Page 1

H25-IR

Infrared Refrigerant Gas Leak Detector

Instruction 3015-4342

Operation & Maintenance

Rev. 1 – January 2006

Product Leadership • Training • Service • Reliability

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects in material and

manufacture and will conform substantially to Bacharach Inc.'s applicable specifications. Bacharach's liability and Buyer's

remedy under this warranty are limited to the repair or replacement, at Bacharach's option, of this Product or parts thereof

returned to Seller at the factory of manufacture and shown to Bacharach Inc.'s reasonable satisfaction to have been

defective; provided that written notice of the defect shall have been given by Buyer to Bacharach Inc. within two (2) years

after the date of delivery of this Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach's liability and Buyer's remedy

under this warranty of title are limited to the removal of any title defects or, at the election of Bacharach, to the

replacement of this Product or parts thereof that are defective in title.

The warranty set forth in paragraph 1 does not apply to parts the Operating Instructions designate as having a limited shelflife or as being expended in normal use (e.g., filters).

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY

AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE: AND (II) ANY

OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACT OR TORT, WHETHER OR NOT

ARISING FROM BACHARACH'S NEGLIGENCE, ACTUAL OR IMPLIED. The remedies of the Buyer shall be limited

to those provided herein to the exclusion of any and all other remedies including, without limitation incidental or

consequential damages. No agreement varying or extending the foregoing warranties, remedies or this limitation will be

binding upon Bacharach, Inc. unless in writing, signed by a duly authorized officer of Bacharach.

Register Your Warranty by Visiting

www.bacharach-inc.com

Notice:

Product improvements and enhancements are continuous; therefore the specifications

and information contained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this

material.

No part of this document may be photocopied, reproduced, or translated to another

language without the prior written consent of Bacharach, Inc.

Copyright © 2005–2006, Bacharach, Inc., all rights reserved.

BACHARACH

names, service marks and logos referenced herein belong to their respective owners.

A Instruction 3015-4342

®

is a registered trademark of Bacharach, Inc. All other trademarks, trade

Page 3

H25-IR Contents

Table of Contents

1 Introduction ................................................................................................................................ 1

1.1 Purpose of Instruction Manual ...........................................................................................................1

1.2 Safety Precautions...............................................................................................................................1

1.2.1 Warning Statements.............................................................................................................1

1.2.2 Caution Statements ..............................................................................................................1

1.2.3 Hazard Symbols ....................................................................................................................1

1.2.4 AC Power and Grounding.....................................................................................................1

1.2.5 Explosive Atmosphere ..........................................................................................................2

1.2.6 Working Inside the Instrument ...........................................................................................2

1.2.7 Misuse and Modifications to Instrument ............................................................................2

1.2.8 In Case of Malfunction..........................................................................................................2

1.2.9 Cleaning.................................................................................................................................2

1.3 Ordering Information ..........................................................................................................................3

1.4 Unpacking and Initial Checks ............................................................................................................3

1.5 Features and Capabilities ...................................................................................................................4

1.6 Functional Overview ...........................................................................................................................5

1.7 Names and Functions of Components................................................................................................6

1.7.1 Front View .............................................................................................................................6

1.7.2 Rear View ..............................................................................................................................7

1.7.3 Interior...................................................................................................................................7

1.7.4 Standard Probe .....................................................................................................................8

1.7.5 Standard Probe with LED and Programmable Pushbutton ..............................................8

1.7.6 Smart Probe...........................................................................................................................9

1.7.7 Smart Probe Keylock Function ............................................................................................9

1.8 Menu System .....................................................................................................................................10

2 Preparing for Operation ........................................................................................................ 11

2.1 Connecting the Probe ........................................................................................................................11

2.2 Connecting the AC Power Cord ........................................................................................................11

2.3 Turning ON the Instrument .............................................................................................................11

2.4 System Setup .....................................................................................................................................12

2.4.1 Gas Type ..............................................................................................................................12

2.4.2 Leak Units ...........................................................................................................................12

2.4.3 Relays...................................................................................................................................13

2.4.4 4–20 mA Loop ......................................................................................................................13

2.4.5 Brightness............................................................................................................................14

2.4.6 Clock ....................................................................................................................................14

2.4.7 PCHK Mode.........................................................................................................................14

2.4.8 Probe Button .......................................................................................................................14

2.4.9 Reset Defaults .....................................................................................................................14

2.5 Configuring the SETUPS Function ..................................................................................................15

2.5.1 Setup Name .........................................................................................................................15

2.5.2 Range ...................................................................................................................................15

2.5.3 Gas Type ..............................................................................................................................16

2.5.4 Feedback Mode....................................................................................................................16

2.5.5 Setpoint................................................................................................................................16

2.5.6 Search Auto Zero.................................................................................................................17

2.6 Calibration .........................................................................................................................................17

2.7 External Relay Connections..............................................................................................................18

2.8 4–40 mA Current Loop Connection ..................................................................................................19

3 Calibration................................................................................................................................. 21

3.1 Selecting Internal or External Calibration ......................................................................................21

3.1.1 Internal Calibration Selection............................................................................................21

3.1.2 External Calibration Selection and Setup.........................................................................22

3.2 Internal Calibration ..........................................................................................................................23

3.3 External Calibration..........................................................................................................................24

Instruction 3015-4342 i

Page 4

Contents H25-IR

3.4 CAL Factor......................................................................................................................................... 25

3.4.1 Simulating Other Internal Leak Source Gas Types Using the CAL Factor.................. 25

3.4.2 Improving PPM Measurement Accuracy using the CAL Factor .....................................26

3.4.3 Adjusting the CAL Factor ..................................................................................................27

3.5 Restoring Factory Calibration .......................................................................................................... 27

4 Operation....................................................................................................................................29

4.1 Instrument Location .........................................................................................................................29

4.2 Using the H25-IR ..............................................................................................................................29

4.2.1 Power ...................................................................................................................................29

4.2.2 Initial Setup ........................................................................................................................29

4.2.3 Range Selection................................................................................................................... 30

4.2.4 Setup Selection ...................................................................................................................30

4.2.5 Volume Adjustment ............................................................................................................31

4.2.6 Searching for a Leak...........................................................................................................31

4.2.7 Measuring the Leak Rate................................................................................................... 32

4.2.8 Measuring the PPM Level.................................................................................................. 32

4.2.9 Logging Measured Readings .............................................................................................. 33

4.2.10 Working with Logged Measurements................................................................................33

4.2.10.1 Viewing Logged Measurements .....................................................................33

4.2.10.2 Clearing the Log..............................................................................................34

4.2.10.3 Viewing the Total of all Logged Measurements............................................ 34

4.2.10.4 Setting the Log Limit...................................................................................... 34

4.3 What to Do when a Fault Occurs .....................................................................................................35

4.4 What is PCHK?.................................................................................................................................. 35

4.5 RS-232 Communication ....................................................................................................................35

5 Maintenance...............................................................................................................................37

5.1 Diagnostics Menu ..............................................................................................................................37

5.1.1 Sensor Data.........................................................................................................................37

5.1.2 Last Fault ............................................................................................................................ 38

5.1.3 IR Emitter ...........................................................................................................................39

5.1.4 Pressure............................................................................................................................... 39

5.2 Factory Menu..................................................................................................................................... 39

5.2.1 Auto Gain ............................................................................................................................40

5.2.2 DIGIPOT .............................................................................................................................40

5.2.3 Leak Rate ............................................................................................................................40

5.2.4 Leak Gas..............................................................................................................................40

5.2.5 Leak Temp...........................................................................................................................40

5.2.6 Leak TEMPCO.................................................................................................................... 41

5.2.7 Sensor Cal ........................................................................................................................... 41

5.2.7.1 Pressure Sensor Calibration Screen ..............................................................41

5.2.7.2 Flow Rate Sensor Calibration Screen (Factory Calibration)........................ 41

5.2.7.3 Box Temperature Calibration Screen ............................................................42

5.2.8 Model Select ........................................................................................................................42

5.2.9 Probe Type........................................................................................................................... 42

5.2.10 Firmware .............................................................................................................................42

5.3 Flashing Memory............................................................................................................................... 43

5.4 Part Replacement .............................................................................................................................. 46

5.4.1 Removing the Top Cover ....................................................................................................46

5.4.2 Fuse Replacement............................................................................................................... 47

5.4.3 Probe Tip Filter & O-Ring Replacement ........................................................................... 47

5.4.4 Internal Filter Replacement ..............................................................................................48

6 Parts and Service......................................................................................................................49

6.1 Replacement Parts ............................................................................................................................ 49

6.2 Service Centers..................................................................................................................................50

7 Specifications ............................................................................................................................51

ii Instruction 3015-4342

Page 5

H25-IR Introduction

1 Introduction

1.1 Purpose of Instruction Manual

This instruction manual provides important information on how to install, operate, and service the

Bacharach H25-IR Refrigerant Gas Leak Detector.

To assure operator safety and the proper use of this instrument, please read, understand, and follow the

contents of this manual.

Please retain these instructions for future reference.

1.2 Safety Precautions

Safety is essential in the use and maintenance of Bacharach equipment. Therefore this instruction manual

and any markings on the exterior of H25-IR case provide important safety information concerning the

operation and maintenance of this instrument.

1.2.1 Warning Statements

The use of the word WARNING in this manual denotes a potential hazard associated with the use of this

equipment. It calls attention to a procedure, practice, condition, or the like, which if not correctly

performed or adhered to, could result in injury or death of personnel using this instrument.

1.2.2 Caution Statements

The use of the word CAUTION in this manual denotes a potential hazard associated with the use of this

equipment. It calls attention to a procedure, practice, condition, or the like, which if not correctly

performed or adhered to, could result in damage to the instrument.

1.2.3 Hazard Symbols

This symbol indicates the need to consult this instruction manual when opening the enclosure.

WARNING: A potential risk exists if the operating instructions are not followed.

This symbol indicates the presence of electric shock hazards when the enclosure is opened.

WARNING: To avoid risk of injury from electric shock, do not open the enclosure when AC

power is applied to the instrument.

1.2.4 AC Power and Grounding

The H25-IR uses a universal power supply that is capable of accepting inputs of 100 to 240 VAC, 50/60 Hz.

Under no circumstances should this instrument be operated without connection to a protective ground.

Doing so creates a potential shock hazard and is also a violation of electrical safety standards applicable to

this type of equipment.

Instruction 3015-4342 1

Page 6

Introduction H25-IR

1.2.5 Explosive Atmosphere

Do not operate this instrument in the presence of flammable liquids, vapors or aerosols. Operation of any

electrical instrument in such an environment constitutes a safety hazard.

1.2.6 Working Inside the Instrument

Only qualified maintenance personnel should access the interior of this instrument. Always unplug the AC

power cord before performing any wiring or maintenance work.

1.2.7 Misuse and Modifications to Instrument

The operation of the H25-IR may be impaired if the instrument is used in a manner not specified in this

instruction manual. Changes or modifications to the instrument, not expressly approved by Bacharach,

will void the warranty.

1.2.8 In Case of Malfunction

Do not continue to use this equipment if there are any symptoms of malfunction or failure. In the case of

such occurrence, unplug the AC power cord and contact a qualified repair technician or the nearest

Bacharach Service Center.

1.2.9 Cleaning

USE a dry cloth to clean the outside of the case. DO NOT use soap and water.

2 Instruction 3015-4342

Page 7

H25-IR Introduction

1.3 Ordering Information

The H25-IR instrument along with its Probe type and Hose length are ordered by specifying 3 codes. The

codes must be listed in the following sequence:

Code A – Model Name

Code B – Gas Type

Code C – Probe Type and Hose Length

Table 1-1. H25-IR Instrument, Probe Type & Hose Length Ordering Information

Code Description

Code A H25IR Infrared Gas Leak Detector

Code B -1

-2

-3

-4

-5

Code C -1

-2

-3

-4

-5

-6

For example, to order an H25-IR that detects CFC type refrigerants, a Standard Probe with LED &

Button, and a 6 foot hose, you would order an: H25IR-1-3

CFC, HFC, HCFC & Halogen Gases

R600a

6

SF

2

CO

R227

Standard Probe, 6 foot Hose

Standard Probe, 12 foot Hose

Standard Probe, LED & Button, 6 foot Hose

Standard Probe, LED & Button, 12 foot Hose

Smart Probe, 6 foot Hose

Smart Probe, 12 foot Hose

1.4 Unpacking and Initial Checks

Your H25-IR Refrigerant Gas Leak Detector and all accessories were carefully inspected at the factory

before shipment, and packed so as to be highly resistant to damage while in transport.

When you receive the instrument, please unpack it promptly and make a visual inspection to make sure

that no damage has occurred during shipment and that all ordered items have been received. Your order

should consists of:

• H25-IR instrument

• Probe and Hose Assembly

• Both an 8 and 15 inch Flexible Probe Tube

• AC Power Cord

• Instruction Manual.

If damage was found, immediately file a claim with the carrier. If an item is missing, please contact

Bacharach’s Service Department for assistance (refer to Section

6.2 Service Centers).

Instruction 3015-4342 3

Page 8

Introduction H25-IR

1.5 Features and Capabilities

• Detects and measures (depending on instrument’s part number):

o CFCs, HCFCs, HFCs and halogens

o R600a

o SF

o CO

o R227

• Infrared detector

• Internal calibration leak standard

• Provision for external calibration on other types of gases

• User selectable leak rate measurement in either Oz/yr, g/yr, mL/s, PaM

• Easy to read Vacuum Flu orescent Display (VFD)

• Excellent background gas rejection

• 4−20 mA current loop output

• Relay outputs for external equipment control

• On screen menu system for system setup, diagnostics, calibration, and data l og gin g

• Assortment of probe and hose assemblies, available in either 6 or 12 fo ot

(1.8 or 3.7 m) hose lengths

• Assortment of fl exible probe tubes, available in either 8 or 15 i nch

(200 or 381 mm) lengths

6

2

3

/s, or ppm

4 Instruction 3015-4342

Page 9

H25-IR Introduction

1.6 Functional Overview

The H25-IR is an industrial gas leak analyzer for the detection of CFCs, HCFCs, HFCs and halogen gas

compounds, R600a, SF

as well as log and totalize a group of leaks in a system.

The H25-IR’s front panel contains 7 membrane pushbuttons, probe connector, calibration gas port, and a

3-¼ x ¾ inch VFD (Vacuum Fluorescent Display) that provides a bright, high-contrast display for easy

viewing. The instrument is housed in an all-metal case with adju stabl e handle.

The instrument has two modes of operation: Search and Measure. The Search mode is used to locate the

source of a leak. While the Measure mode is used to quantify the size of the leak. A hand-held probe is

used to draw in a gas sample from the area under inspection.

With the instrument in its Search mode, the location of a leak is pinpointed by means of visual and audio

indicators positioned on both the instrument and probe*. As the probe tip approaches the leak sourc e the

length of a bar graph at the bottom of the instrument’s front panel display, the blink rate of an LED on the

probe, and the frequency of an audible tone are all affected in a positive manner (bar graph becomes

longer, LED flashes faster, and the audio tone increases in frequency). There are three search sensiti vities

available: SM, MED and LG, indicating the size of the leak being searched for. T h is fe ature is useful in

avoiding being bothered with small leaks when searching for larger ones.

In the Measure mode, the probe tip is held over the leak source until the displayed value of the leak ra te

stabilizes. Leak rates can be displayed in units of Oz/yr, g/yr, mL/s, PaM

be used to display the quantity of gas contained in a confined space with the instrument set up in its

ppm mode.

The leak rate is measured by first capturing all the gas leaking from the component under test. Then by

accurately measuring the flow rate of the sampling stream and the gas concentration within that stream,

the leak rate can be calculated using Equation 1-1. The instrument then converts this d ata into the

desired leak rate units of measure and displays the leak rate on the instrument’s front panel.

Leak Rate = Flow Rate x Gas Concentration Eq. 1-1

where:

Leak Rate = rate of gas leak from component under test

Flow Rate = sample flow rate

Gas Concentration = concentration of gas in the sample (ppm)

A leak measurement can be logged in memory with a time/date stamp. Up to 50 leaks can be logged and

totalized. This feature is useful in testing an installation that has a maximum permissible leak rate.

Logged data can be recalled for viewing on the display.

There are four user-defined setups that allow the operator to quickly switch between frequently used

combinations of Gas Type, Range, Feedback Mode , Setpoint, and the Auto Zero Off condition.

Extensive diagnostics keep track of several system parameters. When a fault is detected, the word

“FAULT” blinks on the display and an audible beep is heard every 2 seconds. Text descriptions of all

current fault conditions can be displayed from the instrument’s Diagnostics menu.

Four SPDT relays provide control over a variety of external equipment (e.g., horns, bells, strobe lights)

that can be automatically triggered when their associated relays are energized by any one of 11 different

operating conditions.

A 4−20 mA current loop output can be used for the connection of external monitoring equipment (e.g.,

chart recorder).

, CO2 or R227. This instrument can be used to locate and then quantify gas leaks,

6

3

/s. The Measure mode can also

* The Standard Probe does not contain an LED.

Instruction 3015-4342 5

Page 10

Introduction H25-IR

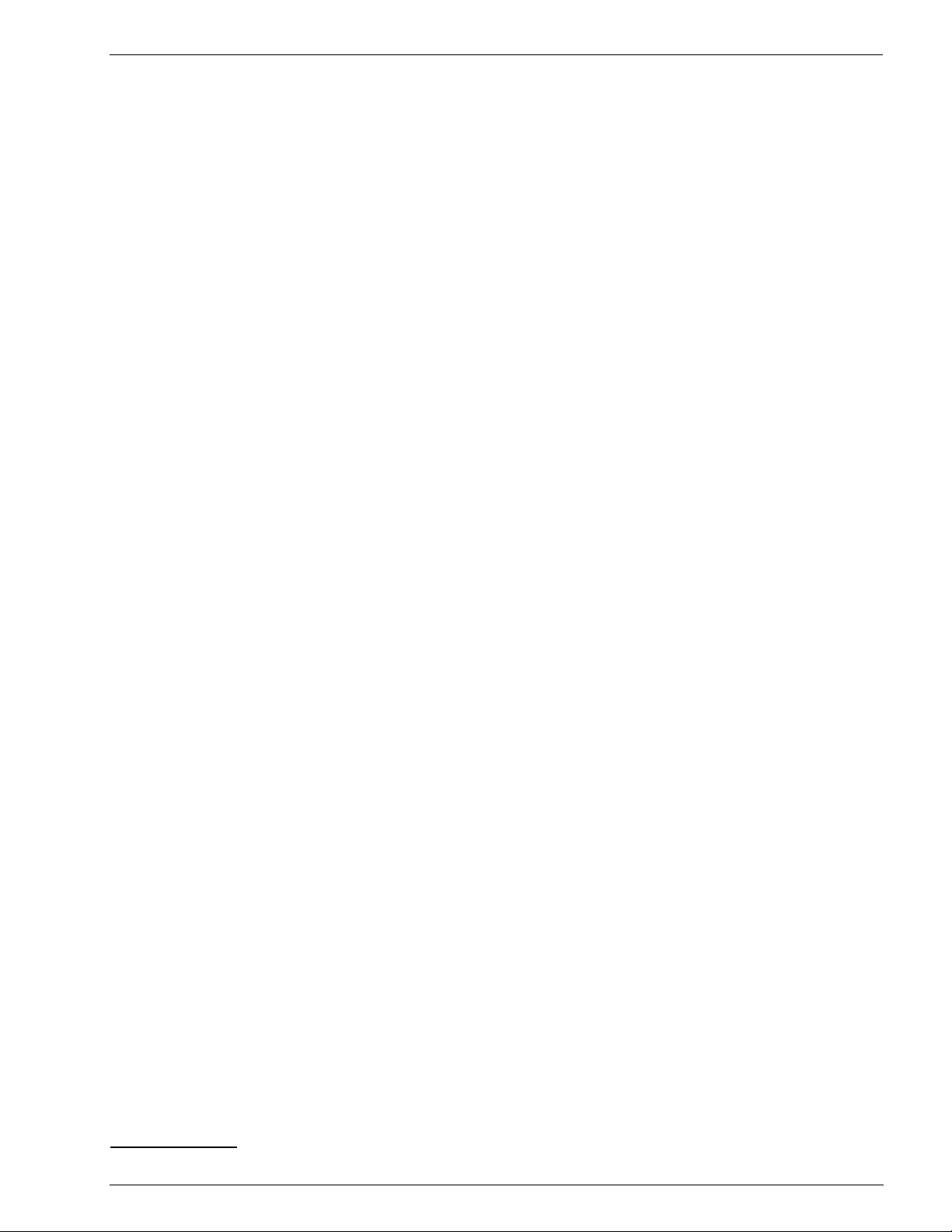

1.7 Names and Functions of Components

1.7.1 Front View

Front Panel Buttons

ENT

(Enter)

ESC

(Escape)

VOL

(Volume)

SETUP

MODE

RANGE

ZERO

LOG

MENU

CAL

(Calibration)

• Selects a highlighted menu item.

• Saves a selection or manually entered data (e.g. date and time).

• Displays a previously viewed menu or data screen.

• Cancels a data entry function; retains old data; and displays previous screen.

Volume adjustment. The Up and Down buttons slowly raise and lower the volume; the

Left button sets volume to minimum; and the Right button set volume to maximum.

Selects one of four user-defined setups consisting of: Range, Gas Type, Feedback Mode,

and the Auto Zero OFF condition.

Toggles the operating mode between Search and Measure.

Selects one of three sensitivity ranges (small, medium, or large leak).

Zeros the gas reading.

Logs the currently displayed gas measurement in memory when in the Measure mode,

where it can later be reviewed using the Main menu’s LOG function.

Press both the ENT and ESC buttons at the same time to display the Main menu.

Starts the calibration process where the instrument is calibrated to a known leak

source using either the instrument’s front panel Calibration Port, or a customer

supplied external leak source.

Menu selection and data entry buttons:

Up − Moves selected (highlighted) menu item up through screen, or increments an

alphanumerical value when entering data.

Down − Moves selected (highlighted) menu item down through screen, or decrements

an alphanumerical value when entering data.

Left − Moves cursor left across screen.

Right − Moves cursor right across screen.

6 Instruction 3015-4342

Page 11

H25-IR Introduction

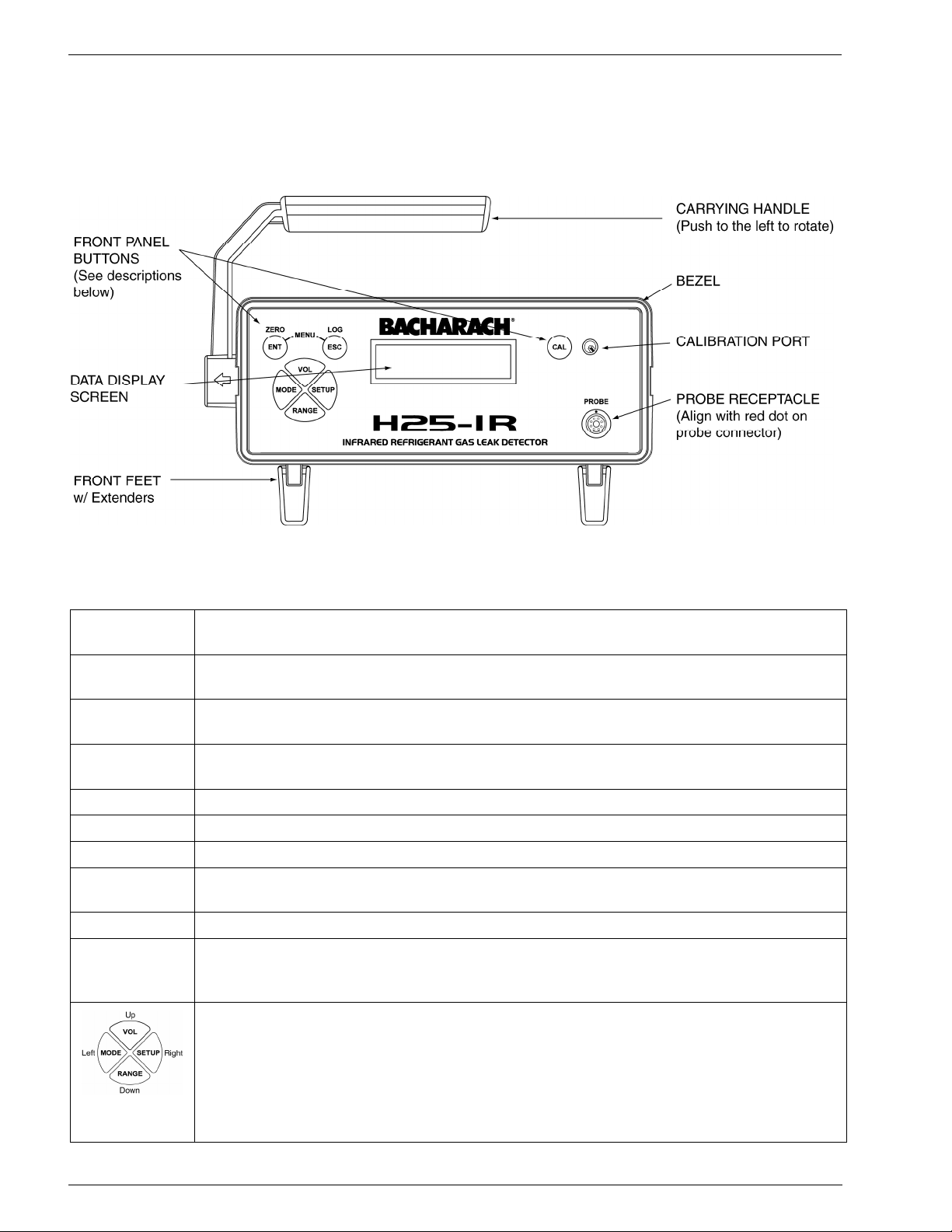

1.7.2 Rear View

1.7.3 Interior

Instruction 3015-4342 7

Page 12

Introduction H25-IR

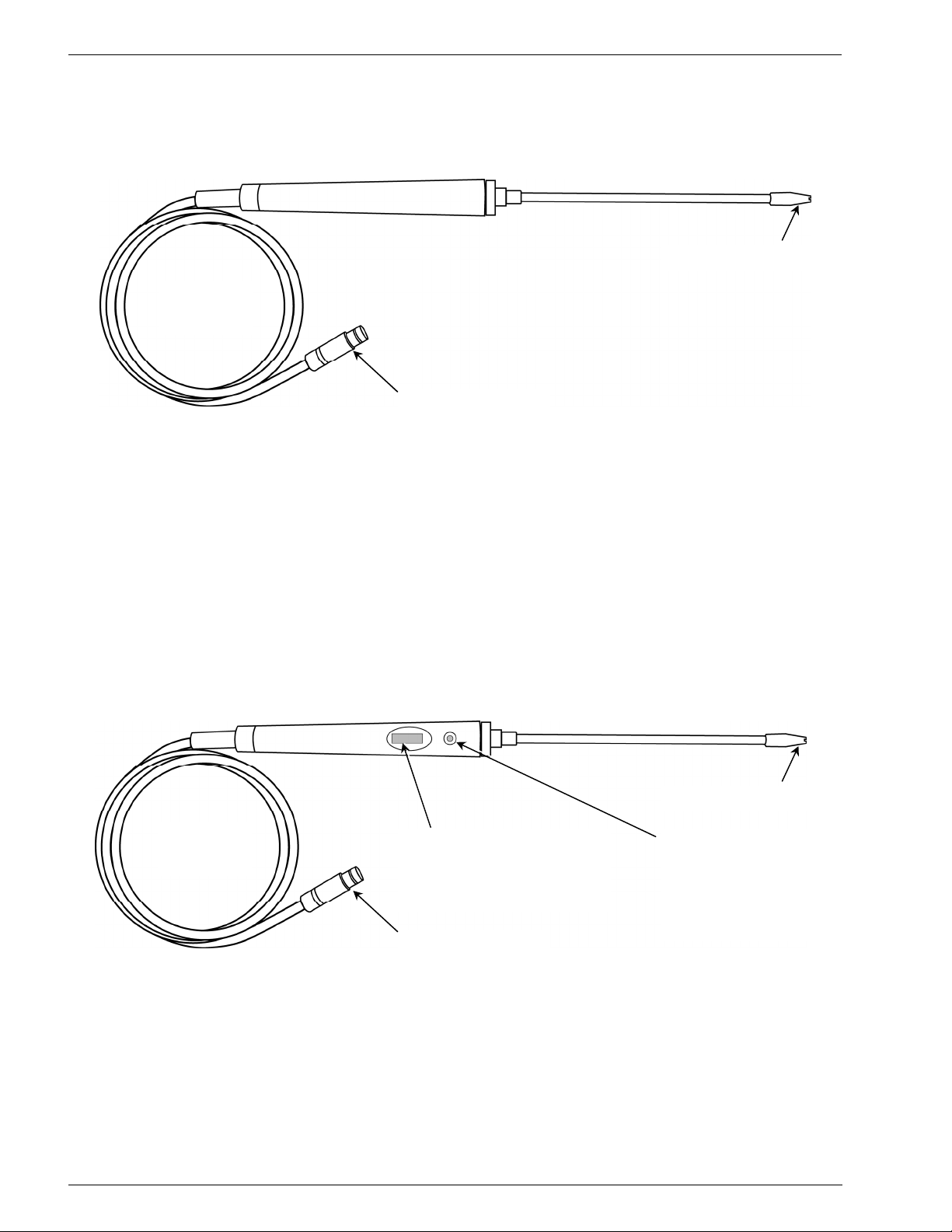

1.7.4 Standard Probe

HOSE

6 or 12 foot

(1.8 or 3.7 m)

PROBE CONNECTOR

(Align with red dot on

instrument’s front panel

PROBE receptacle)

FLEXIBLE PROBE TUBE

8 or 15 inches

(200 or 381 mm)

PROBE TIP with FILTER

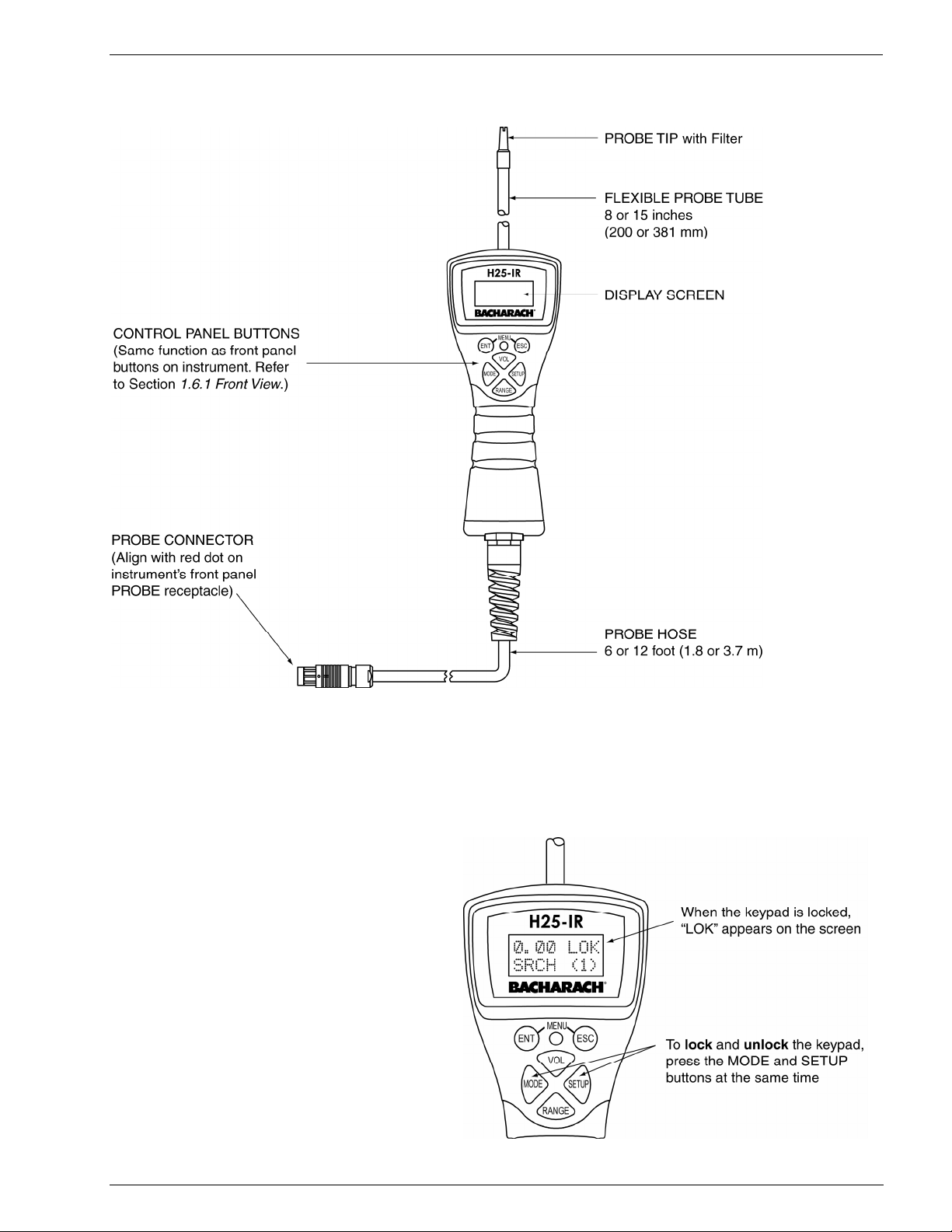

1.7.5 Standard Probe with LED and Programmable Pushbutton

HOSE

6 or 12 foot

(1.8 or 3.7 m)

PROGRAMMABLE PUSHBUTTON

(Can be programmed to either zero

the instrument, or switch between

the Search and Measure mode of

operation)

PROBE CONNECTOR

(Align with red dot on

instrument’s front panel

PROBE receptacle)

FLEXIBLE PROBE TUBE

8 or 15 inches

(200 or 381 mm)

PROBE TIP with FILTER

LED

(Flash rate increases as

the detected gas level

increases, or lights

steady when a user

selected leak rate is

detected.)

8 Instruction 3015-4342

Page 13

H25-IR Introduction

1.7.6 Smart Probe

1.7.7 Smart Probe Keylock Function

The Smart Probe’s keypad can be locked to

prevent accidental key presses when working

in tight spaces.

Instruction 3015-4342 9

Page 14

Introduction H25-IR

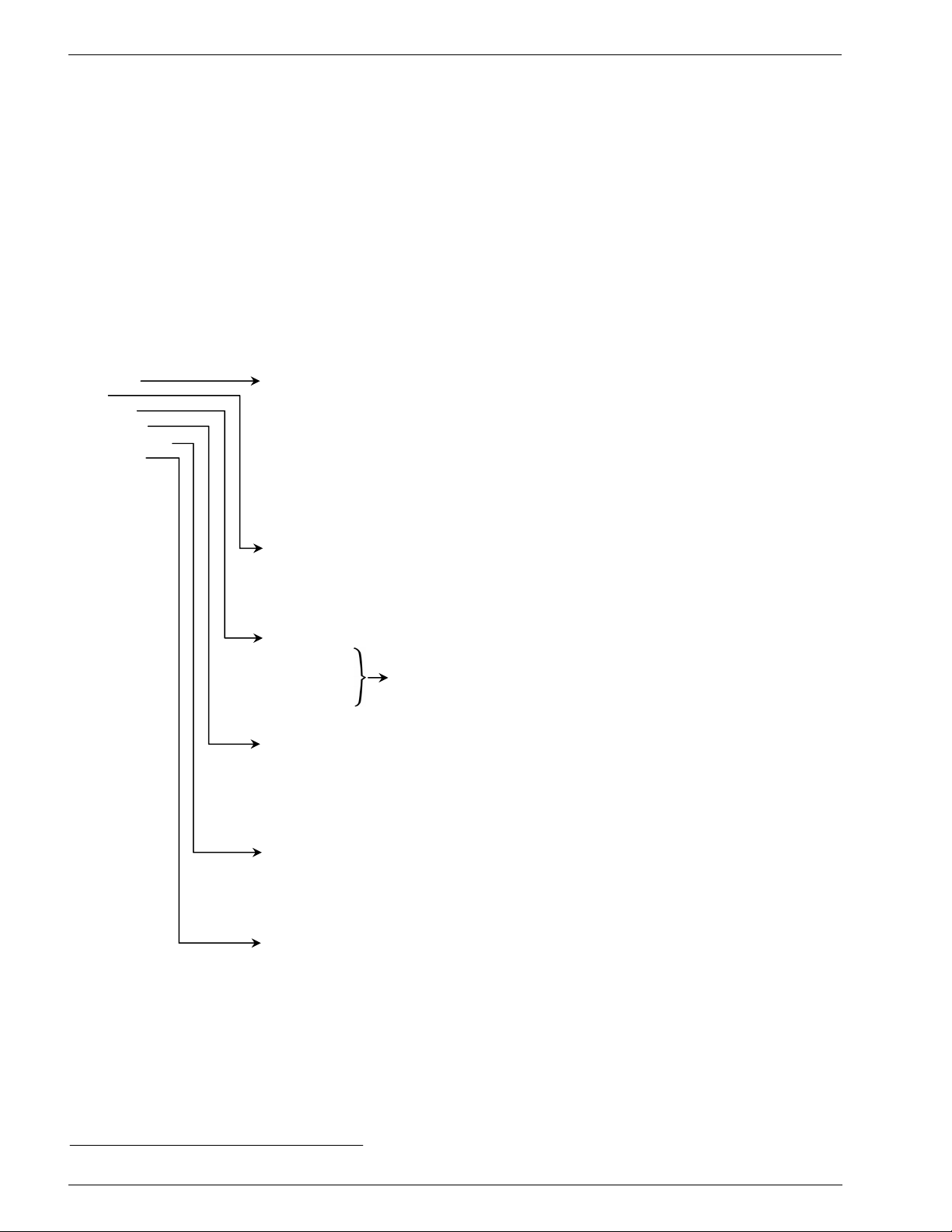

1.8 Menu System

Press the ENT and ESC keys at the same time to access the Main menu.

The menu system enables the operator to perform such functions as setting up the instrument, viewing

logged readings, configuring the four user-defined setups, entering calibration data, and viewing the

instrument’s diagnostic readings.

The buttons on the instrument’s front panel and probe are mapped the same and can be used interchangeably, with exception of the CAL button.

Select a menu item by first using the Up and Down buttons to highlight the desired item, and then

pressing ENT to select that item and display its data screen. After an item has been selected, use the

Left, Right, Up, and Down buttons as necessary to highlight and change data within a screen. Pressing

the ENT button saves the new data, while pressing the ESC button aborts the operation and displays the

previous screen.

Main Menu:

SYSTEM System Menu:

LOG GAS TYPE ........................ Gas being monitored

SETUPS LEAK UNITS ..................... Leak rate units of measure

CAL DATA RELAYS ............................ Relay set up for activating external equipment

DIAGNOSTICS LOOP ................................ 4−20 mA signal’s mA per ppm loop factor

FACTORY* BRIGHTNESS ................... Brightness level of display

CLOCK .............................. Date and time

PCHK MODE .....................Determines when a pressure check is performed

PROBE BUTTON ..............Selects function of button on the Standard Probe

RESET DEFAULTS ...........Resets user programmable parameters to factory defaults

(calibration data is not changed)

Log Menu:

VIEW LOG ......................... View individual logged measurements

CLEAR LOG ...................... Clear total contents of log

LOG TOTAL....................... View a numerical total of all measurements stored in log (up to 50)

LOG LIMIT .........................Total accumulated leak setpoint

Setup Menu: SETUP NAME..................Text name given to the SETUP selection

SETUP NO.1 RANGE.............................Sensitivity of instrument (small, medium, large)

SETUP NO.2 GAS TYPE .......................Gas being monitored

SETUP NO.3 FEEDBACK MODE ..........Gas-level feedback (continuous, setpoint, H25C)

SETUP NO.4 SETPOINT........................Gas value for the Feedback Mode & Search Auto

SEARCH AUTO ZERO ....Sets condition when auto zero is turned OFF

Calibration Data Menu:

CAL TYPE.......................... Internal or external leak source

EXT RATE..........................Leak rate of external leak source

EXT GAS TYPE .................Type of gas in external leak source

CAL FACTOR ....................Calibration factor

RESTORE FACTORY CAL...Restores factory leak rate calibration (internal leak source only)

Diagnostic Menu:

SENSOR DATA .................Raw data from all sensors

LAST FAULT...................... List of all current faults, or last fault

IR EMITTER.......................Infrared emitter’s voltage, amperage, wattage, & resistance

PRESSURE ....................... All measured pressures

Factory Menu:

AUTO GAIN ....................... Automatically set digital potentiometer (zero gas applied)

DIGIPOT ............................ Manually set digital potentiometer (zero gas applied)

LEAK RATE ....................... Leak rate of internal leak source

LEAK GAS .........................Gas type used in internal leak source

LEAK TEMP....................... Specified temperature for internal leak source in °C

LEAK TEMPCO .................Temperature coefficient for internal leak source in % per °C

SENSOR CAL.................... Pressure, temperature, and flow calibration settings

MODEL SELECT ............... Selects model of unit according to part number

PROBE TYPE .................... Selects type of probe connected to instrument

FIRMWARE........................ Date firmware was compiled

* The Factory Menu appears only when activated by service technicians who know the correct activation procedure.

10 Instruction 3015-4342

Page 15

H25-IR Preparing for Operation

2 Preparing for Operation

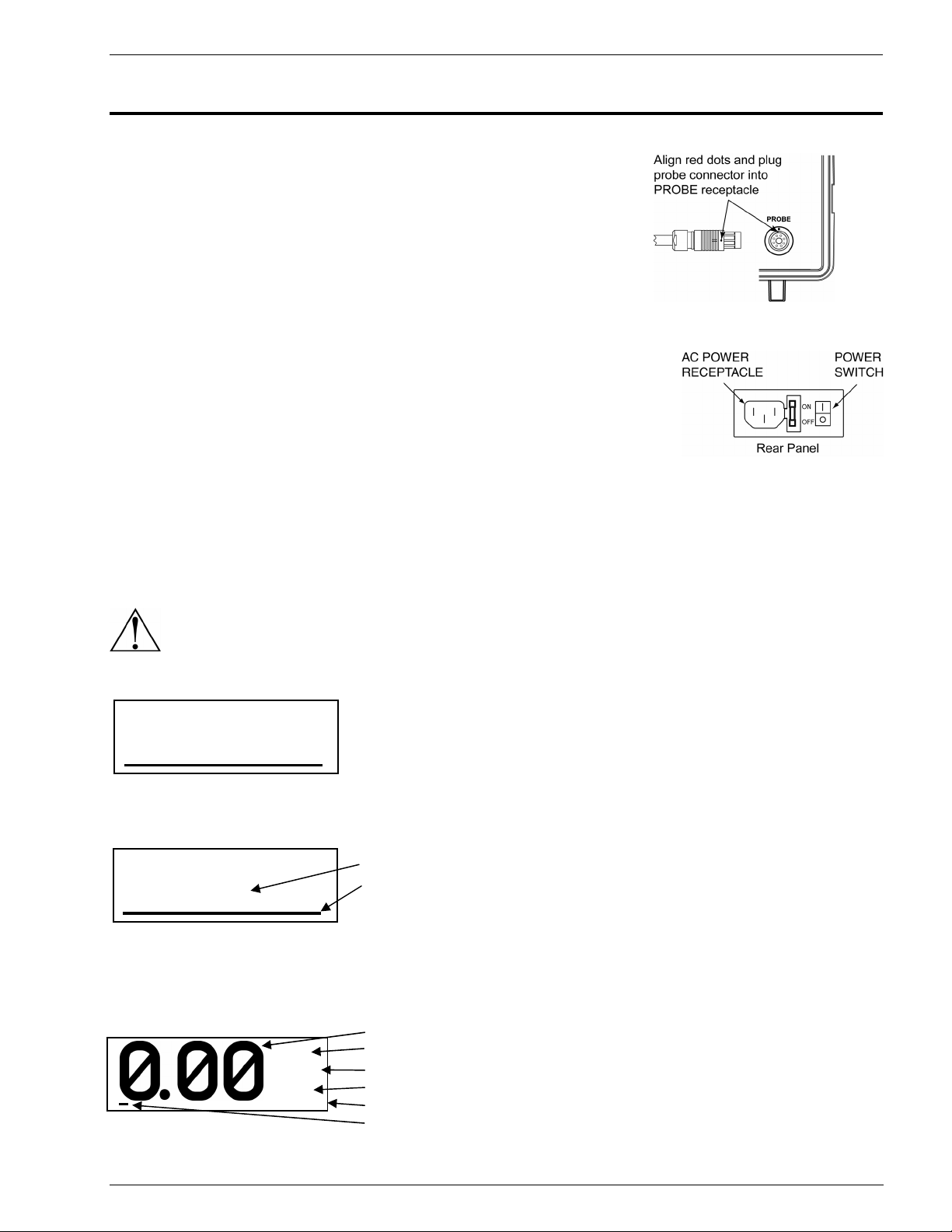

2.1 Connecting the Probe

Plug the probe connector into the front panel PROBE receptacle

by aligning the red dots on both the connector and receptacle. Screw the

desired flexible probe tube (8 or 15 inches) onto the probe assembly.

2.2 Connecting the AC Power Cord

The H25-IR is supplied with a 6 foot grounded AC power cord. Make sure

that an AC power receptacle (socket) compatible with this plug is available

nearby.

The instrument uses a universal AC power supply that accepts inputs of 100

to 240 VAC, 50/60 Hz. Power consumption is approximately 15 Watts.

Before connecting the AC power cord, first make sure the instrument’s power switch is OFF. Next, connect

the power cord to the instrument’s rear panel AC power receptacle, and then plug the power cord into a

nearby AC power receptacle.

2.3 Turning ON the Instrument

WARNING! Explosion Hazard. Do not operate this instrument in the presence of flammable liquids,

vapors or aerosols. Operation of this instrument in such an environment constitutes a safety hazard.

Turn ON the instrument by setting its power switch, located on the rear panel, to ON.

When power is first applied, the instrument produces one short beep and

BACHARACH

VERSION x.xx

Immediately afterwards, the instrument enters its warm-up mode and a countdown from 120 seconds is

started. In addition, a graphical display of the countdown period is provided by a bar graph that moves

down the screen during warm-up.

At the end of warm-up the Data Display screen appears. This screen shows the current gas measurement,

leak units, gas type, setup name, range, and mode of operation. In addition, a graphical display of the

relative gas level is provided by a bar graph that moves up the screen with increasing gas levels. Note that

the sensitivity of the bar graph is dependent on the Range setting.

WARM UP

120

Oz/yr

R134A

SETUP

SM SRCH

then performs a self-diagnostic check while displaying the instrument’s

firmware version number (approx. 15 seconds).

Remaining Warm Up Time in Seconds

Graphical Display of Warm Up Time

Gas Measurement

Leak Units

Gas Type

Setup Name (first 8 characters)

Range and Mode

Graphical Display of Relative Gas Level

Instruction 3015-4342 11

Page 16

Preparing for Operation H25-IR

2.4 System Setup

When shipped from the factory, the H25-IR has been configured according to its part number as described

in Appendix “A”. To change any of the instrument’s system parameters, first enter System Setup by

pressing both the ENT and ESC buttons on either the instrument’s front panel or Smart probe at the

same time to display the Main menu. Next, use the Up and Down buttons to highlight “SYSTEM”, and

then press ENT to display the System Setup menu.

Main Menu:

SYSTEM

LOG

SETUPS

CAL DATA

DIAGNOSTICS

From the System Setup menu, use the Up and Down buttons to highlight the desired function. Press

ENT to select that function and display its setup screen. Then perform the appropriate system setup

procedure as described in Sections

System Setup Menu:

GAS TYPE

LEAK UNITS

RELAYS

LOOP

BRIGHTNESS

CLOCK

PCHK MODE

PROBE BUTTON

RESET DEFAULTS

2.4.1 thru 2.4.9.

2.4.1 Gas Type

GAS TYPE < R134A

R401A

R402A

< R402B

The GAS TYPE function displays a list of gases that the instrument is programmed to monitor. Refer to

Section

7 Specifications for a complete list of these gases.

Use the Up and Down buttons to highlight the desired gas. Press ENT to save the selection.

2.4.2 Leak Units

LEAK UNITS Oz/yr

g/yr

mL/s

PaM/s

ppm

The LEAK UNITS function displays a list of leak rate units of measure that the instrument is capable of

displaying. Leak rates can be displayed in units of ounces/year (Oz/yr), grams/year (g/yr), milliliters/second

(mL/s), Pascal Meters

Use the Up and Down buttons to highlight the desired leak units. Press ENT to save the selection.

3

/second (PaM/s), or parts per million (ppm).

12 Instruction 3015-4342

Page 17

H25-IR Preparing for Operation

2.4.3 Relays

1 = NOT USED

2 = NOT USED

3 = NOT USED

4 = NOT USED

Four SPDT relays (rated 3 A, 240 VAC) can be individually programmed to energize under any one of 11

different operating conditions. The contacts of these relays can be connected to an external device that will

activate when the designated operating condition is met. Refer to Section

Use the Up and Down buttons to highlight the relay to be programmed. Press ENT to make the selection

and display that relay’s assignment screen.

Use the Up and Down buttons to highlight the desired operating condition for the selected relay. Press

ENT to save the selection.

RELAY 1 ASSIGNED TO

NOT USED

CLOSE >= SETPOINT

CLOSE < SETPOINT

CLOSE ON FAULT

CLOSE DURING CAL

CLOSE IN MEASURE

CLOSE AT LOG LIMIT

CLOSE IN SETUP 1

CLOSE IN SETUP 2

CLOSE IN SETUP 3

CLOSE IN SETUP 4

NOTE: SETPOINT is the gas value as entered per Section “

LOG LIMIT is the total accumulated leak value as entered per Section “4.2.10.4 Setting the Log Limit.”

For example: If Relay 1 is programmed to “CLOSE AT LOG LIMIT,” its N.O. contacts can be connected to

an external alarm device (e.g. strobe light or buzzer) that will activate when the total accumulated leak

value in the data log has reached its programmed limit.

TIP: When measuring the total leak-rate of a system, it’s important to clear the log per Section “

Clearing the Log” before starting a new series of leak-rate measurements.

2.5.5 Setpoint.”

2.7 External Relay Connections.

4.2.10.2

2.4.4 4–20 mA Loop

EDIT LOOP FACTOR

0.016ppm

Selecting the 4–20 mA LOOP function allows the current loop factor to be changed from its factory default

of 0.016 ppm (corresponds to 0.016 mA per ppm), which provides an output range of 0 ppm (4 mA) to

1,000 ppm (20 mA). Refer to Equation 3.1.

Use the Left and Right buttons to move the blinking cursor across the screen to highlight the digit to be

modified, and then use the Up and Down buttons to modify that digit. Press ENT to save the new loop factor.

Loop Output in mA = (Loop Factor x ppm) + 4 mA Eq. 3.1

To facilitate loop zero and span checking, note that when the Loop parameter is selected the loop output is

set to 20 mA, and upon exiting this parameter the loop output is set to 4 mA.

Instruction 3015-4342 13

Page 18

Preparing for Operation H25-IR

A

2.4.5 Brightness

BRIGHTNESS

PRESS ARROW KEYS TO

ADJUST

The BRIGHTNESS function changes the brightness level of the instrument’s front panel display.

Use the Up, Down, Left, or Right button to change the brightness to any one of four levels. Press ENT to

save the selected brightness level.

2.4.6 Clock

The CLOCK function sets the instrument’s date (MM/DD/YY) and time (24 hour format, where 1:00 PM is

displayed as 13:00). The clock allows measured values to be logged with a date/time stamp (refer to Section

4.2.9 Logging Measured Readings).

Use the Left and Right buttons to move the blinking cursor across the screen to highlight the digits to be

modified, and then use the Up and Down buttons to modify those digits. Press ENT to save the new date

and time values.

SET DATE & TIME

07/16/04 13:13

2.4.7 PCHK Mode

PCHK MODE

AT CAL

The PCHK Mode setting determines when the instrument performs a ambient pressure check as follows:

AUTO – A pressure check is performed once every 60 minutes.

AT CAL – A pressure check is performed at the end of every calibration.

Note that a pressure check is always performed when the instrument is first turned ON just before the

warm-up period begins, regardless of the PCHK Mode setting.

Use the Up and Down buttons to highlight the desired setting. Press ENT to save the selection.

UTO

2.4.8 Probe Button

PROBE BUTTON

DISABLED

MODE KEY

ENTER KEY

The PROBE BUTTON function selects what action is performed by the pushbutton on the Standard Probe

with LED and Pushbutton.

DISABLED – No action performed.

MODE KEY – Toggles the instrument between its Search and Measure mode.

ENTER KEY – Performs the same function as the ENT / ZERO key on the instrument’s front panel.

Use the Up and Down buttons to highlight the desired setting. Press ENT to save the selection.

2.4.9 Reset Defaults

CONFIRM RESET TO

DEFAULTS BY PRESSING

THE UP ARROW

The RESET DEFAULTS function returns the instrument to its factory default settings per Appendix “A”.

Press the Up button to confirm resetting the instrument back to its factory default settings.

14 Instruction 3015-4342

Page 19

H25-IR Preparing for Operation

2.5 Configuring the SETUPS Function

There are four user-defined Setups that allow the operator to quickly switch between frequently used

combinations of Gas Type, Range, Feedback Mode, Setpoint, and the Auto Zero Off condition. Program the

four Setup configurations as follows:

First enter the Setups menu by pressing both the ENT and ESC buttons on either the instrument’s front

panel or Smart probe at the same time to display the Main menu. Next, use the Up and Down buttons to

highlight “SETUPS”, and then press ENT to display the Setups menu.

Main Menu:

SYSTEM

LOG

SETUPS

CAL DATA

DIAGNOSTICS

NOTE: The names listed in the Setups menu are user defined, and may vary from what is shown above.

From the Setups menu, use the Up and Down buttons to highlight the desired Setup. Press ENT to select

that Setup and display its Configuration menu.

From the Configuration menu, use the Up and Down buttons to highlight the desired function. Press

ENT to select that function and display its setup screen. Perform the appropriate setup procedure as

described in Sections

Setups Menu:

SETUP NO.1

SETUP NO.2

SETUP NO.3

SETUP NO.4

2.5.1 thru 2.5.6.

Configuration Menu:

SETUP NAME

RANGE

GAS TYPE

FEEDBACK MODE

SETPOINT

SEARCH AUTO ZERO

2.5.1 Setup Name

SETUP NAME #1

SETUP NO. 1

The SETUP NAME function allows the operator to give each Setup a unique name that will appear on the

Data Display screen. Use the Left and Right buttons to move the blinking cursor across the screen to

highlight the character to be modified, and then use the Up and Down buttons to modify that character.

When finished entering the desired characters, press ENT to save the new name.

2.5.2 Range

RANGE LG

SETUP NO. 1 MED

SM

The RANGE function sets the sensitivity of the gas-level graphical display (bar graph located at the

bottom of the display), audible tone frequency, and the hand-held probe’s LED blink rate in relation to the

detected gas level. Use the Up and Down buttons to highlight the desired sensitivity. Press ENT to save

the selection.

NOTE: The range setting has no affect on the accuracy of the gas reading as displayed on the instrument

when making a leak-rate measurement.

Instruction 3015-4342 15

Page 20

Preparing for Operation H25-IR

2.5.3 Gas Type

GAS TYPE < R134A

SETUP NO. 1 R401A

R402A

< R402B

The GAS TYPE function sets the type of gas being monitored. Use the Up and Down buttons to highlight

the desired gas. Press ENT to save the selection.

NOTE: The gases displayed depend on which optical bench is installed. Refer to Section “

7 Specifications.”

2.5.4 Feedback Mode

FEEDBACK MODE

SETUP NO. 1

CONTINUOUS

SETPOINT

H25C SETPOINT

The FEEDBACK MODE function provides the operator both visual and audible feedback in regard to the

measured leak rate. This function determines how the gas-level graphical display (bar graph located at the

bottom of the display) and audible tone operate as follows:

CONTINUOUS – The bar graph and audible tone continuously increase and decrease their values in step

with the leak rate. For example, when the leak rate increases, the bar graph moves upscale and the

audible tone increases in frequency. Their maximum values at various leak rates are determined by the

Range setting.

SETPOINT – Both the bar graph and audible tone go to their maximum values when the leak rate equals

or goes above the setpoint. Enter a setpoint value per Section

H25C SETPOINT – This setting emulates the operation of the H25C Industrial Halogen Leak Detector.

The bar graph and audible tone are suppressed when the leak rate is below the setpoint. They both go to

their 50% values when the leak rate reaches the setpoint, and then they both continuously increase in

value as the leak rate increases until reaching their maximum values at 2-times the setpoint. Enter a

setpoint value per Section

2.5.5 Setpoint.

2.5.5 Setpoint.

Use the Up and Down buttons to highlight the desired function. Press ENT to save the selection.

2.5.5 Setpoint

SETPOINT

SETUP NO. 1

00.0000 Oz/yr

The SETPOINT function establishes a leak rate at which the graphical display and audible tone are

turned ON as determined by the Feedback Mode setting (refer to the previous section).

The setpoint value also sets the leak rate at which one or more of the instrument’s relays is energized

whenever the leak rate equals, exceeds, or falls below the setpoint value (refer to Section

plus it establishes a reference point where the instrument’s auto-zero function can be turned OFF while in

the Search mode (refer to Section

Use the Left and Right buttons to move the cursor across the screen to highlight the digit to be modified,

and then use the Up and Down buttons to modify that digit. Press ENT to save the new setpoint.

2.5.6 Search Auto Zero).

2.4.3 Relays),

16 Instruction 3015-4342

Page 21

H25-IR Preparing for Operation

2.5.6 Search Auto Zero

SEARCH AUTO ZERO

SETUP NO.1

< ALWAYS ON

ALWAYS OFF

BELOW SETPOINT

BELOW 90% OF SP

BELOW 75% OF SP

BELOW 50% OF SP

The SEARCH AUTO ZERO function allows the operator to select one of the following conditions when the

auto-zero function is disabled while in the Search mode:

NOTE: This function works in conjunction with the setpoint value as entered in Section “

ALWAYS ON – The background gas level is always zeroed. If the probe is held over a gas leak, the

instrument will automatically zero-out the reading.

ALWAYS OFF – The background gas level is never zeroed. If the probe is held over a gas leak, the

instrument will not zero-out the reading, similar in operation to the Measure mode.

BELOW SETPOINT – The auto-zero function is ON when the leak-rate is below the setpoint value. If the

leak rate goes above the setpoint value, then the auto-zero function turns OFF, allowing the probe to stay

on the leak without the reading being zeroed-out.

For example: If the Setpoint is 2 Oz/yr, then the auto-zero function is ON for leaks rates that are

<2 Oz/yr. If the leak rate is ≥2 Oz/yr, then the auto-zero function turns OFF.

BELOW 90% OF SP – The auto-zero function is ON when the leak-rate is below 90% of the setpoint value.

If the leak rate goes above 90% of the setpoint value, then the auto-zero function turns OFF, allowing the

probe to stay on the leak without the reading being zeroed-out.

For example: If the Setpoint is 2 Oz/yr, then the auto-zero function is ON for leaks rates that are

<1.8 Oz/yr. If the leak rate is ≥1.8 Oz/yr, then the auto-zero function turns OFF.

BELOW 75% OF SP – The auto-zero function is ON when the leak-rate is below 75% of the setpoint value.

If the leak rate goes above 75% of the setpoint value, then the auto-zero function turns OFF, allowing the

probe to stay on the leak without the reading being zeroed-out.

For example: If the Setpoint is 2 Oz/yr, then the auto-zero function is ON for leaks rates that are

<1.5 Oz/yr. If the leak rate is ≥1.5 Oz/yr, then the auto-zero function turns OFF.

BELOW 50% OF SP – The auto-zero function is ON when the leak-rate is below 50% of the setpoint value.

If the leak rate goes above 50% of the setpoint value, then the auto-zero function turns OFF, allowing the

probe to stay on the leak without the reading being zeroed-out.

2.5.5 Setpoint.”

For example: If the Setpoint is 2 Oz/yr, then the auto-zero function is ON for leaks rates that are

<1 Oz/yr. If the leak rate is ≥1 Oz/yr, then the auto-zero function turns OFF.

2.6 Calibration

The H25-IR has been calibrated at the factory, and should not require frequent calibrations when

searching for gas leaks. When making measurements, however, the instrument should be calibrated on a

periodic basis to ensure that it meets its published accuracy specification.

Instructions on how to calibrate the instrument are contained in Section

Instruction 3015-4342 17

3 Calibration.

Page 22

Preparing for Operation H25-IR

2.7 External Relay Connections

The H25-IR includes four SPDT relays whose relay contacts are rated 3 A at 240 VAC. External alarm

devices (e.g., horns, bells, strobe lights, etc.) can be connected to these relays and activated when their

associated relay is energized. Refer to Section

Locate the external relay connector on rear of unit (refer to Section

Secure the leads from the external device and its power source to the external relay connector as shown in

the diagram below. This diagram shows a typical alarm device being connected to Relay 1. Repeat this

procedure, as necessary, for the remaining relays.

- Each relay may be connected as normally open (NO), or normally closed (NC).

2.4.3 Relays.

1.7.2 Rear View).

Typical Relay 1 Wiring

- The relay contacts are rated 3 A at 250 VAC.

- Power for the external alarm devices is supplied from an external power source.

- Jumper the ‘Neutral’ line of an external power source to the ‘Common’ terminals on the relay connector.

- Connect one end of the alarm device to the ‘NO’ terminal of the desired relay.

- The other end of the alarm device is connected to the other leg of the external power source. For protection,

install an in-line fuse of the appropriate size and design for the external alarm device being used.

18 Instruction 3015-4342

Page 23

H25-IR Preparing for Operation

2.8 4–40 mA Current Loop Connection

An external 4−20 mA monitoring device (e.g., chart recorder) can be connected to the H25-IR using a

shielded-twisted-pair cable.

IMPORTANT! The monitoring device must be isolated from ground (floating).

Locate the 4−20 mA connector on the rear of the unit (refer to Section

the resistor or shorting wire from its terminals.

NOTE: A 100 ohm, ¼ W resistor must be connected to the 4–20 mA connector if no external monitoring

device is used. Failure to install this resistor will cause a “Loop Open Error” to occur (refer to Section “

What to Do when a Fault Occurs”).

Secure the wire leads from the external monitoring device to the connector as shown in the diagram below,

making sure that the polarity at this connector matches the wiring at the monitoring device.

4–20 mA Current Loop Connector

CAUTION: Never apply power to the 4–20 mA Current Loop Connector from

an external power supply. In addition, connect only a load resistor or a

floating measurement device.

The default current-to-ppm factor is set to 0.016 mA = 1 ppm, providing a measurement range of 0 ppm

(4 mA) to 1,000 ppm (20 mA). Note that the current-to-ppm factor can be changed using the instrument’s

LOOP function (refer to Section

To facilitate loop zero and span checking, note that when the LOOP function is selected the loop output is

set to 20 mA, and upon exiting this function the loop output is set to 4 mA.

2.4.4 4–20 mA Loop).

1.7.2 Rear View), and then remove

4.3

Instruction 3015-4342 19

Page 24

Preparing for Operation H25-IR

Notes:

20 Instruction 3015-4342

Page 25

H25-IR Calibration

3 Calibration

When the instrument is supplied with an internal leak source, the operator can choose between two types

of calibration: Internal or External. Internal calibration uses the instrument’s built-in leak source, while

External calibration uses a customer supplied calibrated leak source.

If the instrument is supplied without a leak source, then the option of selecting the calibration type is

removed from the menu system. The only option for this model of instrument is to calibrate using an

external leak source.

3.1 Selecting Internal or External Calibration

Use the Main Menu > CAL DATA > CAL TYPE function to select either Internal or External calibration. If

External calibration is selected, then also use the EXT RATE and EXT GAS TYPE functions to enter the

characteristics of the external leak source.

Display the Calibration Data menu by first pressing both the ENT and ESC buttons on either the

instrument’s front panel or Smart probe at the same time to display the Main menu. Next, use the Up and

Down buttons to highlight “CAL DATA”, and then press ENT to display the Calibration Data menu.

Main Menu:

SYSTEM

LOG

SETUPS

CAL DATA

DIAGNOSTICS

Calibration Data Menu:

CAL TYPE

EXT RATE

EXT GAS TYPE

CAL FACTOR

RESTORE FACTORY CAL

3.1.1 Internal Calibration Selection

From the Calibration Data menu, use the Up and Down buttons to highlight “CAL TYPE”, and then

press ENT to display its setup screen. Use the Up and Down buttons to highlight “INTERNAL”,

and press ENT to make the selection and return to the Calibration Data menu. Press ESC as required to

return to the Data Display screen.

CAL TYPE INTERNAL

EXTERNAL

Instruction 3015-4342 21

Page 26

Calibration H25-IR

3.1.2 External Calibration Selection and Setup

When using an external leak source, the instrument must be setup for external calibration along with

entering the leak rate and gas type of the external leak source.

Select external calibration and enter the parameters of the external leak source as follows:

Select External Calibration: From the Calibration Data menu, use the Up and Down buttons to highlight

“CAL TYPE”, and then press ENT to display its setup screen. Use the Up and Down buttons to highlight

“EXTERNAL”, and press ENT to make the selection and return to the Calibration Data menu.

CAL TYPE INTERNAL

EXTERNAL

Enter External Leak Rate: From the Calibration Data menu, highlight “EXT RATE” and press ENT to

display its setup screen. Use the Left and Right buttons to move the blinking cursor across the screen to

highlight the digit to be modified, and then use the Up and Down buttons to modify that digit. Press ENT

to save the new external leak rate value and return to the Calibration Data menu.

IMPORTANT! Be sure to enter the leak rate using the same units of measure as displayed on the EXT

RATE screen. In this example, the units of measure is g/yr. If your leak source is marked in Oz/yr, then

multiply that value by a factor of 28.35. For example: If the leak source is marked 0.9 Oz/yr, then enter a

leak rate of (0.9 x 28.35=) 25.5 g/yr.

NOTE: The minimum calibration leak rate is 2 g/yr.

EXT RATE 25.5 g/yr

Enter External Gas Type: From the Calibration Data menu, highlight “EXT GAS TYPE” and press ENT to

display its setup screen. Use the Up and Down buttons to highlight the type of gas contained in the

external leak source. Press ENT to save the new external gas type and return to the Calibration Data

menu.

NOTE: The gases displayed depend on which optical bench is installed. Refer to Section “

EXT GAS TYPE < R134A

R401A

R402A

< R402B

Press ESC as required to return to the Data Display screen.

7 Specifications.”

22 Instruction 3015-4342

Page 27

H25-IR Calibration

C

3.2 Internal Calibration

Internal calibration uses the instrument’s built-in leak source. Properties of the leak source (i.e. gas type,

leak rate, temperature coefficient, and specification temperature) are entered at the factory and do not

need to be changed by the operator.

The properties of the leak source along with the current internal temperature of the instrument are used

to compute the actual leak rate when a calibration is requested. This number is displayed as the “target”

value during calibration. A spring switch located in front of the CAL Port ensures that the probe is kept in

place for the duration of the calibration process. Calibration will fail if the probe is withdrawn too early in

the process, or if the computed parameters deviate from the stored factory calibration by more than 20%.

1. Turn ON instrument and allow it to complete its 120 second warm-up.

2. Press the front panel CAL button to display the Calibration screen. Note that the display must be

reading a leak rate of “0.00” when the CAL button is pressed; otherwise, the message “LEAK

RATE MUST BE ZERO TO CALIBRATE” will appear. If necessary, press the ZERO button to

zero the display before pressing CAL.

0.89

INSERT

PROBE

TARGET

O/YR

R134A

MEASURED

O/YR

Oz/yr

R134A

SETUP

INT CAL

3. Ensure that the instrument is set up for internal calibration as indicated by “INT CAL” being

displayed at the bottom-right of the display. If “EXT CAL” (external calibration) is displayed,

perform the procedure in Section

Type to Internal.

4. Insert the probe tip into the CAL Port within 10 seconds

after pressing the CAL button. Be sure that the probe tip

makes contact with the spring switch. At this time the

calibration process should automatically start.

The top number of the Calibration screen shows the

“target” value (leak source rate), while the bottom

number shows the current measured value. Keep the

probe tip firmly against the back of the port for the

duration of the calibration process, during which time the

instrument is calibrated at both a high and low flow rate.

If the probe tip looses contact with the spring switch before the

calibration process completes, the message “CAL ABORTED” is

displayed. At this time press any key to retain the previous

calibration curve and return to the Data Display screen.

3.1 Selecting Internal or External Calibration and set the Cal

TARGET

0.89

0.00

O/YR

R134A

MEASURED

O/YR

AL

OK

5. After a successful calibration the new calibration data is saved

and the message “CAL OK” followed by “WITHDRAW PROBE

FROM LEAK SOURCE” will appear.

6. Withdrawing the probe causes the display to switch back to the

Data Display screen. Note, however, if the PCHK Mode is set to

AUTO (refer to Section

is performed prior to the display of the Data Display screen.

NOTE: After being calibrated the instrument is automatically

placed into its Search mode.

2.4.7 PCHK Mode), then a pressure check

WITHDRAW PROBE

FROM LEAK

SOURCE

Oz/yr

R134A

SETUP

INT CAL

Oz/yr

R134A

SETUP

INT CAL

Oz/yr

R134A

SETUP

INT CAL

PCHK

Oz/yr

R134A

SETUP

SM SRCH

Instruction 3015-4342 23

Page 28

Calibration H25-IR

3.3 External Calibration

External calibration uses a customer supplied leak source that matches the gas to be monitored.

Properties of the leak source must be entered by the operator using the EXT RATE and EXT GAS TYPE

functions as described in Section

the number displayed as the “target” value during calibration.

IMPORTANT! The operator is responsible for ensuring that the external leak-rate value has been

corrected for daily changes in ambient temperature and pressure at the time of calibration. It is also the

operator’s responsibility to ensure that a good calibration has been performed.

1. Turn ON instrument and allow it to complete its 120 second warm-up.

2. Press the front panel CAL button to display the Calibration screen. Note that the display must be

reading a leak rate of “0.00” when the CAL button is pressed; otherwise, the message “LEAK

RATE MUST BE ZERO TO CALIBRATE” will appear. If necessary, press the ZERO button to

zero the gas display before pressing CAL.

0.89

0.00

3. Ensure that the instrument is set up for “EXT CAL” (external calibration) as indicated at the

bottom-right of the display. If “INT CAL” (internal calibration) is displayed, perform the procedure

in Section

4. Insert probe tip into the Calibration Port of the external leak source.

5. The top number of the Calibration screen shows the “target” value (leak source rate), while the

bottom number shows the current “measured” value. Keep the probe tip inserted in the Calibration

Port for the duration of the calibration process, during which time the instrument performs a

calibration at both a high and low flow rate.

0.89

0.89

6. After the calibration cycle is complete, the new calibration data is saved and the display

automatically switches back to the Data Display screen. Note, however, if the PCHK Mode is set to

AUTO (refer to Section

of the Data Display screen.

NOTE: After calibration the instrument is automatically placed into its Search mode.

TARGET

O/YR

R134A

MEASURED

O/YR

3.1 Selecting Internal or External Calibration and set the Cal Type to External.

TARGET

OZ/YR

R134A

MEASURED

OZ/YR

3.1.2 External Calibration Selection and Setup. The EXT RATE entry is

Oz/yr

R134A

SETUP

EXT CAL

Oz/yr

R134A

SETUP

EXT CAL

2.4.7 PCHK Mode), then a pressure check is performed prior to the display

Oz/yr

R134A

SETUP

24 Instruction 3015-4342

Page 29

H25-IR Calibration

3.4 CAL Factor

The factory default CAL Factor of 1.000 will provide the level of accuracy as stated in Section 7

Specifications for all gases.

The CAL Factor can be changed for the following two reasons:

• Allow the instrum ent’s in ternal leak source to be used to calibrate the instrument,

regardless of the gas being measured

• Improve the accuracy of ppm measurements

Leak-rate accuracy can be maintained by periodically calibrating the instrument on the gas being

measured. If the instrument’s internal calibration gas is the same as the gas being measured, then it is a

simple matter of calibrating the instrument using the internal leak source. When measuring a gas that is

not the same as the instrument’s internal calibration gas, then there are two options for maintaining

accuracy. The instrument can either be calibrated using an external leak source, or the CAL Factor can be

adjusted to make the internal leak source simulate the gas being measured as described in Section 3.4.1.

The CAL Factor can also be used to improve the accuracy of ppm measurements as described in

Section 3.4.2.

3.4.1 Simulating Other Internal Leak Source Gas Types Using the CAL Factor

When measuring the leak rate of a gas that is not the same as the instrument’s internal calibration gas,

the CAL Factor can be adjusted make the instrument’s internal calibration g as sim ulate the gas being

measured. This allows the operator to calibrate th e instrument using the internal leak source, regardless

of the gas contained in the leak source. Note that this procedure is not necessary for single-gas

instruments.

Material Required:

• Calibrated External Leak Source set up for 5 to 10 times the leak rate

that the instrument is expected to detect

IMPORTANT! Remember that the accuracy will not be better than that of the

external leak source used for calibration.

Procedure:

1. Turn ON the instrument and allow it to warm up for 30 minutes before proceeding.

2. Program the instrument for the Gas Type contained in the external leak source (refer to Section

2.4.1 Gas Type).

3. Verify that the current CAL Factor is set to 1.000 by selecting the Main Menu > CAL DATA > CAL

FACTOR function. If necessary, reset the CAL Factor to 1.000. Refer to Section 3.4.3 Adjusting the

CAL Factor.

4. Perform an internal calibration in the normal way using the internal leak source (refer to Section

3.2 Internal Calibration). Note that it doesn’t matter that the gas in the internal leak source

doesn't match the Gas Type entered in Step 2.

5. Press the MODE key to place the instrument in to its Measure mode.

6. Measure the leak rate of the external leak source and record the displayed reading.

Instruction 3015-4342 25

Page 30

Calibration H25-IR

7. Compute the new CAL Factor by dividing the actual leak rate of the external leak source by the

reading recorded in Step 6. For example, if the leak rate of the external leak source is 0.4 oz/yr and

the measured rate was 0.43 oz/yr, then the new CAL Factor is 0.4 ÷ 0.43 = 0.930.

This new CAL Factor establishes the relationship between the internal calibration gas and the gas

type selected to be measured.

8. Enter the new CAL Factor as described in Section 3.4.3 Adjusting the CAL Factor. Note that the

displayed Gas Type should match the gas selected in Step 2.

9. From this point on the operator can perform an internal calibration and get accurate

measurements for other gas types using whatever gas is contained in the internal leak source.

3.4.2 Improving PPM Measurement Accuracy using the CAL Factor

The CAL Factor can be adjusted to improve the accuracy of the ppm measurement by calibrating the

instrument on the gas being measured. The accuracy of the ppm measurement after performing this

procedure will equal the accuracy of the gas sample, ±1%. Note that the accuracy of the instrument’s ppm

measurement depends on the accuracy of the gas sample.

The new CAL Factor is determined by sampling a known di lution of gas whose accuracy is better than the

ppm measurement accuracy as stated in Section 7 Specifications. The concentration of the sampl e must

also be corrected for ambient temperature and pr essure at the time of calibration. A minimum sample size

of 5 liters is required.

Calibration is best performed at or near full scale, it can however, be done at any concentration and ideally

in the range where maximum accuracy is desired down to, but not below, 100 ppm.

The instrument should be operating for at least 30 minutes prior to performing a calibration.

Verify that the current CAL Factor is set to 1.000 by selecting the Main Menu > CAL D ATA > C AL

FACTOR function. If necessary, reset the CAL Factor to 1.000. Refer to Section 3.4.3 Adjusting the CAL

Factor.

With the instrument operating in its ppm measurement mode (refer to Section 4.2.8 Measuring the PPM

Level), insert the probe tip into the gas-sample bag and allow the instrument to sample until the ppm

reading on the display is stable. At this time record the ppm re ading. The new CAL Factor is computed by

dividing the known gas concentration value by the measured value. Typically this number will be between

0.95 and 1.05. Enter the new CAL Factor as described in Section 3.4.3 Adjusting the CAL Factor.

IMPORTANT! If the instrument is switched back to measuring the leak-rate, then the instrument must be

recalibrated on the gas being measured.

26 Instruction 3015-4342

Page 31

H25-IR Calibration

3.4.3 Adjusting the CAL Factor

Display the Calibration Data menu by first pressing both the ENT and ESC buttons on either the

instrument’s front panel or Smart probe at the same time to display the Main menu. Next, use the Up and

Down buttons to highlight “CAL DATA”, and then press ENT to display the Calibration Data menu.

Main Menu:

SYSTEM

LOG

SETUPS

CAL DATA

DIAGNOSTICS

From the Calibration Data menu, highlight “CAL FACTOR” and press ENT to display its setup screen.

Use the Left and Right buttons to move the blinking cursor across the screen to highlight the digit to be

modified, and then use the Up and Down buttons to modify that digit. Press ENT to save the new CAL

factor value and return to the Calibration Data menu.

CAL FACTOR 1.000

FOR R134A

K1=310.89 K2=703.7 K3=1460.3

K4=0.0 K5=0.0

Calibration Data Menu:

CAL TYPE

EXT RATE

EXT GAS TYPE

CAL FACTOR

RESTORE FACTORY CAL

3.5 Restoring Factory Calibration

NOTE: Factory calibration cannot be restored if the instrument was calibrated using an

external leak source.

Restore an instrument to its factory calibration value as follows:

Display the Calibration Data menu by first pressing both the ENT and ESC buttons on either the

instrument’s front panel or Smart probe at the same time to display the Main menu. Next, use the Up and

Down buttons to highlight “CAL DATA”, and then press ENT to display the Calibration Data menu.

Main Menu:

SYSTEM

LOG

SETUPS

CAL DATA

DIAGNOSTICS

From the Calibration Data menu, use the Up and Down buttons to highlight “RESTORE FACTORY

CAL”, and then press ENT to display the RESTORE FACTORY CAL screen.

RESTORE FACTORY CAL

HIT ENTER TO CONFIRM

Press the ENT button to confirm restoring the instrument to its factory calibration values.

Calibration Data Menu:

CAL TYPE

EXT RATE

EXT GAS TYPE

CAL FACTOR

RESTORE FACTORY CAL

Instruction 3015-4342 27

Page 32

Calibration H25-IR

Notes:

28 Instruction 3015-4342

Page 33

H25-IR Operation

0

S

4 Operation

4.1 Instrument Location

The H25-IR Refrigerant Gas Leak Detector should be placed on a flat, horizontal surface such as a bench

or table top when in use.

When searching for leaks, the instrument does not need to be in a gas-free area. This is because of the

instrument’s ability to automatically zero-out background gases and still be able to locate gas leaks.

When making leak-rate measurements, the instrument needs a location where the air is clean and free of

the gas being monitored − this is necessary for zeroing purposes. If the area is contaminated, then a freshair source (e.g., fresh air piped in from the outside) must be made available so the operator can manually

zero the instrument before making a measurement.

4.2 Using the H25-IR

4.2.1 Power

Plug the instrument into the nearest AC outlet (100 to 240 VAC, 50/60 Hz), and then set the rear panel

power switch to its ON position. After being turned ON, the instrument requires 120 seconds to warm-up.

A detailed description of the front panel display screens that are shown during turn-on and warm-up is

contained in Section

2.3 Turning ON the Instrument.

4.2.2 Initial Setup

At this time the H25-IR should already be set up as described in Section 2 Preparing for Operation.

After warming up, the instrument’s Data Display screen will show the current Gas Measurement, Leak

Units, Gas Type, Setup Name, Range, and Mode of Operation. In addition, a graphical display of the

relative gas level is provided by a bar graph at the bottom of the screen whose length increases up the

screen as the gas level increases. An audible tone may also be heard whose pitch increases in frequency as

the gas level increases. Note that the sensitivity of the bar graph and audible tone for any given gas level

is dependent on the Range setting.

When using the Smart probe, its LCD will show the current Gas Measurement, Range, Mode of Operation,

and Setup Number in parentheses. If the probe contains a red LED, the blink rate of the LED will increase

as the gas level increases. Note that the sensitivity of the LED’s blink rate for any given gas level is

dependent on the Range setting.

Instrument Display Smart Probe Display