Page 1

INSTALLATION INSTRUCTIONS/

OPERATORS MANUAL

This manual provides

Installation & Operating instructions for

TRAY-TRAC

SYSTEM

NOTIFY CARRIER OF DAMAGE AT ONCE.

It is the responsibility of the consignee to inspect the

container upon receipt of same and to determine

the possibility of any damage, including concealed

damage. Avtec suggests that if you are suspicious of

damage to make a notation on the delivery receipt. It will be the responsibility of the consignee to

le a claim with the carrier. We recommend that you

do so at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be

and accurate at the time of printing/creation. Unified Brands

recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and

specifications.

PP MNL0803

current

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

unifiedbrands.net

Page 2

TABLE OF CONTENTS

INSTALLATION INSTRUCTIONS

I. SERVICE CONNECTIONS . . 1

A. Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. Mobile Tray-Trac [Casters] 1

2. Stationary Tray-Trac [Legs] 1

B. Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. Mobile Tray-Trac [Casters] 1

2. Stationary Tray-Trac [Legs] 1

C. Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. Hot Food Well Drain . . 1

2. Refrigeration Drain . . 1

OPERATING INSTRUCTIONS

I. STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

A. Modular Distribution Systems .......................................................................................

B. Start/Stop Stat ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

C. Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

III. ACCESSORIES AND CONTROLS 2

A. Momentary Foot Stop Switch 2

B. Fluorescent Work Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

C. Hot Food Wells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

D. Cold Tops and Cold Pans

E. Checker Audio Call System 3

F. Timer Programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

..

2

3

USER-MAINTENANCE INSTRUCTIONS

IV. PERIODIC CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

A. All Work Surfaces 4

B. Tray Carriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C. Hot Food We ls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

D. Cold Tops and Cold Pans

V. PERIODIC MAINTENANCE 4

A. Gear Reducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Motor Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C. Tray Carrier Drive Chain

D. Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

E. Torque Limiter Sprocket 4

F. Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Grounding Instructions for Permanently Connected Appliances . . . . . . . . . . . . . . . . . . . . . 6

VI. EMERGENCY PARTS LIST . . 7

Randell Manufactured Drop in Units Parts List ............................................................................... . 7

Mechanical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Hot Food Drop Ins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

HOT Food Well Pa

Fluorescent Light Fixture Parts . 9

Electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Component Identification Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

rts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . 4

4

VII. SPECIFIC TECHNICAL DATA AND DIAGRAMS

A. Electrical Schematics

1. Carousel Motor Controls . . 12

VIII. ADDITIONAL INFORMATION

A. Warranty

13

Page 3

INSTALLATION INSTRUCTIONS

I. SERVICE CONNECTIONS

A. Electrical

1.Mobile Tray-Trac [Casters]

a.Power from above

A male connection is provided at the top of

the service pylon. This is the power inlet to

the Tray-Trac System. A drop cord with

matching connector body is supplied for

connecting to the ceiling. To complete the

connection, turn main breakers in each

electrical distribution system OFF, insert

connector body into male receptacle fully

and lock into position with locking collar.

Turn breakers ON to energize Tray-Trac.

b.Power from below

A power supply cord is provided from the

back of the Service Terminal Box to a

matching receptacle in the floor box. To

complete the connection, turn main

breakers in each electrical distribution

system OFF, insert plug fully into receptacle

and lock into position with locking collar.

Turn breakers ON to energize Tray-Trac.

2. Stationionary Tray-Trac [Legs]

a.Power from above

Turn main service breakers in power

supply panel box to OFF while making

connection. The electrical contractor is

to bring rigid or flexible conduit down

from the ceiling into the top of the

service enclosure.

provided within the service enclosure to

which the

connects.

b.Power from below

Turn main service breakers in power

supply panel box to OFF while making

connection. Electrical contractor is to

bring rigid or flexible conduit into back or

bottom of Service Terminal Box. A

terminal is provided within the Service

Terminal Box to which the electrical

contractor connects.

B. Water

1.Mobile Tray-Trac [Casters]

The plumbing connection[s] is usually made

with a flexible hose and quick-disconnect

assembly. To connect quick-disconnect,

slide locking collar on female connector

back and insert male connector. The

A terminal is

electrical contractor

locking collar will snap forward when male

connector is fully inserted. Both halves of

the quick-disconnect are equipped with

self-contained shut-off valves stop the flow

of water as soon as it is uncoupled.

However, we recommend installing a

manual shut-off valve immediately before

the quick-disconnect/hose assembly.

a.Service from above

Install the union end of the water

connector [hose] assembly to the supply

piping in the ceiling.

disconnect male coupling into female on

Tray-Trac unit as described previously.

b.Service from below

A water connector

supplied on the Tray-Trac. If an AVTEC

floor box is supplied, connect the supply

piping to

mounted in AVTEC floor box, then insert

male quick-disconnect as described

above. If an AVTEC floor box is not

supplied, connect female quick-disconnect

to supply piping shut-off valve.

2.Stationary Tray-Trac [Legs]

The plumbing connection[s] is usually

terminated with a 1/4 turn shut-off valve,

which may be located in the base of the unit

[connection from below] or in the service

pylon

plumbing contractor then connects directly

to this valve with rigid pipe.

C. Drains

1.Hot Food Well Drain

a.Direct service connection

Drain normally connected with hard piping

to open floor drain or other waste line.

b.Hose Connection [Optional]

Attach rubber or plastic hose [supplied by

owner] to hose adapter [AVTEC optional

feature] and route to open floor drain.

2.Refrigeration Drain

The drain may be connected if desired, in

the same manner as the hot food well

drain or a bucket may be used in lieu of a

drain connection. The bucket should be

placed under the drain shut-off valve,

located behind the end doors.

[connection from above].

[hose] assembly is

female quick-disconnect

Insert quick-

The

1

1

Page 4

OPERATING INSTRUCTIONS

II. STANDARD CONTROLS

A.Modular Electrical Distribution System

The Tray-Trac has an electrical service

terminal box which is connected to the

main incoming electrical service. From

this point, power supply is provided to

each Modular Electrical Distribution

System [MR0E] running the length of each

side of the Tray-Trac. Each MR0E unit is

a linear panel board, with a main service

disconnect breaker, main system cable

bus and link plates containing a point-ofuse circuit breaker and either receptacle,

switch or internal connection. These link

plates can be moved to any location on

the system, or new plates can be added,

as long as the total kilowatt capacity

[ampacity] of each MR0E unit is not

exceeded.

B.Start/Stop Station

The unit is equipped with one or more pairs

of push buttons which are used to start and

stop the carousel motor. Depressing any of

the STOP buttons will stop the carousel

motor. These switches are intended to start

and stop the carousel at the beginning and

end of the serving period or whenever the

tray carriers will not be in use for an

extended period of time.

C.Speed Control

The unit is supplied with a variable speed

control unit located on the unload end

[inside

STOP/START Station, accessible through

the base cabinet door or access panel.

Trays must be timed manually and

adjustment made on the speed control dial.

See separate instructions for more detailed

information. Max speed of

minute.

III.ACCESSORIES AND CONTROLS

The following optional features may or may

not be supplied. Check drawing and

specifications to determine which features

are included in your systems.

A.Momentary Foot Stop Switch

The Tray-Trac is equipped with a two position

terminal within the Modular Distribution

the Tray-Trac] behind the

10 trays per

2

System at tray unload end. The optional

foot-operated momentary stop switch can be

mounted at this location. Depressing the foot

switch will cause the carousel motor to stop

and it will remain stopped as long as the

switch is depressed. When the operator’s

foot is removed, the carousel will begin

rotating again.

B.Fluorescent Work Lights

Fluorescent work lights may be supplied

beneath the carousel and/or under the

overshelf. The overshelf lights incorporate a

diffuser panel that is integral to the fixture to

reduce glare, protect the bulb an equalize

light distribution. The carousel work lights

use a separate prismatic clear plastic sheet

to protect the bulb and aid in light diffusion.

To replace the carousel bulb, slide the

diffuser panel upward in its slot, and allow the

back edge to drop down and out. The work

lights are operated by a switch that is usually

located alongside the carousel start/stop

switch. Power for the work lights is drawn

from one of the Modular Electrical

Distribution Systems. Three foot fixtures

require #F30-T8 Slimline Lamps, 18” fixtures

require #F15-T8 Slimline Lamps.

C.Hot Food Wells

Heavy-duty rectangular food wells can be

provided with or without drains. Wells are

able to accommodate a standard 12” x 20”

#200 pan up to six inches deep and are

suitable for either wet or dry operation. The

warming element is controlled by an infinite

switch control with a positive-OFF position.

Each food warmer has a separate control A

red signal light indicates a power-ON

condition. Add water to warmer BEFORE

preheating.

DRY, PRE-HEATED WARMER MAY

DAMAGE THE UNIT.

preheating, add hot water, place empty pan

in well, then cover well. Preheating varies

from 15-30 minutes.

NOTE: Hot food wells are warranted

directly by the manufacturer; refer to

separate warranty and owner’s

information.

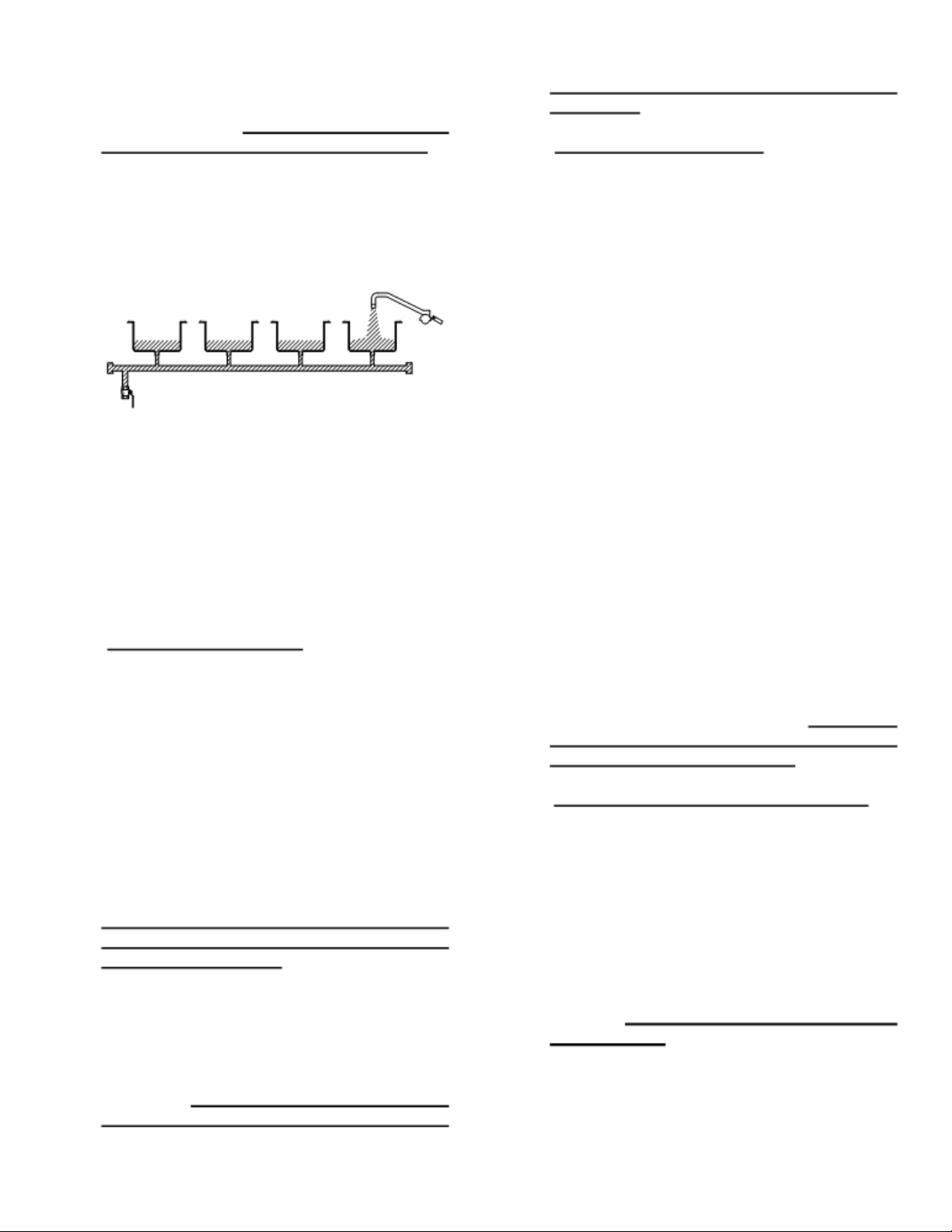

Some hot food wells may be supplied with a

strainer and drain manifold. This manifold is

POURING WATER INTO A

For most efficient

Page 5

equipped with a ¼ turn ball valve for flushing

and threaded caps at each end for easy

periodic rodding. At least 1” of water should

be in all wells prior to each meal assembly.

The most common method for putting water

into the hot food wells is to back feed through

the drain manifold. By closing the drain

manifold shut-off valve [located in the base

near the end doors] and filling one hot food

well, the water will back up into the other hot

food wells. Hot food wells without drains

must be filled individually and drained with a

cup and sponge.

D.Cold Tops and Cold Pans

Cold Tops [raised cooling surfaces] and Cold

Pans

available for full and half base Tray-Tracs.

The circuits for these items are protected by

breakers in the Modular Distribution Systems.

THESE BREAKERS SHOULD NOT BE

USED TO TURN THE UNITS ON AND OFF.

Switches have been provided beside each

breaker for turning these items on and off.

Units should be turned on approximately

thirty minutes prior to use and left on until the

end of the day.

NOTE: Cold tops and cold pans may or may

not frost, depending on humidity and ambient

atmospheric conditions.

The refrigerated surfaces are supplied with a

removable strainer and drain, which is routed

to one end of the Tray-Trac. This piping is

equipped with a 1/4-turn shut off valve for

flushing and threaded caps for periodic

rodding. To prevent back-up into drain

gutter, the drain should be flushed daily into

[recessed cooling surfaces] are

the open floor drain or bucket, and rodded

periodically.

E.Checker Audio Call System

To aid in communications between the

personnel, a Checker Audio Call Station can

be supplied. Power is supplied from a circuit

breaker connection plate in the Modular

Distribution Panel along the side of the unit.

To turn the system on, make sure that the

circuit breaker is on. Depress the ON/OFF

switch and the Power Indicator LED will

illuminate. If only one microphone is used,

adjust volume by turning the know labeled

“INPUT 1” until the desired level is obtained.

If two microphones are used, adjust the

volume of one microphone using the “INPUT

1” knob and adjust the volume of the second

microphone using the “INPUT 2” knob. The

“PROGRAM” knob is not used in Tray-Trac

applications. When the Checker Audio Call

Station will not be in use for an extended

period of time, turn the unit OFF using power

on/off switch.

After adjusting the amplifier, you are ready to

use the Checker Audio Call Station. To use

the system, hold the button on the side of the

microphone IN while speaking.

microphone is ON only while the button is

held IN.

microphone is mounted on an 18” long

adjustable, flexible gooseneck.

adjustments, consult the amplifier and

microphone operations manual.]

F.Timer Programmer [Seven Day, 24-Hour]

The timer programmer is used to

automatically control the ON/OFF of integral

and ancilliary equipment connected to the

Tray-Trac unit, especially heated bases.

Each Modular Electrical Distribution System

[MR0E] is connected separately thru a

bypass switch to the timer/programmer.

Either MR0E unit may be ON or OFF the

program. The timer/programmer and bypass

switches are located as shown on the

drawing. Refer to separate instructions for

programming.

For your convenience, the

[For further

The

3

Page 6

USER-MAINTENANCE INSTRUCTIONS

IV.PERIODIC CLEANING

A.All Work Surfaces

Entire unit should be wiped down after

every meal and cleaned thoroughly daily

with mild soap and water. *Do not use plain

steel wool, plastic or scouring pads. Use

sponge or towel, if necessary.

*NOTE: Use of these pads will affect the

grain and finish of the metal.

B.Tray Carriers

Tray carriers can be hinged up for daily

cleaning and removed for weekly cleaning.

This also allows the trac to be more

thoroughly cleaned. Do not put tray carriers

in dish machine, as menu holders can be

damaged.

C.Hot Food Wells

Hot food wells should be drained and

cleaned daily. 1/4 turn drain shut off valves

are located near end doors.

D.Cold Tops and Cold Pans

Units should be drained and flushed daily to

prevent clogging and back-up into cold top

gutters or cold pan; 1/4 turn shut-off valve

are located near end doors. All surfaces

should be cleaned at the end of the day.

V.PERIODIC MAINTENANCE

A.Gear Reducer

Change oil after the first month of

operation. Thereafter, change oil after one

[1] year of operation.

Recommended lubricants:

Gulf Transgear #EP680

Mobil 600W Super

Texaco Honor Cylinder Oil #680

B.Motor Brushes

After 2,500

recommended that the motor brushes be

replaced. Refer to the parts list for the

appropriate part number.

hours of operation, it is

4

C.Tray Carrier Drive Chain

Use a spray lubricant on the chain after

one [1] month or 250 hours of operation.

Lubricate after four

hours of operation thereafter.

Recommended lubricant:

McMaster Carr No. 6159K11 Roller Chain

Lubricant

RX Silicone Spray

WD-40

D.Drains

Make sure drain strainers are reinserted

after cleaning. If drains become clogged,

remove threaded end cap, run rod through

drain manifold and replace end cap.

E.Torque Limiter Sprocket

At periodic intervals, or if proper torque is

not being maintained, inspect Torque

Limiter for presence of oil, grease,

moisture, or corrosion on the driving

surfaces and for proper setting of spring

load.

Friction facings and bushings are the only

parts that should normally require

replacement or tightening.

F.Refrigeration

The louvers on the condensing unit

enclosures should be brushed regularly to

prevent clogging of the openings. The

condensing coil of the unit should be

cleaned periodically, for proper function of

the cooling system. Access for service is

obtained by removing the side panel

directly below the cold top or cold pan.

Clean and adjust as required.

[4] months or

500

Page 7

IMPORTANT SAFETY INSTRUCTIONS FOR TRAY TRAC

WARNING - When using electric appliances, basic precautions should always be followed, including

the following:

a)

Read all the instructions before using the appliance.

b) To reduce the risk of injury, close supervision is necessary when an appliance is used near children.

c) Do not contact moving parts.

d) Only use attachments recommended or sold by the manufacturer.

e)

Do not use outdoors.

f)

For a cord-connected appliance, the following shall be included:

- To disconnect, turn all controls the off (“O”) position, then remove from outlet.

- Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

- Unplug from the outlet when not in use and before servicing or cleaning.

- Do not operate any appliance with a damaged cord or plug, or after the appliance malfunctions or

is dropped or damaged in any manner. Return appliance to the nearest authorized service facility

for examination, repair, or electrical or mechanical adjustment.

g) For a permanently connected appliance - Turn the power switch to the off position when the appliance

is not in use and before servicing or cleaning.

h)

For an appliance with a replaceable lamp - always unplug before replacing the lamp. Replace only with

the following lamps:

- 36” Fixtures: #F30-T8 Slimline Lamps

- 18” Fixtures: #F15-T8 Slimline Lamps

i)

For a grounded appliance - connect to a properly grounded outlet only. See grounding instructions.

SAVE THESE INSTRUCTIONS

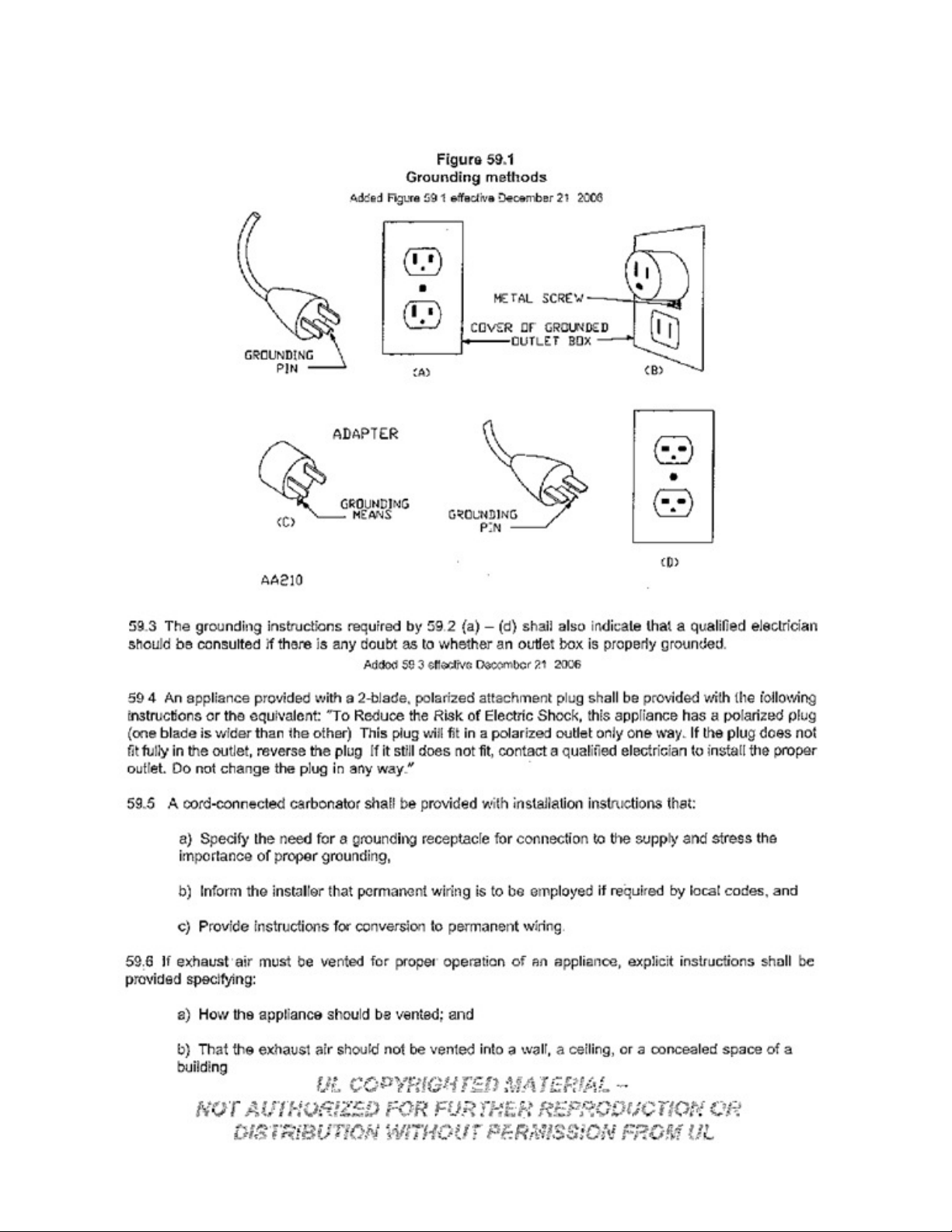

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides a path of least

resistance fro electric current to reduce the risk of electric shock. If this appliance is equipped with a cord that

cord contains an equipment-grounding conductor and a grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

DANGER - Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal. Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if in doubt as to whether the appliance is properly grounded. Do

not modify the plug provided with the appliance - if it will not t the outlet have a proper outlet installed by a

qualified electrician.

a) If this is a mobile unit this appliance is rated more than 15A and is for use on a circuit having a nominal

rating of 120V, and is factory equipped with a specific electric cord and plug. No adapter should be

used with this appliance. If the appliance must be reconnected for use on a different type of electric

circuit, the reconnection should be made by qualified service personnel; and after the reconnection,

the appliance should comply with all local codes and ordinances.

b) A qualified electrician should be consulted if there is any doubt as to whether an outlet box is properly

grounded.

5

Page 8

GROUNDING INSTRUCTIONS FOR PERMANENTLY CONNECTED APPLIANCES

This appliance must be connected to a grounded, metal, permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and connected to the equipment-grounding terminal or lead on

the appliance.

GROUNDING METHODS

6

Page 9

VI. TRAY-TRAC EMERGENCY PARTS LIST

AVTEC PART NO. DESCRIPTION

1 HD LCK0301 Panel Lock w/key

2 HD SPR 0302 Menu Ho

3 RP BRK0314 Cha

4 RP CAR0503 Tray Carrier (Right)

5 RP CAR0504 Tray Carrier Assembly [Left]

6 EL FUS0307 Fuse, 10A, SL

7 HD RED0312 Winsmith Reducer

8 EL REC020

9 EL REC5461

10 EL REC0310 Receptacle9330 [208vac, 30A, 1Φ]

11 EL SWT0304 Square Green Start Button w / N.O. contact

12 EL SWT0305 Square Red Stop Button w / N.C. contact

15 HD CNT0305 Wells Hot Food Well Infinite Control

16 EL BRK0301

17 EL BRK0304

18 EL BRK0305

19 EL BRK0308

20 EL BRK 0371

21 EL PTN0301 Potentiometer, 10K ohm

22 EL DIA0301 Dial (Speed Control)

23 EL KNB0301 Knob (Speed Control)

24 EL RES0301 47K OHM Resistor

25 EL RLY0307 Control Relay

26 HD BRD0304 Motor Controller

27 EL CNT0301 Inhibit Pin for 420-0000

28 HD BRS0301 Motor Brushes ¾ HP [up to 26’]

29 HD BRS0303 Motor Brushes 1HP [26’ and over]

30 EL MTR0203 ¾ HP Motor

31 EL MTR0331 1 HP Motor

32 EL ASY0309 Foot Switch Assembly

1 600-2100 Drop in Frost Top 28” x

2 600-2101 Drop in Frost Top 28” x

3 600-2102 Drop in Frost Top 28” x

4 600-2103 1 pan capacity cold drop in 26” x 1

5 600-2104 2 pan capacity cold drop in 26” x 3

6 600-2105 3 pan capacity cold drop in 26” x 4

7 600-2106 4 pan capacity cold drop in 26” x 5

8 600-2107 5 pan capacity cold drop in 26’ x 6

9 600-2108 6 pan capacity cold drop in 26” x 8

10 600-2109 2 pans front to back 2 total cold drop in 25.42” x 31.10”

11 600-2110 2 pans front to back 4 total cold drop in 31.06” x 46.54”

12 600-2111 2 pans front to back 6 total cold drop in 31.06” x 67.36”

13 600-2112 2 pan capacity combo hot or cold drop in 26” x 31.13”

14 600-2113 3 pan capacity combo hot or cold drop in 26” x 43.63”

15 600-2114 4 pan capacity combo hot or cold drop in 26” x 56.50”

16 600-2115 5 pan capacity combo hot or cold drop in 26” x 69.25”

17 600-2116 Drop in Frost Top 28” x 58”

18 600-2117 2 pans front to back 8 total 31.06” x 88.2”

1 HDPCK0301 UHMW Tray Pucks

Receptacle 5362 DCO [120vac, 1Φ, Duplex

Receptacle 5461 [208vac, 20A, 1Φ]

Circuit Breaker 1503 [120vac, 15A, 3Φ]

Circuit Breaker 2003 BQ [120vac, 20A, 1Φ]

Circuit Breaker 2023 BQ [208vac, 20A, 1Φ]

Circuit Breaker 3023 BQ [208vac, 30A, 3Φ]

Circuit Breaker 8024 BQ [208vac, 80A, 3Φ]

RANDELL MANUFACTURED

DROP IN UNITS PARTS LIST

Mechanical Pa

l d

er Sp

r i

ng

i n

Attachment Bracket

- 1

0 , 30 0

r t

s

v

5 8

”

7 6

”

9 4

”

7 .50 ”

0 .40 ”

3 .31 ”

6 .22 ”

9 .13 ”

2 .06 ”

7

Page 10

2 HD TAB0301 Tab for 120-6004

3 HD SPR0302 Menu Card Holding Spring

4 HD LCH0306 Paddle Latches w/Locks

5 HD LCH0304 Paddle Latches

6 HD BMP0301 Bumper Strip [Length x 2 + 11”]

7 120-6001 3

8 120-6002 ¼” x 1

9 PL EXT0301 UHMW 42-118 Profile Wear S

10 PL EXT0302 UHMW 42-114 Profile for chain track edge

11 HD WRM0301 “Wells” Hot Food Wells w/Drain

12 RP DIF0401 Plexiglass Diffuser Panel [specify size]

13 RP CAR0503 Tray Carrier [Right]

14 RP CAR0504 Tray Carrier [Left]

15 HD SPK0303 60 B 32 1” Sprocket

16 HD CHN0301 No. 60 Chain

17 ST SHF0306 1” x 8” Shaft, W 2” Keyway

18 HD BRG0308 RC J-1 Fafner Bearing

19 HD RED0312 Winsmith Reducer

20 HD LMT0301 Torque Limiter

21 HD BSH0301 Torque Limiter Bushing

22 HD SPK0301 Torque Limiter Sprockets

23 PP LBL0359 Blue Logo, “AVTEC”

24 PP LBL0361 Tray-Trac [marker]

25 EL MTR0203 ¾” HP Motor

26 FA BLT0339 Carriage Bolt for 114-0130

/ 8

x 1” UHMW Bar Stock for Chain

[No. trays x 4.7]

- 1

/2” UHMW Bar Stock track bed

[No. trays x 2.35]

[No. trays x 2.35]

[No. trays x 2.35]

t r

ip [for oval ]

RANDELL MANUFACTURED

Hot Food Drop Ins

1 600-2200 Single we l Drop In with drain

2 600-2201 2 well side by side drop in with drains

3 600-2202 3 well side by side drop in with drains

4 600-2203 4 well side by side drop in with drains

5 600-2204 5 well side by side drop in with drains

6 600-2205 6 well side by side drop in with drains

7 600-2300 2 well front to back drop in with drains

8 600-2301 4 well front to back drop in with drains

9 600-2302 6 well front to back drop in with drains

10 600-2303 8 well front to back drop in with drains

Hot Food Well Parts

1 HD SCR0303 Drain Screens

2 EL ELM0301 Heating Element 50398 [SS

3 HD CNT0305 Hot Food We l Control, includes:

a )

Knob

[ 5

0371]

b ) Inf i

nite Switch [54593]

c )

Pi lot Light [50385]

d )

Face Plate [50410]

Fluorescent Light Fixture P

4 RP DIF0401 Fl

5 EL DIF0301

6 EL DIF0302

a t

Light Di fuser Panel 8” x 11”

1 8

” Alko Light Di fuser

3 6

” Alko Light Di fuser

8

- 2

a r

06D]

ts

Page 11

7 EL DIF0303 18” Duray Di fuser

8 150-0046 36” Duray Di fuser

9 EL STR0301 Starter No. FS-4

Ballast Transformer [Rober

10 EL STR101 Starter No. F2-2

Ballast Transformer [Rober

11 EL LGT0309 3’-0’ Fixture Lamp [Tube] 30 watt F30-T8

[Slimline]

12 EL LGT0310 1’-6” Fixture Lamp [tube] 15 watt No. F15-T8

[Slimline]

13 EL ASY0309 Heavy Duty Foot Switch Assembly Parts

[a] EL GRP0301 Straight Cable Grip

[b] EL SWT0327 Foot Switch SPDT N.C.

[c] EL WSH0301 ¾” x ½” Reducer

[d] EL PLG0322 2 Pin Plug w/Cable

7-Day Timer Pa

14 112-0293 Universal Bracket

15 112-0311 Contactor Bracket

16 EL BRK0368 5 amp Circuit Breaker

17 EL RLY0307 Relay, 2PDT, 30 a, 120 vac coil

18 EK TRN0304 Transformer 120:24, 40VA

19 EL VAR0302 Suppressor

20 EL TMR0303 Timer EC-71-24

21 407-1269 Contactor, 3-Pole, 90A, 120vac coil

22 EL SWT0321 Switch DPST, 10a

23 EL CNT0305 4Pin Amp Plug

24 EL CNT0306 4Pin Amp Cap

Electrical Parts

1 EL REC0350 Connector body 100A Risor

2 EL PLG0351 Flanged Receptacle [male] Connection

3 EL PLG0333 Plug 100A] Floor Box

4 EL REC0343 Receptacle

5 EL SWT0304 Square Green Sta

6 EL SWT0305 Square Red Stop Bu ton

7 EL BLK0313 Normally Open Contacts for Sq. Green S

8 EL BLK0403 Normally Closed Contacts for Sq. Red Stop Bu ton

9 EL RES0301 Resistor 47K

10 EL RLY0307 Relay 30A, DPDT, 120vac

11 EL SWT120 Switch, SPST, Bypass

12 EL SWT0321 Switch, 1222 Lights

13 EL STR0301 Starter for 36” Fluorescent Light

14 EL STR101 Starter for 18” Fluorescent Light

15 EL LGT0309 Light 36”

16 EL LGT0310 Light 18”

17 HD MIC0302 Microphone w/Positive Switch

18 EL SPK0401 Speaker 45 ohm

19 EL AMP0401 Bogan Amplifier C-10C

20 412-0308 Connector, Cannon male XLR-3-12

21 EL REC0325 2Pin Receptacle [Foot Switch Recept]

22 HD BRD0304 Motor Controller

r t

s

1 0

0A] Floor Box

r t

Bu ton

t s

on #340BP]

t s

on #SP-2

1 ]

t a

rt Bu ton

9

Page 12

COMPONENT IDENTIFICATION

TRAY-TRAC

ITEM NO. DESCRIP

1 Service Enclosure from Above [Optional]

2 Service From Below [Optional]

3 Main Service Breaker

4 Incoming Service

5 Motor ¾ HP EL MTR0203

6 Start & Stop Station

7 Light Switch EL SWT0321

8 Motor Control Behind Panel HD BRD0304

9 Receptacle for Footswitch EL PLG0322

10 Terminal Plates

11 Refrigeration Compressors

12 Chain HD CHN0301

13 Hot Food Well Controls 51710 HD CNT0305 [Optional]

14 S/S Back Splash or Light [Optional]

15 Bumper-strip HD BMP0301

16 Fafner Bearing HD BRG0308

17 Door Hinges

18 Drain Pipe for Hot Food Wells [Optional]

19 Drain Valve [Optional]

20 Drain-Pipe for Cold Top [Optional]

21 Valve [Optional]

22 Compressor Switch EL SWT0318 [Optional]

23 Over-shelf w/Lights [Optional]

24 Hot Food Wells [Optional]

25 Seal for hot Food Wells [Optional]

26 Cold Top [Optional] or Cold Pan

27 Lights [Optional]

28 Tray Carrier

29 Menu Holder Springs HD SPR0302

30 Caster [2 with locks]

31 Caster or Bullet Feet Height Adjuster [Optional]

32 Fill Faucet

33 Paddle Latches HD LCH0304

34 Paddle Latches w/Lock HD LCH0306

35 Potentiometer EL PTN0303

36 Field Joints

T I

ON

See drawing 4.4A

10

Page 13

11

Page 14

12

Page 15

-WARRANTY-

AVTEC INDUSTRIES INC. warrants to the original purchaser for use of our products, that any part thereof which

proves to be defective in material or workmanship under normal use within one year from date of installation, will be

replaced free of charge. Labor to replace such part is warranted for one year from installation. All warranty labor

to be performed during regular working hours, with no overtime premium.

All Warranty service must be authorized by the factory and be performed by AVTEC’s authorized service

personnel.

This Warranty is limited to the United States and Canada.

This Warranty does not apply to any damage resulting from shipping, improper installation, accident, unauthorized

alteration, local codes not previously brought to the attention of AVTEC, misuse, or abuse; and does not cover

loss of food, other products or damage to equipment or property resulting from mechanical or electrical failure.

AVTEC neither makes nor assumes and does not authorize any other person to assume any other obligation or

liability in connection with its products other than that covered in this Warranty.

.

13

Loading...

Loading...