Page 1

OPERATORS MANUAL

This manual provides

Installation & Operating instructions for

PAWS VENTILATOR

CONTROLS

For Models:

P30, P31, P32, P33, P34,

P35, P36, P37, P44, P46 and P47

NOTIFY CARRIER OF DAMAGE AT ONCE.

It is the responsibility of the consignee to inspect the

container upon receipt of same and to determine

the possibility of any damage, including concealed

damage. Avtec suggests that if you are suspicious of

damage to make a notation on the delivery receipt.

It will be the responsibility of the consignee to file a

claim with the carrier. We recommend that you do so

at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be

and accurate at the time of printing/creation. Unified Brands

recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and

specifications.

current

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

P/N PP MNL0805 Revised 10/08

unifiedbrands.net

Page 2

TABLE OF CONTENTS

I. GENERAL DESCRIPTION.......................................................................................................... 1-2

A. Model Number Guide ....................................................................................................... 1

1. Models P30, P34 and P44 ........................................................................... .. 1

2. Models P31, P35 and P45 ........................................................................... .. 1

3. Models P32, P36 and P46 ........................................................................... .. 1

4. Models P33, P37 and P47 ........................................................................... .. 1-2

II. INSTALLATION ... ............................................................................................................................ . 2-9

A. Wall Attachment ... ............................................................................................................... . 2

1. Surface Mounted... ......................................................................................... 2

2. Recess Mounted .......................................................................................... .. 2

3. Energy Distribution System Mounted ............................................................... 2

B. Electrical Interconnection ... ............................................................................................. 2-7

1. Control Panel Power Supply .............................................................................. 2

2. Vent Light Switch Power Supply ........................................................................ 2-3

3. Fan Starter(s) ...................................................................................................... 3

4. Vent Exhaust Damper Switch ... ....................................................................... 3-4

a. Resettable Electro-Mechanical Damper ................................................. 3

b. Fusible Link Damper with Thermo-switch ... .............................................. 3-4

c. Fusible Link Damper with Damper-switch............................................... 4

5. Water Solenoid(s) ............................................................................................ 4

6. Fire Pull Switch ... ........................................................................................... 4-5

7. Detergent Pump ... ................................................................................................ 5

8. Detergent Probe... ............................................................................................ 5

9. Gas Shut Off Solenoid ................................................................................. .. 6

10. Electric Shunt Trip Output .................................................................................... 6

11. Kill Switch ............................................................................................................ 6

12. Hood Fire System Inter-Connection ............................................................... 6-7

C. Plumbing Interconnection ... ............................................................................................ 7-9

1. Hot Water Supply ... ............................................................................................ 7

2. Hot Water from Panel to Hood Inlets ................................................................. 7

3. Cold Water Mist Supply ... ................................................................................ 7

4. Cold Water from Panel to Hood Inlet ................................................................. 7

5. Detergent Pump to Pick-up Tube ..................................................................... 8

6. Detergent Pump to Injection Tee ... .................................................................... 8

7. Priming the Detergent Pump........................................................................... 9

8. Detergent Pump Settings ... ................................................................................ 9

III. SEQUENCE OF OPERATION ... ................................................................................................ 9-

A. Manual Inputs ... .......................................................................................................... 9-10

1. Fan Off/Wash Off ........................................................................................... 9-10

2. Fan On/Wash Off ........................................................................................... 10

3. Fan Off/Wash On ........................................................................................... 10

4. Fuel Reset ............................................................................................................. 10

5. Alarm Silence ................................................................................................. 10

B. Programmed Events ... .................................................................................................. 10-11

1. Fan Off Event ...................................................................................................... 10-11

2. Fan On Event ...................................................................................................... 11

3. Wash On Event ... ............................................................................................... 11

C. Device Inputs ........................................................................................................

1. Hood Mounted Exhaust Damper Duct Switch ................................................ 11

2. Hood Fire Suppression system....................................................................... 11-12

3. Fire Pull Switch ... ........................................................................................... 12

4. AC Power Loss .............................................................................................. 12

5. Detergent Probe... ............................................................................................ 12

.. 11-13

Page 3

6. PAWS Supervised Water Supply Valve ...............................................................13

7. PAWS Water Pressure Switch ... .................................................................... 13

IV. PROGRAMMING INSTRUCTIONS............................................................................................. 13-15

A. Holiday Mode... .............................................................................................................. 13

B. Wash Duration ... ............................................................................................................... 13

C. Programmed Event Schedule ... .................................................................................

1. To Program an Event ... .................................................................................. 14

D. Setting the Clock ... ........................................................................................................

1. To Set the Day of the Week ... .......................................................................... 15

2. To Set AM/PM ..................................................................................................15

3. To Set the Hour .............................................................................................. 15

4. To Set Minutes ... .......................................................................................... .. 15

V. ENGINEERING DATA ...................................................................................................................16

A. Component Layout/Parts List ........................................................................................... 16-18

B. Terminal Identification ... .............................................................................................. 19

C. Diagnostic Indicators and Switch Settings ... .................................................................. 20-22

1. Model P30 to P37 PLC ... .................................................................................... 20

2. Model P44 to P47 PLC ... .................................................................................... 21-22

3. Operator Interface ... ......................................................................................... 22

VI. MAINTAINENCE ..................................................................................................................................22-23

A. Detergent Dispensing System .......................................................................................... 22

B. Plumbing.....................................................................................................................

VII WARRANTEE .................................................................................................................................... 23

Appendix ........................................................................................................................................................... 24-45

A. PAWS Programmed Events Worksheet...................................................................... . 25

B. PAWS Sequence of Operation(detailed)........................................................................ 26-33

C. Detergent Spec Sheet ... .............................................................................................

D. Typical Field Wiring Diagram ... .................................................................................

E. Typical Internal Wiring Diagrams ................................................................................. 37-45

. 13

15

. 22-23

. 34-35

.. 36

Page 4

I. General Description

The AVTEC PAWS panel is supplied as a Sub-

Assembly for an AVTEC Energy Aire Auto Wash

Ventilator.

The PAWS panel is provided to control the

exhaust and make-up air fans and the Ventilator

Auto Wash (cleaning) cycle(s).

One panel will control one or more fans if

operated simultaneously.

operate up to 50 linear feet of ventilator with a

single wash output. Sequential wash models

include up to 8 wash outputs and can operate

up to 400 linear feet of ventilator.

Fan and wash operation may be initiated

manually or programmed to occur at a user

specified time. The operation of the wash

output(s) may be set to a value from 2 to 10

minutes.

The PAWS panel may be provided as a wall

mounted unit or integrated into an AVTEC

Energy Distribution System (EDS).

Underwriters Laboratories Inc. (UL) list the

PAWS panel as:

“SUBASSEMBLY FOR EXHAUST HOOD

WITH EXHAUST DAMPER, for USE ONLY

WITH AVTEC LABELED HOOD

ASSEMBLY FOR EXHAUST HOOD WITH

EXHAUST DAMPER”

“SUBASSEMBLY FOR EXHAUST HOOD

WITHOUT DAMPER, for USE ONLY WITH

AVTEC LABELED HOOD ASSEMBLY

FOR EXHAUST HOOD WITHOUT

EXHAUST DAMPER”

All support plumbing and electrical components

for the PAWS panel are located within the panel

or the EDS. Peripheral plumbing components

may be shipped loose for installation in the field

by appropriate trades.

A. Model Number Guide

The PAWS control panels are available with

a wide variety of options specific to each

model number.

To determine the model number of your

panel, press and hold the (UP) (DOWN)

arrows at the same time. The top display

line will read:

Panel Model Number Version

AVTEC IND. P35 v1.0

PROGRAM WASH QTY. 2

Each panel will

-And-

Software

Number

1. Models P30, P34 and P44

Features Include:

Manual or Programmed Fan

Operation

Adjustable Wash Timer

Manual or Programmed Wash

Operation.

Low Detergent Enunciator

Supervised Water Supply Valve

Input (connection optional).

Water Pressure Switch Input

(connection optional).

Ventilator Exhaust Damper Switch

Input (connection optional).

Kill Switch Input (connection

optional).

Ventilator Fire System Input

(connection optional).

Exhaust Fan Output, 120vac or volt-

free normally open contacts.

Supply Fan Output, 120vac or volt-

free normally open contacts.

Electric Shunt Trip Output

P30—Single Wash Output

P34—2 to 3 Wash Outputs

P44—4 to 8 Wash Outputs

2. Models P31, P35 and P45

Features Include:

All items listed for model P30.

Fuel Reset with 1-1/2 second delay

for latching Gas Solenoid output.

P31—Single Wash Output

P35—2 Wash Outputs

P45—3 to 8 Wash Outputs

3. Models P32, P36 and P46

Features Include:

All items listed for model P30.

Fuel Reset with 120-second delay

for latching Gas Solenoid output.

120vac, 600va, Battery Back Up.

Provides 120 seconds of operating

power for the gas solenoid output

and, 4-1/2 hours of power for the

operation of the PAWS panel.

P32—Single Wash Output

P36—2 to 3 Wash Outputs

P46—4 to 8 Wash Outputs

4. Models P33, P37 and P47

Features Include:

All items listed for model P30.

120vac, 600va, Battery Back Up.

Provides 5 hours of power for the

operation of the PAWS panel.

P33—Single Wash Output

P37—2 to 3 Wash Outputs

Wash Output Quantity

1

Page 5

II. Installation

P47—4 to 8 Wash Outputs

For specific operation of the features listed

above refer to the “Sequence of Operation”

section of this manual.

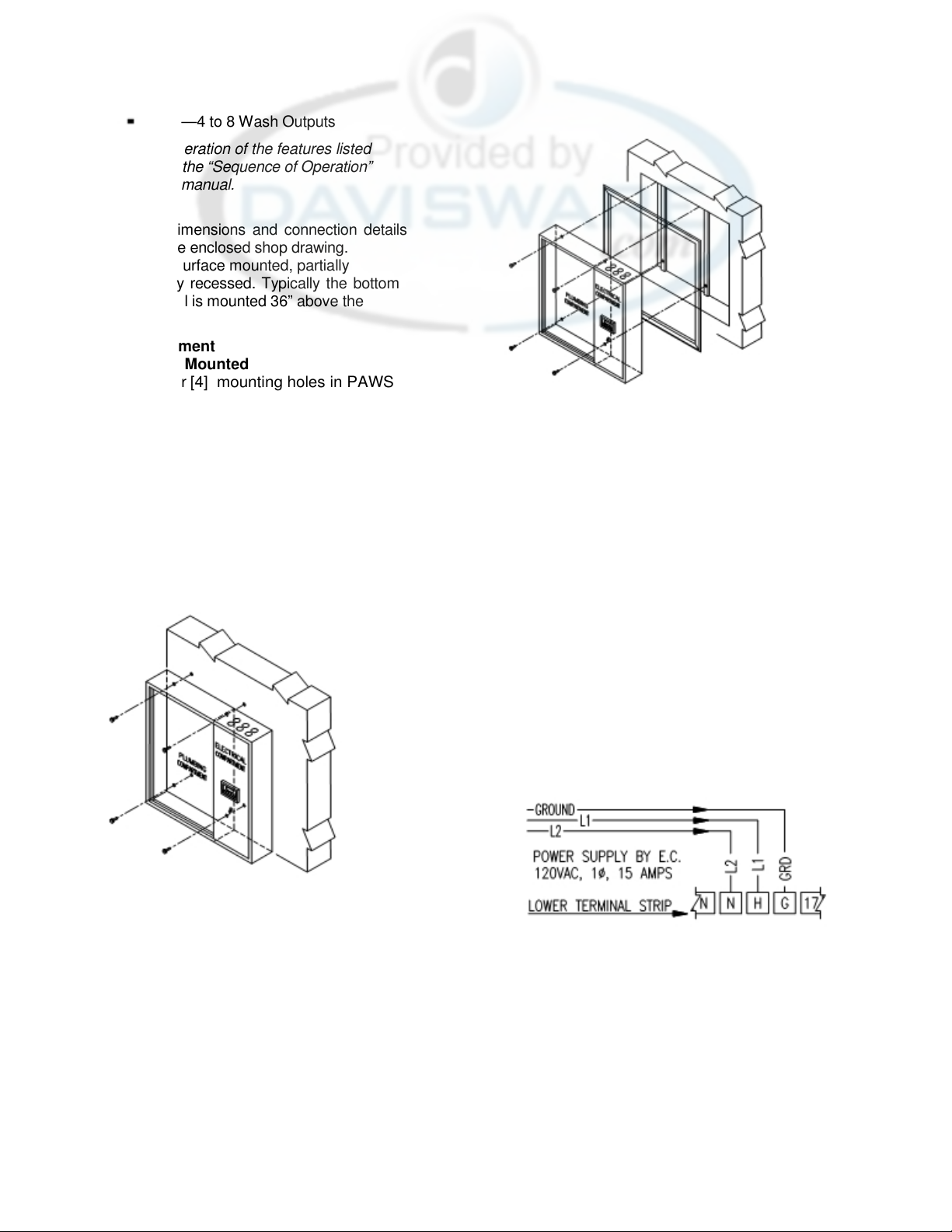

Control panel dimensions and connection details

are shown on the enclosed shop drawing.

Panels may be surface mounted, partially

recessed or fully recessed. Typically the bottom

edge of the panel is mounted 36” above the

floor.

A. Wall Attachment

1. Surface Mounted

Drill four

panel plumbing compartment.

mounting holes should be near each

corner of the box to provide adequate

support. Be careful not to damage any

components.

electrical compartment since component

damage will result. Bolt to wall with

anchor bolts or other acceptable means.

Weight of control panel varies from 90

lbs. to 200 lbs. See Figure II.A.1

[4] mounting holes in PAWS

The

Do not drill in the

Figure II.A.2

3. Energy Distribution System

The PAWS panel may be provided as

an integral part of an AVTEC EDS

(Energy Distribution System). All

components are pre-mounted.

B. Electrical Interconnection

Project specific wiring schematics are

provided in the project installation package.

General Internal Wiring Diagrams

model) and a Field Interconnection

schematic are included in the Appendix of

this manual.

connections are listed below.

1. Control Panel Power Supply

Provide 120vac, 15amps, single-phase

power. Connect the hot (L1) to terminal

“H”, the neutral (L2) to terminal “N”, and

the ground to terminal “G”.

See Figure II.B.1

Individual field inter-

(by

Figure II.A.1

2. Recessed

Cut hole in wall 1/2" greater than overall

dimensions of control box

shop drawing]. Spacers or support

angles may be necessary to provide

proper support. It is recommended that

panel be bolted to wall as described for

surface mounted above. A stainless

steel trim angle is provided and may be

set in place with construction adhesive.

See Figure. II.A.2

[shown on

Figure II.B.1

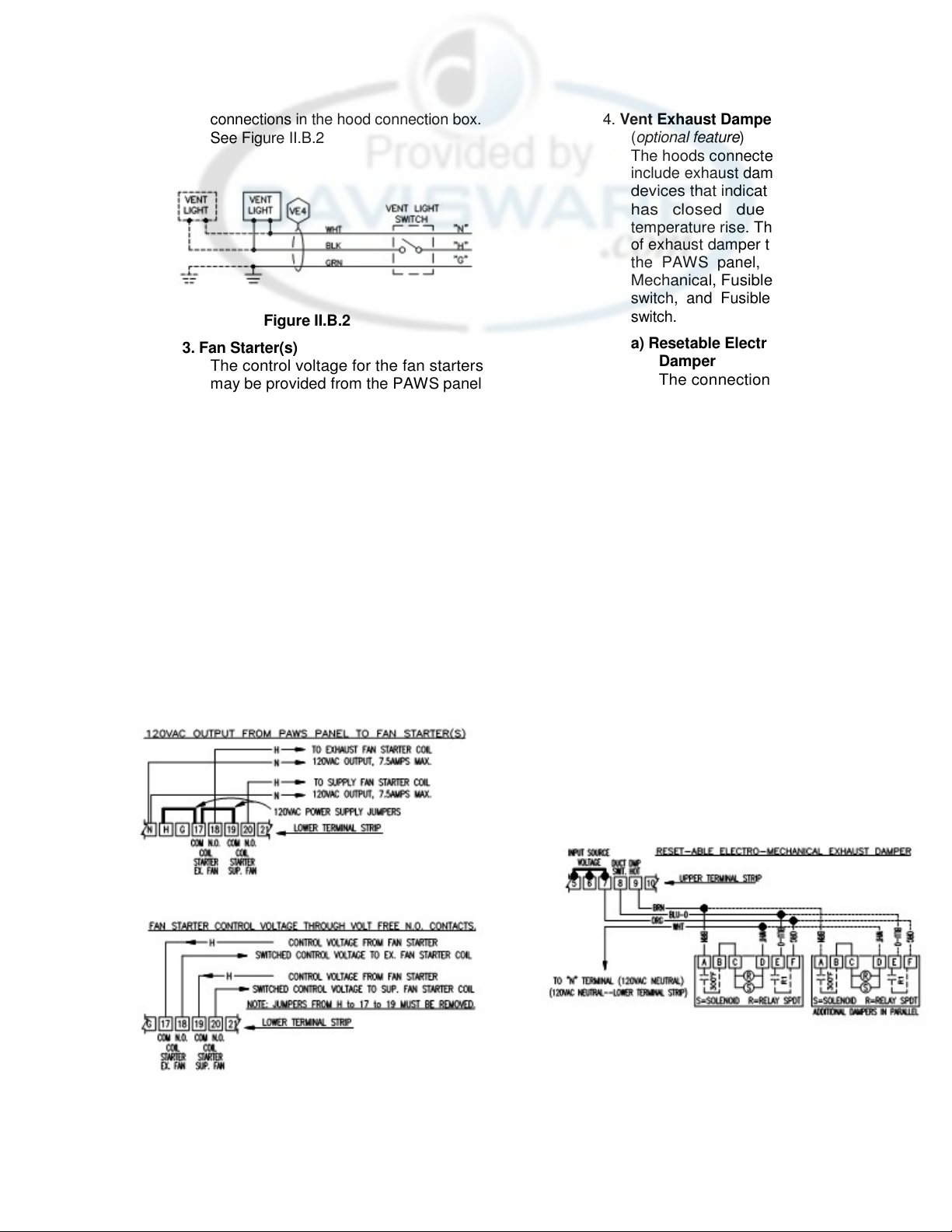

2. Vent Light Switch Power Supply

(optional feature)

Provide 120vac, 20 amps, single-phase

circuit. Connect the hot (L1) to line side

of the switch. Connect the load side of

the switch to the black wire in the hood

connection box. Connect the neutral and

ground wires to the corresponding

2

Page 6

connections in the hood connection box.

See Figure II.B.2

Figure II.B.2

3. Fan Starter(s)

The control voltage for the fan starters

may be provided from the PAWS panel

(120vac) or the outputs may be

configured as volt free normally open

contacts.

a) If the fan starters are not pre-wired

and require 120vac for the control

coils connect as shown in Figure

II.B.3.a,

PAWS PANEL TO FAN

STARTERS”.

b) If the fan starter package is pre-

wired and requires connection to

normally open volt-free

contacts connect as shown in

Figure II.B.3.b “FAN STARTER

CONTROL VOLTAGE THROUGH

VOLT FREE N.O. CONTACTS”.

“120VAC OUTPUT FROM

Figure II.B.3.a

Figure II.B.3.b

(dry)

3

4. Vent Exhaust Damper Switch

(optional feature)

The hoods connected to the panel may

include exhaust dampers with switching

devices that indicate when the damper

has closed due to an extreme

temperature rise. There are three types

of exhaust damper that may connect to

the PAWS panel, Resetable ElectroMechanical, Fusible Link with Thermoswitch, and Fusible Link with damper

switch.

a) Resetable Electro-Mechanical

Damper

The connection is from the PAWS

panel to the hood connection box.

Terminal #7 provides power to the

common terminal on the relay.

PAWS model series P3** provide

120vac to the common terminal on

the relay. PAWS model series P4**

provide

terminal on the relay.

Terminal #8

relay normally open contact. The

source voltage coming from terminal

#7

through this contact.

Terminal #9 provides 120vac to the

Thermo-switch. When the Thermoswitch closes 120vac is passed to

the damper solenoid and relay coil.

Terminal

neutral terminals on the damper

solenoid and relay coil. See Figure

II.B.4.a.

Figure II.B.4.a

b) Fusible Link Damper with

Thermo-switch

The connection is from the PAWS

panel to the hood connection box.

24vdc to the common

is connected to the

dictates the switched power

“N” is connected to the

Page 7

Terminal #7 provides power to the

common terminal on the relay.

PAWS model series P3** provide

120vac to the common terminal on

the relay. PAWS model series P4**

provide

terminal on the relay.

24vdc to the common

Terminal #8

relay normally open contact. The

source voltage coming from terminal

#7

dictates the switched power

through this contact.

Terminal #9 provides 120vac to the

Thermo-switch. When the Thermo-

switch closes 120vac is passed to

the relay coil.

Terminal “N” is connected to the

neutral terminal on the relay coil.

See Figure II.B.4.b.

Figure II.B.4.b

is connected to the

Figure II.B.4.c

5. Water Solenoid

The water wash solenoid is installed and

pre-wired in panels that have a single

wash output.

Water wash solenoids for multiple wash

output panels are pre-mounted on the

hood. The installing electrician must

provide a (2) wire circuit from the panel

terminal strip to the each solenoid valve.

Terminals #22 through #29 are provided

for each wash output

Figure II.B.5.

(1 to

8). See

c) Fusible Link Damper with Damper

Switch

The connection is from the PAWS

panel to the hood connection box.

Terminal #7 provides power to the

normally open contact on the

damper switch. PAWS model series

P3** provide 120vac to the normally

open contact. PAWS model series

P4** provide 24vdc to the normally

open contact.

Terminal #8

common terminal on the damper

switch. The source voltage coming

from terminal

switched power through this

contact. See Figure II.B.4.c

is connected to the

#7

dictates the

4

Figure II.B.5

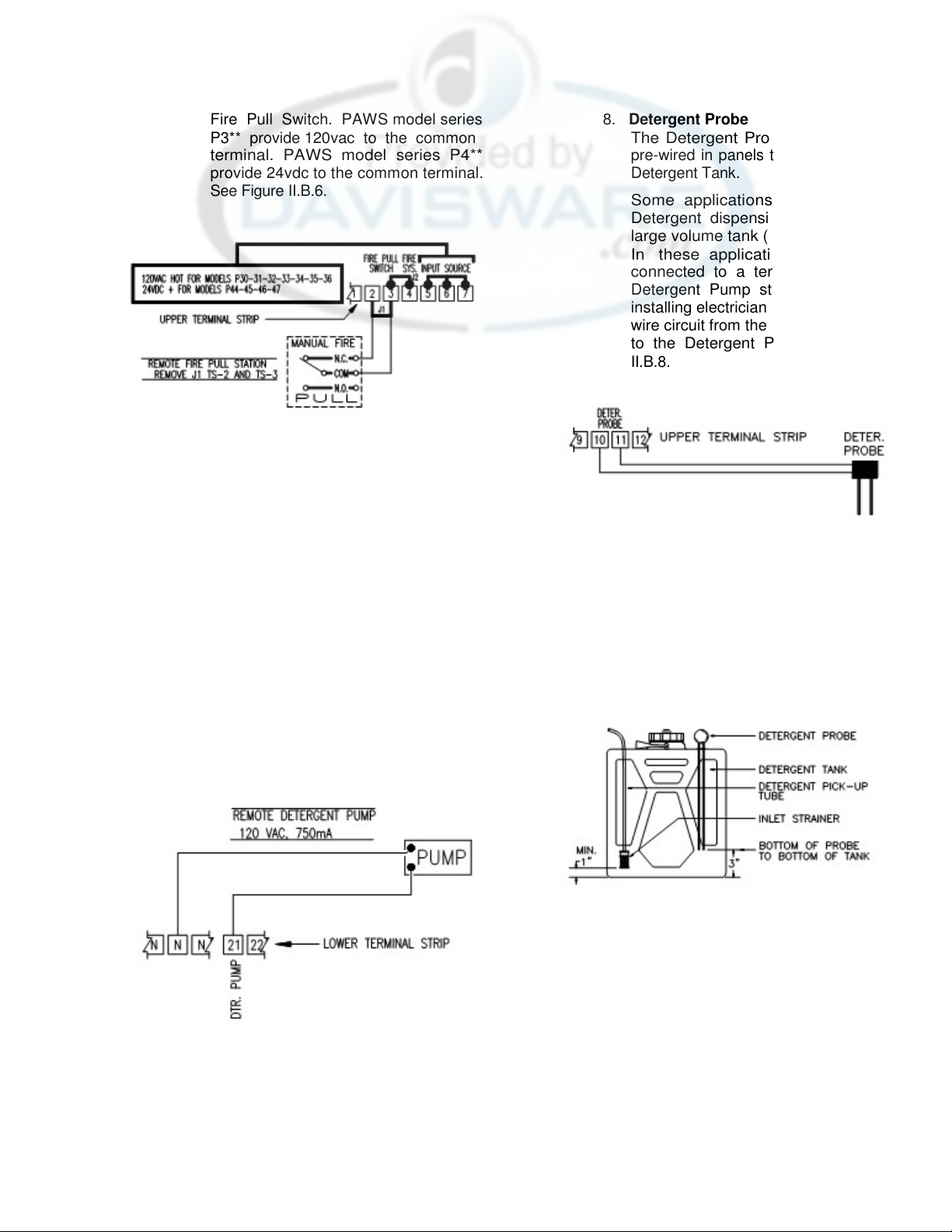

6. Fire Pull Switch (optional feature)

The Fire Pull Switch is an optional

feature that allows the user to activate

the PAWS Fire Condition manually. The

pull switch may be panel mounted and

pre-wired, or installed in a remote

location (typically at the egress of the

kitchen). The normally closed switch is

connected to Terminals # 2 and 3. The

panel is shipped with a jumper between

these terminals. The jumper is removed

and discarded once the Fire Pull Switch

is connected. Terminal

power to the common terminal on the

#3 provides

Page 8

Fire Pull Switch. PAWS model series

P3** provide

terminal. PAWS model series P4**

provide 24vdc to the common terminal.

See Figure II.B.6.

7. Detergent Pump

The Detergent Pump is installed and

pre-wired in panels that have an integral

Detergent Tank.

Some applications use a remote

Detergent dispensing cabinet with a

large volume tank (5 gallons) or drum.

In these applications the pump is

provided in a stainless steel cabinet.

The installing electrician must provide a

(3) wire circuit from the panel terminal

strip to the Detergent Pump. Terminal

#9 is connected to the normally open

contact on the pump prime switch,

terminal 21 is connected to the normally

closed contact on the prime switch. The

neutral lead from the pump motor is

connected to the “N” terminal strip. See

Figure II.B.7.

120vac to the common

Figure II.B.6

Figure II.B.7

8. Detergent Probe

The Detergent Probe is installed and

pre-wired in panels that have an integral

Detergent Tank.

Some applications use a remote

Detergent dispensing cabinet with a

large volume tank (5 gallons) or drum.

In these applications the probe is

connected to a terminal strip in the

Detergent Pump steel cabinet. The

installing electrician must provide a (2)

wire circuit from the panel terminal strip

to the Detergent Probe. See Figure

II.B.8.

Figure II.B.8

The probe should be installed in the

detergent container so that it does not

protrude below the top of the detergent

pump inlet strainer. This is intended to

prevent the pump from losing its prime

and will advise when the tank needs to

be refilled. The probe rods may be cut

to facilitate a neat and effective

installation. See Figure II.B.8.a.

Figure II.B.8.a

5

Page 9

9. Gas Shut Off Solenoid (optional

feature)

An output may be provided to power a

normally closed Gas Solenoid Valve.

The installing electrician must provide a

(2) wire circuit from the panel terminal

strip to the Gas Solenoid. Terminal #14

(120vac hot) and terminal “N” are

connected to the solenoid coil.

Additional valves may be wired in

parallel. See Figure II.B.9.

Figure II.B.9

11. Kill Switch (optional feature)

The Kill Switch is an optional feature

that allows the user to stop the flow of

gas

(for units supplied with a gas

solenoid output) and electricity to the

cooking line served by the panel. Hood

operation

effected. The Kill switch may be panel

mounted and pre-wired, or installed in a

remote location. The Kill Switch is a

momentary, normally open contact set

and is connected to Terminals # 1 and

6. Terminal #6 provides power to the Kill

Switch. PAWS model series P3**

provide 120vac at Terminal #6, PAWS

model series P4** provide 24vdc at

Terminal #6. If more than one Kill Switch

is required additional switches are wired

in parallel. See Figure II.B.11.

(fan and/or wash) is not

10. Electric Shunt Trip Output (optional

connection)

The PAWS panel includes an output

that will energize (120vac) when the

PAWS panel is in a Fire Condition. This

output may be connected to a shunt trip

coil on the main breaker serving the

cooking line.

The installing electrician must provide a

(2) wire circuit from the panel terminal

strip (terminal #15

terminal “N”) to the Electric Shunt Trip

coil. See Figure II.B.10.

Figure II.B.10

(120vac hot) and

Figure II.B.11

12. Hood Fire System Inter-Connection

The Hood Fire Suppression system (for

example, ANSUL R102) must be

electrically connected to the PAWS

panel. When the hood fire system

discharges the PAWS panel will

respond with a Fire Condition (Exhaust

Fan “ON”, Supply Fan “OFF”, Wash

“ON”, Detergent Pump “OFF” Fuel to the

Cooking Equipment “OFF”).

The installing electrician must provide a

(2) wire circuit from the panel terminal

strip (terminal #4 and terminal #5) to a

normally closed (when armed—opens

on discharge) contact set on the hood

Fire Suppression system.

Terminal #5 provides power to the Fire

System Switch. PAWS model series

P3** provide 120vac at Terminal #5,

PAWS model series P4** provide 24vdc

at Terminal #5. See Figure II.B.12.

6

Page 10

Figure II.B.12

C. Plumbing Interconnection

A project specific drawing is provided in the

project installation package that lists specific

connections required, and components that

are supplied by AVTEC.

Individual field interconnections are listed

below.

1. Hot Water Supply

140οF (minimum) hot water, 20-40 psig

is needed to properly clean the extractor

chamber. The Hot Water Supply is

connected to the control panel inlet. A

pressure reducing valve may be

required if water pressure exceeds 60

psig. Refer to your project drawing for

the pipe size required. Typical water

consumption at 30 psig is 1.2 gallons

per minute per linear foot of hood. For

example a

require 12 gallons per minute. Refer to

Figure II.C.1.

2. Hot Water from Panel to Hood Inlets

Hot water piping is required from the

panel outlet to a vacuum breaker-check

valve-detergent injection tee assembly.

NOTE:

Panels with a single wash output

(water solenoid mounted in the

panel) require an atmospheric

vacuum breaker, mounted at least

6” above the hood inlet.

Panels with multiple wash outputs

(water solenoids mounted on hood

sections) require a pressure type

vacuum breaker, mounted at least

18” above the hood inlet.

10’-0” long hood would

Additional piping is required from the

vacuum breaker, check valve, and

detergent injection tee assembly to the

Hood water inlet(s). AVTEC will prepipe multiple hoods to a single inlet

when specified. Refer to your project

drawing for hood inlet connection

requirements. Refer to Figure II.C.1.

3. Cold Water Mist Supply (optional

feature)

When specified, the Cold Water Mist

feature is provided to add an additional

level of grease extraction. The Cold

water mist operates whenever the

Exhaust Fan is running.

The cold water supply (20-30 psig) is

connected to the control panel inlet. A

pressure reducing valve may be

required if water pressure exceeds 30

psig. Refer to your project drawing for

the pipe size required. Typical water

consumption at 30 psig is 0.6 gallons

per minute per linear foot of hood. For

example, a 10’-0” long hood would

require 6 gallons per minute. The Cold

Water Mist manifold is constructed the

same as a single wash Hot Water

manifold. Refer to Figure II.C.1.

4. Cold Water from Panel to Hood Inlet

Cold water piping is required from the

panel outlet to a vacuum breaker-check

valve assembly.

NOTE:

An atmospheric vacuum breaker,

mounted at least 6” above the hood

cold water inlet is required.

The vacuum breaker-check valve

assembly is provided by AVTEC when

specified. Refer to your project drawing.

Additional piping is required from the

vacuum breaker-check valve assembly

to the Hood water inlet(s). AVTEC will

pre-pipe multiple hoods to a single inlet

when specified. Refer to your project

drawing for hood inlet connection

requirements. Refer to Figure II.C.1.

The vacuum breaker-check valve

assembly is provided by AVTEC

when specified. Refer to your

project drawing.

7

Page 11

5. Detergent Pump Pick-up Tube

The pump pick-up tube is provided and

installed by AVTEC when the Detergent

Tank is provided. Some applications use

a remote Detergent dispensing cabinet

with a large volume tank (5 gallons) or

drum. In these applications the pump is

provided with a 5’-0” length of clear PVC

suction tube and a pick-up strainer

screen. The Pick-up tube may not

exceed 5 feet in length. Install as shown

in Figure II.C.1.

6. Detergent Pump to Injection Tee

The output side of the pump (pressure

side) is provided with a pre-piped check

valve. Provide 3/8” O.D. tubing (copper,

or stainless steel) from the detergent

check valve outlet to the injection tee

located between the vacuum breakercheck valve assembly and the ventilator

Figure II.C.1

inlet. Normally the detergent pump and

tank are located in the control panel,

and tubing from the detergent pump to

the detergent tank is factory connected.

Refer to Figure II.C.1.

8

Page 12

7. Priming the Detergent Pump

In order for the pump to function the

pump head must be primed (i.e. all air is

displaced by detergent from the inlet

tube through the pump head). Provided

the Detergent Probe is installed properly

this operation is only required at initial

start-up.

a) Close the PAWS water supply

valve.

b) Ensure that the detergent tank is full

and the pump pick-up tube is

installed as shown in Figure II.C.1.

c) Press the “Fan Off/Wash On”

button.

d) Watch the pre-piped section of clear

output tubing on the pump. Once a

solid column of fluid is present press

the “Fan Off/Wash Off” button. The

pump is primed.

e) Open the PAWS water supply valve.

The Panel is ready for normal

operation.

Figure III

8. Detergent Pump Settings

The pump includes a volume

adjustment. Refer to Figure II.C.1 for the

9

proper setting based on the maximum

hood length washed. To adjust the

pump output:

a) Turn off power to the PAWS panel

by opening DIN rail mounted

fused disconnect.

b) Remove the pump mechanism

cover. It is attached with (1) screw

on the right side. Refer to Figure

II.C.1.

c) Loosen the Adjustment Lock nut

(wing nut).

d) Turn the Graduated Adjustment

Disc so the desired number is in

alignment with the Setting Pointer.

e) While holding the Graduated

Adjustment Disc tighten the

Adjustment Lock nut (wing nut).

f)

Replace the pump mechanism

cover and attachment screw.

g) Restore power to the PAWS panel

by closing the DIN rail mounted

fused disconnect.

III.

Sequence of Operation

A. Manual Inputs

Manual Inputs refer to the operator interface

on the front of the control panel. The five

lower buttons are used for manual operation

of the fans, and to initiate the wash cycle(s).

The five upper buttons are used to program

the PAWS control panel for automatic

operation. See Figure III and III.A.

1. Fan Off/Wash Off button

This button Cancels either fan or wash

operation. A Fire Condition initiated by

the hood Fire System, optional Fire Pull

Switch, or the exhaust damper switch

will override this input. This button will

Figure III.A

Page 13

also cancel the Fire Delay Cycle that

occurs after a Fire Condition has

cleared.

2. Fan On/Wash Off button

This button turns the fans

cancels the wash operation. A Fire

Condition will override this input.

3. Fan Off/Wash On button

This button cancels the fan operation

and initiates the hood wash cycle. The

PAWS panel will wash the hood for an

adjustable period of time (2-10 minutes)

and automatically shut off. This button

is typically used at the end of the day to

shut off the fans and clean the hood.

PAWS models P30* through P33* have

a single wash output. This single output

will control up to a 1-1/2” solenoid valve

that will provide sufficient water flow for

up to 50 linear feet of hood.

PAWS models P34* through P47* have

multiple wash sequences that range

from 2 to 8 outputs, depending on the

model. When a wash cycle is initiated

the outputs operate sequentially, one

after the next. The total time required to

complete all wash sequences is equal to

the length of the wash (adjustable 2-10

minutes) times the number of wash

outputs. For example if you have a 4output PAWS panel and have adjusted

the wash duration for

Wash cycle will operate for 16 minutes

(4 minutes for each output).

4. Fuel Reset button (optional feature)

This button will restore power to the gas

solenoids that control the flow of gas to

the cooking equipment, served by the

hood that is controlled by the panel.

The electrical power to the cooking

equipment may also be restored after

pressing the fuel reset button. A main

service breaker that is equipped with a

shut off device

controls the electrical power.

The fuel-reset feature is provided to

integrate the PAWS panel with the Hood

Fire Suppression system to shut off fuel

to the cooking equipment during a

kitchen fire. There are two types of fuel

reset, one with battery back-up and one

without.

(shunt trip) typically

“ON”, and

4 minutes, the

In the event of a power outage the fuel

reset will:

Units without battery back-up; the

solenoid latching circuit will hold for

1-½ seconds, eliminating the need

to reset the solenoids.

Units with battery back-up; the Gas

Solenoids will remain on for

seconds.

5. Alarm Silence button

This button will silence the horn that

sounds intermittently when the PAWS

panel is in a TROUBLE mode.

A TROUBLE mode may be initiated by a

LOW DETEGENT condition, PAWS

Water Supply Valve Closed (optional),

or, PAWS Water Pressure Low

condition (optional).

If additional trouble conditions occur

after the horn silence button is used; the

horn will not re-sound until all trouble

conditions are cleared and another

trouble condition is initiated.

B. Programmed Events

The PAWS panel can automatically control

the Fan and Wash operation by a user

defined operation schedule. This feature

may or may not be used. It is not required

for the panel to function. There are three

programmable functions:

FAN ON {FAN ON #1 & #2}

FAN OFF {FAN OFF #1 & #2}

WASH ON {WASH ON #1 & #2}

Each of the three functions may be set to

occur twice on a given day (example FAN

ON #1 and FAN ON #2).

Whether a function is initiated manually or

by a programmed event, the last event to

occur takes precedence, with exception to

Fire Conditions. Fire Conditions always

take precedence

1. Fan Off Event

{Fan Off #1 & #2}

This event cancels fan operation. The

Fan Off function is programmed when

the user wishes to cancel fan operation

without initiating a wash, typically used

for daytime fan shut down.

A Fire Condition initiated by the hood

Fire System, optional Fire Pull Switch,

120

10

Page 14

or the exhaust damper switch will

override this input.

Power to the Electric Shunt trip Output

is turned “ON”.

2. Fan On Event

{Fan On #1 & #2}

This event turns the fans “ON”. A Fire

Condition will override this input.

3. Wash On Event

{Wash On #1 & #2}

This event cancels the fan operation

and initiates the hood wash cycle.

The Wash On function is programmed

when the user wishes to cancel fan

operation and initiate the hood wash

cycle. It is best to wash the hood

immediately after the cooking equipment

is shut down, the grease in the hood is

still warm and more easily cleaned. If

the hood is washed after cool down, an

extended wash period may be required.

Typically the user will program this

event as the last function of the work

day, since the fans are shut down and

one wash cycle per day is usually

adequate.

The user may elect to program this

function to occur in the middle of the

night when hot water demand is low.

The fan does not have to be on in order

to program this event.

Please refer to the Programming section

of this manual to ensure the Wash event

does not conflict with other programmed

events.

C. Device Inputs

There are peripheral devices that are

connected to the PAWS panel for purposes

of monitoring operation and causing

variances in panel operation due to external

events. The following is a list of devices and

their effect on panel operation.

1. Hood Mounted Exhaust Damper Duct

Switch (optional hood feature)

Closure of the duct switch indicates that

the exhaust damper on the connected

hood has closed.

Both exhaust and supply fans are turned

“OFF”. The wash spray in the exhaust

plenum is turned

interior of the hood and prevent flame

spread.

“ON” to cool the

In order to return the panel to Normal

operation the Duct Switch must be

open.

When the Duct Switch opens a Fire

Delay Cycle will maintain the plenum

wash spray and fan off condition for a

period of

Delay may be cancelled by pushing the

Fan Off/ Wash Off button.

A Duct Fire Condition takes precedence

over all other events.

A pulsed tone will emanate from the

Alarm Horn while the fire condition is

active.

Following Actions apply to MODELS

P31*, P32*, P35*, P36*, P45* and P46*

ONLY.

Power to the Gas Solenoid output is

turned “Off “

After the Duct Fire Condition and Fire

Delay Cycle are cleared: press the Fuel

Reset button to reset the Gas Solenoid

and Electric Shunt trip outputs.

After the fire condition is cleared the

horn sounds a constant tone until the

Fuel Reset Button is activated.

2. Hood Fire Suppression System

Switch (N.C.) (optional connection)

Normally Closed dry contacts on the

Hood Fire Suppression System (Ansul

R-102, for example) are connected to

the PAWS panel. Upon discharge of the

Fire Suppression system:

The exhaust fan is turned “ON” and the

supply fan is turned “OFF”. The wash

spray in the exhaust plenum is turned

“ON” to cool the interior of the hood and

prevent flame spread.

Power to the Electric Shunt trip Output

is turned “ON”.

In order to return the panel to Normal

operation the Fire Suppression System

must be reset.

When the Fire Suppression System is

reset a Fire Delay Cycle will maintain

the plenum wash spray and fan

condition for a period of 5 minutes. The

5 minutes. The Fire Cycle

11

Page 15

Fire Cycle Delay may be cancelled by

pushing the Fan Off/ Wash Off button.

A Fire System Condition takes

precedence over all events other than a

Duct Switch Event.

Following Actions apply to MODELS

P31*, P32*, P35*, P36*, P45* and P46*

ONLY

Power to the Gas Solenoid output is

turned “Off “.

A pulsed tone will sound from the Alarm

Horn while the fire condition is active.

The following actions apply to

MODELS P31*, P32*, P35*, P36*, P45*

and P46* ONLY

Power to the Gas Solenoid output is

turned “Off “.

After the Fire System Condition and Fire

Delay Cycle are cleared, pressing the

Fuel Reset button will reset the Gas

Solenoid and Electric Shunt trip outputs.

After the fire condition is cleared a

constant tone is delivered until the Fuel

Reset Button is activated.

3. Fire Pull Switch (N.C.) (Panel option)

The optional Fire Pull switch may be

mounted on the PAWS panel or in a

remote location, such as at the point of

egress. When the Fire Pull Switch is

activated:

The exhaust fan is turned “ON” and the

supply fan is turned “OFF”. The wash

spray in the exhaust plenum is turned

“ON” to cool the interior of the hood and

prevent flame spread.

Power to the Electric Shunt trip Output

is turned “ON”.

In order to return the panel to Normal

operation the Fire Pull Switch must be

reset.

When the Fire Pull Switch is reset a Fire

Delay Cycle will maintain the plenum

wash spray and fan condition for a

period of 5 minutes. The Fire Cycle

Delay may be cancelled by pushing the

Fan Off/ Wash Off button.

A Fire Pull Switch Condition is equal to

a Fire System Condition and takes

precedence over all events other than a

Duct Switch Event.

A pulsed tone will emanate from the

Alarm Horn while the fire condition is

active.

After the Fire Pull Switch condition and

Fire Delay Cycle are cleared, the Gas

Solenoid and Electric Shunt trip outputs

can be reset by pushing the Fuel reset

button.

After the fire condition is cleared a

constant tone is delivered until the Fuel

Reset Button is activated.

4. AC Power Loss (N.C.) (Panel option)

Loss of AC power will disable the

outputs of the panel with exception of

the Gas Solenoid circuit (when

provided).

The Fire Pull Switch, Fire System

Switch, Duct Switch, or Kill Switch will

override the AC power loss condition

and cause the actions listed for each

input.

Models P32*, P36*, and P46 ONLY!

After a 2-minute delay, power to the Gas

Solenoid output is turned “OFF”. When

AC Power is restored the “Fuel Reset”

button must be pushed to close the

circuit to the gas solenoid valve output

and open the circuit to the shunt trip

output.

5. Detergent Probe (N.C.)

The detergent probe is provided with the

PAWS panel detergent tank. When the

detergent in the tank is low, the probe

initiates a Low Detergent Condition

(PAWS Trouble Condition).

The Detergent Pump Output is turned

“OFF”.

The Probe is set to disable the pump

prior to losing fluid in the pump body.

The pump will not need to be primed

once the detergent supply is

replenished.

The horn will sound intermittently and

may be silenced with the Alarm Silence

button.

12

Page 16

6. PAWS Supervised Water Supply

Valve (N.O.) (Panel option)

The PAWS panel water supply valve

may be equipped with a switch to

monitor the status of the valve. If the

valve is closed a PAWS Trouble

Condition is initiated. The horn will

sound intermittently and may be

silenced with the Alarm Silence button.

7. PAWS Water Supply Pressure Switch

(N.O.) (Panel option)

The PAWS panel may be equipped with

a pressure switch to monitor adequate

water supply. If the pressure switch is

activated due to low water pressure a

PAWS Trouble Condition is initiated.

The horn will sound intermittently and

may be silenced with the Alarm Silence

button.

IV. Programming Instructions

A. HOLIDAY MODE (Intermittent use)

The

HOLIDAY MODE

suspend programmed Fan/Wash operation.

Set this feature “ON” when normal operation

is suspended during a holiday or shut down

period. Manual operation of the panel is still

active when in Holiday Mode.

When the panel is in “HOLIDAY MODE” the

bottom display line message will alternate

between Fan/Wash status and “

MODE ON”.

To Set HOLIDAY MODE

1. Press the MENU key. Display

Reads: ”SET CLOCK”.

2. Use the (DOWN) arrow key until

the display reads “SET HOLIDAY”.

3. Press the ENTER key. Display

Reads: “SET HOLIDAY MODE”

4. Press the ENTER key. The bottom

display line reads: “SET MODE

X ENTER”.

5. Use the (UP) (DOWN) arrow

keys to adjust the HOLIDAY MODE

ON--OFF

[0=OFF, 1=ON].

6. Press the ENTER key to accept the

adjusted value. Display Reads:

“SET HOLIDAY MODE”.

7. To EXIT press the CLEAR/ABORT

key. To return to the MENU tree

press the MENU key.

is provided to

HOLIDAY

13

B. Set the WASH DURATION

The WASH DURATION is the length of time

each vent wash cycle will run. When a

sequential wash

output) panel is provided each wash will

operate for the set wash duration. The

minimum operational setting is 2 minutes.

The maximum setting is 10 minutes. Typical

setting is 4 to 5 minutes. Under heavy loads

a value of 7 to 10 minutes may be required.

To set the WASH DURATION

1. Press the MENU key. Display

Reads: ”SET CLOCK”.

2. Use the (UP) arrow key until the

display reads “SET WASH

DURATION”.

3. Press the ENTER key. Display

Reads: “SET WASH TIME”

4. Press the ENTER key. The bottom

display line reads: “SET WASH

XX MINUTES”.

5. Use the (UP) (DOWN) arrow

keys to adjust the Wash Time value.

6. Press the ENTER key to accept the

adjusted value. Display Reads:

“SET WASH TIME”.

7. To EXIT press the CLEAR/ABORT

key. To return to the MENU tree

press the MENU key.

C. Set the Programmed Events Schedule

(Automatic Fan On-Off and Wash Cycle)

The PAWS panel can automatically control

the Fan and Wash operation by a user

defined operation schedule.

This feature may or may not be used. It is

not required for the panel to function. There

are three programmable functions:

1. FAN ON {FAN ON #1 & FAN

2. FAN OFF {FAN OFF #1 & FAN

3. WASH ON {WASH ON #1 &

Each of the three functions may be set to

occur twice on a given day (example FAN

ON #1 and FAN ON #2).

Please refer to the PAWS Programmed

Events Worksheet included in the Appendix

of this manual for an outline of the Event

Schedule.

Plan the Programmed Event Schedule.

(more than one wash

ON #2}

OFF #2}

WASH ON #2}

Page 17

Determine your operation schedule by

completing a copy

PAWS Programmed Event Schedule

Worksheet

installation package).

When planning the event schedule you must

account for the time required by the wash

cycle.

In the previous section

Duration” the length of the wash cycle was

determined. Do not schedule fan operation

until sufficient time has passed for the wash

cycle to run to completion.

If your panel includes sequential wash

operation determine the wash output

quantity.

(

DOWN)

bottom display line will read “PROGRAM

WASH QTY. X

the “X” is shown, is the wash quantity value.

Multiply the quantity of wash outputs by the

wash duration to determine the total wash

time required.

EXAMPLE: If

DURATION

output quantity is 4, total wash time is 16

minutes (4 min. wash duration x 4 wash

outputs = 16 minutes).

To stop the operation of the fans a “

OFF” event OR a “WASH ON” event may be

scheduled. While both functions turn the

fans off, the WASH ON function will also run

the hood(s) through a wash cycle.

You may schedule any function independent

of relative functions. For example, if you

normally operate the fans manually, but

want to ensure that the fans are shut off

each night, you could program a “FAN OFF”

event at the end of the day.

operations cook past midnight, so you may

want to program a “

start of the cooking operation, and schedule

a “

FAN OFF”

following day.

1. To Program an Event

a) Press the

b) Use the (UP)

c) Press the

(copy included in the project

Press and hold the

arrows at the same time. The

for 4 minutes, and the wash

Reads: ”SET CLOCK”.

display reads “SET PROGRAM”.

Reads: “SELECT DAY”

(or facsimile) of the

“Setting Wash

”. The value placed where

or “

WASH ON”

MENU

ENTER

you set the

FAN ON

key. Display

arrow key until the

key. Display

WASH

FAN

Some

” event at the

event for the

(UP)

14

d) Press the ENTER key. The bottom

display line reads: “SET DAY

X ENTER”.

e)

Use the

keys to adjust the Day value to the

day you wish to program

[1=Sunday, 2=Monday, 3=Tuesday,

4=Wednesday, 5=Thursday,

6=Friday, 7=Saturday].

f) Press the ENTER key to accept the

adjusted value. Display Reads:

“SELECT DAY”.

g)

Use the (

display reads “SELECT PROGRAM

EVENT”.

h)

Press the

Reads: “FAN ON #1”.

i)

Use the

keys until the display shows the

function you wish to program. In the

following example the “FAN ON #1”

function is used to demonstrate the

programming process.

j)

Press the

Reads:

“FAN ON #1 HOUR X”

k)

Use the

keys to adjust the hour value. If you

wish to clear this programmed

event, adjust the hour value to “0”.

l) Press the ENTER key to accept the

adjusted value. If you accepted a

value other than “0”. Display reads:

“FAN ON #1 MIN. XX”

m)

Use the

keys to adjust the minute value. n)

Press the ENTER key to accept the

adjusted value. Display Reads:

“FAN ON #1 AM/PM. X”

o)

Use the

keys to adjust the AM/PM value

[1=AM, 2=PM].

p) Press the ENTER key to accept the

adjusted value. Display Reads:

“FAN ON #1”.

q) To continue programming

additional events for the same

day:

Use the

arrow keys until the display shows

the function you wish to program.

Repeat steps j to q. Each function

may be scheduled to occur twice

(UP) (DOWN)

UP)

arrow key until the

ENTER

ENTER

key. Display

(UP) (DOWN)

key. Display

(UP) (DOWN)

(UP) (DOWN)

(UP) (DOWN)

(UP) (DOWN)

arrow

arrow

arrow

arrow

arrow

Page 18

per day (Fan On #1-Fan on #2, et

cetera).

r)

To select a new day to program:

Press the

Reads “SELECT PROGRAM

EVENT

arrow key. Display Reads “SELECT

DAY”. Repeat steps c to i.

s)

To back up one level in the menu

tree press the MENU key.

t)

To EXIT and return to the default

Display Messages press

CLEAR/ABORT

only programmed values that will be

saved are those that were

confirmed with an ENTER key.

D. Setting the Clock

The clock does not continue to keep time

when the MENU mode is active. Therefore

the time of day is the last item that should

be set.

1. To Set Day of Week

(a) Press the MENU key. Display

Reads: ”SET CLOCK”.

(b) Press the ENTER key. Display

Reads: “SET MINUTES”

(c) Use the (UP) arrow key until the

display reads “SET DAY OF

WEEK”.

(d) Press the ENTER key. The bottom

display line reads: “SET DAY

X ENTER”.

(e) Use the (UP) (DOWN) arrow

keys to adjust the Day value to the

current day [1=Sunday, 2=Monday,

3=Tuesday, 4=Wednesday,

5=Thursday, 6=Friday, 7=Saturday].

(f) Press the ENTER key. The bottom

display line reads: “SET DAY OF

WEEK”.

MENU

”. Press the

key. Display

at any time. The

(DOWN)

3. To Set Hour

(a) Use the (UP) arrow key until the

display reads “SET HOUR”.

(b) Press the ENTER key. Display

Reads: “SET HOUR X

Enter”.

(c) Use the (UP) (DOWN) arrow

keys to adjust the Hour value to the

current time.

(d) Press the ENTER key to accept the

adjusted value. Display Reads:

“SET HOUR

4. To Set Minutes

(a) Use the (UP) arrow key until the

display reads “SET MINUTES”.

(b) Press the ENTER key. Display

Reads: “SET MIN. XX

Enter”.

(c) Use the (UP) (DOWN) arrow

keys to adjust the Minute value to

the current time.

(d) Press the ENTER key to accept the

adjusted value. Display Reads:

“SET MINUTES.

(e) To back up one level in the menu

tree press the MENU key.

(f) To EXIT and return to the default

Display Messages press

CLEAR/ABORT at any time.

2. To Set AM/PM

(a) Use the (UP) arrow key until the

display reads “SET AM/PM”.

(b) Press the ENTER key. Display

Reads: “SET AM/PM X

Enter”.

(c) Use the (UP) (DOWN) arrow

keys to adjust the AM/PM value to

the current time [1=AM, 2=PM].

(d) Press the ENTER key to accept the

adjusted value. Display Reads:

“SET AM/PM”.

15

Page 19

V. Engineering Data

A. Component Layout/Part Numbers

All PAWS panels share a common chassis

and base components. Following is a list of

components, AVTEC part number,

description, and additional drawings when

necessary. Refer to Figure V.A as a general

reference.

1. Panel Faceplate

A stainless steel faceplate is provided

as an integral part of the PAWS control

panel.

2. AVTEC PAWS Overlay P/N PP LBL0342

An adhesive backed polycarbonate

colorfast label. All printing is printed

second surface. The label is die-cut to

index with # 3 (operator interface”).

3. Operator Interface - P/N EL MOD0303

Includes 2-line by 20 character LCD

display, 5

control keys.

programming keys and

5

Figure

V.A

4. Vent Light Switch - P/N EL SWTO318

5. Fire Pull Switch - P/N EL STA0301

Optional feature, Yellow pull switch with

replaceable glass rod, (1) normally open

contact and (1) normally closed contact.

6. PAWS PLC Chassis

Pre-punched stainless steel chassis with

integral threaded fasteners for

component mounting. Provided as an

integral part of the PAWS control panel.

Suitable for all PAWS models.

16

Page 20

7. Programmable Logic Control

The PAWS panel uses a standard PLC

with a proprietary program. Depending

on the PAWS model the PLC part

number will vary. AVTEC must load the

program prior

Applications are listed below by model:

a) PAWS Model P30* through P37*

PLC (DL130AR) - P/N EL PLC0301

120vac PLC as provided includes

10 inputs, 8

integral 24vdc power supply.

b) PAWS Model P44* through P47*

PLC DL240 includes:

120vac PLC as provided includes 8

DC inputs,

integral 24vdc power supply.

8. Din Rail (typical)

9. Relay (Exhaust Fan) - EL RLY0334,

SPDT Relay with 120/1 coil, 7.5a @

120vac contacts and ELRLY 0327 relay

socket

10. Relay (Supply Fan) - EL RLY0334, SPDT

Relay with 120/1 coil, 7.5a @ 120vac

contacts and EL RLY0327 relay socket

11. Relay (Fuel Shut Off) - EL RLY0334,

SPDT Relay with 120/1 coil, 7.5a @

120vac contacts and EL RLY0327 relay

socket

Relay (AC Power Loss, not shown) EL RLY0334, SPDT Relay with 120/1 coil,

7.5a @ 120vac contacts and EL RLY0327

relay socket

12. Liquid Level Control - EL SEN0401, and

135664 (8-pin socket)

relay outputs, and

CPU - P/N EL CPU0301

CPU battery P/N EL BAT 0302

4-slot i/o base P/N EL BSE 0301

DC Input Module P/N EL MOD0302

AC Relay Output Module P/N EL RLY0316

16 relay outputs, and

to shipment.

13.1” x 1” wire Duct with Cover -

HD DCT0303

14. Din Rail (typical)

15. Power Plug for # 3 (operator

Interface) included with operator

interface

16. Operator Interface Serial Cable

(connects #3 to # 7) EL CBL0301

17. Gas Delay Board RP ASY0308

For models P31, P35, & P45 Only.

18. PAWS Terminal Block Assembly

(Upper) - EL BLK0316, |(includes

lower terminal block #21

19. Horn - EL HRN0301

22. Main Power Fused disconnect

(includes 15A fuse). Included with

EL BLK0316

Main Power Replacement Fuse “Bus”

MDL 15 P/N EL FUS0305

20. PAWS Terminal Block Assembly

(Lower) - EL BLK0316, |(included with

upper terminal block #18

21. Detergent Pump Fused disconnect

(includes 750mA time lag fuse).

Included with EL BLK0316

Detergent Pump Replacement Fuse “Bus”

750MA, 250V P/N EL FUS0306.

For the Following components refer to

Figure II.C.1

22. Detergent Probe - P/N RP PRB0601

Cut to length.

23.5-Gallon Detergent Tank P/N HD TNK0302

Standard with Energy Distribution

System mounted panels.

24.2-Gallon Detergent Tank P/N TNK0302

Standard with wall mounted panels.

25. ¾” Water Solenoid - P/N PB SOL0302

120vac coil.

26.1” Water Solenoid - P/N PB SOL0303

120vac coil.

27.11/4” Water Solenoid P/N PB SOL0304 120vac coil.

17

Page 21

28.11/2” Water Solenoid -

P/N PB SOL0305

120vac coil.

29. ¾” Ball Valve- P/N PB VLV756

30.1” Ball Valve- P/N PB VLV750

31.11/4” Ball Valve- P/N PB VLV790

32.11/2” Ball Valve- P/N PB VLV0306

33.1” Supervised Valve-

P/N PB VLV0311

Optional valve replaces ball valve.

34.11/4” Supervised Valve-

P/N PB VLV0312

Optional valve replaces ball valve.

35.11/2” Supervised ValveP/N VLV0313

Optional valve replaces ball valve.

36. Water Pressure SwitchP/N EL SWT0345

Optional feature to monitor PAWS water

pressure.

37. Pressure Temperature GaugeP/N HD GGE0303

38. ¾” Brass Check Valve-

P/N PB VLV0303

39.1” Brass Check Valve-

P/N PB VLV0304

40.11/4” Brass Check ValveP/N PB VLV0305

49.11/4” Atmospheric Vacuum Breaker

- P/N PB BRK0306

For use with single wash output panels

50.11/2” Atmospheric Vacuum Breaker

- P/N PB BRK0312

For use with single wash output panels

51.3/4” Pressure Type Vacuum Breaker

- P/N VLV0321

For use with multiple wash output

panels

52.1” Pressure Type Vacuum Breaker P/N PB BRK0307

For use with multiple wash output

panels

53. 11/4” Pressure Type Vacuum

Breaker - P/N PB BRK0311

For use with multiple wash output

panels

54. 11/2” Pressure Type Vacuum

Breaker - P/N PB BRK0312

For use with multiple wash output

panels

55. Detergent Pump - P/N HD PMP0301

56. Foot Valve - P/N HD PMP0303

With strainer screen

57. Check Valve - P/N PB VLV0342

Specific use for detergent pump with

3/8” O.D. tubing

41.11/2” Brass Check ValveP/N PB VLV0316

42. ¾” Wye (line) Strainer-

P/N PB WYE0301

43.1” Wye (line) Strainer-

P/N HD STN0306

44.11/4” Wye (line) StrainerP/N PB WYE0302

45.11/2” Wye (line) StrainerP/N HD STN0305

46.1/2” Shock Arrestor -

P/N PB SUP0301

47.3/4” Atmospheric Vacuum Breaker P/N PB BRK0305

For use with single wash output panels

48.1” Atmospheric Vacuum Breaker P/N PB BRK0302

For use with single wash output panels

18

Page 22

B. Terminal Identification

Important note to installing electrician: The installation must comply with the information provided

below to avoid damage to the electrical components and circuitry.

ϖ Refer to the job specific wiring diagram for electrical interconnections.

ϖ Apply external power only to those terminals coded with a shaded box. Applied power may not

exceed specified electrical ratings.

ϖ Do not exceed the specified output terminal current ratings.

ϖ If you are unsure or require assistance, contact AVTEC Product Service (800-621-8560) before

proceeding with installation.

AVTEC will not honor warranty claims result from of improper electrical interconnection or abuse.

TERMINAL

NUMBER

1

2

3

4

5, 6, 7

8

9

10

11

12

13

14

15

16

N

H

G

FUNCTION

OUTPUT, KILL SWITCH (OPTIONAL): SWITCHED

CURRENT FROM TERMINAL 5, 6, or 7

OUTPUT, FIRE PULL SWITCH (OPTIONAL):

NORMALLY CLOSED, SWITCHED CURRENT FROM

TERMINAL 5, 6, or 7

OUTPUT, FIRE PULL SWITCH (OPTIONAL):

COMMON, SWITCHED CURRENT FROM TERMINAL

5, 6, or 7

OUTPUT, HOOD FIRE SYSYTEM SWITCH:

SWITCHED CURRENT FROM TERMINAL 5, 6, or 7

OUTPUT: SOURCE VOLTAGE FOR INPUT

DEVICES. 120VAC FOR MODELS P30 TO P37,

24VDC + FOR MODELS P44 TO P47.

OUTPUT, HOOD EXHAUST DUCT SWITCH:

SWITCHED CURRENT FROM TERMINAL 5, 6, or 7

OUTPUT EXHAUST DAMPER HOT, 120VAC, 15A

OUTPUT: 20VDC, 2ma, DETERGENT PROBE

OUTPUT: 20VDC, 2ma, DETERGENT PROBE

OUTPUT, SUPERVISED WATER SUPPLY VALVE

(OPTIONAL): SWITCHED CURRENT FROM

TERMINAL 5, 6, or 7

OUTPUT, WATER SUPPLY PRESSURE SWITCH

(OPTIONAL): SWITCHED CURRENT FROM

TERMINAL 5, 6, or 7

OUTPUT, (OPTIONAL): 120VAC GAS SOLENOID,

HOT

OUTPUT, (OPTIONAL): 120VAC ELECTRIC SHUNT

TRIP, HOT

AVTEC USE ONLY, (OPTIONAL UPS POWER

INPUT)

POWER INPUT, 120VAC, 15 AMPS, NEUTRAL BUS.

COMPOSED OF 9 JUMPERED TERMINALS POWER

INPUT, 120VAC, 15 AMPS, HOT

GROUND TERMINAL (CHASSIS GROUND)

TERMINAL

NUMBER

17 NOT USED IN THIS APPLICATION.

18 OUTPUT, 120VAC SWITCHED HOT TO EXHAUST

19 NOT USED IN THIS APPLICATION.

20 OUTPUT, 120VAC SWITCHED HOT TO SUPPLY FAN

ALTERNATE FAN STARTER WIRING, N.O. DRY CONTACTS

(HOA STARTERS OR CONTROL VOLTAGE FROM STARTERS)

NOTE: PRE-WIRED JUMPER FROM TERMINAL H TO 17 AND 19

MUST BE REMOVED PRIOR TO APPLICATION OF POWER

17 TO EXHAUST. FAN STARTER, CONTACT (C)

18 TO EXHAUST. FAN STARTER, CONTACT (NO)

19 TO SUPPLY FAN STARTER, CONTACT (NO)

20 TO SUPPLY FAN STARTER, CONTACT (C)

21 OUTPUT: 120VAC, DETERGENT PUMP

22 OUTPUT: 120VAC, WASH SOLENOID #1

23 OUTPUT: 120VAC, (OPTIONAL) WASH SOLENOID #2

24 OUTPUT: 120VAC, (OPTIONAL) WASH SOLENOID #3

25 OUTPUT: 120VAC, (OPTIONAL) WASH SOLENOID #4

26 OUTPUT: 120VAC, (OPTIONAL) WASH SOLENOID #5

27 OUTPUT: 120VAC, (OPTIONAL) WASH SOLENOID #6

28 OUTPUT: 120VAC, (OPTIONAL) WASH SOLENOID #7

29 OUTPUT: 120VAC, (OPTIONAL) WASH SOLENOID #8

FAN STARTER 120VAC OUTPUT

FAN STARTER COIL.

STARTER COIL.

7.5A @ 120VAC MAX.

7.5A @ 120VAC MAX

7.5A @ 120VAC MAX

7.5A @ 120VAC MAX

FUNCTION

19

Page 23

L

Y4 = Wash #2 Solenoid

C. Diagnostic Indicators and Switch

Settings

The Programmable Logic Controller that is except P31, P35)

provided with the PAWS panel includes

diagnostic lights that will illuminate when an P35)

input or output is active.

The PLC and Operator Interface also

include switches that must be configured in

order for the panel to operate. Details are

shown below.

1. Model P30 to P37 PLC

Refer to Figure V.C.1 for terminal

locations. The diagnostic LED's are

shown in Figure V.C.1 with their

identifying labels. Input and Output

assignments are as follows:

INPUTS

120vac is applied through switch

devices to the terminals outlined below.

The associated COMMON is connected to

120vac neutral. When an input is

“ON” the associated diagnostic LED will

light. Some inputs will have a lit LED in

normal operation while others will

illuminate only when the device is “ON”.

Normal status is listed below as M to

indicate a lit LED, and L to indicate the

LED is “OFF”.

L

Y5 = Ex. Fan Relay

L

Y6 = Wash #3 Solenoid (all

L

Y6 = GDR Reset (models P31,

L

Y7 = Supply Fan Relay

Figure V.C.1

L X0 = Exhaust Duct Switch

M X1 = Fire System Switch

L X2 = Kill Switch

L X3 = Spare

L X4 = Water Valve

L X5 = Water Pressure Switch

L X6 = Detergent Probe

L X7 = Spare

L X10 = Spare

M X11 = AC Power Loss

OUTPUTS

120vac, “hot”, is applied to the common

terminal for all outputs. When an output is

“ON” the associated diagnostic LED will

light. Normal status for each Input is listed

below as M to indicate a lit LED, and L to

indicate the LED is “OFF”.

L Y0 = Audible Alarm (Horn)

L Y1 = Detergent Pump

L Y2 = Wash #1 Solenoid

L Y3 = elec. Shunt Trip (all except

P31, P35)

M Y3 = GDR Power (models P31,

P35)

20

Page 24

2. Model P44 to P47 PLC

Refer to Figure V.C.2

locations. The diagnostic LED’s are

shown in Figure V.C.2

identifying labels. Input and Output

assignments are as follows:

INPUTS

24vdc positive is applied through switch

devices to the terminals outlined below.

The associated COMMON is connected

to 24vdc negative. When an input is

“ON” the associated diagnostic LED will

light. Some inputs will have a lit LED in

normal operation while others will

illuminate only when the device is “ON”.

Normal status is listed below as M to

indicate a lit LED, and L to indicate the

LED is “OFF”.

L X0 = Exhaust Duct Switch

M X1 = Fire System Switch

L X2 = Kill Switch

L X3 = Spare

L X4 = Water Valve

L X5 = Water Pressure Switch

L X6 = Detergent Probe

M X7 = AC Power Loss

for terminal

with their

Figure

V.C.2

OUTPUTS

120vac, “hot” is applied to the common

terminal for all outputs. When an output

is

“ON” the associated diagnostic LED

will light. Normal status for each Input is

listed below as M to indicate a lit LED,

and L to indicate the LED is “OFF”.

Relay Output Module #1, (Slot 3)

L Y0 = Audible Alarm (Horn)

L Y1 = Detergent Pump

L Y2 = Wash #1 Solenoid

L Y3 = elec. Shunt Trip (all except

P45)

M Y3 = GDR Power (model P45)

L Y4 = Spare

L Y5 = Ex. Fan Relay

L Y6 = Spare (all except P45)

L Y6 = GDR Reset (model P45)

L Y7 = Supply Fan Relay

Relay Output Module #2, (Slot 4)

Program address is shown in ( )

L Y0 (Y10) = Wash #2 Solenoid

L Y1 (Y11) = Wash #3 Solenoid

L Y2 (Y12) = Wash #4 Solenoid

L Y3 (Y13) = Wash #5 Solenoid

L Y4 (Y14) = Wash #6 Solenoid

L Y5 (Y15)= Wash #7 Solenoid

L Y6 (Y16)= Wash #8 Solenoid

L Y7 (Y17) = Spare

21

Page 25

A “Run-Terminal“ switch is provided on VI.

the PLC. The

must be in the “

the panel to operate.

3. Operator Interface

Refer to Figure V.C.3 for switch settings

and diagnostic LED locations.

For the panel to operate switch 1 and 2

must be in the “OFF” position (all the

way to the left).

A transmit (labeled “TX”) and receive

(labeled “RX”) LED are located on the

back of the unit. The LED’s will light

when the operator interface is

communicating with the PLC.

A serial communication port is provided

on the back of the unit. This port is

connected to the PLC with a special

cable that is supplied with the panel.

See Figure V.C.3.

Figure V.C.3

”Run-Terminal“ switch

Termina

l” position for

Maintenance

A. Detergent Dispensing System (pump)

1. Detergent Tank

The detergent tank should be

replenished at least weekly. The

Low Detergent Probe will monitor

the need for more frequent refills.

After an extended period of time the

tank may require cleaning. The

probe and pick up tube may be

removed, but ensure they are reinstalled as shown in Figure II.C.1.

2. Detergent

AVTEC EVAC is a biodegradable

detergent specifically formulated for

use with water wash hoods.

AVTEC will provide a Lifetime

Warrantee for the PAWS Detergent

Dispensing System when AVTEC

EVAC is used exclusively.

EVAC can be obtained through

Authorized AVTEC Service Agents.

Refer to the EVAC spec sheet in the

Appendix of this manual.

3. Detergent Pump

Every six months:

Check the Foot Strainer Pick-Up

to ensure the screen is not

clogged. Refer to Figure II.C.1.

Check all tubing fittings to

ensure they are tight.

For additional information refer to

the pump manufacturer's manual

that is included in the AVTEC

Ventilator manual.

B. Plumbing

A Wye (line) strainer is included in the

PAWS water manifold to protect the

water solenoid(s) and hood spray

nozzles. If you experience a loss in

water pressure it is frequently due to a

clogged wye strainer.

Before opening the cleanout on the wye

strainer make sure the water is “OFF”

and the water manifold is not under

pressure.

A bucket should be placed under the

cleanout prior to removing the cleanout

plug. Some water spill will occur.

22

Page 26

Figure

Once the cleanout plug is removed

withdraw the strainer screen.

Thoroughly clean the strainer screen

and make sure additional debris is not

lodged in the wye strainer body. Refer to

Figure VI.B.

VII. Warranty

AVTEC INDUSTRIES INC. warrants to the original

purchaser for use of our products, that any part

thereof which proves to be defective in material or

workmanship under normal use within one year from

date of installation, will be replaced free of charge,

labor to replace such part is warranted for one year

from installation. All warranty labor to be performed

during regular working hours, with no overtime

premium.

All Warranty service must be authorized by the

factory and be performed by AVTEC's authorized

service personnel.

This Warranty is limited to the United States and

Canada.

VI.B

other products or damage to equipment or property

resulting from mechanical or electrical failure.

AVTEC neither makes nor assumes and does not

authorize any other person to assume any other

obligation or liability in connection with its products

other than that covered in this Warranty.

FOR THE NAME AND LOCATION OF THE

NEAREST

AVTEC SERVICE AGENCY, CALL OR WRITE TO:

AVTEC / Unified Brands

525 S. Coldwater Rd.

Weidman MI 48893

PH. 800/621-8560

This Warranty does not apply to any damage

resulting from shipping, improper installation,

accident, unauthorized alteration, local codes not

previously brought to the attention of AVTEC,

misuse, or abuse; and does not cover loss of food,

Rev. 10/08

23

Loading...

Loading...