Page 1

H-10PM

Congratulations! You have just

purchased the most versatile, high

performance service leak detector

available in the industry today. It

will detect refrigerants with a sensitivity to effectively pinpoint both

small and large leaks quickly and

efficiently.

We encourage your review of this

manual to assure satisfactory performance and a long

service life.

Refrigerant

Leak Detector

Page 2

WARNING: This deviceis not to be

used in any application that is beyond its

intended purpose or beyond the scope of its

specifications. For details on appropriate

use, refer to the rest of this manual. Before

risking equipment damage or personal

injury, contact Bacharach if you are unsure

of the validity of a particular combustion

analyzer application.

How the H-10PM Works

The sensor in the H-10PM uses positive

ion emission technology, commonly known

as a heated diode. It is very sensitive to only

halon substances (refrigerants) making this

product highly resistive to false alarming,

while retaining superior sensitivity for pinpointing the most difficult to find refrigerant leaks.

A pump inside the unit draws air through

the sensor. Any presence of halogen gases

(such as refrigerants) causes an ionized

current to flow that sounds a speaker

and illuminates a neon light in the probe.

Sensitivity to pinpoint both large and small

leaks can be controlled by setting the three

position Leak Size switch.

Battery

Charge

Light

Calibration

Reference

Bottle

2

Charger

Plug

Power

Switch

Low Battery

Indicator

Leak Size

Switch

Adjustment (turn

to increase heat)

Manual Balance

Panel Operating Controls

Heater

clockwise

Mode Switch

MANUAL /

AUTO

Sensor

Heater Adjust

LEDs

Control

Page 3

Before you use the unit the first time . . .

1. Remove the sticky-label disc from the

cap of the Calibration Reference Bottle.

This disc can be reused to help seal the

vial when the leak detector is not in use,

or it can be discarded. DO NOT attempt

to unscrew the cap, you may damage the

bottle! It is filled with enough refrigerant

to last approximately six months.

2. With the Power switch in the OFF position, charge the internal battery using the

furnished wall adapter. Charge time is

8–10 hours or, until the red Full Charge

LED turns green.

Adjusting the Sensitivity

Set the Leak Size switch as follows:

SMALL switch position is the highest sensitivity. The unit will indicate 0.1 ounce or

greater leak rates and is used for fluorine

based gases like R134a and SF6. This position also assures highest repeatability for

locating 0.5 ounce or greater R134a leaks

(per SAE Std. J1627 moving probe test conditions). It must always be used to verify

performance and calibration when using the

Calibration Reference Bottle.

MEDIUM switch position is used for

chlorine and chlorine based gases like R12,

R22, R123, etc. and will indicate a 0.1

ounce per year or greater leak rate. This

position supports finding a 0.5 ounce or

greater leak during the moving probe test as

defined in SAE J1627. It is also useful for

locating larger R134a leaks of one ounce or

greater.

LARGE switch position is used to zero

in on large leaks of any refrigerant. If a

large leak is suspected, switch unit to its

Manual mode. Adjust the Manual Balance

control for 2-3 ticks per second and slowly

3

Page 4

approach the test equipment/area. Adjust

the Manual Balance control counterclockwise as necessary to maintain 2-3 ticks

per second. As you approach the vehicle

or equipment, the gas concentration will

increase, causing an alarm condition. Each

time an alarm occurs, readjust the Manual

Balance control. Continue this process until

the leak is located. Blowing out the test site

with shop air may enable you to locate the

leak more quickly.

NOTE: After the large leak is located and

repaired, blow out the area again with shop air,

set the unit on the small leak sensitivity and

double check equipment for small leaks.

Operating Instructions

1. Slide mode switch to AUTO position.

2. Slide power switch to ON position and

sensitivity switch to SMALL position.

3. Check Low Battery LED. If it glows red,

the battery needs charging, or you may

operate the unit from a 12VDC source, or

with optional AC Adapter of the correct

voltage and current.

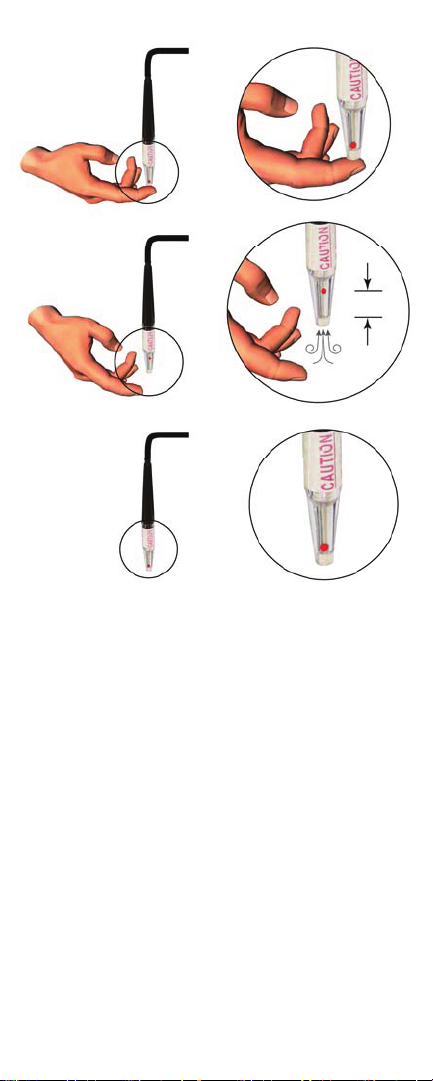

4. Check for sufficient airflow by pointing

the probe tip toward the floor, covering

it with your finger, then releasing your

finger. If proper flow exists, the red ball

should noticeably rise up into the probe

when you uncover the probe tip. Note

that the actual height and final resting

position of the red ball are not important.

If the airflow ball does not rise:

- Tap the probe lightly to ensure the

ball is not sticking.

- Check the filter in the probe tip, as

described in the Maintenance

section.

If the flow is still insufficient, then the

unit should be forwarded for repair to the

nearest Authorized Service Center.

4

Page 5

5. Allow two minutes for the sensor to

warm up, after which the flashing probe

light and sound indicator will idle at 2-3

clicks per second.

6. Test operation by quickly touching the

top of the calibration reference bottle

(make sure sticky label is removed). The

unit should respond with a rapid flash

rate and sound verifying correct operation and optimum sensitivity for detecting

all refrigerant leaks. During product life,

if unit does not respond correctly, see

“Heater Adjustment” section.

5

Page 6

WARNING: Personal Injury Hazard

Do not use the H-10PM in an explosive or combustible atmosphere. The ambient atmosphere is

drawn through the probe and through the sensor,

which operates at approximately 1472°F (800°C).

The resulting hot mixture of air and combustible

gas could explode.

YOU’RE READY TO FIND THE LEAK !

(You have a choice of two modes)

Auto Mode

This mode is preferred because the unit

effectively auto zeros to block out background levels of refrigerants and changes

in background contamination. This greatly

reduces and/or eliminates false alarms

while retaining sensitivity to quickly locate

small or medium size leaks. Pinpointing

leaks in this mode requires continuous

probe movement. (We recommend 2 inches

per second as specified in SAE J1627

and J1628). If the probe is held stationary over the leak the unit will zero out the

leak, going into the idle 2-3 ticks/second

condition. Briefly moving the probe away

from the leak, for 1-2 seconds, permits the

unit to re-establish sensitivity. Returning

to the leak site, the unit will alarm again.

Continuing this procedure will reliably and

repeatedly pinpoint the leak with each pass

over the leak site.

If a large leak is present, the auto zero circuit may reduce sensitivity to an unacceptable level to find small and medium sized

leaks. If this condition exists, the manual

mode will enable you to pinpoint the large

leak. The manual mode is also an effective means to determine if a large leak of

any refrigerant exists prior to searching for

leaks (see “Adjusting the Sensitivity”).

6

Page 7

Manual Mode

In the Manual Mode the auto-zero

circuit is disabled. The unit will not zero out

the leak if the probe is held over the leak

site. This mode may require frequent readjustment of the Manual Balance control to

maintain the required 2-3 ticks per second

that indicates proper adjustment and calibration for all three sensitivity switch positions.

In this mode you may notice sensitivity is

slightly greater (10-20%) than the auto-zero

mode. This is normal.

Heater Adjustment

(for optimum performance and calibration)

The Calibration Reference Bottle sensor

heater circuit controls the sensitivity of the

unit. A heat setting that is too high causes

instability due to excessive sensitivity

and shortens sensor life. The LOW / OK /

HIGH LEDs in conjunction with the Heater

Adjustment and Calibration Reference Bottle

is a unique system for setting the correct

sensor heat (sensitivity) for optimum performance and long sensor life.

The unit is pre-set for optimum initial

operation. To check the setting, slide the

mode switch to AUTO, turn ON the unit and

allow it to stabilize (approximately 2 minutes). When stabilized, at 2-3 clicks per second, briefly touch the Calibration Reference

Bottle with the probe (after removing the

sticky label disc from the top of the bottle).

If adjusted properly the red LOW LED will

go out and the green OK LED will briefly

glow. This indicates the sensor’s heat/sensitivity is adjusted for optimum performance.

If the red LOW LED remains on when you

briefly touch the bottle, the sensor heat is

set too low and the Heater Adjustment must

be turned slightly clockwise. Allow unit to

stabilize about one minute and retest. Repeat

7

Page 8

this procedure until the green OK LED

briefly glows.

If the red HIGH LED glows, the heat is set

too high and the Heater Adjustment should

be turned slightly counterclockwise. Allow

the unit to stabilize and then repeat the test.

Continue this procedure until the proper

green OK LED indication has been achieved.

NOTES:

A. After initial check for correct adjustment,

disregard the LOW / OK / HIGH LEDs. Their

indication is meaningless during subsequent leak

testing activity.

B. Check for proper heat adjustment the first time

the unit is turned on and repeat on a daily basis.

This assures the product is calibrated for the correct

sensitivity in all leak size switch positions for your

daily test activity.

C. Frequency of sensor heat adjustment is a

function of how much exposure the sensor has

to refrigerant. Adjustment may be required every

couple of weeks for heavy duty service and once

every few months for light duty

service. The sensor LED status indicators will

accurately tell you when adjustment is necessary

during the daily check.

D. Over the usable sensor life, when heater

adjustment is fully clockwise and the green OK

LED will not come on, it is time to replace the

sensor. Before plugging in a new one, turn the

Heater Adjustment fully counterclockwise then

plug in the new sensor and test and adjust as

described above to calibrate the instrument.

Application Notes

1. Start leak checking anywhere and continue in a logical progression through the

entire system to locate all leaks. If surfaces are particularly dirty, or wet, wipe

them off with a clean, dry cloth to reduce

8

Page 9

filter clogging and extend sensor life. DO

NOT allow the unit to ingest moisture.

Use of the supplied rubber probe tip helps

prevent moisture from being drawn into

the unit. Check ports for moisture before

inserting the probe.

2. After locating and repairing any leaks

requiring the use of the LARGE switch

setting, switch to the MEDIUM setting

and verify the system is free of leaks. For

HFC refrigerants only (such as R134a),

you also must verify the system is leak

free using the SMALL setting. For CFC

and HCFC systems (such as R11, R12,

R22, R123), the MEDIUM setting is sufficient to verify that the system is free of

leaks that require repairing.

Caution: Equipment Damage Hazard

A. Submerging the probe in liquid will damage

the air pump.

B. Exposing the probe to a stream of pure refrigerant coming out of a tank will severely reduce

the life or destroy the sensor. Life of this rareearth sensor technology is directly proportional to

the amount of refrigerant that passes through it.

With normal intermittent service, the sensor can

last for one year or longer.

C. Exposure to high concentrations of refrigerant

may require adjustment of sensor heat. To check,

repeat the test procedure in “Heater Adjustment”

section.

9

Page 10

Maintenance

(replacing the filter and airflow indicator)

To protect the air pump from damage due

to foreign particles and moisture, replace

the filter as it becomes dirty. With moderate use (15 to 30 minutes a day), it is

recommended that the filter be replaced

once a month. In dirty environments or

with heavy use, replace the filter more

frequently. Always replace the filter when

it is

visibly dirty or wet.

Replacing the Filter:

1. Remove the black rubber probe tip.

2. Pick out the filter with a pin or tweezers. A

fine screen will remain in the tip of the

probe.

3. Insert the new filter in the probe tip.

Make sure that the filter is firmly seated

against the fine screen.

4. Replace the rubber probe tip.

Filter

Probe Tip

Airflow

Indicator Ball

Rubber

Probe Tip

Replacing Airflow Ball Indicator:

1. Remove the clear plastic section of the

probe tip by gently pulling and twisting

the white grip.

2. Turn the probe tip upside-down and tap

on it to remove the old airflow indicator

ball.

3. Insert the new airflow indicator ball into

the tip.

4. Reattach the probe tip to the probe

assembly.

10

Page 11

Replacing the Sensor:

The sensor is a plug-in unit that can be

thrown away when expended. It needs

replaced when the H-10PM no longer

responds to the Calibration Reference Bottle,

even with the Heater Adjustment turned fully

clockwise (make sure the reference bottle

contains some refrigerant).

Caution: Personal Injury Hazard

Sensor surface temperature may reach 390°F

(200°C) during operation, and may cause a burn

if not allowed to cool.

1. Turn the leak detector OFF.

2. Unplug the power cord if the unit is

plugged in and open the sensor cover.

3. Allow the sensor to cool before

touching it.

4. Unplug and discard the sensor.

5. Insert a new sensor and close the sensor

cover.

6. Turn the Heater Adjustment to its full

counterclockwise position.

7. Apply power to the unit and adjust

the sensor’s heat setting (see “Heater

Adjustment” section).

Troubleshooting

Problem Responds to reference leak in

LARGE leak switch position

Cause Heat Adjustment set too high

Solution Readjust heater (see “Heater

Adjustment” section)

continued on next page

11

Page 12

** Solution # corresponds to Cause # **

Problem No response to Calibration

Reference bottle

Cause

1

Heat Adjustment set too low or

bottle is empty

2

No air flow (indicator ball in

probe doesn’t float)

3

Sensor exposed to excessive

amounts of halogen gas

4

Water in probe

Solution

1

Readjust heater (see “Heater

Adjustment” section) or replace

bottle (3015-0864)

2

Replace filter in probe tip

(3015-0784). Check air pump

operation.

3

Move probe to clean atmosphere for several minutes while

sensor purges itself.

4

Turn unit off and disconnect

probe from chassis. Remove

screws and take out chassis.

Look at the underside of the leak

detector and follow the probe

to the air pump. Remove this

hose from the pump. Blow clean

air (5 psi) into the probe tip for

one or two minutes. Reassemble

unit and replace the filter

(3015-0784).

Problem Probe tip lamp does

not flash

Cause Burned out or damaged probe

lamp

Solution Return for repair

12

Page 13

** Solution # corresponds to Cause # **

Problem Erratic response in all leak posi-

tions

Cause

1

Filter is clogged

2

Dirt in sensor

3

Short circuit in sensor

4

Atmosphere contaminated with

excessive refrigerant gas.

Solution1Replace the filter (3015-0784)

2

Remove sensor and blow it out

with clean air (not over 10psi).

If unsuccessful, replace the sensor (3015-0486). Replace the

filter (3015-0784).

3

Replace sensor (3015-0486)

4

Ventilate area

Problem Responds continuously only in

SMALL leak switch position

Cause Excessive sensitivity

Solution Readjust heater (see “Heater

Adjustment” section)

13

Page 14

Ordering Information

3015-0627 H-10PM Refrigerant Leak Detector

w/ Battery & Charger

3015-0326 14 inch Flexible Probe Extension

3015-0119 100-240VAC Charge/Run AC

Adapter

3015-0895 Battery Clamp / Cigarette Adapter

assembly

3015-0641 Clear Probe Tip

3015-0680 Rubber Probe Tip

3015-0486 Replacement Sensor

3015-0781 Tune-up Kit: Sensor, 100 Filters,

3 Airflow Balls, 3 Rubber Probe

Tips, and Calibration Bottle

3015-0784 Maintenance Kit: 100 Filters,

3 Airflow Balls, 3 Rubber Probe

Tips, and Calibration Bottle

3015-0737 Maintenance Kit:

12 Filters, 3 Airflow Balls

3015-0864 Calibration Reference Bottle

3015-0103 Battery

14

Page 15

Repair Information

Should it become necessary to repair your

H-10PM, please contact an Authorized

Service Center. Units should be carefully

packed to prevent shipping damage and

shipped prepaid.

Warranty

Send units under warranty and a copy of the

purchase receipt to an Authorized Service

Center for repairs. Please include your company name, telephone number including area

code, and a contact name.

Non-Warranty

Units that are no longer under warranty will be

repaired to factory specifications for a nominal fee. Please include your company name,

telephone number including area code, and a

contact name.

Limited Warranty

The purchaser is warranted that this leak detector will be free of defects in material and workmanship for 3 years from date of purchase.

This warranty does not cover sensors, reference

leaks, filters, airflow balls, lamps, batteries, or

probe tips. Damages caused by the user will not

be covered. If any defects are discovered during the warranty period, an Authorized Service

Center will repair or replace the unit at their

option.

The foregoing limited warranty is exclusive

and in lieu of all other warranties, whether

written or implied, and no warranty of merchantability or fitness for purpose will apply.

15

Page 16

Authorized Service Centers

United States

Bacharach Sales/Service Center

621 Hunt Valley Circle

New Kensington, PA 15068

Phone: 724-334-5051

Fax: 724-334-5723

E-mail: help@mybacharach.com

Canada

Bacharach of Canada, Inc.

20 Amber St. Unit #7

Markham, Ontario L3R 5P4

Canada

Phone: 905-470-8985

Fax: 905-470-8963

E-mail: bachcan@idirect.com

16

Page 17

Notes:

17

Page 18

Notes:

18

Page 19

Notes:

19

Page 20

New Kensington, PA 15068

Ph: 724-334-5000 Fax: 724-334-5001 Toll Free: 1-800-736-4666

Website: http://www.mybacharach.com E-mail: help@mybacharach.com

621 Hunt Valley Circle

3015-0925

Rev 9 9/2012

Loading...

Loading...