Page 1

OPERATORS MANUAL

This manual provides

Installation & Operating instructions for

ENERGY

DISTRIBUTION

SYSTEMS

NOTIFY CARRIER OF DAMAGE AT ONCE.

It is the responsibility of the consignee to inspect the

container upon receipt of same and to determine

the possibility of any damage, including concealed

damage. Avtec suggests that if you are suspicious

of damage to make a notation on the delivery receipt. It will be the responsibility of the consignee to

file a claim with the carrier. We recommend that you

do so at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be

current and accurate at the time of printing/creation.

Unified Brands recommends referencing our product line

websites, unifiedbrands.net, for the most updated product

information and specifications.

P/N OMANUAL_EDSC-09/06

1055 Mendell Davis Drive

Jackson, MS 39272

888-994-7636, fax 888-864-7636

avtecind.com

Page 2

TABLE OF CONTENTS

I. ENERGY DISTRIBUTION SYSTEM INSTALLATIONS

A. Island Style

1. Field Joint Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Control Tower Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3. Pedestal Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4. Pedestal Floor Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5. Tower Interface Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6. Hanging Rod Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

7. Side Panel Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

B. Wall Mounted Energy Distribution System

1. Field Joint Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Risor Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Wall Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4. Service Enclosure Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. Side Panel Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

C. Plumbing Connection at Field Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

D. Electrical Connections at Field Joints . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. Bus Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Cable Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Control Circuit Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

E. Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

II. CONNECTION TO REMOTE FIRE-FUEL SHUT-OFF SYSTEM

A. Electrical Shut-Off Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Gas Fire-Fuel Shut-Off System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C. Gas and Electric Fire-Fuel Shut-Off Detail . . . . . . . . . . . . . . . . . . . . . . . 4

III. STEAM VALVE TIMER

A. Valve Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Steam Purging System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

C. Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

D. Timer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IV. REMOTE BREAKER STATUS INDICATOR LIGHTS

A. Operation and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B. Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

V. GROUND FAULT EQUIPMENT PROTECTION [GFEP]

A. Operation and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

B. Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

VI. BREAKER CONNECTION PLATE

A. Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1. Model Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Amperage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Voltage/Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

C. Installation and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VII. REMOTE GUAGES AND VALVES

A. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

B. Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Page 3

VIII

. VENTILATOR LIGHT SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IX. STEAM SUPPORT MODULE [Kettle Arm]

A. Installation and Connection to Raceway . . . . . . . . . . . . . . . . . . . . . . . . 7

B. Water Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

C. Electronic Cooking Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

D. Cook/Chill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

E. Motorized Steam Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

X. CORDSETS

A. Sizing and Connection to Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B. Connection to Raceway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

C. Care in Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

D. Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

1. Amperage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Voltage/Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Plug Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

XI. FLEXIBLE HOSE

A. Connection to Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

B. Connection to Raceway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

C. Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

D. Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Gas, Water, Steam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. Stainless Steel Braid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. Length in Inches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

XII. DRAIN HOSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XIII. PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-11

XIV. WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XV. EC-71D TIMER INSTRUCTIONS [In booklet form] . . . . . . . . . . . . . . . . . . . . .

XVI. SPECIFIC TECHNICAL DATA

A. Electrical

1. Load Balance Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Electrical Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Overall Electrical Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Ventilator Control Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Kettle Arm Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Plumbing

1. Plumbing Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Kettle Arm Plumbing Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Shop Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

9

15

Page 4

I. ENERGY DISTRIBUTION SYSTEMS

INSTALLATION

A. Island Style

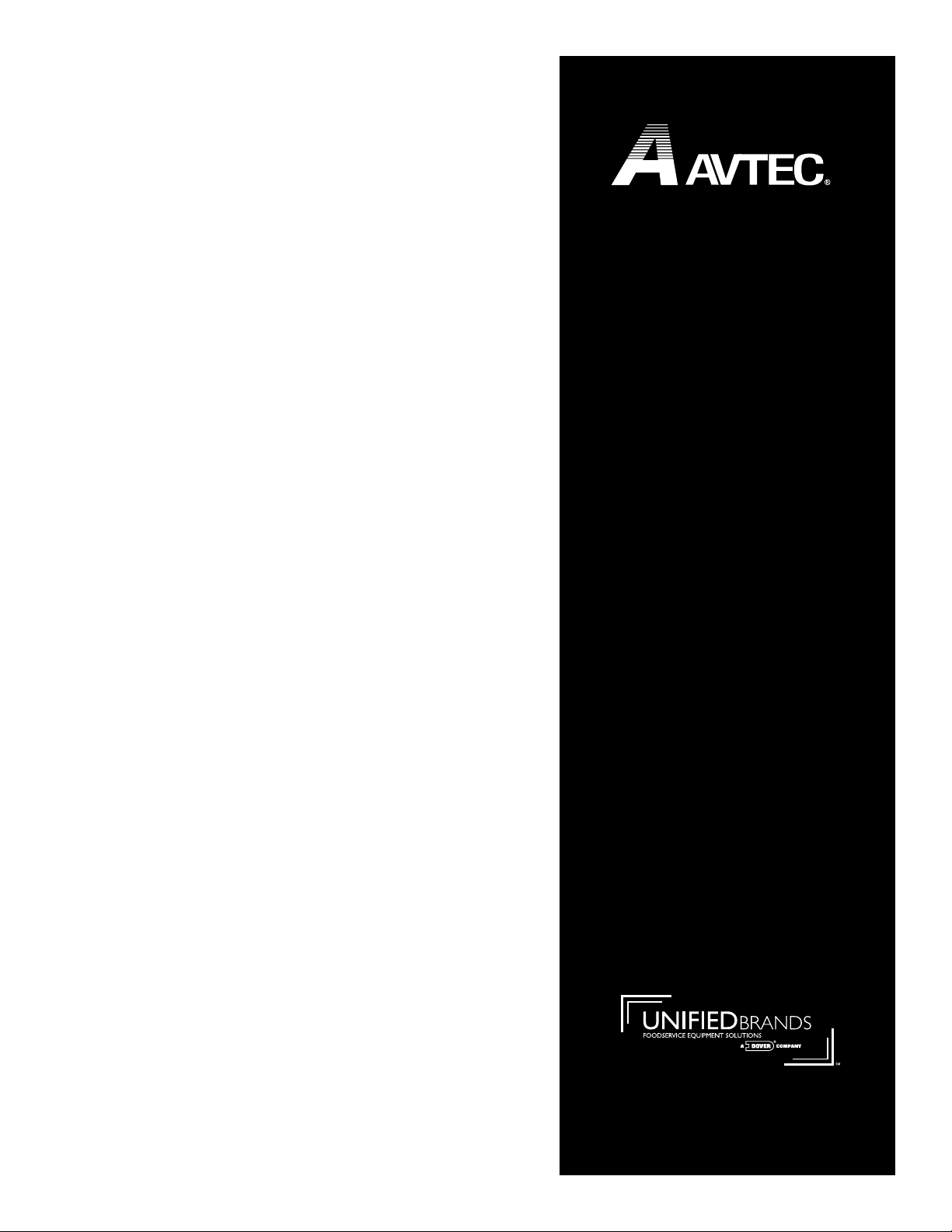

1. Field Joint Detail

Bolt field joint[s] together as shown.

NOTE: Access plates as shown for flat-top unit allows bolts

above partition to be secured. All bolts are ¼”-20. Use flat

washers beneath head of bolt and under nut when bolting

through slots.

2. Control Tower Mounting Detail

Use ¼”-20 bolts between raceway and

control tower as shown on typical

construction below.

beneath head of bolt and under nut

when bolting through slots. Note that

removable panels are facing sides of

raceway. Slots are provided to aid in

ease of assembly. Adjust pedestal so

that it is centered under raceway and

one inch [1”] from end of raceway.

Pedestals under field joints are to be

centered under field joint.

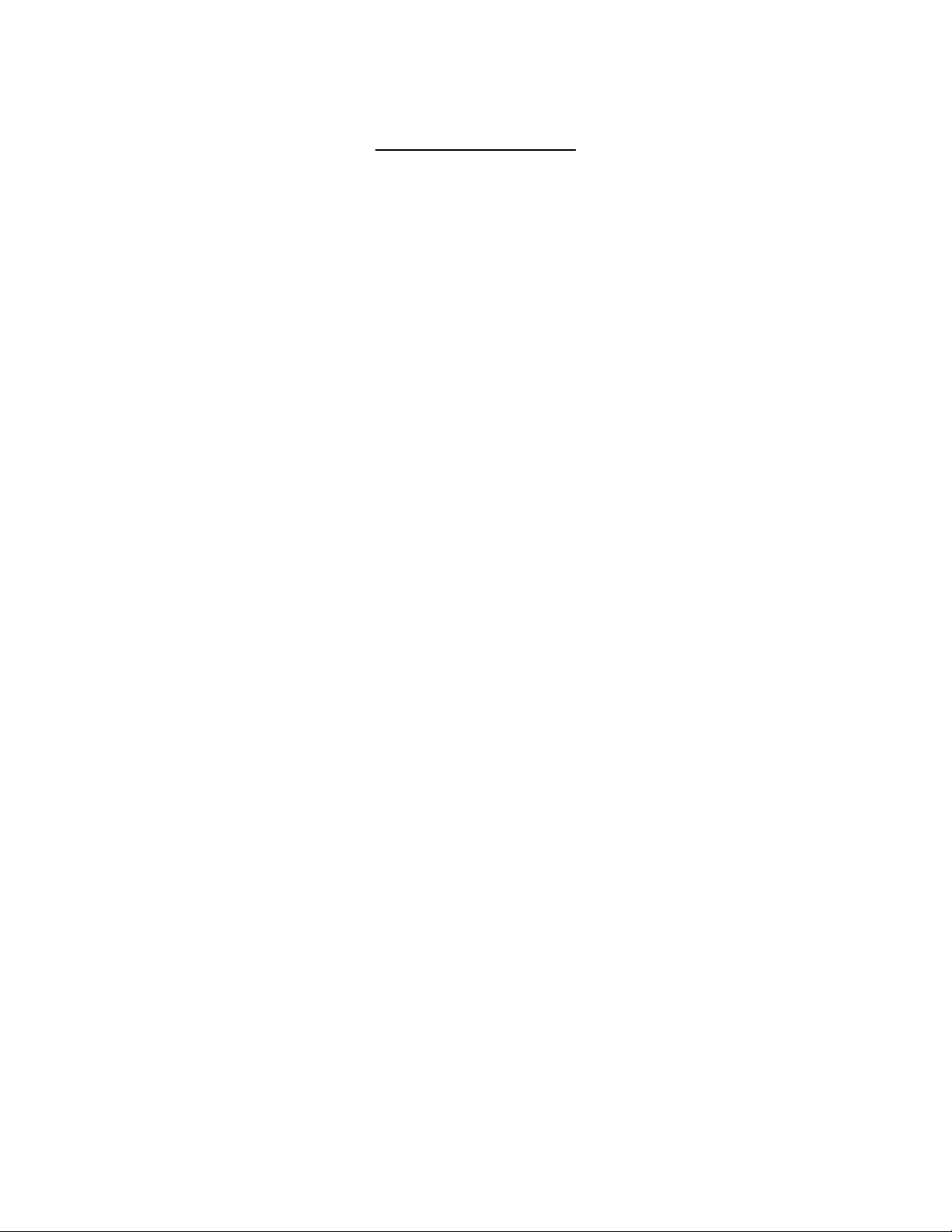

4. Pedestal Floor Mounting Detail

After attaching risors and pedestals

place raceway in position. Level

raceway [shims or spacers may be

required beneath pedestals to

accomplish this] mark position of

holes in bottom of pedestal on floor.

Carefully lift raceway and remove

pedestals to allow installation of

mounting hardware into floor. Use

extreme care to avoid placing lifting

devices across breaker plates as this

will damage lights, switches, knobs or

receptacles. Floor mounting

hardware [not provided by AVTEC]

should be installed in all four corners

of pedestal. Re-attach pedestals to

raceway and lower into position,

bolting through pedestal base into

floor. Use flat washers beneath

heads of bolts used to attach unit to

floor.

3. Pedestal Mounting Detail

Bolt raceway to pedestals with ¼”-20

bolts and nuts. Use flat washers

5. Tower Interface Detail

Place trim collar on tower, Position

tower under hood. Fully tighten trim

collar retaining hardware after the UDS

tower is in proper location. See

diagrams f-1,2,3. See pages 12,13,14.

Page 5

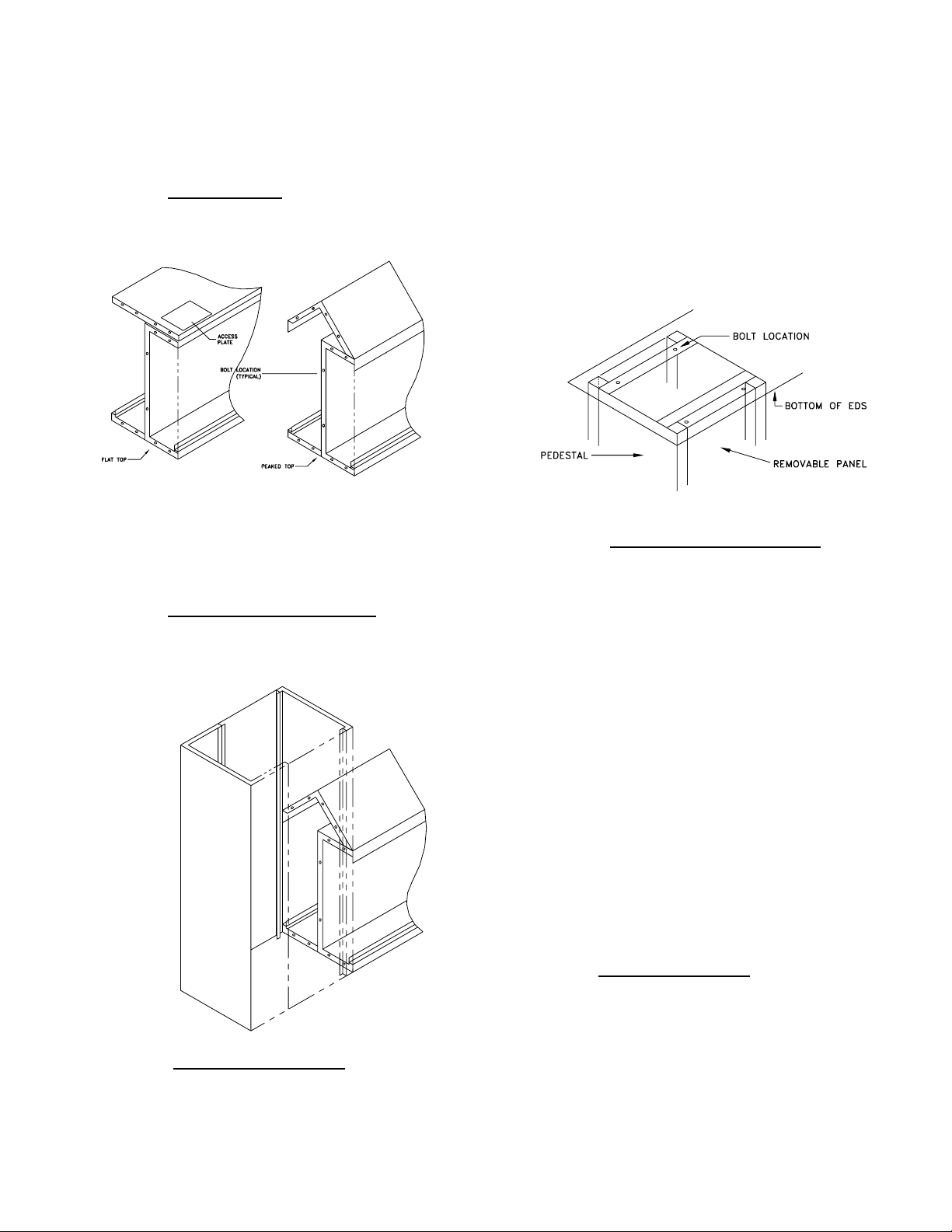

6. Hanging Rod Detail

7.

Locate raceway in position and attach

hanging rod to structural ceiling. Use

turnbuckles to make final adjustments

in raceway height. Level raceway

with level [do not use floor for leveling

purposes, as it may be pitched for

drainage].

7. Side Panel Detail

The side panels slip fit in place at the

top, #8-32 screws fasten the panel to

the bottom of the housing. The side

panel[s] is installed by fitting the top of

the panel into the top of the housing

and then sliding the bottom of the panel

into position. The #8-32 screws are

then installed into the bottom housing

securing the panel.

B. Wall Mounted Energy Distribution

System

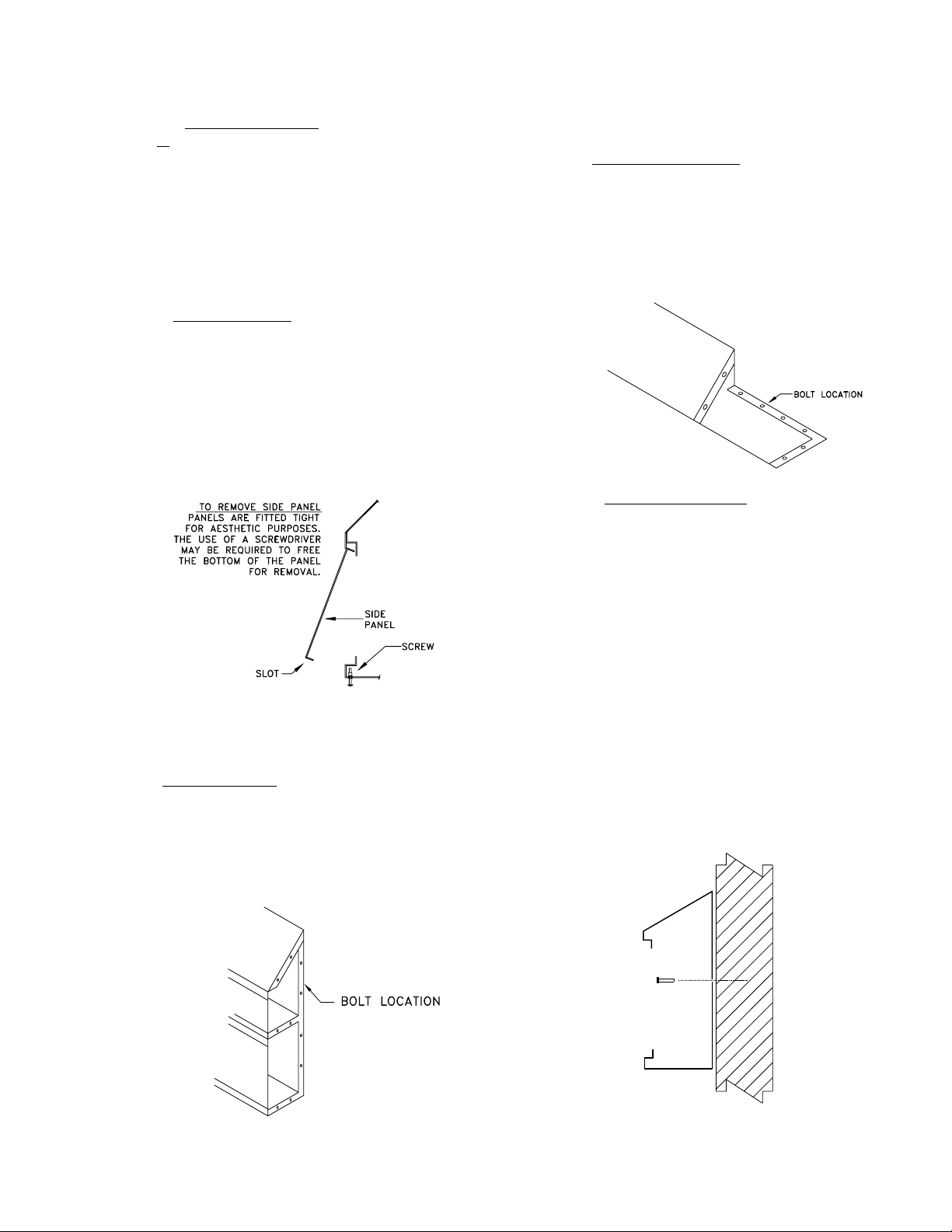

1. Field Joint Detail

Bolt field joints together as shown with

¼”-20 bolts and nuts. Use flat washers

beneath heads of bolts and under nut

when bolting through slots.

2. Risor Mounting Detail

Bolt risor to raceway through flange and

to sloped-top through side of risor with

¼”-20 nuts and bolts. Use flat washers

beneath head of bolt and under nut

when bolting through slots. Square-up

edges before finally torqueing bolts to

present a satisfactory appearance.

3. Wall Mounting Detail

Locate stud centerlines on INSIDE of

unit if mounting to a stud wall. Drill

corresponding mounting holes in the

back of the unit. Care must be taken

to prevent metal shavings from

contacting electrical components.

Vacuum ALL metal fragments

immediately and thoroughly. When

measuring height above finished floor,

be aware that floor may be pitched.

Mark wall through holes, remove unit

and drill into wall for anchors. Avoid

drilling through unit to avoid

accumulations of debris. Secure unit

to wall with quarter-inch [1/4”]

minimum diameter hardware.

NOTE: VERIFY THAT THE WALL IS CAPABLE

OF BEARING THE LOAD.

2

Page 6

4. Service Enclosure Detail

Mounting the back of the service

enclosure to the wall by drilling through

the back of the housing. Attach front of

enclosure to back with hardware

provided.

5. Side Panel Detail

The side panels slip fit in place at the

top, #8-32 screws fasten the panel to

the bottom of the housing. The side

panel[s] is installed by fitting the top of

the panel into the top of the housing

and then sliding the bottom of the panel

into position. The #8-32 screws are

then installed into the bottom housing,

securing the panel.

C. Plumbing Connection at Field Joints

It is the plumbing contractor’s responsibility

to insure that all unions are tightened and

leaks do not exist. Take care when

tightening unions that they are not loosened

from the pipe. Pipe sealant may be

required to be applied to the face of the

union to prevent leakage. Use care to keep

contaminants and sealant from entering the

pipe where it might cause blockage of traps

and lines when the unit is brought into

operation.

D. Electrical Connections at Field Joints

1. Field joints for bus bar are generally 24”

long sections fastened in four [4]

locations. Note that the field joint

section of bus bar is usually insulated

where possible short spacing may

occur. When bolting down field joint

section, be sure that it makes complete

contact with mating bus bar.

2. Where space limitations prohibit the

use of bus bar, cable bus is used.

Sections of wire with lugs are provided

at field joints. These wires should be

routed through a protective bushing

when they may be subjected to

abrasion.

3. Control circuit wiring at field joints use

quick-connect plug-in connectors.

These can be assembled in only one

way. When more than one connector is

located at a field joint, they should be

different configurations. If not, plug

together the connectors with the same

color wires leading into them. Be

certain that the connections are fully

inserted and that they are making good

contact.

E. Care and Maintenance

The protective coating on the stainless

steel should be removed after installation is

completed. Traces of marking pens can be

removed with careful use of acetone and a

soft cloth. Fingerprints and most stains can

be removed with a soft cloth dampened

with water and mild detergent. The unit

should not be hosed or sprayed with either

steam or water. In order to further seal the

unit, silicone sealant may be applied to the

seams. Annually, the power should be

turned OFF and threaded connections [both

electrical and mechanical] should be

tightened as required.

II. CONNECTION TO REMOTE FIRE-FUEL SHUT

OFF SYSTEM

A. Electrical Shut-Off Detail, No Vent Controls

The AVTEC Electrical Fire-Fuel Shut-Off

System uses a shunt trip circuit breaker[s].

The breakers will trip OFF whenever

120vac is applied to the Red and

White/Red wires [excluding M*** series

style connection plates]. A single main shut

off shunt trip breaker may be used in lieu of

individual shunt trips.

3

Page 7

B. Gas Fire-Fuel Shut-Off Systems, No Vent

Controls

The AVTEC Gas Fire-Fuel Shut-Off System

uses constant 120vac power supply to hold

open an electrically operated solenoid

valve[s]. There is a delay of approximately

1-1/2 seconds built into the system which

holds the circuit [internal to the raceway]

closed in the event of a momentary power

loss. [The Gas Solenoid Valve[s], however,

will close for the duration of the power loss.]

Upon application of power to the Black and

White/Red wires, a horn will sound and a

yellow LED will light, indicating that power

is available for the gas solenoid[s] and

warning that the pilot light[s] will have to be

lit on the accompanying cooking

equipment. The gas solenoid[s] will open

and gas flow begins when the fuel reset

button is depressed.

III. STEAM VALVE TIMER

A. Valve Installation

The Steam Valve consists of three (3)

assemblies. 1. The motor, 2. The linkage

and 3. The steam valve body. Instructions

for assembling and adjusting these parts

are provided in the shipping boxes [except

when the Valve is an integral part of the

raceway, in which case the valve is

assembled at the factory]. The valve is

intended to shut OFF the flow of steam to a

particular area [or perhaps one particular

raceway] upon completion of the work day.

The amount of equipment involved is

dependent upon placement of the valve. A

manual valve should be installed parallel to

the motorized steam valve [as shown in the

accompanying drawing] so that the steam

equipment could be made operative in the

event of an electrical malfunction. In the

event of a power loss, the valve remains in

the position it was in at that time.

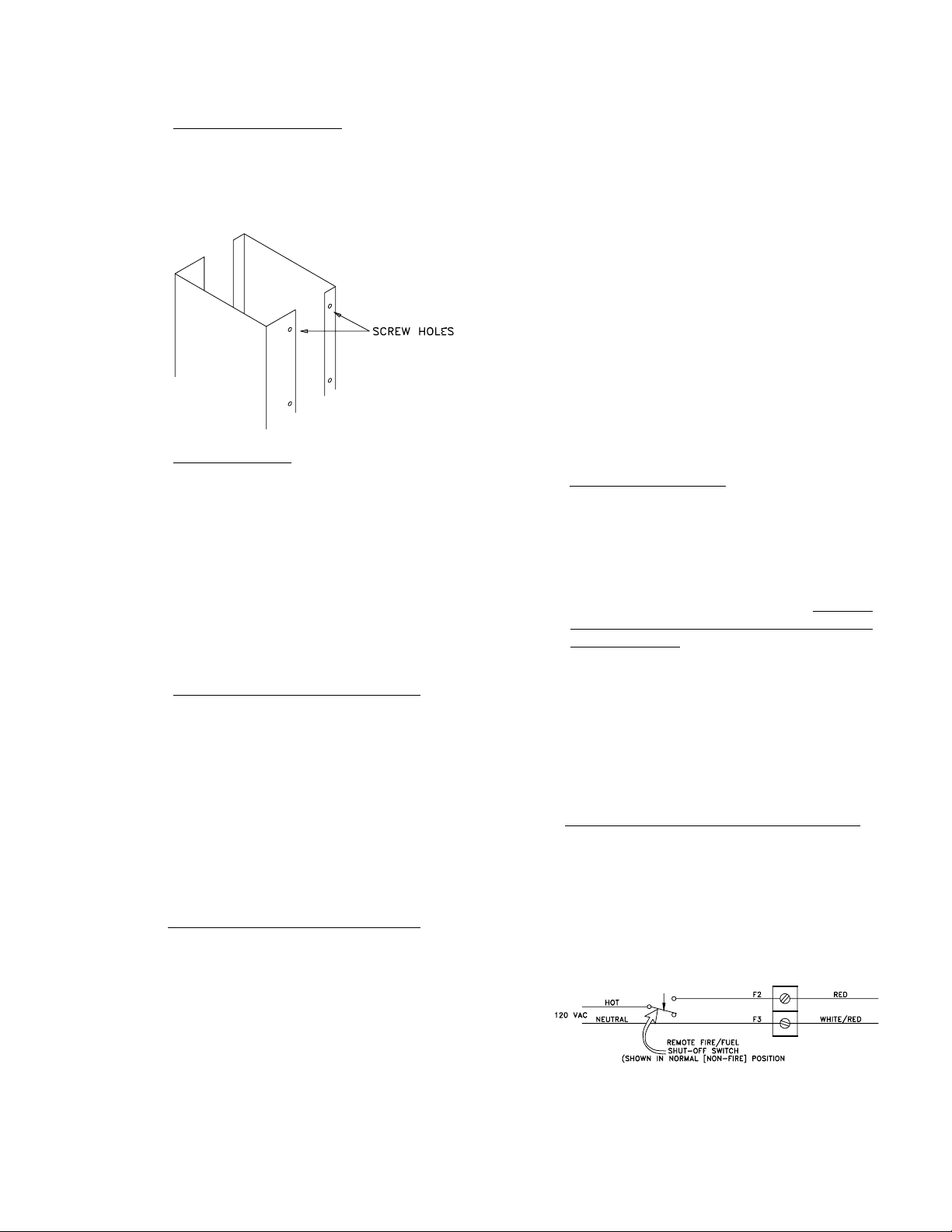

C. Gas and Electric Fire-Fuel Shut-Off Detail

When both Gas and Electric Fire-Fuel ShutOff options are used, a form “C” [SPDT]

switch can be employed. The contact

which is held open during normal [non-fire]

operation is connected to the Red wire and

the contact which is held closed during

normal [non-fire] operation is connected to

the Black wire. The neutral to complete the

120vac circuit is connected to the

White/Red wire.

B. Steam Purging System

In most applications, the AVTEC raceway is

equipped to constantly remove condensate from

the steam supply line as it accumulates. In units

with a condensate return line this condensation

is routed to the condensate return line. On units

without a condensate return line, this

condensation is routed to a drain.

C. Start Up

After the raceway and valve are installed and

steam is available, the steam trap should be

removed. Steam should then be allowed to flow

through the unit, flushing the lines of any debris

which may have accumulated during installation.

This debris is removed by opening the ball valve

leading to the steam trap. After the lines are

cleared, the steam should be shut OFF and the

steam trap assembly re-installed. It is

imperative that the lines be flushed before any

4

Page 8

equipment is used and before the steam trap

assembly is put into operation to void damage

by large pieces of debris [pipe dope, metal

chips, etc.] Every effort should be made to keep

the inside of the pipes clean.

D. Timer Operation

The timer is a single channel circuit electronic

programmable time control. Instructions for

programming the timer are enclosed in this

folder. Turn ON the circuit by pressing in the

circuit breaker. Note the Light Emitting diode

[LED] on the door. When the Motorized Steam

Valve is fully open, the LED is green and when it

is fully closed the LED is red.

IV. REMOTE BREAKER STATUS INDICATOR

LIGHTS (E-Series only.)

A. Operation and Function

As an optional feature, remote LED’s can

be located in a more accessible area. The

number immediately above the LED

indicates the corresponding breaker plate

location. These LED’s glow Red when the

breaker is OFF and Green when the

breaker is ON. W here there are future

electrical connections, the LED’s remain

unlit. Note that these LED’s do not

whether or not there actually is equipment

connected nor does it indicate if the

equipment, if connected, is ON or OFF,

merely whether the breaker is ON or OFF.

B. Power Supply

Power for the LED’s is provided by a

transformer which steps down the line

voltage to 24vac. That power is further

reduced by a resistor and rectified by a

diode which is built on to each breaker

connection plate. The transformer is

protected by a fuse[s].

V. GROUND FAULT EQUIPMENT PROTECTION

[GFEP] (E-Series only.)

A. Operation and Function

GFEP is designed to protect pieces of

equipment from damage due to loss of

current to ground. It operates by sensing

the amount of power being delivered to the

equipment and the amount of power

returning to the raceway. Any imbalance

greater than 0.5 amps will cause the circuit

breaker to trip OFF. [In some cases where

the voltage and amperage is low enough to

indicate

allow, the GFEP trip amperage may be as

low as 0.15 amps.] It is necessary to have

all power conductors [including the neutral

wire where appropriate] passing through

the center of the current sensor the same

number of times and in the same direction

relative to line and load. A “Push to Test”

button is provided on each unit.

At initial start up, the equipment should be

disconnected and the circuit breaker turned

OFF. With the equipment turned OFF, it

should be connected and the breaker

turned ON. If the equipment trips the circuit

breaker, immediately [or as soon as the

equipment if turned ON] disconnect the

equipment and check it thoroughly. If the

equipment trips the circuit breaker during

operation, immediately disconnect the

equipment and have it checked thoroughly.

Repeatedly turning ON a breaker

connected to a piece of equipment which

has a ground fault or a short circuit can

damage the ground fault sensor.

When checking the equipment, bear in

mind that conditions can change while the

equipment is in use, and the problem may

not exist after the equipment has cooled.

B. Power Supply

The GFEP receives 24vac power from the

same transformer as the Breaker Status

Indicators. If you suspect that the GFEP

has been damaged, and the circuit breaker

connection plate will not reset, you can

check this by turning OFF the 24vac

transformer, and removing the 10 amp

fuse. If the breaker will then reset, but

turns OFF again as soon as the control

circuit transformer is repowered, then the

current sensor should be replaced. If,

however, the circuit breaker will not reset,

even with the control circuit transformer

turned OFF, then most likely, the problem is

either the fire-fuel shut-off remote wiring or

circuit breaker itself is damaged. Note that

when checking the GFEP, the equipment

should be disconnected.

VI. BREAKER CONNECTION PLATE

A. Nomenclature

When referring to a connection plate, use

the Reference Number and UDS Model No.

[e.g., MIDE999999A] and the connection

[enclosed in this folder]

5

Page 9

[#1E, 2E, etc.]. The connection plate can

be further identified by including the

amperage and the voltage/phase. The

model no’s. connection plates are shown

below.

X X XXX XX XXX

[1] [2] [3] [4] [5]

[1] Model Number

L “L” or “M” series

E “E” series

[2] Type

F Electric fire shutoff (Model “E” Only)

G GFEP (Model “E” Only)

H Electric fire shutoff and GFEP (Model

“E” Only)

I GFCI (Only used with 20 amp breaker

single pole 120v/1 phase)

J Electric fire shutoff and GFCI (Model

“E” only: same as “I” in usage)

N Plate with receptacle only

X Electric (No f/f GFEP of Aux switch)

[3] Amperage

15 15 amp A = 1 pole

20 20 amp B = 2 pole

30 30 amp C = 3 pole

40 40 amp

50 50 amp

60 60 amp

80 80 amp

100 100 amp A,B, C not used

[4] Voltage/Phase

03 120v/1 phase

23 208v/1 phase

24 208v/3 phase

14 120/208v/1 phase

15 120/208v/3 phase

43 480v/1 phase

44 480v/3 phase

45 277/480v/3 phase

Note: #’s 43, 44 & 45 only used on “E”

series, 3 pole.

[5] Receptacle

Straight blade receptacle

AR

Switch and straight blade receptacle

AS

No receptacle

BO

Turn and lock receptacle

CR

Duplex convenience outlet, straight blade

DC

Switch only, used only 20 amp 1 pole

SW

Flexible seal tite conduit (pigtail)

P

Note:

Add “W” to #5 for watertite cover.

Pigtail is “special,” pigtails do not get

watertite covers.

B. Operation

The Circuit Breaker is turned ON by means

of a lever actuator located behind an

optional hinged cover. When plugging

equipment into the receptacle the breaker

should be OFF. Insert cordset fully into

receptacles and turn to secure into position

[twist/lock outlets only]. Some

receptacle/plug types have a locking collar

which should be tightened. Twist/lock type

plugs and receptacles will require care

upon insertion to prevent the natural

straightening tendency of the cord from

unlocking the plug from the receptacle.

C. Installation and Replacement

The breaker connection plate assembly is

held in position by four (4) or six [6] #8-32 x

½” stainless steel screws. It is attached to

the bus by wires and is connected to the

control circuit harness by means of a 6-pin

quick-connect plug which provides power

for the LED indicator and Fire-Fuel ShutOff, Ground Fault Equipment Protection

and/or remote lights.

VII. REMOTE GAUGES AND VALVES

A. Installation

As an option, ½” Male NPT

temperature/pressure gauges may be

provided for hot water, cold water and

steam supply incoming services. When

provided, gauges are located near the

incoming service to the raceway by the

plumbing contractor.

B. Purpose

The temperature/pressure gauges are

intended to provide information on the

quality of services; i.e., whether or not there

is sufficient pressure or if the hot water, for

example, has lost too much heat en route

to the raceway.

VIII. VENTILATOR LIGHT SWITCH

In some cases, a switch and circuit breaker

is provided which controls the lights in the

hood above the equipment. A ten ft. [10’0”] length of ½” flexible conduit is provided

with three wires [black for hot, white for

neutral, green for ground] for connection to

a junction box above the ventilation unit.

This flexible conduit can be trimmed to

6

Page 10

length in the field by the electrical

contractor.

IX. STEAM SUPPORT MODULE [Kettle Arm]

A. Installation and Connection to Raceway

The kettle arms are attached to the

raceway by bolts and on non-cantilevered

units to the floor by short legs. It is

imperative that the arms and kettles [or fry

pans] be level and bolted to the floor during

installation. Flexible conduit and/or cable

are provided on kettle/arm assemblies

manufactured by AVTEC for electrical

connections and pipe or hoses for plumbing

connections. Refer to schematics for proper

connection.

B. Water Meter

A water meter may be provided as an

option to regulate the amount of water

used. The water meter is a microprocessor

based counter. Instructions for its use are

on a label affixed to the panel in proximity

to the counter. The Green button starts the

flow of water by opening an electrically

operated solenoid valve. The Red button

will stop the flow of water at that point.

While the meter is stopped, the desired

number of gallons can be set by adjusting

the dials to the appropriate digits. As the

water flows through the flowmeter, the

display will automatically countdown,

constantly indicating the number of gallons

remaining. When the display reaches 000

it will automatically shut OFF the flow of

water. A switch is provided marked “FreeFlow” and “Metered.” In the “Metered”

position, the flow of water is regulated by

the Water Meter. In the Free-Flow position,

the solenoid valve is electrically held open

which allows an unlimited flow of water. In

the event of an electrical power loss, the

flow of water will cease as there will be no

power to hold the solenoid valve open.

C. Electronic Cooking Timer

An electronic timer may be provided as an

option. It is used to display time remaining

when cooking a particular product. After

the heat level has been set, the time [in

hours and minutes] is set on the display

similar to the manner used on the Water

Meter. The Green button starts the timer.

The timer may be stopped at any time by

pressing the Red button. When the display

reaches 000, a horn sounds for

approximately five seconds.

D. Cook/Chill

As an option, an electrically operated

Cook/Chill feature can be provided, through

a series of solenoid valves. With the switch

in the “Cook” position, the steam supply

and condensate return solenoids are

opened and the coolant and drain solenoids

are closed. In the “Chill” position, the

7

Page 11

coolant and drain solenoids are open and

the steam supply and condensate return

solenoids are closed. With the switch in the

center position, all solenoid valves are

closed. To Cook in a kettle after it has

passed through the Chill cycle, it may be

expeditious to open the kettle jacket drain

to remove coolant. Kettles may be

equipped with an optional drain solenoid

which allows for removal of the fluid within

the kettle jacket whenever the switch is in

the "OFF” position.

X. CORDSETS

A. Sizing and Connection to Equipment

Cordsets provided by AVTEC include a

strain relief grip for attachment to the

equipment. The length of cord may be

trimmed at the time of installation by the

electrical contractor in order to present a

neat appearance and prevent excessive

lengths of cable from resting on the floor.

Care should be taken, however, especially

on mobile items, to allow enough slack to

allow the operator to move the equipment

far enough to disconnect it from the raceway

without stressing the connections.

B. Connection to Raceway

The plug for connecting to the raceway

receptacle is generally one of three types:

Straight Blade, Twist/lock, and Locking

Collar.

E. Motorized Steam Control

A motorized steam valve control can be

provided as an option on some kettle/arm

assemblies. This valve is controlled by a

knob which in turn operates a motor. This

to to permit mild warming or rapid heating

of the product, or anywhere in between.

This feature can be used in conjunction

with the Cook/Chill option when the latter is

in the “Cook” position. The control plate is

not graduated as heating potential varies

greatly depending on steam pressure and

temperature.

Be sure that the plug blades are fully

inserted into the receptacle in order to

prevent arcing and escessive heating. On

twist/lock plugs, care should be taken to

make sure that the natural straightening

tendencies of the cable do not cause the

plug to twist out and loosen away from the

receptacle. On plugs equipped with a

locking collar, be sure that the collar is

tightened on to the receptacle, thus

drawing the blades fully into the receptacle

and insuring proper contact.

C. Care in Operation

When moving equipment, turn off the

breaker and disconnect the plug from the

receptacle before reaching the limit of the

cordset. Excessive strain can cause

damage to the plug and/or receptacle and

present a very serious situation. If

problems arise because of operator abuse,

you may consider securing the equipment

8

Page 12

to a tether which limits the travel before the

7cable is strained. When cleaning the

equipment, it should be OFF and the circuit

breaker turned OFF before disconnecting

the cordset. Though the cable is oil

resistant, solvents should not be used to

clean the cordset. Use a moist cloth and

mild detergent. Be sure that all parts are

dry before re-connecting the equipment to

the outlet.

D. Nomenclature

Error! Not a valid link.

Model No.

50

24 - AN 6

[1[ [2[ [3] Cable length in ft.

[1] Amperage

20 20amp

30 30amp

50 50amp

60 60amp

80 80amp

100 100amp

[2] Voltage/Phase

03 120v/1φ

23 208v/1φ

24 208v/3φ

14 120/208v/1φ

15 120/208v/3φ

43 480v/1φ

44 480v/3φ

45 277/480v/3φ

[3] Plug Type

AN Straight Blade Straight Cap

BN Straight Blade Angle Cap

CN Twist Lock Straight Cap

DN Twist Lock/Water Tight/Straight

Cap

EN StraightBlade/Water

Tight/Straight Cap

XI. FLEXIBLE HOSE

A. Connection to Equipment

One end of the hose is provided with a union for

connecting to the equipment. Care should be

taken to prevent sharp bends in the hose while

in its operating position and when the equipment

is moved for cleaning and/or service. Elbow,

nipples, etc., may be necessary to accomplish

this.

B. Connection to Raceway

On water lines the raceway is equipped with

quick-disconnect fittings. The supply side is

female for hot water and male for cold water.

Both sides are equipped with shut off valves

which automatically close when disconnected on

water quick disconnects.

On gas lines the raceway is equipped with a

female quick-disconnect which incorporates an

automatic shut off valve which closes when it is

not connected. The raceway also has a manual

ball valve to further ensure that there is no flow of

gas. The male half of the quick-disconnect is

attached to the hose and does not have an

automatic shut off feature. [The double shut off

option is, however, available for use with

manifolded equipment fed by a looped service].

Hoses for steam lines have an insulation layer to

reduce heat flow to the outer braiding. The outer

surface, however, does get hot when in use, so

caution should be used. The raceway is

equipped with a ball shut off valve only. A union

and close nipple can be added between the hose

and ball valve to further facilitate assembly. Take

care to avoid twisting the hose when connecting

the hoses.

C.Care and Maintenance

The hoses can be cleaned easily with a damp

cloth and mild detergent. Do not place undue

stress on the hose when moving equipment.

D.Nomenclature

Model No.

075

G S 48

[1] [2] [3] [4]

[1] Diameter

025 - ¼”

038 - 3/8”

050 - ½”

075 - ¾”

100 - 1”

0125 - 1-1/4”

[2] G GAS

W WATER

SM STEAM

[3] S Stainless Steel Braid [All hoses]

P Stainless Steel Braid with

Polytec [plastic] Coating

9

Page 13

N NSF Potable Water/Steam

[4] Length in inches [12” increments]

XII. DRAIN HOSES

Flexible drain hoses may be supplied as an

option. These are supplied with a union at one

end for connection to the ventilator and a

smooth pipe extension to be inserted into the air

gap drain. The length of pipe between the

ventilator and the drain hoses will determine the

amount of penetration into the air gap. [which

should be just above the flood level, but kept to

a minimum to reduce splash].

10

Page 14

XIII. PARTS LIST

ENERGY DISTRIBUTION SYSTEM – ELECTRICAL

“L” OR “M” SERIES BREAKERS

AVTEC PART NO. DESCRIPTION

EL BRK 0301

EL BRK 0302

EL BRK 0303

EL BRK 0304

EL BRK 0305

EL BRK 0306

EL BRK 0307

EL BRK 0308

EL BRK 0309

EL BRK 0364

EL BRK 0310

EL BRK 0311

EL BRK 0312

EL BRK 0313

EL BRK 0371

EL BRK 0315

EL BRK 0316

15 amp, 240v, 3F, 3 pole, BQ3B15

15 amp, 120v, 1F, 1 pole, BQ1B15

15 amp, 240v, 1F, 2 pole, BQ2B015

20 amp, 120v, 1F, 1 pole, BQ1B020

20 amp, 240v, 1F, 2 pole, BQ2B020

20 amp, 240v, 3F, 3 pole, BQ3B020

30 amp, 120v, 1F, 1 pole, BQ1B030

30 amp, 240v, 1F, 2 pole, BQ2B030

30 amp, 240v, 3F, 3 pole, BQ3B030

50 amp, 120v, 1F, 1 pole, BQ1B050

50 amp, 240v, 1F, 2 pole, BQ2B050

50 amp, 240v, 3F, 3 pole, BQ3B050

60 amp, 240v, 1F, 2 pole, BQ2B060

60 amp, 240v, 3F, 3 pole, BQ3B060

80 amp, 240v, 3F, 3 pole, BQ3B080

100 amp, 240v, 1F, 2 pole, BQ2B100

100 amp, 240v, 3F, 3 pole, BQ3B100

“E” SERIES BREAKERS

AVTEC PART NO. DESCRIPTION

EL BRK 0318

EL BRK 0319

EL BRK 0376

EL BRK 0320

EL BRK 0321

EL BRK 0322

EL BRK 0323

EL BRK 0324

EL BRK 0325

EL BRK 0331

EL BRK 0365

EL BRK 0326

EL BRK 0327

EL BRK 0328

EL BRK 0329

EL BRK 0330

EL BRK 0332

15 amp, 120v, 1F, 1 pole, Circuit Breaker with shunt trip, BQ1B015

15 amp, 240v, 1F, 2 pole, Circuit Breaker with shunt trip, BQ2B015

15 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B015

20 amp, 120v, 1F, 1 pole, Circuit Breaker with shunt trip, BQ1B020

20 amp, 240v, 1F, 2 pole, Circuit Breaker with shunt trip, BQ2B020

20 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B020

30 amp, 120v, 1F, 1 pole, Circuit Breaker with shunt trip, BQ1B030

30 amp, 240v, 1F, 2 pole, Circuit Breaker with shunt trip, BQ2B030

30 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B030

40 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B040

50 amp, 120v, 1F, 1 pole, Circuit Breaker with shunt trip, BQ1B050

50 amp, 240v, 1F, 2 pole, Circuit Breaker with shunt trip, BQ2B050

50 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B050

60 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B060

80 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B080

100 amp, 240v, 3F, 3 pole, Circuit Breaker with shunt trip, BQ3B100

20 amp, 480v, 3F, 3 pole, Circuit Breaker with shunt trip, CQD320

-deunitnoc-

11

Page 15

AVTEC PART NO. DESCRIPTION

EL BRK 0333

EL BRK 0338

EL BRK 0334

EL BRK 0335

EL BRK 0336

EL BRK 0337

EL TRN 0304

PB MTR 0401

HD BRK 0310

EL RLY 0325

EL CVR 0328

30 amp, 480v, 3F, 3 pole, Circuit Breaker with shunt trip, CQD330

40 amp, 480v, 3F, 3 pole, Circuit Breaker with shunt trip, CQD340

50 amp, 480v, 3F, 3 pole, Circuit Breaker with shunt trip, CQD350

60 amp, 480v, 3F, 3 pole, Circuit Breaker with shunt trip, CQD360

80 amp, 480v, 3F, 3 pole, Circuit Breaker with shunt trip, CQD380

100 amp, 480v, 3F, 3 pole, Circuit Breaker with shunt trip, CQD3100

Transformer [Control Harness] 120:24v 40va

¾” Water Flow Meter

Current Sensor Bracket

Current Sensor

Breaker Cover

12

Page 16

131415

Page 17

Page 18

Page 19

XIV.WARRANTY

-

WARRANTY-

AVTEC INDUSTRIES INC. warrants to the original purchaser for use of our products, that any part

thereof which proves to be defective in material or workmanship under normal use within one year from

date of installation, will be replaced free of charge, labor to replace such part is warranted for one year

from installation. All warranty labor to be performed during regular working hours, with no overtime

premium.

All W arranty service must be authorized by the factory and be performed by AVTEC’s authorized service

personnel.

This Warranty is limited to the United States and Canada.

This Warranty does not apply to any damage resulting from shipping, improper installation, accident, unauthorized

alteration, local codes not previously brought to the attention of AVTEC, misuse, or abuse; and does not cover loss

of food, other products or damage to equipment or property resulting from mechanical or electrical failure.

AVTEC neither makes nor assumes and does not authorize any other person to assume any other obligation or

liability in connection with its products other than that covered in this Warranty.

16

Loading...

Loading...