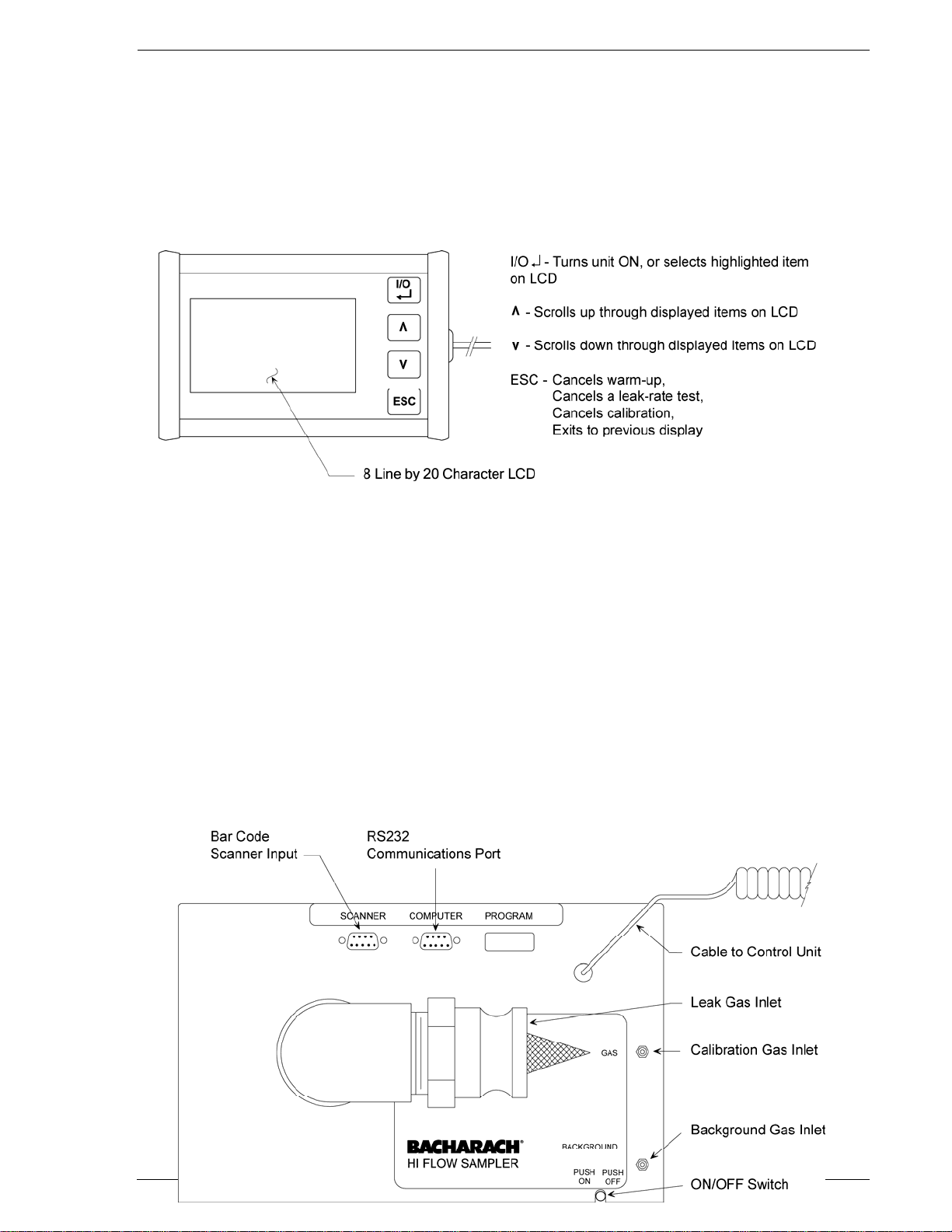

1.4 Control Unit Description

The control unit consists of an 8 line by 20 character LCD and the four

pushbuttons.

Figure 1-1. Control Unit

1.5 Top Panel Connections & Controls

The top panel contains the following items:

SCANNER – Bar code scanner input

COMPUTER – RS232 communications port for downloading stored

test data to an external computer

Leak Gas Inlet – Main hose connection used to collect gas from

leak source

BACKGROUND Gas Inlet – Gas hose connection used to sample

background levels of CH

GAS Inlet – Calibration gas connection

ON/OFF Switch – Turns unit ON and OFF

Figure 1-2. Top Panel Connections

4

Instruction 0055-9017

3

Page 8

Introduction Hi Flow Sampler

Notes:

4

Instruction 0055-9017

Page 9

Hi Flow Sampler Technical Data

2 Technical Data

Information Displayed .......... - Date and Time

- Battery voltage

- Sampling flow rate in cfm

- Background gas concentration in ppm or % by volume

- Leak concentration in ppm or % by volume

- Leak rate in cfm

- Percent difference between leak rate measurements #1 and #2

- Latitude, Longitude, Altitude, and Time of Fix, when the

optional GPS receiver is attached

Display................................. 8 line by 20 character LCD

Pushbutton Controls ............ - I/O

-

-

- ESC (Escape)

Communication.................... Three DB9 connectors providing serial data transfer at 115200

baud to a personal computer, bar code reader, and GPS receiver

Measured Values.................. - Sampling flow rate

- Background gas concentration

- Sample gas concentration

- Battery voltage

Calculated Values ................ - Leak concentration corrected for background gas level

- Leak rate

- Percent difference between leak rate measurements #1 and #2

Measurable Leak Rate .......... 0.05 to 8.00 SCFM (1.42 to 226 LPM)

0.05 to 6.00 SCFM (1.42 to 170 LPM)

Accuracy of Calculated

Leak Rate ............................. ±10% of reading

Temperature:

Operating .......................... 0 to 50 °C (32 to 122 °F)

Storage.............................. –40 to 60 °C (–40 to 140 °F)

Humidity .............................. 5 to 95% RH (non-condensing)

Sampling Flow Rate:

Maximum.......................... 10.5 SCFM (297 LPM) at full battery charge

Operating Flow Points ....... Initial flow approx. 10 SCFM (283 LPM)

Second flow approx. 8 SCFM (226 LPM)

(The second flow rate is 25% of the initial flow)

Measurement Method........ Differential pressure across restriction

Accuracy ........................... ±5% of reading

(Enter)

(Up Arrow)

(Down Arrow)

Instruction 0055-9017

5

Page 10

Technical Data Hi Flow Sampler

Natural Gas Sensor:

Detection Method...............Catalytic oxidation / Thermal conductivity

Range:

Catalytic oxidation......... 0 to 5% by volume methane

Thermal conductivity ..... 5 to 100% by volume methane

Accuracy............................±5% of reading or 0.02 % methane, whichever is greater

Battery:

Type ..................................Intrinsically Safe NiMH rechargeable pack

Voltage ..............................4.8 V, max.

Recharge Time ...................8 to 10 hours

Run Time........................... >4.5 hours continuous operation @ 20 °C (68 °F)

Memory ................................Stores up to 1000 individual test parameters

Dimensions ..........................18L x 12W x 7H inches (457 x 305 x178 mm)

Weight ..................................20 lbs (0.9 kg)

Agency Approvals .................Designed to be intrinsically safe for use in hazardous locations

Class I, Division 1, Groups A, B, C & D in North America

CAN/CSA-C22.2 No. 157 – (June 1992)

ANSI (June 27, 2002)/UL913-2002

Intrinsically Safe Apparatus and Associated Apparatus for use in

Class I, Division 1, Hazardous (Classified) Locations

CE Mark – See this manual’s inside front cover for Declaration of

Conformity statement

6

Instruction 0055-9017

Page 11

Hi Flow Sampler Operation

3 Operation

3.1 Operating Precautions

(Please Read)

To ensure that the gas sensors are properly zeroed at startup, the Hi

Flow Sampler must be turned ON in clean air (free of combustible gases

or vapors).

Calibrate the instrument about every 30 days to assure its accuracy. The

frequency of calibration, however, may change depending on how often

the instrument is used and the amount of gas that was sampled. Create

a maintenance log to keep track of when an instrument was calibrated,

and then use this log to help develop a calibration schedule. For

example, an instrument that fails its calibration after only being

calibrated a single time should be calibrated more often.

Important: Avoid sampling leaded gasoline vapors, or gases or vapors that

contain silicones or sulfur compounds. Tetraethyl lead, silicones, and

sulfur compounds can form contaminating compounds on the sensor

element (poison the sensor), with resulting loss in sensitivity.

Always purge the instrument with clean air after testing. This removes

combustibles from the sensor chambers and prolongs the life of the

sensors.

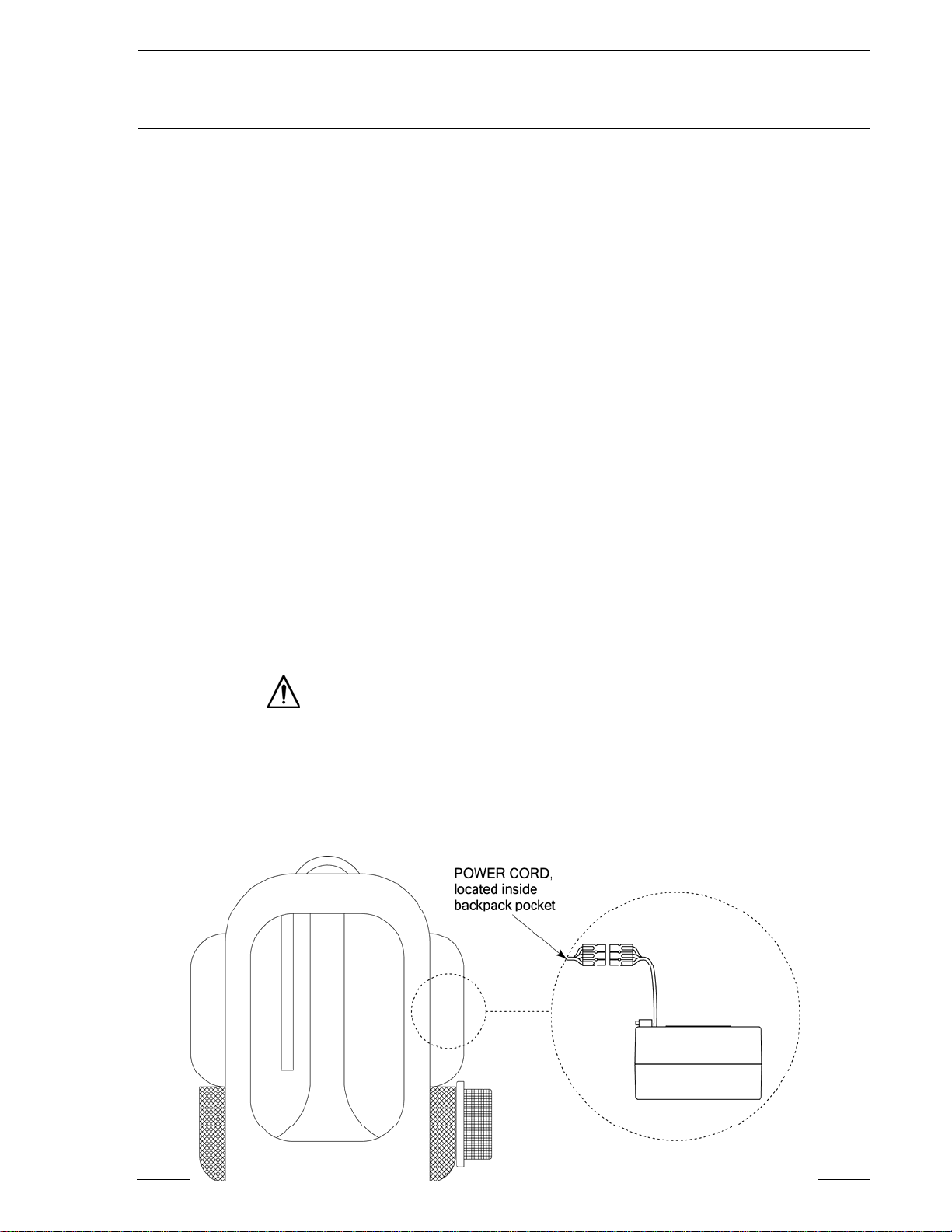

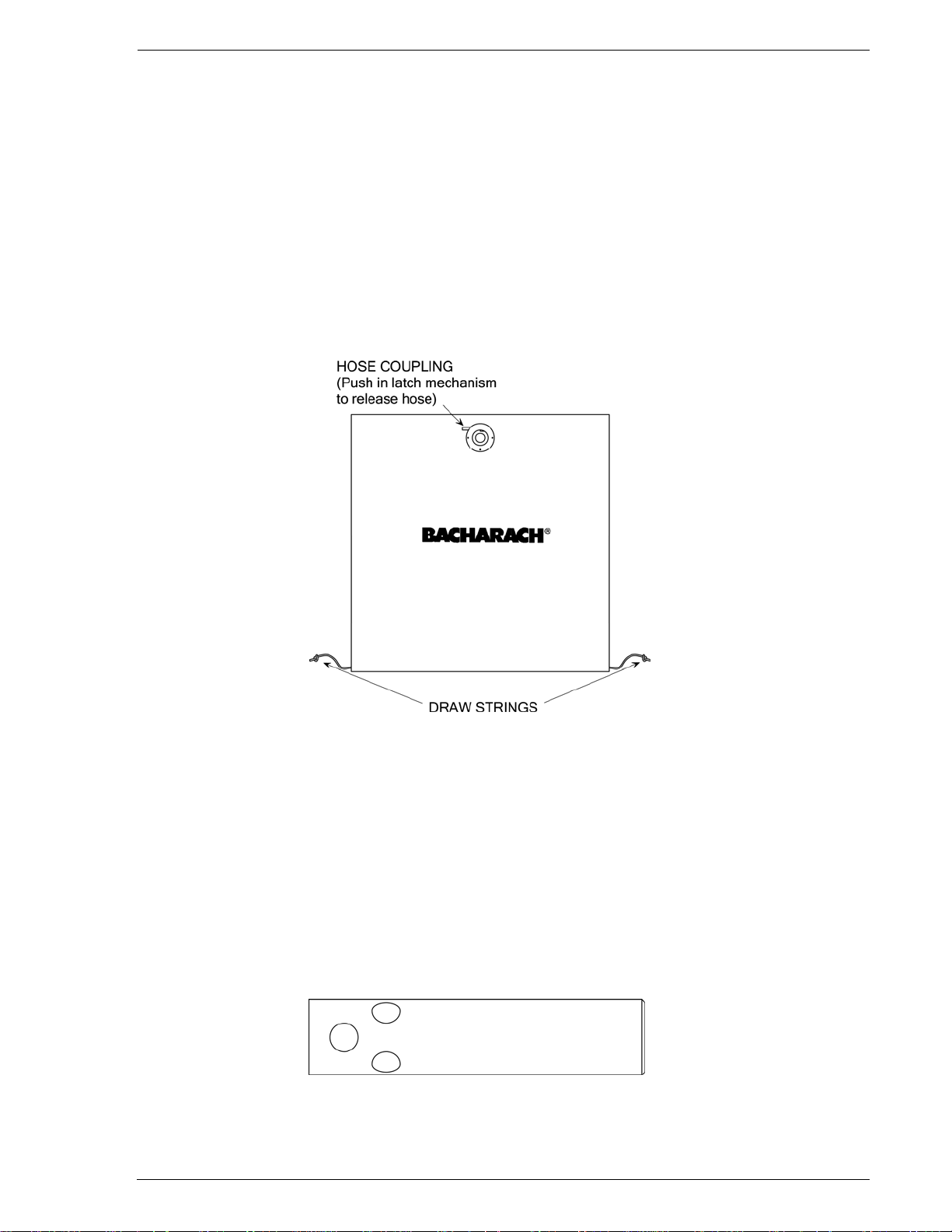

3.2 Battery Connection

WARNING: Explosion hazard! DO NOT connect or disconnect the battery in

an unsafe atmosphere.

The instrument’s power cord is located inside the backpack’s right-side

pocket. Insert a battery pack into this pocket and connect it to the power

cord.

Figure 3-1. Battery Pack Connection

Instruction 0055-9017

7

Page 12

Operation Hi Flow Sampler

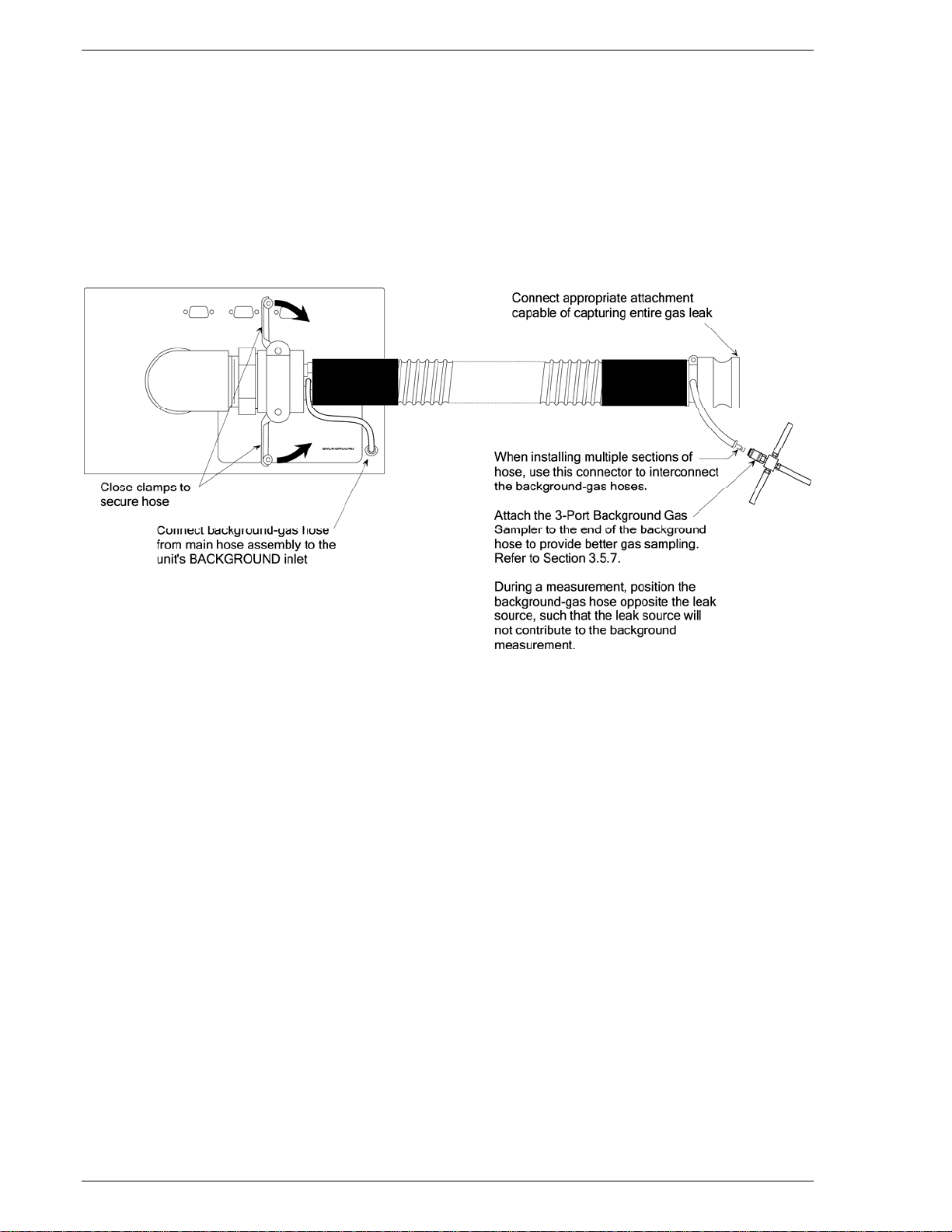

3.3 Sampling Hose & Attachment Connections

Connect the sampling hose to the instrument’s leak-gas inlet by

clamping the hose to the inlet as shown in Figure 3-2. Also connect the

background gas sampling hose to the unit’s BACKGROUND inlet.

Figure 3-2. Hose and Attachment Connections

The standard sampling hose is 6 foot long. If a longer length is needed,

the optional 12 foot hose (P/N 0055-0287) can be ordered, or additional

sections of hose can be added by simply clamping them together along

with connecting together the background-gas hose.

Choose an attachment (refer to Section 3.5 Attachments) that will capture

the entire leak and attach it to the end of the hose.

8

Instruction 0055-9017

Page 13

Hi Flow Sampler Operation

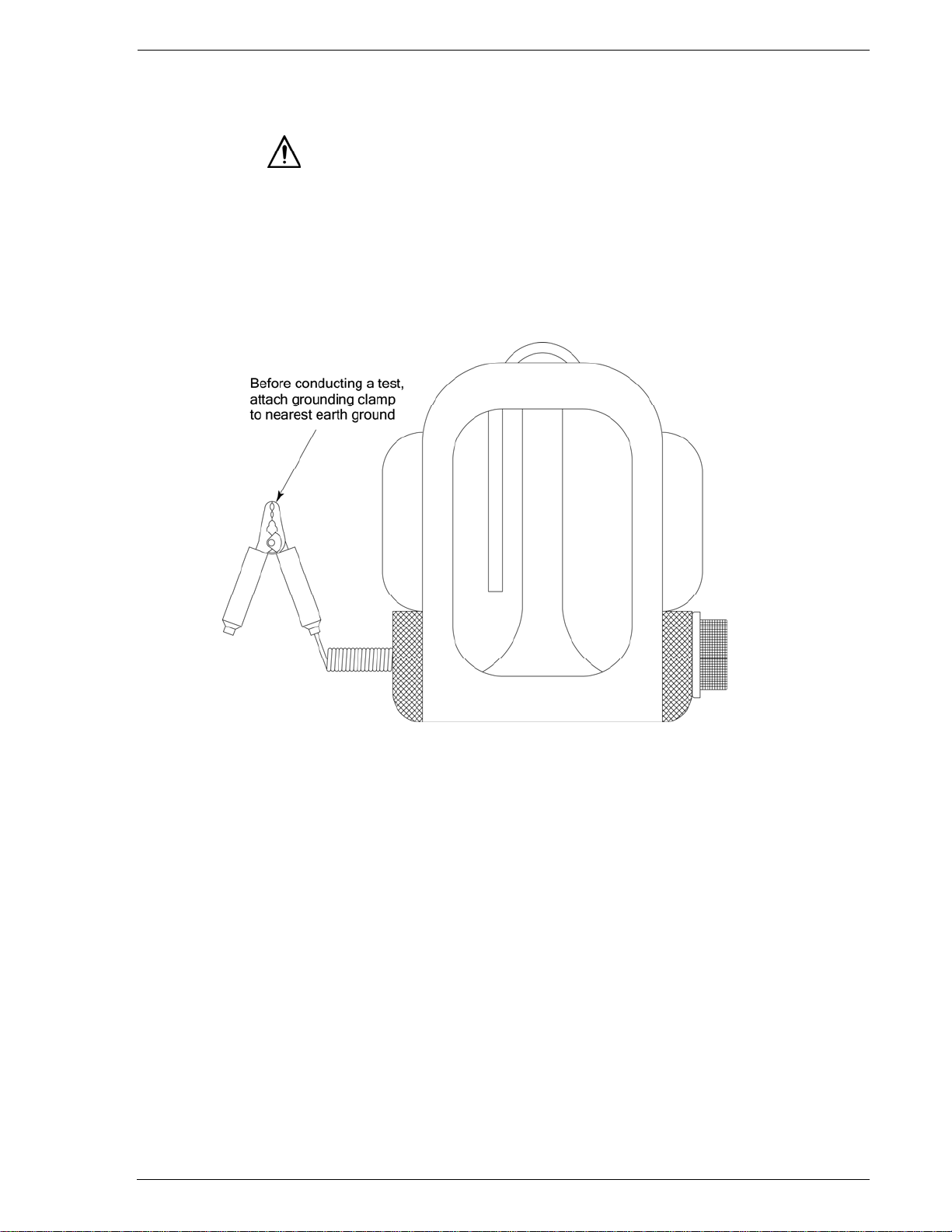

3.4 Grounding

WARNING: To prevent the possibility of a static discharge, the Hi Flow

Sampler should be grounded while conducting a leak test.

Attach the unit’s grounding clamp to the nearest earth ground.

Tip: When not in use, the grounding clamp can be stored by attaching it to

one of the shoulder straps.

Figure 3-3. Grounding Clamp

Instruction 0055-9017

9

Page 14

Operation Hi Flow Sampler

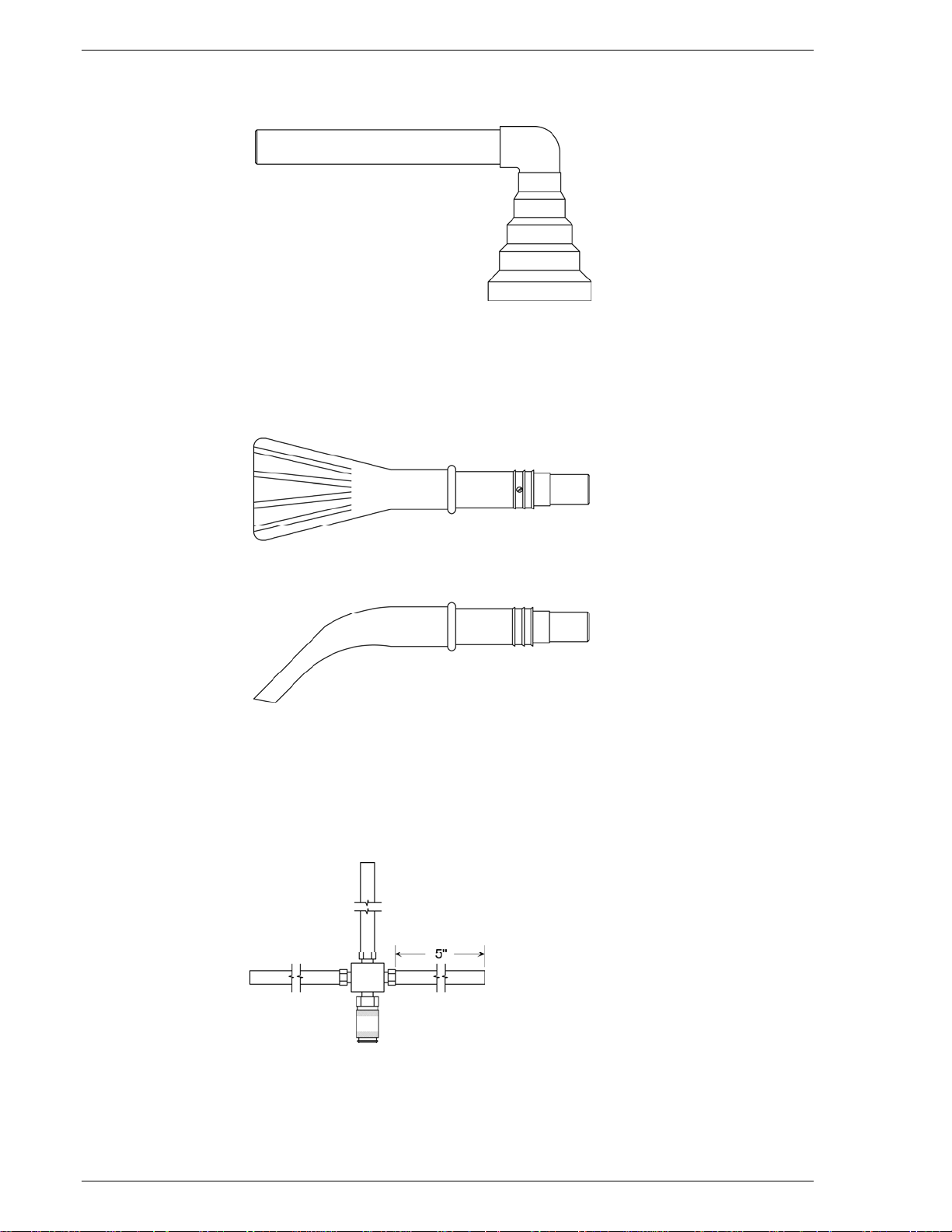

3.5 Attachments

A variety of attachments are available for the Hi Flow Sampler that

simplifies the task of capturing the entire gas leak. Choose the

appropriate attachment for the type of component being tested from the

ones listed below, and then connect it to the end of the instrument’s

main sampling hose.

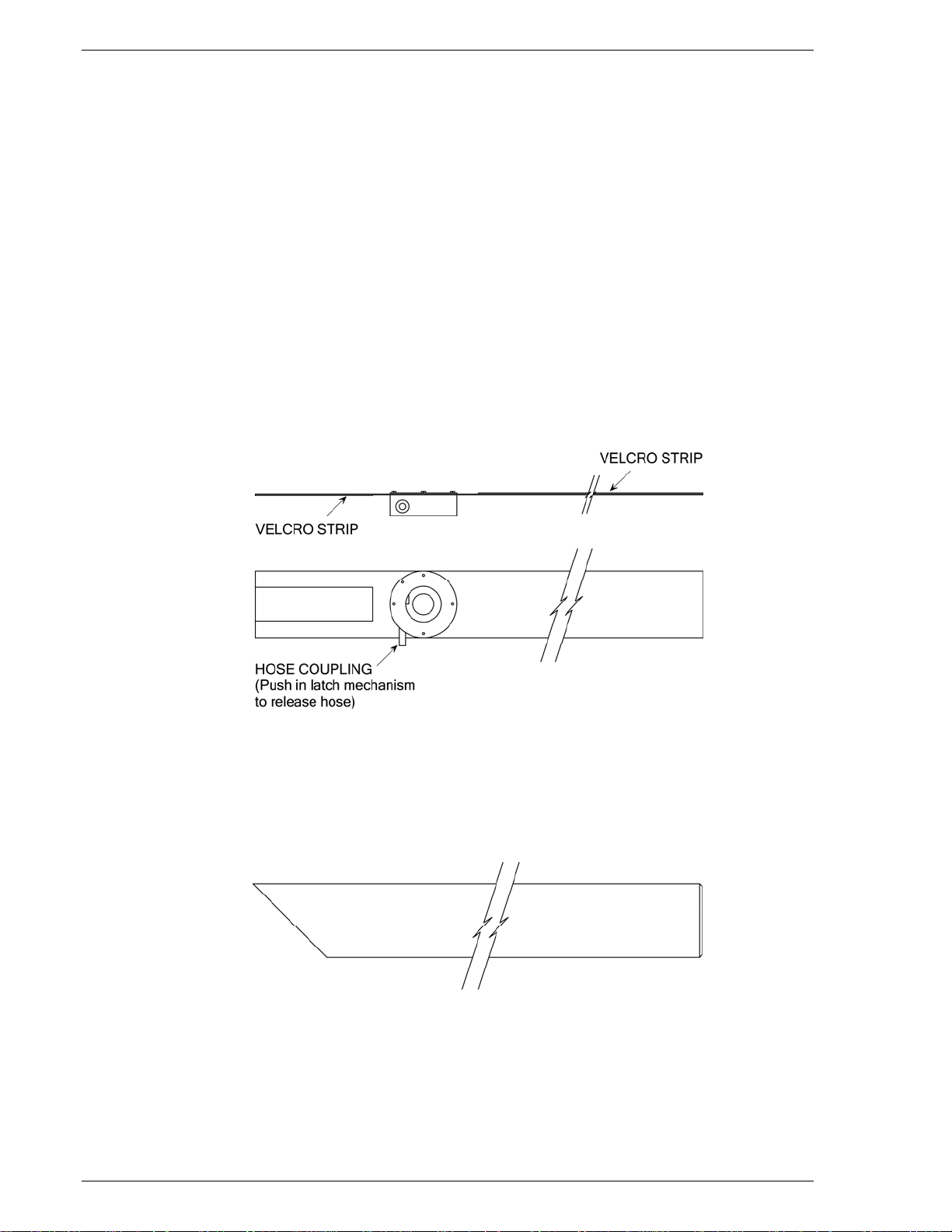

3.5.1 Flange Strap (34", 80" & 137")

Flange leaks can be captured by wrapping this attachment around the

edge of the flange, and securing in place using the two Velcro strips.

Attach the Hi Flow Sampler’s main sampling hose to the flange strap by

simply pushing the end of the hose into the attachment’s hose coupling.

A click should be heard when the hose has been successfully connected.

Release the hose by pushing in the coupling’s release mechanism.

3.5.2 Beveled Nozzle Tool (6.5" & 24")

For simple pin-hole type leaks, position this attachment directly over the

leak source.

10

Instruction 0055-9017

Page 15

Hi Flow Sampler Operation

3.5.3 Capture Bag

This reusable capture bag measures 36" x 36" and can be used to

completely surround a component that may have multiple leak sources,

or contains a leak source that is difficult to pinpoint or reach.

Attach the Hi Flow Sampler’s main sampling hose to the bag by simply

pushing the end of the hose into the bag’s hose coupling. A click should

be heard when the hose has been successfully connected. Release the

hose by pushing in the coupling’s release mechanism.

Use the draw strings to close up the end of the bag. DO NOT, however,

completely close off the bag – allow air to flow into the bag so as to

replace the volume of gas and air being removed during the test.

3.5.4 Disposable Bags with Nozzle

These disposable capture bags measure 38" x 60" and can be used to

completely surround a component that may have multiple leak sources,

or contains a leak source that is difficult to pinpoint or reach.

When using a disposable bag to surround the leak source, insert the bag

nozzle into the bag to take a gas sample.

DO NOT completely close off the bag – allow air to flow into the bag so as

to replace the volume of gas and air being removed during the test.

3.5.5 Bellows Tool

Instruction 0055-9017

11

Page 16

Operation Hi Flow Sampler

This tool is useful in capturing leaks in valve stems and small fittings.

3.5.6 Claw Tool

Use this tool when the leak source is spread out over a narrow area,

such as a crack in a pipe, square flanges, and cylinder heads.

3.5.7 3-Port Background Gas Sampler

Attaches to the end of the background gas sample hose to give better

average background gas readings.

3.6 Turning ON the Hi Flow Sampler

12

Instruction 0055-9017

Page 17

Hi Flow Sampler Operation

With the Hi Flow Sampler located in an area containing clean air (no

combustible gases or vapors), turn ON the instrument by first pulling up

the ON/OFF switch and then moving it to its ON position.

WARNING: Turning ON the instrument in air contaminated with

combustible gas will cause false readings to occur. Use one of Bacharach’s

portable gas detection instruments to sample the surrounding area for

levels of combustible gas before turning ON the instrument.

An initial banner screen is first displayed for 3 seconds that shows the

instrument’s name, software version, and the software’s Month, Day,

Year, and Time of creation.

B a c h a r a c h , I n c .

H i F l o w S a m p l e r

v e r 1 . 4 0

N o v 1 3 2 0 0 4 1 1 : 2 0

After the banner screen is displayed, the sensors are automatically

zeroed to ambient conditions. Zeroing time is dependent on the

temperature of the sensors, and whether there is residual gas present

inside the sensor chambers. If a sensor fails to zero, a message appears

at the bottom of the LCD describing the cause of the failure. Refer to

Section 6 Troubleshooting for possible causes and remedies for this

failure.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

Z e r o i n g S e n s o r s

P l e a s e W a i t . . .

[ 0 0 0 1 ] ( M ) S - -

After the sensors are zeroed, either the instrument’s Basic or Expanded

Main Screen appears (refer to Section 3.8). The example below shows the

Basic Main Screen.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

B a c k ( % ) 0 . 0 0

L e a k ( % ) 0 . 0 0

L e a k ( N o t A v a i l . )

S p e e d ( L O < > H I )

S t a r t

[ 0 0 0 1 ] ( M ) S - -

T h e a r r o w s y m b o l s o n t h e l e f t i n d i c a t e t h a t

t h e r e a r e m o r e i t e m s t o v i e w a b o v e a n d / o r

b e l o w t h e c u r r e n t d i s p l a y .

P r e s s k e y s t o v i e w a d d i t i o n a l i t e m s .

3.7 Turning OFF the Hi Flow Sampler

Turn OFF the unit by simply pulling up the ON/OFF switch and moving

it to its OFF position.

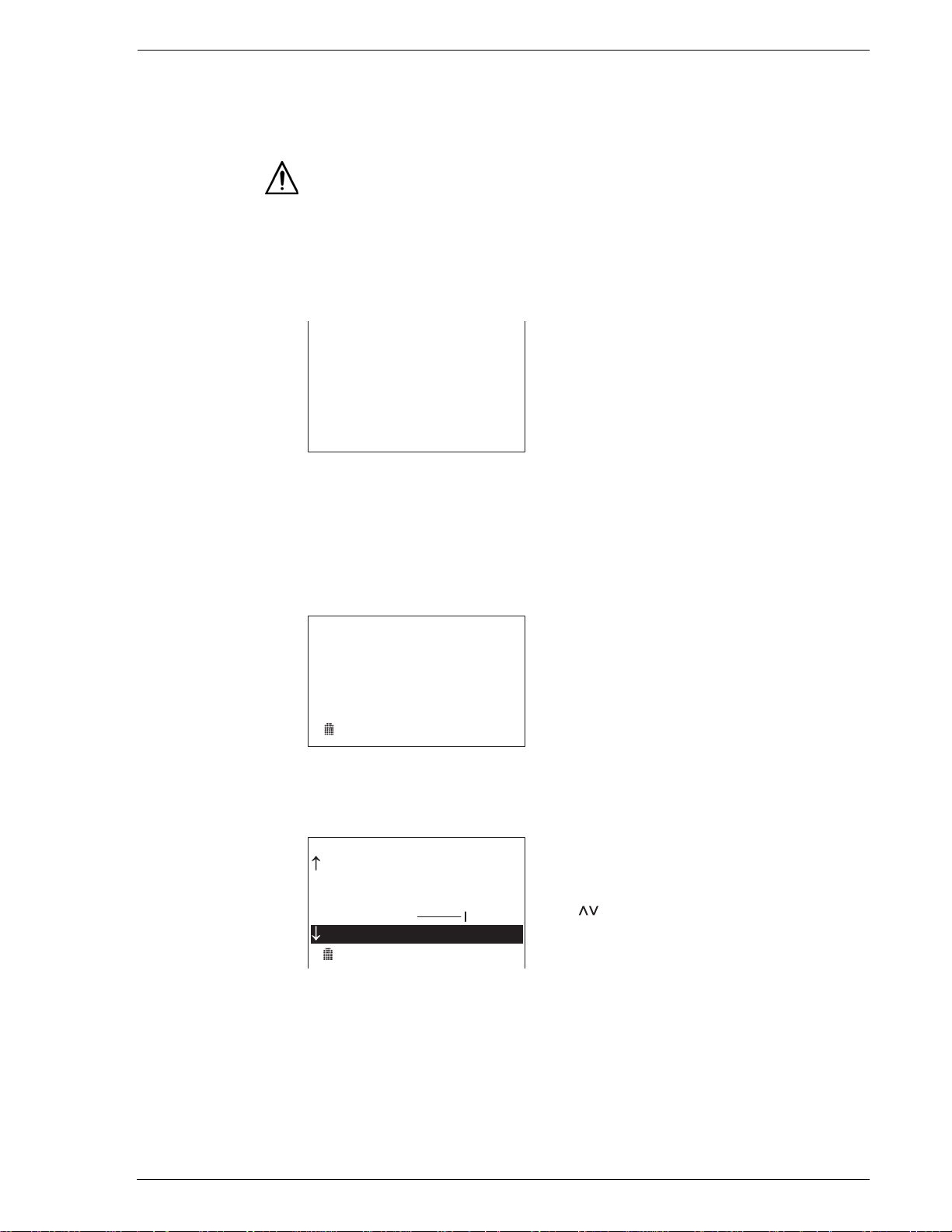

3.8 Selecting the Basic or Expanded Menu Mode

Instruction 0055-9017

13

Page 18

Operation Hi Flow Sampler

Select the Basic or Expanded Menu Mode as follows:

1. From either the Basic or Expanded Main Screen, select Menu >

Menu Mode.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

C a l i b r a t i o n

S e t F l o w U n i t s

M e n u M o d e

[ 0 0 0 1 ] ( M ) S - -

2. Highlight the desired menu mode, and then press the I/O key to

select that mode.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

B a s i c M e n u

E x p a n d e d M e n u

[ 0 0 0 1 ] ( M ) S - -

3. Press ESC to return to the Main Screen.

Refer to Sections 3.8.1 and 3.8.2 for detailed descriptions of the

information contained in the Basic and Expanded Main Screens.

14

Instruction 0055-9017

Page 19

Hi Flow Sampler Operation

3.8.1 Basic Main Screen

Date and Time: Date displayed as

mm/dd/yy, while time is displayed in a 12hour format. The date and time are set per

Section 5.8.

Btry(V): Battery voltage

Flow(lpm): Sample flow rate in either

liters/min or cu.ft./min.

: GPS (Global Positioning System) icon

appears when instrument detects that a GPS

receiver is connected to the unit’s GPS port

: Barcode icon appears when the instrument

detects that a barcode reader wand is

connected to the unit’s SCANNER port

: Battery status icon (refer to Section 3.10)

Back(%): Measured background gas level in

[0001]: Current Test ID number

either percent-by-volume or ppm

(A)or (M): Automatic or Manual mode (refer to

Leak(%): Measured natural gas leak

Section 3.14)

concentration at the current sample flow rate

in either percent-by-volume or ppm

Leak(lpm): Calculated leak rate in either

liters/min or cu.ft./min.*

Speed(LO<––––|>HI): Blower speed indicator.

Start / Stop: Select to Start and Stop a test**

S--: Standby

-1-: Measurement #1 (maximum flow rate)

--2: Measurement #2 (reduced flow rate)

Message Line: Various messages appear

during operation describing the current

function being performed, or errors that have

occurred (refer to Section 3.19)

Menu: Select to display the first of several

submenus (refer to Section 3.9)**

* “Not Avail.” is displayed when a value cannot be calculated from available information.

** Selections are made by using the keys to highlight the desired function, and then

pressing the I/Okey to activate that function.

Instruction 0055-9017

15

Page 20

Operation Hi Flow Sampler

3.8.2 Expanded Main Screen

Date and Time: Date displayed as

mm/dd/yy, while time is displayed in a 12hour format. The date and time are set per

Section 5.8.

Save: Select to save all current measurement

parameters in memory**

Start / Stop: Select to Start and Stop a test**

Lat(°): Latitude in degrees*

Lon(°): Longitude in degrees*

Alt(ft): Altitude in feet*

Fix(sec): Time Of Fix between –1 and

−10 seconds (time lag between the received

GPS signal and the displayed values of

latitude, longitude, and altitude)*

Btry(V): Battery voltage

#1 – #2(%): Difference between test measure-

ments #1 and #2 in percent*

Flow(lpm): Sample flow rate in either

liters/min or cu.ft./min.

Back(%): Measured background gas level in

either percent-by-volume or ppm

Leak(%): Measured natural gas leak

concentration at the current sample flow rate

in either percent-by-volume or ppm

Leak(lpm): Calculated leak rate in either

liters/min or cu.ft./min.*

Menu: Select to display the first of several

submenus (refer to Section 3.9)**

: GPS (Global Positioning System) icon

appears when instrument detects that a GPS

receiver is connected to the unit’s GPS port

: Barcode icon appears when the instrument

detects that a barcode reader wand is

connected to the unit’s SCANNER port

: Battery status icon (refer to Section 3.10)

[0001]: Current Test ID number

(A)or (M): Automatic or Manual mode (refer to

Section 3.14)

S--: Standby

-1-: Measurement #1 (maximum flow rate)

--2: Measurement #2 (reduced flow rate)

Message Line: Various messages appear

during operation describing the current

function being performed, or errors that have

occurred (refer to Section 3.19)

Speed(LO<––––|>HI): Blower speed indicator.

* “Not Avail.” is displayed when a value cannot be calculated from available information.

** Selections are made by using the keys to highlight the desired function, and then

pressing the I/Okey to activate that function.

16

Instruction 0055-9017

Page 21

Hi Flow Sampler Operation

3.9 Menu System

Selecting Menu from either the Basic or Expanded Main Screen provides

the user access to a system of submenus as shown in Figures 3-4 and 3-

5.

The items that are listed in the submenus depend on whether the

instrument is in its Basic or Expanded menu mode.

The functions listed are described in their associated sections of this

manual.

Figure 3-4. Basic Menu System

Figure 3-5. Expanded Menu System

Instruction 0055-9017

17

Page 22

Operation Hi Flow Sampler

3.10 Battery Status

Battery status is displayed as a single battery icon shown in the lowerleft hand portion of the LCD. Since the voltage curve of the battery pack

drops off rapidly towards the end of its charge, the Battery status icon is

useful only in showing when the battery pack is nearing depletion. It

does not show the pack’s remaining percentage-of-charge.

4.0 volts and above

(Shutdown imminent, less than 5 minutes of operating time remain)

3.11 Calibration Menu

Selecting Calibration from the Menu System allows the user to either:

1) calibrate the sensors, 2) verify calibration, 3) view dates on which

calibrations were performed, 3) view amplifier gain values (in

hexadecimal) of each sensor circuit, or 4) erase calibration.

A detailed description of each calibration function is provided in

Section 4 Calibration.

3.12 Set Flow Units – lpm or cfm

Selecting Set Flow Units from the Menu System allows the user to select

whether the flow rate is displayed in either lpm (liters per minute), or cfm

(cubic feet per minute).

Select the desired flow rate unit of measure as follows:

1. From the Main Screen, select Menu > Set Flow Units.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

C a l i b r a t i o n

S e t F l o w U n i t s

M e n u M o d e

[ 0 0 0 1 ] ( M ) S - -

2. Highlight the desired units of measure and then press the I/O key.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

c f m ( c u . f t . / m i n . )

l p m ( l i t e r s / m i n . )

18

[ 0 0 0 1 ] ( M ) S - -

3. Press ESC to return to the Main Screen.

Instruction 0055-9017

Page 23

Hi Flow Sampler Operation

3.13 Menu Mode – Basic or Expanded

Selecting Menu Mode from the Menu System allows the user to select

whether only the most basic amount of information is displayed on the

Main Screen (Basic Menu mode), or if all available information is

displayed (Expanded Menu mode).

Refer to Section 3.8 Selecting the Basic or Expanded Menu Mode for

detailed information on how to select the desired menu mode, and learn

about what type of information is displayed in each mode.

3.14 Operating Mode – Automatic or Manual

Note: The Operating Mode can only be selected if operating in the Expanded

Menu Mode. Refer to Section 3.8.

Selecting Operating Mode from the Expanded Menu System allows the

user to set the instrument’s operating mode to either Automatic or

Manual.

3.14.1 Automatic 2-Stage Measurement Mode

In the Automatic 2-Stage Mode the unit performs a leak rate

measurement at first a high flow rate for 1 minute, and then

automatically shifts to a lower flow rate and performs another

measurement for another minute. The final measured and calculated

values are automatically saved in memory. This mode is used to measure

leaks that are easily identifiable and captured.

Select the automatic measurement mode as follows:

1. From the Expanded Main Screen, select Menu > Operating Mode.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

C a l i b r a t i o n

S e t F l o w U n i t s

M e n u M o d e

O p e r a t i n g M o d e

A c c e s s R e c o r d s

[ 0 0 0 1 ] ( M ) S - -

2. Highlight Automatic 2-Stage, and then press the I/O key.

0 2 / 2 1 / 0 3 0 9 : 4 5 : 3 0

A u t o m a t i c 2 - S t a g e

M a n u a l 2 - S t a g e

M a n u a l 1 - S t a g e

Instruction 0055-9017

[ 0 0 0 5 ] ( M ) S - -

3. Press ESC to return to the Main Screen. Observe that (A) should

appear at the bottom of the screen

19

Page 24

Operation Hi Flow Sampler

3.14.2 Manual Measurement Mode

3.14.2.1 Manual 2-Stage Mode

In the Manual 2-Stage mode the user starts a measurement at a high

flow rate, waits for a stable leak rate reading, and then manually saves

the readings using the Save function. The unit then automatically lowers

the flow rate, at which time the user makes a second leak rate

measurement. After waiting for the leak rate reading to once again

stabilize, the user then manually saves all final measured and calculated

measurements in memory. This mode is used when more control of the

leak rate measurement process is required.

Select Manual 2-Stage operation as follows:

1. From the Expanded Main Screen, select Menu > Operating Mode.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

C a l i b r a t i o n

S e t F l o w U n i t s

M e n u M o d e

O p e r a t i n g M o d e

A c c e s s R e c o r d s

[ 0 0 0 1 ] ( M ) S - -

2. Highlight Manual 2-Stage, and then press the I/O key.

0 2 / 2 1 / 0 3 0 9 : 4 5 : 3 0

A u t o m a t i c 2 - S t a g e

M a n u a l 2 - S t a g e

M a n u a l 1 - S t a g e

[ 0 0 0 5 ] ( M ) S - -

3. Press ESC to return to the Main Screen. Observe that (M) should

appear at the bottom of the screen

20

Instruction 0055-9017

Page 25

Hi Flow Sampler Operation

3.14.2.2 Manual 1-Stage Mode

In the Manual 1-Stage mode the user starts a measurement at a high

flow rate and then waits for a stable leak rate reading to occur. During

this time the flow rate can be changed using the Speed function on the

Main Screen. After a stable leak rate reading is obtained, the user can

manually save all final measured and calculated values in memory using

the Save function on the Expanded Main Screen. This mode is used

when more control of the leak rate measurement process is required.

Select Manual 1-Stage operation as follows:

1. From the Expanded Main Screen, select Menu > Operating Mode.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

C a l i b r a t i o n

S e t F l o w U n i t s

M e n u M o d e

O p e r a t i n g M o d e

A c c e s s R e c o r d s

[ 0 0 0 1 ] ( M ) S - -

2. Highlight Manual 1-Stage, and then press the I/O key.

0 2 / 2 1 / 0 3 0 9 : 4 5 : 3 0

A u t o m a t i c 2 - S t a g e

M a n u a l 2 - S t a g e

M a n u a l 1 - S t a g e

[ 0 0 0 5 ] ( M ) S - -

3. Press ESC to return to the Main Screen. Observe that (M) should

appear at the bottom of the screen

Instruction 0055-9017

21

Page 26

Operation Hi Flow Sampler

3.15 Access Records

Note: Send Records can only be selected if operating in the Expanded Menu

Mode. Refer to Section 3.8.

Selecting Access Records from the Expanded Menu System allows a

user to either: 1) send all saved records to a personal computer, 2) view

the records on the unit’s LCD screen, or 3) erase all saved records.

3.15.1 Send Records

All the measured and calculated values that were saved in memory can

be downloaded to a personal computer as comma-delimited ASCII text,

which can later be imported into most spreadsheet programs for

analysis.

The following describes how to download saved records to a computer

that is running Windows

program. If a different operating system and/or communications

program is being used, then please consult the appropriate instruction

manuals for those products.

Note: Send Records can only be selected if operating in the Expanded Menu

Mode. Refer to Section 3.8.

1. Install serial data cable P/N 104-4027 (straight through, 6 foot, DB9

male to DB9 female) between the computer’s COM port and the Hi

Flow’s COMPUTER connector. (For computers having a 25-pin or

USB COM port, the user must supply the appropriate adapter, or use

a serial cable with appropriate connectors on each end.)

2. On the computer, start HyperTerminal by doing one of the following:

- If HyperTerminal has already been set up to communicate with the

Hi Flow Sampler, then select Start > Programs > Accessories >

Communications > HyperTerminal, and double-click the filename

or icon that has been associated with the instrument.

- If HyperTerminal has never been run in association with the Hi

Flow Sampler, then a new HyperTerminal connection needs to be

made as follows:

a. Select Start > Run. In the Run box type “hypertrm.exe” and

click OK. The New Connection dialog box should appear.

b. Type in a New Connection Name such as “HiFlow”. Click OK to

select the default icon (if desired, select a different icon before

clicking OK). The Connect To dialog box should appear.

c. Click the Connect using drop-down menu and choose the COM

port to which the Hi Flow is connected. Then click OK to display

the COM Properties dialog box for that COM port.

®

HyperTerminal as the communications

22

Instruction 0055-9017

Page 27

Hi Flow Sampler Operation

d. Set Port Settings to:

- Bits per second: 115200

- Data bits: 8

- Parity: None

- Stop bits: 1

- Flow control: None

Then click OK to display HyperTerminal’s main window.

e. Click File > Save. This creates a file with an .ht extension using

the name that was entered in Step b.

3. After HyperTerminal is running: click Transfer > Capture Text >

Start to accept the default drive\directory\filename to which all

received data will be stored as an ASCII text file.

Note: The captured text file will be stored on the hard drive in the folder

shown in the File dialog box. If desired, click Browse to select a different

drive, directory and filename. The next time data is captured, it will be

stored under the same location and filename.

Tip: Changing the filename extension to “CSV” (comma separated

variable) will allow the file to be directly opened in the spreadsheet

program. For example, double clicking the filename CAPTURE.CSV in

Windows Explorer will automatically start Microsoft Excel and load the file.

4. From the High Flow Sampler’s Expanded Main Screen, start the

download process by selecting Menu > Access Records > Send

Records.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e n d R e c o r d s

V i e w R e c o r d s

E r a s e R e c o r d s

Instruction 0055-9017

[ 0 0 0 1 ] ( M )

S - -

Observe that the Hi Flow’s LCD displays the message “Sending record

x of y @ 115.2kbps,” where “x” is the current record being sent and

“y” is the number of records in memory. Also observe that

HyperTerminal displays the data as its being received.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e n d i n g r e c o r d

x o f y

@ 1 1 5 . 2 k b p s

[ 0 0 0 1 ] ( M )

S - -

5. After all data has been transmitted, stop HyperTerminal from

capturing data by clicking Transfer > Capture Text > Stop.

6. The saved data can now be viewed in a spreadsheet for analysis as

described in Section 3.16 Importing Saved Data into a Spreadsheet.

23

Page 28

Operation Hi Flow Sampler

3.15.2 View Records

View the records stored in memory on the unit’s LCD screen as follows:

1. Access the Review Record Screen from the Expanded Main Screen by

selecting Menu > Access Records > View Records. This screen

allows the user to view a short summary of each record stored in

memory. If no records are in memory, then the message “No Records

Saved” briefly appears in the message line.

The first two lines in this screen contain the Test ID information as

entered per Section 3.17 Access Test IDs.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

T e s t I D L i n e 1

T e s t I D L i n e 2

L e a k ( l p m ) x . x x

# 1 - # 2 ( % ) y y . y

[ 0 0 0 1 ] ( M )

Where: x.xx is the recorded leak rate in ether lpm or cfm

yy.y is the percent difference between measurements #1 and

#2

2. Use the keys to scroll through the saved records.

3. Press ESC three times to return to the Main Screen.

3.15.3 Erase Records

Erase all records from memory as follows:

1. From the Expanded Main Screen, select Menu > Access Records >

Erase Records.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e n d R e c o r d s

V i e w R e c o r d s

E r a s e R e c o r d s

[ 0 0 0 1 ] ( M )

2. Confirm or cancel the erase process by selecting Yes or No.

0 2 / 2 1 / 0 3 0 9 : 4 5 : 3 0

S - -

S - -

24

E r a s e a l l r e c o r d s ?

Y e s

N o

[ 0 0 0 1 ] ( A )

S - -

3. Observe the message “Erasing all records” appears at the bottom of

the display during the erase process.

Instruction 0055-9017

Page 29

Hi Flow Sampler Operation

3.16 Importing Saved Data into a Spreadsheet

Test records that were downloaded to a personal computer per Section

3.15.1 can be imported into spreadsheet programs that are capable of

importing comma-delimited files. Note that each data record consists of

24 fields, some of which may be blank because of options not being

installed.

TABLE 3-1. COMMA-DELIMITED FIELDS

Field

1 Record# Test Record Number

2 Inst.Serial# Instrument’s Serial Number

3 Date#1(MM/DD/YY) Date (Measurement #1)

4 Time#1(HH:MM:SS) Time (Measurement #1)

5 Btry#1(V) Battery Voltage (Measurement #1)

6 Flow#1(cfm) Sample Flow Rate (Measurement #1) in cfm

7 Back#1(%) Background Gas Level (Measurement #1) in %

8 Leak#1(%) Sample Leak Rate (Measurement #1) in %

9 Leak#1(cfm) Leak Rate of Component Under Test (Measurement #1) in

10 Date#2(MM/DD/YY) Date (Measurement #2)

11 Time #2(HH:MM:SS) Time (Measurement #2)

12 Btry#2(V) Battery Voltage (Measurement #2)

13 Flow#2(cfm) Sample Flow Rate (Measurement #2) in cfm

14 Back#2(%) Background Gas Level (Measurement #2) in %

15 Leak#2(%) Sample Leak Rate (Measurement #2) in %

16 Leak#2(cfm) Leak Rate of Component Under Test (Measurement #2) in

17 Leak#1-#2(%) Percent Difference Between Leak Measurements #1 and #2

18 Error Codes Error Codes identifying problems that occurred during the

19 Barcode# Barcode Type (UPC, EAN, Code 128, Cadabar)

20 Barcode Symbology Barcode Number Scanned

21 GPS Latitude(deg) Latitude of Instrument in Degrees

22 GPS Longitude(deg) Longitude of Instrument in Degrees

23 GPS Altitude(ft) Altitude of Instrument in Meters

24 Test Description Test ID Information (refer to Section 3.15 Access Test IDs)

Instruction 0055-9017

Label in Column

Heading

Description

cfm

cfm

test (refer to Section 6.3 Error Codes in Saved Test Records)

25

Page 30

Operation Hi Flow Sampler

TABLE 3-2. TYPICAL SPREADSHEET*

Record# Instr.Serial# Date#1(MM/DD/YY) Time#1(HH:MM:SS) Btry#1(V) Flow#1(cfm)

1 123456 01/20/03 10:15:05 4.9 9.9

2 123457 01/20/03 01:25:30 4.8 9.8

Back#1(%) Leak#1(%) Leak#1(cfm) Date#2(MM/DD/YY) Time#2(HH:MM:SS) Btry#2(V)

0.0350 15.1500 1.49 01/20/03 10:16:05 4.9

0.0155 21.3250 2.09 01/20/03 01:27:45 4.8

Flow#2(cfm) Back#2(%) Leak#2(%) Leak#2(cfm) Leak#1-#2(%) Error Codes Barcode#

7.4 0.0375 21.2300 1.5 5.0 UPC

7.3 0.0245 29.1800 2.1 1.8 UPC

Barcode Symbology GPS Latitude(deg) GPS Longitude(deg) GPS Altitude(ft)

031323078 56098 40.5370 –80.252 900

031323078 56099 40.5450 –80.300 1000

GPS Fix(s) Test Description

–3 Test Location 1 Operator John Doe

–6 Test Location 2 Operator John Doe

* Line 1: Column Headings

Line 2: Record 1, Typical Test Automatic Mode

Line 3: Record 2, Typical Test Manual Mode

The following describes how to generate a spreadsheet from a comma-

®

delimited text file using Microsoft

Excel 2000. If a different spreadsheet

program is being used, then please refer to its instruction manual for

information on how to import comma-delimited text files.

Tip: If the text file was saved with the filename extension “CSV” as

described in Section 3.13.1, a spreadsheet will automatically be created

when that file is opened in Microsoft Excel.

1. Start Microsoft Excel.

2. Click File, then click Open to display the Open dialog box.

3. Change the Files of type: to Text Files. Then navigate to the

directory containing the text file to be imported.

4. Double-click the desired filename to display the Text Import Wizard –

Step 1 of 3 dialog box.

5. Select the Delimited radio button; then click Next to display the Text

Import Wizard – Step 2 of 3 dialog box.

6. Under Delimiters, select the Comma check box. Then click Next to

display the Text Import Wizard – Step 3 of 3 dialog box.

7. Click Finish to create the spreadsheet.

26

Instruction 0055-9017

Page 31

Hi Flow Sampler Operation

3.17 Access Test IDs

Note: Access Test IDs can only be selected if operating in the Expanded

Menu Mode. Refer to Section 3.8.

Saved test records can be identified (e.g., location of test, type of test,

name of operator, etc.) by manually entering up to two lines of text, with

each line containing a maximum of 20 alphanumerical characters. This

information will be associated with all succeeding tests, and will appear

when the test record is either viewed or printed. The chosen Test ID

remains in effect until a new Test ID is selected.

Selecting Access Test IDs from the Expanded Menu System allows the

user to select a previously entered Test ID, create a new Test ID or edit

an old one, send the Test IDs to a computer, or erase all existing Test

IDs.

3.17.1 Select Test IDs

Select a Test ID as follows:

1. From the Expanded Main Screen, select Menu > Access Test IDs >

Select Test IDs.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e l e c t T e s t I D s

E d i t T e s t I D s

S e n d T e s t I D s

E r a s e T e s t I D s

[ 0 0 0 4 ] ( A ) S - -

2. Use the keys to scroll through any previously stored Test IDs until

the desired ID is displayed. In the example below, Test ID 0005 has been

chosen.

Tip: To quickly scroll through the Test IDs, press and hold down

the or key.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

T e s t L o c a t i o n 1

O p e r a t o r J o h n D o e

[ 0 0 0 5 ] ( A ) S - -

Instruction 0055-9017

27

Page 32

Operation Hi Flow Sampler

3. Select the displayed Test ID by pressing the I/Okey, and then

return to the Main Screen by pressing ESC twice. Observe that [0005]

is now displayed at the bottom of the screen.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

L e a k ( N o t A v a i l . )

S p e e d ( L O < > H I )

S a v e

S t a r t

M e n u

[ 0 0 0 5 ] ( A ) S - -

3.17.2 Edit Test IDs

Edit a previously entered Test ID or to create a new one as follows:

1. First select the Test ID to edit per Section 3.17.1 Select Test IDs. To

create a new Test ID, select the last Test ID number that can be

displayed – the last Test ID number will always be blank.

2. From the Expanded Main Screen, select Menu > Access Test IDs >

Edit Test IDs.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e l e c t T e s t I D s

E d i t T e s t I D s

S e n d T e s t I D s

E r a s e T e s t I D s

[ 0 0 0 5 ] ( A ) S - -

3. Use the following keys to select and then enter the desired character.

– displays desired alphanumerical character

I/O – selects displayed character and moves cursor one space

to the right

ESC – moves cursor one space to the left

Tip: To quickly scroll through the characters, press and hold down

the or key.

Tip: The “space” character is between the number “9” and the capital

“A”.

In the example below, the Test Location has been changed from 1 to

2 with the cursor positioned to the immediate right of the number 2.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

T e s t L o c a t i o n 2 |

O p e r a t o r J o h n D o e

[ 0 0 0 5 ] ( A ) S - -

4. After all characters have been selected, press and hold down the

I/Okey to move the cursor to the end of the screen; after which, the

screen shown in Step 2 should reappear.

28

Instruction 0055-9017

Page 33

Hi Flow Sampler Operation

5. Press the ESC key twice to return to the Main Screen.

3.17.3 Send Test IDs

The following describes how to download the current list of Test IDs to a

computer that is running Windows

communications program. If a different operating system and/or

communications program is being used, then please consult the

appropriate instruction manuals for those products.

1. Install serial data cable P/N 104-4027 (straight through, 6 foot, DB9

male to DB9 female) between the computer’s COM port and the Hi

Flow’s COMPUTER connector. (For computers having a 25-pin or

USB COM port, the user must supply the appropriate adapter, or use

a serial cable with appropriate connectors on each end.)

2. On the computer, start HyperTerminal by doing one of the following:

- If HyperTerminal has already been set up to communicate with the

Hi Flow Sampler, then select Start > Programs > Accessories >

Communications > HyperTerminal, and double-click the filename

or icon that has been associated with the instrument.

- If HyperTerminal has never been run in association with the Hi Flow

Sampl-er, then a new HyperTerminal connection needs to be made as

follows:

a. Select Start > Run. In the Run box type “hypertrm.exe” and

click OK. The New Connection dialog box should appear.

b. Type in a New Connection Name such as “HiFlow”. Click OK to

select the default icon (if desired, select a different icon before

clicking OK). The Connect To dialog box should appear.

c. Click the Connect using drop-down menu and choose the COM

port to which the Hi Flow is connected. Then click OK to display

the COM Properties dialog box for that COM port.

d. Set Port Settings to:

- Bits per second: 115200

- Data bits: 8

- Parity: None

- Stop bits: 1

- Flow control: None

Then click OK to display HyperTerminal’s main window.

e. Click File > Save. This creates a file with an .ht extension using

the name that was entered in Step b.

3. After HyperTerminal is running: click Transfer > Capture Text >

Start to accept the default drive\directory\filename to which all

received data will be stored as an ASCII text file.

Note: The captured text file will be stored on the hard drive in the folder

shown in the File dialog box. If desired, click Browse to select a different

drive, directory and filename. The next time data is captured, it will be

stored under the same location and filename.

®

HyperTerminal as the

Instruction 0055-9017

29

Page 34

Operation Hi Flow Sampler

4. From the High Flow Sampler’s Expanded Main Screen, start the

download process by selecting Menu > Access Test IDs > Send Test

IDs.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e l e c t T e s t I D s

E d i t T e s t I D s

S e n d T e s t I D s

E r a s e T e s t I D s

Observe that the Hi Flow’s LCD displays the message “Sending record

x of y @ 115.2kbps,” where “x” is the current record being sent and

“y” is the number of records in memory. Also observe that

HyperTerminal displays the data as its being received.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e n d i n g r e c o r d

x o f y

@ 1 1 5 . 2 k b p s

5. After all data has been transmitted, stop HyperTerminal from

capturing data by clicking Transfer > Capture Text > Stop.

6. The saved data can now be viewed on the computer using any

program capable of displaying “txt” files.

3.17.4 Erase Test IDs

Erase all Test ID information and reset the Test ID index back to 0001 as

follows:

1. From the Expanded Main Screen, select Menu > Access Test IDs >

Erase Test IDs.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

S e l e c t T e s t I D s

E d i t T e s t I D s

S e n d T e s t I D s

E r a s e T e s t I D s

[ 0 0 0 4 ] ( A ) S - -

[ 0 0 0 4 ] ( A )

S - -

30

[ 0 0 0 4 ] ( A ) S - -

Instruction 0055-9017

Page 35

Hi Flow Sampler Operation

2. Select Yes to erase all Test ID information, or select No to return to

the previous screen.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

E r a s e A l l T e s t I D s ?

Y e s

N o

[ 0 0 0 4 ] ( A ) S - -

3. Press ESC twice to return to the Main Screen.

Instruction 0055-9017

31

Page 36

Operation Hi Flow Sampler

3.18 Making a Leak Rate Measurement

Before making a leak rate measurement, the user must decide whether

to use . . .

the Basic or Expanded Menu Mode (Section 3.8)

lpm or cfm for the flow rate (Section 3.12)

the Automatic 2-Stage, Manual 2-Stage, or Manual 1-Stage

method of making a measurement when operating in the

Expanded Menu Mode (Section 3.14)

a Test ID when operating in the Expanded Menu Mode (Section

3.17)

3.18.1 Leak Rate Measurement – Basic Menu Mode

While operating in the Basic Menu Mode, the user starts a measurement

at a high flow rate and then waits for a stable leak rate reading to occur.

During this time the flow rate can be changed using the Speed function

on the Main Screen. This mode is used when more control of the leak

rate measurement process is required, and when saving data is not

desired.

1. If not already done, place the instrument into its Basic Menu Mode

per

Section 3.8 Selecting the Basic or Expanded Menu Mode.

2. Choose an attachment that will ensure the complete capture of the

gas leak. Connect this attachment to the end of the Hi Flow

Sampler’s main sampling hose and position the attachment’s inlet

over the leak source.

3. Position the inlet of the instrument’s background gas sampling hose

opposite the leak source, such that the leak source will not

contribute to the background measurement.

4. Select Start from the Main Screen.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

B a c k ( % ) 0 . 0 0

L e a k ( % ) 0 . 0 0

L e a k ( N o t A v a i l . )

S p e e d ( L O < > H I )

S t a r t

[ 0 0 0 1 ] ( M ) S - -

5. Begin measuring until a stable leak measurement is achieved—this

may take several minutes.

If desired, the flow rate can be manually controlled by using the

Speed function. Each press of the I/O key will lower the flow rate as

indicated by the speed bar moving to the left.

32

Instruction 0055-9017

Page 37

Hi Flow Sampler Operation

1 1 / 2 2 / 0 4 0 9 : 4 7 : 3 0

F l o w ( l p m ) 2 1 6 . 5

B a c k ( % ) 0 . 8 0

L e a k ( % ) 1 5 . 0 0

L e a k ( l p m ) 4 2 . 5

S p e e d ( L O < > H I )

[ 0 0 0 1 ] ( M ) - 1 -

S a m p l e T i m e - > 0 2 : 0 0

6. In the example below, the current flow rate is 216.5 lpm, the

background gas concentration is 0.8%, the leak concentration is 15%

gas, and the calculated leak rate is 42.5 lpm.

1 1 / 2 2 / 0 4 0 9 : 4 7 : 3 0

F l o w ( l p m ) 2 1 6 . 5

B a c k ( % ) 0 . 8 0

L e a k ( % ) 1 5 . 0 0

L e a k ( l p m ) 4 2 . 5

S p e e d ( L O < > H I )

[ 0 0 0 1 ] ( M ) - 1 -

S a m p l e T i m e - > 0 2 : 0 0

7. The measurement process continues until Stop is selected.

1 1 / 2 2 / 0 4 0 9 : 5 0 : 0 0

B a c k ( % ) 0 . 8 0

L e a k ( % ) 1 5 . 0 0

L e a k ( l p m ) 4 2 . 5

S p e e d ( L O < > H I )

S t o p

S a v e

[ 0 0 0 1 ] ( M ) - 1 -

S a m p l e T i m e - > 0 4 : 3 0

3.18.2 Leak Rate Measurement – Automatic 2-Stage Mode

Note: The Automatic 2-Stage Mode can only be selected if operating in the

Expanded Menu Mode. Refer to Section 3.8.

1. If not already done, place the instrument into its Automatic 2-Stage

measurement mode (denoted by the letter (A) appearing at the bottom

of the screen). Refer to Section 3.14.1 Automatic 2-Stage Measurement

Mode.

2. Choose an attachment that will ensure the complete capture of the

gas leak. Connect this attachment to the end of the Hi Flow

Sampler’s main sampling hose and position the attachment’s inlet

over the leak source.

3. Position the inlet of the instrument’s background gas sampling hose

opposite the leak source, such that the leak source will not

contribute to the background measurement.

4. Begin the measurement process by selecting Start from the Main

Screen.

Instruction 0055-9017

33

Page 38

Operation Hi Flow Sampler

ar

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

L e a k ( % ) 0 . 0 0

L e a k ( N o t A v a i l . )

S p e e d ( L O < > H I )

S a v e

S t a r t

[ 0 0 0 1 ] ( A ) S - -

5. The user is now asked to choose a new or different Test ID.

Selecting Yes causes the Access Records menu to appear (refer to

Section 3.15). After selecting or creating a new Test ID, start the

measurement by pressing ESC until the Main Screen appears.

Selecting No returns the display to the Main Screen and starts the

measurement using the current Test ID.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

A s s i g n n e w t e s t I D ?

Y e s

N o

[ 0 0 0 1 ] ( A ) S - -

6. (Optional) The instrument normally controls the flow rate for

measurements #1 and #2; however, the user can manually set the

flow rate using the Speed function. Each press of the I/O key will

lower the flow rate as indicated by the speed bar moving to the left.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

F l o w ( l p m ) 0 . 0

B a c k ( % ) 0 . 0 0

L e a k ( % ) 0 . 0 0

L e a k ( l p m ) 0 . 0

S p e e d ( L O < > H I )

[ 0 0 0 1 ] ( A ) - 1 -

Speed B

34

Instruction 0055-9017

Page 39

Hi Flow Sampler Operation

7. After both measurements are complete, the values in the Main Screen

are put on hold (as indicated by “H--” appearing at the bottom of the

screen), allowing the user to make note of these values before turning off

the instrument or proceeding to the next measurement.

In the examples below, the measured leak concentration was 15% gas

during the first measurement and 18% gas in the second, while the

calculated leak rates were 42.5 and 40.8 lpm, respectively. A difference

of 4%.

Important: For a test to be considered valid, the percent difference

between measurements #1 and #2 must be less than 10%. Scroll up to

the #1–#2 function on the Main Screen to see the percent difference

between the last two measurements.

1 1 / 2 2 / 0 4 1 0 : 4 6 : 3 0

F l o w ( l p m ) 2 1 6 . 5

B a c k ( % ) 0 . 8 0

L e a k ( % ) 1 5 . 0 0

L e a k ( l p m ) 4 2 . 5

S p e e d ( L O < > H I )

[ 0 0 0 5 ] ( A ) - 1 -

S a m p l e T i m e - > 0 1 : 0 0

0 2 / 2 1 / 0 3 1 0 : 4 7 : 3 0

F l o w ( l p m ) 1 8 0 . 5

B a c k ( % ) 0 . 0 7

L e a k ( % ) 1 8 . 0 0

L e a k ( l p m ) 4 0 . 8

S p e e d ( L O < > H I )

[ 0 0 0 5 ] ( A ) - - 2

S a m p l e T i m e - > 0 2 : 0 0

8. When in the automatic mode, measurements are automatically

saved. These saved measurements along with their associated Test

IDs can be downloaded to a personal computer at a later time for

analysis. Refer to Section 3.16 Importing Saved Data into a

Spreadsheet.

Instruction 0055-9017

35

Page 40

Operation Hi Flow Sampler

ar

3.18.3 Leak Rate Measurement – Manual 2-Stage Mode

Note: The Manual 2-Stage Mode can only be selected if operating in the

Expanded Menu Mode. Refer to Section 3.8.

1. If not already done, place the instrument into its Manual 2-Stage

mode. Refer to Section 3.14.2.1 Manual 2-Stage Mode.

2. Choose an attachment that will ensure the complete capture of the

gas leak. Connect this attachment to the end of the Hi Flow

Sampler’s main sampling hose and position the attachment’s inlet

over the leak source.

3. Position the inlet of the instrument’s background gas sampling hose

opposite the leak source, such that the leak source will not

contribute to the background measurement.

4. Begin the measurement process by selecting Start from the Main

Screen.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

L e a k ( % ) 0 . 0 0

L e a k ( N o t A v a i l . )

S p e e d ( L O < > H I )

S a v e

S t a r t

[ 0 0 0 1 ] ( M ) S - -

5. The user is now asked to choose a new or different Test ID.

Selecting Yes causes the Access Records menu to appear (refer to

Section 3.15). After selecting or creating a new Test ID, start the

measurement by pressing ESC until the Main Screen appears.

Selecting No returns the display to the Main Screen and starts the

measurement using the current Test ID.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

36

A s s i g n n e w t e s t I D ?

Y e s

N o

[ 0 0 0 1 ] ( M ) S - -

6. Begin measuring at the first flow rate until a stable leak

measurement is achieved—this may take several minutes.

If desired, the flow rate can be manually controlled by using the

Speed function. Each press of the I/O key will lower the flow rate as

indicated by the speed bar moving to the left.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

F l o w ( l p m ) 0 . 0

B a c k ( % ) 0 . 0 0

L e a k ( % ) 0 . 0 0

L e a k ( l p m ) 0 . 0

S p e e d ( L O < > H I )

[ 0 0 0 1 ] ( M ) - 1 -

Speed B

Instruction 0055-9017

Page 41

Hi Flow Sampler Operation

7. Once a stable leak measurement is obtained, highlight Save and

press the I/Okey. Observe that the measurement is saved in

memory, and that the flow rate is automatically lowered.

In the example below, the measured leak concentration for

measurement #1 was 15% gas, and the calculated leak rate was 42.5

lpm.

1 1 / 2 2 / 0 4 0 9 : 4 7 : 1 5

B a c k ( % ) 0 . 8 0

L e a k ( % ) 1 5 . 0 0

L e a k ( l p m ) 4 2 . 5

S p e e d ( L O < > H I )

S a v e

[ 0 0 0 1 ] ( M ) - 1 -

S a m p l e T i m e - > 0 1 : 4 5

8. Continue sampling at the reduced flow rate until once again a stable

leak measurement is achieved. If desired, the flow rate can again be

manually controlled by using the Speed function.

With Save highlighted, press the I/Okey to save measurement #2 in

memory. The blower then stops and the values in the Main Screen are

put on hold (as indicated by “H--” appearing at the bottom of the screen),

allowing the user to make note of these values before turning off the

instrument or proceeding to the next measurement.

In the example below, the leak concentration was 18% gas, the leak

rate was 40.8 lpm, and the percent difference between measurements

#1 and #2 was 4%.

Important: For a test to be considered valid, the percent difference

between measurements #1 and #2 must be less than 10%. Scroll up to

the #1–#2 function on the Main Screen to see the percent difference

between the last two measurements.

1 1 / 2 2 / 0 4 0 9 : 4 9 : 0 0

B a c k ( % ) 0 . 8 0

L e a k ( % ) 1 8 . 0 0

L e a k ( l p m ) 4 0 . 8

S p e e d ( L O < > H I )

S a v e

[ 0 0 0 1 ] ( M ) - - 2

S a v e

S a m p l e T i m e - > 0 3 : 3 0

9. Saved measurements can downloaded to a personal computer at a

later time for analysis. Refer to Section 3.16 Importing Saved Data

into a Spreadsheet.

Instruction 0055-9017

37

Page 42

Operation Hi Flow Sampler

3.18.4 Leak Rate Measurement – Manual 1-Stage Mode

Note: The Manual 1-Stage Mode can only be selected if operating in the

Expanded Menu Mode. Refer to Section 3.8.

1. If not already done, place the instrument into its Manual 1-Stage

mode. Refer to Section 3.14.2.2 Manual 1-Stage Mode.

2. Choose an attachment that will ensure the complete capture of the

gas leak. Connect this attachment to the end of the Hi Flow

Sampler’s main sampling hose and position the attachment’s inlet

over the leak source.

3. Position the inlet of the instrument’s background gas sampling hose

opposite the leak source, such that the leak source will not

contribute to the background measurement.

4. Begin the measurement process by selecting Start from the Main

Screen.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

L e a k ( % ) 0 . 0 0

L e a k ( N o t A v a i l . )

S p e e d ( L O < > H I )

S a v e

S t a r t

[ 0 0 0 1 ] ( M ) S - -

5. The user is now asked to choose a new or different Test ID.

Selecting Yes causes the Access Records menu to appear (refer to

Section 3.15). After selecting or creating a new Test ID, start the

measurement by pressing ESC until the Main Screen appears.

Selecting No returns the display to the Main Screen and starts the

measurement using the current Test ID.

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

38

A s s i g n n e w t e s t I D ?

Y e s

N o

[ 0 0 0 1 ] ( M ) S - -

6. Begin measuring until a stable leak measurement is achieved—this

may take several minutes.

If desired, the flow rate can be manually controlled by using the

Speed function. Each press of the I/O key will lower the flow rate as

indicated by the speed bar moving to the left.

Instruction 0055-9017

Page 43

Hi Flow Sampler Operation

ar

1 1 / 2 2 / 0 4 0 9 : 4 5 : 3 0

F l o w ( l p m ) 0 . 0

B a c k ( % ) 0 . 0 0

L e a k ( % ) 0 . 0 0

L e a k ( l p m ) 0 . 0

S p e e d ( L O < > H I )

[ 0 0 0 1 ] ( M ) - 1 -

Speed B

7. Once a stable leak measurement is obtained, all current readings can

be saved in memory by highlighting Save and pressing the I/Okey.

In the example below, the current measured leak concentration is

15% gas, and the calculated leak rate is 42.5 lpm.

1 1 / 2 2 / 0 4 0 9 : 4 7 : 1 5

B a c k ( % ) 0 . 8 0

L e a k ( % ) 1 5 . 0 0

L e a k ( l p m ) 4 2 . 5

S p e e d ( L O < > H I )

S a v e

[ 0 0 0 1 ] ( M ) - 1 -

S a m p l e T i m e - > 0 1 : 4 5

8. The measurement process continues until Stop is selected.

1 1 / 2 2 / 0 4 0 9 : 4 9 : 0 0

L e a k ( % ) 1 5 . 0 0

L e a k ( l p m ) 4 2 . 5

S p e e d ( L O < > H I )

S a v e

S t o p

S a v e

[ 0 0 0 1 ] ( M ) - 1 -

S a m p l e T i m e - > 0 3 : 3 0

9. Measurements that were saved can be downloaded to a personal

computer at a later time for analysis. Refer to Section 3.16 Importing

Saved Data into a Spreadsheet.

Instruction 0055-9017

39

Page 44

Operation Hi Flow Sampler

3.19 Message Line

Various messages will appear at the bottom of the LCD that describe

what functions are currently being performed or errors that have been

detected. The following list describes the meaning of these messages.

Note that detailed explanations of the error messages can be found in

Section 6.2 Troubleshooting Guide.

Calibration Passed

Calibration procedure was successful.

Calibration Failed

Error – The calibration procedure was not successful. Refer to

Section 6.2.

Saving Record

A test record is currently being saved to memory.

Memory Full

Error – The instrument tried to save a test record with 1000 records

already stored in memory. Refer to Section 6.2.

No Records Saved

An attempt was made to send records to a computer with no test

records stored in memory.

Flow Rate Lowered

The flow rate has just been lowered signaling the start of

measurement #2 during an automatic or manual leak test. Refer to

Section 3.14.

Erasing All Records

All test records are being erased after selecting “Erase records” per

Section 3.15.3.

Check Background Pump

Error – The background-gas pump’s flow rate has been severely

reduced. Refer to Section 6.2.

Check Leak Pump

Error–The leak-gas pump’s flow rate has been severely reduced. Refer

to Section 6.2.

Check Background Calibration

Error – The background-gas sensor needs calibrated. Refer to

Section 6.2.

Check Leak Calibration

Error – The leak-gas sensor needs calibrated. Refer to Section 6.2.

Check Background Offset

Error – The background-gas sensor did not properly zero during

startup. Refer to Section 6.2

Check Leak Offset

Error – The leak-gas sensor did not properly zero during startup. Refer

to Section 6.2.

40

Instruction 0055-9017

Page 45

Hi Flow Sampler Operation

Check Zeroing Bypassed

Error – The ESC key was pressed during start up, thus bypassing the

normal sensor-zeroing process. Refer to Section 6.2.

Check Leak Rate Difference

Error–The calculated leak rate difference between measurements #1

and #2 during an automatic or manual leak test was greater than

100%. Refer to Section 6.2.

Check Background Greater Than Leak

Error–The measured background gas level was greater than the

measured leak gas concentration. Refer to Section 6.2

Sample Time