Page 1

Conveyors Slat Belt Conveyor System model CIDW

Description:

The AVTEC Model CIDW is a dual belt soiled tray/dish return conveyor

utilizing an interlocking style plastic slat connected by stainless steel

pins. The model CIDW is used to return soiled trays from the dining

room to the dish room or to move dishes or racks within the dish

room. Belt is returned in self-cleaning slider pan for easy cleaning and

maintenance. The model CIDW is used for straight applications only

and cannot make turns. Unit is provided with automatic detergent

injection wash system.

Specifications:

Provide AVTEC NSF Approved dual soiled tray/dish conveyor system, Model CIDW. Unit shall be integral with dish table and tray scrapping system

and will be size and shape as shown in project drawings. Top and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4

mill nish. Drive housing shall be of uni-body construction, completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter

stainless steel with 1 ½” diameter welded cross members for support. Drive motor to be stainless steel (½)(¾) hp, 208/3 and shall be water

resistant. Motor is to be located in separate housing from wash tank compartment. Housing is to be provided with door safety shut-off switch.

Unit is to include wash housing with strategically designed spray jets for cleaning of both sides of belt. Belts ride on self-cleaning return and top

track system. Detergent designed to drip on belt for maximum exposure to cleaning action. Wash housing is designed with large access panels

for inspection of wash chamber and comes complete with stainless steel latches to seal openings and removable scrap basket for waste. Belts

are to be interlocking style gray plastic on continuous length UHMW, driven by a UHMW sprocket mounted on stainless steel bearings and shafts

utilizing slip collar in lieu of keyways. Tail section includes auto-tensioning device to keep constant equal tension on the belt. Motor control panel

to be designed with main service disconnect switch, variable speed controls and of sealed water-tight construction. Conveyor is designed to

include a photo electric accumulation switch at terminal end of unit to shut down system when conveyor is full.

Standard Features:

• S/S drive housing

• S/S drive motor

• Door conveyor shut off

safety switch(s)

• Removable scrap basket in drive

and tail housings

• Access panel for wash housing

• 1 ½” Drain in drive

• Anti-jam safety switch at

drive opening

• Detergent pump housing

• Belt wash, with auto wash option

(PIC programmed timer for optimal

cleanness and performance)

• Main control panel with start/stop,

wash selector, belt speed, limit

switch, main disconnect.

• Limit switch

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

• Auto belt tensioner

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Work surface: 14 ga S/S construction,

fully welded and polished.

• 1/2 HP S/S drive motor (typ. for

under 60’)

• 3/4 HP S/S drive motor (typ. for

over 60’)

• S/S side exing #60 chain

• Side exing slats with rollers, for

smooth turns. Standard color

black, also available in gray, and blue.

• Self cleaning return track

• S/S drive sprockets

• Lifetime drive bearings

• Tail cover

• Slats can be easily replaced

Optional Accessories:

Hinged tail access door

Additional start/stop box(s)

Wall or post mounted overshelf

Wall or post mounted tubularovershelf

Hose reel:

30’ hose

50’ hose

Side skirting:

Hinged

Removeable

Avtec Conveyors, Page 8

PP SPEC1058 Rev. A

Revised 11/07

Page 2

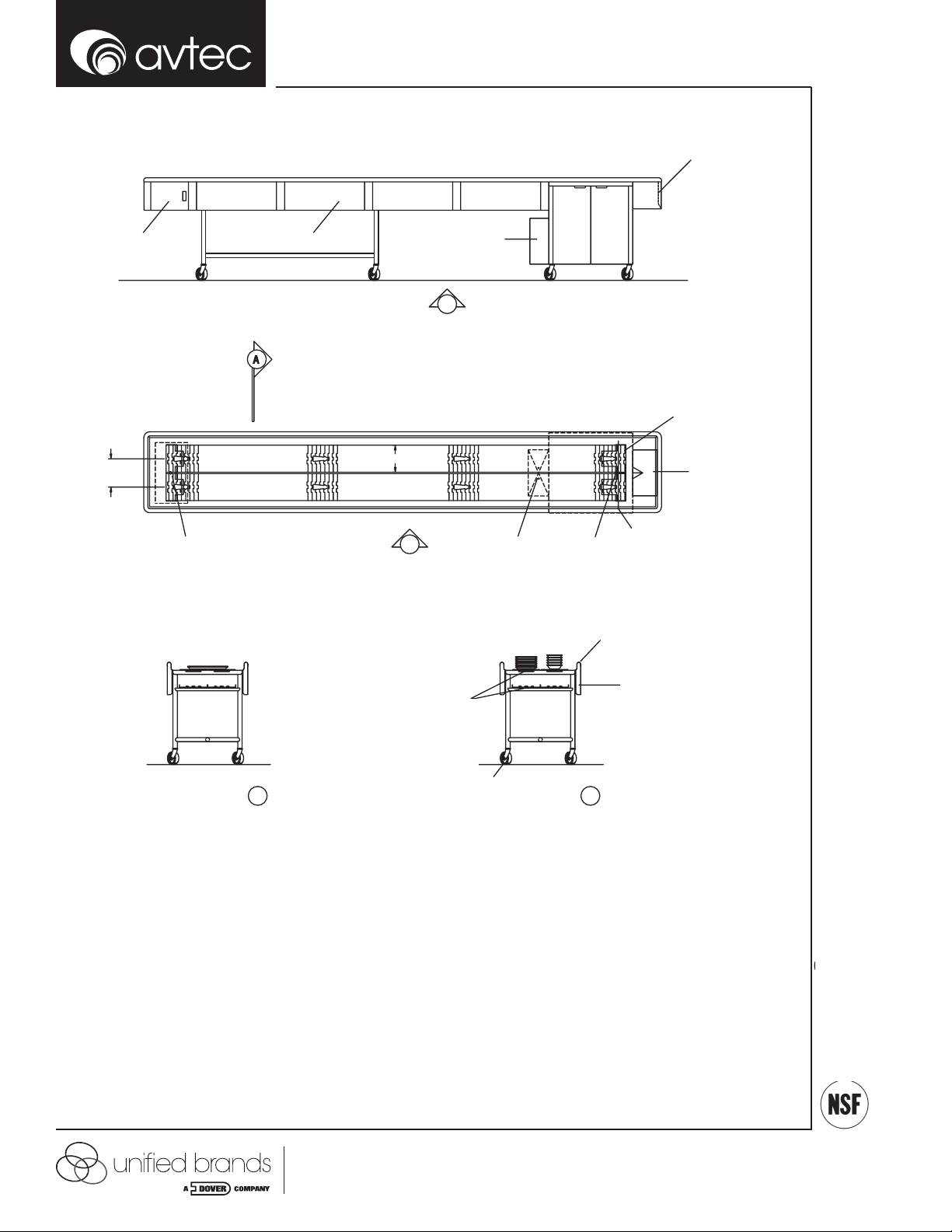

Front, Top & Side Views

Model CIDW

RECESSED MAIN CONTROLS

10 1/2" BELT

CENTERLINE

1 1/2" WASTE

SIDE SKIRTINGHINGED TAIL ACCESS

ELEVATION VIEW

DETERGENT PUMP HOUSING

1

A

ANTI-JAM

PLAN VIEW

10.000

1

SELF CLEANING

BELT TRACKS

1/2 H&C WATER

DETERGENT PUMP

HOUSING

1 1/2" WASTE

ROLLED EDGE

SIDE SKIRTING

(BOTH SIDED)

LIMIT SWITCH

RECESSED MAIN CONTROLS

5" CASTER

SECTION VIEWSECTION VIEW

AA

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...