Page 1

Low Volume Exhaust

Canopy for Use

Over 400°F & 600°F

Cooking Equipment

EcoArch™ Energy Efficient Ventilation

Description:

The EA2 model exhaust only canopy is UL 710 Listed

for use over 400 and 600˚F commercial cooking

appliances. This non compensating high exhaust

velocity style canopy is intended for use over light

and heavy-duty types of cooking appliances and

is recommended for all projects where energy

consumption is a factor or when adequate make up air

is not available from the heating and cooling system.

Specifications:

Model EA2 exhaust only type I commercial kitchen ventilation canopy UL 710 Listed without a re damper in the exhaust collar.

Canopy is constructed of a minimum 18 gauge, high grade, corrosive resistant, non-magnetic stainless steel on all surfaces. Top

of canopy to be constructed to incorporate exclusive aerodynamic arch. All exterior joints and seams shall be continuously welded

liquid tight, ground smooth, and polished to match the original nish. Construction to conform to NFPA 96 standards and shall meet

UL 710 standards for operation. Canopy is constructed using the standing seam method for optimum strength. Exhaust Canopy shall

be complete with stainless steel removable grease extractors running the full length of canopy. Grease extraction is accomplished

by way of front located high velocity exhaust slot running the full length at the top of hood through grease lters. Grease lters are

removable through exhaust plenum access doors. Grease trough is concealed within the hood and slopes to a removable grease cup

located at the end of the front exhaust canopy. Canopy comes complete with UL Listed uorescent light xtures.

EA2000

model EA2

Standard Features: Optional accessories:

• High grade, corrosive resistant, non-magnetic

stainless steel construction on all surfaces

• UL Listed uorescent light xtures

• 3” Rear air space

• Full length concealed grease trough

pitched to a removable grease cup

• Pre-drilled hanger brackets

• Stainless steel grease extractors

• Exclusive aerodynamic arch

• Front mounted exhaust plenum

• Front located high velocity exhaust slot

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Insulated 3” air space

Pre-plumbed re suppression

Fire suppression complete installation

Stainless steel top ceiling enclosures

Utility re system cabinet, mounted on end of hood

Fan/light switches

Stainless steel wall panel

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

units with (2) or more exhaust collars

Melink Intelli-Hood® system controls

Avtec EcoArch Ventilation, Page 1

PP SPEC1001 Rev. E

Revised 05/09

Page 2

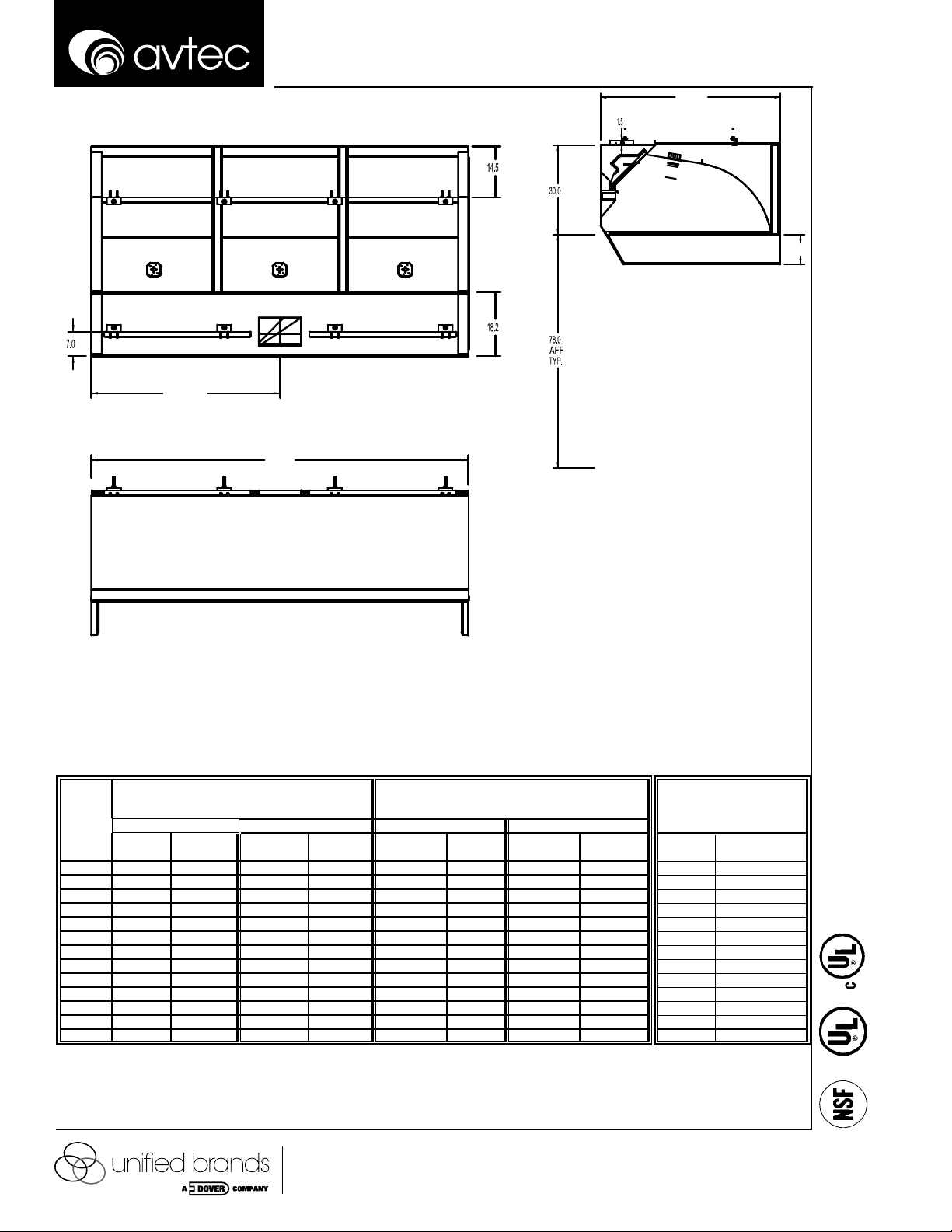

8.0

54”-66”

Center Line

Model EA2

54”-66”

8.0

PLAN VIEW

CROSS SECTION VIEW

4’-16’

ELEVATION VIEW

Light Duty 400ºF Cooking Equipment

Length

4’-0” 560 8 x 6 560 8 x 6 720 8 x 8 720 8 x 8

5’-0” 700 8 x 8 700 8 x 8 900 8 x 10 900 8 x 10

6’-0” 840 8 x 10 840 8 x 10 1080 8 x 12 1080 8 x 12

7’-0” 980 8 x 10 980 8 x 10 1260 8 x 14 1260 8 x 14

8’-0” 1120 8 x 12 1120 8 x 12 1440 8 x 16 1440 8 x 16

9’-0” 1260 8 x 14 1125 (2) 8 x 6 1620 8 x 18 1485 (2) 8 x 8

10’-0” 1400 8 x 16 1250 (2) 8 x 8 1800 8 x 20 1650 (2) 8 x 8

11’-0” 1540 8 x 18 1375 (2) 8 x 8 1980 8 x 22 1815 (2) 8 x 10

12’-0” 1680 8 x 18 1500 (2) 8 x 8 2160 8 x 24 1980 (2) 8 x 12

13’-0 1820 8 x 20 1625 (2) 8 x 10 2340 8 x 26 2145 (2) 8 x 12

14’-0” 1960 8 x 22 1750 (2) 8 x 10 2520 10 x 22 2310 (2) 8 x 12

15’-0” 2100 8 x 24 1875 (2) 8 x 10 2700 10 x 24 2475 (2) 8 x 14

16’-0” 2240 8 x 26 2000 (2) 8 x 12 2880 10 x 26 2640 (2) 8 x 14

Note: Depending on building conditions greater exhaust air ow rates may be required for each specic installation in order to obtain complete vapor and

smoke removal. UL710 Listing information is available upon request.

Note: Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are located on centerline of canopy, unless otherwise specied.

Hoods with Double exhaust collar are located on ¼ lines of canopy unless otherwise specied. Canopy is to have a minimum 6” overhang on all exposed

sides of cooking equipment.

Single Collar Double Collar Single Collar Double Collar

CFM @

.875 SP

Exhaust CFM

Duct

Collar

CFM @

. 875” SP

Duct

Collar

Medium and Heavy Duty 600ºF Cooking

Equipment Exhaust CFM

CFM @

1.125” SP

Duct

Collar

CFM @

1.125” SP

Duct

Collar

Extra Heavy Duty 700ºF

Cooking Equipment

Exhaust CFM

CFM @

1.375 SP

1400 8 x 16

1750 8 x 20

2100 8 x 24

2450 10 x 22

2800 10 x 26

3150 (2) 8 x 18

3500 (2) 8 x 20

3850 (2) 8 x 22

4200 (2) 8 x 24

4550 (2) 8 x 26

4900 (2) 10 x 22

5250 (2) 10 x 24

5600 (2) 10 x 26

Duct Collar

NFPA-96

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 3

Low Volume Exhaust

Canopy for Use

Over 400°F & 600°F

Cooking Equipment

EcoArch™ Energy Efficient Ventilation EA2000P

model EA2

Description:

The EA2 model with PBB make-up air canopy is UL

710 Listed for use over 400 and 600˚F commercial

cooking appliances. This non compensating high

exhaust velocity style canopy is intended for use over

light and heavy-duty types of cooking appliances

and is recommended for all projects where energy

consumption is a factor or when adequate make up air

is not available from the heating and cooling system.

Specifications:

Model EA2 PBB exhaust type I commercial kitchen ventilation canopy, incorporating PBB make-up air plenum box, UL 710 Listed

without a re damper in the exhaust collar. Canopy is constructed of a minimum 18 gauge, high grade, corrosive resistant, nonmagnetic stainless steel on all surfaces. Top of canopy to be constructed to incorporate exclusive aerodynamic arch. All exterior

joints and seams shall be continuously welded liquid tight, ground smooth, and polished to match the original nish. Construction

to conform to NFPA 96 standards and shall meet UL 710 standards for operation. Canopy is constructed using the standing seam

method for optimum strength. Exhaust Canopy shall be complete with stainless steel removable grease extractors running the full

length of canopy. Grease extraction is accomplished by way of front located high velocity exhaust slot running the full length at the

top of hood through grease lters. Grease lters are removable through exhaust plenum access doors. Grease trough is concealed

within the hood and slopes to a removable grease cup located at the end of the front exhaust canopy. Canopy comes complete with

UL Listed uorescent light xtures.

Standard Features: Optional accessories:

• High grade, corrosive resistant, non-magnetic

stainless steel construction on all surfaces

• UL Listed uorescent light xtures

• 3” Rear air space

• Full length concealed grease trough

pitched to a removable grease cup

• Pre-drilled hanger brackets

• Stainless steel grease extractors

• Exclusive aerodynamic arch

• Front mounted exhaust plenum

Insulated 3” air space

Pre-plumbed re suppression

Fire suppression complete installation

Stainless steel top ceiling enclosures

Utility re system cabinet, mounted on end of hood

Fan/light switches

Stainless steel wall panel

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

units with (2) or more exhaust collars

Melink Intelli-Hood® system controls

• Front located high velocity exhaust slot

• PBB make-up air plenum box

(attached or shipped loose)

• 1” thick supply air plenum insulation

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec EcoArch Ventilation, Page 2a

PP SPEC1002 Rev. E

Revised 05/09

Page 4

54”-66”

8.0

54”-66”

Model EA2

8.0

Center Line

PLAN VIEW

CROSS SECTION VIEW

4’-16’

ELEVATION VIEW

Light Duty 400ºF Cooking Equipment

Length

4’-0” 560 8 x 6 560 8 x 6 720 8 x 8 720 8 x 8

5’-0” 700 8 x 8 700 8 x 8 900 8 x 10 900 8 x 10

6’-0” 840 8 x 10 840 8 x 10 1080 8 x 12 1080 8 x 12

7’-0” 980 8 x 10 980 8 x 10 1260 8 x 14 1260 8 x 14

8’-0” 1120 8 x 12 1120 8 x 12 1440 8 x 16 1440 8 x 16

9’-0” 1260 8 x 14 1125 (2) 8 x 6 1620 8 x 18 1485 (2) 8 x 8

10’-0” 1400 8 x 16 1250 (2) 8 x 8 1800 8 x 20 1650 (2) 8 x 8

11’-0” 1540 8 x 18 1375 (2) 8 x 8 1980 8 x 22 1815 (2) 8 x 10

12’-0” 1680 8 x 18 1500 (2) 8 x 8 2160 8 x 24 1980 (2) 8 x 12

13’-0 1820 8 x 20 1625 (2) 8 x 10 2340 8 x 26 2145 (2) 8 x 12

14’-0” 1960 8 x 22 1750 (2) 8 x 10 2520 10 x 22 2310 (2) 8 x 12

15’-0” 2100 8 x 24 1875 (2) 8 x 10 2700 10 x 24 2475 (2) 8 x 14

16’-0” 2240 8 x 26 2000 (2) 8 x 12 2880 10 x 26 2640 (2) 8 x 14

Note: Depending on building conditions greater exhaust air ow rates may be required for each specic installation in order to obtain complete vapor and

smoke removal. UL710 Listing information is available upon request.

Note: Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are located on centerline of canopy, unless otherwise specied.

Hoods with Double exhaust collar are located on ¼ lines of canopy unless otherwise specied. Canopy is to have a minimum 6” overhang on all exposed

sides of cooking equipment.

Single Collar Double Collar Single Collar Double Collar

CFM @

.875 SP

Exhaust CFM

Duct

Collar

CFM @

. 875” SP

Duct

Collar

Medium and Heavy Duty 600ºF Cooking

Equipment Exhaust CFM

CFM @

1.125” SP

Duct

Collar

CFM @

1.125” SP

Duct

Collar

Extra Heavy Duty 700ºF

Cooking Equipment

Exhaust CFM

CFM @

1.375 SP

1400 8 x 16

1750 8 x 20

2100 8 x 24

2450 10 x 22

2800 10 x 26

3150 (2) 8 x 18

3500 (2) 8 x 20

3850 (2) 8 x 22

4200 (2) 8 x 24

4550 (2) 8 x 26

4900 (2) 10 x 22

5250 (2) 10 x 24

5600 (2) 10 x 26

Duct Collar

NFPA-96

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 5

ECO ARCH SUPPLY COLLAR SIZING CHART

Model EA2

Light Duty 400ºF

Cooking Equipment

Length

4’-0” 450 8 x 12 575 8 x 12 1120 8 x 24

5’-0” 560 8 x 12 720 10 x16 1400 8 x 24

6’-0” 670 10 x 16 865 10 x 16 1680 10 x 30

7’-0” 785 10 x 16 1000 8 x 24 1960 10 x 30

8’-0” 895 10 x 16 1150 10 x 20 2240 10 x 40

9’-0” 1000 (2) 8 x 12 1295 (2)10 x 16 2520 (2)10 x 20

10’-0” 1120 (2)10 x 10 1440 (2)10 x 16 2800 (2)10 x 30

11’-0” 1230 (2)10 x 10 1585 (2)10 x 16 3080 (2)10 x 30

12’-0” 1345 (2)10 x 16 1725 (2)10 x 16 3360 (2)10 x 30

13’-0 1455 (2)10 x 16 1870 (2)10 x 16 3640 (3)10 x 20

14’-0” 1570 (2)10 x 16 2015 (2)10 x 20 3920 (3)10 x 20

15’-0” 1680 (2)10 x 16 2160 (2)10 x 20 4200 (3)10 x 30

16’-0” 1790 (2)10 x 16 2300 (2)10 x 20 4480 (3)10 x 30

Note: Depending on building conditions greater or lesser supply air ow rates may be required for each specic installation in order to obtain complete

vapor and smoke removal. UL710 Listing information is available upon request.

Note: Supply collar sizing is based on an average range of 800 FPM. Single Duct collars are located on centerline of canopy, unless otherwise specied.

Double Supply Collars are located on ¼ lines unless otherwise specied. Triple Supply collars are located on 1/3 lines unless otherwise specied.

CFM @

.25” SP

Duct Collar

Medium and Heavy Duty

600ºF Cooking Equipment

CFM @

.375” SP

Duct Collar

Extra-Heavy Duty 700ºF

Cooking Equipment

CFM @

.50” SP

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

NFPA-96

Page 2b

Page 6

Page 7

Low Volume Exhaust

Canopy for Use

Over 400°F & 600°F

Cooking Equipment

EcoArch™ Energy Efficient Ventilation

Description:

The EA4 model exhaust only canopy is UL 710 Listed

for use over 400 and 600˚F commercial cooking

appliances. This non compensating high exhaust

velocity style canopy is intended for use over light

and heavy-duty types of cooking appliances and

is recommended for all projects where energy

consumption is a factor or when adequate make up air

is not available from the heating and cooling system.

Specifications:

Model EA4 exhaust only type I commercial kitchen ventilation canopy UL 710 Listed without a re damper in the exhaust collar.

Canopy is constructed of a minimum 18 gauge stainless steel on all surfaces. Top of canopy to be constructed to incorporate

exclusive aerodynamic arch. All exterior joints and seams shall be continuously welded liquid tight, ground smooth, and polished

to match the original nish. Construction to conform to NFPA 96 standards and shall meet UL 710 standards for operation. Canopy

is constructed using the standing seam method for optimum strength. Exhaust Canopy shall be complete with stainless steel

removable grease extractors running the full length of canopy. Grease extraction is accomplished by way of front located high

velocity exhaust slot running the full length at the top of hood through grease lters. Grease lters are removable through exhaust

plenum access doors. Grease trough is concealed within the hood and slopes to a removable grease cup located at the end of the

front exhaust canopy. Canopy comes complete with UL Listed incandescent bulb type light xtures.

EA4000

model EA4

Standard Features: Optional accessories:

•

UL Listed incandescent bulb type light xtures

• 3” Rear air space

• Full length concealed grease trough

pitched to a removable grease cup

• Pre-drilled hanger brackets

• Stainless steel grease extractors

• Exclusive aerodynamic arch

• Front mounted exhaust plenum

• Front located high velocity exhaust slot

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Insulated 3” air space

Pre-plumbed re suppression

Fire suppression complete installation

Stainless steel top ceiling enclosures

Utility re system cabinet, mounted on end of hood

Fan/light switches

Stainless steel wall panel

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

units with (2) or more exhaust collars

Melink Intelli-Hood® system controls

Avtec EcoArch Ventilation, Page 3

PP SPEC1003 Rev. D

Revised 05/09

Page 8

8.0

54”-66”

Center Line

Model EA4

54”-66”

8.0

PLAN VIEW

CROSS SECTION VIEW

4’-16’

ELEVATION VIEW

Light Duty 400ºF Cooking Equipment

Length

4’-0” 560 8 x 6 560 8 x 6 720 8 x 8 720 8 x 8

5’-0” 700 8 x 8 700 8 x 8 900 8 x 10 900 8 x 10

6’-0” 840 8 x 10 840 8 x 10 1080 8 x 12 1080 8 x 12

7’-0” 980 8 x 10 980 8 x 10 1260 8 x 14 1260 8 x 14

8’-0” 1120 8 x 12 1120 8 x 12 1440 8 x 16 1440 8 x 16

9’-0” 1260 8 x 14 1125 (2) 8 x 6 1620 8 x 18 1485 (2) 8 x 8

10’-0” 1400 8 x 16 1250 (2) 8 x 8 1800 8 x 20 1650 (2) 8 x 8

11’-0” 1540 8 x 18 1375 (2) 8 x 8 1980 8 x 22 1815 (2) 8 x 10

12’-0” 1680 8 x 18 1500 (2) 8 x 8 2160 8 x 24 1980 (2) 8 x 12

13’-0 1820 8 x 20 1625 (2) 8 x 10 2340 8 x 26 2145 (2) 8 x 12

14’-0” 1960 8 x 22 1750 (2) 8 x 10 2520 10 x 22 2310 (2) 8 x 12

15’-0” 2100 8 x 24 1875 (2) 8 x 10 2700 10 x 24 2475 (2) 8 x 14

16’-0” 2240 8 x 26 2000 (2) 8 x 12 2880 10 x 26 2640 (2) 8 x 14

Note: Depending on building conditions greater exhaust air ow rates may be required for each specic installation in order to obtain complete vapor and

smoke removal. UL710 Listing information is available upon request.

Note: Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are located on centerline of canopy, unless otherwise specied.

Hoods with Double exhaust collar are located on ¼ lines of canopy unless otherwise specied. Canopy is to have a minimum 6” overhang on all exposed

sides of cooking equipment.

Single Collar Double Collar Single Collar Double Collar

CFM @

.875 SP

Exhaust CFM

Duct

Collar

CFM @

. 875” SP

Duct

Collar

Medium and Heavy Duty 600ºF Cooking

Equipment Exhaust CFM

CFM @

1.125” SP

Duct

Collar

CFM @

1.125” SP

Duct

Collar

Extra Heavy Duty 700ºF

Cooking Equipment

Exhaust CFM

CFM @

1.375 SP

1400 8 x 16

1750 8 x 20

2100 8 x 24

2450 10 x 22

2800 10 x 26

3150 (2) 8 x 18

3500 (2) 8 x 20

3850 (2) 8 x 22

4200 (2) 8 x 24

4550 (2) 8 x 26

4900 (2) 10 x 22

5250 (2) 10 x 24

5600 (2) 10 x 26

Duct Collar

NFPA-96

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 9

Low Volume Exhaust

Canopy for Use

Over 400°F & 600°F

Cooking Equipment

EcoArch™ Energy Efficient Ventilation EA4000P

model EA4

Description:

The EA4 model with PBB make-up air canopy is UL

710 Listed for use over 400˚ and 600˚F commercial

cooking appliances. This non compensating high

exhaust velocity style canopy is intended for use over

light and heavy-duty types of cooking appliances

and is recommended for all projects where energy

consumption is a factor or when adequate make up air

is not available from the heating and cooling system.

Specifications:

Model EA4 PBB exhaust type I commercial kitchen ventilation canopy, incorporating PBB make-up air plenum box, UL 710 Listed

without a re damper in the exhaust collar. Canopy is constructed of a minimum 18 gauge stainless steel on all surfaces. Top of

canopy to be constructed to incorporate exclusive aerodynamic arch. All exterior joints and seams shall be continuously welded

liquid tight, ground smooth, and polished to match the original nish. Construction to conform to NFPA 96 standards and shall meet

UL 710 standards for operation. Canopy is constructed using the standing seam method for optimum strength. Exhaust Canopy shall

be complete with stainless steel removable grease extractors running the full length of canopy. Grease extraction is accomplished

by way of front located high velocity exhaust slot running the full length at the top of hood through grease lters. Grease lters are

removable through exhaust plenum access doors. Grease trough is concealed within the hood and slopes to a removable grease cup

located at the end of the front exhaust canopy. Canopy comes complete with UL Listed incandescent bulb type light xtures.

Standard Features: Optional accessories:

•

UL Listed incandescent bulb type light xtures

• 3” Rear air space

• Full length concealed grease trough

pitched to a removable grease cup

• Pre-drilled hanger brackets

• Stainless steel grease extractors

• Exclusive aerodynamic arch

• Front mounted exhaust plenum

• Front located high velocity exhaust slot

• PBB make-up air plenum box

Insulated 3” air space

Pre-plumbed re suppression

Fire suppression complete installation

Stainless steel top ceiling enclosures

Utility re system cabinet, mounted on end of hood

Fan/light switches

Stainless steel wall panel

Exhaust fan / cooking equipment interlock control

UL Listed exhaust volume damper available on

units with (2) or more exhaust collars

Melink Intelli-Hood® system controls

(attached or shipped loose)

• 1” thick supply air plenum insulation

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec EcoArch Ventilation, Page 4a

PP SPEC1004 Rev. E

Revised 05/09

Page 10

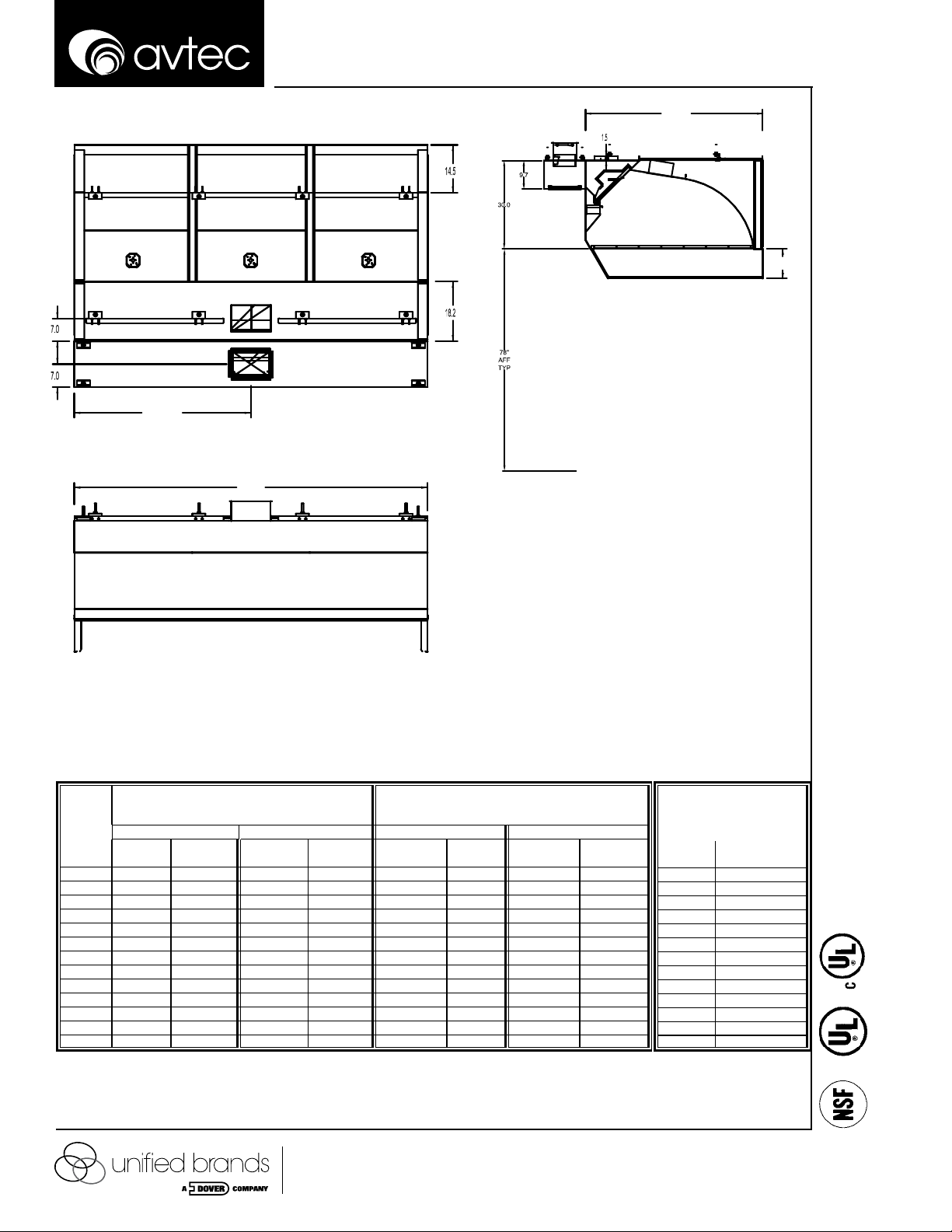

8.0

54”-66”

54”-66”

Model EA4

8.0

Center Line

PLAN VIEW

CROSS SECTION VIEW

4’-16’

ELEVATION VIEW

Light Duty 400ºF Cooking Equipment

Length

4’-0” 560 8 x 6 560 8 x 6 720 8 x 8 720 8 x 8

5’-0” 700 8 x 8 700 8 x 8 900 8 x 10 900 8 x 10

6’-0” 840 8 x 10 840 8 x 10 1080 8 x 12 1080 8 x 12

7’-0” 980 8 x 10 980 8 x 10 1260 8 x 14 1260 8 x 14

8’-0” 1120 8 x 12 1120 8 x 12 1440 8 x 16 1440 8 x 16

9’-0” 1260 8 x 14 1125 (2) 8 x 6 1620 8 x 18 1485 (2) 8 x 8

10’-0” 1400 8 x 16 1250 (2) 8 x 8 1800 8 x 20 1650 (2) 8 x 8

11’-0” 1540 8 x 18 1375 (2) 8 x 8 1980 8 x 22 1815 (2) 8 x 10

12’-0” 1680 8 x 18 1500 (2) 8 x 8 2160 8 x 24 1980 (2) 8 x 12

13’-0 1820 8 x 20 1625 (2) 8 x 10 2340 8 x 26 2145 (2) 8 x 12

14’-0” 1960 8 x 22 1750 (2) 8 x 10 2520 10 x 22 2310 (2) 8 x 12

15’-0” 2100 8 x 24 1875 (2) 8 x 10 2700 10 x 24 2475 (2) 8 x 14

16’-0” 2240 8 x 26 2000 (2) 8 x 12 2880 10 x 26 2640 (2) 8 x 14

Note: Depending on building conditions greater exhaust air ow rates may be required for each specic installation in order to obtain complete vapor and

smoke removal. UL710 Listing information is available upon request.

Note: Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are located on centerline of canopy, unless otherwise specied.

Hoods with Double exhaust collar are located on ¼ lines of canopy unless otherwise specied. Canopy is to have a minimum 6” overhang on all exposed

sides of cooking equipment.

Single Collar Double Collar Single Collar Double Collar

CFM @

.875 SP

Exhaust CFM

Duct

Collar

CFM @

. 875” SP

Duct

Collar

Medium and Heavy Duty 600ºF Cooking

Equipment Exhaust CFM

CFM @

1.125” SP

Duct

Collar

CFM @

1.125” SP

Duct

Collar

Extra Heavy Duty 700ºF

Cooking Equipment

Exhaust CFM

CFM @

1.375 SP

1400 8 x 16

1750 8 x 20

2100 8 x 24

2450 10 x 22

2800 10 x 26

3150 (2) 8 x 18

3500 (2) 8 x 20

3850 (2) 8 x 22

4200 (2) 8 x 24

4550 (2) 8 x 26

4900 (2) 10 x 22

5250 (2) 10 x 24

5600 (2) 10 x 26

Duct Collar

NFPA-96

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 11

ECO ARCH SUPPLY COLLAR SIZING CHART

Model EA4

Light Duty 400ºF

Cooking Equipment

Length

4’-0” 450 8 x 12 575 8 x 12 1120 8 x 24

5’-0” 560 8 x 12 720 10 x16 1400 8 x 24

6’-0” 670 10 x 16 865 10 x 16 1680 10 x 30

7’-0” 785 10 x 16 1000 8 x 24 1960 10 x 30

8’-0” 895 10 x 16 1150 10 x 20 2240 10 x 40

9’-0” 1000 (2) 8 x 12 1295 (2)10 x 16 2520 (2)10 x 20

10’-0” 1120 (2)10 x 10 1440 (2)10 x 16 2800 (2)10 x 30

11’-0” 1230 (2)10 x 10 1585 (2)10 x 16 3080 (2)10 x 30

12’-0” 1345 (2)10 x 16 1725 (2)10 x 16 3360 (2)10 x 30

13’-0 1455 (2)10 x 16 1870 (2)10 x 16 3640 (3)10 x 20

14’-0” 1570 (2)10 x 16 2015 (2)10 x 20 3920 (3)10 x 20

15’-0” 1680 (2)10 x 16 2160 (2)10 x 20 4200 (3)10 x 30

16’-0” 1790 (2)10 x 16 2300 (2)10 x 20 4480 (3)10 x 30

Note: Depending on building conditions greater or lesser supply air ow rates may be required for each specic installation in order to obtain complete

vapor and smoke removal. UL710 Listing information is available upon request.

Note: Supply collar sizing is based on an average range of 800 FPM. Single Duct collars are located on centerline of canopy, unless otherwise specied.

Double Supply Collars are located on ¼ lines unless otherwise specied. Triple Supply collars are located on 1/3 lines unless otherwise specied.

CFM @

.25” SP

Duct Collar

Medium and Heavy Duty

600ºF Cooking Equipment

CFM @

.375” SP

Duct Collar

Extra-Heavy Duty 700ºF

Cooking Equipment

CFM @

.50” SP

Duct Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

NFPA-96

Page 4b

Page 12

Loading...

Loading...