Page 1

Low Volume Exhaust

Ultra Violet

Canopy for Use

Over 400°F & 600°F

Cooking Equipment

EcoArch™ Energy Efficient Ventilation UV

with model EA2000/4000 UV

Description:

The Avtec UV air cleaning system is ETL Listed to UL and ETL

standards and is designed for use in the Avtec EA 2000 and EA

4000 model exhaust canopies. The system is intended to break

down grease molecules, oxidize grease vapors, and reduce

grease odors in exhausted air. It is intended for reduced duct

cleaning and decreased fire risk in kitchen ductwork.

model EA2000UV shown

Specifications:

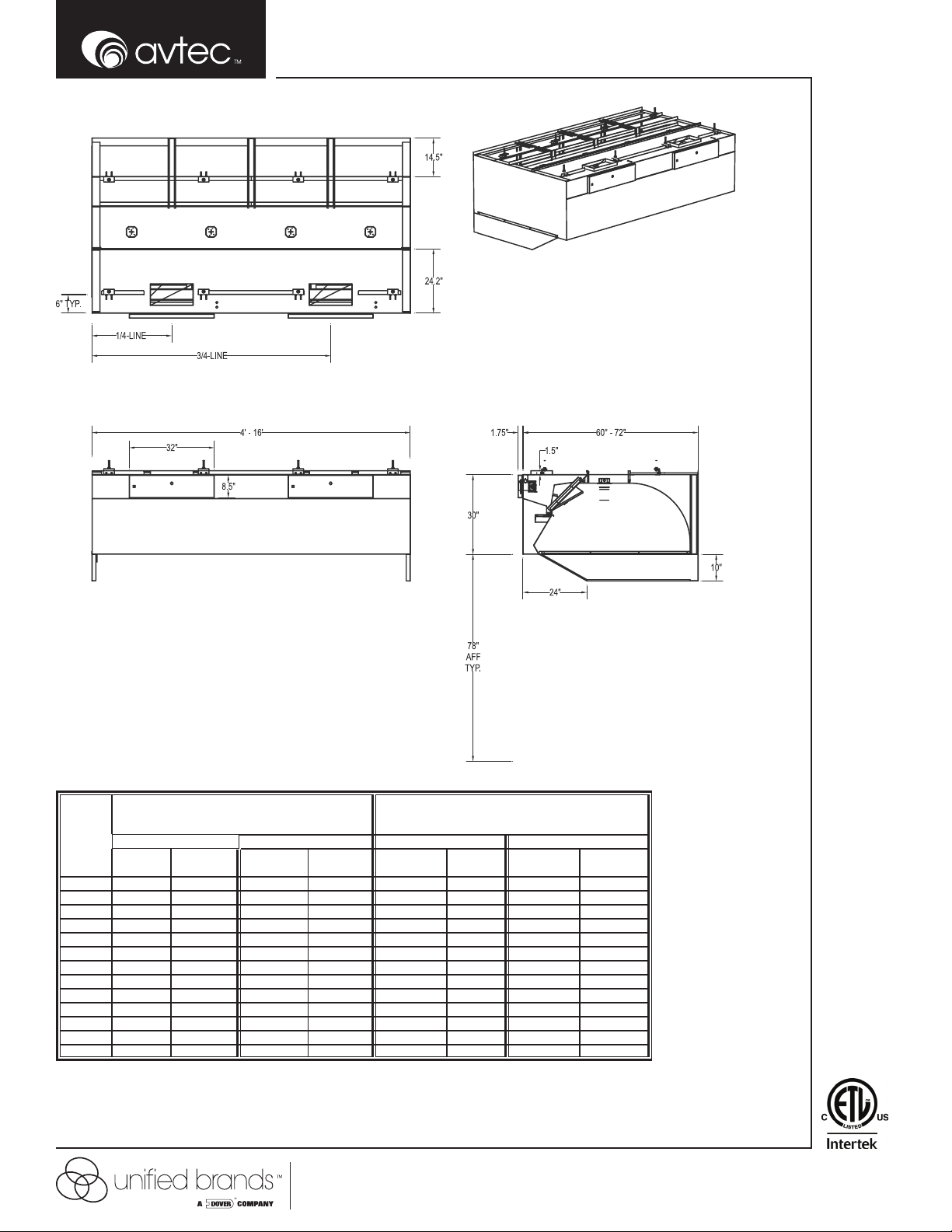

Provide Avtec UV air cleaning system, ETL Listed, with single 150 W quartz UV lamp, and UV “light on” view port with UV filter.

Unit to be designed with Avtec model EA 2000/4000 and be easily accessible through the front face of the exhaust canopy for ease of cleaning

and bulb replacement.

Avtec UV air cleaning system, to utilize both 185 and 254nm UV light to break down long-chain grease molecules and produce low levels of

ozone to oxidize grease vapors. Bulb to be single, rugged, 150 W UVc lamp with 12,000 hour life span.

Unit complete with control switch and interlocks for fan, door and cartridge lock-outs.

Standard Features:

• UV “on” viewing port with UV screen

• Locking access door for controlled access to UV bulb

• On/off switch with safety interlocks

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec EcoArch Ventilation UV, page 1

PP SPECUVEA Rev. C

Updated 09/11

Page 2

Ultraviolet Air Cleaning System

Light Duty 400ºF Cooking Equipment

Length

4’-0” 560 8 x 6 560 8 x 6 720 8 x 8 720 8 x 8

5’-0” 700 8 x 8 700 8 x 8 900 8 x 10 900 8 x 10

6’-0” 840 8 x 10 840 8 x 10 1080 8 x 12 1080 8 x 12

7’-0” 980 8 x 10 980 8 x 10 1260 8 x 14 1260 8 x 14

8’-0” 1120 8 x 12 1120 8 x 12 1440 8 x 16 1440 8 x 16

9’-0” 1260 8 x 14 1125 (2) 8 x 6 1620 8 x 18 1485 (2) 8 x 8

10’-0” 1400 8 x 16 1250 (2) 8 x 8 1800 8 x 20 1650 (2) 8 x 8

11’-0” 1540 8 x 18 1375 (2) 8 x 8 1980 8 x 22 1815 (2) 8 x 10

12’-0” 1680 8 x 18 1500 (2) 8 x 8 2160 8 x 24 1980 (2) 8 x 12

13’-0 1820 8 x 20 1625 (2) 8 x 10 2340 8 x 26 2145 (2) 8 x 12

14’-0” 1960 8 x 22 1750 (2) 8 x 10 2520 10 x 22 2310 (2) 8 x 12

15’-0” 2100 8 x 24 1875 (2) 8 x 10 2700 10 x 24 2475 (2) 8 x 14

16’-0” 2240 8 x 26 2000 (2) 8 x 12 2880 10 x 26 2640 (2) 8 x 14

Note: Depending on building conditions greater exhaust air flow rates may be required for each specific installation in order to obtain complete vapor and

smoke removal. UL710 Listing information is available upon request.

Note: Exhaust collar sizing is based on an average range of 1600 FPM. Duct collars are located on centerline of canopy, unless otherwise specified.

Hoods with Double exhaust collar are located on ¼ lines of canopy unless otherwise specified. Canopy is to have a minimum 6” overhang on all exposed

sides of cooking equipment.

Single Collar Double Collar Single Collar Double Collar

CFM @

.875 SP

Exhaust CFM

Duct

Collar

CFM @

. 875” SP

Duct

Collar

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2011 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of

Dover Corporation.

Medium and Heavy Duty 600ºF Cooking Equip-

CFM @

1.125” SP

ment Exhaust CFM

Duct

Collar

CFM @

1.125” SP

Duct

Collar

Loading...

Loading...