Page 1

Instruction 5209-9000

Operation Manual

Rev. 0 - May 2011

Product Leadership • Training • Service • Reliability

Page 2

GDC-150 Operation Manual

IMPORTANT NOTE

READ AND UNDERSTAND THIS MANUAL PRIOR TO USING THIS INSTRUMENT.

THIS INSTRUMENT SHOULD BE INSPECTED AND PROGRAMMED BY

QUALIFIED AND TRAINED PERSONNEL.

THIS INSTRUMENT HAS NOT BEEN DESIGNED TO BE INTRINSICALLY S AFE IN

HAZARDOUS OR EXPLOSION-RATED ENVIRONMENTS. FOR YOUR SAFETY,

DO NOT

USE OR I NSTALL IT IN AREAS CLASSIFIED AS HAZARDO US AREAS

(E.G., EXPLOSION-RATED ENVI RO NM ENTS).

ii 5209-9000 Rev 0

Page 3

DISCLAIMER

UNDER NO CIRCUMSTANCES WILL BACHARACH, INC. BE LIABLE FOR ANY

CLAIMS, LOSSES OR DAMAGES RESU LTING FROM OR ARISING OUT OF THE

REPAIR OR MODIFICATION OF THIS EQUIPMENT BY A PARTY OTHER THAN

BACHARACH, INC. OR ITS AUTHORI ZED SERVIC E REPRE SENTATIVES, OR BY

OPERATION OR USE OF THE EQUIPMENT OTHER THAN IN ACCORDANCE

WITH THE PRINTED INSTRUCTIONS CONTAINED W ITHIN THIS MANUAL OR IF

THE EQUIPMENT HAS BEEN IMPROPERLY MAINTAINED OR SUBJECTED TO

NEGLECT OR ABUSE. ANY OF THE FORGOING WILL VOID THE WARRANTY.

GDC-150 Operation Manual

WARRANTY POLICY

BACHARACH, INC. WARRANTS THIS INSTRUMENT TO BE FREE FROM

DEFECTS IN MATERIALS AND WORKMANSHIP FOR A PERIOD OF TWO (2)

YEARS FROM THE DATE OF PURCHASE. THIS INCLUD ES ALL ELECTRONICS,

SOLID-STATE SENSORS, CATALYTIC SENSORS, AND ELECTROCHEMICAL

CARBON MONOXIDE (CO) SENSORS. OTHER ELECTROCHEMICAL S ENSORS

ARE WARRANTED FOR ONE YEAR.

THE WARRANTY STATU S WILL BE AFFECTED (VOIDED) I F THE INSTRUMENT

HAS NOT BEEN INSTALLED AND MAINTAINED ACCORDING TO THE

INSTRUCTIONS INDICATED IN THIS MANUAL OR HAS BEEN ABUSED,

DAMAGED (ROUGH HANDLING, MECHANICAL DAMAGE, ELECTRICAL SHOCK

DAMAGE, ETC.) OR MODIFIED IN ANY WAY. THIS INSTRUMENT IS ONLY TO BE

USED FOR THE PURPOSES STATED HEREIN. THIS WARRANTY INDICATES

THE FULL EXTENT OF OUR LI ABILITY AND WE ARE NOT RESPONSI BLE FOR

REMOVAL OR REPLACEMENT COSTS, LOCAL REPAIR COSTS,

TRANSPORTATION COSTS OR CONTINGENT EXPENSE S INCURRED W ITHOUT

PRIOR APPROVAL.

BACHARACH, INC. WILL N O T BE HELD LIABLE FOR INDIRECT, INCIDENTAL OR

CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND TO EQUIPMENT

CONNECTED, IN ANY WAY, TO THE EQUIPMENT MANUFACTURED BY US.

THIS WARRANTY COVERS EQUIPMENT AND PARTS SOLD TO USERS ONLY BY

AUTHORIZED DISTRIBUTORS, D EALERS, AGENTS OR REPRESENTATIVES, AS

AUTHORIZED AND APPOINTED BY BACHARACH.

DUE TO ONGOING RESEARCH, DEVELOPMENT AND PRODUCT TESTING, THE

MANUFACTURER RESERVES THE RIGHT TO CHANGE SPECIFICATIONS

WITHOUT NOTICE. THE INFORMATION CONTAINED HEREIN IS BASED ON

DATA CONSIDERED ACCURATE. HOW EVER, NO WARRANTY IS EXPRESSED

OR IMPLIED REGARDING THE ACCURACY OF THIS DATA.

ALL GOODS MUST BE SHIPPED TO THE MANUFACTURER BY PREPAID

FREIGHT. ALL RETURNED GOODS MUST BE ACCOMPANIED BY AN RMA

NUMBER.

5209-9000 Rev 0 iii

Page 4

GDC-150 Operation Manual

BACHARACH, INC. MAINTAINS AN INSTRUMENT SERVICE FACILITY AT THE

FACTORY. SOME BACHARACH DISTRIBUTORS / AGENTS MAY ALSO HAVE

REPAIR FACILITIES, HOWEVER, BACHARACH ASSUMES NO LIABILITY FOR

SERVICE PERFORMED BY A NYONE OTHER THAN BACHARACH PERSONNEL.

REPAIRS ARE WARRANTED FOR 90 DAYS AFTER DATE OF SHIPMENT

(SENSORS, PUMPS, FILTERS AND BATTERIES HAVE INDIVIDUAL

WARRANTIES). SHOULD YOUR INSTRUMENT REQUIRE NON-WARRANTY

REPAIR, YOU MAY CONTACT THE DISTRIBUTOR FROM WHOM IT WAS

PURCHASED OR YOU MAY CONTACT BACHARACH DIRECTLY.

IF BACHARACH IS TO DO THE REPAIR WORK, SEND THE INSTRUMENT,

PREPAID, TO BACHARACH, INC. AT THE FOLLOWING ADDRESS.

BACHARACH, INC.

621 HUNT VALLEY CIRCLE

NEW KENSINGTON, PA 15068

ATTENTION: SERVICE DEPARTMENT

ALWAYS INCLUDE YOUR RMA #, ADDRESS, TELE PHONE NUMBER, CONTACT

NAME, SHIPPING/BILLING INFORMATION AND A DESCRIPTION OF THE

DEFECT AS YOU PERCEIVE IT. YOU WILL BE CONTACTED WITH A COST

ESTIMATE FOR EXPECTED REPAI RS PRIOR TO THE PERFORMANCE O F ANY

SERVICE WORK. FOR LI ABILITY REASONS, BACHARACH HAS A POLICY OF

PERFORMING ALL NEEDED REPAIRS TO RESTORE THE INSTRUMENT TO

FULL OPERATING CONDITION.

PRIOR TO SHIPPING EQUIPMENT TO BACHARACH, CONTACT OUR OFFICE

FOR AN RMA # (RETURNED MERCHANDISE AUTHORIZATION). ALL

RETURNED GOODS MUST BE ACCOMPANIED WITH AN RMA NUMBER.

PACK THE EQUIPMENT WELL (IN ITS ORIGINAL PACKING IF POSSIBLE), AS

BACHARACH CANNOT BE HELD RESPONSIBLE FOR ANY DAM AGE INCURRED

DURING SHIPPING TO OUR FACILITY.

COPYRIGHTS: THIS MANUAL IS SUBJ ECT TO COPYRIGHT PROTECTION; ALL

RIGHTS ARE RESERVED UNDER INTERNATIONAL AND DOMESTIC

COPYRIGHT LAWS. THIS MANUAL M AY NOT BE COPIED OR TRANSLATED, IN

WHOLE OR IN PART, IN ANY MANNER OR F ORMAT, WITHOUT THE WRITTEN

PERMISSION OF BACHARACH, INC.

SERVICE POLICY

NOTICES

iv 5209-9000 Rev 0

Page 5

REVISIONS

BACHARACH, INC. MAKES NO WARRANTY OR REPRESENTATION,

EXPRESSED OR IMPLIED INCLUDING ANY W ARRANTY OF MERCHANTABI LITY

OR FITNESS FOR PURPOSE, WITH RESPECT TO THIS MANUAL. ALL

INFORMATION CONTAINED IN THIS MANUAL IS BELIEVED TO BE TRUE AND

ACCURATE AT THE TIME OF PRI NTING. HOWEVER, BACHARACH RESERVES

THE RIGHT TO MAKE CHANGES AT ANY TIME WITHOUT NOTICE. REVISED

COPIES OF THIS MANUAL CAN BE O BTAINED BY CONTACTING BACH ARACH,

INC.

SHOULD YOU DETECT ANY ERRORS OR OMISSIONS IN THIS MANUAL,

PLEASE CONTACT THE COMPANY AT THE FOLLOWING ADDRESS.

GDC-150 Operation Manual

TOLL FREE: 1-800-736-4666

FAX: 724-334-5001

E-MAIL: help@MyBacharach.com

WEBSITE: www.MyBacharach.com

IN NO EVENT WILL BACHARACH, INC., OR ITS OFFICERS OR EMPLOYEES BE

LIABLE FOR ANY DIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES RESULTING FROM ANY DEFECT IN ANY MANU AL, EVEN IF ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES.

BACHARACH, INC.

621 HUNT VALLEY CIRCLE

NEW KENSINGTON, PA 15068-7074

USA

5209-9000 Rev 0 v

Page 6

GDC-150 Operation Manual

1. OVERVIEW ................................................................................................................ 1

1.1. General Description ............................................................................................ 1

1.2. Enclosures .......................................................................................................... 1

1.3. Key Components ................................................................................................ 3

2. SPECIFICATIONS ..................................................................................................... 4

2.1. General ............................................................................................................... 4

2.2. Standard Enclosures .......................................................................................... 4

2.3. Optional Enclosures ............................................................................................ 4

2.4. Sensors (Solid-State and Catalytic) .................................................................... 5

2.5. Sensors (Electrochemical) .................................................................................. 6

2.6. Sensor Cross Sensitivity (Electrochemical) ......................................................... 7

3. INSTALLATION ......................................................................................................... 8

3.1. Mounting Holes and Conduit Ports ...................................................................... 8

3.2. Enclosure Door ................................................................................................... 9

3.3. Sensor Mounting Height Recommendations ......................................................10

3.4. Wiring the GDC-150 for Power ..........................................................................10

4. OPERATION ............................................................................................................ 13

4.1. General ..............................................................................................................13

4.2. Detecting Gas ....................................................................................................14

4.3. System Failure ...................................................................................................14

4.4. Sensor Notes .....................................................................................................14

4.5. Open Loop Diagnostic .......................................................................................15

4.6. Jumper Functions ...............................................................................................15

4.7. Adjusting the Alarm Set Point (For Relay Option Only) ......................................15

4.7.1. Calculating the Alarm Set Point Value .................................................... 15

4.7.2. Adjusting the Alarm Set Point ................................................................. 16

5. CALIBRATION ......................................................................................................... 16

5.1. Frequency Recommendations ...........................................................................16

5.2. Calibration Specifications – Gases .....................................................................17

5.3. Regulators and Flow – Solid-State and Catalytic Sensors ..................................17

5.4. Regulators and Flow – Electrochemical Sensors ...............................................17

5.5. Calculating the Span Gas Value ........................................................................18

5.6. Setting the Span Gas Value ...............................................................................19

5.7. Calibrating the Null (Zero) Value ........................................................................19

5.8. Calibrating the Span Value ................................................................................20

6. ACCESSORIES AND REPLACEMENT PARTS ...................................................... 21

6.1. Metal Protective Guards ....................................................................................21

6.2. Accessory and Replacement Part Numbers .......................................................21

TABLE OF CONTENTS

vi 5209-9000 Rev 0

Page 7

GDC-150 Operation Manual

1. OVERVIEW

1.1. General Description

GDC-150 trans mitters are rugged, user -friendly, configurable anal og transmitter gas

detectors for use in non-hazardous (non-explosion rated) environments for

commercial HVAC and light industrial use. It can be configured for either

electrochemical toxic gas sensors, solid-state sensors, or catalytic sensors.

A standard transmitter provides a bi-color LED indicating light for power, fault

condition, and alarm (option with one dry contact relay). An optional LED digital

display is available as well as other enclosure options.

The electrochemical sensor s utilized in this device are acc urate enough to measure to

Occupational Health and Safety hazardous levels for t oxic gases and oxygen levels.

NOTE: The GDC-150 analog transmitters operate by diffusion. If a

sample draw system is desired, consult a Bacharach authorized

distributor or the factory for details.

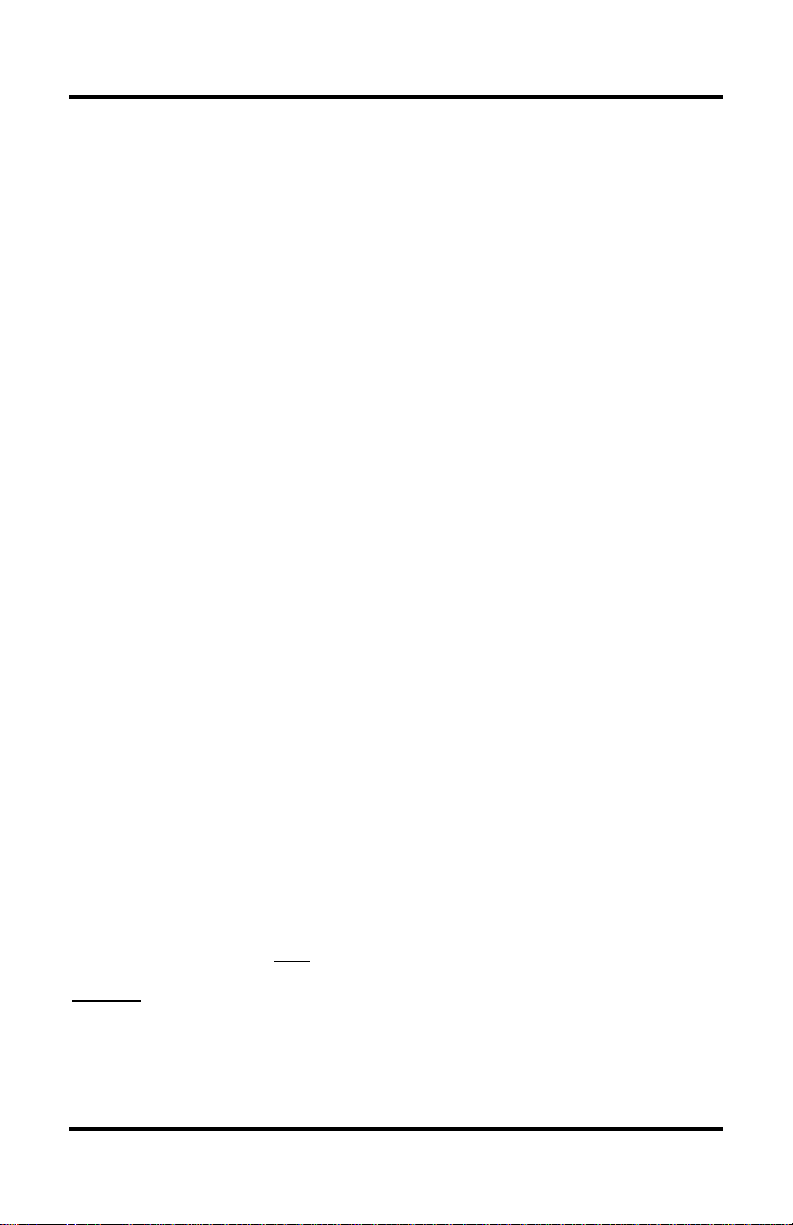

1.2. Enclosures

Figure 1-1. Standard (NEMA 1X) Enclosures

5209-9000 Rev 0 1

Page 8

GDC-150 Operation Manual

150 transmitters utilizing catalytic combustible or

Figure 1-2. Optional Water-Tight (NEMA 4X) Enclosure

Figure 1-3. Water-Tight Enclosure (Side View) Showing Optional Splash Guard

NOTE: GDC-

electrochemic al H2S/SO2 s ensors are suppli ed with the water - and dusttight NEMA 4X enclosure standard.

2 5209-9000 Rev 0

Page 9

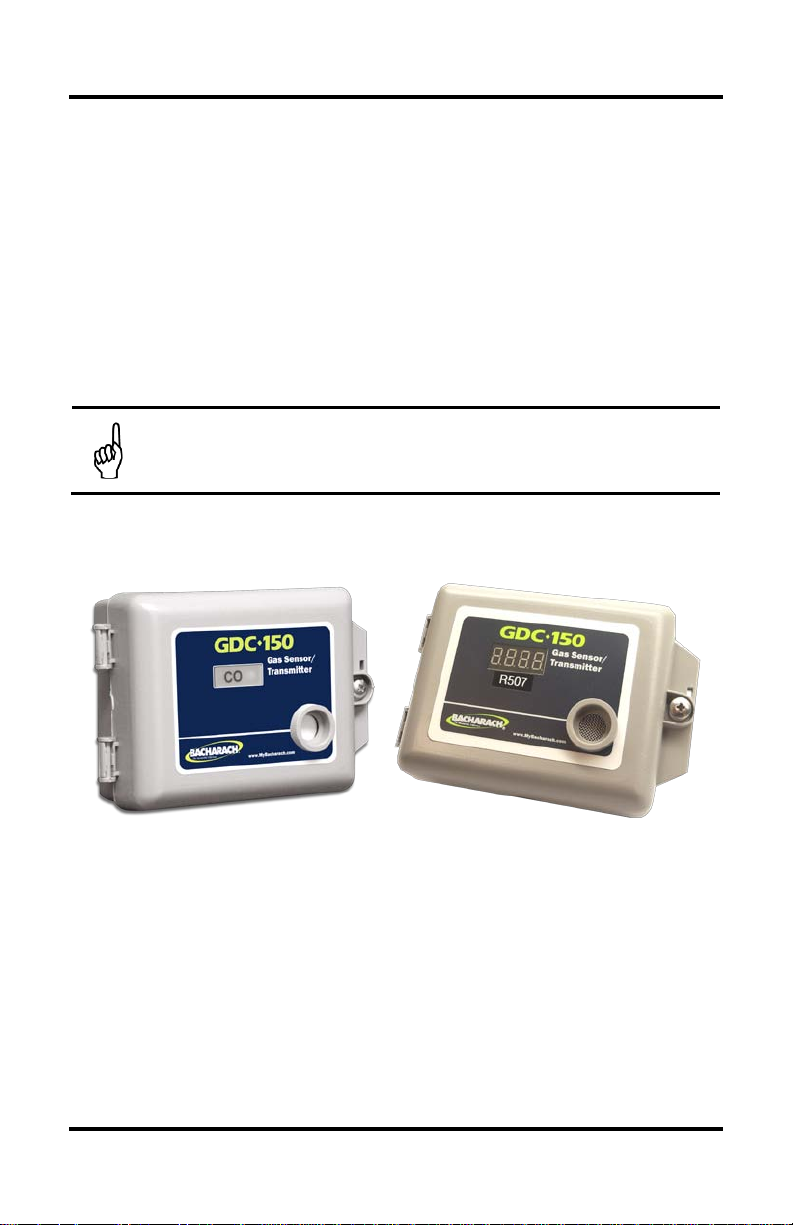

1.3. Key Components

GDC-150 Operation Manual

Figure 1-4. Key Components on GDC-150 Ci rcuit Board

5209-9000 Rev 0 3

Page 10

GDC-150 Operation Manual

Flash Green = Warm-up

Flash Red = Fail

2. SPECIFICATIONS

2.1. General

All Sensor Types

Power 12 VAC to 30 VAC or 16 VDC to 30 VDC

Current

80 to 120 mA

2

1

One bi-color LED:

• Green = Power • Red = Alarm

Indicators

•

One amber LED (int ernal relay coil status indicator)

•

3

One red LED (4-20 mA open-loop indic ator for remote transmitter)

• LED digital display (3.5 digits)

Options

• Relay (one SPDT dry contact relay rated 2A @ 30 VAC)

• Water/dust tight enclosure

• Splash guard (water-tight enc losure only)

2.2. Standard Enclosures

Solid-State Catalytic Electrochemical

Type PVC Polycarbonate PVC

Dims

(HxWxD)

6.5 x 4.4 x 2.5 in

165 x 113 x 65 mm

4.9 x 4.9 x 2.9 in

125 x 125 x 75 mm

6.5 x 4.4 x 2.5 in

165 x 113 x 65 mm

Weight 20 ounces 16 ounces 20 ounces

Construction

2.3. Optional Enclosures

Drip-proof overlap

with hinged door

Solid-State Catalytic Electrochemical

Type Polycarbonate

Dims

(HxWxD)

4.9 x 4.9 x 2.9 in

125 x125 x 75 mm

Weight 16 ounces

Construction

Water- & dust-tight

with hinged door

Water- & dust-tight

with hinged door

Drip proof overlap

with hinged door

Polycarbonate

4.9 x 4.9 x 2.9 in

125 x125 x 75 mm

16 ounces

Water- & dust-tight

with hinged door

1

Non ground referenced supply only

2

For electro-chemical sensors, this depends on the options that are selected.

3

Only supplied if relay option has been selected

4 5209-9000 Rev 0

Page 11

2.4. Sensors (Solid-State and Catalytic)

Type Solid-state MOS

Range

Combustible: 0-50% LEL

Refrigerant: 0-2000 ppm

Solid-State Catalytic

4

Catalytic pellistor

0-100% LEL of target

combustible gas or vapor

Combustible: Approximately 5

to 8 years in clean, ambient

Life Span

conditions

Refrigerant: Approximately 5+

Approximately 5 years in clean,

ambient conditions

years in clean, ambient

1% LEL

-20°C to +40°C

(-4°F to +104°F)

Resolution

Temperature

conditions

Combustible: 1% LEL

Refrigerant: 2 ppm

-20°C to +40°C

(-4°F to +104°F)

Humidity 0-90% non-condensing 0-90% non-condensing

Response

Warm-up

Combustible: T90 = <60 seconds

Refrigerant: T

for most refrigerants

= <120 seconds

90

2 minute delay

24 hours for best performance

(maximum accuracy)

T90 from air to 50% LEL = <12

seconds

2 minute delay

1 hour for best performance

(maximum accuracy)

4

MOS: Metal Oxide Semiconductor

GDC-150 Operation Manual

5209-9000 Rev 0 5

Page 12

GDC-150 Operation Manual

Life

Span

Resolution

Response

Time (T90)

Warm

Up

-40 TO

1

ppm

Hydrogen Sulfide

(H2S)

0-50

ppm

0.5

ppm

-30 to

+50°C

<35 sec

(0-20 ppm)

Nitrogen Dioxide

0-5.0

0.1

-30 to

<60 sec

1-2

ppm

+50°C

(0-50 ppm)

hrs

0-25.0

% vol

0.1%

vol

-30 to

+50°C

<15 sec

(20.9%-0%)

Sulfur Dioxide

(SO2)

0-20

ppm

-30 to

+50°C

<30 sec

(0-20 ppm)

Formaldehyde

0-10

0.2

-20 to

2.5. Sensors (Electrochemical)

Sensor Range

5

Temp RH

6

Ammonia (NH3)

Carbon Monoxide

(CO)

0-500

ppm

0-200

ppm

2

5-8

3

3

3 1 ppm

2

(NO2)

Nitric Oxide (NO)

Oxygen (O2)

ppm

0-100

2 1 ppm

(HCHO)

ppm

2

5

Approximate, in years

6

Non-condensing

7

Temperature drift occurs

8

Without regular calibration

9

Minimum warm-up time

1-2

+50°C715-90% <90 sec

ppm

ppm,

3

8

-20 to

+50°C

10-95% <2 min 1 hr

15-90%

ppm

+50°C

-30 to

15-90%

15-90%

5-95%

15-90%

ppm

+50°C

15-90% <80 sec 1 hr

(0-10 ppm)

<20 sec

2-6

hrs

1 hr

hrs

1-2

1 hr

2 hrs

9

9

9

6 5209-9000 Rev 0

Page 13

GDC-150 Operation Manual

2.6. Sensor Cross Sensitivity (Electrochemical)

Sensor Cross Sensit ivity – Electrochem ical Sensors Only

Ammonia

0-500 ppm

300 ppm CO = 8 10% vol CO2 = -15 35 ppm NO = 6

15 ppm H2S = 30 1 ppm Cl2 = -1 5 ppm HCl = -3

5 ppm SO2 = -0.5 200 ppm H2 = 4 5 ppm NO2 = -1

Carbon

Monoxide

Hydrogen

Sulfide

Conforms to UL 2034 performance specification.

20 ppm SO2 ≤18 50 ppm NO ≤ 6 10 ppm NO2 ≤ -30

10 ppm Cl2 ≤ -25 400 ppm H2 ≤ 1 400 ppm C2H4 ≤ 0.8

400 ppm CO ≤ 4 400 ppm NH3 ≤ 0.1

Nitrogen

Dioxide

50 ppm NO ≤ 0.5 20 ppm SO2 ≤ -2 10 PPM Cl2 = 100

400 ppm H2 ≤ 0.1 20 ppm H2S = -100 400 ppm CO ≤ 0.1

400 ppm C2H4 ≤ 0.1 20 ppm NH3 ≤ 0.1

Nitric Oxide 10 ppm NO2 ≤ 5 20 ppm SO2 ≤ 4 10 ppm Cl2 ≤ 5

400 ppm H2 ≤ 0.1 20 ppm H2S ≤ 60 400 ppm CO ≤ 0.1

20 ppm NH3 ≤ 0.1

Oxygen 5% volume CO2 = 0.1 0% to 95% RH @ 40°C ≤ 0.7

Sulfur Dioxide 50 ppm N O ≤ -3 10 ppm NO2 ≤ -100 10 ppm Cl2 ≤ -70

400 ppm H2 ≤ 0.1 400 ppm CO ≤ 1 400 ppm C2H4 ≤ 40

20 ppm NH3 ≤ 0.1

Formaldehyde

(HCHO)

100 ppm CO <18 100 ppm H2 ≤ 3

Other reducing gases such as alcohol (N ote: Formalin –

commercial gr ade formaldehyde – contains alcohol.)

5209-9000 Rev 0 7

Page 14

GDC-150 Operation Manual

3. INSTALLATION

3.1. Mounting Holes and Conduit Ports

The GDC-150 should be inst alled on a flat vertical s urface with the sensor pointi ng

outwards in a clean, dry environment. If the GDC-150 is to be ins talled in a potentially

wet environment, t he optional water-tight enclosure shoul d have been sel ected. This

reference refers to the standard, general purpose PVC enclosure. Four mounting

holes are provided i n the enclosure bas e for securing the GDC-150 to the wall. Do

not block the front of the encl osure as this is where the sensor is situated and where it

monitors the air for the target gas.

NOTE: Four mounting holes are provided in the enclosure base for

securing the GDC-150 to the w all. The mounting holes ar e 3/16″ (4.8

mm) in diameter.

Conduit entry points are provided for the PVC enclosure.

Figure 3-1. Standard Enclosure Showi ng Mounting Holes

The water-tight enclosure mus t be ins t all ed wi th t he mount ing s c r ews pass i ng thr ough

the same openings t hat accommodate the four door securing screws . This ensures

the mounting screws are outside of the door gasket and confirms a water-tight

installation.

NOTE: No conduit entry points are provided for the water-tight

enclosure. The reason is the installer may not want one where we

would place it and this would result in unnecessary openin gs into this

enclosure.

8 5209-9000 Rev 0

Page 15

GDC-150 Operation Manual

Figure 3-2. Water-Tight Enclosure Showing Mounting Holes

WARNING: Do not dril l holes in the back of the bas e of the enclosure

for the purpose of mounting the sensor/transmitter. Leak paths can

occur. Corr osion damage will not be covered under warrant y.

NOTE: Use caution when drilli ng holes in the water-tight enclos ure for

conduit entry so as not to damage the circuit board inside. Use liquid

tight conduit hubs wherever conduit enters the water-tight enclosure.

Failure to do so cr eates a leak path. Water r unning down the conduit

enters the inter ior of the enclosure and c ould corrode the c ircuit board.

This is not covered under warranty.

NOTE: When mounting either enclosure, allow enough room to enable

the end user to open the door fully to acc ess the internal adjustments.

3.2. Enclosure Door

The standard enclosure has one s crew securing the door to the base for electr ical

safety and provid es an opening to al low the user to ap ply a zip ti e if they desire t he

transmitter to be locked more securely. Refer to Figure 1-1 on page 1.

The door of the standard enclosure c an be easily removed to fac ilitate instal lation of

the base. Simply grasp t he lid with one hand, being careful not to make cont act with

any of the intern al components (circuit board) , and grasp the bas e with your other

hand. Tug on the base, pulling i t towards you. The section of the hinges located on

the base should “snap” apart from the part of the hinges locat ed on the door.

5209-9000 Rev 0 9

Page 16

GDC-150 Operation Manual

After instal lation, simply l ocate the lid hinges over the inst alled base hinges and pull

toward you. The hinges should easily “snap” back into place.

By design, the overlapping d oor of the PVC enclosure makes i t inherently drip proof,

although it is not water ti ght or dust t ight. The opti onal water-t ight encl osure has four

screws for sealing the door to the base. Refer to Figure 1-2 on page 2.

3.3. Sensor Mounting Height Recommendations

Some toxic gases such as ammoni a (NH

) are light er than air, therefore the sensor/ transmitter should be installed on or

(CH

4

near the ceiling.

Some toxic gases s uc h as carbon monoxide are o nly s l ight ly l i ghter than ai r , t her efor e

the sensor/transmitter should be i nstalled at approximately 4’ to 6’ from t he floor.

Oxygen sensors should be installed at approximately 4’ to 6’ from the floor.

For toxic gases, combustible gases, and vapors that are heavier than air, the

sensor/transmitter should be inst alled with the sensor opening at 6” from the f loor.

Although most r efrigerant s (e. g., Freons) are hea vier than ai r, some applicat ions may

be better suited t o a slightly higher mount ing height for ref rigerant sensors.

NOTE: If the area to be monitored is a wet environment, water-tight

enclosures shoul d be used. Th e water -ti ght encl osure m ust be ins tall ed

using the indic ated holes or it may leak. Damage c aused by leaking

because of improperly installed enclosures is not covered under

warranty. If the area to be monitored has the potential for water spray, a

splash guard should be used to protect the sensor.

3.4. Wiring the GDC-150 for Power

If powering the GDC-150 with 24 VAC, use terminals 1 and 2. If powering the

GDC-150 wit h 24 VDC, the posi tive (r ed) wire should be c onnected to ter minal 2 and

the negative (bl ack) wire shoul d be connected to term inal 3. The signal wire is always

connected to termi nal 4. See Figure 3-4 for proper wiring examples and Figure 3-5

for improper wi ring examples.

Terminals 5, 6, and 7 are used only if the relay option has been supplied. Double

check the relay r atings in the s pecifications section of this m anual before oper ation.

For normal operatio n, the relay contr ol wiring should be connec ted to N/C and COM

(fail-safe operation is used).

) an d combusti ble gases suc h as methane

3

10 5209-9000 Rev 0

Page 17

GDC-150 Operation Manual

Figure 3-3. Power and Optional Rela y Wiring

NOTE: The m ain wiri ng terminal strip on t he GDC-150 circ uit board can

be unplugged for eas ier wiring inst allation. Grasp the two s ides of the

terminal stri p and lift upward with a sl ight side to side rock ing motion.

NOTE: DO NOT use solid-core wire for connection to wiring terminal

strip. Any damag e caused by using sol id-core wire will voi d warranty.

Use stranded wire ONLY.

IMPORTANT: The GDC-150 is a low voltage powered device. Any

application of operating voltages higher than indicated in the manual

may result in damage. Double check wiring connections prior to

powering the trans mitter. Damage f rom incorrec t wiring conne ctions or

from too much volt age are not covered under w arranty.

IMPORTANT: When providing power to the GDC-150, use nongrounded referenc e suppl ies onl y. Refer to Figure 3-4 for prope r wiri ng

examples and Figure 3-5 for improper wiring examples.

5209-9000 Rev 0 11

Page 18

GDC-150 Operation Manual

Figure 3-4. Proper Wiring Examples

12 5209-9000 Rev 0

Page 19

Figure 3-4. Proper Wiring Exampl es ( Continued)

Figure 3-5. Improper Wiring Example

4. OPERATION

4.1. General

After installation, double check wiring prior to applying power to the GDC-150

transmitter. Remember, these are low voltage devices. Af ter power up, the outer

LED will flash gr een indicating the sys tem is in a warm -up period. During the warm up period, the si gnal o ut put f r om the GDC-150 is fixed at 4.0 m A . If the di gi tal dis pl ay

option has been fitted, t he LED displ ay will indic ate a scroll ing decimal “…..” unti l the

warm-up is completed. If the relay option has been s elected, the relay is not activat ed

during warm-up. The GDC-150 has been programmed with a 5-minute warm-up

period. After the warm-up is compl eted, the signal output and digital display (i f this

option has been supplied) will indicate current gas readings (if any).

If the relay option has been sup plied, i t will have a factor y preset al arm set poi nt (this

can easily be changed in the field). In a non-alarm state, the outer LED will be

illuminated green and the amber relay coil inner LED will be illuminated. The

illuminated relay coil LED indicat es to the user that the relay coil i s energized. The

relay option on the GDC-150 has been designed to operate in a fail-safe manner,

meaning that the rel ay c oil is energized in non-gas-alarm stat e and de-ener gize whe n

a gas alarm is indi cated. The devi ce t o be contr olled s hould be connec ted to t he N/C

(normally closed) and COM (common) terminals. In the event of a sensor failure,

anything control led by the relay is activated continuously until the fail condit ion has

been corrected.

5209-9000 Rev 0 13

GDC-150 Operation Manual

Page 20

GDC-150 Operation Manual

4.2. Detecting Gas

Upon detecti on of the presence of target gas, t he signal output increases t o a value

equal to the amo unt of gas being d etected by the s ensor. If the LED display option

has been supplied, t his value wil l be displayed. If the c oncentration of gas is above

the preset alarm threshold, the outer LED changes to red, the alarm relay deenergizes and the am ber relay coil LED goes out.

As the detected gas l evel subsides, t he output signal will dec rease again to a value

equal to anythin g being det ected by the sensor an d this wi ll be indic ated on th e LED

display (if this option has been selected). T he relay will aut omaticall y reset after the

signal drops below the set point value.

4.3. System Failure

In the event of a system failure, the outer LED will flash red, the r elay will de-energize,

the relay coil LED will go out an d the output signal wi ll drop bel ow 4.0 mA . A failure

can consist of a burned out sensor element (solid-state or catalytic), a failed or

damaged component on the circuit board, or a wiring-relat ed problem.

4.4. Sensor Notes

Sensor Type

Solid-State

(Refrigerant)

Solid-State

(Combustible)

Catalytic

(Combustible)

Electrochemical

(E.g., Oxygen)

10

Sensors require lengthy warm up and stabilization time after installation. Do not

perform any calibration functions until the sensors have been operating for at least 24

hours.

10

Operation Notes

• Not gas specific

• Respond to a fairly wide range of interfering gases and

vapors

• Temperature and humidity compensated to reduce drif t in

environments wher e these values c hange regularly

• Not gas specific, but are less likely to suffer from false

alarms from interfering gases (due to the extremely high

measuring range for which they have been calibrated)

• Specific to combustible gases and vapors

• Temperature compensated

• These sensors are qui te gas specific

• Will respond to some other gases (s ee cross sensitive

gases table on page 7 for more informati on)

• Temperature compensation to reduce drift in environments

where the temperat ure changes regularly

14 5209-9000 Rev 0

Page 21

GDC-150 Operation Manual

4.5. Open Loop Diagnostic

The GDC-150 circuit board h as been fitted with a r ed LED located near t he bottom

center of the c i rc ui t boar d. Thi s is an “ open l oop” in dic at or and h as been des ign ed as

a quick trouble shooting device. If the 4-20 m A signal loop has not been c onnected

properly or has be en damaged in s ome manner between t he analog trans mitter and

the device to which i t is sending its signal output , this LED il luminates. At this point,

the wiring should be i nspected for potential problems.

4.6. Jumper Functions

Figure 4-1. Jumper Functions

4.7. Adjusting the Alarm Set Point (For Relay Option Only)

If the optional r elay has been s upplied, the alar m set point on the GDC-150 can be

adjusted. The alarm set point value is converted to a voltage in the range of 0-4 VDC.

This voltage range correlates to the full measurement range of the installed sensor.

4.7.1. Calculating the Alarm Set Point Value

Prior to adjusting t he alarm set point, calc ulate the voltage value required using the

following formul a.

Example: Catalytic combustible sensors have a standard measurement range of

0-100% LEL. Therefore 4.0 VDC = 100% LEL. Using the values below, 10% of

4.0 VDC = 0.4 VDC. Therefore, the required volt age setting to ac hieve an alarm s et

point of 10% LEL is 0.4 VDC.

5209-9000 Rev 0 15

Page 22

GDC-150 Operation Manual

Figure 4-2. Calculating the Alarm Set Point

4.7.2. Adjusting the Alarm Set Point

Step Description

Move the jumper t o position P5. The green outer LED will flash onc e

1.

within 2 seconds for confir mation. The system is now wait i ng fo r the us er

to set the desired value.

Attach volt met er leads to test points TP1 and TP2 (see Figure 1-4 on

2.

page 3). Alt ernativel y, if the op tional LED digital di splay has been fi tted,

read the value indic ated on the display.

Use the UP or DOWN push buttons until the calculated voltage is

3.

displayed on the volt m eter (or on the optional LED digital display).

Move the jumper bac k to its resting posit ion (P1). At this time the new

4.

value is saved and the green LED flashes once for confirmation.

5. CALIBRATION

5.1. Frequency Recommendatio ns

Sensor Types / Applications Calibration Frequency

Parking garage detectors Once every 12 months

OHS (Occupational Health and Safety) appl ications Once every 6 months

For the purposes of safety in O HS applicati ons, sensor s should be gas t ested (bump

tested) once every m onth to confirm response.

Required Equipment :

• Vol t meter

• Calibration kit

• Calibration gases.

Users can order the calibration kit, calibration accessories and/or gases from any

Bacharach authorized distribut or or they can suppl y their own gas and eq uipment as

long as the gas meets the minimum specifications indicated in this manual.

16 5209-9000 Rev 0

Page 23

GDC-150 Operation Manual

NOTE: It is recommended that a c alibration label should be applied after

every calibration to confirm work performed and the date it was

confirmed. If a controller is involved, the alarm set points should be

indicated on a label on the front door of the enclosure so anyone

working in the envir onment will be aware.

NOTE: For best performance and to ensure the sensor meets the

indicated specifications, all electrochemical sensors should be calibrated

every six months. The sensors may not perform to the listed

specificati ons if they are not maintai ned regularly.

5.2. Calibration Specifications – Gases

Calibration span gases should be at least ±5% accuracy and have a current date

stamp. Gas generator s s hould hav e a cur rent dat ed cel l ins talled. Ser vic e pers onnel

should flow zero emissions air or oxygen bef ore attempting to null adjust toxic gas

sensors.

NOTE: For most electrolytic sensors, nitrogen (N

for zero air. However, f or solid-state and catal yti c sens ors, nitr ogen ( N

should not be substituted for zero air because all solid-state and

catalytic s ensors requir e at least a small volume of Oxygen to operat e.

Calibration wil l be inaccurate.

5.3. Regulators and Flow – Solid-State and Catalytic Sensors

Calibration gases that ar e li ghte r than or t he s ame wei ght as air ( CH4, H2, etc.) should

be flowed at 0.5 LPM . Gases h eavier tha n air (C

, etc.) should be f lowed between

3H8

0.5 and 1.0 LPM. Fixed flow r egulators provide more accur acy. Gases should be

flowed over the sensor for at least 3 minutes.

The proper calibr ation adapter should be util ized to allow the gas to proper ly diffuse

around the sensor . They are available from Bacharach (see table on page 21).

A humidification chamber must be utilized for all solid-state sensors. This is also

available from Bacharach (see table on page 21).

5.4. Regulators and Flow – Electrochemical Sensors

Calibration gases should be flowed at 0. 5 LPM. Fixed flow regul ators provide more

accuracy. Zero air and span gases should be flowed over the sensor for at least

3 minutes.

The proper calibr ation adapter should be util ized to allow the gas to proper ly diffuse

around the sensor . They are available from Bacharach (see tabl e on page 21).

For best perform ance an d to ensur e the s ensor m eets t he indicated specific ations , all

electrochemical sensors s hould be calibrated every six months. The sensors may n ot

perform to the li sted specificati ons if they are not maintained regularly.

5209-9000 Rev 0 17

) can be substituted

2

)

2

Page 24

GDC-150 Operation Manual

line between the cylinder of span gas and the calibration adapter.

he chamber and wet it under the tap.

5.5. Calculating the Span Gas Value

To achieve calibr at ion t he user m ust f irst tel l the GD C-150 w hat c onc entr ati on of span

he is going to fl ow over the sensor . Within the transmitter, this is a voltage s etting.

The range of 0-4 VDC is equal to the full meas urement range of the sensor . Pri or t o

attempting to calibrate, determine the voltage value required.

Use the following formula to calculat e the voltage required.

Therefore, in this example, the required voltage setting to calibrate a 0-2000 ppm

sensor with 1000 ppm is 2.0 VDC.

NOTE: When calibrating solid-state sensors for combustibles or

refrigerants, the span gas must be humidified. The use of a

humidificati on chamber is required. The h umidification cham ber sits in

Remove the sponge inside t

Squeeze out the e xcess w ater s o it i s not dr ipping w et and pl ace i t back

inside the chamber. As gas flows through the chamber, it absorbs wat er

which acts to humidify it and the humidified span gas flows over the

sensor. See page

NOTE: Values for

21 for ordering information.

Calibration Span Gas and Sensor Range in the

above equations mus t have the same Engineer ing Units (e.g. , PPM, %

of LEL, % vol, etc.).

18 5209-9000 Rev 0

Page 25

GDC-150 Operation Manual

5.6. Setting the Span Gas Value

Step Setting the Span Gas Value Procedure

Move the jump er to positi on P2 (see Figure 4-1 on page 15). The green

1

outer LED flashes once for conf irmation. The syst em is now waiting f or

the user to set the desired value.

Attach volt met er leads to test points TP1 and TP2 (see Figure 1-4 on

2

page 3). Alt ernativel y, if the op tional LED digital di splay has been fi tted,

read the value indic ated on the display.

Use t he UP or DOWN push-buttons (see Figure 1-4 on page 3) until the

3

calculated voltage is displayed on the volt meter (or the optional LED

digital display).

Move the jumper bac k to its resting posit ion (P1). At this time the new

4

value is saved and the green LED flashes once for confirmation.

5.7. Calibrating the Null (Zero) Value

Step Calibrating the Null ( Zero) Value Procedure

1 Attach a regulator to a cylinder of zer o air (or nitrogen).

Insert the cal ibration adapter in to the sensor opening i n the front of the

enclosure door. Use a slight twisting motion as you gently push the

calibration ada pter into the sensor opening. If the calibr ation adapter is

hard to insert, moisten the "O" ring s lightly then try r e-inserting it. If the

2

transmitter has been fitted with an optional splash guard, remove the

plastic plug from the center of the splash guard to gain access to the

sensor opening. To r emo ve th e plas t ic pl ug, pus h inw ard at th e center of

the plug until the edg es l ift slightl y then s lip a smal l fl at blade scr ewdri ver

under and pop the plug off.

3 Open the regulator valve fully and allow zero air to flow over sensor.

Move the jumper t o position P3 (see Figure 4-1 on page 15). The outer

4

LED will change to a steady amber color. The system now waits 30

seconds to ensur e the user is flowing zero air.

The GDC-150 then enters a c ount down duri ng which tim e it adjusts t he

null value. The length of this count down period is:

• 90 seconds for catalytic and solid-stat e sensors

5

6 Move the jumper back t o its resting posit ion (P1) and remove the zero air.

5209-9000 Rev 0 19

• 60 seconds for electrochemical sensors.

If desired, attach the volt meter leads to test points TP1 and TP2 (see

Figure 1-4 on page 3). The meter will show 0.0 VDC, climb t o a higher

value, th en slowly descend back t o 0.0 VDC indicati ng the GDC-150 has

null adjusted the c ircuit. Onc e the count down is fi nished, the outer LED

changes back to gr een indicating the proc edure is complete.

Page 26

GDC-150 Operation Manual

IMPORTANT: If the user attempts to null adjust the sensor without

applying zero air and the sensor detects background gas the amber

LED flashes to advise the user that it is out of tolerance.

5.8. Calibrating the Span Value

Step Calibrating the Span Value Procedure

1 Attach regulator to cylinder of span gas.

Insert the cal ibration adapter in to the sensor opening i n the front of the

enclosure door. Use a slight twisting motion as you gently push the

2

calibration ada pter into the sensor opening. If the calibrati on adapter is

hard to insert, m oisten the “o” ring seal slightly then try re-inserting it.

3 Open regulator valv e fully and allow span gas to flow over sensor.

Move the jumper to J4 positi on (see Figure 4-1 on p age 15). The tri-color

4

outer LED will change to a stead y am ber color. The system now waits 30

seconds to ensur e the user is flowing span gas.

The GDC-150 then ent ers a count down (180 s econds for catalytic and

solid-state sensors, 150 seconds for Electrochemical sensors) during

which time it adjusts the circuit to the span value whi ch was set earlier

(see “Setting t he Span Gas Value”).

If the user wishes to view this, att ach meter leads to test poi nts TP1 and

5

TP2 (see Figure 1-4 on page 3). The meter will show an increasing

voltage indicat ing t he GDC-150 sensor is r espondin g t o the s pan gas and

the circuit is being adjusted for accuracy. Alternatively, If the optional

LED digital dis play has been f itted, r ead the valu e indicated on the out er

digital display. Onc e the count down is finished, t he outer LED chang es

back to green indicating the procedure is complete.

Before removing the span gas, move the jumper back to its resting

6

position (J1) and the new value is saved.

IMPORTANT: If the user attempts to span adjust the sensor without

applying span gas or the proper value of span gas, the sensor will

produce a respo nse that i s outside of the cir cuit pres et toleranc e value.

The amber LED flashes to advise the user that it is out of toler ance.

20 5209-9000 Rev 0

Page 27

6.1. Metal Protective Guards

6. ACCESSORIES AND REPLACEMENT PARTS

GDC-150 series analog transmitters are all

supplied in very rugged, non-metallic

enclosures. However, in some applications

more protection may be desired. Bacharach

can provide protective guards made from 16

gauge galvanized metal with a pattern of

square perforations to permit air and gas to

diffuse easil y to the sensor.

6.2. Accessory and Replacement Part Numbers

Part

Number

5209-0002 LED digital display (must be select ed w hen ordering)

5209-0003 Relay (rated 2A @ 30 VAC)

5209-0005 Water- and dust-tight NEMA 4X enclosure

5209-0004 Splash guard (NEMA 4X enclosure only)

5209-0006 Calibration adapter for all other sensors

5209-0016 Calibration adapter for catalytic sensors

5209-0017 Sample draw pump (24 VAC-powered)

5209-0018 Sample draw pump (24 VDC-powered)

5209-0019 Transmitter guard (16 gauge galvanized metal)

5209-0021 Humidification chamber (for calibration of solid-state sens ors)

5209-9000 Rev 0 21

GDC-150 Operation Manual

Figure 6-1. Protective Gu ard

Description

∇ ∇ ∇

Page 28

GDC-150 Operation Manual

World Headquarters

621 Hunt Valley Circle, New Kensington, Pennsylvania 15068

Phone: 724-334-5000 • Toll Free: 1-800-736-4666 • Fax: 724-334-5001

Website: www.MyBacharach.com • E-mail: help@MyBacharach.com

22 5209-9000 Rev 0

Loading...

Loading...