Page 1

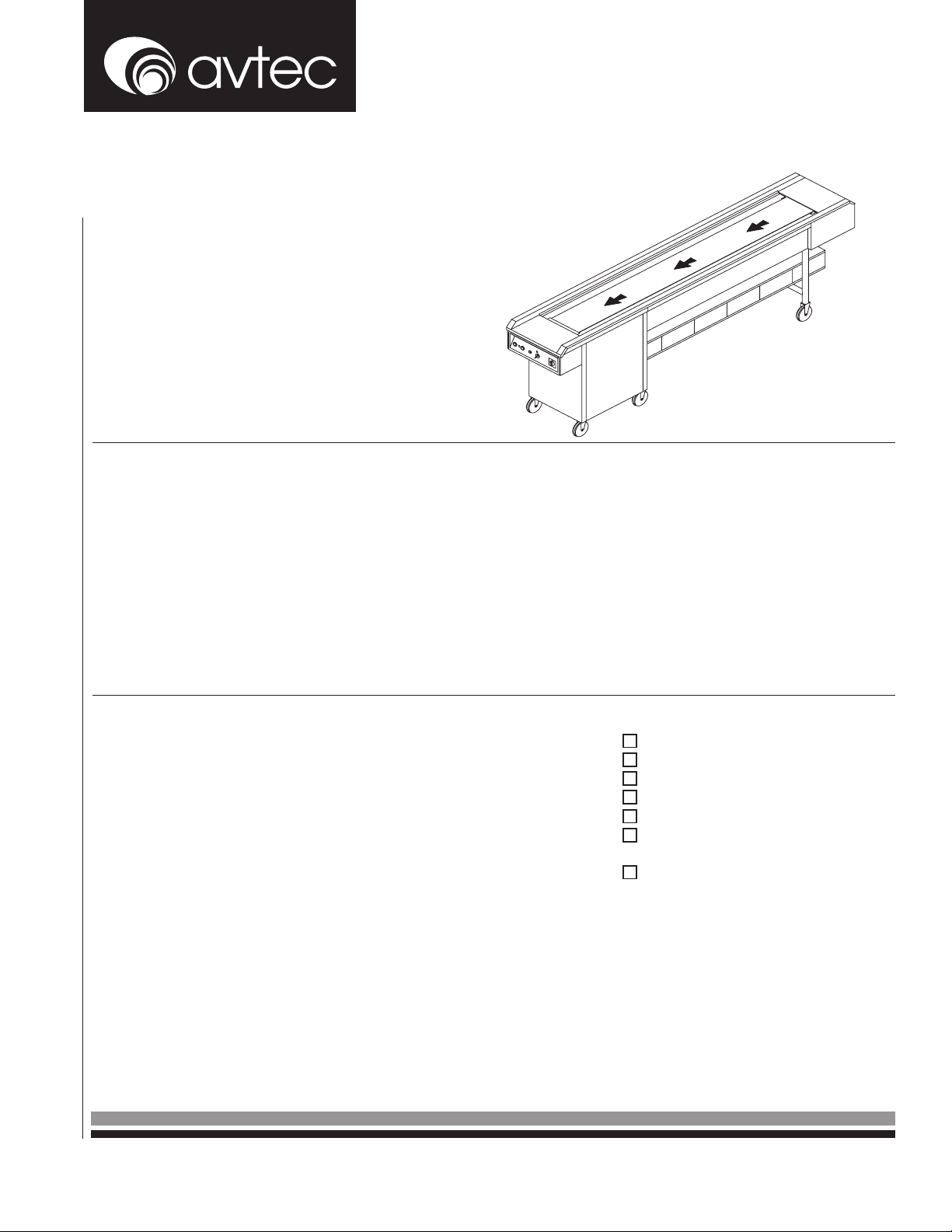

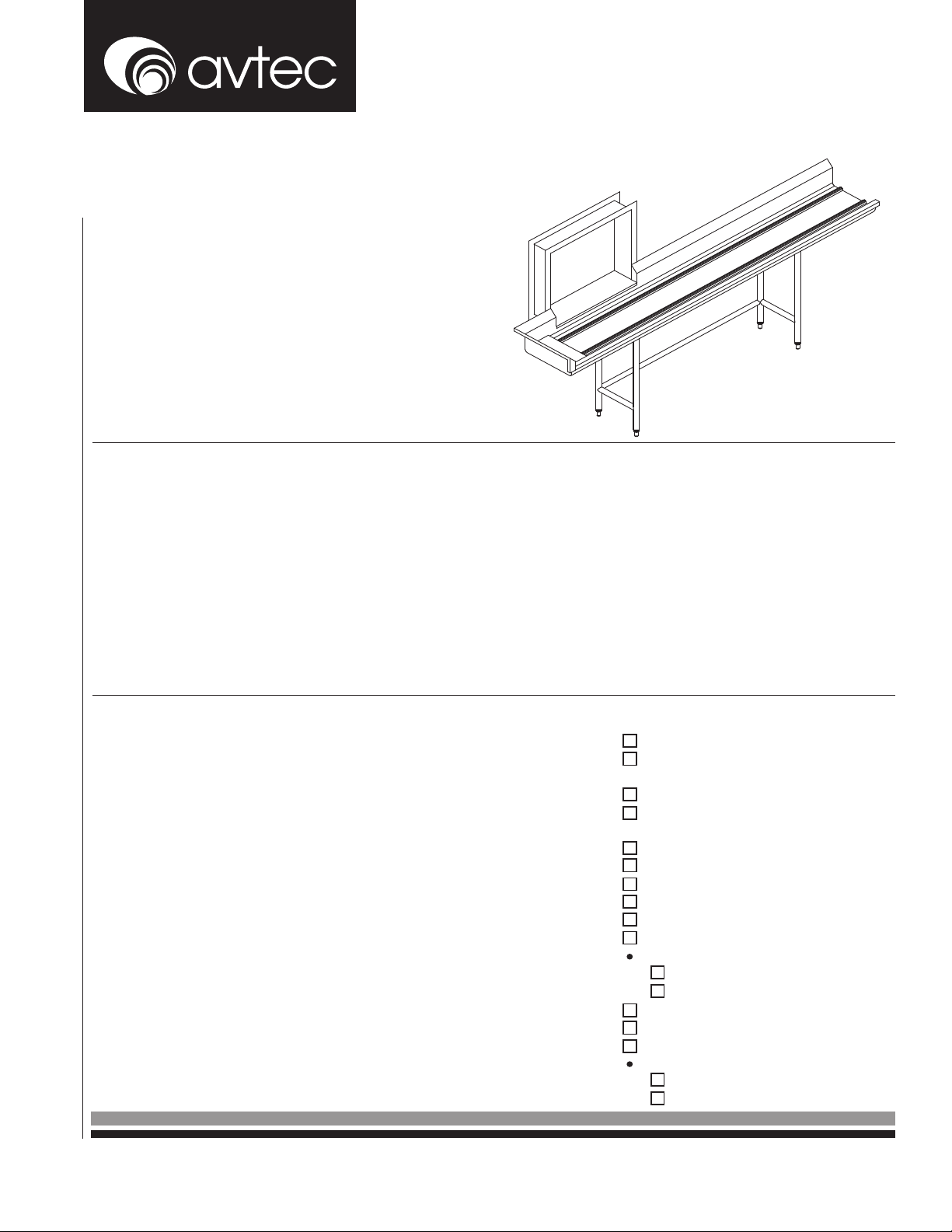

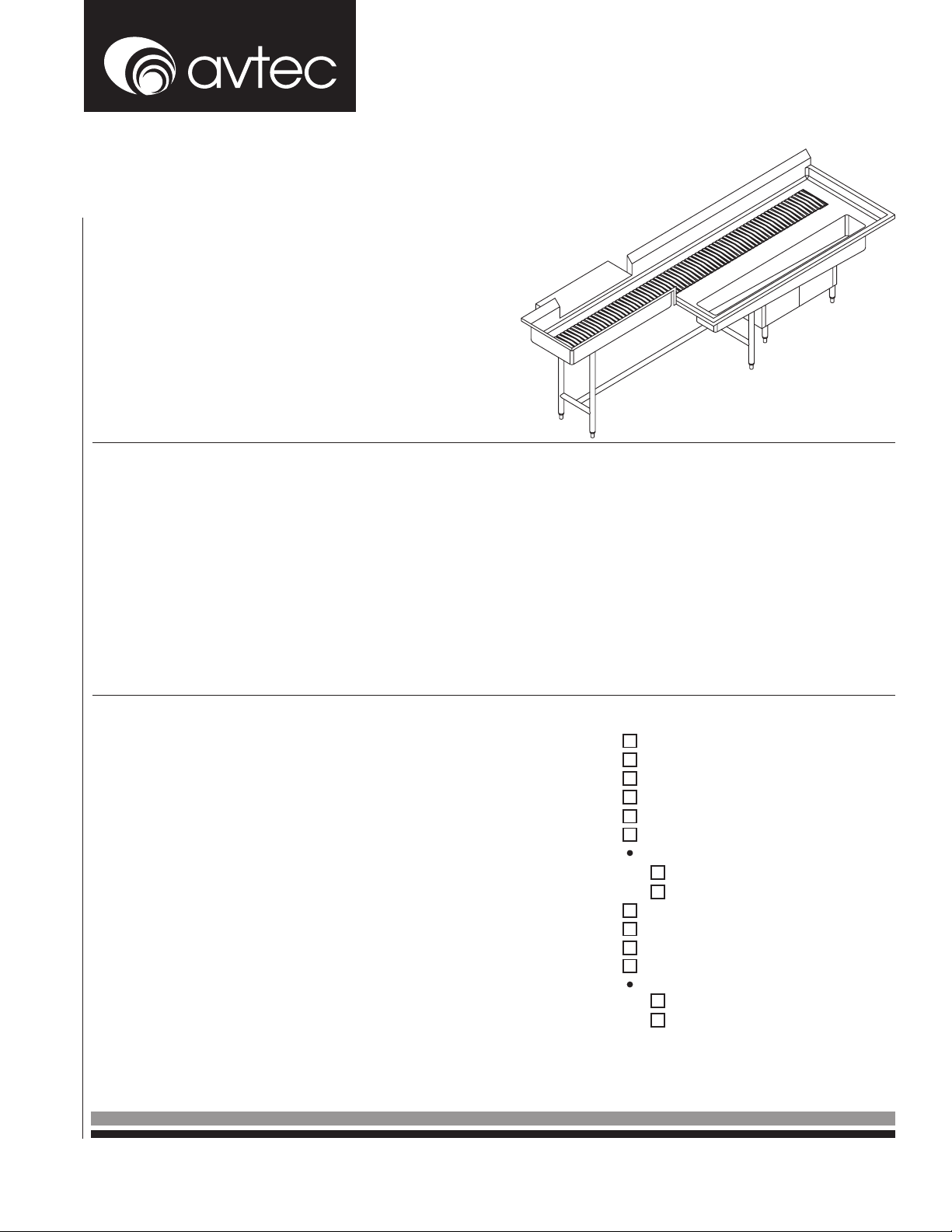

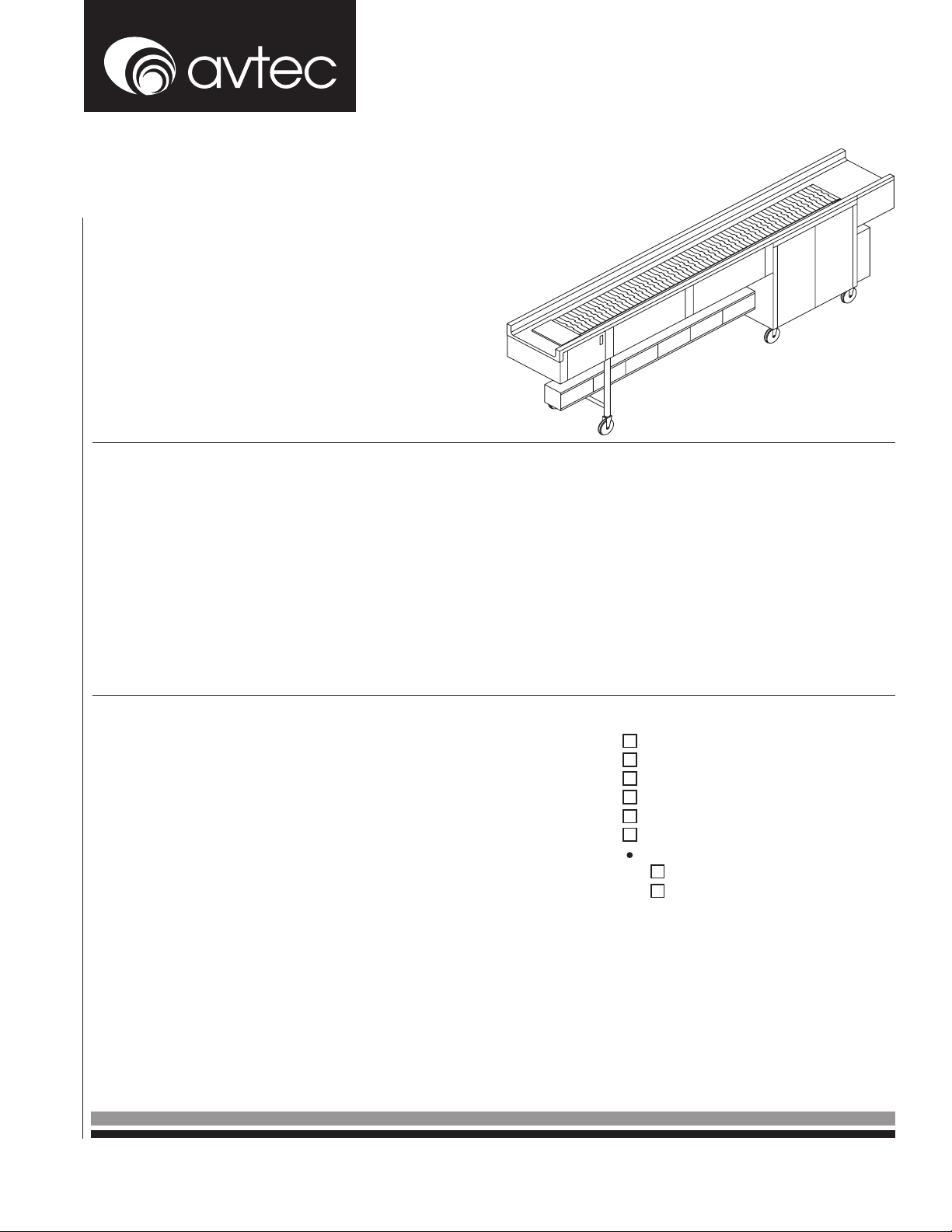

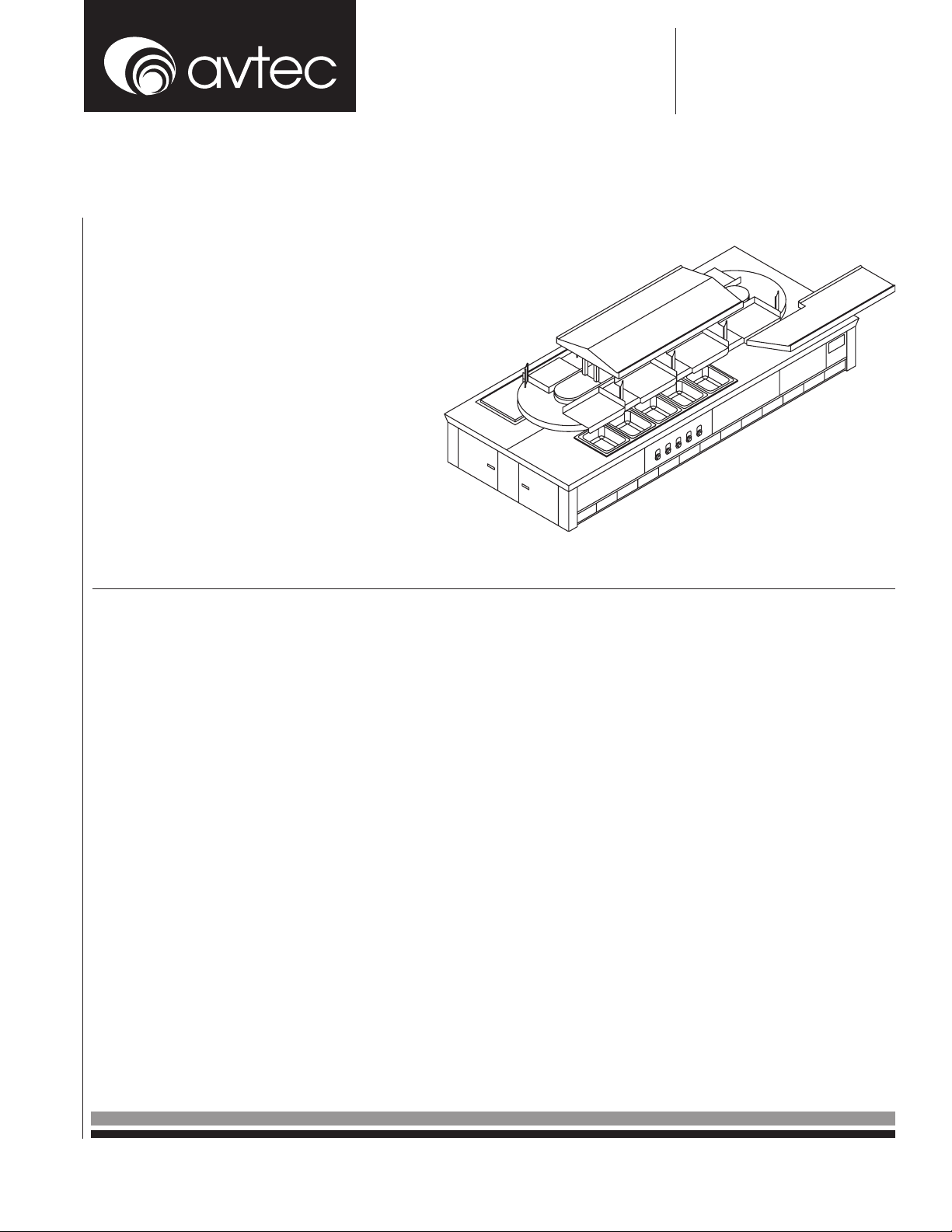

Conveyors Fabric Belt Conveyor System model CFBK

Description:

The AVTEC Model CFBK is a fabric belt conveyor utilized

for tray or plate assembly lines. The conveyor uses a PVC

coated fabric belt to move trays or plates through the

tray assembly or banquet plating line. Belt material is

durable and easily cleaned. Unit may be specied with a

Modular Energy Distribution System for powering ancillary

equipment, such as hot food tables or refrigerated units.

This design is utilized for lengths up to 30 feet in length.

Specifications:

Provide AVTEC UL Listed and NSF Approved tray/plate make-up conveyor system, Model CFBK. Unit shall be the size and shape as shown

in project drawings. Top and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4 mill nish. Drive housing shall

be of uni-body construction, completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter stainless steel with 1 ½”

diameter welded cross members for support. Drive motor to be stainless steel 1/2 hp, 208/3 and shall be water resistant. Belt returns on

support roller return system. Housing includes belt scraper and is designed with large access panels for inspection of chamber and comes

complete with stainless steel latches to seal openings and removable scrap basket for waste. Housing is to be provided with door safety

shut-off switch. Belt is to be 10” wide PVC coated fabric material, easily cleaned and connected with stainless steel pin assembly. Belt is

driven by a chain driven 6” diameter drive pulley and s/s sprocket mounted on stainless steel bearings and shafts utilizing slip collar in lieu

of keyways. Tail section includes auto-tensioning device to keep constant equal tension on the belt. Motor control panel to be designed with

main service disconnect switch, variable speed controls and of sealed water-tight construction. Conveyor is designed to include a photo

electric accumulation switch at terminal end of unit to shut down system when conveyor is full.

Standard Features:

• Tail auto-belt take-up

• Hinged safety plate on drive opening

• 1 5/8” S/S legs with 1 1/2” S/S

crossmembers

• Fabric belt scraper with removable

scrap basket

• Limit switch

• Main control panel with start/stop,

speed control, limit switch, and

main disconnect

• PVC return rollers.

• 14 Ga S/S construction

• S/S ½ HP Motor with

S/S drive housing

• Drive door shut off safety switches the belt rides on an anti-spill raised

edge, for easier cleaning and better

performance

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

Momentary run foot switch

Modular energy distribution system

Casters, bullet or ange feet

Cord and receptacle

Floor box

Stainless steel lift-off cover for covering

unit with handles

Starter Station

Avtec Conveyors, Page 1

PP SPEC1051 Rev. A

Revised 11/07

Page 2

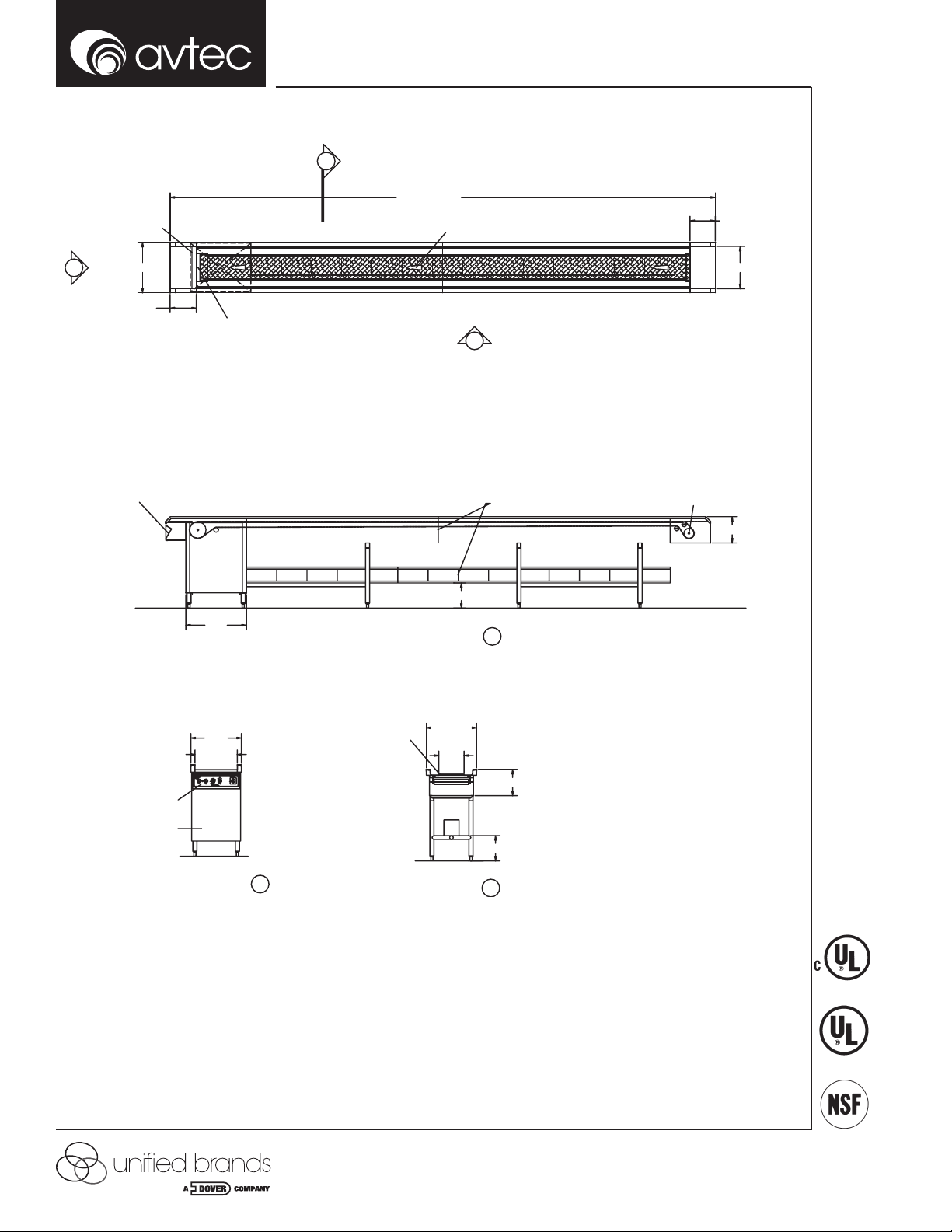

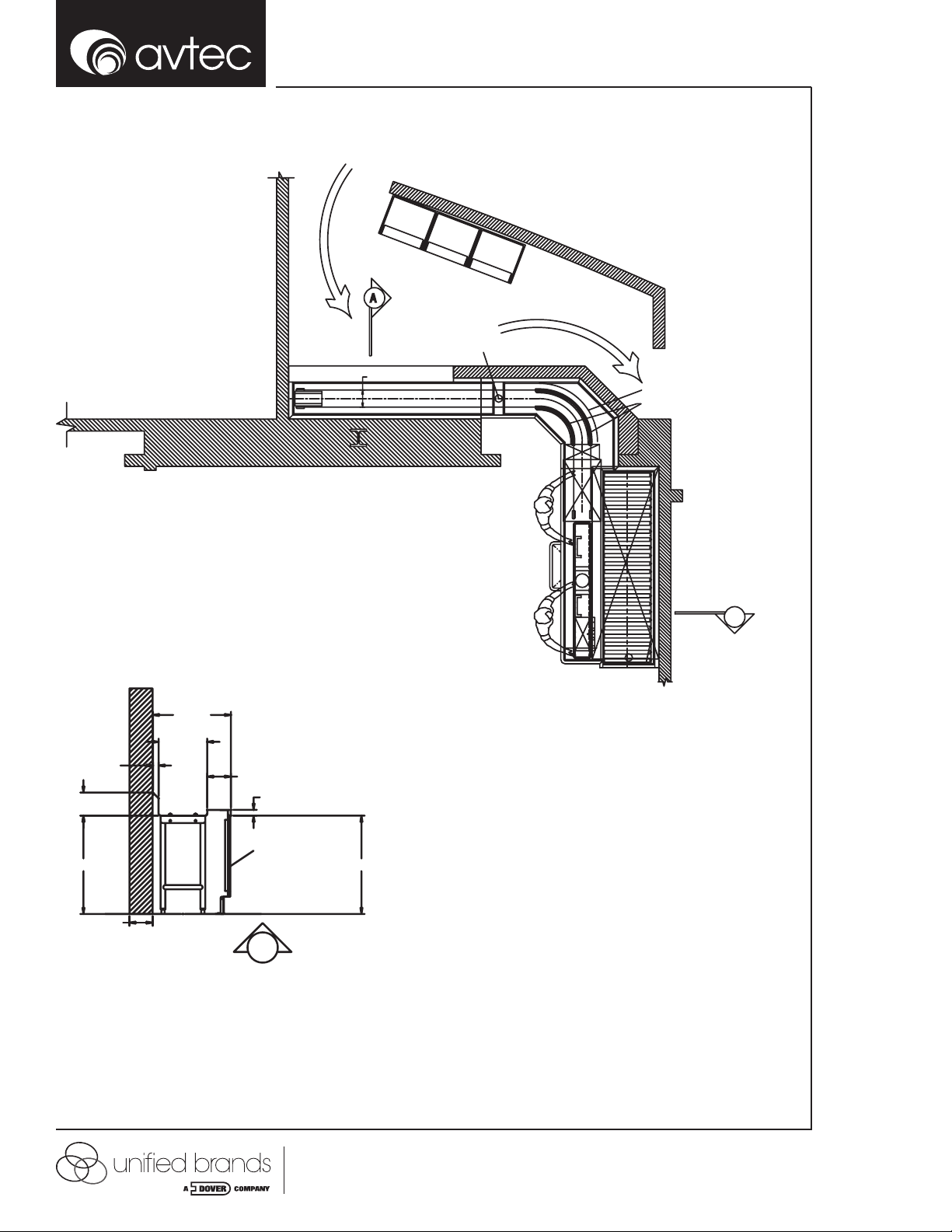

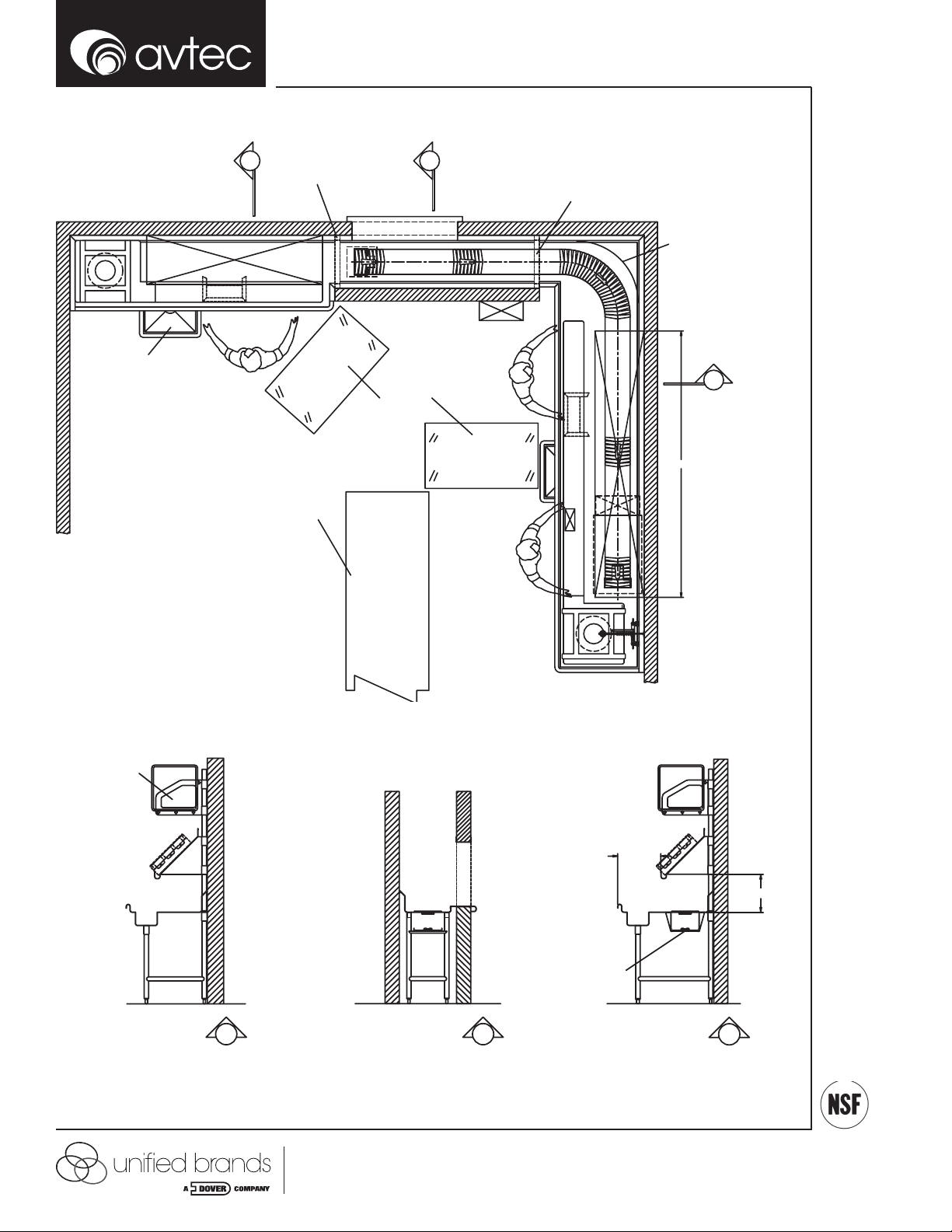

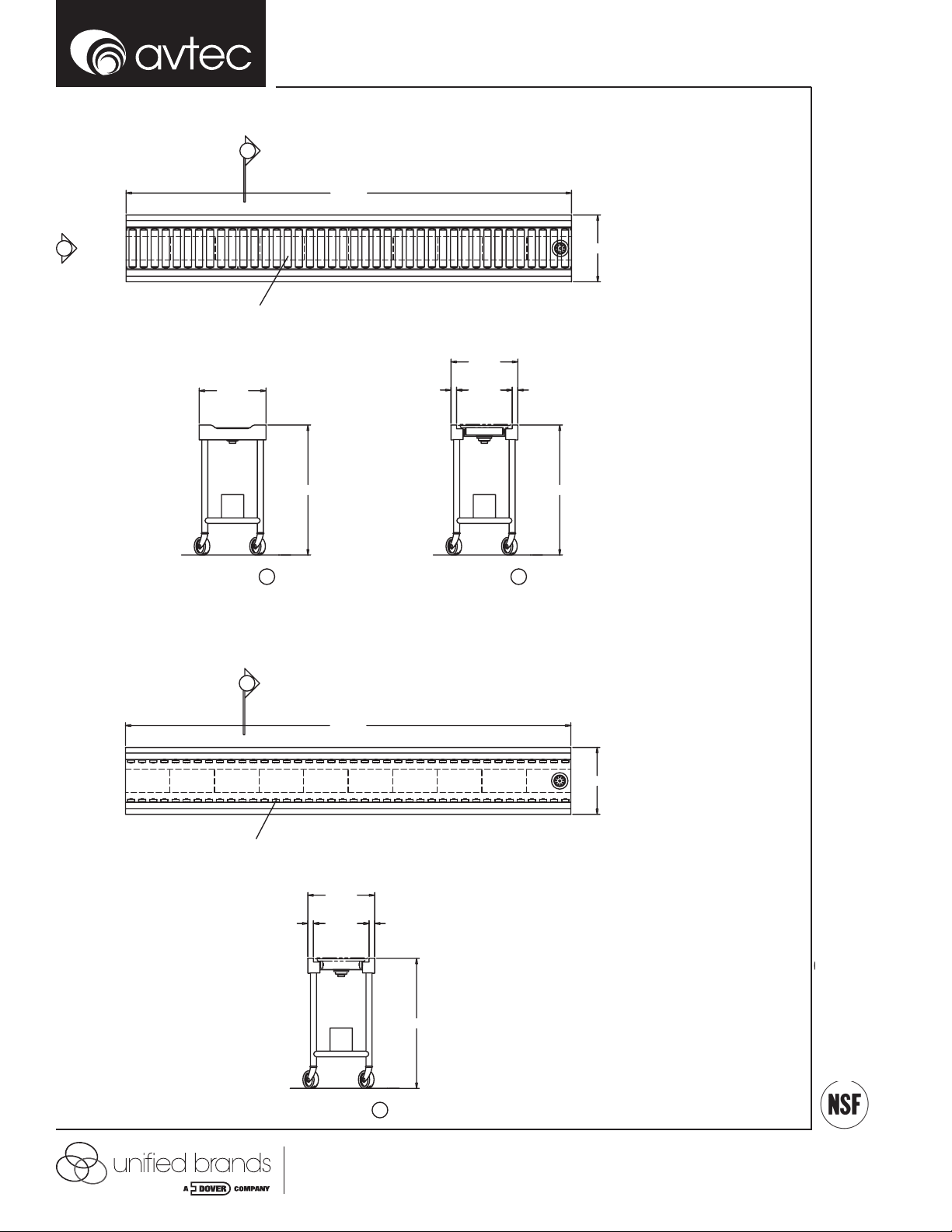

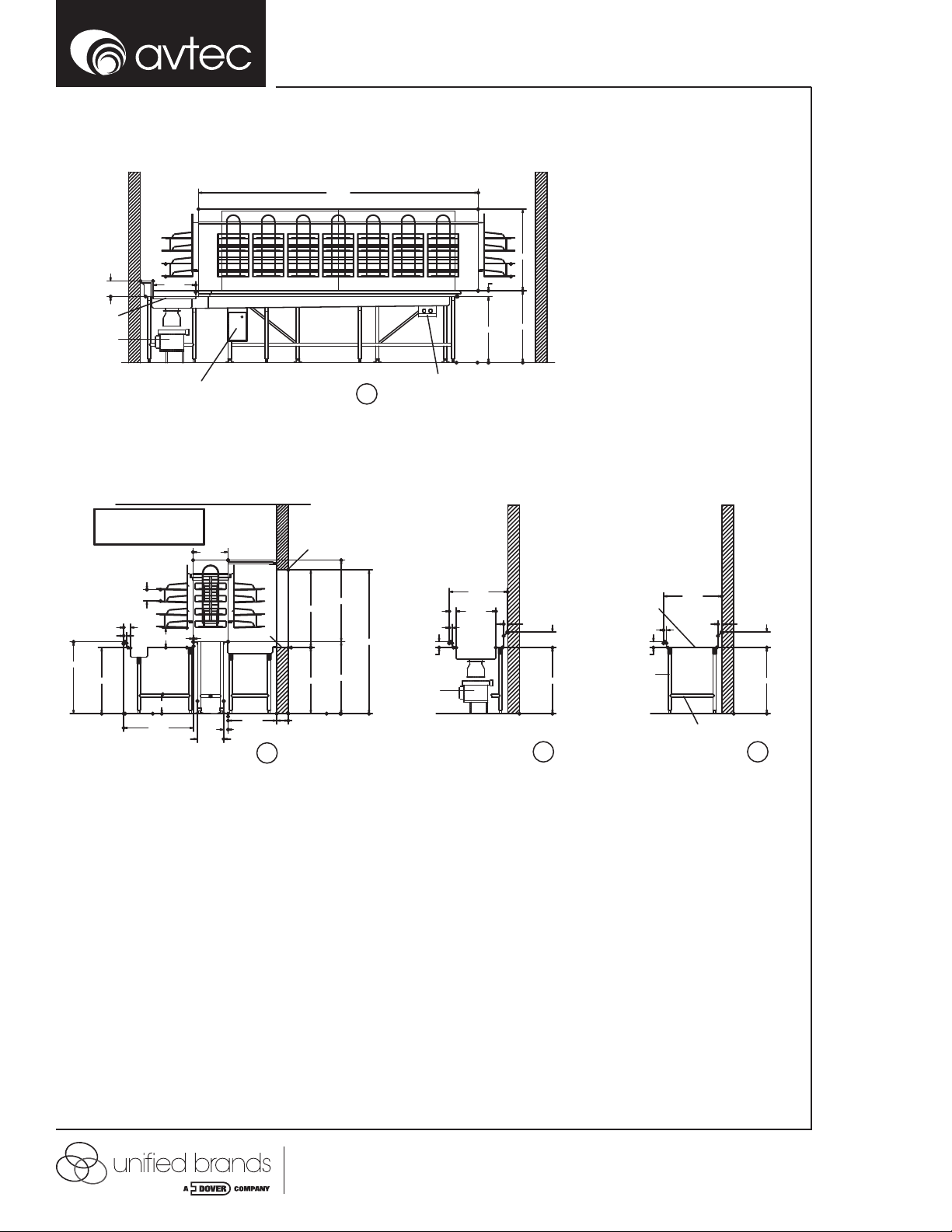

Front, Top & Side Views

THROUGH-BEAM

ACCUMULATION SENSOR

Model CFBK

D

(30' MAX LENGH)

10" STANDARD

BELT SPEED 5 TO 30 FT/MIN.

(7.5" MIN.)

C

CONVEYOR CONTROLS

10 3/8"

1'-8"

1'-4 3/4"

SPRING LOADED SAFETY PLATE

PLAN VIEW

CFBK WITH MULTI-OUTLET

POWERCHAIN ASSEMBLEY

A

OPTIONAL FIELD JOINT

AUTOMATIC BELT TAKE-UP

10 3/8"

10"

2'

DRIVE

ELEVATION VIEW

A

RECESSED CONTROLS

DRIVE HOUSING

1'-8"

1'-4 3/4"

120 KENDALL POINT DRIVE, OSWEGO, IL 60543

(630) 851-4800 FAX (630) 851-5777

3

2

STOP SPEED CONTROL

START

SECTION VIEW

ANTI-SPILL RAISED

BELT DECK (SEE DETAIL)

1'-8"

10"

MAIN DISCONNECT

I ON

5

ONOFF

4

6

7

8

0 OFF

1

9

LIMIT SWITCH

CONVEYOR CONTROLS

10 3/8"

10"

C

SECTION VIEW

D

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 3

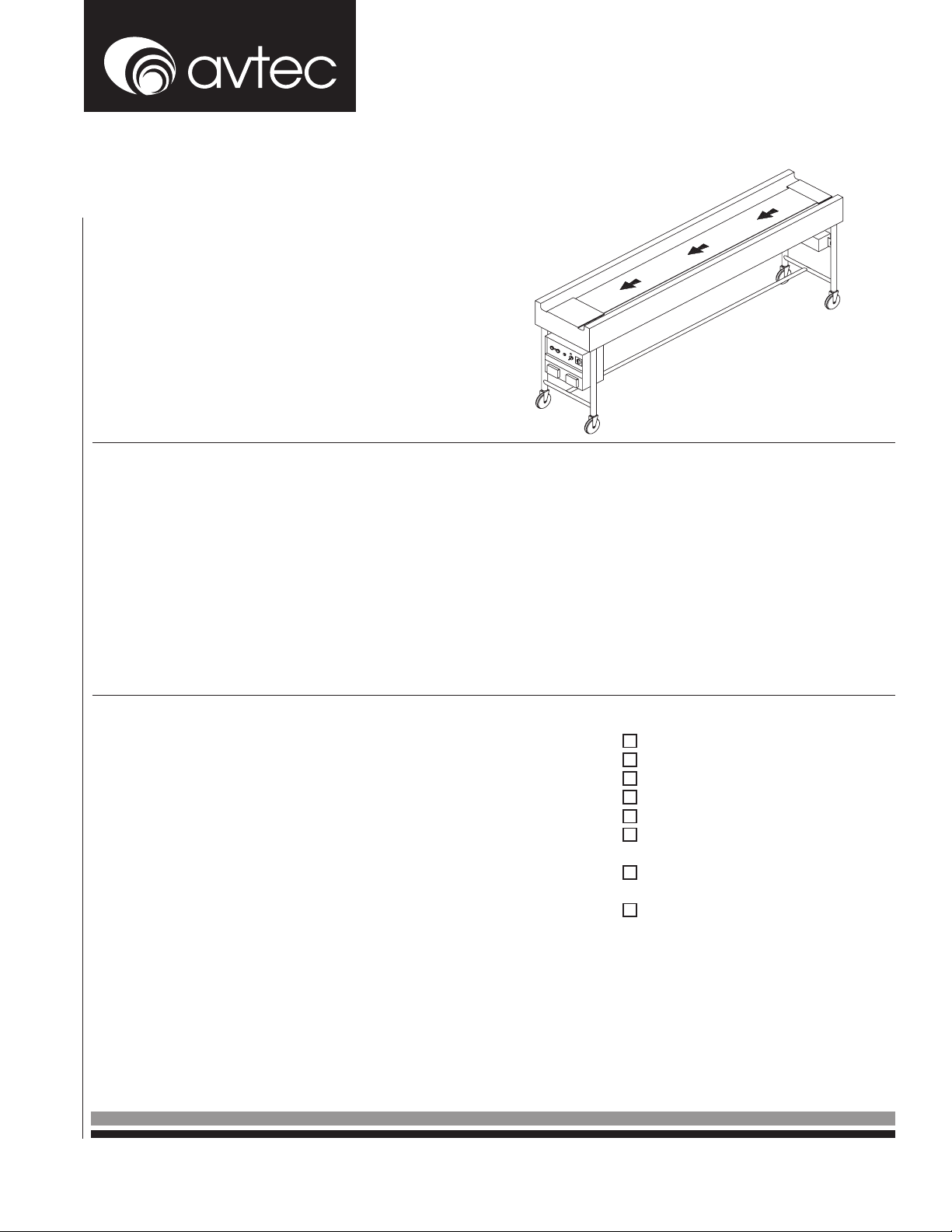

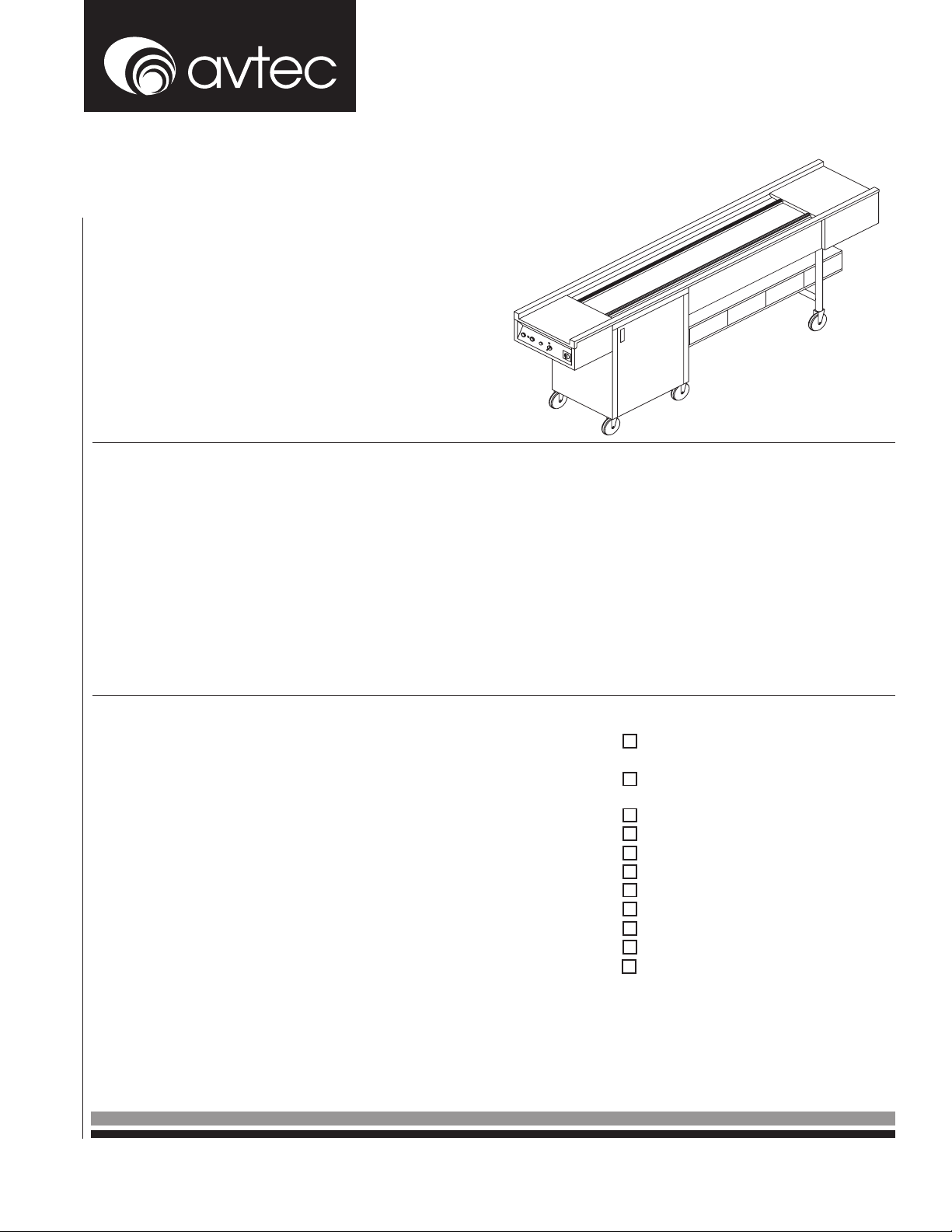

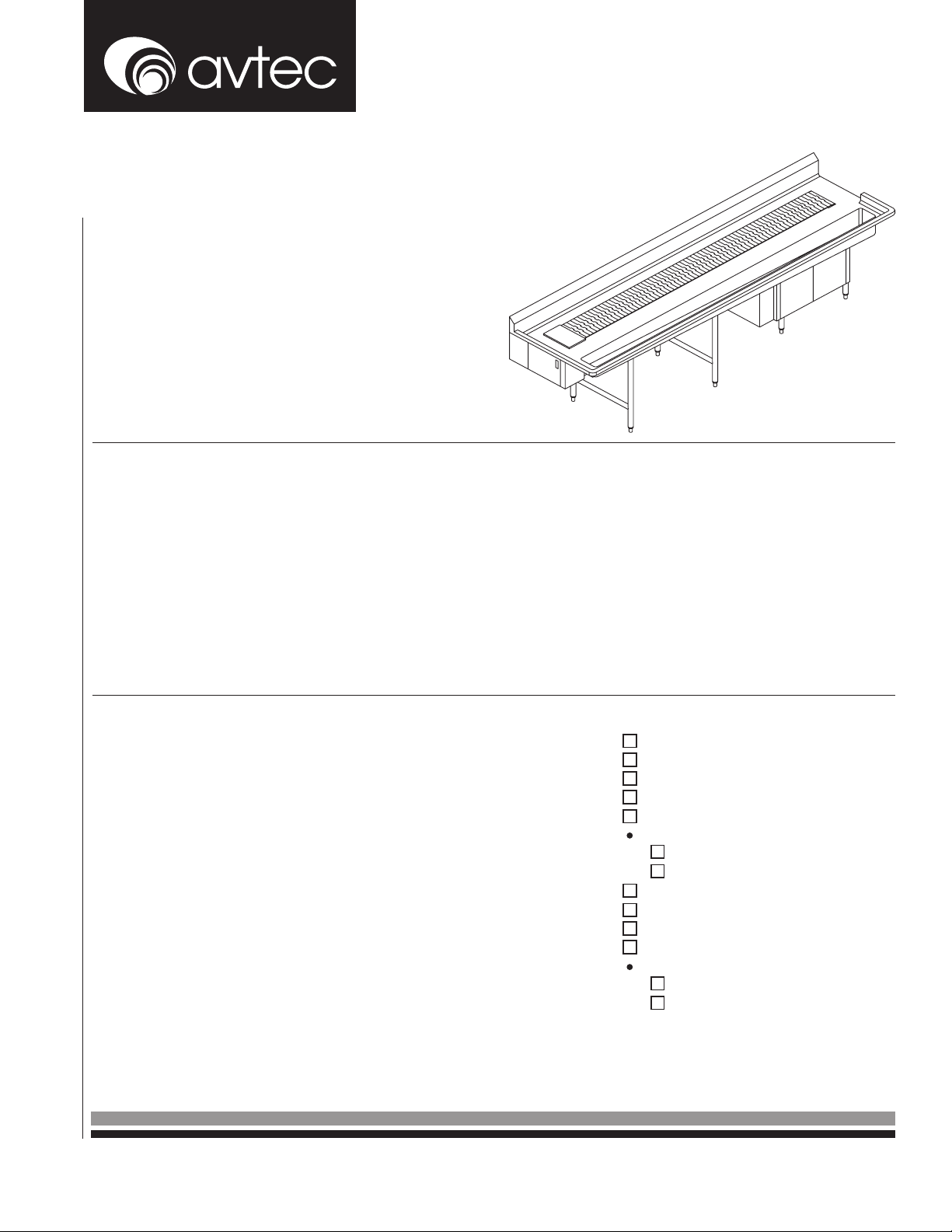

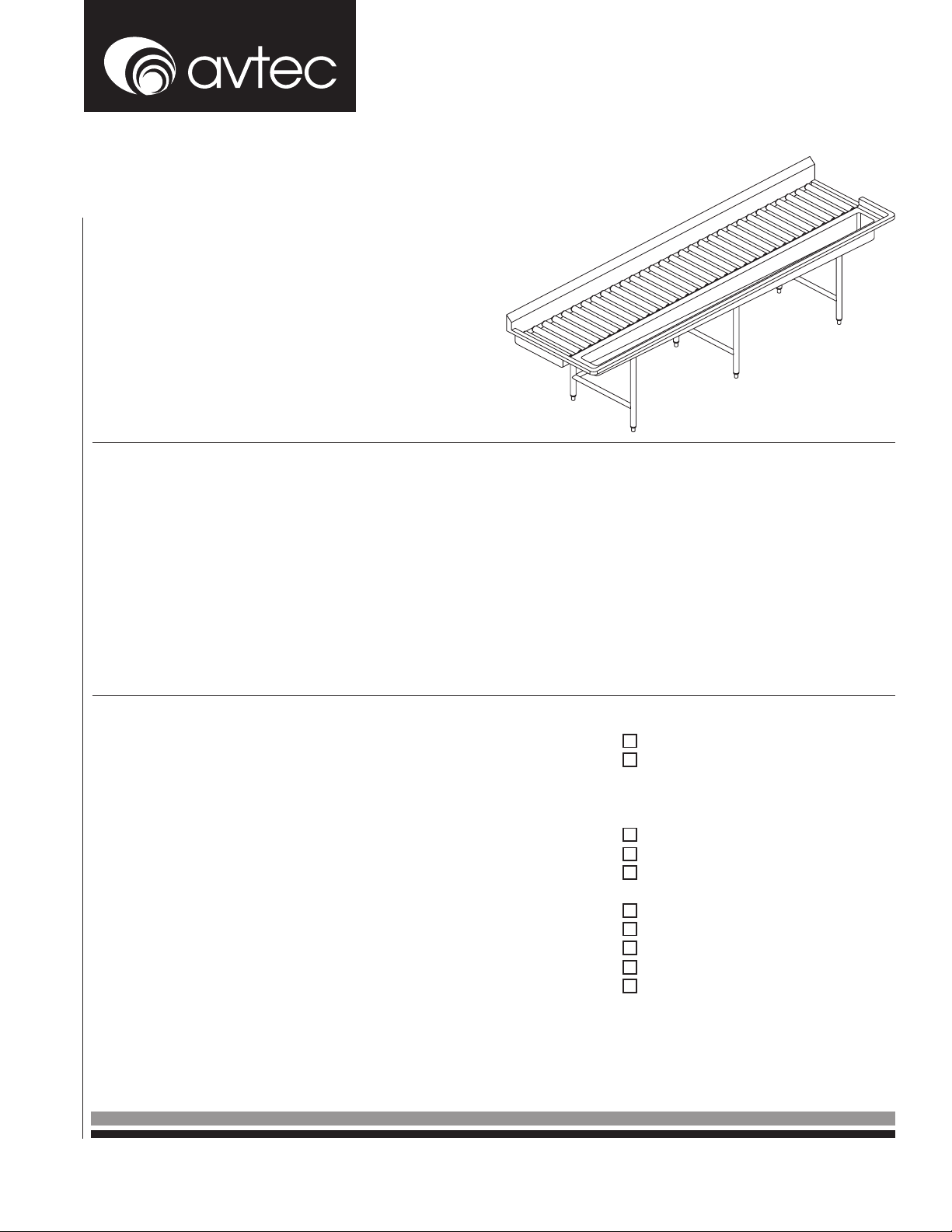

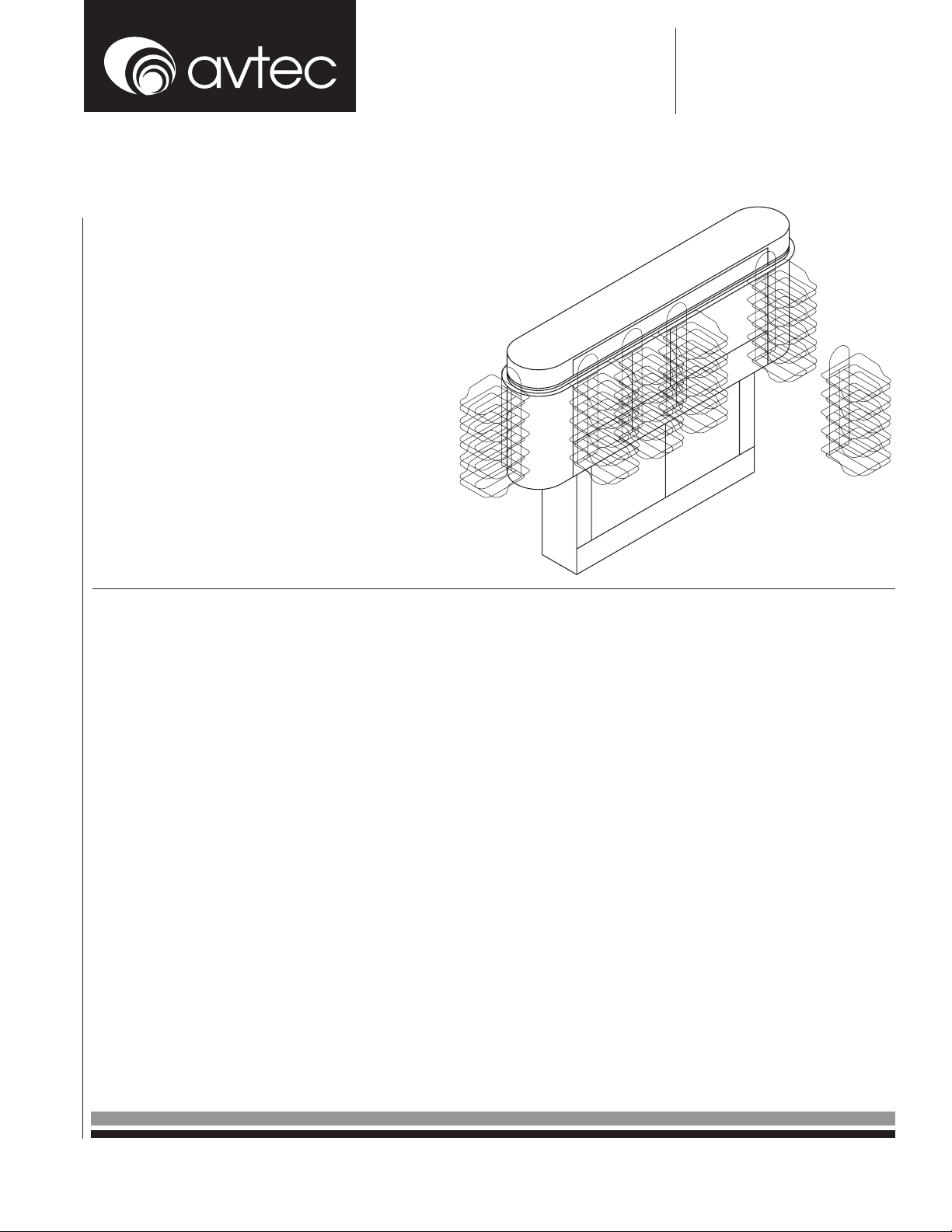

Conveyors Fabric Belt Conveyor System model CFBS

Description:

The AVTEC Model CFBS is a fabric belt conveyor utilized for

tray or plate assembly lines. The slim-line low prole design

allows for only an 8 5/8” conveyor housing. The conveyor

uses a PVC coated fabric belt to move trays or plates through

the tray assembly or banquet plating line. Belt material is

durable and easily cleaned. Unit may be specied with a

Modular Energy Distribution System for powering ancillary

equipment, such as hot food tables or refrigerated units. This

design is utilized for lengths up to 15 feet in length.

Specifications:

Provide AVTEC tray/plate make-up conveyor system, Model CFBS. Unit shall be the size and shape as shown in project drawings. Top and

slide bed shall be constructed of 14 gauge 300 series stainless steel with #4 mill nish. Drive housing shall be of uni-body construction,

completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter stainless steel with 1 ½” diameter welded cross

members for support. Unit is driven by a 4 1/2” diameter drive pulley mounted on stainless steel bearings and shafts utilizing slip collar in

lieu of keyways. No chain or sprockets required. Belt returns on support roller return system. Low-prole housing includes belt scraper and

is designed with access panels for inspection of chamber and comes complete with stainless steel latches to seal openings and removable

scrap basket for waste. Belt is to be 10.75” wide PVC coated fabric material, easily cleaned and connected with stainless steel pin assembly.

Tail section includes auto-tensioning device to keep constant equal tension on the belt. Motor control panel to be designed with main

service disconnect switch, variable speed controls and of sealed water-tight construction. Conveyor is designed to include a photo electric

accumulation switch at terminal end of unit to shut down system when conveyor is full.

Standard Features:

• Tail auto-belt take-up

• Hinged safety plate on drive

opening

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Fabric belt scraper with removable

scrap basket

• Limit switch

• Main control panel with start/stop,

speed control, limit switch, and

main disconnect

• PVC return rollers.

• 16 Ga S/S construction

• 4.5” High output belt drive roller the belt rides on an anti-spill raised

edge, for easier cleaning and better

performance

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

Momentary run foot switch

Modular energy distribution system

Casters, bullet or ange feet

Cord and receptacle

Floor box

(2) 20 Amp duplex convenience outlets

with water proof cover on each end

Stainless steel lift-off cover for covering

unit with handles

Starter Station

Avtec Conveyors, Page 2

PP SPEC1052 Rev. A

Revised 11/07

Page 4

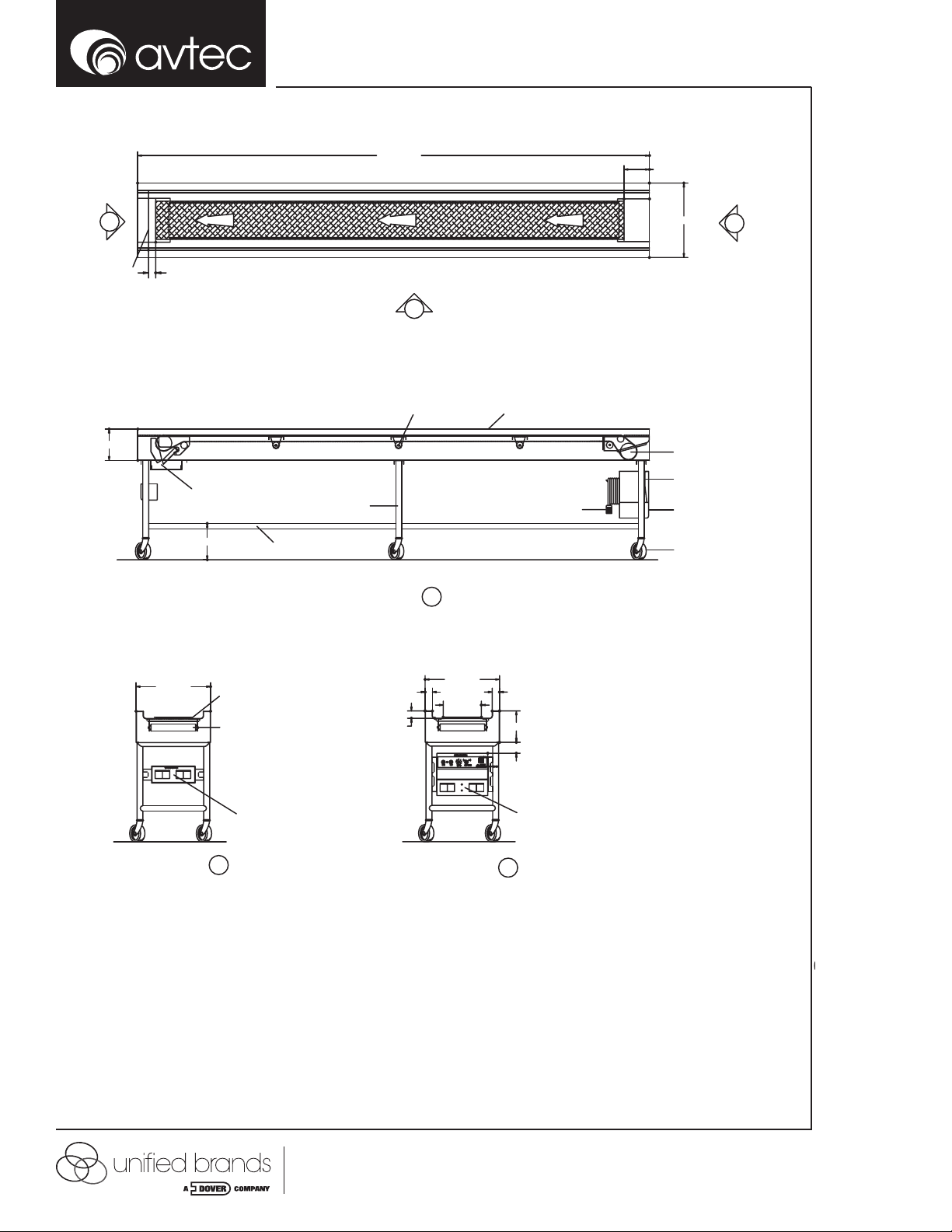

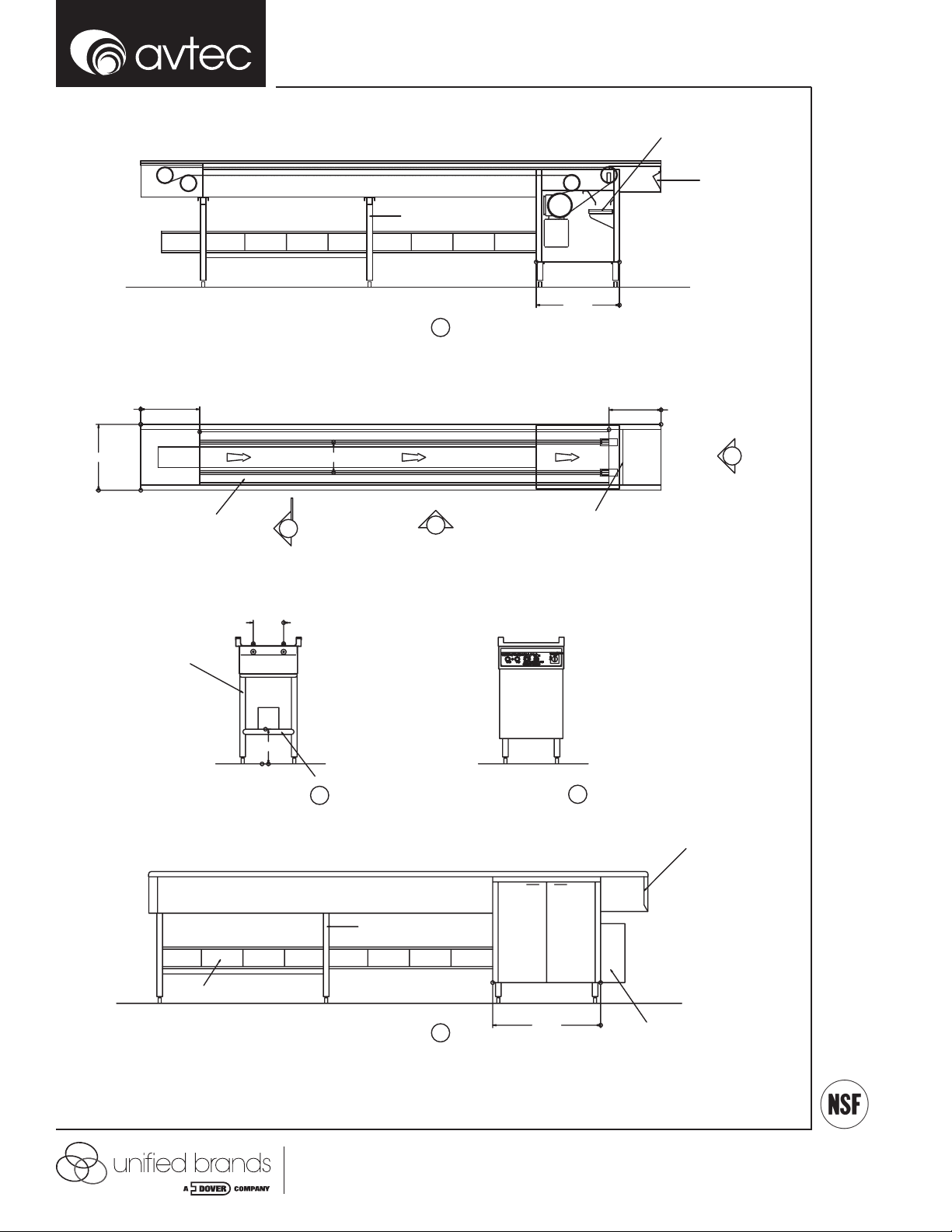

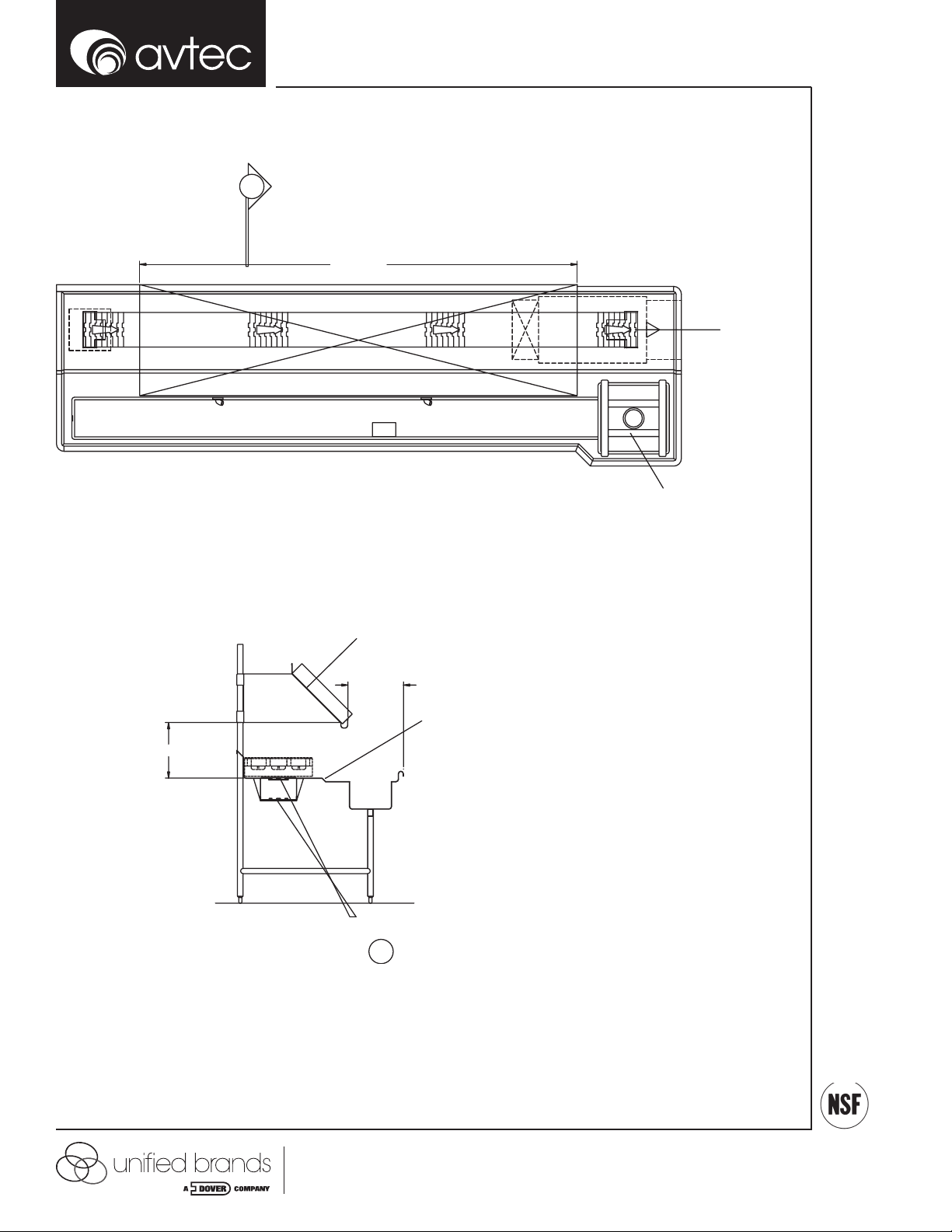

Front, Top & Side Views

Model CFBS

B

ACCUMULATION SWITCH

8 5/8"

2"

REMOVABLE S/S SCRAP TRAY

10"

1 1/2" S/S CROSSMEMBERS

PLAN VIEW

1 5/8" S/S LEG

ELEVATION VIEW

(MAX OF 18')

A

RETURN IDLERS

(7" MIN.)

16GA S/S SLIDEBED

OPTIONAL CORD & PLUG

1'-8 1/2"

AUTO TAIL TAKE-UP

RECESSED CONVEYOR CONTROLS

(2) 120V, 20A OUTLETS,

W/WATER PROOF SNAP COVERS

5" SWIVEL CASTERS W/BRAKES

C

A

1'-8 1/2"

CONVEYOR CONTROL STATION

SECTION VIEW

ANTI-SPILL RAISED EDGE (SEE DETAIL)

RETURN IDLERS

RECESSED 120V RECEPTACLE

W/WATER PROOF COVER (2)

B

1'-8 1/2"

2" 2"

10 1/2"

2"

CONVEYOR CONTROL STATION

MAIN DISCONNECT

ON

OFF

3

OFF0AUTO

2

4

1

5

6

START STOP

SPEED

ACCUM SWITCH

CONTROL

120 KENDALL POINT DR. OSWEGO, IL 60543-8898

SECTION VIEW

8 5/8"

3"

(2) 120V, 20AMP, OUTLETS

W/ WATER PROOF SNAP COVERS

C

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 5

Conveyors Cordveyor Conveyor System model CCSW

Description:

The AVTEC Model CCSW is a soiled tray/dish return conveyor

utilizing a dual poly cord to return soiled trays from the dining

room to the dish room. Dual poly cords are easy to maintain

and keep clean. Turns are accomplished by use of microroller sections, which take the strain off of the cord and

relieve stretching and extend cord life. Unit is available with

or without wash system.

Specifications:

Provide AVTEC soiled tray return conveyor system, Model CCSW. Unit shall be integral with dish table and tray scrapping system and will

be size and shape as shown in project drawings. Top and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4 mill

nish. Drive housing shall be of uni-body construction, completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter

stainless steel with 1 ½” diameter welded cross members for support. Drive motor to be stainless steel (½)(¾) hp, 208/3 and shall be water

resistant. Motor is to be located in separate housing from wash tank compartment. Housing is to be provided with door safety shut-off

switch. Unit is to include wash housing with perforated stainless wash arm for cleaning of cords and separate detergent tank. Housing is

to be provided with cord wipers to clean and dry cords upon exit from housing. Cords are to be ½” blue/green reinforced polyurethane, riding in continuous length UHMW tracks, driven by stainless steel pulleys mounted on stainless steel shafts and bearings. Corners are to be

designed with Micro roller turn assemblies to relieve strain on the cords. Roller assemblies are designed to be easily removable for cleaning.

Drive section includes auto-tensioning device to keep constant equal tension on the cords. Motor control panel to be designed with main

service disconnect switch, variable speed controls and of sealed water-tight construction. CordVeyor is designed to include a photo electric

accumulation switch at terminal end of unit to shut down system when conveyor is full.

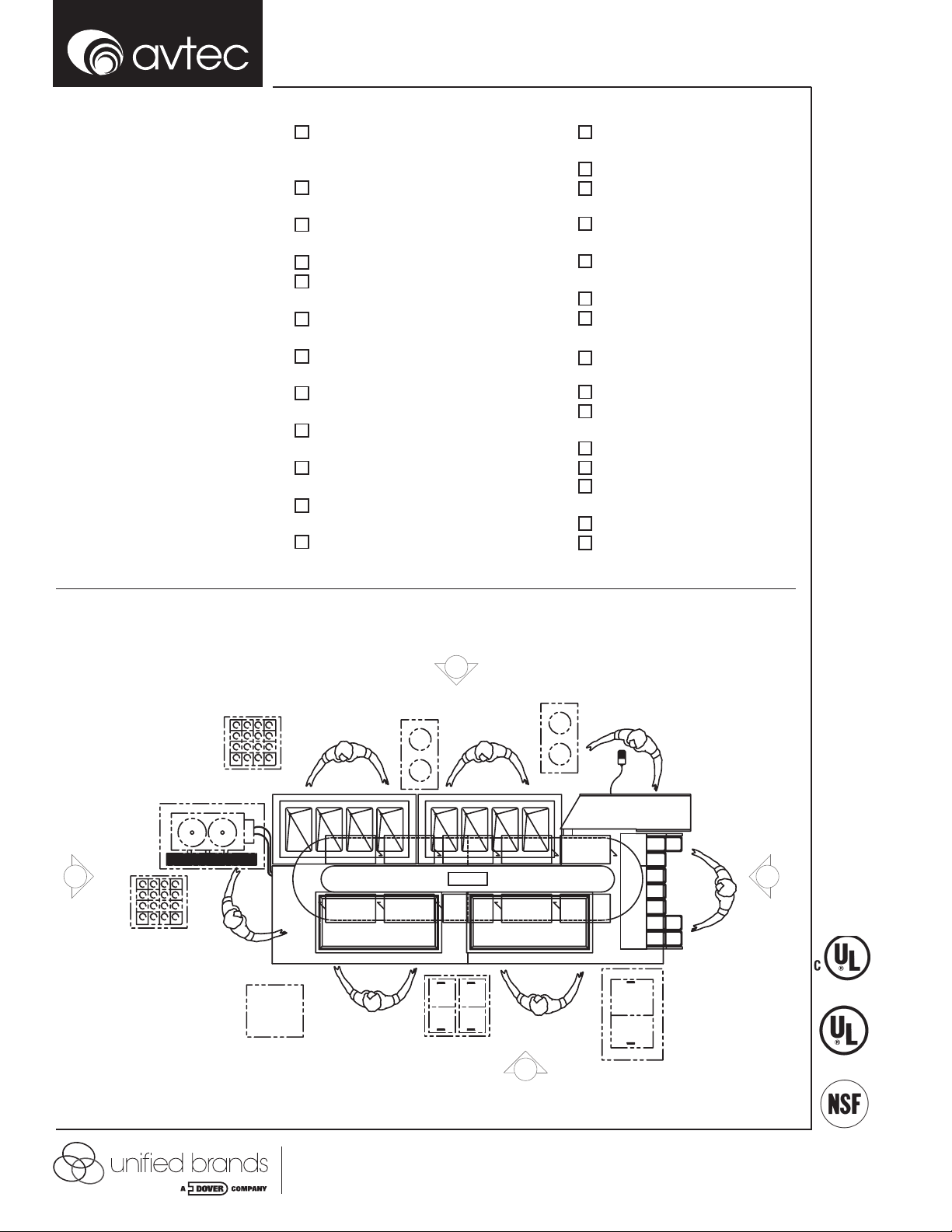

Standard Features:

• S/S drive housing

• Door shut off safety switch(s)

• Removable scrap basket in

drive housing

• 1 ½” Drain in drive

• S/S drive motor

• UHMW guide strip for cord

• 1/2” Blue/green reinforced poly-cord

• 1/2 HP S/S drive motor (typ. for under

60’ with one turn)

• 3/4 HP S/S drive motor (typ. for over

60’ with one or more turns)

• Detergent pump housing

• Belt wash, with auto wash option

(PLC programmed timer for optimal

cleanness and performance)

• Main control panel with start/stop,

wash selector, belt speed, limit

switch, main disconnect.

• Limit switch

• Cord take-up bracket

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Work surface: 14 ga S/S construction

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

Tail drip pan (under tail opening only)

Tail loading deck (the drip pan is not

offered or required with this option)

Intermediate sump(s) with 1 ½” drain

1 ½” Drains over drive unit, at tray

drop-off, or intermediate

90 and 45 degree micoturns

Auto (APRs) or manual (MPRs) plate rinses

Additional start/stop box(s)

Auto-index

Overshelf

Tubular overshelf

Hose reel:

30’ hose

50’ hose

Laminated or S/S panels at drop off

Sight and sound barrier

Security door (door notched for cord)

Side skirting:

Hinged

Removeable

Avtec Conveyors, Page 3

PP SPEC1053 Rev. A

Revised 11/07

Page 6

Front, Top & Side Views

A

PLAN VIEW

CORD MICRO-TURNS

GUIDE RAIL

8.750

4" DEEP SUMP

WITH 1 1/2" DRAIN

Model CCSW

8.000

2.000

27.000

16.750

8.250

2.000

A

8.750

PLAN VIEW

4" DEEP SUMP

WITH 1 1/2" DRAIN

GUIDE RAIL

CORD MICRO-TURNS

B

8.000

SECTION VIEW

DROP-OFF W/HINGED

S/S PANELS

34.00034.000

A

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 7

Conveyors Cordveyor Conveyor System model CCTN

Description:

The AVTEC Model CCTN is a tray assembly conveyor utilizing

a dual poly cord to transport trays through a tray assembly

system. Dual poly cords are easy to maintain and keep

clean. Turns are accomplished by use of micro-roller

sections, which take the strain off of the cord and relieve

stretching and extend cord life. Unit is available with or

without wash system.

Specifications:

Provide AVTEC NSF Approved tray assembly conveyor system, Model CCTN. Unit shall be size and shape as shown in project drawings. Top

and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4 mill nish. Drive housing shall be of uni-body construction,

completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter stainless steel with 1 ½” diameter welded cross members for support. Drive motor to be stainless steel (½)(¾) hp, 208/3 and shall be water resistant. Motor is to be located in separate housing

from wash tank compartment. Housing is to be provided with door safety shut-off switch. Unit is to include wash housing with perforated

stainless wash arm for cleaning of cords and separate detergent tank. Housing is to be provided with cord wipers to clean and dry cords

upon exit from housing. Cords are to be ½” blue/green reinforced polyurethane, riding in continuous length UHMW tracks, driven by stainless

steel pulleys mounted on stainless steel shafts and bearings. Corners are to be designed with Micro roller turn assemblies to relieve strain

on the cords. Roller assemblies are designed to be easily removable for cleaning. Drive section includes auto-tensioning device to keep

constant equal tension on the cords. Motor control panel to be designed with main service disconnect switch, variable speed controls and of

sealed water-tight construction. CordVeyor is designed to include a photo electric accumulation switch at terminal end of unit to shut down

system when conveyor is full.

Standard Features:

• S/S drive housing

• Door shut off safety switch(s)

• Removable scrap basket in

• 3/4 HP S/S drive motor (typ. for over

60’ with one or more turns)

• Fixed side skirting

drive housing

• 1 ½” Drain in drive

• S/S drive motor

• Main control panel with start/stop,

wash selector, belt speed, limit

switch, main disconnect.

• Limit switch

• Cord take-up bracket

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Work surface: 14 ga S/S construction

• UHMW guide strip for cord

• 1/2” Blue/green reinforced poly-cord

• 1/2 HP S/S drive motor (typ. for under

60’ with one turn)

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

Tail loading deck (the drip pan is not

offered or required with this option)

1 ½” Drains over drive unit, at tray

drop-off, or intermediate

90 and 45 degree micoturns

Additional start/stop box(s)

Momentary run foot switch

Overshelf

Tubular overshelf

Starter station

Modular energy distribution system

Belt wash, with auto wash option

Detergent pump housing

Avtec Conveyors, Page 4

PP SPEC1054 Rev. A

Revised 11/07

Page 8

Front, Top & Side Views

ELEVATION VIEW

1 5/8" S/S LEGS

Model CCTN

REMOVABLE SCRAP BASKET

RECESSED CORDVEYOR CONTROLS

24.000

DRIVE

A

17.000 LOADING DECK

19.000 8.750

14GA S/S WORK SURFACE

8.750

1 5/8" S/S LEGS

10.000

SECTION VIEW

B

PLAN VIEW

1 1/2" S/S CROSSMEMBERS

B

15.000 UNLOADING DECK

C

LIMIT SWITCH

A

120 KENDALL POINT DRIVE, OSWEGO, IL 60543

(630) 851-4800 FAX (630) 851-5777

SECTION VIEW

MAIN DISCONNECT

I ON

5

OFF ON

436

7

2

8

0 OFF

9

1

START

SPEED CONTROLSTOP

LIMIT SWITCH

TM

CORDVEYOR CONTROLS

C

RECESSED MAIN CONTROLS

MCOE

1 5/8" S/S LEGS

SHOWN WITH OPTIONAL

DETERGENT PUMP HOUSING

FOR BELT WASH

ELEVATION VIEW

31.125

A

DRIVE

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 9

Conveyors Slat Belt Conveyor System model CBSW

Description:

The AVTEC Model CBSW is a soiled tray/dish return conveyor

utilizing an overlapping style plastic slat attached to a stainless

steel chain to return soiled trays from the dining room to the

dish room or to move dishes or racks within the dish room. Belt

is returned in self-cleaning slider pan for easy cleaning and

maintenance. Turns are accomplished by use of an internal roller

in each slat, which takes the strain off of the belt and relieves

stretching and extends belt life. Unit is provided with automatic

detergent injection wash system.

Specifications:

Provide AVTEC NSF Approved soiled tray/dish conveyor system, Model CBSW. Unit shall be integral with dish table and tray scrapping system and

will be size and shape as shown in project drawings. Top and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4 mill nish.

Drive housing shall be of uni-body construction, completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter stainless steel

with 1 ½” diameter welded cross members for support. Drive motor to be stainless steel (½)(¾) hp, 208/3 and shall be water resistant. Motor is

to be located in separate housing from wash tank compartment. Housing is to be provided with door safety shut-off switch. Unit is to include wash

housing with strategically designed spray jets for cleaning of both sides of belt. Belt returns on self-cleaning return track system. Detergent designed

to drip on belt for maximum exposure to cleaning action. Wash housing is designed with large access panels for inspection of wash chamber and

comes complete with stainless steel latches to seal openings and removable scrap basket for waste. Belt is to be overlapping style black plastic with

integral rollers to minimize belt friction, riding in continuous length UHMW tracks, driven by a stainless steel sprocket mounted on stainless steel

bearings and shafts utilizing slip collar in lieu of keyways. Tail section includes auto-tensioning device to keep constant equal tension on the belt.

Motor control panel to be designed with main service disconnect switch, variable speed controls and of sealed water-tight construction. Conveyor is

designed to include a photo electric accumulation switch at terminal end of unit to shut down system when conveyor is full.

Standard Features:

• S/S drive housing

• S/S drive motor

• Door conveyor shut off

safety switch(s)

• Removable scrap basket in drive

and tail housings

• Access panel for wash housing

• 1 ½” Drain in drive

• Anti-jam safety switch at

drive opening

• Detergent pump housing

• Belt wash, with auto wash option

(PIC programmed timer for optimal

cleanness and performance)

• Main control panel with start/stop,

wash selector, belt speed, limit

switch, main disconnect.

• Limit switch

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

• Auto belt tensioner

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Work surface: 14 ga S/S construction,

fully welded and polished.

• 1/2 HP S/S drive motor (typ. for

under 60’ with one turn)

• 3/4 HP S/S drive motor (typ. for

over 60’ with one or more turns)

• S/S side exing #60 chain

• Side exing slats with rollers, for

smooth turns. Standard color

black, also available in gray, and blue.

• Self cleaning return track

• S/S drive sprocket

• Lifetime drive bearings

• Tail cover

• Slats can be easily replaced

Optional Accessories:

Hinged tail access door

Auto (APRs) or manual (MPRs) plate rinses

Additional start/stop box(s)

Auto-index

Wall or post mounted overshelf

Wall or post mounted tubular overshelf

Hose reel:

30’ hose

50’ hose

Laminated or S/S panels at drop off

Sight and sound barrier

Security door

Dual belt

Side skirting:

Hinged

Removeable

Avtec Conveyors, Page 5

PP SPEC1055 Rev. A

Revised 11/07

Page 10

Front, Top & Side Views

SECTION VIEW

A

TUBULAR RACK OVERSHELF

SOAK SINK

Model CBSW

A B

SECURITY DOOR

SECURITY DOOR

GUIDE RAIL

C

MOBILE CARTS

TUBULAR RACK OVERSHELF

PLAN VIEW

FLIGHT-TYPE

WAREWASHER

OVERSHELF

16" MAX

14" TO 18"

SECTION VIEW

SELF CLEANING

RETURN TRACK

A

SECTION VIEW

B

SECTION VIEW

C

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 11

Conveyors Slat Belt Conveyor System model CISW

Description:

The AVTEC Model CISW is a soiled tray/dish return conveyor

utilizing an interlocking style plastic slat connected by

stainless steel pins. The model CISW is used to return soiled

trays from the dining room to the dish room or to move dishes

or racks within the dish room. Belt is returned in self-cleaning

slider pan for easy cleaning and maintenance. The model

CISW is used for straight applications only and cannot make

turns. Unit is provided with automatic detergent injection

wash system.

Specifications:

Provide AVTEC NSF Approved soiled tray/dish conveyor system, Model CISW. Unit shall be integral with dish table and tray scrapping system

and will be size and shape as shown in project drawings. Top and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4

mill nish. Drive housing shall be of uni-body construction, completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter

stainless steel with 1 ½” diameter welded cross members for support. Drive motor to be stainless steel (½)(¾) hp, 208/3 and shall be water

resistant. Motor is to be located in separate housing from wash tank compartment. Housing is to be provided with door safety shut-off switch.

Unit is to include wash housing with strategically designed spray jets for cleaning of both sides of belt. Belt returns on self-cleaning return track

system. Detergent designed to drip on belt for maximum exposure to cleaning action. Wash housing is designed with large access panels for

inspection of wash chamber and comes complete with stainless steel latches to seal openings and removable scrap basket for waste. Belt is to

be interlocking style gray plastic on continuous length UHMW tracks, driven by a UHMW sprocket mounted on stainless steel bearings and shafts

utilizing slip collar in lieu of keyways. Tail section includes auto-tensioning device to keep constant equal tension on the belt. Motor control panel

to be designed with main service disconnect switch, variable speed controls and of sealed water-tight construction. Conveyor is designed to

include a photo electric accumulation switch at terminal end of unit to shut down system when conveyor is full.

Standard Features:

• S/S drive housing

• Door conveyor shut off

safety switch(s)

• Removable scrap basket in

drive and tail housings

• Access panel for wash housing

• 1 ½” Drain in drive

• S/S drive motor

• Anti-jam safety switch at

drive opening

• Detergent pump housing

• Auto belt tensioner

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Work surface: 14 ga S/S construction,

fully welded and polished.

• 1/2 HP S/S drive motor

• Interlocking belt slats, gray

• UHMW drive sprockets

• Self cleaning top and return tracks

• Lifetime drive bearings

• Tail cover

• Belt wash, with auto wash option

(PLC programmed timer for optimal

cleanness and performance)

• Main control panel with start/stop,

wash selector, belt speed, limit

switch, main disconnect

• Limit switch

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

Auto (APRs) or manual (MPRs) plate rinses

Additional start/stop box(s)

Auto-index

Wall or post mounted overshelf

Wall or post mounted tubular overshelf

Hose reel:

30’ hose

50’ hose

Laminated or S/S panels at drop off

Sight and sound barrier

Security door

Hinged tail access door

Side skirting:

Hinged

Removeable

Avtec Conveyors, Page 6

PP SPEC1056 Rev. A

Revised 11/07

Page 12

Front, Top & Side Views

Model CISW

A

OVERSHELF

LIMIT SWITCH

14" TO 18" TYP.

PLAN VIEW

POST MOUNTED OVERSHELF

16" MAX.

SELF CLEANING TRACKS

H-FRAME SINK BRIDGE

TRANSFER EDGE

SECTION VIEW

A

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 13

Conveyors Slat Belt Conveyor System model CITW

Description:

The AVTEC Model CITW is a tray assembly conveyor utilizing

an interlocking style plastic slat connected by stainless steel

pins to move trays through a tray assembly system. Belt is

returned in self-cleaning slider pan for easy cleaning and

maintenance. The model CITW is used for straight applications

only. Unit is provided with or without an automatic detergent

injection wash system.

Specifications:

Provide AVTEC NSF Approved tray make-up conveyor system, Model CITW. Unit shall be the size and shape as shown in project drawings.

Top and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4 mill nish. Drive housing shall be of uni-body

construction, completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter stainless steel with 1 ½” diameter welded

cross members for support. Drive motor to be stainless steel (½)(¾) hp, 208/3 and shall be water resistant. Unit is to include wash housing

with strategically designed spray jets for cleaning of both sides of belt. Belt returns on self-cleaning return track system. Detergent designed

to drip on belt for maximum exposure to cleaning action. Wash housing is designed with large access panels for inspection of wash chamber

and comes complete with stainless steel latches to seal openings and removable scrap basket for waste. Housing is to be provided with

door safety shut-off switch. Belt is to be interlocking style gray plastic on continuous length UHMW tracks, driven by a UHMW sprocket

mounted on stainless steel bearings and shafts utilizing slip collar in lieu of keyways. Tail section includes auto-tensioning device to keep

constant equal tension on the belt. Motor control panel to be designed with main service disconnect switch, variable speed controls and of

sealed water-tight construction. Conveyor is designed to include a photo electric accumulation switch at terminal end of unit to shut down

system when conveyor is full.

Standard Features:

• S/S drive housing

• Door conveyor shut off

safety switch(s)

• Removable scrap basket in

drive and tail housings

• Access panel for wash housing

• 1 ½” Drain in drive

• S/S drive motor

• Anti-jam safety switch at

drive opening

• Detergent pump housing

• Auto belt tensioner

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Work surface: 14 ga S/S construction,

fully welded and polished.

• 1/2 HP S/S drive motor

• Interlocking belt slats, gray

• UHMW drive sprockets

• Self cleaning top and return tracks

• Lifetime drive bearings

• Tail cover

• Belt wash, with auto wash option

(PLC programmed timer for optimal

cleanness and performance)

• Main control panel with start/stop,

wash selector, belt speed, limit

switch, main disconnect

• Limit switch

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

Additional start/stop box(s)

Post mounted tubular overshelf

Starter station

Hinged tail access door

Modular energy distribution system

Momentary run foot switch

Side skirting:

Hinged

Removeable

Avtec Conveyors, Page 7

PP SPEC1057 Rev. A

Revised 11/07

Page 14

Front, Top & Side Views

Model CITW

HINGED TAIL ACCESS

MCOE

1 1/2" WASTE

SIDE SKIRTING

A

ELEVATION VIEW

PLAN VIEW

RECESSED MAIN CONTROLS

DETERGENT PUMP HOUSING

1

1/2 H&C WATER

DETERGENT PUMP

HOUSING

1

1 1/2" WASTE

LIMIT SWITCH

ANTI-JAM

RECESSED MAIN CONTROLS

SECTION VIEW

MCOE

A

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 15

Conveyors Slat Belt Conveyor System model CIDW

Description:

The AVTEC Model CIDW is a dual belt soiled tray/dish return conveyor

utilizing an interlocking style plastic slat connected by stainless steel

pins. The model CIDW is used to return soiled trays from the dining

room to the dish room or to move dishes or racks within the dish

room. Belt is returned in self-cleaning slider pan for easy cleaning and

maintenance. The model CIDW is used for straight applications only

and cannot make turns. Unit is provided with automatic detergent

injection wash system.

Specifications:

Provide AVTEC NSF Approved dual soiled tray/dish conveyor system, Model CIDW. Unit shall be integral with dish table and tray scrapping system

and will be size and shape as shown in project drawings. Top and slide bed shall be constructed of 14 gauge 300 series stainless steel with #4

mill nish. Drive housing shall be of uni-body construction, completely constructed of 300 series stainless steel. Legs shall be 1 5/8” diameter

stainless steel with 1 ½” diameter welded cross members for support. Drive motor to be stainless steel (½)(¾) hp, 208/3 and shall be water

resistant. Motor is to be located in separate housing from wash tank compartment. Housing is to be provided with door safety shut-off switch.

Unit is to include wash housing with strategically designed spray jets for cleaning of both sides of belt. Belts ride on self-cleaning return and top

track system. Detergent designed to drip on belt for maximum exposure to cleaning action. Wash housing is designed with large access panels

for inspection of wash chamber and comes complete with stainless steel latches to seal openings and removable scrap basket for waste. Belts

are to be interlocking style gray plastic on continuous length UHMW, driven by a UHMW sprocket mounted on stainless steel bearings and shafts

utilizing slip collar in lieu of keyways. Tail section includes auto-tensioning device to keep constant equal tension on the belt. Motor control panel

to be designed with main service disconnect switch, variable speed controls and of sealed water-tight construction. Conveyor is designed to

include a photo electric accumulation switch at terminal end of unit to shut down system when conveyor is full.

Standard Features:

• S/S drive housing

• S/S drive motor

• Door conveyor shut off

safety switch(s)

• Removable scrap basket in drive

and tail housings

• Access panel for wash housing

• 1 ½” Drain in drive

• Anti-jam safety switch at

drive opening

• Detergent pump housing

• Belt wash, with auto wash option

(PIC programmed timer for optimal

cleanness and performance)

• Main control panel with start/stop,

wash selector, belt speed, limit

switch, main disconnect.

• Limit switch

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

• Auto belt tensioner

• 1 5/8” S/S legs with 1 1/2”

S/S crossmembers

• Work surface: 14 ga S/S construction,

fully welded and polished.

• 1/2 HP S/S drive motor (typ. for

under 60’)

• 3/4 HP S/S drive motor (typ. for

over 60’)

• S/S side exing #60 chain

• Side exing slats with rollers, for

smooth turns. Standard color

black, also available in gray, and blue.

• Self cleaning return track

• S/S drive sprockets

• Lifetime drive bearings

• Tail cover

• Slats can be easily replaced

Optional Accessories:

Hinged tail access door

Additional start/stop box(s)

Wall or post mounted overshelf

Wall or post mounted tubularovershelf

Hose reel:

30’ hose

50’ hose

Side skirting:

Hinged

Removeable

Avtec Conveyors, Page 8

PP SPEC1058 Rev. A

Revised 11/07

Page 16

Front, Top & Side Views

Model CIDW

RECESSED MAIN CONTROLS

10 1/2" BELT

CENTERLINE

1 1/2" WASTE

SIDE SKIRTINGHINGED TAIL ACCESS

ELEVATION VIEW

DETERGENT PUMP HOUSING

1

A

ANTI-JAM

PLAN VIEW

10.000

1

SELF CLEANING

BELT TRACKS

1/2 H&C WATER

DETERGENT PUMP

HOUSING

1 1/2" WASTE

ROLLED EDGE

SIDE SKIRTING

(BOTH SIDED)

LIMIT SWITCH

RECESSED MAIN CONTROLS

5" CASTER

SECTION VIEWSECTION VIEW

AA

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 17

Conveyors Roller Conveyor Systems model CRPN

Description:

Up-racking, soiled, S/S power roller conveyor.

Specifications:

21 1/2” long, 1.9dia S/S rollers on 5.5” centers. 22” BFR. 26.250” O.A. width, typical 8” tall back splash at rear, from 6’ to 30’

long. Power roller motor: 1/3 HP. When required main control connection changes from 15amp to 20amp.

Standard Features:

• A slip-type drive feature allows the

operator to stop items on the

rollers without damage or injury

to the equipment or operator

• #50 S/S chain (bottom driven)

• 14 Ga S/S housings

• 18 Ga S/S removable access panels

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

Standard or inverted drive housing

End load with standard drive

Stacking plates

Hose reel:

30’ hose

50’ hose

Sliding racking stations:

___Single basket station

___Double basket station

Avtec Conveyors, Page 9

PP SPEC1059 Rev. A

Revised 11/07

Page 18

Front, Top & Side Views

Model CRPN

A

PULPER CONNECTION FLANGE

SUMP TYPE

SILVER SAVER

CORD MICRO-TURNS

RACKING STATIONS

PLATE STACKS

AUTO-PLATE RINSE (APR's)

MAIN CONTROL PANEL,

PEDESTAL MOUNTED

LIMIT SWITCH

TRAY STAC

PLAN VIEW

1.9ÿ S/S ROLLERS

5.500 CENTERS

1.9ÿ PVC ROLLERS, PITCHED

DOWN TO DISH MACHINE

POWER ROLLERS

B

COUNTER WEIGHTED

HINGED BRIDGE

START/STOP

1 1/2" WASTE

1/2" H&C WATER

RACK SHELF (5)

PLATE STACKS

PITCHING DOWN FROM

POWER ROLLERS

22.000

APR'S

POWER ROLLERS

SELF CLEANING

RETURN TRACK

ASECTION VIEW

24.000

12.000 I.D.

BSECTION VIEW

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 19

Conveyors Roller Conveyor Systems model CRGN

Description:

Gravity roller conveyor sections utilized to move trays/

racks in the dish room environment. Rollers can be

utilized for drop-off of trays, moving racks into and out

of rack type dish machines or various other dish room

applications. Rollers are available in removable sections

and rollers can be spaced varying distances apart,

depending on the product being conveyed. Rollers are

available in PVC plastic or stainless steel.

Specifications:

Provide AVTEC model GRNP (gray PVC) (stainless steel) (straight) (curved) roller sections, (17”) (21 ½”) (26 ½”) wide as shown

on drawings. Roller shall consist of 1.9” diameter (PVC) (stainless steel) tubing with stainless steel bearings mounted in lift out

sections. Removable sections shall be supported above dish table in recessed cavity. Rollers shall have anodized aluminum

axles for maximum corrosion resistance and shall be mounted with stainless steel hardware.

Standard Features:

• 11 Ga side rails

• Easily removable sections

• 7/16” Hex aluminum shafts, tapped

for 5/16-18 x 5/8” deep,

anodized clear

• Roller sections, when applicable,

are placed on pins for easy

cleaning

• Interroll rollers with S/S bearings

• Three rollers per shaft, instead of

one, for all turns

• 1 5/8” S/S legs with 1.5”

cross-members

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

S/S rollers can be substituted for PVC

Skate wheels substituted for rollers:

• 1.9Dia skate wheels

• Individually bolted through work surface

• On 3” to 5” centers

Pitched work surface to drain

Open pan construction

Rollers sections on work surface instead

of pins

Spring loaded shafts

Blue rollers

Rollers with side rails only

Pitched down from power rollers

Hinged roller bridge, counter weighted

for easy lifting

Avtec Conveyors, Page 10

PP SPEC1060 Rev. A

Revised 11/07

Page 20

Front, Top & Side Views

2.000

14GA S/S (TYP.)

4.500

1.500 24.875

28.375

10.000

1 5/8" S/S TUBING

10.000

21.468

UNDERSHELF

SECTION VIEW

A

31.125

34.250

OPTIONAL UNDERSHELF

1.9ÿ PVC ROLLERS

DISHMACHINE CONNECTION

(PER CUT CHEET)

PLAN VIEW

CRGN

30.875

Model CRGN

BUILT IN GUIDE RAIL

1 1/2" WASTE

22.000

R36.000

117.875

A

1.9ÿ PVC ROLLERS

1.500 24.875

14GA S/S (TYP.)

4.500

31.125

10.000

34.250

UNDERSHELF

SECTION VIEW

21.468

28.375

2.000

A

10.000

1 5/8" S/S TUBING

OPTIONAL UNDERSHELF

OPTIONAL DISH MACHINE MOUNTED

LIMIT SWITCH (PROVIDED BY

DISH MACHINE MANUFACTURER)

28.375

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 21

Conveyors Roller Conveyor Systems model CRTN

Description:

The AVTEC Model CRTN is a gravity roller tray

assembly conveyor utilizing PVC or stainless steel

rollers to transfer trays between stations in a tray

assembly system. The full length integral side rails

guide the tray down the length of the unit. The

conveyor is available in various lengths and several

widths to accommodate a variety of tray sizes and

tray assembly system designs.

Specifications:

Provide NSF approved AVTEC model CRTN gravity manual tray assembly conveyor. Unit is to be provided the size and shape

as shown on drawings. Unit shall be mounted on (table) (oor) as shown. Entire unit shall be constructed of #300 series

stainless steel with a #4 nish. Design to include integrally formed side rails for guiding trays and mounting over-shelves

and accessories. Conveyor bed shall be constructed of 14 gauge stainless steel. Unit shall be provided with 1 5/8 “diameter

stainless steel legs with 1 ½” diameter welded cross members. Legs shall be provided with telescoping sleeves for adjustment

of height. Provide (gray PVC) (stainless steel) rollers, consisting of 1.9” diameter (PVC) (stainless steel) tubing with stainless steel

bearings mounted in lift out sections. Rollers shall have anodized aluminum axles for maximum corrosion resistance and shall

be mounted with stainless steel hardware.

Standard Features:

• Integral side rails

• Easily removable sections

• 7/16” Hex aluminum shafts, tapped

for 5/16-18 x 5/8” deep,

anodized clear

• Interroll rollers with S/S bearings

• 1 5/8” S/S legs with 1 1/2”

cross-members

• Neoprene bumper stripping full

length, both sides

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Optional Accessories:

S/S rollers can be substituted for PVC

Skate wheels substituted for rollers:

• 1.9Dia skate wheels

• Individually bolted through work surface

• On 3” to 5” centers

Open pan construction

Spring loaded shafts

Blue rollers

Rollers with side rails only

Adjustable bullet feet in lieu of casters

Starter station

Modular energy distribution system

Avtec Conveyors, Page 11

PP SPEC1061 Rev. A

Revised 11/07

Page 22

Front, Top & Side Views

Model CRTN

B

120.000

A

1.9ÿ PVC ROLLERS,

IN REMOVABLE SECTIONS

18.000

SECTION VIEW

2

35.000

PLAN VIEW

SECTION VIEW

18.000

15.000 1.5001.500

BA

18.000

35.000

1.9ÿ SKATE WHEELS

120.000

18.000

PLAN VIEW

18.000

1.500 1.50015.000

35.000

SECTION VIEW

2

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 23

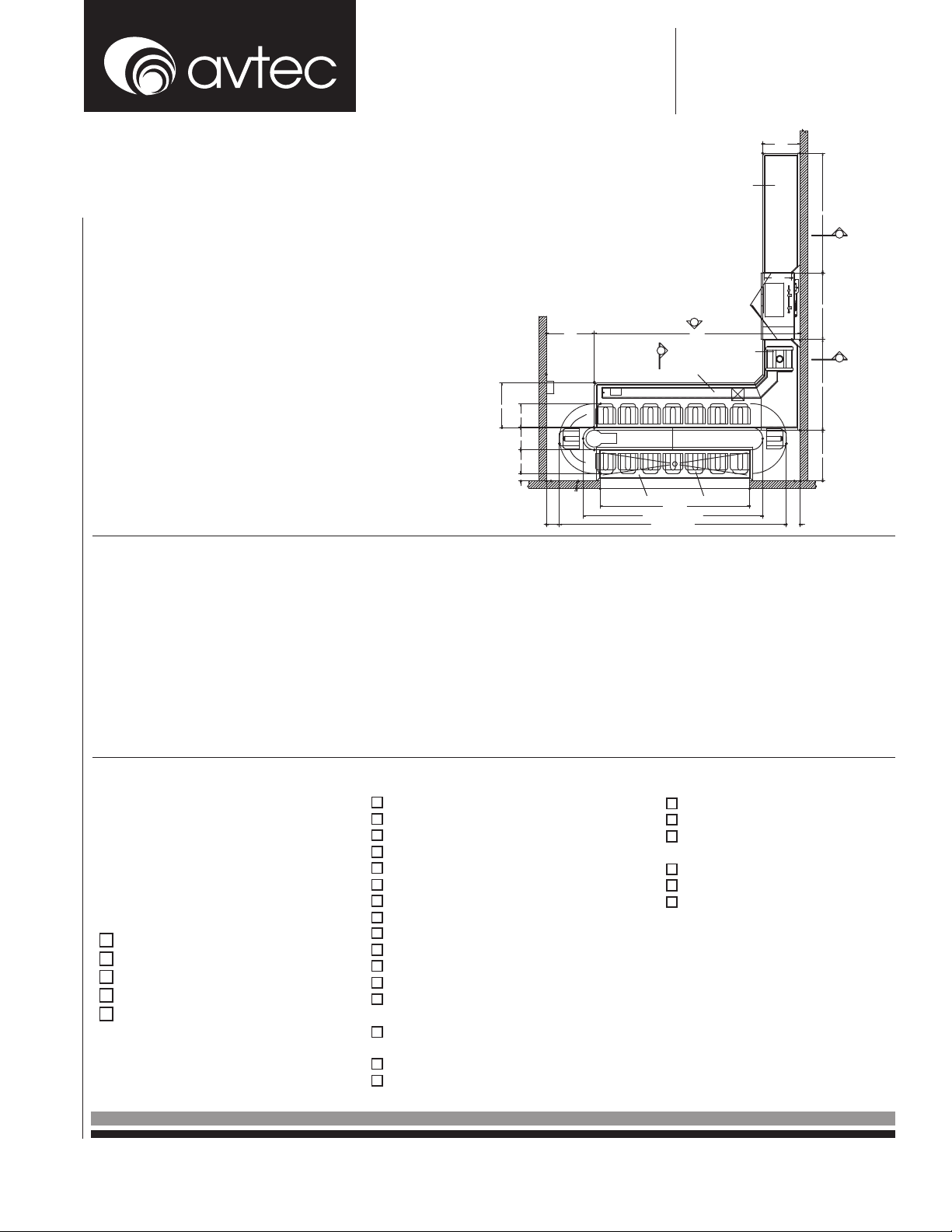

Clean Dish Table or

A

B C

37.000

74.000

42.000

25.000

2.250

13.500

0.250

34.000

36.000

3.500

10.000

34.000

37.000

1.500

6.000

5.875

10.108

30.000

2.000

8.000

34.000

1.500

3.500

3.000

20.500

DISPOSER

3.000

1.500

34.000

8.000

2.000

30.000

40.000

FULL WINDOW TRIM

WINDOW SILL

18.000

14GA S/S WORK

SURFACE (TYP.)

1 5/8" S/S LEGS

1 1/2" CROSS MEMBERS

DISPOSER

DISPOSER CONTROLS BRACKET

144.000

34.000

3.000

37.000

BUS TRAC START/STOP

42.000

DISHMACHINE CONNECTION

FLANGE (PER CUT CHEET)

22.000

8.000

SECTION VIEW

FOR LATERAL SUPPORT.

CEILING OR OTHER STRUCTURE

ATTACH TOP OF BUS TRAC TO

IMPORTANT

SECTION VIEW SECTION VIEW

ELEVATION VIEW

1

Soiled Dish Table

Conveyors Dish Table Conveyor models CDTN & SDTN

CDTN, CLEAN DISHTABLE

Description:

CDTN: Clean dish table.

SDNT: Soiled dish table.

A

SDTN, SOILED DISHTABLE

DROP OFF TABLE

WITH SILL & TRIM

119.875 SILL

144.000 O.A. BUS TRAC HOUSING

1

165.00038.500

BT20, BUSTRAC

PLAN VIEW

BUS TRAC

STOP/

36.000

19.000

18.000

19.000

6.000

MINIMUM

6.000

START

TURN DOWN INTO

DISHMACHINE,

PER CUTSHEET

DISPOSER

CONTROLS

BRACKET

30.000

96.000

C

22.000

53.375

H-FRAME

11.000182.000 O.A. BUS TRAC10.500

B

72.750

40.750

Specifications:

None.

Standard Features: Optional Accessories:

• 14 ga S/S worksurface

• 1 5/8” S/S legs with

1 1/2” S/S

crossmembers

CDTN Optional Accessories:

Sink

H-frame

Hose reel:

Wall or post mounted overshelf

Wall or post mounted tubular overshelf

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

SDTN Optional Accessories:

Trough

Trough extension with or without cover

Pulper connection ange

Bridge

H-frame

Hose reel:

Weld in customer provided disposer ring

Disposer controls bracket

Mixing valve bracket

Transfer edge

Auto (APRs) or manual (MPRs) plate rinses

Manual plate rinses

Wall or post mounted tubular overshelf

clean dish table

Wall or post mounted overshelf

Hinged drop-off panels:

Laminated doors

Stainless steel doors

Sink

Soak sink

Mobile bridge

Silver Saver:

Dam type

Sump type with lever drain

Magnetic type

Avtec Conveyors, Page 12

PP SPEC1062 Rev. A

Revised 11/07

Page 24

Front, Top & Side Views

DISPOSER

DISPOSER CONTROLS BRACKET

144.000

34.000

3.000

37.000

BUS TRAC START/STOP

42.000

DISHMACHINE CONNECTION

FLANGE (PER CUT CHEET)

22.000

8.000

ELEVATION VIEW

1

Model CDTN & SDTN

144.000

42.000

DISHMACHINE CONNECTION

FLANGE (PER CUT CHEET)

DISPOSER

ATTACH TOP OF BUS TRAC TO

CEILING OR OTHER STRUCTURE

FOR LATERAL SUPPORT.

3.500

1.500

37.000

34.000

8.000

IMPORTANT

22.000

DISPOSER CONTROLS BRACKET

5.875

10.108

10.000

36.000

SECTION VIEW

ELEVATION VIEW

18.000

WINDOW SILL

0.250

25.000

2.250

13.500

3.000

37.000

34.000

BUS TRAC START/STOP

1

FULL WINDOW TRIM

42.000

40.000

37.000

34.000

6.000

74.000

3.000

DISPOSER

A

30.000

3.500

20.500

1.500

SECTION VIEW SECTION VIEW

2.000

8.000

34.000

B C

14GA S/S WORK

SURFACE (TYP.)

3.000

1 5/8" S/S LEGS

30.000

1.500

2.000

8.000

34.000

1 1/2" CROSS MEMBERS

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 25

Bus Trac™

Soiled Tray Accumulator

Conveyors Bus Trac™ Conveyor Systems model BT

Description:

The AVTEC Bus Trac™ is a soiled tray accumulator,

utilizing vertical accumulation of soiled trays to form

a “buffer” between the dining area and patrons

returning trays and the dish room and scrapping

personnel. The system consists of a series of rotating

tray carrier baskets, either three, four or ve tier

high. The unit is available in any number of lengths,

depending on the sizing requirements.

Specifications:

Provide AVTEC UL listed & NSF approved Bus Trac™ Soiled Tray Return System, Model BT. System designed to be mounted on stainless

steel legs, pedestal base or wall. Overall size shall be (56”) wide x long, (minimum length 9’-0”), with tray holding capacity. Main housing

shall be 18” wide x long. (minimum length 5’-10”).

System shall consist of a series of rotating removable tray carriers, with inserts, hangers and UHMW self-lubricating glides cantilevered from

a 1/8” steel track, attached to a concealed closed-path drive system. Unit to have removable stainless steel side panels for access to drive

components.

Main frame to be constructed of stainless steel structural channel, with 16 gauge, 300 series stainless steel enclosure and 18 gauge, removable access panels.

Tray carriers shall be (3) (4) (5) tier with buff colored molded ABS plastic insert on bottom tier, and shall be easily removable, without tools,

and shall be capable of being cleaned in any conveyor style dish machine. Carriers shall be constructed of 1/4” electro-polished stainless

steel wire: hangers shall be constructed of 3/8” stainless steel wire, with spacer wheel at bottom.

Drive system shall consist of motor, drive chain, axle and sprockets powering a steel conveyor chain rotating in a concealed , milled UHMW

inner channel and attached to individual tray carrier hangers with Chain tabs and UHMW glides. Provide 2” chain take-up, sprocket adjustment and 3% chain stretch allowance utilizing special offset links.

Motor to be (¾) (1) hp, 120 VDC, with variable speed drive and permanently lubricated bearings. Provide gasketed stainless steel control

panel, (10” x 15” x 6”) with SCR solid state control and innite speed dial and hour meter. Mandatory supervision of assembly and start-up

by factory authorized technician is required. Two weeks written notice of installation time required.

¾ HP drive motor, 15 amp 120/1F, incoming electrical service to AVTEC main control panel. Interconnection of 120 volt motor control circuit

from control panel to drive motor. Interconnection of 120 volt circuit from start/stop switch to main control panel. Interconnection of 120

volt circuit from control panel to beam limit switch.

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec Conveyors, Page 13a

PP SPEC1063 Rev. A

Revised 11/07

Page 26

A

B C

37.000

74.000

42.000

25.000

2.250

13.500

0.250

34.000

36.000

3.500

10.000

34.000

37.000

1.500

6.000

5.875

10.108

30.000

2.000

8.000

34.000

1.500

3.500

3.000

20.500

DISPOSER

3.000

1.500

34.000

8.000

2.000

30.000

40.000

FULL WINDOW TRIM

WINDOW SILL

18.000

14GA S/S WORK

SURFACE (TYP.)

1 5/8" S/S LEGS

1 1/2" CROSS MEMBERS

DISPOSER

DISPOSER CONTROLS BRACKET

144.000

34.000

3.000

37.000

BUS TRAC START/STOP

42.000

DISHMACHINE CONNECTION

FLANGE (PER CUT CHEET)

22.000

8.000

SECTION VIEW

FOR LATERAL SUPPORT.

CEILING OR OTHER STRUCTURE

ATTACH TOP OF BUS TRAC TO

IMPORTANT

SECTION VIEW SECTION VIEW

ELEVATION VIEW

1

• Chain link drive system with

removable carriers—no belt service

headaches

• Removable tray carriers—easily

cleaned in any commercial conveyor

dish machine

• Removable tray insert on bottom tier

to accommodate patrons without

trays

• Vertical accumulation offers 3-5

times the accumulation of soiled

tray in the same space as standard

tray return conveyors

• Infrared, polarized retro-reective

beam type limit switch, self

contained and fully gasketed with

stainless steel mounting brackets

Optional Accessories:Standard Features:

Half-round clear plastic insignia mounted

at top of hanger, printed with logo or motto

(Provide copy of logo or motto)

Full base 13 ½ “ x

____

Additional buff colored ABS molded

plastic tray carrier inserts.

____

Additional remote stop start switch(es)

in stainless steel housing

Custom fabricated front drop table, 14

gauge, #300 series stainless steel, per

drawings

Custom fabricated dish table, with

Scrapping trough

Silver saver

sliding bridges

pre-installed transition hardware

for (pulper) (disposer) (Trayveyor)

(Hardware supplied by KEC)

Over shelf (wall) (table) mounted

per drawings

Sink, size and shape per drawings

(Removable) (Mobile) bridges

Vacuum breaker cutouts in backsplash

Gravity Roller sections, recessed, per drawing

____

, stainless steel

Model BT

____

Mobile silver soak sink (s)

____

Mobile dish table bridge(s)

with 14 gauge stainless steel tops,

(and over shelf) for holding two

20” x 20” dish racks

Cafeteria side front enclosure

panels to be clad with #

plastic laminate manufactured by

____

, or equal

Cafeteria side stainless steel base

to be clad with #

laminate manufactured by

or equal

Molded plastic tray carrier inserts

to be ABS color #

black, red, or gray standard

colors available at additional

price—additional colors available

in quantities of 100 or more at

additional price (twelve week

delivery time required)

____

color plastic

____

(white,

____

color

____

,

Top View

30.000

CDTN, CLEAN DISHTABLE

96.000

C

22.000

TURN DOWN INTO

DISHMACHINE,

PER CUTSHEET

A

SDTN, SOILED DISHTABLE

119.875 SILL

1

165.00038.500

BT20, BUSTRAC

PLAN VIEW

BUS TRAC

STOP/

36.000

19.000

18.000

19.000

6.000

MINIMUM

6.000

START

DROP OFF TABLE

WITH SILL & TRIM

144.000 O.A. BUS TRAC HOUSING

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

H-FRAME

DISPOSER

CONTROLS

BRACKET

11.000182.000 O.A. BUS TRAC10.500

53.375

B

72.750

40.750

Page 27

Front & Side Views

DISPOSER

DISPOSER CONTROLS BRACKET

144.000

34.000

3.000

37.000

BUS TRAC START/STOP

42.000

DISHMACHINE CONNECTION

FLANGE (PER CUT CHEET)

22.000

8.000

ELEVATION VIEW

1

DISHMACHINE CONNECTION

FLANGE (PER CUT CHEET)

DISPOSER

Model BT

144.000

42.000

34.000

3.000

37.000

8.000

22.000

BUS TRAC START/STOP

14GA S/S WORK

2.000

8.000

34.000

SURFACE (TYP.)

1 5/8" S/S LEGS

B C

ATTACH TOP OF BUS TRAC TO

CEILING OR OTHER STRUCTURE

FOR LATERAL SUPPORT.

37.000

34.000

IMPORTANT

3.500

1.500

5.875

10.108

10.000

36.000

SECTION VIEW

DISPOSER CONTROLS BRACKET

40.000

34.000

6.000

FULL WINDOW TRIM

42.000

37.000

18.000

0.250

13.500

WINDOW SILL

25.000

2.250

A

Bus Trac Application Data

ELEVATION VIEW

74.000

3.000

DISPOSER

1

30.000

3.500

20.500

1.500

SECTION VIEW SECTION VIEW

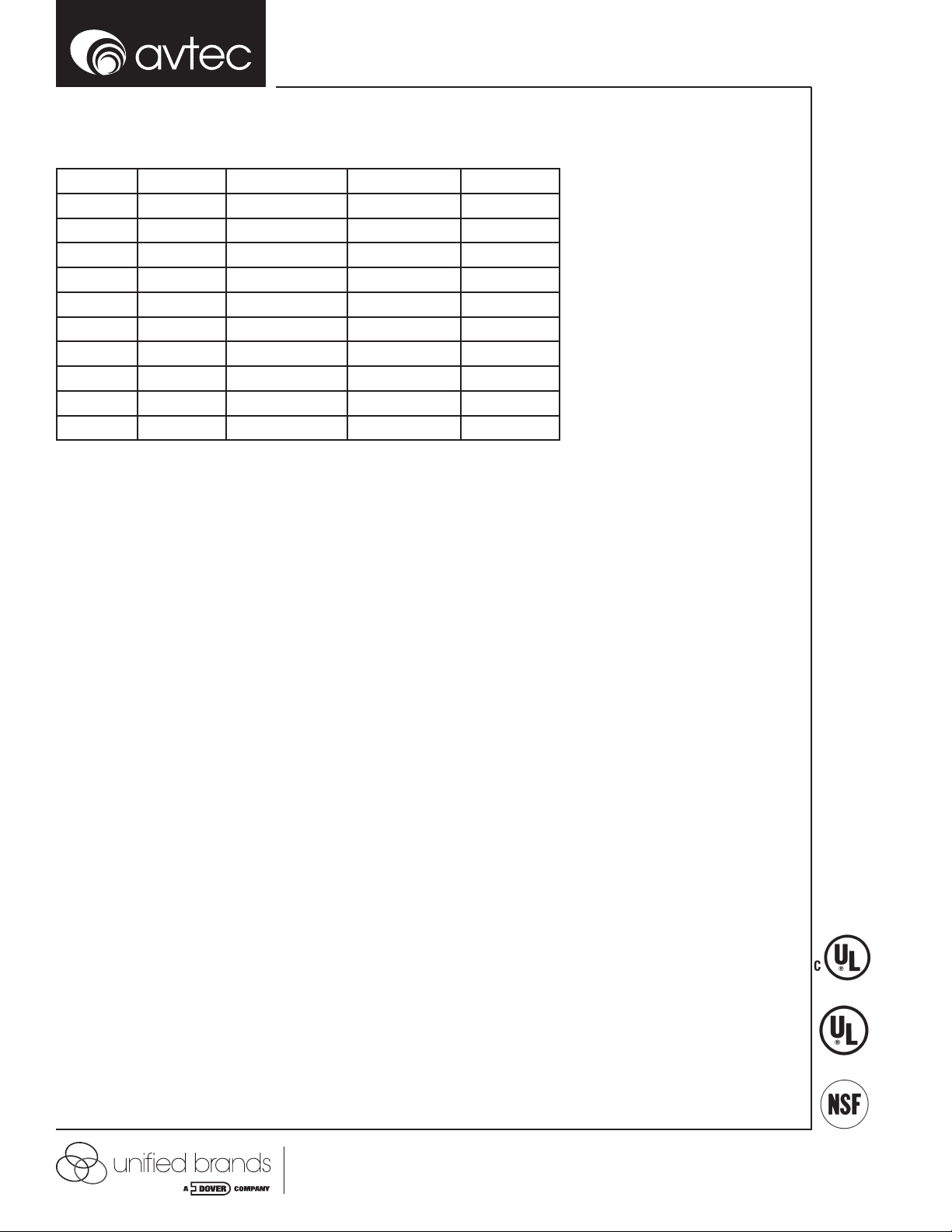

Number of Tray Carriers

*OA Length Housing Length Optional Base Length No. of Tray Hgrs. 2 Tier 3 Tier 4 Tier

9’ 5’ 10” 4’ 2” 8 16 24 32

10’ 6.5” 7’ 4.5” 5’ 8.5” 10 20 30 40

12’ 1” 8’ 11” 7’ 3” 12 24 36 48

13’ 7.5” 10’ 5.5” 8’ 9.5” 14 28 42 56

15’ 2” 12’ 10’ 4” 16 32 48 64

16’ 8.5” 13’ 6.5” 11’ 10.5” 18 36 54 72

18’ 3” 15’ 1” 13’ 5” 20 40 60 80

19’ 9.5” 16’ 7.5” 14’ 11.5” 22 44 66 88

21’ 4” 18’ 2” 16’ 6” 24 48 72 96

22’ 10.5” 19’ 8.5” 18’ .5” 26 52 78 104

24’ 5” 21’ 3” 19’ 7” 28 56 84 112

26’ 22’ 10” 20’ 2” 30 60 90 120

27’ 6.5” 24’ 4.5” 22’ 8.5” 32 54 96 128

30’ 7.5” 27’ 5.5” 25’ 9.5” 36 72 108 144

33’ 8.5” 30’ 6.5” 28’ 10.5” 40 80 120 160

36’ 9.5” 33’ 7.5” 31’ 11” 44 88 132 176

30.000

1.500

3.000

2.000

8.000

34.000

1 1/2" CROSS MEMBERS

*Required 5” clearance each side.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 13b

Page 28

Page 29

Tray Trac™

Tray Assembly System

Half Base Unit

Conveyors Tray Trac™ Conveyor Systems model TTH

Description:

The AVTEC Tray Trac™ is a unique tray assembly

system, designed for tray preparation for hospitals,

nursing homes, prisons and anywhere an assembly

line to prepare trays is required. The system utilizes

a series of tray carriers mounted to a drive chain,

rotating around a series of sprockets. The system

utilizes the “work facing approach to tray assembly

and thus eliminates the extraneous motion of

twisting and turning associated with straight-line

tray systems. The system utilizes consistent spacing,

easy recognition of tasks, limited range of motion,

and consistent delivery to increase tray production.

The Model TTH, half -base unit, allows for the use

of existing or other mobile hot and or cold units to

standardize the tray line and utilize the Tray Trac™

“work facing” design.

Specifications:

Provide AVTEC UL listed, NSF approved, Tray Trac Assembly System, Model TTH, with half base, ______ long x ______ wide, with food

holding surface 30 ½” to 34 ½ “ above nished oor. Conveyor track length to be ________ long. Table base side of unit shall contain nonrefrigerated surfaces, integral refrigerated sections, integral hot food wells, and other items as specied and shown on drawings. System

shall consist of a series of rotating removable tray carriers with UHMW polyethylene wear strips riding on a stainless steel track, cantilevered

above the nished oor and 12” above the food holding surfaces. Removable tray carriers shall attach to a closed-path steel sprocket and

chain located in a stainless steel housing. Top of drive housing shall be removable for access to all drive chain components.

Unit shall be constructed of stainless steel channel framing with exterior of 300 series, #4 nish stainless steel. Table top shall be 14 gauge,

with all side panels access doors and mullions 16 gauge stainless steel. Access doors to be hinged and provided with recessed handles.

Unit to be provided with adjustable leg assemblies with 4” adjustment. Unit to be complete with neoprene bumper guards on all four sides

and stainless steel splash guards over work surfaces.

Power for drive to be provided by a (¾) (1) HP 120VDC motor with silicone controlled rectier, solid state controls and automatic bearing

lubrication. Speed control and hour meter to be located inside access doors. Start /stop controls to be located at starter (and/or) checker

station of tray line. Unit to include main disconnect for drive mechanism and individual modular energy distribution systems.

Unit to be provided with UL listed, AVTEC Modular Energy Distribution System running full length on each side of base with main electrical

disconnects. Modular system to house connection link plates consisting of point-of-use circuit breaker, and matching electrical outlet or

connection. Link plates on 12” centers and shall provide power for all ancillary equipment as shown on drawing. Connection plates shall

be interchangeable, with blank plates available for future connections.

KEC to determine size of crates that can be received at site and moved through building. If unit is to be shipped in sections, standard spline

joints will be supplied at eld joints. Field welding, if required, is the responsibility of the KEC. Mandatory supervision of assembly and startup by factory authorized technician is required. Two weeks written notice of installation time required.

_______ Amps, 120/208/3F, _____ KW, 4-wire

_______ Amps, 120/208/3F, _____ KW, 4-wire

½” Hot and ½” cold water (Electrical) (Plumbing) services to terminate in (ceiling) (oor) by trades. Final connection by trades.

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec Conveyors, Page 14a

PP SPEC1064 Rev. A

Revised 11/07

Page 30

ELEVATION VIEW

ELEVATION VIEW

B

• Chain link drive with removable tray

carriers – no conveyor belt service

problems

• Cantilevered tray carrier design

saves oor space

• Tray carriers easily removable for

cleaning

• Operator is facing tray line during

operation – no turning or extraneous

motions

• Tray interval remains constant

• Checker unload station allows

continuous operation-no stoppage

on the line for checking

• Uniform work surface on one

containing hot or cold units, other

side can accommodate mobile units

• Menu cards easily readable at 45%

angle towards operator

• AVTEC Modular EDS allows for

powering ancillary equipment w/one

electrical service for entire system

• Allows for easy relocation or adding

of electrical connection

Optional Accessories:Standard Features:

Integral starter station: (side mounted) (end

mounted) with: ____ additional bins in

table top and top shelf

Floor mounted starter station: (2 tier, 6-bin)

(3 tier, 9-bin) with top shelf

____” x ____” cutout in base for

tray dispenser

Tray unload station, ____long (5’-0” std.)

____(Qty.) Hot food wells, standard

conguration, (with covers)

____(Qty.) Hot food wells, “doubled”

conguration, (with covers)

____(Qty.) Cold food wells, standard

conguration, with drains

____(Qty.) Cold food wells, “doubled”

conguration, with drains

____(Qty.) Cold top, __ sheet pan size,

____” x ____”

____(Qty.) Cold top, __ sheet pan size,

____” x ____”

____(Qty.) Cold pan unit,

____” L x ____” W x ____” D

____(Qty.) Cold pan unit,

____” L x ____” W x ____”

Model TTH

____(Qty.) Foot operated

momentary stop switch(es)

Secondary start/stop station

____(Qty.) Fill faucet(s) ½” NPT

(hot) (cold) water

Flat (single) (double) sided over

shelf, ____” x ____”

Slanted (single) (double) sided

over shelf, ____” x ____”

End over shelf, ____”W x 72” L

Stainless steel uorescent work

light xtures over work surface

Stainless steel uorescent work

light xtures over tray carriers

Door locks

Checker audio call system, complete

with microphone and 2 speakers

Heavy duty casters in lieu of legs

Matching cord sets for ancillary equip.

Water connectors for (hot) (cold) water with matching quick-disconnects

Outside drain lever

Hose bib on drain line (Service Pylon) (Floor box) for incoming service

Top View

C

B

D

PLAN VIEW

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

A

Page 31

ELEVATION VIEW

B

B

C

D

ELEVATION VIEW

D

MOBILE HOT FOOD WELL CART

ELEVATION VIEW

PLAN VIEW

ELEVATION VIEW

A

B

B

D

D

Front & Side Views

Model TTH

ELEVATION VIEW

ELEVATION VIEW

B

A

MOBILE HOT FOOD WELL CART

ELEVATION VIEW

C

ELEVATION VIEW

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

D

Page 14b

Page 32

Tray Trac Application Data

*Maximum No. of Hot Food Wells

OA Length Trac Length Overshelf Length Single Double

12’ 11’ 2” 9’ 6 8

15’ 13’ 5” 11’ 3” 8 10

17’ 15’ 8” 13’ 6” 9 12

19’ 17’ 11” 15’ 9” 10 14

21’ 20’ 2” 18’ 13 16

24’ 22’ 5” 20’ 3” 15 18

26’ 24’ 8” 22’ 6” 17 22

28’ 26’ 11” 24’ 9” 19 24

30’ 29’ 2” 27’ 21 26

33’ 31’ 5” 29’ 3” 23 28

*If used with integral unload station. Add 3” in width if “double” hot food wells are used.

Model TTH

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 33

Tray Trac™

Tray Assembly System

Modular Base Unit

Conveyors Tray Trac™ Conveyor Systems model TTM

Description:

The AVTEC Tray Trac™ is a unique tray assembly

system, designed for tray preparation for hospitals,

nursing homes, prisons and anywhere an assembly

line to prepare trays is required. The system

utilizes a series of tray carriers mounted to a drive

chain, rotating around a series of sprockets. The

system utilizes the “work facing approach to tray

assembly and thus eliminates the extraneous motion

of twisting and turning associated with straightline tray systems. The system utilizes consistent

spacing, easy recognition of tasks, limited range

of motion, and consistent delivery to increase tray

production. The Model TTM, modular-base unit,

utilizes AVTEC manufactured hot and or cold portable

units to standardize the tray line, allow exibility, and

eliminate the need for many ancillary pieces.

Specifications:

Provide AVTEC UL listed, NSF approved, Tray Trac Assembly System, Model TTM, with table base, ______ long x ______ wide, with food

holding surface 30 ½” to 34 ½ “ above nished oor. Conveyor track length to be ________ long. Modular System shall contain non-refrigerated surfaces, mobile refrigerated units, mobile hot food well units, and other items as specied and shown on drawings.

System shall consist of a series of rotating removable tray carriers with UHMW polyethylene wear strips riding on a stainless steel track,

cantilevered above the nished oor and 12” above the food holding surfaces. Removable tray carriers shall attach to a closed-path steel

sprocket and chain located in a stainless steel housing. Top of drive housing shall be removable for access to all drive chain components.

Unit shall be constructed of stainless steel channel framing with exterior of 300 series, #4 nish stainless steel. Table top shall be 14 gauge,

with all side panels access doors and mullions 16 gauge stainless steel. Access doors to be hinged and provided with recessed handles.

Unit to be provided with adjustable leg assemblies with 4” adjustment. Unit to be complete with neoprene bumper guards on all sides and

stainless steel splash guards over work surfaces.

Power for drive to be provided by a (¾) (1) HP 120VDC motor with silicone controlled rectier, solid state controls and automatic bearing

lubrication. Speed control and hour meter to be located inside access doors. Start /stop controls to be located at starter (and/or) checker

station of tray line. Unit to include main disconnect for drive mechanism and individual modular energy distribution systems.

Unit to be provided with UL listed, AVTEC Modular Energy Distribution System running on each side of base and as part of the individual

mobile sections, with main electrical disconnects. Modular system to house connection link plates consisting of point-of-use circuit breaker,

and matching electrical outlet or connection. Link plates on 12” centers and shall provide power for all ancillary equipment as shown on

drawing. Connection plates shall be interchangeable, with blank plates available for future connections.

KEC to determine size of crates that can be received at site and moved through building. If unit is to be shipped in sections, standard spline

joints will be supplied at eld joints. Field welding, if required, is the responsibility of the KEC. Mandatory supervision of assembly and startup by factory authorized technician is required. Two weeks written notice of installation time required.

_______ Amps, 120/208/3F, _____ KW, 4-wire

_______ Amps, 120/208/3F, _____ KW, 4-wire

½” Hot and ½” cold water (Electrical) (Plumbing) services to terminate in (ceiling) (oor) by trades. Final connection by trades.

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Avtec Conveyors, Page 15a

PP SPEC1065 Rev. A

Revised 11/07

Page 34

ELEVATION VIEW

ELEVATION VIEW

B

D

• Chain link drive with removable tray

carriers – no conveyor belt service

problems

• Cantilevered tray carrier design

saves oor space

• Tray carriers easily removable

for cleaning

• Operator is facing tray line during

operation – no turning or extraneous

motions

• Tray interval remains constant

• Checker unload station allows

continuous operation-no stoppage

on the line for checking

• Uniform work surface containing

hot and cold units

• Menu cards easily readable at 45%

angle towards operator

• AVTEC Modular EDS allows for

powering ancillary equipment w/one

electrical service for entire system

• Allows for easy relocation or adding

of electrical connection

Optional Accessories:Standard Features:

Integral Starter Station: Side mounted 2 tier, 6

bin with: 3 extra bins in table top

and top shelf

End mounted over trac, 2-tier,

10 bin w/top shelf

Mounted under trac, 5-bin

____” x ____” cutout for tray dispenser

( to be veried )

Tray Unload Station, 5 ft. (5 ft. std.)

____(Qty) Portable 6-well (Cold)(Hot) Food Units

____(Qty) Portable 5 well (Cold)(Hot) Food Units

____(Qty) Portable 4 well (Cold)(Hot) Food Units

____(Qty) Portable Cold Top Units3 Bun Pan size

____(Qty) Foot Operated Momentary

Stop Switch(es)

____(Qty)Angle Double Side Over shelf,

38”d x ____ft. lg.

S/S Fluorescent Work Light Fixtures

(over table base)

S/S Fluorescent Work Light Fixtures

(over tray carrier)

Checker Audio Call System w/ microphone

& 2 speakers

Model TTM

Timer/Programmer, 7-Day,

single channel

Door Locks (2)

Heavy duty casters, in lieu of legs

Top View

C

PLAN VIEW

B

D

A

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 35

Front & Side Views

ELEVATION VIEW

ELEVATION VIEW

B

B

C

D

ELEVATION VIEW

PLAN VIEW

ELEVATION VIEW

A

B

B

D

D

Model TTM

ELEVATION VIEW

ELEVATION VIEW

B

A

ELEVATION VIEW

C

ELEVATION VIEW

D

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

Page 15b

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 36

Tray Trac Application Data

*Maximum No. of Hot Food Wells

OA Length Trac Length Overshelf Length Single Double

12’ 11’ 2” 9’ 6 8

15’ 13’ 5” 11’ 3” 8 10

17’ 15’ 8” 13’ 6” 9 12

19’ 17’ 11” 15’ 9” 10 14

21’ 20’ 2” 18’ 13 16

24’ 22’ 5” 20’ 3” 15 18

26’ 24’ 8” 22’ 6” 17 22

28’ 26’ 11” 24’ 9” 19 24

30’ 29’ 2” 27’ 21 26

33’ 31’ 5” 29’ 3” 23 28

*If used with integral unload station. Add 3” in width if “double” hot food wells are used.

Model TTM