Page 1

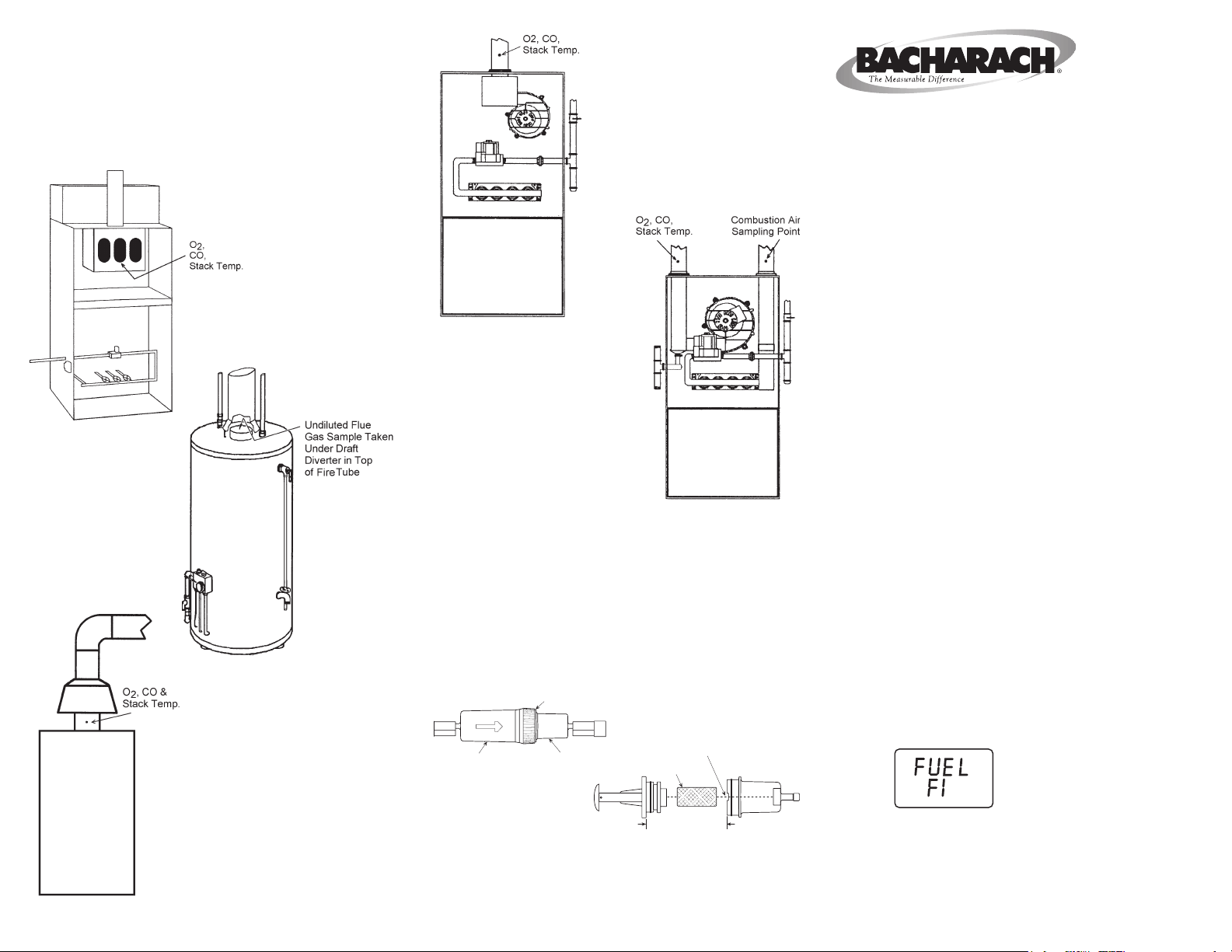

Sampling Locations

WATER TRAP

CHAMBER

Pull apart using a slight

twisting motion

FILTER

CHAMBER

FILTER ELEMENT

Pry apart filter chamber using

a small flat-blade screwdriver

inserted into notch

“A” “B”

When reassembling

the trap, make sure

that surfaces “A” and

“B” are in contact

Insert the probe in the areas shown in the

following illustrations to measure stack

temperature, ue‑gas O2 content, and ue‑gas CO

content (Model 60 only).

Atmospheric Burner or

Gravity Vented Forced Air

Hot Water

Tank

80% Eff. Fan Assist

or Power Vented

Furnace/Boiler

90% Eff.

Condensing

Furnace/Boiler

Fyrite® Tech 50 & 60

Quick Start Guide 24-9429

Rev. 1 – Septe mber 2 003

This Guide provides basic information about how

to turn ON the analyzer and conduct a combustion

efciency test. Detailed information concerning

the analyzer’s operation, set up, and calibration is

contained in Instruction 24‑9428.

Turning ON the Analyzer

1. Place the probe tip in the area that contains

the burner’s combustion‑air source. This

step allows the analyzer to measure the

combustion‑air temperature during the

analyzer’s warm‑up period.

2. Press analyzer’s I/O button.

Atmospheric or

Gravity Vented

Boiler

Water Trap / Filter Maintenance

Drain the water condensate collected in the water

trap after every test.

Replace the lter element (P/N 07‑1644) when dirty.

- 5 - - 6 -

3. Wait for the analyzer to complete its

60 second warm‑up period.

Performing a Combustion Test

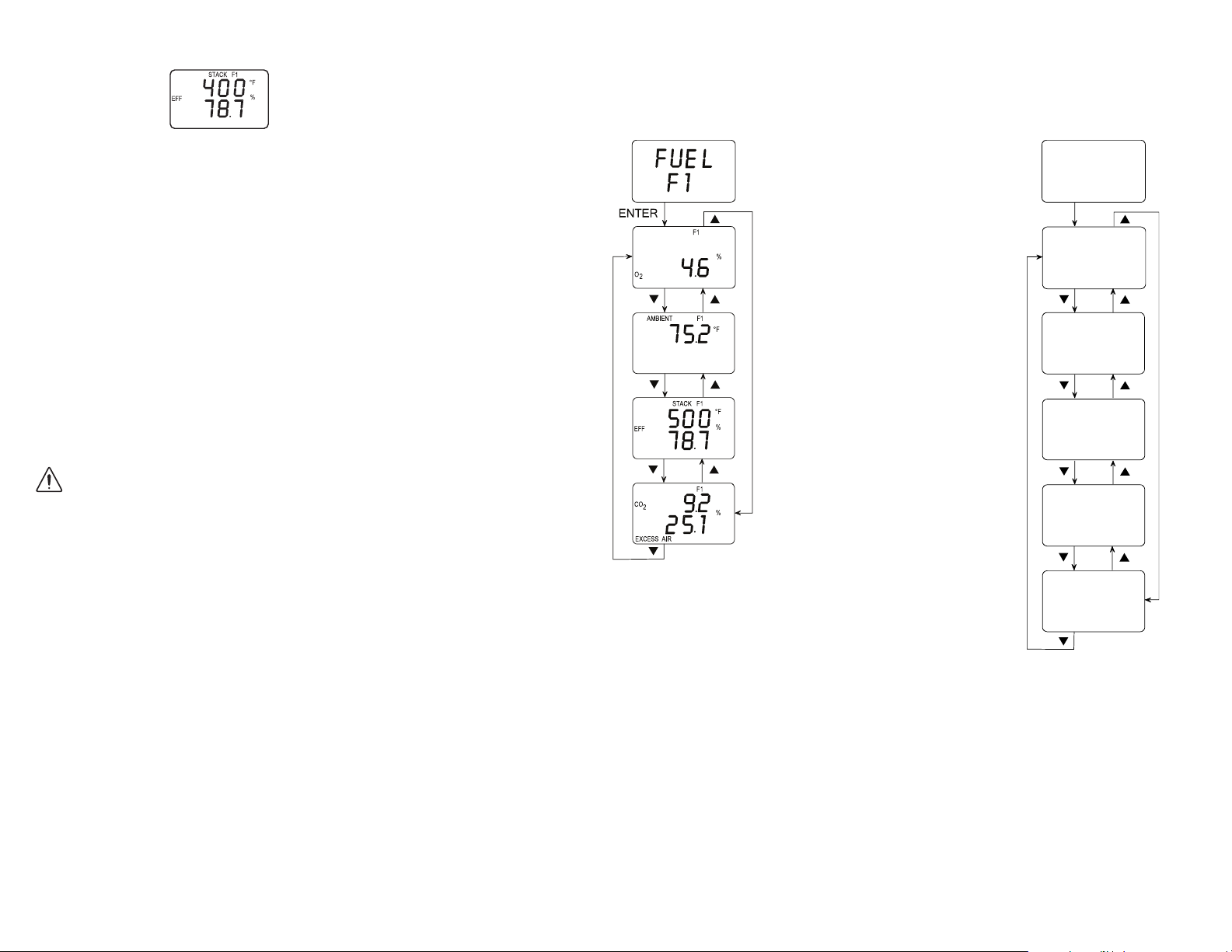

4. Press the or button to select the desired

fuel and then press ENTER. The fuel codes are:

F1 = Natural Gas F3 = LPG

F2 = Oil #2 F4 = Kerosene

Example: “F1” denotes

Natural Gas

Bacharach, Inc.

621 Hunt Valley Circle, New Kensington, PA 15068

Ph: 724-334-5000 • Fax: 724-334-5001 • Toll Free: 800-736-4666

Website: www.bacharach-inc.com • E-mail: help@bacharach-inc.com

Printed in U.S.A. ® Registered Trademark

Page 2

5. Press the or button to display the “Stack

F1

E

L

U

F

251

92

CO

2

%

.

.

EXCESS AIR

F1

787

0

0

STACK F1

EFF

°F

%

5

.

5

2

AMBIENT F1

°F

7

.

46

9

F1

CO

O

2

ppm

%

.

12

CO

ppm

AIR

FREE

F1

ENTER

Temperature & Efciency” Screen.

Screen Displays – Fyrite Tech 50

Screen Displays – Fyrite Tech 60

6. Insert probe into the burner’s ue‑gas stream

(see Sampling Locations on Pages 5 and 6).

7. Burner‑service procedures can now begin.

The readings diplayed on the analyzer will

update continuously, showing the changes in

burner performance.

8. Use the and buttons to scroll through the

analyzer’s other screen displays while a test is

in progress. (The order in which the screens

are displayed is shown on Pages 3 and 4.)

9. Press the HOLD button to stop the pump and

freeze all readings. Press ENTER to resume

testing.

Ending a Combustion Test

WARNING! Burn hazard. Do not touch

the probe after removing it from the ue-gas

stream. Allow the probe to cool before handling (about 5 minues).

10. End a test by rst removing the probe from

the ue‑gas stream, and then allowing the

pump to run until the O2 reading reaches

approximately 20.9%.

Turning OFF the Analyzer

Use the and buttons to scroll through the

screens.

Fuel Select:

F1 = Natural Gas

F2 = Oil #2

F3 = LPG

F4 = Kerosene

O

2

Ambient Air

Temperature

Stack

Temperature &

Efciency

CO2 &

Excess Air

Use the and buttons to scroll through the

screens.

Fuel Select:

F1 = Natural Gas

F2 = Oil #2

F3 = LPG

F4 = Kerosene

CO &

O

2

CO Air Free

Ambient Air

Temperature

Stack

Temperature &

Efciency

CO2 &

Excess Air

11. Turn OFF the analyzer by pressing the I/O

button. There is a 5‑second delay before the

analyzer actually turns OFF, during which

time the unit can be turned back ON by

pressing the ENTER button.

A Fyrite Tech 60 will not turn OFF if a high

level of CO is still being detected. The pump

will remain running and the message “PurG

CO” is displayed until the detected CO level

drops below 50 ppm. This purge process can be

bypassed by again pressing the I/O button.

- 2 -

- 3 - - 4 -

Loading...

Loading...