Page 1

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic safety precautions should always be taken, including the following:

Read all instructions before using.

DANGER - To reduce the risk of electric shock:

1. The machine should never be left unattended while plugged in. Always unplug the machine from the electrical

outlet immediately after using and before cleaning.

WARNING - To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow this machine to be used as a toy. Close attention is necessary when the machine is used by or

near children.

2. Use this machine only for its intended use as described in this manual. Use only accessories recommended by

the manufacturer as contained in this manual.

3. Never operate this machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped

or damaged, or dropped into water. Return the machine to the nearest authorized retailer or service center for

examination, repair, electrical or mechanical adjustment.

4. Never operate the machine with any air openings blocked. Keep ventilation openings of the machine and foot

control free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn the main switch to the symbol “ ” position which represents off, then remove plug from

outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch the machine to the symbol “ ” position when making any adjustments in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot, and the like.

15. Always unplug the machine from the electrical outlet when removing covers, lubricating, or when making any

other user servicing adjustments mentioned in the instruction manual.

16. This sewing machine is not intended for use by young children or infirm persons without supervision.

17. Young children should be supervised to ensure that they do not play with this machine.

18. If the LED light unit (light-emitting diode) is damaged, it must be replaced by authorized retailer.

SAVE THESE INSTRUCTIONS

This machine is intended for household use.

1

Page 3

FOR USERS IN THE UK, EIRE, MALTA

AND CYPRUS ONLY

If this machine is fitted with a three-pin non-rewireable BS plug then please read the following.

IMPORTANT

If the available socket outlet is not suitable for the plug supplied with this equipment, it should be cut off and an

appropriate three-pin plug fitted. With alternative plugs an approved fuse must be fitted in the plug.

NOTE

The plug served from the main lead must be destroyed as a plug with bared flexible cords is hazardous if engaged in

a live socket outlet. In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying

the mark, rating as marked on plug.

Always replace the fuse cover, never use plugs with the fuse cover omitted.

WARNING

DO NOT CONNECT EITHER WIRE TO THE EARTH TERMINAL WHICH IS MARKED WITH THE LETTER ‘E’, BY

THE EARTH SYMBOL OR COLOURED GREEN OR GREEN AND YELLOW.

The wires in this main lead are coloured in accordance with the following code:

Blue Neutral

Brown Live

As the colours of the wiring in the main lead of this appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows.

The wire which is coloured blue must be connected to the terminal which is marked with the letter ‘N’ or coloured

black or blue.

The wire which is coloured brown must be connected to the terminal which is marked with the letter ‘L’ or coloured

red or brown.

2

Page 4

Federal Communications Commission (FCC)

Declaration of Conformity (For USA Only)

Responsible Party: Tacony Corporation

1760 Glisinn Lane

Fenton, Missouri 63026

declares that the product

Product Name:

Model Number:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

Baby Lock Sewing Machine

BLSR

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is con-

nected.

• Consult the retailer or an experienced radio/TV technician for help.

• The included interface cable should be used in order to ensure compliance with the limits for a Class B

digital device.

• Changes or modifications not expressly approved by Tacony Corporation could void the user's author-

ity to operate the equipment.

3

Page 5

CONGRATULATIONS ON CHOOSING

OUR MACHINE

Your machine is the most advanced computerized household sewing machine. To fully enjoy all the features incorporated, we suggest that you study the manual.

PLEASE READ BEFORE USING THIS MACHINE

For safe operation

1. Be sure to keep your eye on the needle while sewing. Do not touch the handwheel, thread take-up lever, nee-

dle, or other moving parts.

2. Remember to turn off the power switch and unplug the cord when:

• Operation is completed

• Replacing or removing the needle or any other parts

• A power failure occurs during use

• Maintaining the machine

• Leaving the machine unattended.

3. Do not store anything on the foot controller.

4. Plug the machine directly into the wall. Do not use extension cords.

5. Do not place or store the machine near heaters or other hot appliances, in any location exposed to extremely

high or low temperatures, high humidity or dusty locations. Doing so could cause the machine to malfunction.

6. Never operate the machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped

or damaged, or water is spilled on the unit. Return the machine to the nearest authorized retailer or service center for examination, repair, electrical or mechanical adjustment.

For a longer service life

1. When storing this machine, avoid direct sunlight and high humidity locations. Do not use or store the machine

near a space heater, iron, halogen lamp, or other hot objects.

2. Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders can damage

the machine, and should never be used.

3. Do not drop or hit the machine.

4. Always consult the operation manual when replacing or installing any assemblies, the presser feet, needle, or

other parts to assure correct installation.

5. Use only the interface cable (USB cable) included with this machine.

For repair or adjustment

In the event a malfunction occurs or adjustment is required, first follow the troubleshooting table in the back of the

operation manual to inspect and adjust the machine yourself. If the problem persists, please consult your local

authorized Baby Lock retailer.

For additional product information and updates, visit our web site at www.babylock.com

The contents of this manual and specifications of this product are subject to change without notice.

4

Page 6

HOW TO USE THIS MANUAL

Chapters 1 and 2 describe to the first-time user the initial operations for using this machine and the basic

sewing operations.

To sew utility stitches

Continue with chapter 3 to learn how to select a stitch and sew using the various stitches.

Chapter 1

To sew characters and patterns

Continue with chapter 4 to learn basic operations, from selecting patterns to sewing, in addition to

operations such as combining and editing patterns to rotate or resize them, and storing combined

patterns.

Chapter 1

• Parts related to operations described in the procedures are highlighted in gold.

Perform the operations while comparing the screens in the procedures with those that appear on the

machine.

Chapter 2

Chapter 2

Chapter 3

Chapter 4

• If, while using the machine, you have questions about an operation or you would like to know more

about a specific function, refer to the index (Page 147) and the table of contents to find the section of

the manual to refer to.

5

Page 7

CONTENTS

NAMES OF MACHINE PARTS AND THEIR

FUNCTIONS..........................................................9

Machine ..................................................................... 9

Needle and Presser Foot Section ............................... 10

Operation Buttons .................................................... 11

Included Accessories ................................................ 11

Options .................................................................... 16

Chapter 1 Getting Ready 17

TURNING THE MACHINE ON/OFF ....................18

LCD SCREEN .......................................................19

Using the Machine Setting Mode Key ...................... 22

Using the Machine Operation Mode Key ................. 23

Using the Pattern Explanation Key ........................... 24

LOWER/UPPER THREADING ..............................25

Winding the Bobbin ................................................. 25

Setting the Bobbin .................................................... 28

Pulling Up the Bobbin Thread .................................. 28

Upper Threading ...................................................... 29

Using the Twin Needle ............................................. 32

CHANGING THE PRESSER FOOT .......................34

Removing the Presser Foot ........................................ 34

Attaching the Presser Foot......................................... 34

CHANGING THE NEEDLE ...................................35

SEWING LARGE PIECES OF FABRIC....................38

Chapter 2 Sewing Basics 39

SEWING ..............................................................40

Sewing a Stitch ......................................................... 40

Sewing Reinforcement Stitches ................................. 42

Sewing Curves.......................................................... 42

Changing Sewing Direction ...................................... 43

Sewing Heavyweight Fabric...................................... 43

Sewing Lightweight Fabric ........................................ 43

ADJUSTING STITCH SETTINGS...........................44

Adjusting the Stitch Width ........................................ 44

Adjusting the Stitch Length ....................................... 44

Adjusting the Thread Tension ................................... 45

USEFUL FUNCTIONS..........................................45

Automatic Reinforcement Stitching ........................... 45

Automatic Thread Cutting......................................... 46

Pivoting .................................................................... 47

Automatic Fabric Sensor System

(Automatic Presser Foot Pressure) ............................. 48

Locking the Screen ................................................... 49

Chapter 3 Utility Stitches 51

SELECTING A UTILITY STITCH............................52

Selecting a Stitch ...................................................... 53

Saving Stitch Settings ................................................ 53

Using the Sewing Type Selection Key ...................... 54

SEWING THE STITCHES ......................................56

Quilting.................................................................... 56

Straight Stitches ........................................................ 66

Darts Seams.............................................................. 70

Gathering ................................................................. 71

Flat Fell Seams.......................................................... 71

Pintucks.................................................................... 72

Zigzag Stitches.......................................................... 73

Elastic Zigzag Stitches............................................... 75

Overcasting .............................................................. 76

Blind Hem Stitches ................................................... 80

Appliqués ................................................................. 81

Shell Tuck Stitching .................................................. 82

Scalloping................................................................. 82

Top Stitching............................................................. 83

Smocking.................................................................. 83

Fagoting.................................................................... 84

Tape or Elastic Attaching........................................... 85

Heirloom Stitching.................................................... 86

Buttonhole Stitches................................................... 88

Bar Tacks.................................................................. 93

Button Sewing........................................................... 95

Eyelets ...................................................................... 96

Multi-Directional Sewing

(Straight Stitch and Zigzag Stitch).............................. 97

Zipper Insertion ........................................................ 98

Chapter 4 Character/Decorative Stitches 101

SELECTING STITCH PATTERNS ........................ 102

Selecting Decorative Stitch Patterns/

7 mm Decorative Stitch Patterns/

Satin Stitch Patterns/

7 mm Satin Stitch Patterns/Cross Stitch Patterns/

Utility Decorative Stitch Patterns............................. 103

Alphabet Patterns.................................................... 103

SEWING STITCH PATTERNS............................. 105

Sewing Attractive Finishes....................................... 105

Basic Sewing........................................................... 105

Adjusting Patterns ................................................... 106

EDITING STITCH PATTERNS ............................ 108

Changing the Pattern Size ....................................... 109

Changing the Pattern Length

(7 mm Satin Stitch Patterns Only)............................ 109

Creating a Vertical Mirror Image............................. 109

Creating a Horizontal Mirror Image ........................ 109

Selecting a Single/Repeating Pattern........................ 110

Changing the Thread Density

(Satin Stitch Patterns Only)...................................... 110

Returning to the Beginning of the Pattern................ 111

COMBINING STITCH PATTERNS ..................... 112

Before Combining Patterns...................................... 112

Combining Patterns from Different Categories......... 112

Combining Stitch Patterns of Different Sizes............ 114

Combining Stitch Patterns of

Different Orientations ............................................. 115

Combining Stitch Patterns of Different Lengths........ 116

Creating Step Patterns

(7 mm Satin Stitch Patterns Only)............................ 117

USING THE MEMORY FUNCTION................... 119

Stitch Data Precautions........................................... 119

Saving Stitch Patterns in the Machine’s Memory ..... 119

Saving Stitch Patterns to the Computer.................... 121

Retrieving Stitch Patterns from the Machine’s

Memory.................................................................. 122

Retrieving Stitch Patterns from the Computer .......... 123

Chapter 5 Appendix 125

CARE AND MAINTENANCE ............................. 126

Cleaning the LCD ................................................... 126

Cleaning the Machine Casing ................................. 126

Cleaning the Race................................................... 126

Cleaning the Bobbin Case....................................... 127

ADJUSTING THE SCREEN................................. 128

Screen Visibility Is Low........................................... 128

Touch Panel Is Malfunctioning................................ 128

6

Page 8

TROUBLESHOOTING .......................................130

ERROR MESSAGES ............................................133

SPECIFICATIONS ...............................................136

UPGRADING YOUR MACHINE’S

SOFTWARE........................................................137

STITCH SETTING CHART ..................................139

INDEX................................................................147

1

2

3

4

5

7

Page 9

8

Page 10

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

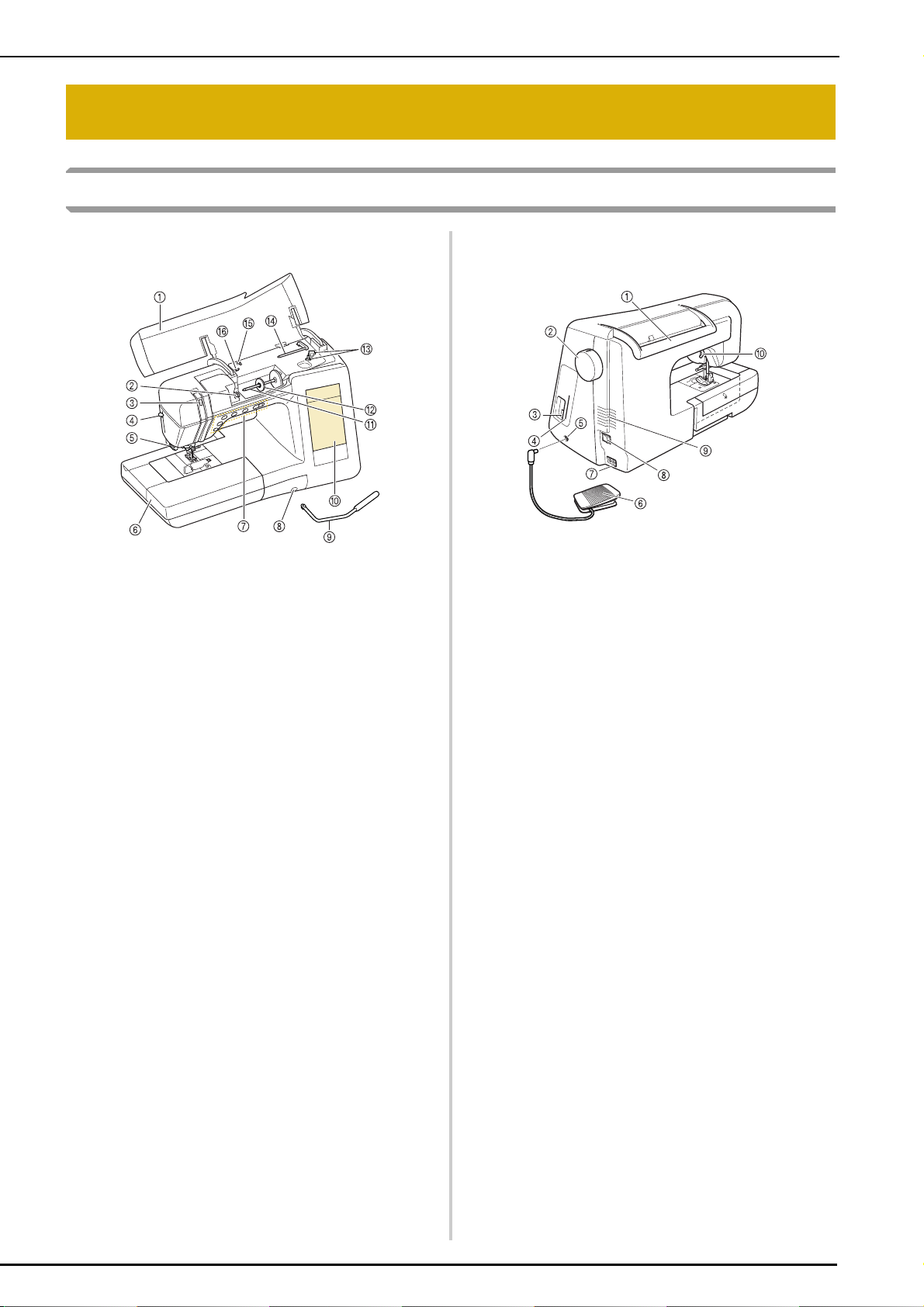

Machine

■ Front View

a Top cover

Open the top cover to thread the machine and wind the bobbin.

b Thread guide plate

Pass the thread around the thread guide plate when threading

the upper thread.

c Thread take-up lever check window

Look through the window to check the position of the take-up lever.

d Needle threader lever

Use the needle threader lever when threading the needle

automatically.

e Thread cutter

Pass the threads through the thread cutter to cut them.

f Flat bed attachment with accessory compartment

Store presser feet and bobbins in the accessory compartment

of the flat bed attachment. Remove the flat bed attachment

when sewing cylindrical pieces such as sleeve cuffs.

g Operation buttons (5 buttons) and sewing speed

controller

Use these buttons to perform various operations, such as

starting sewing and raising or lowering the needle.

Slide the sewing speed controller to adjust the sewing speed

while using utility stitches.

h Knee lifter slot

Insert the knee lifter into the slot.

i Knee lifter

Use the knee lifter to raise and lower the presser foot.

j LCD (liquid crystal display)

Stitch settings can be viewed and edited, and operations for

using the machine can be displayed, and error messages

appear in the LCD.

k Spool pin

Place a spool of thread on the spool pin.

l Spool cap

Use the spool cap to hold the spool in place.

m Bobbin winder

Use the bobbin winder when winding the bobbin.

n Supplemental spool pin

Use this spool pin to wind the bobbin thread while sewing or to

sew with the twin needle.

o Thread guide

Pass the thread through this thread guide when winding the

bobbin thread.

p Bobbin winding thread guide

Pass the thread around this thread guide when winding the

bobbin thread.

■ Right-side/Rear View

a Handle

When transporting the machine, carry it by this handle.

b Handwheel

Turn the handwheel toward you to sew one stitch or to raise or

lower the needle.

c USB connector

Plug in a USB cable to connect a computer.

d Touch pen holder

Use the touch pen holder to hold the touch pen when it is not

being used.

e Foot controller jack

Insert the plug on the end of the foot controller cord into the foot

controller jack.

f Foot controller

Press the foot controller to control the speed of the machine.

g Jack connector

Insert the power cord into the jack connector.

h Main power switch

Use the main power switch to turn the machine ON and OFF.

i Air vent

Do not cover the air vent while the sewing machine is being

used.

j Presser foot lever

Raise and lower the presser foot lever to raise and lower the

presser foot.

9

Page 11

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

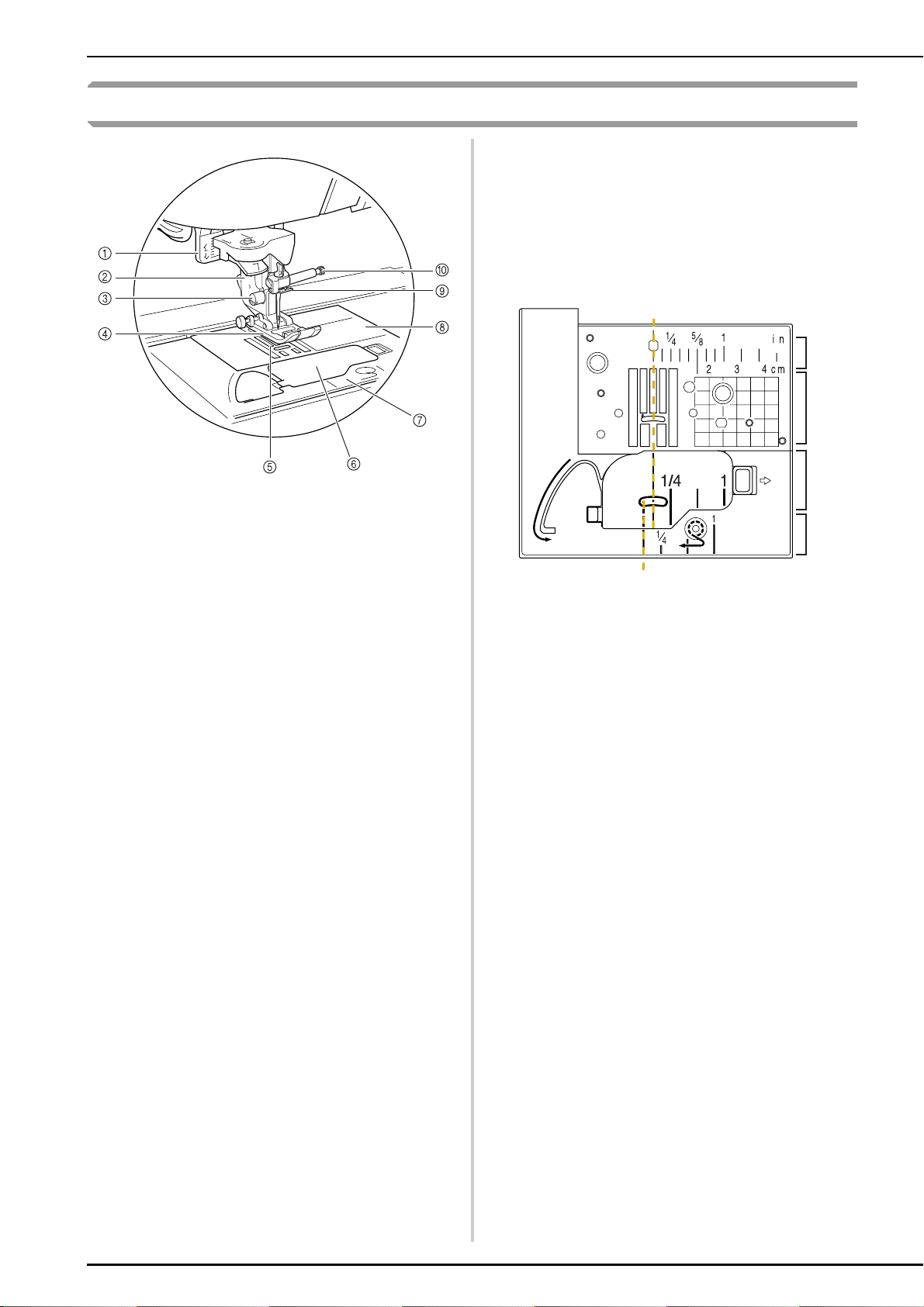

Needle and Presser Foot Section

Measurements on the needle plate, bobbin cover

and needle plate cover

The measurements on the needle plate and bobbin

cover are references for patterns with a middle

(center) needle position. The measurements on the

needle plate cover is a reference for stitches with a

left needle position.

a

c

d

a Buttonhole lever

Lower the buttonhole lever when sewing buttonholes and bar

tacks.

b Presser foot holder

The presser foot is attached to the presser foot holder.

c Presser foot holder screw

Use the presser foot holder screw to hold the presser foot

holder in place.

d Presser foot

The presser foot consistently applies pressure to the fabric as it

is sewn. Attach the appropriate presser foot for the selected

stitch.

e Feed dogs

The feed dogs feed the fabric in the sewing direction.

f Bobbin cover

Open the bobbin cover to insert the bobbin.

g Needle plate cover

Remove the needle plate cover to clean the bobbin case and

race.

h Needle plate

The needle plate is marked with guides to help sew straight

seams.

i Needle bar thread guide

Pass the upper thread through the needle bar thread guide.

j Needle clamp screw

Use the needle clamp screw to hold the needle in place.

e

f

b

a For stitches with a middle (center) needle position

b For stitches with a left needle position

c Middle (center) needle position <inch>

d Middle (center) needle position <cm>

e Middle (center) needle position <inch>

f Left needle position <inch>

10

Page 12

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

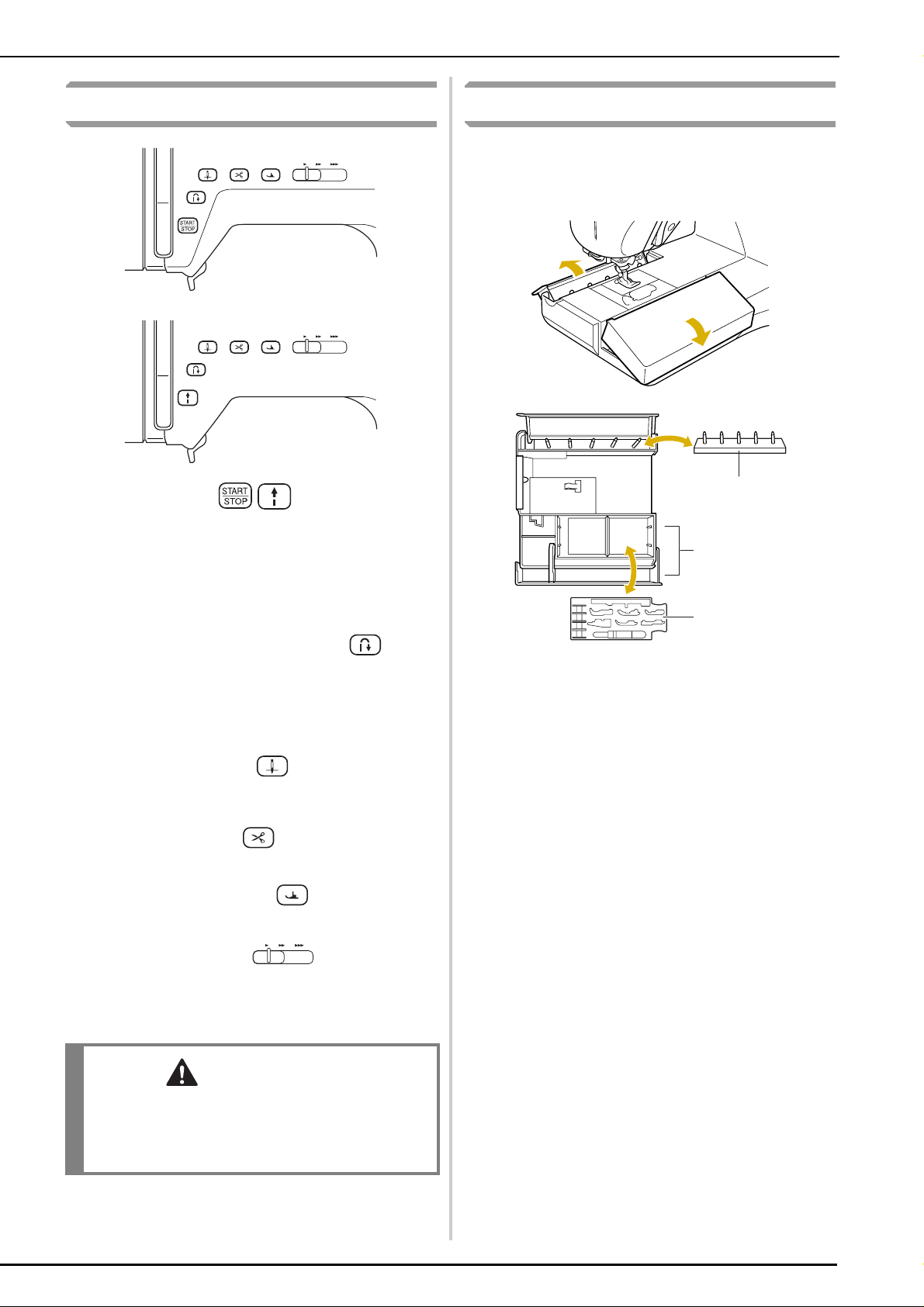

Operation Buttons

a “Start/Stop” button

When this button is pressed, the machine sews a few stitches at

a low speed, then begins sewing at the speed set by the sewing

speed controller. Press this button again to stop sewing. This

button lights up in a different color depending on the machine’s

operating condition.

Green: The machine is ready to sew or is sewing.

Red: The machine cannot sew.

Included Accessories

The accessories are stored in the flat bed

attachment. Open the flat bed attachment as

shown below.

a

b

c

b “Reverse/Reinforcement Stitch” button

This button is used to sew reinforcement stitches at the

beginning and end of stitching. When this button is pressed, the

machine sews 3 to 5 stitches in the same spot, then stops

automatically. For straight and zigzag stitches that take reverse

stitches, the machine sews reverse stitches (stitches sewn in

the opposite direction) at low speed only while the “Reverse/

Reinforcement Stitch” button is held down.

c “Needle Position” button

Use this button to change the sewing direction or for detailed

sewing in small areas. Press this button to raise or lower the

needle position. Press this button twice to sew a single stitch.

d “Thread Cutter” button

Press this button after sewing to automatically trim the excess

thread.

e “Presser Foot Lifter” button

Press this button to lower the presser foot and apply pressure to

the fabric. Press this button again to raise the presser foot.

f Sewing speed controller

Slide the sewing speed controller to the left or right to adjust the

sewing speed. Slide the controller to the left to sew at lower

speeds. Slide the controller to the right to sew at higher speeds.

Beginners should sew at a lower speed until they become

familiar with the machine.

CAUTION

• Do not press the “Thread Cutter” button after

the threads have already been cut. Otherwise,

the needle may break, the threads may become

tangled, or damage to the machine may occur.

a Bobbin stand

(Place the bobbins on the pins to store them.)

b Storage space

c Presser foot storage tray

(Store presser feet marked A, G, I, J, M, N, and R.)

11

Page 13

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

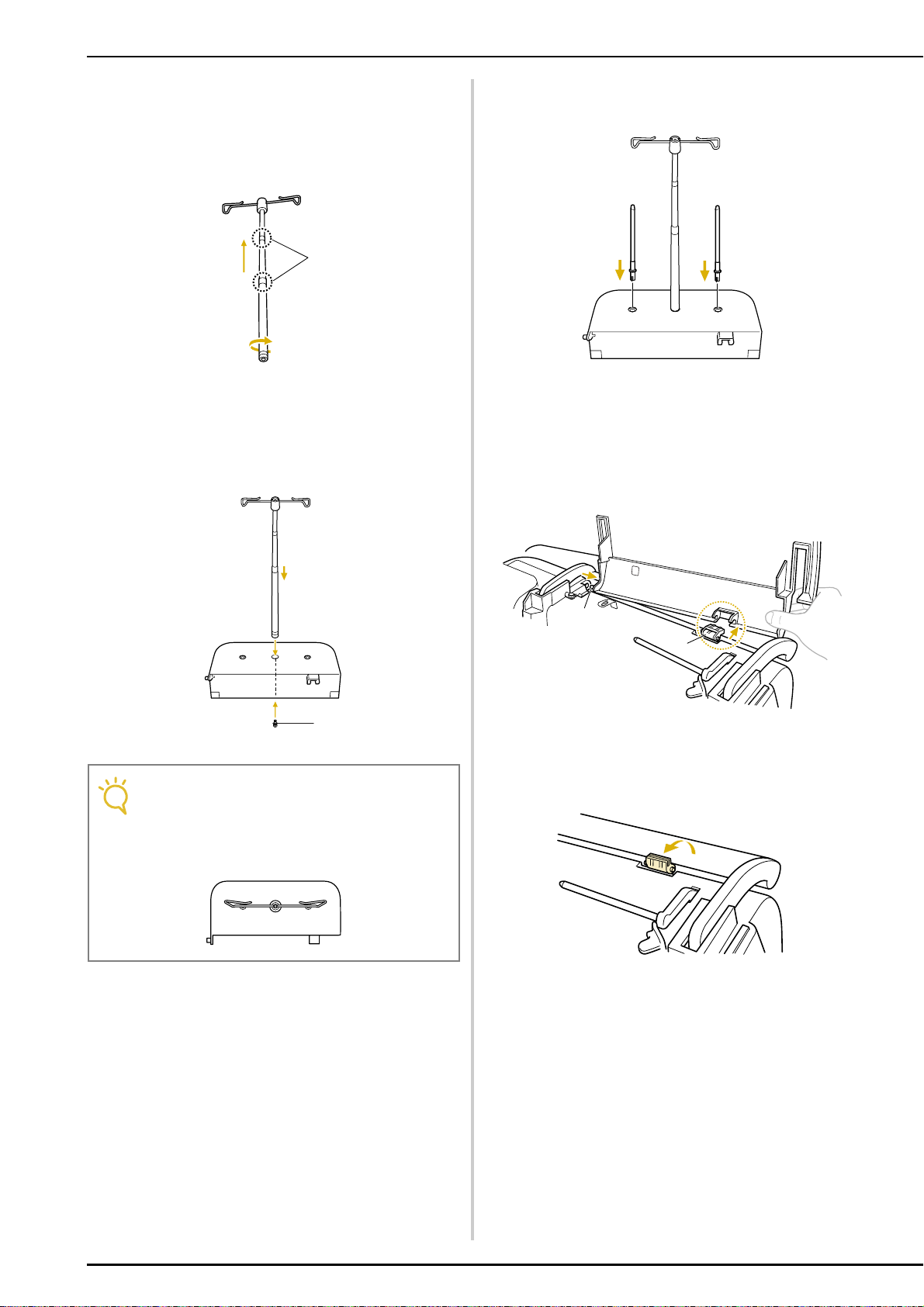

■ How to Assemble the Spool Stand

Fully extend the telescopic thread guide shaft,

a

and then rotate the shaft until the two stoppers

click into place.

a

a Stoppers

Insert the telescopic thread guide into the round

b

hole at the center of the spool support, and then

use a screwdriver to securely tighten the screw

from the reverse side.

Firmly insert the two spool pins into the two

c

holes in the spool support.

Open the upper cover of the machine. With

d

your right hand, snap the cover toward the back

to release the cover from the latch. Slide the

upper cover to the right so that the pin on the

left side is disengaged, and then remove the

upper cover.

a

a Screw

Note

Make sure that the stoppers on the telescopic thread

guide shaft are firmly in place and that the top of the

thread guide is parallel to the spool support. In addition,

check that the shaft is straight up from the spool support.

b

a

a Latch

b Pin

Raise the latch on the machine toward you.

e

12

Page 14

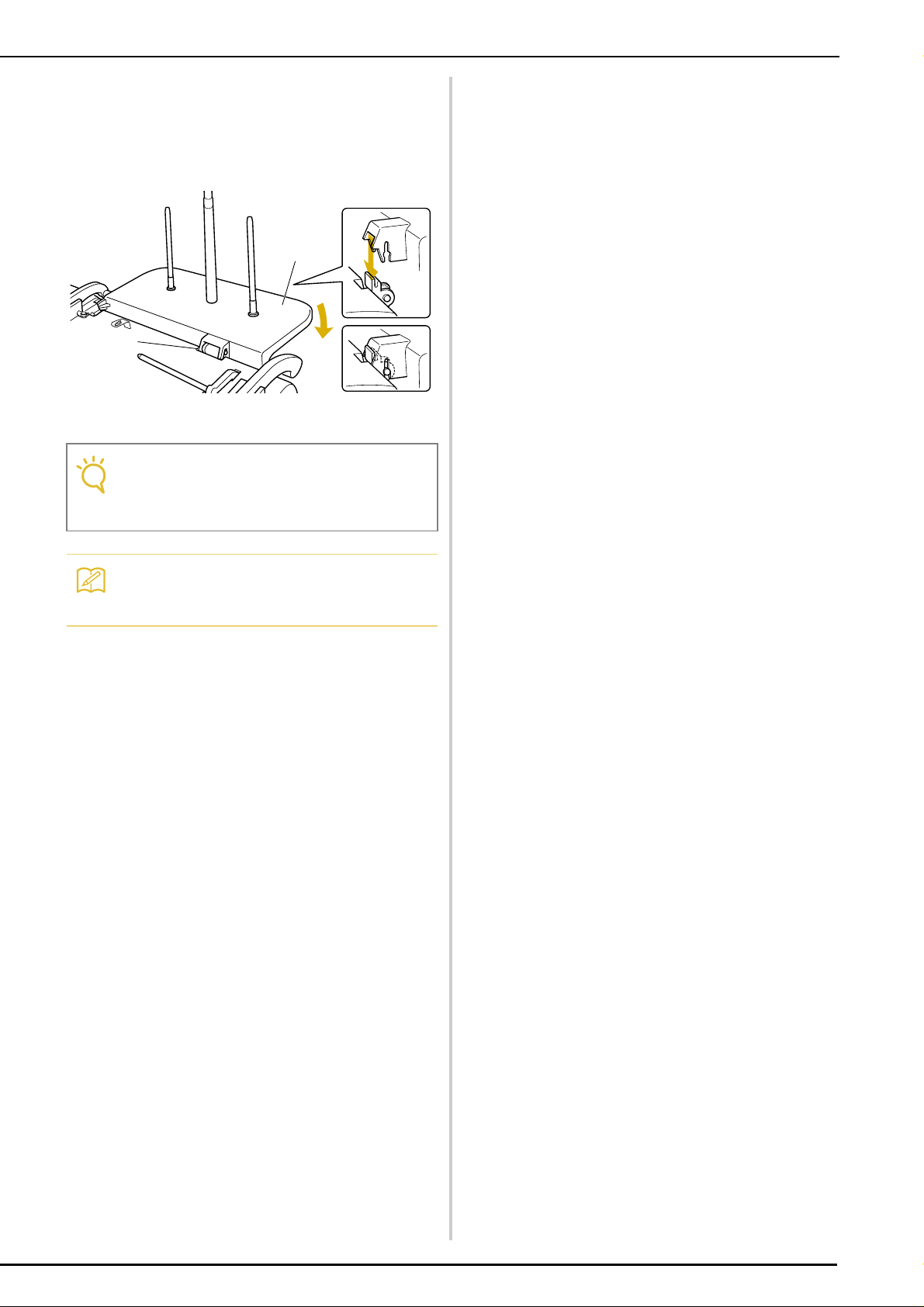

With the lower part of the stand between the

f

handle and machine, slide the spool stand to the

left so that the pin fits into the hole in the

machine, and then fit the spool stand into the

latch.

b

a

a Latch

b Spool stand

Note

Make sure that the latch of the machine is positioned

toward you and that the spool stand firmly fits into the

groove in the latch.

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

Memo

For details on using the spool stand, refer to the

enclosed instruction sheet.

13

Page 15

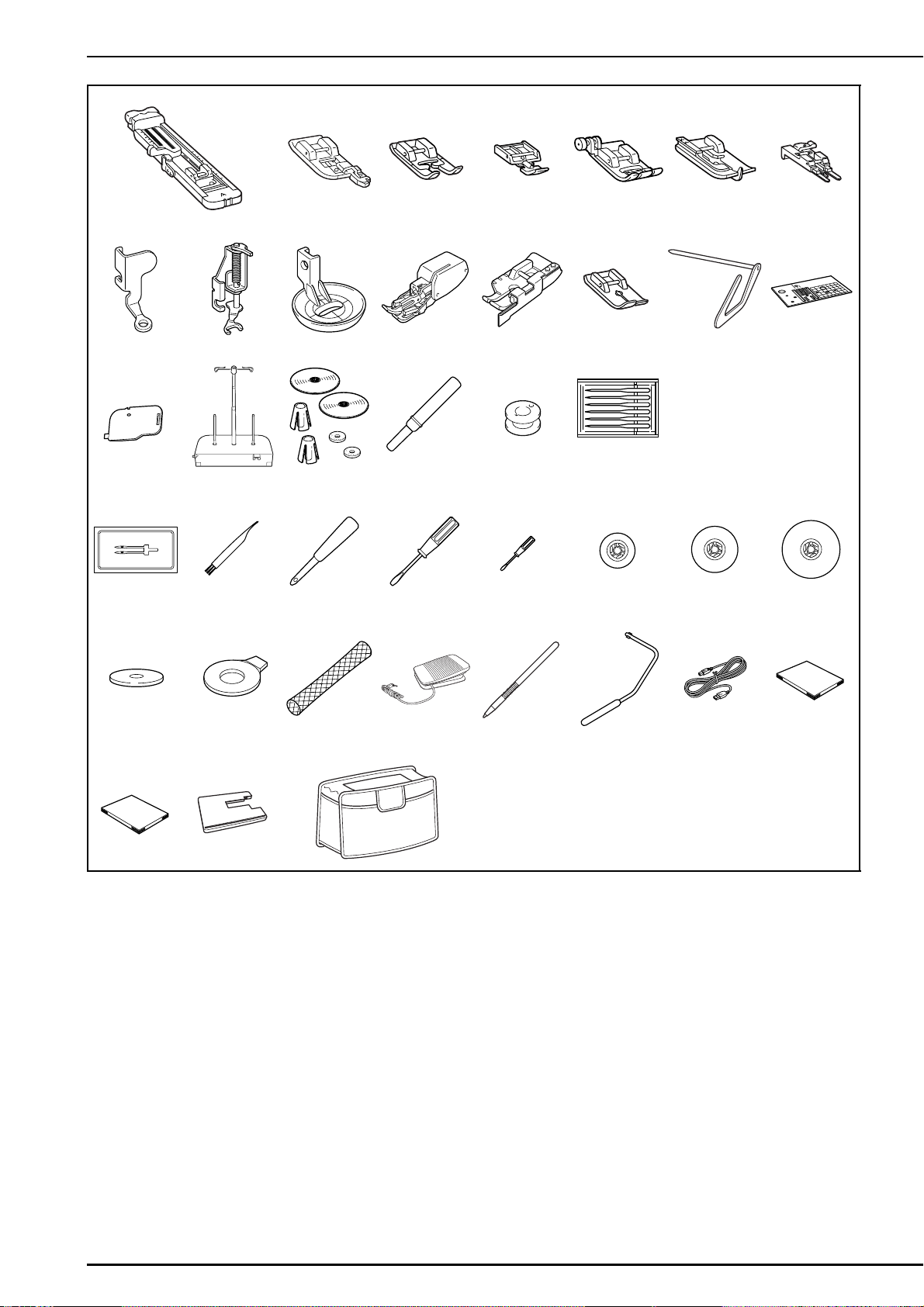

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

1 234567

8 9 10 11 12 13 14 15

16 17 18 19 20

75/11 2 needles

90/14 2 needles

90/14 2 needles:

Ball point needle (gold colored)

21 22 23 24 25 26 27 28

29 30 31 32 33 34 35 36

37 38 39

14

Page 16

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

No. Part Name Part Code

1 Buttonhole foot “A” X57789-151

2 Overcasting foot “G” XC3098-051

3 Monogramming foot “N” X53840-351

4 Zipper foot “I” X59370-051

5 Zigzag foot “J” (on machine) XC3021-051

6 Blind stitch foot “R” X56409-051

7 Button fitting foot “M” 130489-001

8 Free-motion quilting foot “C” XE0765-001

9 Free-motion open toe quilting foot

“O”

10 Free-motion echo quilting foot “E” XE0766-001

11 Walking foot XA8320-104

12 1/4” quilting foot with guide XC6800-251

13 Straight stitch foot XD0826-051

14 Quilting guide XA7208-001

15 Straight stitch needle plate XC8362-051

Cord guide bobbin cover

16

(with single hole)

17 Spool stand XE0774-001

18 Seam ripper X54243-051

19 Bobbin × 10 X52800-150

20 Needle set X58358-051

21 Twin Needle X59296-151

22 Cleaning brush X59476-051

23 Eyelet punch 135793-001

24 Screwdriver (large) XC8349-051

25 Screwdriver (small) X55468-051

26 Spool cap (small) × 2 130013-154

Spool cap (medium) × 2

27

One is on the machine.

28 Spool cap (large) × 2 130012-054

29 Spool felt X57045-051

30 Disc-shaped screwdriver XC1074-051

31 Spool net XA5523-050

32 Foot controller XC8816-051

33 Touch pen (stylus) XA9940-051

34 Knee lifter XA6941-052

35 USB cable XD0745-051

36 Instruction and Reference Guide XE1070-001

37 Quick Reference Guide XE1071-001

38 Extension table XE0796-001

39 Soft cover XE1123-001

XE0767-001

XC8449-051

X55260-153

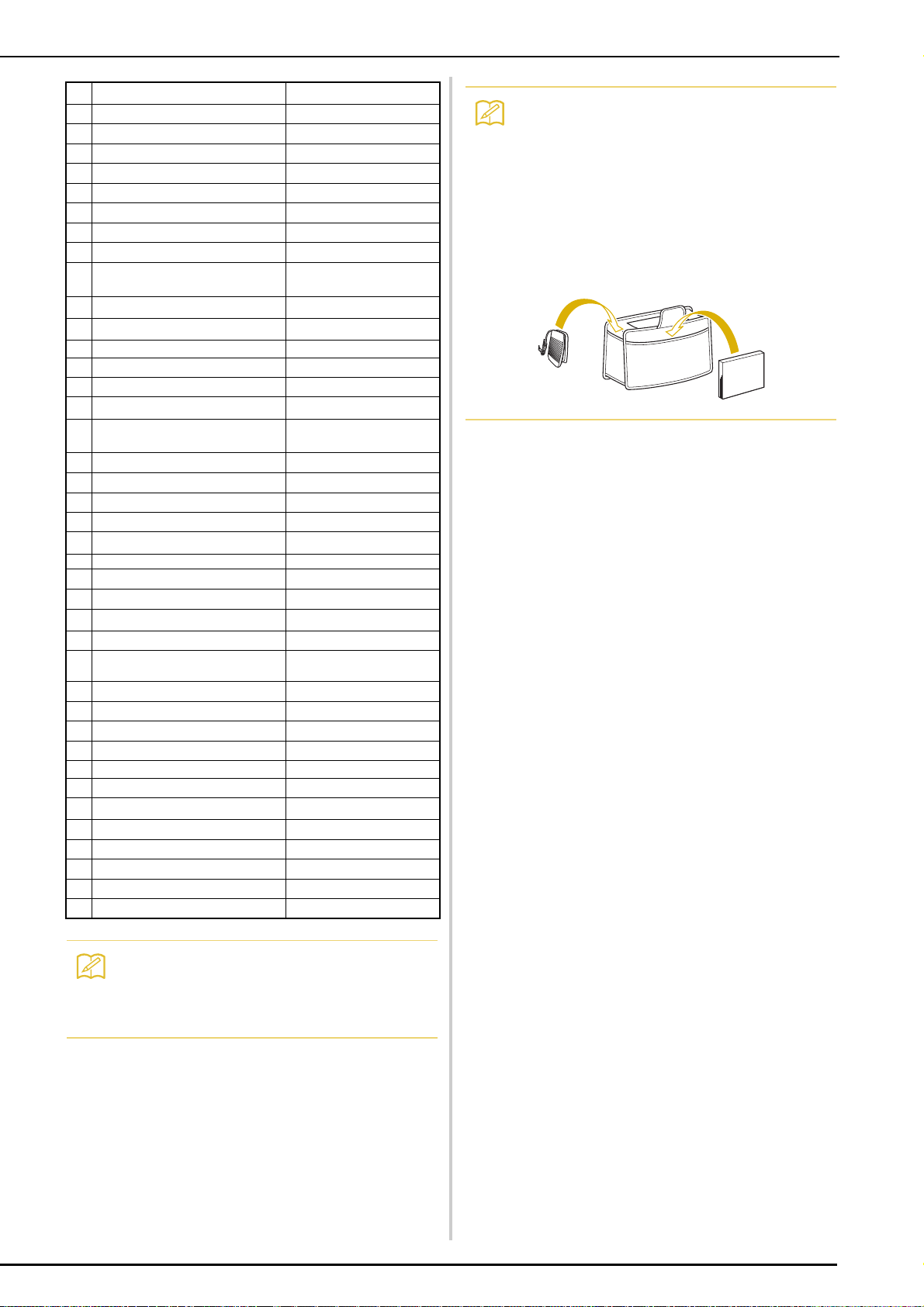

Memo

• For details on using parts 13, 17 and 38, refer to the

instruction sheet enclosed with item.

• Always use accessories recommended for this

machine.

• The screw for the presser foot holder is available

through your authorized retailer (part code: XA4813-

051).

• This instruction and reference guide and the foot

controller can be stored in the soft cover.

Memo

(For U.S.A. only)

Foot controller: Model T

This foot controller can be used with this machine

model BLSR.

15

Page 17

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

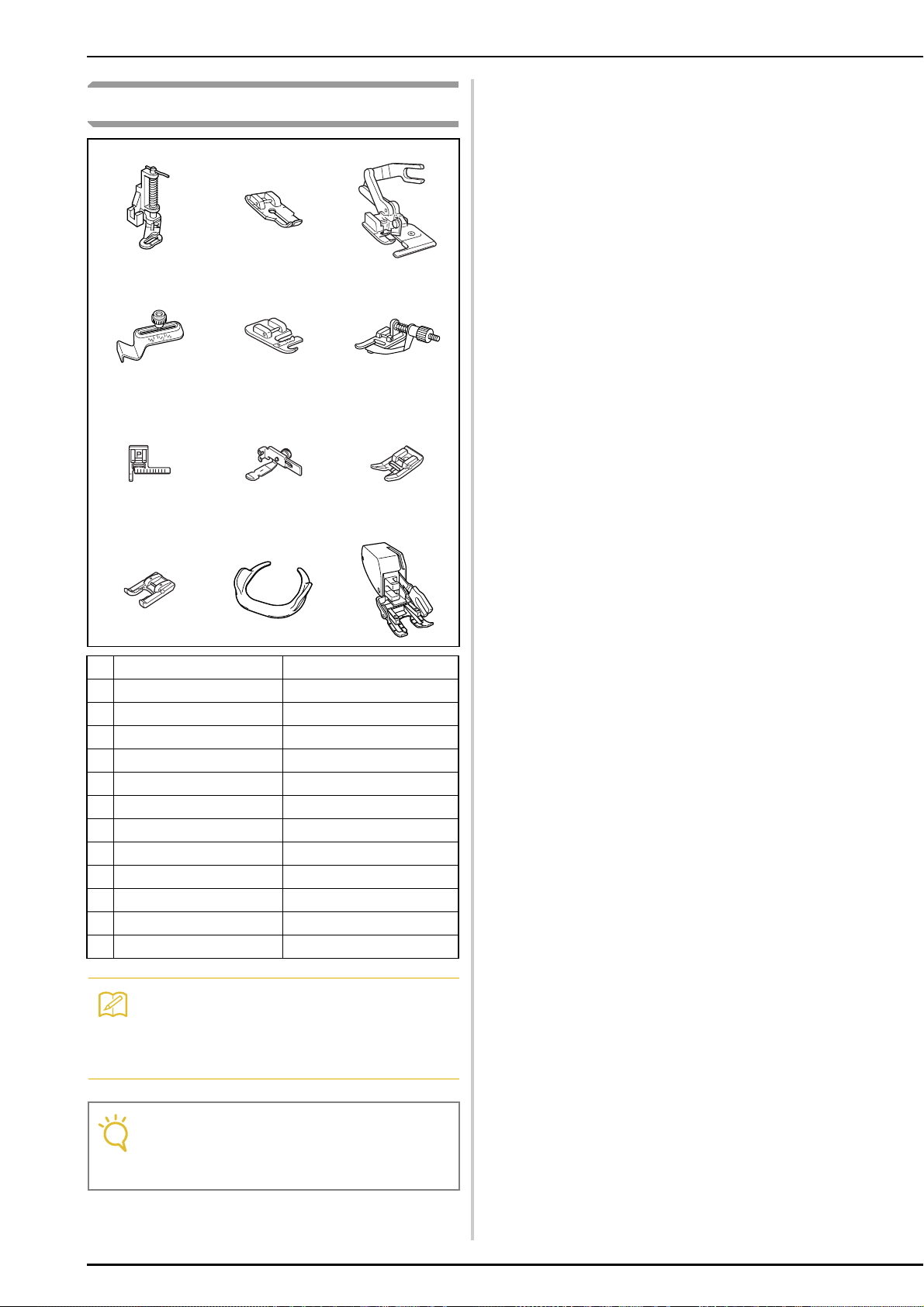

Options

123

456

789

10 11 12

No. Part Name Part Code

1

Quilting foot FA2

2

1/4” quilting foot FA1

3 Side cutter foot FA10

4 Seam guide BLG-SG

5 Cording foot (3 cord guide) XA6871-001

6 Blind stitch foot (with guide) XA0059-001

7 Stitch guide foot “P” FA6

8 Adjustable zipper/piping foot FA9

9 Non stick foot FA8

10 Open toe foot FA7

11 Free-motion grip * See note.

12 Open toe walking foot * See note.

16

Memo

• All specifications are correct at the time of printing.

• Please be aware that some specifications may

change without notice.

Note

Visit your authorized Baby Lock retailer for complete

listing of optional accessories available for your

machine.

Page 18

Chapter 1

Getting Ready

1

TURNING THE MACHINE ON/OFF....................................................18

LCD SCREEN........................................................................................19

■ Display Precautions.........................................................................................................19

■ Key Functions..................................................................................................................20

Using the Machine Setting Mode Key......................................................................22

Using the Machine Operation Mode Key ................................................................ 23

■ Contents of Each Category ..............................................................................................23

Using the Pattern Explanation Key ..........................................................................24

LOWER/UPPER THREADING..............................................................25

Winding the Bobbin ................................................................................................25

■ Using the Supplemental Spool Pin...................................................................................25

■ Winding the Bobbin Using the Spool Pin.........................................................................27

Setting the Bobbin................................................................................................... 28

Pulling Up the Bobbin Thread ................................................................................. 28

Upper Threading ..................................................................................................... 29

Using the Twin Needle ............................................................................................ 32

CHANGING THE PRESSER FOOT .......................................................34

Removing the Presser Foot ......................................................................................34

Attaching the Presser Foot ...................................................................................... 34

CHANGING THE NEEDLE...................................................................35

■ Checking the Needle .......................................................................................................35

■ About the Needle ............................................................................................................37

■ Fabric/Thread/Needle Combinations ..............................................................................37

SEWING LARGE PIECES OF FABRIC ...................................................38

Page 19

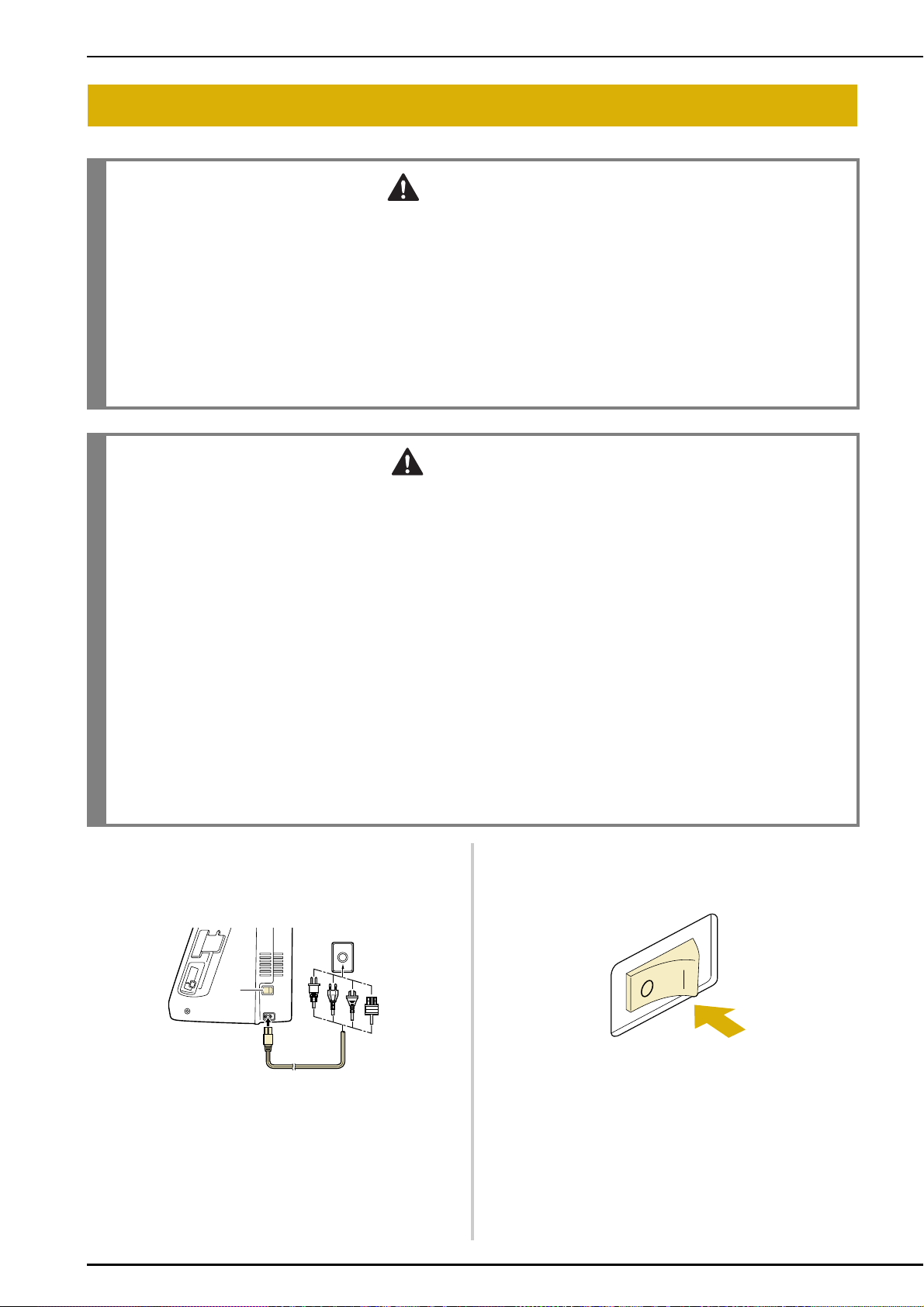

TURNING THE MACHINE ON/OFF

TURNING THE MACHINE ON/OFF

WARNING

• Use only regular household electricity as the power source. Using other power sources may result in fire, electric

shock, or damage to the machine.

• Make sure that the plugs on the power cord are firmly inserted into the electrical outlet and the power supply jack on

the machine.

• Do not insert the plug on the power cord into an electrical outlet that is in poor condition.

• Turn the main power to OFF and remove the plug in the following circumstances:

• when you are away from the machine

• after using the machine

• when the power fails during use

• when the machine does not operate correctly due to a bad connection or a disconnection

• during electrical storms

CAUTION

• Use only the power cord included with this machine.

• Do not use extension cords or multi-plug adapters with many other appliances plugged in to them. Fire or electric

shock may result.

• Do not touch the plug with wet hands. Electric shock may result.

• When unplugging the machine, always turn the main power to OFF first. Always grab the power cord plug or power

cord connector to remove it from the wall outlet or power cord jack connector. Pulling on the cord may damage the

cord, or lead to fire or electric shock.

• Do not allow the power cord to be cut, damaged, modified, forcefully bent, pulled, twisted, or bundled. Do not place

heavy objects on the cord. Do not subject the cord to heat. These things may damage the cord, or cause fire or electric

shock. If the cord or plug is damaged, take the machine to your authorized retailer for repairs before continuing use.

• Unplug the power cord if the machine is not to be used for a long period of time. Otherwise, a fire may result.

• When leaving the machine unattended, either the main switch of the machine should be turned to OFF or the plug

must be removed from the socket-outlet.

• When servicing the machine or when removing covers, either the machine or the electrical set must be unplugged.

• For U.S.A. only

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electrical shock, this plug is

intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install

the proper outlet. Do not modify the plug in any way.

18

Insert the power cord into the power cord

a

jack connector, then insert the plug into a

wall outlet.

a

b

a Main power switch

b Power cord

Turn the main power switch to “I” to turn on

b

the machine.

b

a

a OFF

b ON

Turn the main power switch to “O” to turn

c

off the machine.

Page 20

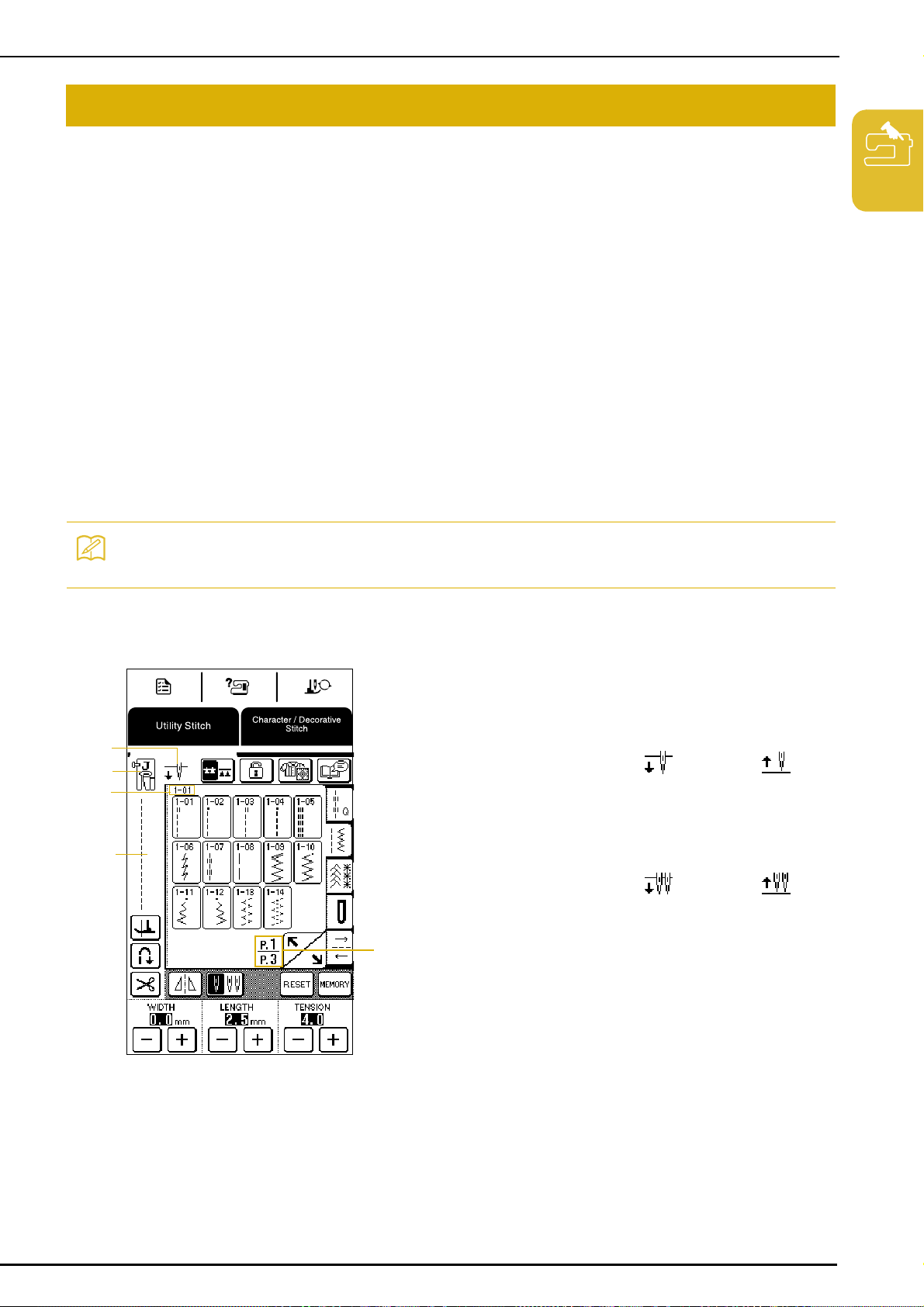

LCD SCREEN

LCD SCREEN

■ Display Precautions

• Only touch the display with your finger or the touch pen included with the machine. Do not use a

mechanical pencil, screwdriver or any other hard or sharp objects. In addition, do not press the display with

extreme pressure, otherwise damage to the display may result.

• All or part of the display may sometimes become darker or lighter due to fluctuations in the surrounding

temperature or other changes in the environment. This is not a sign of a malfunction. If the display is difficult

to read, adjust its brightness (see page 22).

• The display may be dark immediately after the machine is turned on. This is a normal characteristic of the

backlight and is not a sign of a malfunction. After approximately 10 minutes, the display should reach its

normal level of brightness.

• If you are not directly facing the display, the colors may be distorted or the screen may be difficult to read.

This is a normal characteristic of the display and is not a malfunction. Be sure to sit in front of the display

while using it.

When the machine is turned on, the opening screen appears. The machine can be set so that the opening screen is

not displayed (see page 22).

Lightly press the display with your finger. Depending on the setting, either “Q-01 Piecing stitch (Middle)”, “1-01

Straight stitch (Left)” or “1-03 Straight stitch (Middle)” is automatically selected (see page 22).

1

Getting Ready

Memo

It may take some time until the opening screen appears. This is not a sign of a malfunction.

a Shows whether the machine is set for a single needle

or twin needle, and the needle position when the

machine is stopped. The desired needle position can

be set (see page 22).

For a single needle

a

b

c

d

e

For a twin needle

b Presser foot code

Attach the indicated presser foot before sewing.

c Shows the number for the selected stitch (only for

utility stitches).

d Shows a preview of the selected stitch.

e Shows the current page number and the total number

of pages available in the category selected.

Single needle/down

position

Twin needle/down

position

Single needle/up

position

Twin needle/up

position

19

Page 21

LCD SCREEN

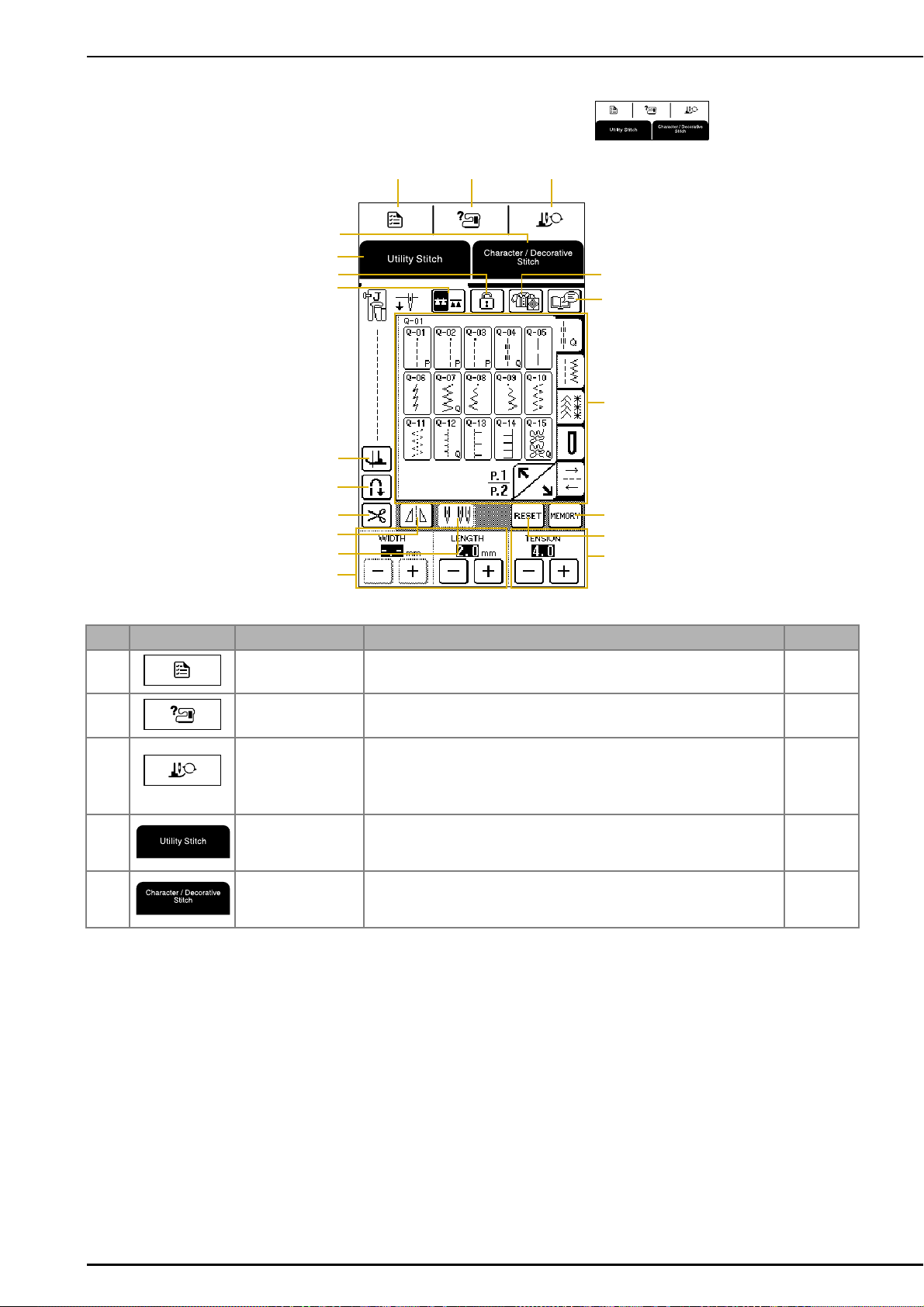

■ Key Functions

With your finger or the touch pen, press a key at the top of the display (

screen that is displayed.

1

2

3

5

4

g

f

k

l

m

n

o

r

h

i

j

q

p

s

) to change the

Operation panel

No. Key Name Function Page

1

2

3

4

5

Machine setting mode

key

Machine operation

mode key

Presser foot / Needle

exchange key

Utility stitch key Press this key to select a straight stitch, zigzag stitch, buttonhole, blind hem

Character/Decorative

Stitch key

Press this key to change the needle stop position, turn the buzzer on/off, adjust

the pattern or screen, and change other machine settings.

Press this key to see descriptions for upper threading, winding the bobbin,

changing the presser foot, and other operations for using the machine.

Press this key when changing the needle or presser foot. Pressing this key locks

all keys and operation buttons so that parts can safely be changed. Press this key

again to unlock the keys and buttons.

When machine operations are displayed, the screen for the needle/presser foot

replacement mode is not displayed.

stitch, or other stitch (utility stitch) commonly used in quilting or garment sewing.

Press this key to select character or decorative stitches. 102

22

23

34, 35

52

20

Page 22

LCD SCREEN

Screen

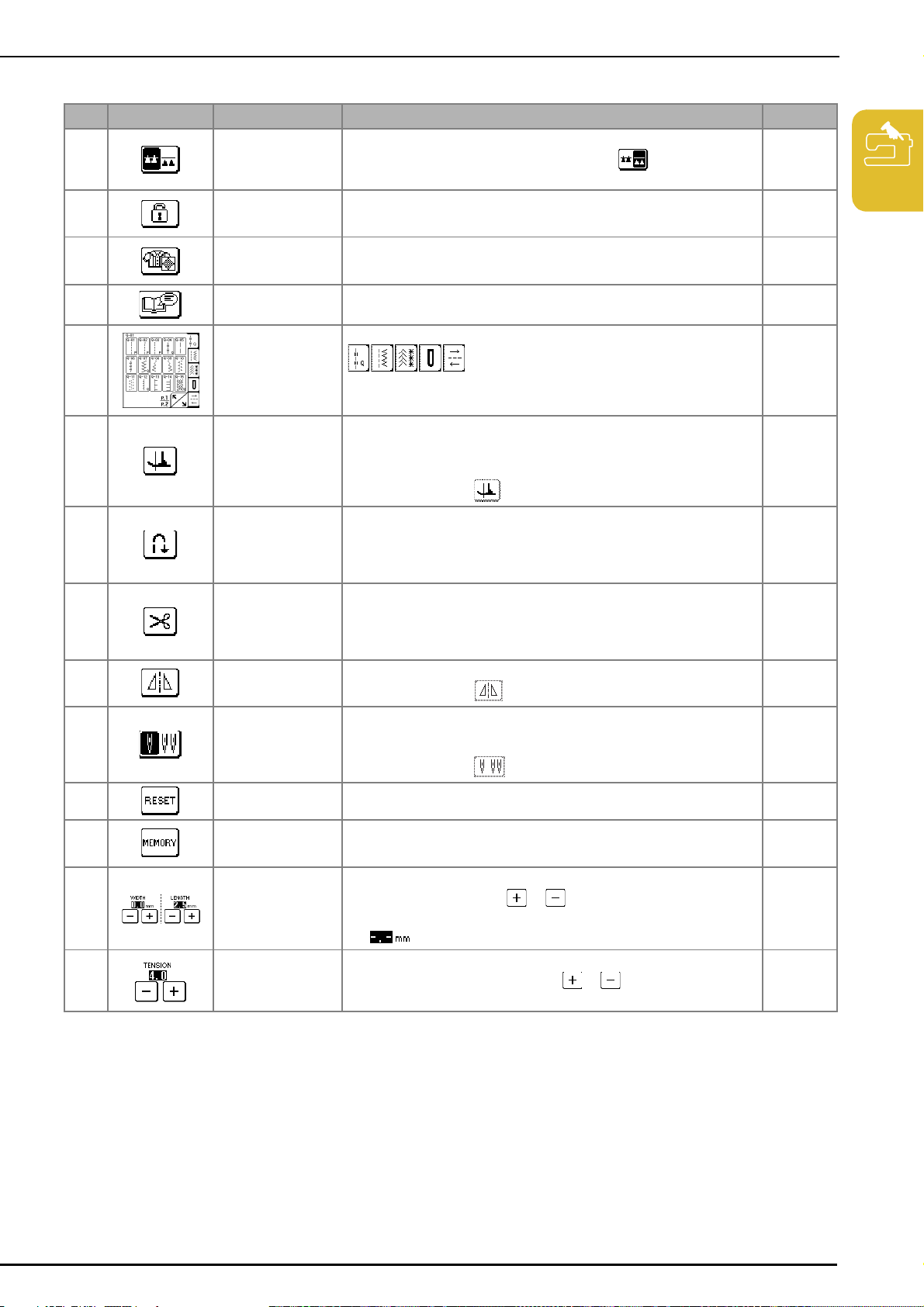

No. Key Name Function Page

f

g

h

i

Drop feed key For free-motion sewing, press this key to lower the feed dogs (free-motion sewing

mode). In addition, the key automatically appears as and the feed dogs

are lowered when button sewing is selected.

Screen lock key Press this key to lock the screen. When the screen is locked, the various settings,

Sewing type selection

key

Pattern explanation key Press this key to see how the selected stitch can be used. 24

such as the stitch width and stitch length, are locked and cannot be changed.

Press this key again to unlock the settings.

Press this key when you need help selecting the appropriate stitch for the sewing

application and when you need instructions on how to sew the selected stitch.

This key is very helpful for beginners.

62, 95

49

54

1

Getting Ready

j

k

l

m

n

o

p

Stitch selection display Press the key for the stitch that you want to sew. Press one of the

keys to change the pattern selection screen.

Pivot key Press this key to select the pivot setting. When the pivot setting is selected,

Automatic

reinforcement stitch key

Automatic thread

cutting key

Mirror image key Press this key to create a mirror image of the selected stitch.

Needle mode selection

key (single/twin)

Reset key Press this key to return the selected stitch saved settings to the original settings. 53

stopping the machine lowers the needle and slightly raises the presser foot

automatically. In addition, when sewing is restarted, the presser foot is

automatically lowered.

• If this key appears as , it cannot be used.

Press this key to select the automatic reinforcement stitching (reverse stitching)

setting. If you select this setting before sewing, the machine will automatically

sew reinforcement stitches at the beginning and end of stitching (depending on

the selected stitch, reverse stitches may be sewn). Press this key again to cancel

the setting.

Press this key to select the automatic thread cutting setting.

If you select this setting before sewing, the machine will automatically sew

reinforcement stitches (or reverse stitches, depending on the selected stitch) and

trim the threads when the “Reverse/Reinforcement Stitch” button is pressed.

Press this key again to cancel the setting.

• If this key appears as , it cannot be used.

Before sewing with the twin needle, press this key to select the setting for twin

needle sewing. Each time this key is pressed, the setting switches between that

for single needle sewing and twin needle sewing.

• If this key appears as , it cannot be used.

52

47

45

46

53

32

q

r

s

Manual memory key Change the stitch settings (zigzag width and stitch length, thread tension,

Stitch width and stitch

length keys

Thread tension keys Shows the thread tension setting of the currently selected stitch. The thread

automatic thread cutting or automatic reinforcement stitching, etc.), then save

them by pressing this key.

Shows the stitch width (zigzag width) and the stitch length settings of the

currently selected stitch. Press or to adjust the stitch width and stitch

length settings.

• If appears, the setting cannot be adjusted.

tension is usually set automatically. Press or to adjust the thread

tension setting.

53

44

45

21

Page 23

LCD SCREEN

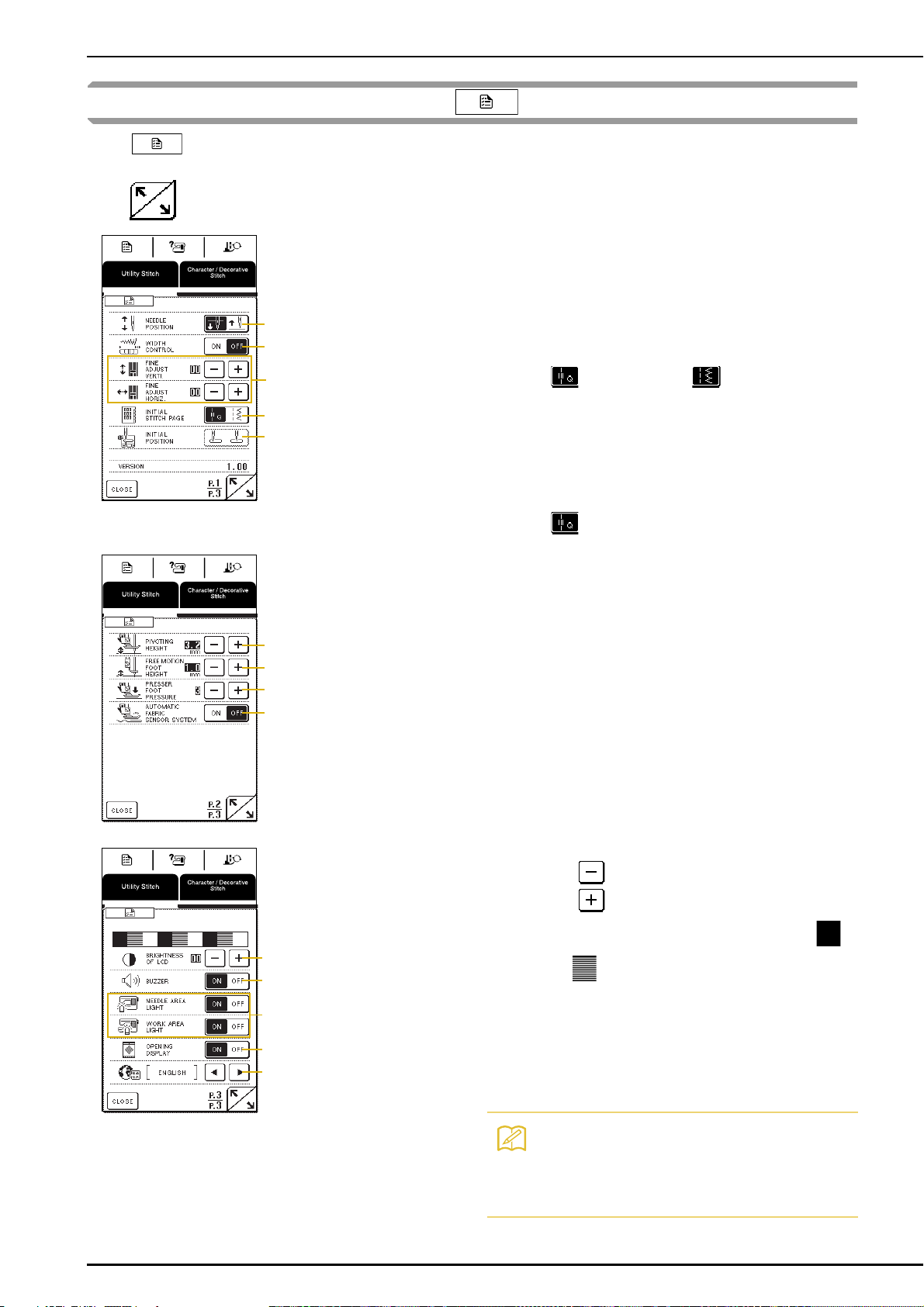

Using the Machine Setting Mode Key

Press to change the needle stop position, turn the buzzer on/off, adjust the pattern or screen, and change

other basic machine settings. The settings specified here are the default settings.

Press to display the previous or next page.

a Select whether the needle stops in the raised or

lowered position when the machine is stopped.

b Select whether to use the sewing speed controller or

to adjust the zigzag width (see page 61).

a

b

c

d

e

c Make adjustments to the character and decorative

stitches (see page 106).

d Select whether the screen containing quilting stitches

( ) or utility stitches ( ) is the first screen that

is displayed.

e Select whether “1-01 Straight stitch (Left)” or “1-03

Straight stitch (Middle)” is the utility stitch that is

automatically selected when the machine is turned

on.

Cannot be selected if the quilting stitch category

( ) is selected for “INITIAL STITCH PAGE”.

a

b

a

b

c

d

a Change the height of the presser foot when sewing is

stopped when the pivot setting is selected (see page

47). Adjust the presser foot to one of the three heights

(3.2 mm, 5.0 mm and 7.5 mm).

b Change the height of the presser foot when the

machine is set to free-motion sewing mode (see page

62).

c Adjust the presser foot pressure between 1 (light) and

4 (firm).

* Set the pressure to 3 for normal sewing.

d When set to “ON”, the thickness of the fabric is

automatically detected by an internal sensor while

sewing, so the fabric can be fed smoothly (see pages

43, 48 and 62).

When “PRESSER FOOT PRESSURE” is set to “1”,

this function is not available even if it is set to “ON”.

a Adjust the brightness of the display.

* Press to make the screen lighter.

* Press to make the screen darker.

Adjust the brightness so that the contrast between

and can be clearly seen.

22

c

d

e

b Turn on/off the buzzer.

c Turn on/off the needle area and work area lights.

d Select whether or not the opening screen appears

when the machine is turned on.

e Select one of the 3 display languages:

[English], [French], [Spanish]

Memo

The latest version of software is installed in your

machine. Check with your local authorized Baby Lock

or our web site (www.babylock.com) for notification of

available updates (see page 137).

Page 24

LCD SCREEN

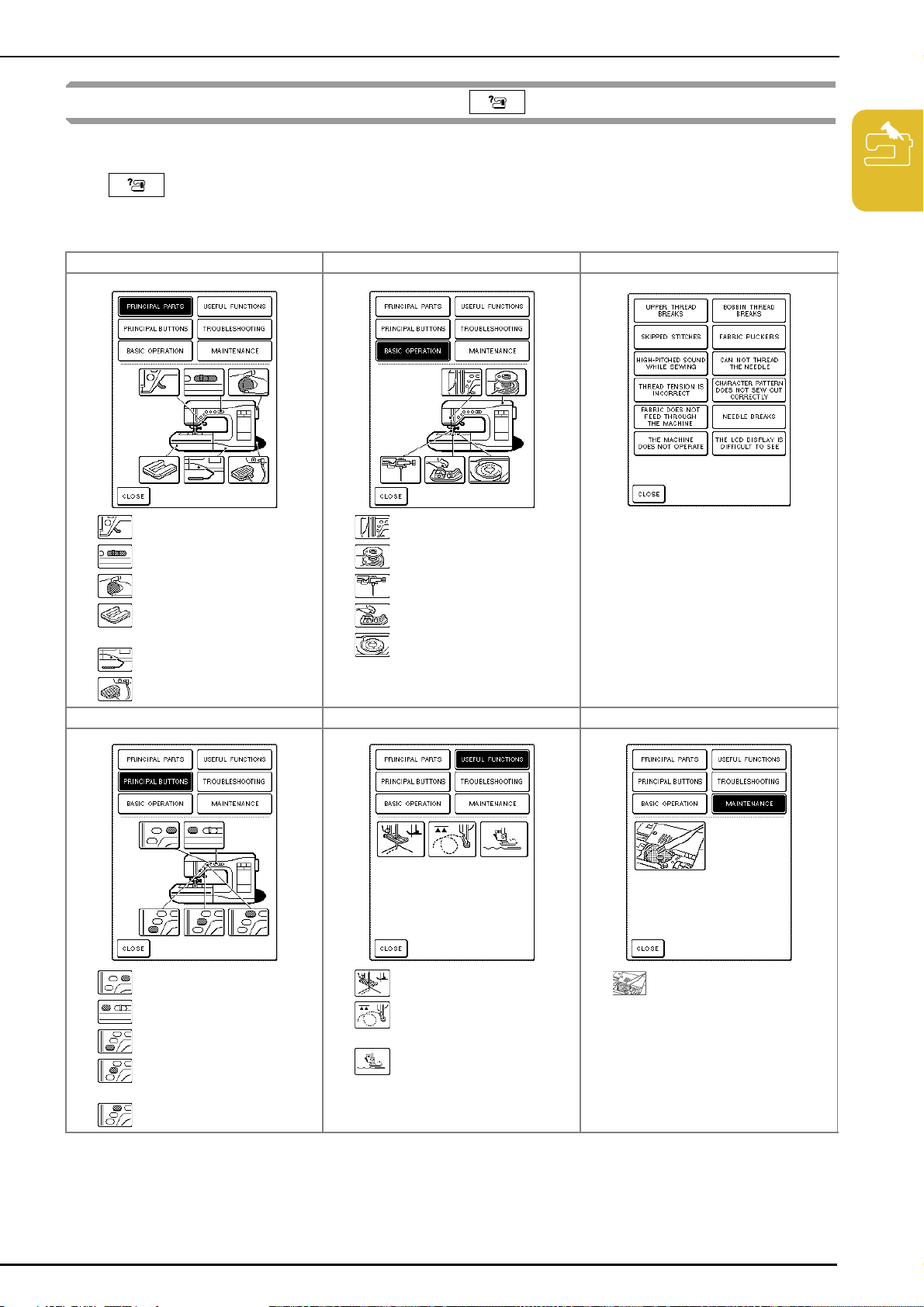

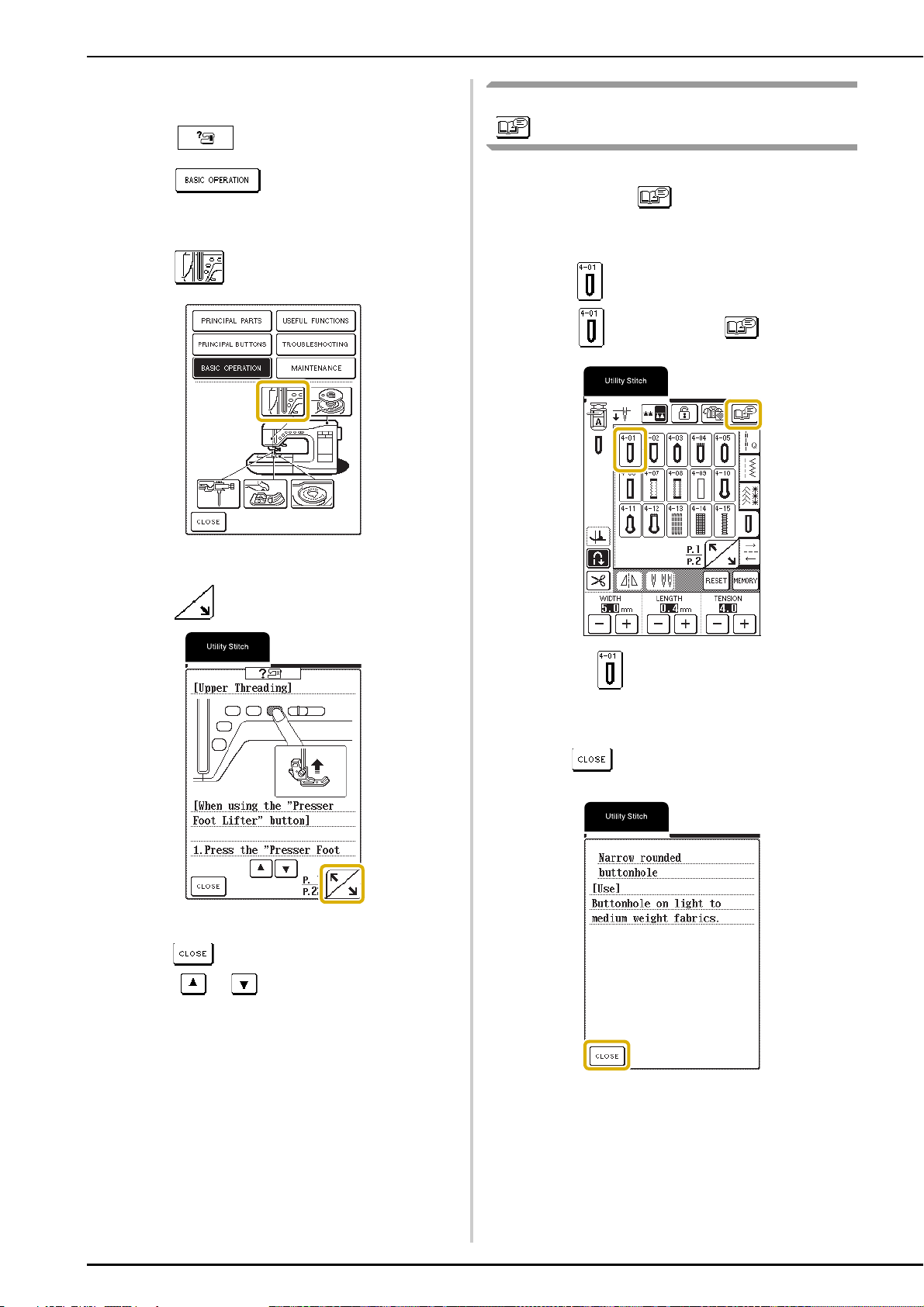

Using the Machine Operation Mode Key

Basic machine operations and other information based on the contents of this Operation Manual are stored in this

machine.

Press to open the screen shown below. Six categories are displayed at the top of the screen. Press a key to

see more information about that category.

■ Contents of Each Category

Names of Machine Parts and Their Functions Sewing Basics Troubleshooting

Presser foot lever

Sewing speed controller

Handwheel

Flat bed attachment with

accessory compartment

Knee lifter

Upper threading

Bobbin winding

Changing the needle

Changing the presser foot

Setting the bobbin

1

Getting Ready

Foot controller

Main Buttons Useful Functions Maintenance

“Thread Cutter” button

“Presser Foot Lifter” button

“Start/Stop” button

“Reverse/Reinforcement Stitch”

button

“Needle Position” button

Pivoting

Automatic drop feed

(Free-motion mode)

Automatic fabric sensor system

(Automatic Presser Foot Pressure)

Cleaning the Race and Shuttle

23

Page 25

LCD SCREEN

Example: Displaying information about upper

threading

Press .

a

Press .

b

→ A list of basic operations appears in the lower half of

the screen.

Press (upper threading).

c

Using the Pattern Explanation Key

To learn more about the uses for a stitch, select the

stitch, and then press to see a description of the

selected stitch.

Example: Displaying information on the use for

.

Select , and then press .

a

→ The instructions for threading the machine appear.

Press to view the next page.

d

When you are finished with the instructions,

e

press .

→ Press or to scroll through additional

information for that page.

→ Uses for appear.

When you are finished with the instructions,

b

press .

24

Page 26

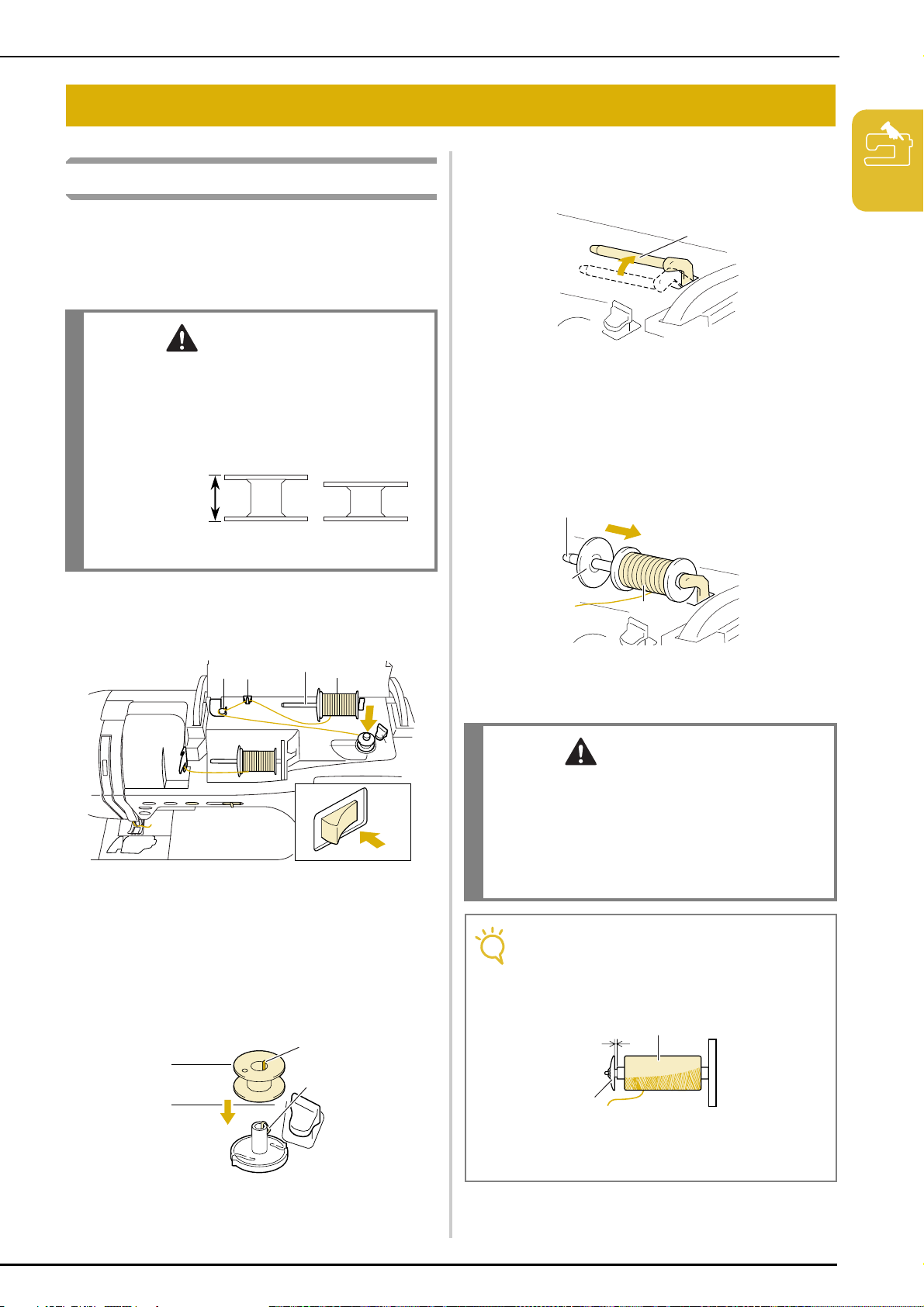

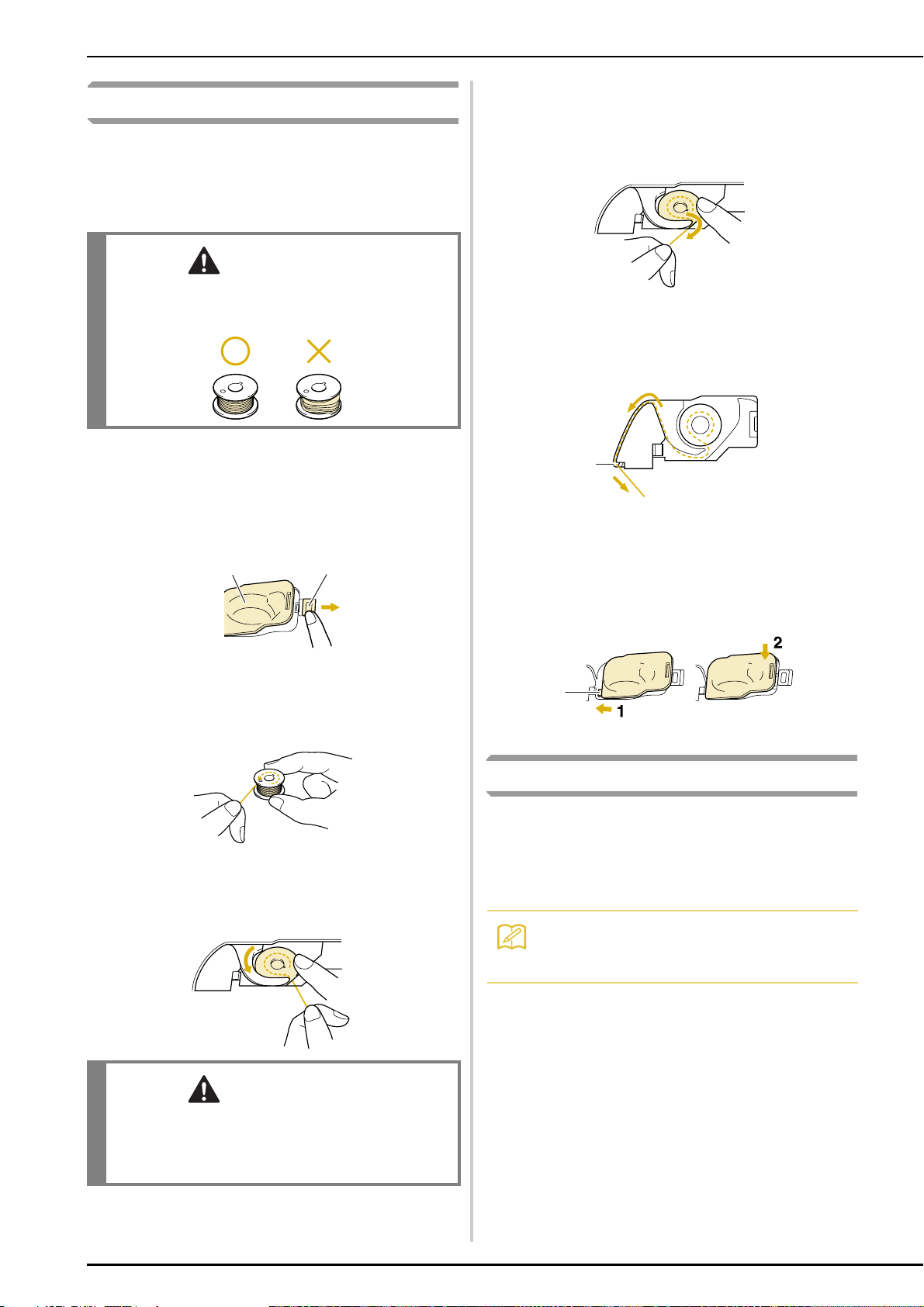

LOWER/UPPER THREADING

Winding the Bobbin

This section describes how to wind thread onto a

bobbin. With this machine, you can use the

supplemental spool pin to wind the bobbin while

sewing using the main spool pin.

CAUTION

• The included bobbin was designed specifically for

this sewing machine. If bobbins from other models

are used, the machine will not operate correctly.

Use only the included bobbin or bobbins of the same

type (part code: X52800-150).

Actual size

11.5 mm

(approx.

7/16 inch)

This model Other models

LOWER/UPPER THREADING

Set the supplemental spool pin in the “up”

c

position.

a

a Supplemental spool pin

Place the spool of thread on the supplemental

d

spool pin so that the thread unwinds from the

front. Then, slide the spool cap as far as

possible onto the supplemental spool pin to

secure the thread spool.

a

1

Getting Ready

■ Using the Supplemental Spool Pin

While sewing, the bobbin can conveniently be

wound.

56

a

3, 4

7, 8

o

a Supplemental spool pin

Turn on the machine, and then open the top

a

cover.

Align the groove in the bobbin with the spring

b

on the bobbin winder shaft, and then set the

bobbin on the shaft.

a

b

c

a Supplemental spool pin

b Spool cap

2

9,10

l

1

c Thread spool

CAUTION

• If the thread spool and/or spool cap are set

incorrectly, the thread may tangle on the spool pin

and cause the needle to break.

• Use the spool cap (large, medium, or small) that is

closest in size to the thread spool. If a spool cap

smaller than the thread spool is used, the thread may

become caught in the slit on the end of the spool.

Note

When using cross-wound thread on a thin spool, use

the small spool cap, and leave a small gap between

the cap and the thread spool.

b

a

a Groove in bobbin

b Spring on bobbin winder shaft

b

c

a

Gap

b

Cross-wound thread

c

Spool cap (small)

25

Page 27

LOWER/UPPER THREADING

While holding the thread from the spool in

e

your right hand, hold the end of the thread

with your left hand, and then pass the thread

through the thread guide.

a

a Thread guide

Pass the thread under the pin on the bobbin

f

winding thread guide, and then pass it around

the pretension disk.

* Make sure that the thread passes under the pretension disk.

a

Slide the bobbin holder to the left until it

i

snaps into place.

* When the bobbin holder is set to the left, it works as a

switch to make the bobbin wind automatically.

a

a Bobbin holder (switch)

→ The bobbin stops spinning automatically when it is

full, and the bobbin holder returns to its original

position.

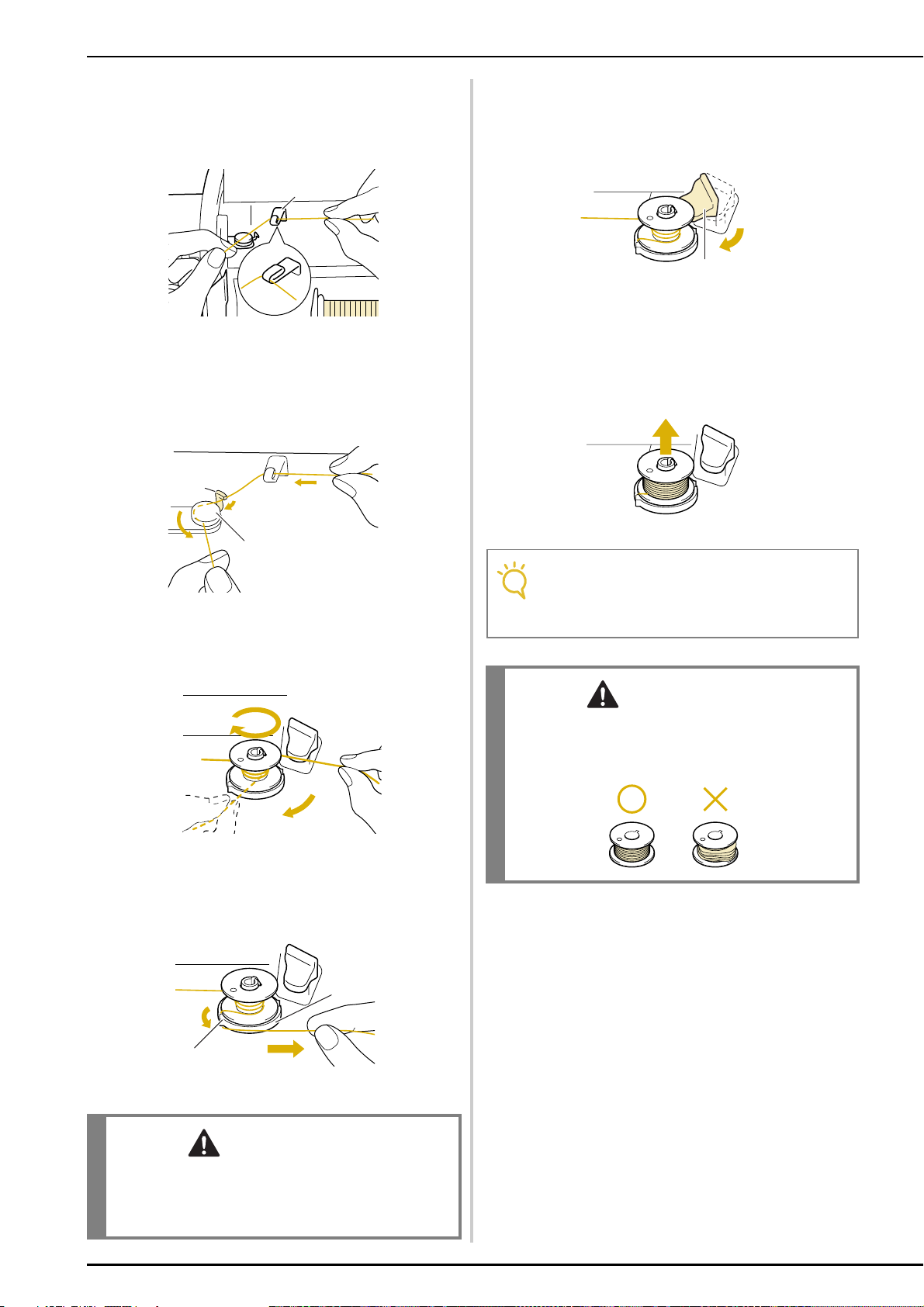

Cut the thread, and then remove the bobbin.

j

b

a Pin

b Pretension disk

Wind the thread clockwise around the bobbin

g

four or five times.

2

3

Pass the end of the thread through the guide

h

slit in the bobbin winder seat, and then pull

the thread to the right to cut it with the

cutter.

1

b

Note

When removing the bobbin, pull up only on the bobbin.

Do not pull on the bobbin winder seat, otherwise it may

become loose, resulting in damage to the machine.

CAUTION

• Setting the bobbin improperly may cause the thread

tension to loosen, breaking the needle and possibly

resulting in injury.

26

a

a Guide slit

b Bobbin winder seat

CAUTION

• Be sure to follow the process described. If the thread

is not cut with the cutter, and the bobbin is wound,

when the thread runs low, it may tangle around the

bobbin.

Page 28

LOWER/UPPER THREADING

■ Winding the Bobbin Using the Spool Pin

The main spool pin cannot be used to wind the

bobbin while sewing. For details, see “Using the

Supplemental Spool Pin” on page 25.

2

7

8

3

6

4

5

9

l

o

Turn on the machine.

a

Open the top cover.

b

Slide the spool cap as far as possible onto the

e

spool pin, and then return the spool pin to its

original position.

While holding the thread from the spool with

f

both hands, pull the thread through the lower

notch in the thread guide plate, then through

the upper notch.

b

a

a Lower notch in the thread guide plate

b Upper notch in the thread guide plate

1

Pass the thread through the thread guide.

g

a

1

Getting Ready

Align the groove in the bobbin with the spring

c

on the bobbin winder shaft, and then slide the

bobbin onto the shaft.

a

b

a Groove in bobbin

b Spring on bobbin winder shaft

Pivot the spool pin so that it angles upward,

d

and then place the spool of thread on the

spool pin.

* Make sure that the thread unwinds from the front.

c

a Thread guide

Pass the thread under the pin on the bobbin

h

winding thread guide, and then pass it around

the pretension disk.

* Make sure that the thread passes under the pretension disk.

a

b

a Pin

b Pretension disk

Follow steps g through j on page 26.

i

a

b

a Spool cap

b Thread spool

c Spool pin

27

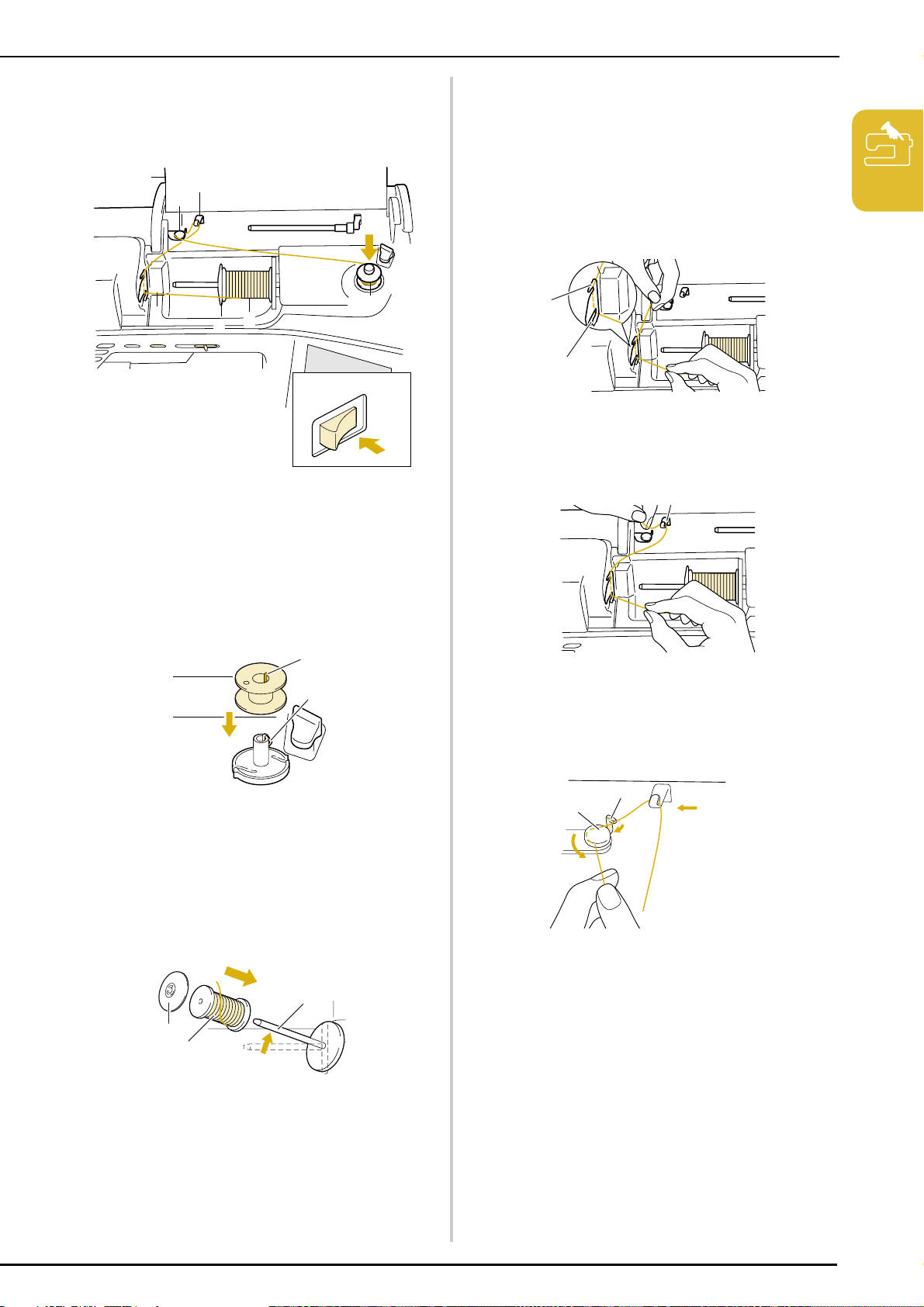

Page 29

LOWER/UPPER THREADING

Setting the Bobbin

This section describes how to set a bobbin wound with

thread into the machine. You can begin sewing without

pulling up the bobbin thread. If you wish to pull up the

bobbin thread, for example, when sewing gathers,

follow the procedure described in the next section.

CAUTION

• Use a bobbin thread that has been correctly wound.

Otherwise, the needle may break or the thread

tension will be incorrect.

Press the “Presser Foot Lifter” button to raise

a

the presser foot.

Lightly hold down the bobbin with your right

e

hand, and then, while slightly pulling the

thread with your left hand, guide it through

the groove.

After guiding the thread completely through

f

the groove, pull it toward you to cut it with

the cutter.

a

Slide the bobbin cover latch to the right, and

b

then remove the bobbin cover.

a

a Bobbin cover

b Latch

Hold the bobbin with your right hand and hold

c

the end of the thread with your left hand.

Insert the wound bobbin into the bobbin case

d

so that the thread unwinds in the direction of

b

the arrow.

a Cutter

Attach the bobbin cover by inserting the tab

g

in the lower-left corner of the bobbin cover,

then lightly press down on the right side of

the cover until it snaps into place.

a

a Tab

Pulling Up the Bobbin Thread

There may be some sewing applications where you

may want to pull up the bobbin thread, for example,

when making gathers or with free-motion quilting.

Follow the procedure described below to pull up the

bobbin thread.

Memo

Thread the upper thread before pulling up the bobbin

thread. For details, see “Upper Threading” on page 29.

28

CAUTION

• Be sure to hold down the bobbin with your finger

and unwind the bobbin thread correctly. Otherwise,

the thread may break or the thread tension will be

incorrect.

Follow steps a through d from the previous

a

section to insert the bobbin into the bobbin

case.

Page 30

Guide the bobbin thread through the groove,

b

following the arrow in the illustration.

LOWER/UPPER THREADING

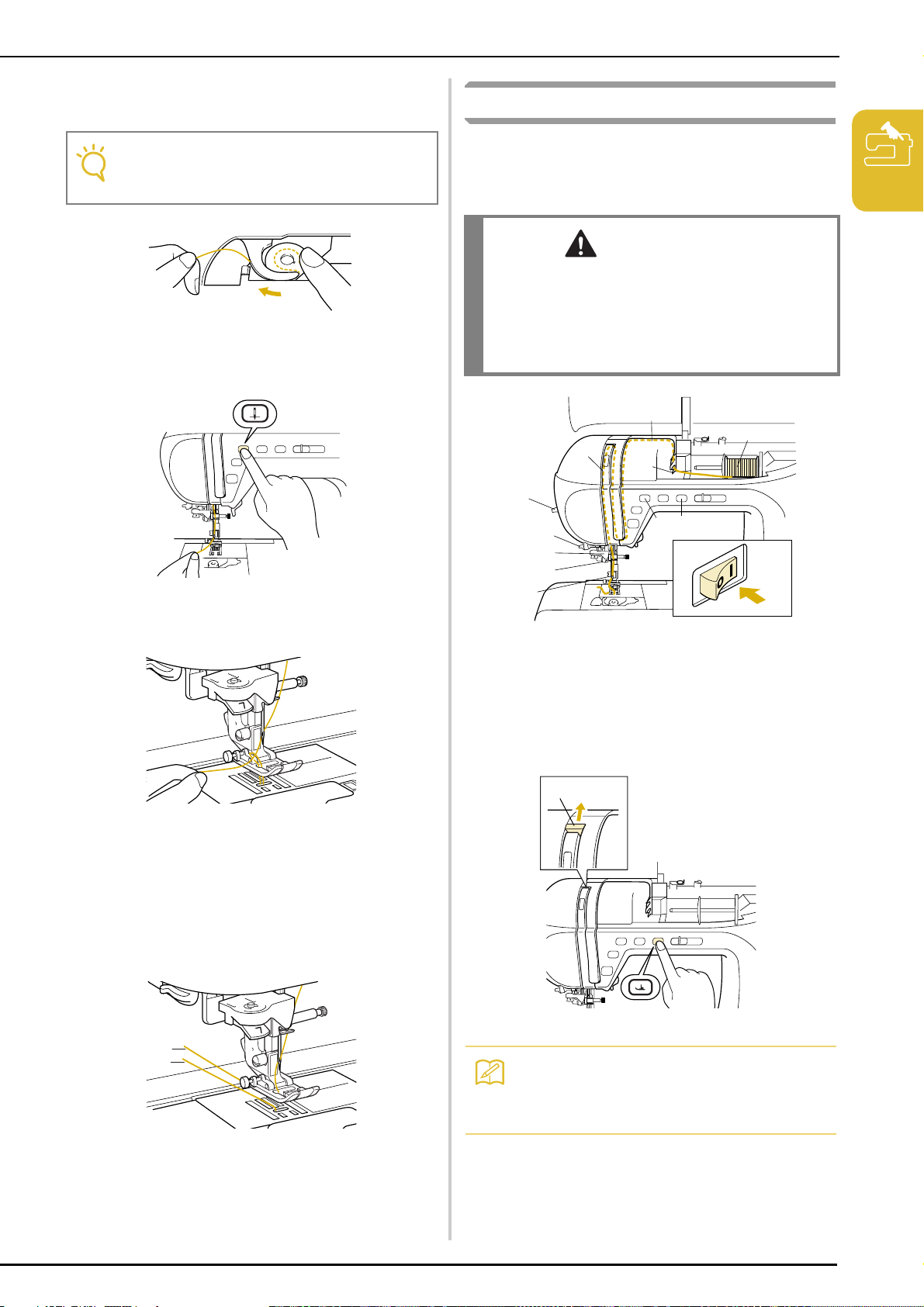

Upper Threading

Note

• Do not cut the thread with the cutter.

• Do not attach the bobbin cover.

While lightly holding the upper thread, press

c

the “Needle Position” button twice to lower,

then raise the needle.

Gently pull the upper thread to pull up the

d

bobbin thread.

This section describes how to thread the machine and

the needle. The machine is marked with numbers that

indicate the threading order.

CAUTION

• Be sure to thread the machine properly. Improper

threading can cause the thread to tangle and break

the needle, leading to injury.

• When using accessories not included with this

machine, attach the accessory to the machine after

threading the machine.

7

4, 5

8

6

12,13

2,16

11

10

9

14,15

Turn on the machine.

a

3

1

1

Getting Ready

→ A loop of the bobbin thread comes out from the hole

in the needle plate.

Pull out about 100 mm of the bobbin thread,

e

and then pass it under the presser foot toward

the rear of the machine, making it even with

the upper thread.

a

b

a Upper thread

b Bobbin thread

Press the “Presser Foot Lifter” button to raise

b

the presser foot.

→ The upper thread shutter opens so the machine can

be threaded.

a

Upper thread shutter

a

Memo

This machine is equipped with an upper thread

shutter, allowing you to check that the upper threading

is performed correctly.

Attach the bobbin cover.

f

29

Page 31

LOWER/UPPER THREADING

Press the “Needle Position” button to raise

c

the needle.

Note

If you try to thread the needle with the needle threader

lever without raising it, damage to the machine may

result.

Pivot the spool pin so that it angles upward,

d

and then place the spool of thread on the

spool pin.

* Make sure that the thread unwinds from the front.

While holding the thread from the spool in

g

your right hand, hold the end of the thread

with your left hand, and then guide the thread

through the groove, following the arrows in

the illustration.

Guide the thread down, up, then down

h

through the groove, as shown in the

illustration.

a

c

a

b

a Spool cap

b Thread spool

c Spool pin

Slide the spool cap as far as possible onto the

e

spool pin, and then return the spool pin to its

original position.

CAUTION

• If the thread spool and/or spool cap are set

incorrectly, the thread may tangle on the spool pin

and cause the needle to break.

• Use the spool cap (large, medium, or small) that is

closest in size to the thread spool. If a spool cap

smaller than the thread spool is used, the thread may

become caught in the slit on the end of the spool and

cause the needle to break.

While holding the thread from the spool with

f

both hands, pull the thread through the lower

notch in the thread guide plate, then through

the upper notch.

a Upper thread shutter

Memo

Look through the take-up lever check window to check

the position of the take-up lever. Before threading the

machine, make sure that the take-up lever is in the

raised position.

a

b

a Upper thread shutter

b Thread take-up lever check window

Pass the thread through the needle bar thread

i

guide (marked “6”).

* Hold the thread with both hands and fully pass it through

the guide, as shown in the illustration.

30

b

a

a Lower notch in the thread guide plate

b Upper notch in the thread guide plate

a

a Needle bar thread guide

Page 32

LOWER/UPPER THREADING

Pass the thread through the thread guide disks

j

(marked “7”).

* Make sure that the thread passes through the groove in the

thread guide.

* Make sure that the thread securely enters the thread guide

disks, otherwise the needle may not be threaded.

a

a Groove in thread guide

Pull the thread up through the thread cutter

k

to cut the thread, as shown in the illustration.

a

a Thread cutter

Note

When using thread that quickly winds off the spool,

such as metallic thread, it may be difficult to thread the

needle if the thread is cut.

Therefore, instead of using the thread cutter, pull out

about 80 mm (approx. 3 inches) of thread after

passing it through the thread guide disks (marked “7”).

Release the needle threader lever.

m

→ The thread passes through the eye of the needle.

Carefully pull the end of thread that was

n

passed through the eye of the needle.

Note

Do not pull the thread strongly. Otherwise, the needle

may bend or break.

* If a loop was formed in the thread passed through the eye

of the needle, carefully pull on the loop of thread through

to the back of the needle.

Pull out about 100 mm (approx. 3-4 inches) of

o

the thread, and then pass it under the presser

foot toward the rear of the machine.

a

1

Getting Ready

a

a 80 mm or more

Lower the needle threader lever slowly until it

l

clicks.

* The hook is rotated and passes through the eye of the

needle.

Note

• If the needle threader lever is lowered quickly, the

needle may not be threaded.

• Make sure that no objects, such as the fabric, are

touching the hook.

b

a 100 mm

Press the “Presser Foot Lifter” button to lower

p

the presser foot before starting to sew.

Memo

This completes the upper threading procedure.

Note

• The needle threader can be used with home sewing

machine needles 75/11 through 100/16. For details

on appropriate needle and thread combinations, see

“Fabric/Thread/Needle Combinations” on page 37.

• If automatic needle threading could not be

completed correctly, repeat the procedure, starting

with the needle bar thread guide (marked “6”).

• Some needles cannot be threaded with the needle

threader. In this case, instead of using the needle

threader after passing the thread through the needle

bar thread guide (marked “6”), manually pass the

thread through the eye of the needle from the front.

a Hook

b Needle thread lever

a

31

Page 33

LOWER/UPPER THREADING

Using the Twin Needle

Using the twin needle, you can sew two parallel lines of

the same stitch. Although the same bobbin thread is

used, interesting patterns can be sewn by threading

each needle with a different color of thread. Both upper

threads should have the same thickness and quality.

The twin needle can only be used with patterns where

appears when they are selected. Check the

“STITCH SETTING CHART” at the end of this manual

for patterns that can be used with the twin needle.

CAUTION

• Use only twin needles made for this machine (part

code X59296-151). Other needles could break,

resulting in damage.

• Be sure to set the twin needle mode when using the

twin needle. Using the twin needle while the

machine is in single needle mode could cause the

needle to break, resulting in damage.

• Do not sew with bent needles. The needle could

break and cause injury.

• When using the twin needle, be sure to use presser

foot “J”. In case bunched stitches may occur, use the

presser foot “N”.

Press , and then install the twin

a

needle (see “CHANGING THE NEEDLE” on

page 35).

Pass the thread through the needle bar thread

c

guide, and then manually thread the needle

on the left side.

* Do not use needle threader when threading a twin needle.

a

a Needle bar thread guide

Set the supplemental spool pin in the “up”

d

position.

a

a Supplemental spool pin

Place the additional spool of thread on the

e

supplemental spool pin so that the thread

unwinds from the front. Then, slide the spool

cap as far as possible onto the supplemental

spool pin to secure the thread spool.

b

Thread the machine for the first needle

b

according to the procedure for threading a

single needle (see “Upper Threading” on page

29).

a

c

a Spool cap

b Supplemental spool pin

c Thread spool

While holding the thread from the spool in

f

your right hand, hold the end of the thread

with your left hand, and then pass the thread

through the thread guide.

* Do not pass the thread through the bobbin winding thread

guide.

a

a Bobbin winding thread guide

b Thread guide

b

32

Page 34

LOWER/UPPER THREADING

While holding the thread from the spool with

g

both hands, pull the thread through the lower

notch in the thread guide plate, then through

the upper notch. Hold the end of the thread

with your left hand, and then guide the thread

through the groove, following the arrows in

the illustration.

a

Press to select the setting for twin

k

needle sewing.

* The stitch width becomes narrower than with single needle

sewing.

a

a Single needle/twin needle setting

→ appears.

1

Getting Ready

a Shutter

Without passing the thread through the

h

needle bar thread guide, manually thread the

needle on the right side.

a

a Needle bar thread guide

Note

The needle threader cannot be used. Manually pass the

thread through the eye of the needle from the front. If the

needle threader is used, damage to the machine may

result.

Press , or press in the

i

screen.

CAUTION

• Be sure to set the twin needle mode when using the

twin needle. Using the twin needle while the

machine is in single needle mode could cause the

needle to break, resulting in damage.

Press the “Start/Stop” button after lowering

l

the presser foot lever.

Memo

To change the sewing direction with the twin needle,

raise the needle from the fabric, raise the presser foot

lever, and then turn the fabric.

Select a stitch.

j

Note

If appears as after a stitch is selected,

the twin needle cannot be used with the selected

stitch.

33

Page 35

CHANGING THE PRESSER FOOT

CHANGING THE PRESSER FOOT

CAUTION

• Always press in the operation panel before changing the presser foot. If is not pressed and the

“Start/Stop” button or another button is pressed, the machine will start and may cause injury.

• Always use the correct presser foot for the selected stitch. If the wrong presser foot is used, the needle may strike the

presser foot and bend or break, and may cause injury.

• Only use presser feet made for this machine. Using other presser feet may lead to accident or injury.

Raise the presser foot lever.

Removing the Presser Foot

Press the “Needle Position” button to raise

a

the needle.

c

Press .

b

→ The screen changes, and all keys and operation

buttons are locked.

Press the black button on the presser foot

d

holder to remove the presser foot.

a

b

a Black button

b Presser foot holder

Attaching the Presser Foot

Place the presser foot under the holder,

a

aligning the pin on the foot with the notch in

the holder, and then lower the presser foot

lever so that the presser foot pin snaps into

the notch in the holder.

a

b

34

a Notch

b Pin

Press , or press in the

b

screen.

→ All keys and operation buttons are unlocked, and

the previous screen is displayed.

Raise the presser foot lever.

c

Page 36

CHANGING THE NEEDLE

CHANGING THE NEEDLE

CAUTION

• Always press in the operation panel before changing the needle. If is not pressed and the “Start/

Stop” button or another operation button is pressed accidentally, the machine will start and injury may result.

• Use only sewing machine needles made for home use. Other needles may bend or break and may cause injury.

• Never sew with a bent needle. A bent needle will easily break and may cause injury.

■ Checking the Needle

Place the flat side of the needle on a flat surface

(such as the needle plate or a piece of glass) and

check that the gap between the needle and the flat

surface is even.

Note

Never use bent or blunt needles.

a

b

a Even gap

b Flat surface (bobbin cover, glass, etc.)

Press .

b

1

Getting Ready

Press the “Needle Position” button to raise

a

the needle.

→ The screen changes, and all keys and operation

buttons are locked.

35

Page 37

CHANGING THE NEEDLE

Use the included screwdriver to turn the

c

needle clamp screw toward the front of the

machine to loosen it, and then remove the

needle.

Note

Do not apply extreme force when loosening or

tightening the needle clamp screw, otherwise damage

to the machine may result.

With the flat side of the needle facing the

d

back, insert the new needle until it touches

the needle stopper. Use the screwdriver to

securely tighten the needle clamp screw.

a

b

c

a Needle stopper

b Hole for setting the needle

c Flat side of needle

CAUTION

• Be sure to push in the needle until it touches the

stopper, and securely tighten the needle clamp

screw with a screwdriver. If the needle is not

completely inserted or the needle clamp screw is

loose, the needle may break or the machine may be

damaged.

36

Press , or press in the

e

screen.

→ All keys and operation buttons are unlocked, and

the previous screen is displayed.

Page 38

CHANGING THE NEEDLE

■ About the Needle

The sewing machine needle is probably the most important part of the sewing machine. Choosing the proper

needle for your sewing project will result in a beautiful finish and fewer problems. Below are some things to keep

in mind about needles.

• The smaller the needle number, the finer the needle. As the numbers increase, the needles get thicker.

• Use fine needles with lightweight fabrics, and thicker needles with heavyweight fabrics.

• To avoid skipped stitches, use ball point needle (gold colored) 90/14 with stretch fabrics.

• To avoid skipped stitches, use ball point needle (gold colored) 90/14 when sewing character or decorative

stitches.

• Use a 90/14 to 100/16 needle with transparent nylon threads, regardless of the fabric being sewn.

• A home sewing machine needle 75/11 is inserted in the sewing machine.

■ Fabric/Thread/Needle Combinations

The following table provides information concerning the appropriate thread and needle for various fabrics.

Please refer to this table when selecting a thread and needle for the fabric you wish to use.

1

Getting Ready

Fabric

Medium weight fabric Broadcloth Cotton 60 - 80 75/11 - 90/14

Taffeta Synthetic mercerized 60 - 80

Flannel, Gabardine Silk or silk finished 50

Lightweight fabric Lawn, Batiste Cotton 60 - 80 65/9 - 75/11

Georgette Synthetic mercerized 60 - 80

Challis, Satin Silk 50

Heavyweight fabric Denim Cotton 30 - 50 90/14 - 100/16

Corduroy Synthetic mercerized 50

Tweed Silk 50

Stretch fabric Jersey Thread for knits 50 - 60 Ball point needle

Tr ic o t

Easily frayed fabrics Cotton thread 50 - 80 65/9 - 90/14

Synthetic thread

Silk thread 50

For top stitching Synthetic mercerized 30 90/14 - 100/16

Silk 30

Thread

Typ e Size

Size of needle

(gold colored)

75/11 - 90/14

Memo

For transparent nylon thread, always use needle 90/14 - 100/16.

The same thread is usually used for the bobbin thread and upper threading.

CAUTION

• Be sure to follow the needle, thread, and fabric combinations listed in the table. Using an improper combination,

especially a heavyweight fabric (i.e., denim) with a small needle (i.e., 65/9 - 75/11), may cause the needle to bend or

break, and lead to injury. Also, the seam may be uneven, the fabric may pucker, or the machine may skip stitches.

37

Page 39

SEWING LARGE PIECES OF FABRIC

SEWING LARGE PIECES OF FABRIC

The extension table makes sewing large pieces of fabric

easier.

CAUTION

• Do not move the sewing machine while the

extension table is attached, otherwise damage or

injuries may occur.

• Do not use the extension table for other purposes

such as an ironing board. This can cause damage

and injury.

Open up the legs at the bottom of the

a

extension table.

Pull out the four legs until they snap into place.

Rotate the rubber foot attached to the bottom

d

of each leg to adjust the height.

Make sure that the extension table is either at the same

level or slightly lower than the surface of the needle

plate.

When you are finished using the extension

e

table, remove it.

While slightly lifting up the extension table to release

the mounting hook, pull the table off to the left.

Turn off the power and pull the flat bed

b

attachment off to the left.

→ With the flat bed attachment removed, free-arm

sewing is possible.

Install the extension table.

c

Keeping the extension table level, slowly slide it into

place until the mounting hook clicks into position.

a

Memo

The knee lifter can be snapped into the bottom of the

extension table for storage.

Install the flat bed attachment back in its

f

original position.

CAUTION

• Do not install or remove the extension table with

force, otherwise the mounting hook may be

damaged.

38

Mounting hook

a

a

Mounting hook

a

Page 40

Chapter 2

Sewing Basics

2

SEWING ..............................................................................................40

Sewing a Stitch ........................................................................................................40

■ Using the Foot Controller................................................................................................41

■ Using the Knee Lifter.......................................................................................................42

Sewing Reinforcement Stitches ...............................................................................42

Sewing Curves .........................................................................................................42

Changing Sewing Direction .....................................................................................43

■ Sewing a Seam Allowance of 0.5 cm or Less ...................................................................43

Sewing Heavyweight Fabric ....................................................................................43