Page 1

INSTRUCTION 0011-9026

®

20

16

12

8

4

%CO

2

0

®

FYRITE

CO

2

Operation/Maintenance

Rev. 12 – December 2012

Gas Analyzer

and O2 Indicators

Printed in U.S.A.

Instruction 0011-9026 Page 1

® Registered Trademarks

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will

be free from defects in mater ial and manufac ture and will conform substan tially

to Bacharach Inc.’s ap plicable specifi cations. Bacharach’s liability and Buyer’s

remedy under this warranty are limited to the repair or replacement, at Bacharach’s option, of this Product or parts thereof returned to Seller at the factory

of manufac ture and shown to Bacharach Inc.’s reasonable satisfaction to have

been defective; provided that written notice of the defect shall have been given

by Buyer to Bacharach Inc. within one (1) year after the date of delivery of this

Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product.

Bacharach’s liability and Buyer’s remedy under this warranty of title are limited

to the removal of any title defects or, at the election of Bachara ch, to the replacement of this Product or parts thereof that are defective in title.

The warranty set forth in paragraph 1 does not apply to parts the Operating

Instructions designate as having a limited shelf-life or as being expended in

normal use.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND

ACCEPTED IN LIEU OF (I) ANY AND ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING WITHOUT LIMITATION THE IMPLIED WARANTIES OF MERCHAN TABILITY AND FITNESS FOR A PARTICULAR PURPOSE:

AND (II) ANY OBLIGA TION, LIABILITY, RIGHT, CLAIM OR REMEDY IN

CONTACT OR TORT, WHETHER OR NOT ARISING FROM BACH A RACH’S

NEGLIGENCE, ACTUAL OR IMPLIED. The remedies of the Buyer shall be

limited to those provided herein to the exclusion of any and all other remedies

includ ing, without limita tion incidental or consequen tial damages. No agree ment

varying or extending the foregoing warranties, remedies or this limitation will

be binding upon Bacharach, Inc. unless in writing, signed by a duly authorized

offi cer of Bacharach.

NOTE: Gaskets are considered consum able items and are excluded

from the terms of this warranty.

Register Your W arranty by V isiting

www.mybacharach.com

CAUTION

Corrosive fl uid is contained inside this unit.

These instructions should be thoroughly

read before operation is attempted.

Copyright © 1998-2012 Bacharach, Inc., all rights reserved.

Page 3

FYRITE SAFETY PRECAUTIONS

®

20

16

12

8

%CO

2

20

®

16

12

4

%CO

2

20

16

12

8

4

%CO

2

0

®

20

®

16

12

8

4

%CO

2

0

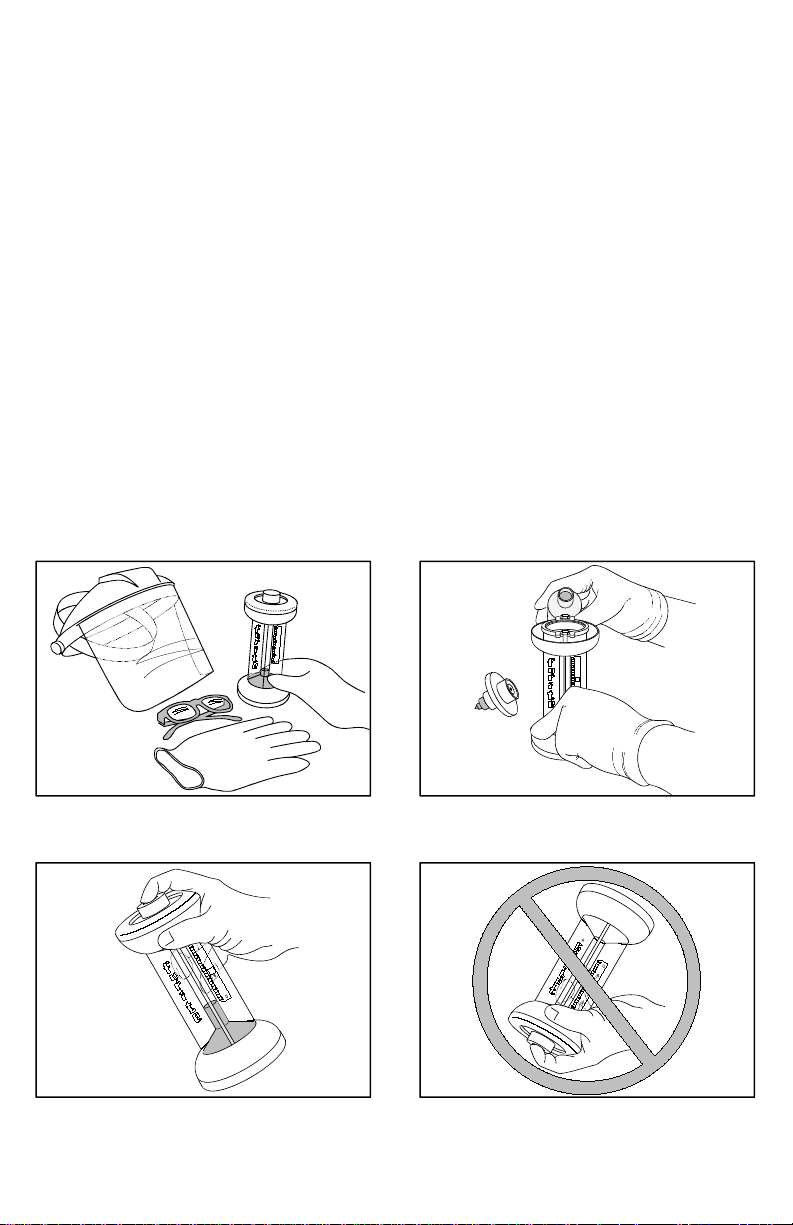

The operator (s) of this instrument should thoroughly familiarize themselves with the

applicable safety precautions before handling or using the FYRITE for gas analysis.

Review Figures 1a,1b, 1c and 1d on this page. Make certain to follow the steps outlined below and read the fl uid handling precautions for your personal safety.

1) Always use protective equipment such as safety goggles, gloves, and protective

clothing as illustrated in Figure 1a.

2) Read the instruction manual thoroughly. When fi lling the FYRITE with the appli-

cable fl uid charge, use safety equipment and perform the operation in the vicinity

of running tap water (Figure 1b).

3) The FYRITE fl uid should always be in the bottom reservoir before and during

sample introduction to the FYRITE. When venting the FYRITE to atmosphere,

hold the instrument in the vertical position and at a location away from your face

(Figure 1c).

4) NEVER vent FYRITE in the inverted position (with the plunger facing downward). This will cause fl uid to spill, which is corrosive and contains harmful ele-

ments (Figure 1d).

NOTE: In the event of fl uid spill - refer to Section 2.2 (FYRITE Handling

Precautions). For Maintenance - refer to Section 6.0.

Figure 1a. Protective equipment

required before attempting gas

analysis.

Figure 1c. Venting FYRITE to atomsphere at 45° angle.

Figure 1b. Preparing to fi ll FY-

RITE using recommended protective safety equipment.

Figure 1d. NEVER vent FYRITE in

the inverted position, which will

cause fl uid to spill.

Page 4

TABLE OF CONTENTS

1.0 DESCRIPTION................................................................................................................................................1

2.0 FYRITE INSPECTION BEFORE AND DURING TEST ..............................................................................1

2.1 Pre-Operational Check .......................................................................................................................1

2.2 FYRITE FLUID HANDLING PRECAUTIONS ...............................................................................2

3.0 BASIC FYRITE OPERATION PERCENT CO

3.1 Determining CO2 and O2 FYRITE Fluid Strength .............................................................................7

AND 02 ...............................................................................3

2

3.2 Operating Precautions to Ensure Maximum Accuracy ......................................................................7

3.2.1 Draining Fluid Droplets .....................................................................................................8

3.3 FYRITE Temperature .........................................................................................................................8

3.3.1 Temperature of Gas Sample ...............................................................................................8

4.0 PRINCIPLE OF OPERATION ........................................................................................................................9

5.0 APPLICATION INFORMATION .................................................................................................................10

5.1 FYRITE Absorbing Fluid .................................................................................................................10

5.1.1 FYRITE Refi ll Fluid (Storage Life, etc.) .........................................................................10

5.2 FYRITE Operating Temperature Range ...........................................................................................11

5.3 Typical FYRITE Applications ..........................................................................................................11

5.4 CO2 FYRITE Only Combustion Testing ..........................................................................................12

5.4.1 Percent CO2 Shows Volume of Excess Air ......................................................................12

5.4.2 Too Much Excess Air Means Ineffi cient Combustion .....................................................13

5.4.3 What is Proper CO2 Value? ..............................................................................................13

5.4.4 How To Calculate Combustion Effi ciency .......................................................................13

5.5 O2 FYRITE Only Combustion Testing .............................................................................................13

5.5.1 Percent O2 Shows Volume of Excess Combustion Air ....................................................13

5.5.2 Too Much Excess Air Means Ineffi cient Combustion .....................................................13

5.5.3 What is Proper O2 Value? .................................................................................................14

5.5.4 Measuring O2 in Addition to CO2 ...................................................................................14

5.5.5 Where is Percent CO2 or O2 Measured? ..........................................................................14

5.6 Background Gases Affecting FYRITE Readings .............................................................................16

5.7 General FYRITE Applications .........................................................................................................17

5.8 Altitude Correction Table .................................................................................................................18

6.0 FYRITE MAINTENANCE ..........................................................................................................................18

6.1 Increasing FYRITE Fluid To Proper Level ......................................................................................18

6.1.1 Decreasing FYRITE Fluid to Proper Level .....................................................................19

6.2 Checking FYRITE Fluid Strength ....................................................................................................19

6.2.1 CO2 FYRITE Fluid Only .................................................................................................19

6.2.2 O2 FYRITE Fluid Only ....................................................................................................21

6.3 Replacing FYRITE Fluid ................................................................................................................21

6.4 Inspection of FYRITE for Fluid Leakage ........................................................................................22

6.5 Cleaning FYRITE .............................................................................................................................24

6.6 Replacing FYRITE Plastic and Rubber Parts ...................................................................................24

6.7 Aspirator Bulb - Sampling Assembly ...............................................................................................26

6.8 Storing FYRITE and Refi ll Fluid .....................................................................................................26

6.9 Replacing Saturator Filter Packing Part #11-0121 ..........................................................................26

7.0 ILLUSTRATED PARTS LIST FYRITE CO2/O2 ..........................................................................................29

7.1 FYRITE Illustrated Parts ..................................................................................................................30

7.2 FYRITE Sampling Assemblies ........................................................................................................31

Page 5

INSTRUCTIONS 0011-9026

OPERATION/MAINTENANCE

BACHARACH FYRITE MODELS

CO2 and O2 INDICATORS

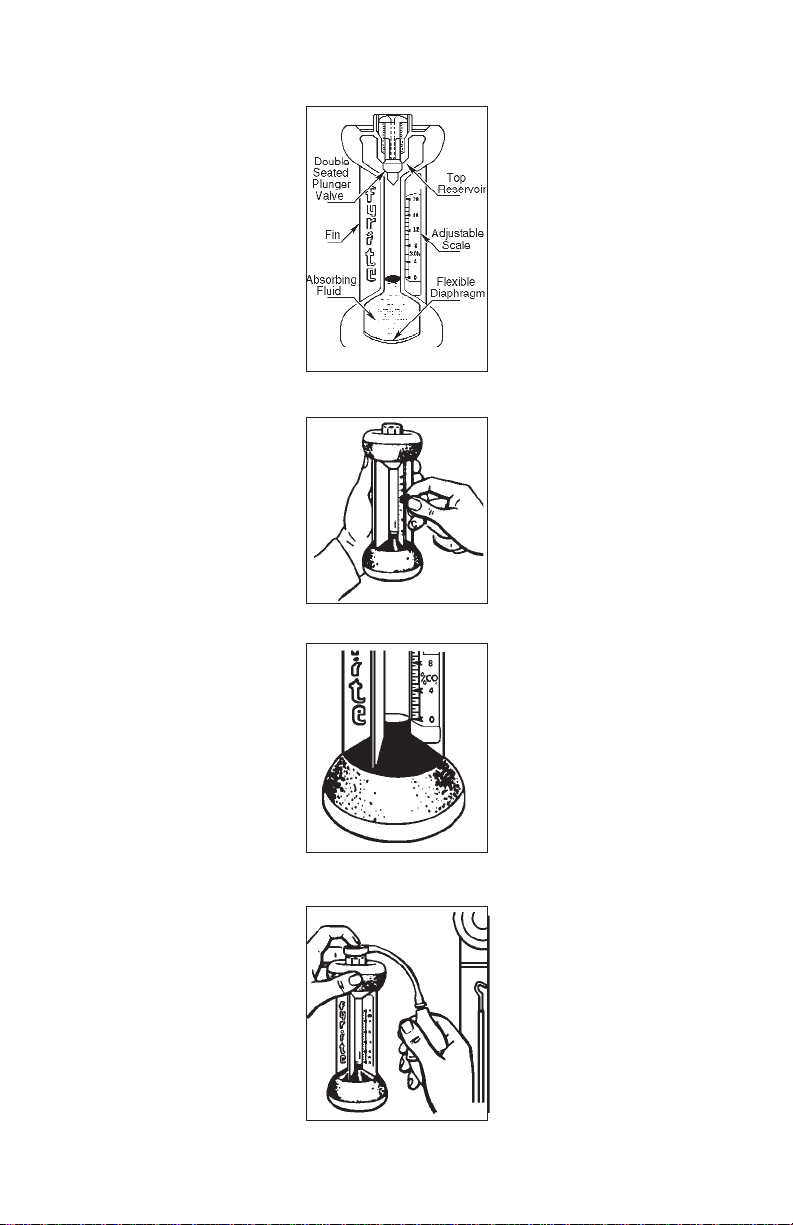

1.0 DESCRIPTION (Refer to Figure 1)

The FYRITE employs the well-known “Orsat” method of volumetric analysis involving

chemical absorption of a sample gas, such as carbon dioxide or oxygen. The reagent

used to absorb carbon dioxide (CO

chloride (blue) is the absorbent for oxygen (O

that the absorbing fl uid is also used as the indicating fl uid so that one vessel takes the

place of both measuring burette and absorption pipette.

The body of the FYRITE is molded of clear high-strength plastic, comprises top and

bottom reservoirs and a center tube connecting the two reservoirs. The bottom of the

lower reservoir is sealed off by a synthetic rubber diaphragm that rests on a perforated metal plate. The upper reservoir is covered by a molded plastic cap that contains

a double -seated plunger valve. A spring holds this valve against a carefully fi nished

seat in the top cap providing a perfect seal which makes the instrument spill-proof in

any position. When the valve is partially depressed, the entire instrument is open to

the atmosphere and the instrument is, of course, is no longer spill-proof.

The bottom reservoir is fi lled with the absorbing fl uid, which extends about 1/4 inch

into the bore of the center tube when the instrument is held upright. The scale position, mounted to one side of the center tube, is adjustable.

) is potassium hydroxide (dyed red), and chromous

2

). The unique feature of the FYRITE is

2

2.0 FYRITE INSPECTION BEFORE AND DURING TEST

CAUTION

Corrosive fl uid is contained inside unit, instructions should be

thoroughly read before operation is attempted.

2.1 Pre-Operational Check

To ensure proper FYRITE operation and reliable results, check the following:

(a) With FYRITE vented and in a vertical position, it should be possible to adjust

scale zero to the top of the fl uid column. Refer to FYRITE Operation for proper

setup (Section 3.0 Steps 1 through 5). If this is not possible, add or remove a small

amount of fl uid per Section 6.1.

Instruction 0011-9026 Page 1

Page 6

(b) FYRITE Fluid Strength

To check fl uid strength.

NOTE: When repeating procedures as outlined in Section 3.0

Steps 7 through 9 (absorbing and reading percent O

sorbing and reading percent CO2) and before venting FYRITE

and ab-

2

to atmosphere for next sample, if the reading increases by more

than 1/2 percent for either CO

or O2, replace the fl uid.

2

It is often desirable to check fl uid strength before taking the FYRITE to a location

where it will be used. It can be tested on sample atmospheric air (which contains

20.9% O

mum accuracy. (See Section 6.9)

O

samples containing 10% O

CO

proximately 350 samples containing 10% CO

). Be certain to wet Filter Saturator when checking atmospheric air for maxi-

2

(Oxygen) Fluid - Fresh FYRITE fl uid will absorb all O2 from approxi mately 100

2

(Carbon Dioxide) Fluid - Fresh FYRITE Fluid will absorb all CO2 from ap-

2

.

2

.

2

(c) FYRITE Sampling Assembly - Always check sampling assembly for proper (leak-

free) operation as outlined in Section 6.7 before pro ceeding with test.

(d) Make certain wool in Filter Saturator Tube is moistened with water if using

either O

is not fully saturated with water vapor. Examples where fi lter-saturator must

or CO2 FYRITE in a noncombustible application where the gas sample

2

be wetted include measuring CO2 or O2 in ambient air or from compressed gas

samples. Refer to Section 6.9 when replacing or moistening saturator (wool) fi lter

is required.

FYRITE OPERATION PRECAUTION: To prevent fl uid

spill, never depress Plunger Valve to vent FYRITE when unit

is in the inverted or any other non-upright position. When depressing Plunger Valve in the upright position to vent FYRITE,

hold at a slight angle away from the operator’s face.

2.2 FYRITE FLUID HANDLING PRECAUTIONS

CAUTION

FYRITE fl uids used in the CO

and contain poisonous elements which must not be taken internally. In the event of a spill or accidental body contact with

FYRITE fl uid, read the following carefully.

Instruction 0011-9026Page 2

and O2 analyzers are corrosive

2

Page 7

HAZARDS

Corrosive liquid causes burns. May cause blindness if splashed in eyes. Vapors are

irritating and may be harmful.

PRECAUTIONS

Prevent contact with eyes, skin and clothing. Wear eye protection and gloves. Do not

vent instrument until fl uid has drained from top well. Do not vent instrument (FY-

RITE) in inverted position.

FIRST AID

For contact with eyes: Immediately fl ush eyes with water 20 minutes. Get immediate

medical attention.

For contact with skin: Immediately fl ush skin with water 20 minutes. Get immediate

medical attention.

For inhalation overexposure: If irritation develops, move victim to fresh air.

For swallowing: Do not induce vomiting. Give two glasses of water or milk if conscious

and not convulsing. Get immediate medical attention.

Refer to the material safety data sheet for further information.

3.0 BASIC FYRITE OPERATION PERCENT CO2 AND 0

2

Four basic steps are required when making an analysis, many being common to both

the CO

FYRITE MODEL CO

(Red Fluid) (Blue Fluid)

and O2 FYRITE.

2

FYRITE MODEL O

2

2

(a) Vent and adjust scale zero. (a) Vent and adjust scale zero.

(b) Pump sample into FYRITE. (b) Pump sample into FYRITE.

(c) Absorb CO2 from sample. (c) Absorb O2 from sample.

(d) Read % CO2 on scale. (d) Read % O2 on scale.

NOTE: To prevent warming of FYRITE fl uid during analysis,

hold FYRITE by the fi ns only.

Instruction 0011-9026 Page 3

Page 8

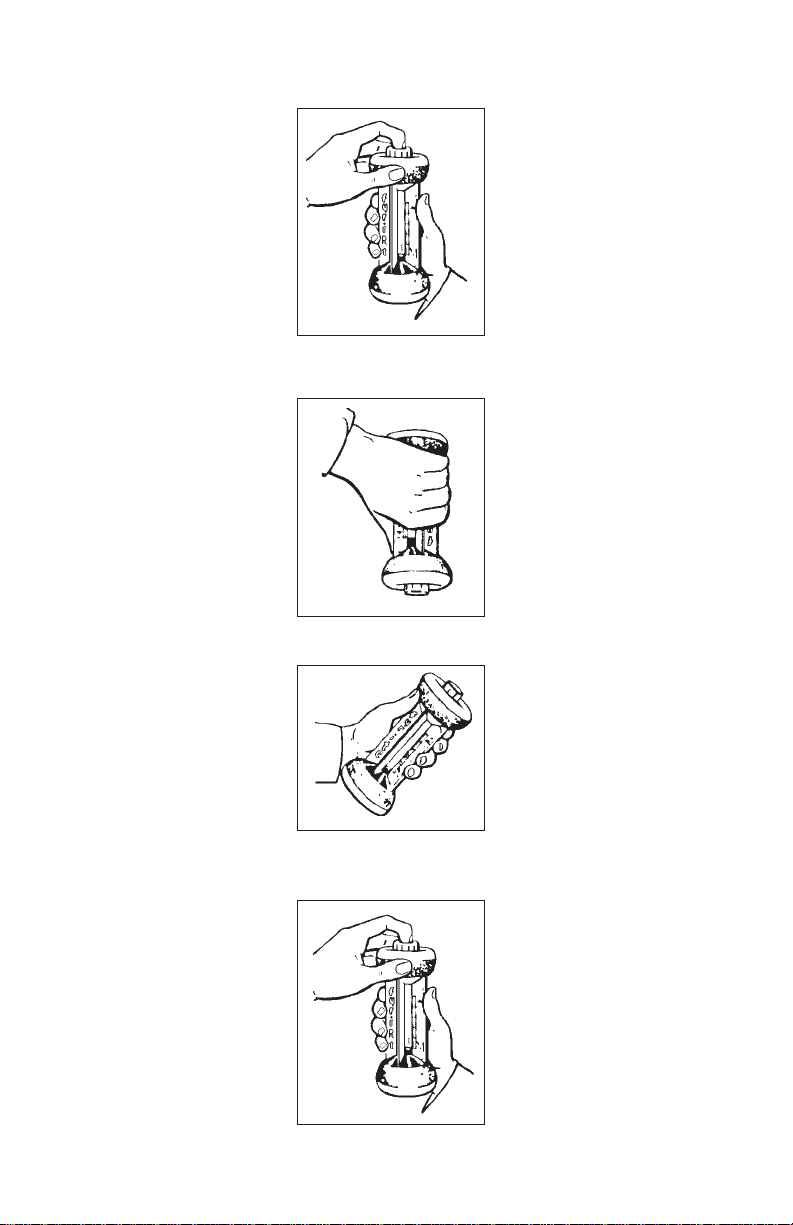

CO2 FYRITE OPERATION O2 FYRITE OPERATION

(RED FLUID) (BLUE FLUID)

1. Hold upright (Fig. 1) and

away from face. Depress

Plunger Valve (momentarily) to vent FYRITE,

and release.

2. Invert FYRITE (Fig. 2).

Hold at slight angle to

drain fl uid into top reser-

voir.

3. Turn upright. Hold FY-

RITE at 45° angle (Fig. 3)

momentarily to allow

fl uid droplet drainage

into bottom reservoir.

Figure 1

Figure 2

1. Hold upright (Fig. 1) and

away from face. Depress

Plunger Valve (momentarily) to vent FYRITE,

and release.

2. Invert FYRITE (Fig. 2) to

absorb O

RITE whenever Plunger

drawn into FY-

2

Valve is depressed). Hold

at slight angle to drain

fl uid into top reservoir.

3. Turn upright. Hold

FYRITE at 45° angle to

drain fl uid into bottom

reservoir. Turn upright.

Repeat sequence of Steps

1, 2, and 3 twice until

fl uid level does not drop

more that 1/2% when

Plunger Valve is depressed. Turn upright.

Hold FYRITE at 45° angle (Fig. 3) momentarily

until excess fl uid droplets

have been drained from

inside surfaces.

4. Hold FYRITE in upright

(Fig. 4) position and

away from face. Depress

Plunger Valve (momentarily) and release.

Instruction 0011-9026Page 4

Figure 3

4. Hold FYRITE in upright

(Fig. 4) position and away

from face. Note fl uid

level in column. Depress

Plunger Valve (momentarily), and release.

Figure 4

Page 9

CO2 FYRITE OPERATION O2 FYRITE OPERATION

(RED FLUID) (BLUE FLUID)

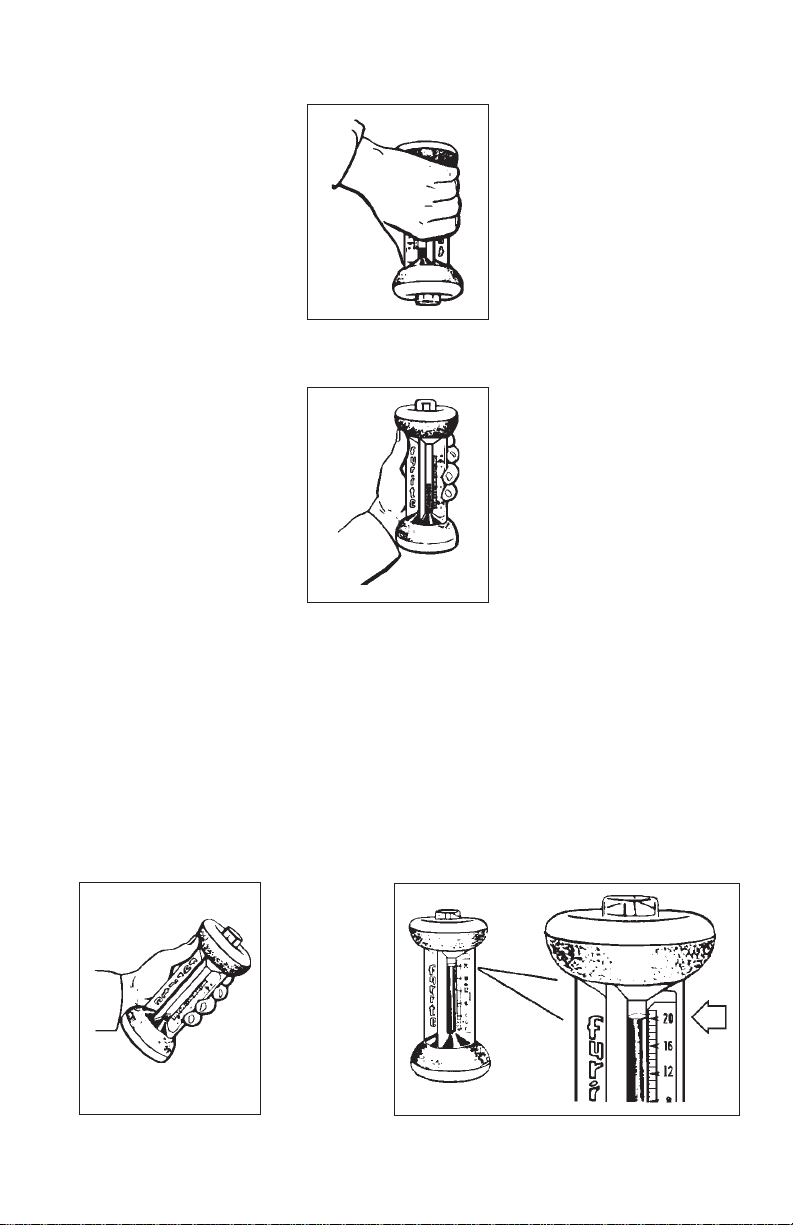

5. Holding FYRITE upright

(Fig. 5), loosen locknut at

rear of scale. Slide scale

(Fig. 5a) until top of fl uid

column lines up with zero

line on scale (Fig. 5b).

Tighten scale locknut.

NOTE: When setting

scale zero, hold FYRITE

vertically as shown and

level with eyes while

sighting across scale to

top of fl uid column.

6. To pump gas sample

into FYRITE (Fig. 6),

insert open end of metal

sampling tube into area

bearing gas for analysis.

Hold FYRITE in upright

position and place sampling assembly rubber

connector tip over the

Plunger Valve.

Depress Plunger Valve

fi rmly with connector tip.

Figure 5

Figure 5a

Figure 5b

5. Holding FYRITE upright

(Fig. 5), loosen locknut at

rear of scale. Slide scale

(Fig. 5a) until top of fl uid

column lines up with zero

line on scale (Fig. 5b).

Tighten scale locknut.

NOTE: When setting

scale zero, hold FYRITE

vertically as shown and

level with eyes while

sighting across scale to

top of fl uid column.

6. To pump gas sample

into FYRITE (Fig. 6),

insert open end of metal

sampling tube into area

bearing gas for analysis.

Hold FYRITE in upright

position and place sampling assembly rubber

connector tip over the

Plunger Valve.

Depress Plunger Valve

fi rmly with connector tip.

Pump sample by squeez-

ing and releasing aspirator bulb 18 times.

During 18th bulb squeeze

(with bulb held defl ated)

release connector tip and

Plunger Valve.

Pump sample by squeez-

ing and releasing aspirator bulb 18 times.

During 18th bulb squeeze

(with bulb held defl ated)

release connector tip and

Plunger Valve.

Figure 6

Instruction 0011-9026 Page 5

Page 10

FYRITE OPERATION O2 FYRITE OPERATION

CO

2

(RED FLUID) (BLUE FLUID)

7. Absorb sample gas into

FYRITE by inverting

until fl uid drains into top

reservoir (Fig. 7). Then

turn upright (Fig. 8) to

drain fl uid into bottom

reservoir. Repeat this

step once.

8. Hold FYRITE at 45°

angle (Fig. 9) momentarily to allow fl uid droplets

to drain into the bottom

reservoir.

9. With FYRITE held

upright (Fig. 10), permit fl uid in column to

stabilize a few seconds,

then immediately read %

carbon dioxide on scale at

the point corresponding to

top of the fl uid column.

7. Absorb sample gas into

FYRITE by inverting

until fl uid drains into top

reservoir (Fig. 7). Then

turn upright (Fig. 8) to

drain fl uid into bottom

reservoir. Repeat this

step three (3) more times

(four complete inversions

total).

Figure 7

8. Hold FYRITE at 45°

angle (Fig. 9) momentarily to allow fl uid droplets

to drain into the bottom

reservoir.

Figure 8

9. With FYRITE held

upright (Fig. 10), permit fl uid in column to

stabilize a few seconds,

then immediately read

% oxygen on scale at the

point corresponding to top

of the fl uid column.

Instruction 0011-9026Page 6

Figure 9

Figure 10

Page 11

10. This step completes CO2 or O2 FYRITE gas sample analysis. A few points to remember when reading the FYRITE:

(a) FYRITE accuracy is within ±1/2% CO2 or O2 compared to actual value.

(b) Always handle FYRITE by fi ns to ensure body heat is not absorbed by fl uid.

(c) A delay in reading of 5 or 10 seconds may decrease accuracy of reading

slightly but longer delays may cause substantial error.

(d) The FYRITE is calibrated to indicate on a “dry” basis for fl ue gas samples,

which are normally fully saturated with moisture. Failure to artifi cially

moisten wool packing in Filter Saturator Tube when actual sample is not

fully saturated will cause FYRITE to read slightly low.

Therefore, make certain wool packing in Filter Saturator Tube is suffi ciently

moistened with water for accurate results on non-fl ue gases. Avoid excessive

moisture which can be drawn into the Aspirator Bulb and forced into the

FYRITE during sampling.

CAUTION

Never depress plunger valve to vent FYRITE in the inverted

position. This will cause fl uid to spill, which is corrosive and

contains poisonous elements. In the event of a spill, read Instructions in Section 2.2 FYRITE fl uid handling precautions.

3.1 Determining CO2 and O2 FYRITE Fluid Strength

FYRITE Fluid strength can be conveniently checked immediately after the fi rst

sample reading. Without venting, repeat the absorbing operations (Steps 7 through

9) by inverting FYRITE again and positioning upright until all fl uid drains to the bot-

tom reservoir. Observe scale reading. An increase of more than 1/2% CO

second reading as compared to the fi rst indicates a need for fl uid replacement.

or O2 in the

2

3.2 Operating Precautions to Ensure Maximum Accuracy

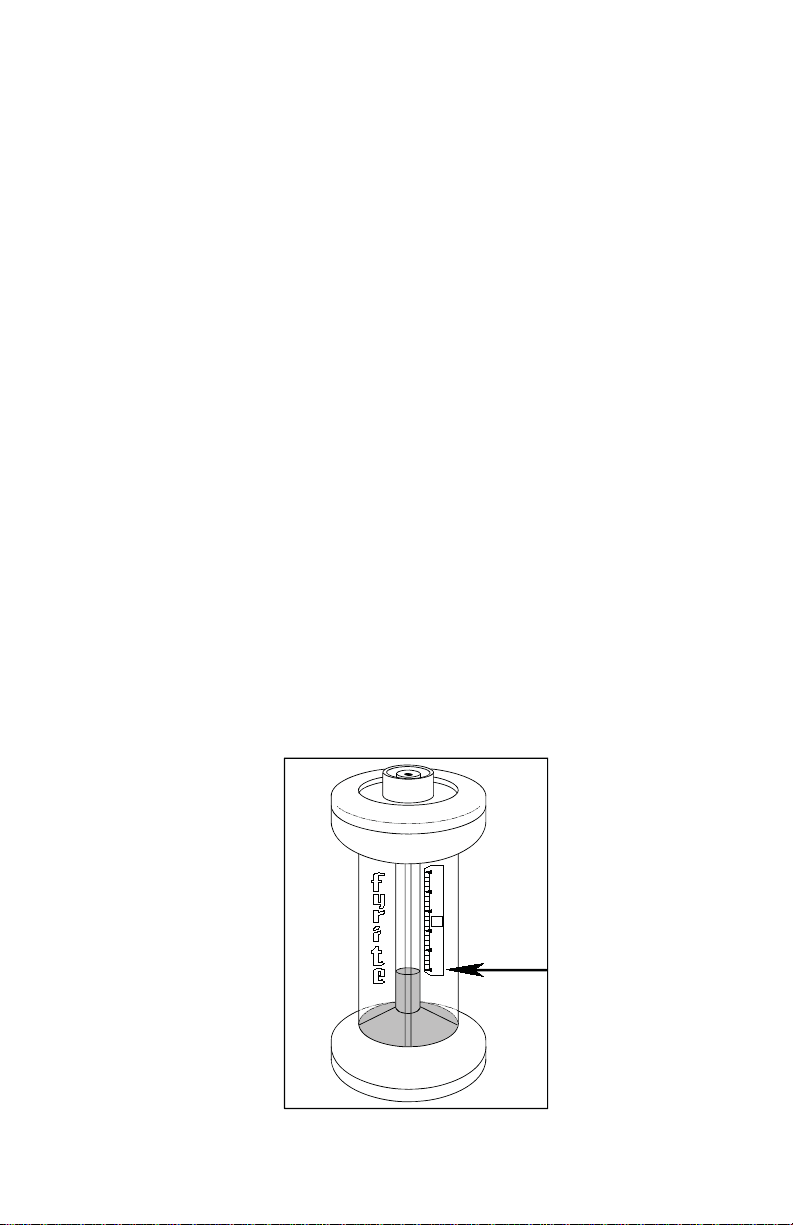

Locate top of fl uid column (refer to Fig. 11). The surface at the top of the fl uid column

(meniscus) in the small, center bore will be dish-shaped as shown in Figure 11. Either

the high or low point of this dish- shaped surface may be used to locate top of fl uid col-

umn providing the same point is always used both for setting scale zero and reading

percent CO

other will cause an error.

Best practice is to use high point of this fl uid surface just at the small center bore

wall. In setting scale zero or reading percent CO

level with eyes and sight across scale to top of fl uid column.

Instruction 0011-9026 Page 7

or O2. Obviously, using high point for one operation and low point for the

2

or 02, hold FYRITE vertically and

2

Page 12

3.2.1 Draining Fluid Droplets

®

20

16

12

8

4

%CO2

0

For maximum accuracy, it is important to form the habit of follow ing a standard

procedure in this operation and to use the same procedure both before adjusting scale

zero and before reading percent CO

or O2 .

2

3.3 FYRITE Temperature

The FYRITE temperature should be at or close to the temperature of the working

environment where the analysis is being made and should not be subject to sudden

temperature changes. If FYRITE is carried from cooler to warmer location or vice

versa, expose FYRITE to new temperature condition to permit uniform temperature

stabilization. Usually 15 or 20 minutes will suffi ce, except when extreme temperature

variations are involved. Temperature stabilization can also be accelerated by inverting FYRITE frequently.

3.3.1 Temperature of Gas Sample

The gas sample as it enters FYRITE should be cooled (or warmed if sampling cool

gases) to same (ambient) temperature as the FYRITE.

Capacity of Standard Aspirator Bulb and Sampling Assembly (Part # 11-7029) to cool

the gas sample is suffi cient if the temperature of gas being sampled does not exceed

850°F (454°C), even where a large number of consecutive samples are required if there

is an interval of not less than 5 minutes between samples.

FYRITE indicators operate over a wide temperature range. They may be exposed to

ambient temperatures from –30° to 150°F (–34° to 66° C). Gases up to 850° F (454° C)

may be tested with Standard Aspirator Sampling Assembly (11-7029).

Instruction 0011-9026Page 8

Top of

Fluid

Column

Figure 11. Locating Top of Fluid Column.

Page 13

4.0 PRINCIPLE OF OPERATION

(Refer to Figures 12, 13, and 14)

Figure 12. When plunger

valve is depressed, a gas

sample is pumped through

top reservoir with center

bore is sealed off.

Figure 14. Absorption of

gas sample by fl uid cre-

ates suction, which causes

diaphragm to fl ex up and

fl uid to rise in center bore

to replace gas absorbed.

Figure 13. When plunger

valve is released, the gas

sample is locked into FYRITE and the top reservoir

is opened to center bore so

that gas sample can pass

through absorbing fl uid.

Instruction 0011-9026 Page 9

Page 14

To make a test with the FYRITE, the metal Sampling Tube at one end of Sampling

Assembly Hose is inserted into the gas to be analyzed. The rubber Connector Plug at

the other end of the Rubber Hose is then fi rmly pressed down on the spring-loaded

Valve of the instrument (See Figure 12). This simultaneously opens a passage into the

Top Reservoir and seals off the center bore.

Next, a sample of the gas is pumped into the Top Reservoir by squeezing the rubber Aspirator Bulb. At least 18 bulb squeezes are required to assure that the rubber

Sampling Hose and the Top Reservoir of the FYRITE are thoroughly purged of the

previously analyzed sample. During the 18th Aspirator Bulb squeeze and immediately

before releasing Bulb, the fi nger is lifted from the Connector Plug, which automati-

cally returns the Plunger Valve to upper position against its top seat.

Refer to Figure 13. With the Valve in this position, the fi nal 60 cc of the gas sample is

locked into the FYRITE and the Top Reservoir is opened to the center bore so that the

gas sample can pass to the absorbing fl uid. The FYRITE is then inverted, forcing the

gas sample to bubble through the absorbing solution which absorbs either CO

depending on the type FYRITE in use.

or O2

2

Refer to Figure 14. The instrument is then turned and held upright. Absorption of the

or O2 by the absorbing fl uid creates a suction, which causes the Diaphragm at the

CO

2

bottom to fl ex upward permitting the level of the absorbing fl uid to rise in the center

tube an amount proportional to the gas absorbed. The scale indication corresponding to the top of the fl uid column is then read as a percentage of gas absorbed by the

FYRITE fl uid.

5.0 APPLICATION INFORMATION

FYRITE Analyzers are available for either Carbon Dioxide or Oxygen analysis, and

each of these models is made in the three scale ranges shown in Section 5.3. All six

instruments are similar in appearance and size, but they differ in important construction details, as well as in absorbing fl uids.

5.1 FYRITE Absorbing Fluid

FYRITE absorbing fl uid is selective in the chemical absorption of carbon dioxide or ox-

ygen respectively. Therefore, the FYRITE’s accuracy is well within the range required

for industrial and professional applications, and does not depend upon complicated

sequential test procedures. Further more, the FYRITE readings are unaffected by the

presence of most back ground gases in the sample.

The appearance of a dark red fl uid fl oating on top of CO

normal. The darker fl uid consists of a small amount of material added to prevent

excessive foaming at the meniscus and improves readability.

5.1.1 FYRITE Refi ll Fluid (Storage Life, etc.)

FYRITE refi ll bottles should be stored at room temperature (70° F [21° C]) in the car-

ton provided, and placed in use within one year.

NOTE: Before opening refi ll bottle, read the label and make

certain to observe all precautions.

Instruction 0011-9026Page 10

FYRITE solu tion is entirely

2

Page 15

FYRITE CO2 refi ll fl uid may develop a white insoluble precipitate upon aging. The

precipitate does not affect fl uid performance in any way, but if present, should be

fi ltered out to prevent adherence to internal surfaces of the FYRITE.

To fi lter, place a clean piece of thin cloth or netting loosely over the open CO

and slowly pour refi ll contents into top reservoir. Before disposing of cloth, rinse thor-

FYRITE

2

oughly with water. FYRITE fl uid is corrosive!

FYRITE O

can be prevented by purging the FYRITE body with Nitrogen, natural gas or other

refi ll fl uid reacts very rapidly with oxygen in air. Oxidation of absorbent

2

oxygen-free gas, just before fi lling, and by maintaining a stream of this gas around

mouth of the bottle (see Figure 21) while its contents are emptied into the FYRITE.

Another method for refi lling the O

absorbent) is to invert the unit and place it over the 60 cc bottle of fl uid. Then invert

both so that the FYRITE is now upright and the O

Figure 21a). Immediately install plastic Top Cap Ring without delay. This method

FYRITE (and still limiting the oxidation of the

2

fl uid is fi lling the instrument (see

2

helps to minimize oxidation and improve the life of the fl uid.

5.2 FYRITE Operating Temperature Range

The FYRITE indicators operate over a wide temperature range, and may be exposed

to ambient temperatures from –30° to 150° F. (–34° to 66°C). Gases up to 850° F (454°

C) may be tested with standard aspirator sampling equipment (11-7029).

NOTE: Remember, for most accurate results, the FYRITE must

be at temperature equilibrium with its sur roundings (ambient

temperature) and the incoming gas sample at the same temperature as the FYRITE.

5.3 Typical FYRITE Applications

Listed below are six models of FYRITE Indicators and two Aspirator Sampling Assemblies with part numbers identifying their application.

Bacharach Part Numbers

For Testing

Carbon

Dioxide

Scale

Range

FYRITE

Aspirator Sampling Assy.

Fluid Complete Kit

with Case

0 - 7.6% 11-7042 11-7029 10-5100 10-5053

0 - 20% 11-7032 11-7029 10-5057 10-5000

0 - 60% 11-7034 11-7029 10-5057 10-5032

Oxygen

0 - 21% 11-7036 11-7029 10-5060 10-5011

0 - 60% 11-7038 11-7029 10-5060 10-5046

TYPICAL APPLICATIONS WITH FULL SIZE

SECTIONS OF FYRITE SCALES

Instruction 0011-9026 Page 11

Page 16

0-7.6% CO2 or O

2

CO2 tests of controlled atmospheres in fruit,

vegetable, and meat storage rooms. Oxygen

determination in fl ammable gases. Oxygen tests

to check atmospheres made inert with nitrogen

(silos, fuel tanks, etc.)

0-20% CO

or 0-21% O

2

2

Flue gas combustion tests, oxygen defi ciency tests,

and CO

Checking oxygen concentrations in hydrogen-cooled

tests of heat treating atmospheres.

2

generators and oil-sealed inert-gas transformers.

0-60% CO

Checking CO

barges carrying gasoline and other com bustibles.

CO

2

plant digesters. Oxygen tests in connection with

or O2

2

in inert gas blankets in tankers and

2

tests on lime kilns. Checking CO2 in sewage

oxygen and gas anesthesiology.

5.4 CO2 FYRITE Only Combustion Testing

5.4.1 Percent CO2 Shows Volume of Excess Air (Refer to Figure 15)

For any given fuel, theoretical maximum percent CO

duced when exactly enough air (but no excess air whatsoever) is supplied to burn all

of the fuel. As increasing amounts of excess air are supplied, percentage CO

decreases from theoretical Ultimate CO

due to the diluting effect of excess air.

2

(Ultimate CO2 ) would be pro-

2

naturally

2

Thus, measuring percent CO

enough is supplied to permit clean combustion without adding so much that combus-

is also a method of indicating excess air to ensure that

2

tion effi ciency is unnecessarily decreased.

5.4.2 Too Much Excess Air Means Ineffi cient Combustion

Instruction 0011-9026Page 12

Page 17

Excess combustion air is heated and carries some of this heat to the fl ue where it is

wasted. The FYRITE CO

mum (maximum CO

Analyzer is used to adjust combustion excess air to a mini-

2

), which will permit clean effi cient combustion.

2

Calculation of combustion effi ciency is possible (assuming com plete combustion) if

percentage of CO2 and net temperature of combustion products are known.

5.4.3 What is Proper CO

Proper CO

margin for variations in fuel, draft, atmospheric con ditions, and mechanical wear.

is that which will ensure complete, clean combustion with some safety

2

Value?

2

Consult manufacturer of heating equipment for specifi c recommendations. Generally

accepted values for good combustion practice in residential furnaces and boilers when

fi ring the following fuels are:

Natural Gas ......8 to 9.5% CO

No.2 Oil ............10 to 12.5% CO

2

2

These are only guidelines, however, and in all cases recommendations of the equipment or fuel supplier would also include recommendations for allowable smoke (oil

fi ring) or combustibles (gas fi ring), which are undesirable combustion by-products.

Testing for smoke, CO, or combustibles is important since in extreme fuel rich fi ring,

high CO

values also occur (see Figure 16).

2

5.4.4 How To Calculate Combustion Effi ciency

Measure percent CO

with a suitable thermometer (e.g., TEMPOINT) at the same sampling point. Deduct

in fl ue gases with FYRITE. Then measure fl ue gas temperature

2

temperature of basement or combustion air supplied from measured fl ue gas tem-

perature to obtain net fl ue gas temperature. Use a Bacharach FIRE EFFICIENCY

FINDER to calculate combustion effi ciency. Instructions for using the FIRE EFFI-

CIENCY FINDER are printed on the face of this slide rule calculator.

5.5 O2 FYRITE Only Combustion Testing

5.5.1 Percent O2 Shows Volume of Excess Combustion Air (Refer to Fig. 15)

All fuels require some excess air (in addition to air theoretically re quired to burn the

fuel) to ensure clean, complete combustion. As the amount of this excess air increases,

the percentage of O

5.5.2 Too Much Excess Air Means Ineffi cient Combustion

Excess combustion air is heated and carries some of this heat to the fl ue where it is

wasted. The FYRITE O

excess air (minimum O

5.5.3 What is Proper O2 Value?

Instruction 0011-9026 Page 13

in combustion products increase.

2

analyzer is used when adjusting combustion air to minimum

2

) which will permit clean, effi cient combustion.

2

Page 18

Proper O2 content for any fuel fi red is the lowest O2 value that will ensure complete,

clean combustion with adequate safety margin for variations in fuel, draft, atmospheric conditions, and mechanical wear. Consult manufacturer of heating equipment or

local authorities for specifi c recommendations. Figure 15 illustrates the relationship

between CO

, excess air and oxygen for gas and oil.

2

For guidance, it should be added that modern boilers are capable of 80% or greater

combustion effi ciency. Rough guidelines for setting conventional power burners are

10-15% excess air for natural gas and 15-20% excess air for oil, with little or no smoke

and carbon monoxide formation.

5.5.4 Measuring O

in Addition to CO

2

2

Figure 16 illustrates why it is good practice to measure oxygen, in addition to carbon

dioxide, when fi ring gaseous fuels. Note that the same CO

on both sides of the stoichiometric (or perfect) mixture. Carbon dioxide alone cannot

reading can be obtained

2

defi ne proper excess air operation for gaseous fuels.

A check must also be made for the presence of oxygen, which confi rms operation with

excess air. Gaseous fuels should also be checked for presence of carbon monoxide (CO)

in the fl ue gases and adjusted for either “no CO” or to conform to applicable safety

regulations.

5.5.5 Where is Percent CO

For residential and most commercial and industrial combustion units, percent CO

is measured by analyzing gas sample obtained through a 1/4-inch diameter hole lo-

O

2

cated between the fl ue outlet (breeching) and any mechanical opening in the fl ue such

or O2 Measured? (Refer to Figure 17)

2

2

or

as the barometric draft regulator or draft diverter. Best practice is to locate sampling

hole at least six inches upstream from such fl ue openings. The metal FYRITE Sam-

pling Tube should extend at least 2-1/2 inches into the fl ue gases.

For larger installations, consult manufacturer of combustion equip ment for special

instructions regarding sampling point, special sampling tube required, or advice on

averaging readings.

Residential gas furnaces with built-in draft diverter (gas designed) will require the

FYRITE metal Sampling Tube to be inserted as illustrated in Figure 17 to avoid dilution of fl ue gas sample.

Additional information on residential furnace combustion testing may be obtained

from the following Bacharach publication:

Bulletin 4097 - Technical Combustion Brochure

5.6 Background Gases Affecting FYRITE Readings

Instruction 0011-9026Page 14

Page 19

PERCENT EXCESS AIR

Figure 15. Relation between Oxygen, CO2 and excess

air in fl ue gases for Natural Gas and Fuel Oil.

THEORETICAL EXCESS AIR CURVE

STOICHIOMETRIC MIX

Figure 16. CO

combustion air setting when fi ring gaseous fuels.

Instruction 0011-9026 Page 15

measurements alone do not determine

2

Page 20

As a rule of thumb, background gases/vapors may be present in con centrations up to

1/2% by volume (5000 ppm) before they present a signifi cant interference problem to

the CO

or O2 FYRITE (20/21% ranges).

2

An exception exists with the action of ammonia on Oxygen FYRITE Fluid. Ammonia

neutralizes the acidic solution of chromous chloride, and therefore use of the O2 FYRITE with even trace amounts of ammonia in the backgrounds is not advised unless

suitable fi lters are used.

Inert gases, even in concentrations approaching 100% by volume, do not interfere with

either the CO

reaction initiated) or a mechanical nature, with resultant error, but are also given up

or O2 FYRITE. In general, interferences can be of a chemical (chemical

2

by the solution when the sample no longer contains the interfering substance. They

can therefore be compensated for by saturating the FYRITE solution with samples

containing the mechanical interferant as long as the background stays reasonably

constant. Usually 3 or 4 tests are suffi cient to saturate FYRITE solution with the

mechanical interferant in question.

TYPICAL TYPE OF APPROXIMATE

INTERFERENCE INTERFERENCE EFFECT

(CO

FYRITE)

2

All Acid Gases Chemical 1:1

(SO

cynanic Acid,

, H2S, Hydro-

2

Cyanogen, etc.).

TYPICAL TYPE OF APPROXIMATE

INTERFERENCE INTERFERENCE EFFECT

(O

FYRITE)

2

Acetone Chemical 1:1

Acetylene Chemical 1:1

and other

unsaturated

hydrocarbons

CO

Mechanical, 20% CO2 Can be zeroed out up

2

background can be to approximately 30%

zeroed out in 3 to 4 CO2 background.

tests if background

remains constant.

Ammonia Chemical Ammonia neutralizes

O

and instrument use on

FYRITE solution

2

this background is not

advised unless suit able fi lters are used.

Nitrous Oxide (N

Instruction 0011-9026Page 16

O) Mechanical - - -

2

Page 21

Figure 17. Checking CO2 of gas

designed furnace (sampling tube

inserted through draft diverter;

fl ue gas temperature test can

be made at same point).

5.7 General FYRITE Applications

It is only possible to specify a few general rules for such applications. Where possible,

sample should be obtained at a point where the gases are well mixed to a uniform

composition. Where this is impossible; it will be necessary to average a number of

measurements taken at different locations to obtain representative average. Where

gases being sampled are not saturated with moisture (many non-combustion applications), it is very important to maintain the wool packing of Filter Saturator Tube in a

moist condition.

NOTE: The FYRITE is calibrated to analyze gases which are

normally saturated with moisture. Failure to moisten wool

packing in fi lter saturator tube with water will cause FYRITE

to indicate slightly lower than actual gas concentration.

Where special length sampling lines are required, add one more bulb squeeze to the

18 required with standard Sampling Assembly for each additional 3 cubic inches

(50cc) volume of special sampling line.

EXAMPLE: For each 9 ft. of 3/1 6 inch (I.D.) additional

length of sampling line, add one more bulb squeeze.

If it is necessary to trap a sample over water for later analysis, a minimum of 900 cc of

sample will be required. If sample is trapped over water, it is good practice to use 10

to 15% NaCl (table salt) in the water to minimize absorption of CO

or O2 by water.

2

Trapping a sample over mercury will eliminate any possible error due to absorption of

CO2 or O2.

5.8 Altitude Correction Table

Instruction 0011-9026 Page 17

Page 22

The gas concentration read on the FYRITE is directly dependent upon the mass of air

in the sample. The aspirator bulb used in the FYRITE is a constant-volume pump,

not a constant-mass pump. Altitude, therefore, affects the FYRITE reading due to the

air’s density changing with altitude, thus requiring higher CO

reach the same mark on the scale.

or O2 concentrations to

2

Use the following table to fi nd the altitude correction (e.g., add the correction to the

reading to get the correct concentration).

TABLE 5-1. ALTITUDE CORRECTION TABLE

Altitude Correction %

Ft. (Meters) 20% CO

21% O2 7% O2 or CO

2

2

1000 (305) 0.0 0.0 0.0

2000 (610) 0.0 0.0 0.0

3000 (914) 0.1 0.1 0.0

4000 (1575) 0.1 0.2 0.1

5000 (1219) 0.2 0.2 0.2

6000 (1829) 0.2 0.3 0.2

7000 (2134) 0.3 0.3 0.3

8000 (2438) 0.4 0.4 0.3

9000 (2743) 0.4 0.5 0.4

10,000 (3048) 0.5 0.6 0.5

11,000 (3353) 0.6 0.7 0.5

12,000 (3658) 0.7 0.8 0.6

13,000 (3962) 0.7 0.8 0.6

14,000 (4267) 0.8 0.9 0.7

6.0 FYRITE MAINTENANCE

NOTE: With FYRITE vented and in a vertical position, it

should be possible to adjust scale zero to the top of the fl uid col-

umn. Refer to FYRITE Operation (Section 3.0) Steps 1 through

4 (for CO2) or Steps 1 through 5 (for O2) for proper setup. If

this is not possible, add or remove a small amount of fl uid as

described below.

6.1 Increasing FYRITE Fluid To Proper Level

Refer to Figure 18. Hold FYRITE upright and cover hole in center of Plunger Valve

with fi nger. Add clean water, a few drops at a time (dripping water faucet is con-

venient) into space around Plunger Valve. Work Plunger Valve up and down several

times. Repeat process until fl uid is at proper level.

6.1.1 Decreasing FYRITE Fluid to Proper Level

Instruction 0011-9026Page 18

Page 23

Refer to Figure 19. To remove excess fl uid, insert small diameter glass tube into FY-

RITE fl uid through the small center FYRITE bore (with Top Cap Assembly removed).

Seal open end of glass tube with fi nger and dip out fl uid with glass tube until FYRITE

fl uid is at proper level. Avoid unnecessary exposure of O2 fl uid to air since it will rap-

idly absorb O2 and become exhausted.

6.2 Checking FYRITE Fluid Strength

6.2.1 CO2 FYRITE Fluid Only

Fresh FYRITE fl uid will absorb all CO

. Where it is desirable to check fl uid strength before taking FYRITE to the test

CO

2

location to be used, or when a questionable (low) FYRITE reading is obtained the

instrument may be tested on any sample of CO

mately 4% CO

) is often most convenient.

2

from more than 350 samples containing 10%

2

. Exhaled breath (containing approxi-

2

Disconnect the rubber bushing and Sampling Hose Assembly from the Filter Saturator Tube. Place the rubber connector tip over the Plunger Valve and depress Plunger

Valve down fi rmly with rubber connector tip. Take a deep breath, hold for 3 or 4

seconds and exhale at a steady rate into the rubber bushing end of the Sampling Hose

Assembly. Simultaneously squeeze the Aspirator Bulb several times while exhaling

breath. Release rubber connector tip from Plunger Valve while still exhaling breath.

Perform steps outlined below to absorb exhaled breath into FYRITE fl uid.

1. Absorb sample gas into FYRITE by inverting until fl uid drains into top reser-

voir, then turn upright to drain fl uid into bottom reservoir. Repeat this step once

more (two complete inversions total).

2 Hold FYRITE at 45° angle momentarily to allow fl uid droplets to drain into bot-

tom reservoir.

3. With FYRITE held upright, permit fl uid in column to stabilize a few seconds, then

immediately read % carbon dioxide on scale at point corresponding to top of fl uid

column.

To check CO

gas by inverting and turning upright. Repeat this step once more (two complete inversions total). If reading increases by more than 1/2 percent CO

reading; replace fl uid.

FYRITE fl uid strength - DO NOT VENT FYRITE but reabsorb sample

2

as compared to initial

2

Formation of a frothy, persistent foam on FYRITE fl uid also indicates need for fl uid

replacement. A few “beads” or small air bubbles fl oating near the small center bore

wall is not considered foaming. FYRITE fl uid may be colored for ease in readings.

Color has no bearing on fl uid strength or ability to absorb CO

Cloudy fl uid or small fl akes of solid material in fl uid do not necessarily mean CO

fl uid is exhausted. Precipitate may form in CO

and can be fi ltered through cheese cloth or other screen like material when refi lling

Refi ll Bottles due to extended storage,

2

.

2

2

FYRITE.

NOTE: If compressed gas standards are used to check FYRITE

Instruction 0011-9026 Page 19

Page 24

®

20

16

12

8

4

%CO

2

0

20

20

16

12

8

4

%O

2

0

®

16

12

8

%CO

2

4

0

®

Figure 18. Increasing FYRITE

fl uid to proper level.

Figure 19. Decreasing FYRITE

fl uid to proper level

TOP GASKET

20

16

12

8

%CO

2

4

0

®

OVAL HEAD

SCREWS

Figure 20. Removing top gasket. Figure 21. Flushing FYRITE with

TOP CAP/

PLUNGER

VALVE

ASSEMBLY

TOP CAP RING

WITH GASKET

a stream of O

see Fig. 21a for alternate method).

free, inert gas (Also

2

Instruction 0011-9026Page 20

Page 25

accuracy don’t forget to saturate fi lter saturator wool packing

as such gas standards are usually supplied “bone dry”.

6.2.2 O

Fresh FYRITE fl uid will absorb all O

10% O

RITE Fluid strength can be checked by performing steps outlined below:

FYRITE Fluid Only

2

from approximately 100 samples containing

. After completing test (as outlined in Section 3.0 Steps 1 through 9) O2 FY-

2

2

1. DO NOT VENT FYRITE, but reabsorb sample gas into FYRITE by inverting until

fl uid drains into top reservoir, then turn upright to drain fl uid into bottom reser-

voir. Repeat this step three (3) more times (four complete inversions total).

2. Hold FYRITE at 45° angle momentarily to allow fl uid droplets to drain into bot-

tom reservoir.

3. With FYRITE held upright, permit fl uid in column to stabilize a few seconds, then

immediately read % oxygen on scale at the point corresponding to top of fl uid col-

umn. If reading increases by more than 1/2 percent O

reading, replace fl uid.

as compared to the initial

2

When it is desirable to check fl uid strength before taking the FYRITE to a location

where it will be used, it can be conveniently tested on a sample of atmospheric air

which contains 20.9% O

.

2

NOTE: Make certain wool in fi lter saturator tube is moistened

with water when using FYRITE in a non -combustible application where the gas sample is not fully saturated with water

vapor.

Formation of a frothy, persistent foam on FYRITE fl uid also indi cates need for fl uid

replacement. A few “beads” or small air bubbles fl oating near the small center bore

wall is not considered foaming. Color of FYRITE O

ability to absorb oxygen although towards the end of fl uid life, a greenish cast can be

(blue) fl uid is not an index of

2

detected.

NOTE: If compressed gas standards are used to check FYRITE

accuracy, don’t forget to saturate fi lter saturator wool packing

as such gas standards are usually supplied “bone dry”.

6.3 Replacing FYRITE Fluid (Refer to Figs 20, 21, and 22)

CAUTION

Because of the corrosive effect of the FYRITE fl uid, always

change FYRITE fl uid in immediate vicinity of a sink with run-

ning water available as shown in Figure 18.

Remove 4 screws, metal Top Cap Ring, plastic Top Cap Assembly and Top Gasket.

Instruction 0011-9026 Page 21

Page 26

Drain old fl uid from FYRITE and rinse all parts in clean, lukewarm water.

NOTE: FYRITE fl uid is corrosive to skin, clothing, some met-

als, and painted or lacquered surfaces. Dispose of these fl uids

in accordance with Local, State and Federal Laws. If draining

into a porcelain sink is permitted, keep water faucet turned on

while draining and fl ush for at least 1/2 minute afterwards.

NOTE: Examine top gasket for warpage, if distorted as shown

in Figure 22, replace gasket with part # 11-0143 before proceeding.

Drain all parts of excess water. Stand FYRITE Body upright to center replacement

Top Gasket in recess provided in top fl ange of body.

FYRITE Only: Before adding fl uid, fl ush FYRITE with a stream of O2 - free, inert

O

2

gas (Figure 21) or be prompt in reassembling Top Cap to prevent excessive fl uid con-

tact with air.

Uncap FYRITE fl uid bottle, invert FYRITE and place over the bottle. Invert both

FYRITE and bottle (Figure 21a) so that FYRITE comes to an upright position and the

fl uid is fi lling the unit. Immediately install plastic Top Cap Assembly and metal Top

Cap Ring without delay.

FYRITE Only: Uncap CO2 Refi ll Bottle and pour entire contents into FYRITE.

CO

2

Reinstall plastic Top Cap Assembly and metal Top Cap Ring.

CO2 / O2 FYRITEs: Make certain that Top Cap Ring Gasket (11-0109, Figure 33) is in

place between metal Top Cap Ring and plastic Top Cap. Draw the 4 machine screws

down with light screwdriver force.

Then, going from one screw to the next, draw down 1/4 turn until all are fi rmly tight-

ened. Avoid excessive force in tightening which may damage plastic parts.

6.4 Inspection of FYRITE for Fluid Leakage

Gradual loss of fl uid, moisture or dried encrustation around Plunger Valve does not

indicate fl uid leakage. Gas enters and leaves unit during sampling with considerable

velocity and some fl uid vapor is carried out during normal sampling. To check Top As-

sembly for fl uid leakage in upright position, depress Plunger Valve and release.

Note the scale reading at top of fl uid column, and then stand FYRITE upside down

overnight in glass or porcelain test dish (See Figure 23). Then, return FYRITE to upright position and, after allowing 5 minutes for drainage, depress and release Plunger

Valve. Leakage will be evidenced by lower scale reading. Extreme leakage will be apparent by presence of fl uid in test dish.

Follow the same procedure to check fl uid leakage from Bottom Cap Assembly with

FYRITE stood overnight in the upright position.

When leakage is proven, examine plastic and rubber parts for deterioration to deter-

Instruction 0011-9026Page 22

Page 27

20

16

12

8

4

%CO

2

0

20

16

12

8

4

%CO

2

0

®

Figure 21a. Alternate fi lling meth-

od. Invert FYRITE (with bottle in

Figure 22. Examining top gasket

for warpage.

place) to upright position.

TOP CAP

ASSEMBLY

GASKET

20

®

0

4

%CO

2

8

12

16

20

16

12

8

%CO

2

4

Top Gasket used in 7%,

0

®

20% & 21% Models only

Figure 23. FYRITE inverted in test

disk (overnight) for leakage test.

Figure 24. Top gasket properly

centered in top fl ange of body.

Instruction 0011-9026 Page 23

BODY

Page 28

mine replacement parts necessary for repair, or drain instrument and return if factory

service or repair is desired.

6.5 Cleaning FYRITE

Use only soapy lukewarm water if cleaning is required (lukewarm water is usually

suffi cient).

NOTE: Use of gasoline, naptha, carbon tetrachloride or any

other organic solvent or oil will destroy plastic and rubber

parts.

6.6 Replacing FYRITE Plastic and Rubber Parts (Refer to Illustrated

Parts List FYRITE CO

Replace plastic parts when cracked or crazed in location exposed to fl uid and rubber

parts when badly swollen, warped or showing other evidence of deterioration.

In replacing Top Gasket, make certain it is properly centered in the recess provided in

top fl ange of FYRITE Body (See Figure 24). When installing plastic Top Cap Assem-

bly, be sure that assembly is centered on Top Gasket.

To remove Top Cap Assembly or replace Top Cap, Plunger Valve, or Plunger Tip Gasket, use the procedure as outlined in Section 6.3.

When replacing Plunger Tip Gasket, simply depress Plunger Valve against its spring

limit and strip old Gasket from the end of Plunger Valve.

[Section 7.0 and Fig. 33])

2/O2

Before assembling new Gasket, wet inside surface of Tip Gasket, then force it over the

end of Plunger Valve (after depressing Plunger Valve against the spring limit).

Make certain that new Tip Gasket is seated uniformly against the mating surface in

plastic Top Cap.

To replace Diaphragm, stand FYRITE upside down, remove 4 screws and metal Bottom Cap.

Refer to Figure 25a. Remove old Diaphragm and center new replacement with the

lettering facing you, so that after the FYRITE Bottom Cap is installed the letters will

face up into its recess. Center Bottom Cap Assembly in Body Recess and reinstall 4

screws, observing same precautions in tightening as outlined in Section 6.3.

To replace Body, remove the 4 hex head Bezel screws and 4 Bezels. Install Bezels on

new Body.

NOTE: Make certain the rubber bezel gaskets are properly

seated and clamped between bezel and body as shown in Figure

25.

6.7 Aspirator Bulb - Sampling Assembly (Refer to Figs. 26, 27, & 28)

Defective Check Valves or a leaking Sampling Assembly can result in sample loss, or

sample dilution with resultant loss of accuracy.

To inspect Sampling Assembly, seal hole in the center of rubber Connector Tip fi rmly

Instruction 0011-9026Page 24

Page 29

Figure 25a. Replacement Diaphragm

20

16

12

8

4

%CO2

0

®

LETTERING

BOTTOM CAP

(RECESS)

properly installed.

Figure 25. Locating Bezel

Rubber Gaskets.

Figure 26. FYRITE Sampling Assembly;

Locating Inlet/Outlet Check Valves.

Instruction 0011-9026 Page 25

Page 30

with fi nger and squeeze Aspirator Bulb (Figure 27). Bulb should remain fi rm. If Bulb

collapses, check Bulb and Hose to Connector Tip for cracks or other source of leakage.

Replace defective parts. If there are no apparent leaks in the Sampling Assembly,

replace Inlet Check Valve. Small hole end of Inlet Check Valve fi ts in Hose and

large hole end fi ts in the Aspirator Bulb (Figure 26).

Now seal end of metal Sampling Tube with fi nger, and collapse Aspirator Bulb. (Fig-

ure 28). If the Bulb returns to original shape in less than 15 seconds, inspect Hose,

Filter, Saturator Tube and Metal Sampling Tube for leaks. If none are found, replace

the Outlet Check Valve. Small hole end of Outlet Check Valve fi ts in Aspirator

Bulb and large hole end fi ts in the Hose (Figure 26).

Discard Filter Packing when it becomes dirty or clogged. Push old packing out of, and

new packing into, Filter Saturator Tube with a pencil or small rod (See Section 6.9).

6.8 Storing FYRITE and Refi ll Fluid

When FYRITE is not used over periods between tests, store it and its Sampling Assembly in a cool, dry place. Prolonged storage, for example, at high temperatures

reached in an automobile trunk over the Summer is not recommended. When stored

unused over the Summer, it is good practice to drain old fl uid and replace with fresh

charge (fl uid) when needed in the Fall.

FYRITE Refi ll Fluid should also be stored in a cool, dry location in the carton pro-

vided. A recommended practice is to accumulate stock only suffi cient for one year

requirement and to use oldest stock fi rst. Fluid can be tested for performance accord-

ing to Section 6.2.

Use only Bacharach CO

below contain three Refi ll Bottles each.

7% CO

20% and 60% CO2 range .............Refi ll Kit 10-5057

or O2 Fluid Refi lls for the range FYRITE selected. The Kits

2

range ..............................Refi ll Kit 10-5100

2

7% O2 range .................................Refi ll Kit 10-5103

21% and 60% O2 range ................Refi ll Kit 10-5060

6.9 Replacing Saturator Filter Packing Part #11-0121

(Refer to Figs 29 thru 32)

Remove the fi lter tube nipple and bushing (See Figure 29) from each end of the tube.

Use a pencil or similar object to remove packing when it becomes dirty or clogged.

Wrap replacement packing around the hand (See Figure 30). If testing unsaturated

gases (most non-combustion applications), saturate packing in water as shown in

Figure 3, and squeeze out excess moisture.

Insert saturated packing using a pencil or small rod into fi lter tube (See Figure 32);

then reassemble nipple and bushing.

7.0 ILLUSTRATED PARTS LIST FYRITE CO2/O2

(Refer to Figure 33 FYRITE Parts Breakout)

Instruction 0011-9026Page 26

Page 31

RUBBER CONNECTOR TIP

(HOLD FINGER HERE)

ASPIRATOR BULB SHOULD

REMAIN FIRM WHEN SQUEEZED

Figure 27. Testing Sampling Assembly (outlet side) for leaks.

CHECK FOR BULB INFLATION

AFTER SQUEEZING

SAMPLING TUBE END

(HOLD FINGER HERE)

Figure 28. Testing Sampling Assembly (inlet side) for leaks.

Figure 29. Removing End Plugs from Saturator Filter Tube.

Instruction 0011-9026 Page 27

Page 32

Figure 30. Wrapping Replacement Filter Material.

Figure 31. Wet Filter Material then squeeze out excess water.

Figure 32. Installing wetted Filter Material into Saturator Tube.

Instruction 0011-9026Page 28

Page 33

Part # Description Qty-Rq’d

11-0102 Bezel 4

11-0188 Oval Head Screw 8

11-0110 Bezel Screw 4

11-0109 Top Cap Ring Gasket (Optional, Part of 11-0136) 1

11-0105 Scale Screw 1

02-3690 Scale Screw Nut 1

11-0021 Diaphragm 1

11-0126 Bottom Cap 1

11-0132 Top Cap 1

11-0019 Valve Plunger 1

11-0026 Valve Plunger Spring 1

11-0020 Valve Plunger Gasket 1

11-0136 Top Cap Ring with Gasket 1

11-0143 Top Gasket (7%, 20% & 21% Models only) 1

11-0140 FYRITE Body (All Models except 7.0% CO

/ O2) 1

2

11-0154 FYRITE Body (7% Models only) 1

11-0062 Filler 60% FYRITE (Adapter Plug) 1

05-5134 Bezel Gasket “O” Ring 2

05-5169 O-Ring Filler (Outer 60%) 1

05-5155 O-Ring Filler (Inner 60%) 1

11-0144 CO

Scale 20% 1

2

11-0145 O2 Scale 21% 1

11-0147 CO2 Scale 60% 1

11-0150 O2 Scale 60% 1

11-0155 CO2 Scale 7% 1

11-0157 O2 Scale 7% 1

10-5057 Carton of FYRITE CO2 Fluid (3 Bottles) 20/60% range Models 1

10-5060 Carton of FYRITE O2 Fluid (3 Bottles) 21/60% range Models 1

10-5100 Carton of FYRITE CO2 Fluid (3 Bottles) 7% range Models 1

10-5103 Carton of FYRITE O2 Fluid (3 Bottles 7% range Models 1

Instruction 0011-9026 Page 29

Page 34

7.1 FYRITE ILLUSTRATED PARTS

11-0026

11-0188

11-0019

11-0102

11-0102

11-0188

11-0110

11-0140

11-0136

11-0109

11-0132

11-0143 (7%, 20%, and 21% Models Only)

11-0020

11-0110

05-5134

11-0105

11-0154

11-0062

05-5169

05-5155

02-3690

05-5134

11-0102

11-0110

11-0021

Instruction 0011-9026Page 30

11-0126

11-0110

11-0102

11-0188

Figure 33. FYRITE parts breakout.

Page 35

7.2 PARTS LIST FOR FYRITE SAMPLING ASSEMBLIES

STANDARD SAMPLING ASSEMBLY

Part No. 11-7029

Gases saturated with water vapor (combustion products).

Dry gases when fi lter material is wetted.

0011-0122

0011-0152

0011-0106

0011-0118

0011-0118

0011-0138 0011-0138

(0011-0180 + 0011-0130)

0011-0120

0011-0119

Instruction 0011-9026 Page 31

Page 36

Current Former

Part # List # Description # Req'd

11-0152 10-0019 Connector Tip with Tube 1

11-0156 10-0029 Rubber Tubing, 10' Length 1

11-0118 10-0020 Rubber Tubing, 6" Length 2

11-0165 10-0030 Filter Tube, Aluminum 1

19-5004 19-9004 Gas Collecting Bladder with Orifi ce 1

11-0120 10-0022 Aspirator Bulb 1

11-0138 10-0023 Inlet/Outlet Valve (Red) 2

11-0119 10-0024 Rubber Tubing, 3' length 1

11-0180 10-0025 Filter Nipple with Bushing 2

11-0130 10-0026 Filter Tube, Plastic 1

11-0106 10-0027 Sampling Tube 1

11-0161 10-0040 Condenser Coil 1

11-0179 10-0042 Rubber Tubing, 15' length 1

11-0121 10-0033 Envelope of Filtering Material (10 per pack)

11-0181 10-0032 Filter Saturator (Aluminum) Assembly

Comprising 11-0180, 11-0122, and 11-0165

Instruction 0011-9026Page 32

Page 37

Notes

Instruction 0011-9026 Page 33

Page 38

Notes

Instruction 0011-9026Page 34

Page 39

Notes

Instruction 0011-9026 Page 35

Page 40

Instruction 0011-9026Page 36

Bacharach, Inc.

621 Hunt Valley Circle, New Kensington, PA 15068

Phone: 724-334-5000 • Fax: 724-334-5001 • Toll Free: 800-736-4666

Web: www.mybacharach.com • E-mail: help@mybacharach.com

Loading...

Loading...