Avia D 60, D65, D70, D75, D 80 Owner's Manual

...

Dear driver,

This driver‘s manual was worked out for familiarising with operation and basic

maintenance of Your new AVIA truck and it should provide you with important

information from point of view of safe operation.

We recommend you to read it carefully and to follow instructions mentioned in it.

This way, you will gain pleasant and safe vehicle operation without problems.

For long-term vehicle life and certain operational reliability, it is necessary to have

vehicle repaired and maintained in some of our numerous authorised repair shops.

We would like to take advantage of this occasion to thank you for purchasing product

of AVIA company and assure you about our interest of your maximum

satisfaction..

We wish you to cover many thousands kilometres without accident.

AVIA ASHOK LEYLAND MOTORS s.r.o.

Praha - Letňany

Czech republic

Cargo truck

documentation

Owner's Manual

To become perfectly familiar with the

vehicle, it is necessary to study thoroughly Owner's manual and all additional instructions that are part of your

vehicle documentation (e.g. Owner's

Manual of automobile radio, certificate

of warranty for battery etc.).

Service Booklet

Documentation also contains Service

Booklet that contains:

n Identification data of vehicle

n Basic warranty conditions

n Warranty registration certificate

n Record of regular service inspec-

tions

n Labour activities, maintenance in-

tervals

n Record of car body inspections

n Specific Activities and maintenance

n Contract repair shops list

Components of equipment that are

designated with * are series mounted

only on certain models or they are

delivered only as exceptional equipment.

Warning!

n It is necessary to adhere at maximum rate the texts in this frame

(Warning!).

In the case of vehicle sale, it is necessary to hand over complete documentation.

ContentsInformation

Description

Compartment.......................................4

Keys......................................................6

Door......................................................6

Electric window winder*......................7

Instrument panel - indicators.............8

Indicator lamps....................................8

Combined switch over switch..........12

Cruise control ISBe...........................14

Diagnostic sockets............................17

Switchbox and steering lock...........18

Gear-shifting lever............................19

Steering-wheel inclination

adjustment.........................................19

Heating and ventilation.....................20

Air conditioner* ...................................... 22

Seats..................................................24

Headrests...........................................25

Safety belts........................................26

Rear view mirrors..............................28

Rear view mirror remote control*....28

Headlamps inclination adjustment..29

Cab interior illumination...................29

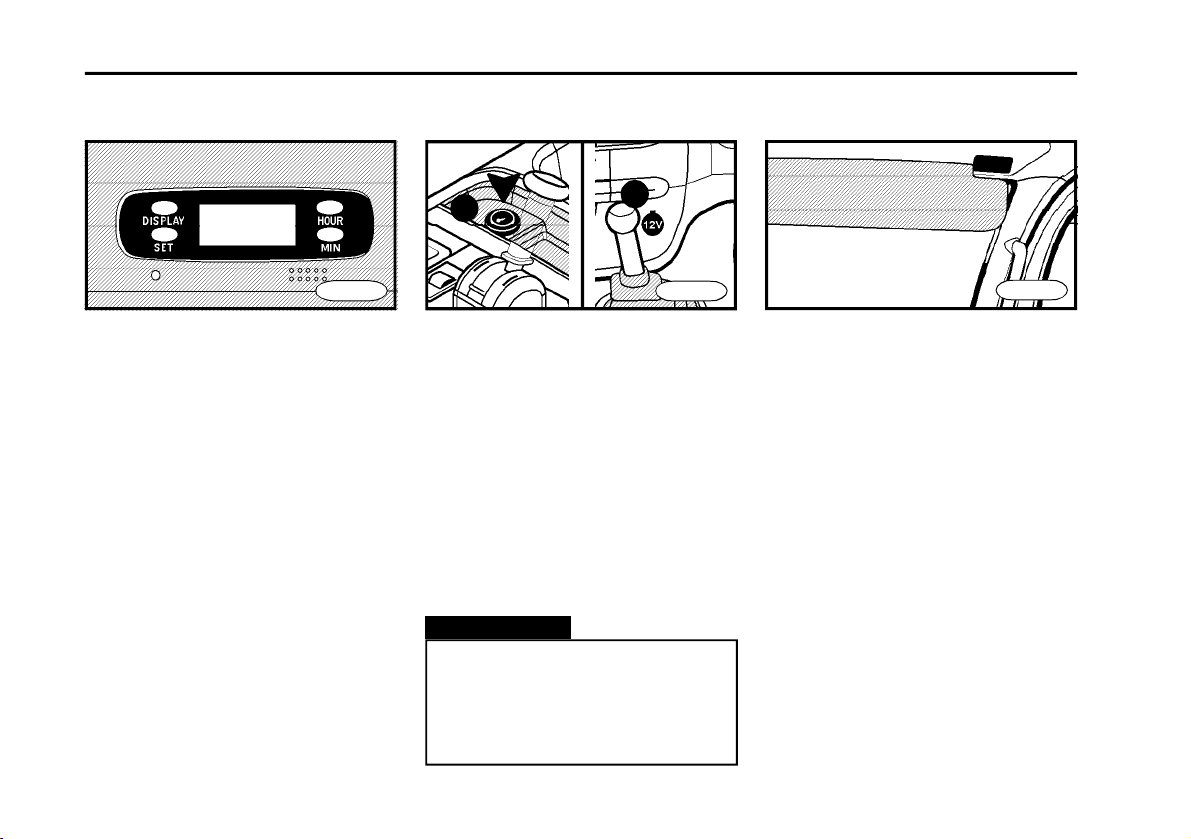

Digital clock*......................................30

Socket / cigarette lighter...................30

Sun visors..........................................30

Cup holder.........................................31

Ashtray...............................................31

2

Hanger, storage pocket....................31

Engine bonnet...................................32

Tools and equipment........................33

Hydraulic tilting of cab......................34

Instructions for cab tilting.................34

Chassis and cab................................36

Operating instructions

Inspection before drive.....................38

Running-in of vehicle........................38

Maintenance......................................38

Engine starting..................................39

During drive.......................................40

Engine stopping................................41

Engine for D family vehicles............42

Engine lubricating system................42

Turbocharger.....................................44

Fuel filter draining..............................45

Engine Cummins ISBe

- Tensioning of belts....................46,47

Engine Dwav D432

- Tensioning of belts....................48,49

Fuel tank............................................50

Fuel.....................................................50

Cooling system..................................51

Air cleaner.........................................52

Steering..............................................53

Gearbox.............................................54

Clutch.................................................56

Rear axle............................................57

Front axle...........................................57

Brake system.....................................58

Driving brake.....................................60

Brake lining inspection.....................62

Anti - Blocking - System...................64

Emergency brake..............................65

Parking brake....................................66

Washer and wiper.............................67

Tyres and wheels..............................68

Load transport...................................69

Electric equipment............................71

Battery attachment............................72

Battery................................................73

Alternator...........................................73

Headlamps and lamps - location....74

Care of vehicle..................................75

Malfunctions and their remedy

Engine................................................77

Electric equipment............................83

Monoblock hydraulic

power-assisted steering...................84

Brake..................................................84

Parking and spring-actuated brake.85

Vehicle towing and rescue...............86

Spare wheel carrier (N, L, E)...........87

Wheel chock (N, L, E)......................87

Spare wheel carrier (K).....................88

Wheel chock (K)................................88

Change of wheel...............................89

Change of bulbs................................90

Fuse box - cab...................................96

Fuse box - under battery

cover...................................................98

Starting by means of jumper

cables (D432)..................................100

Technical data

Engine..............................................102

Chassis............................................104

Brake................................................167

Dimensions of chassis-cabs..........108

Weights and weight on axles.........109

Tyre inflation....................................110

Truck circle diameter......................110

Gear ratios.......................................111

Maximum vehicle speed, climbing

performance....................................112

Electric equipment..........................113

Bulbs................................................114

Fuel consumption............................115

Service fluids...................................115

Vehicle identification number.........116

Labels...............................................117

3

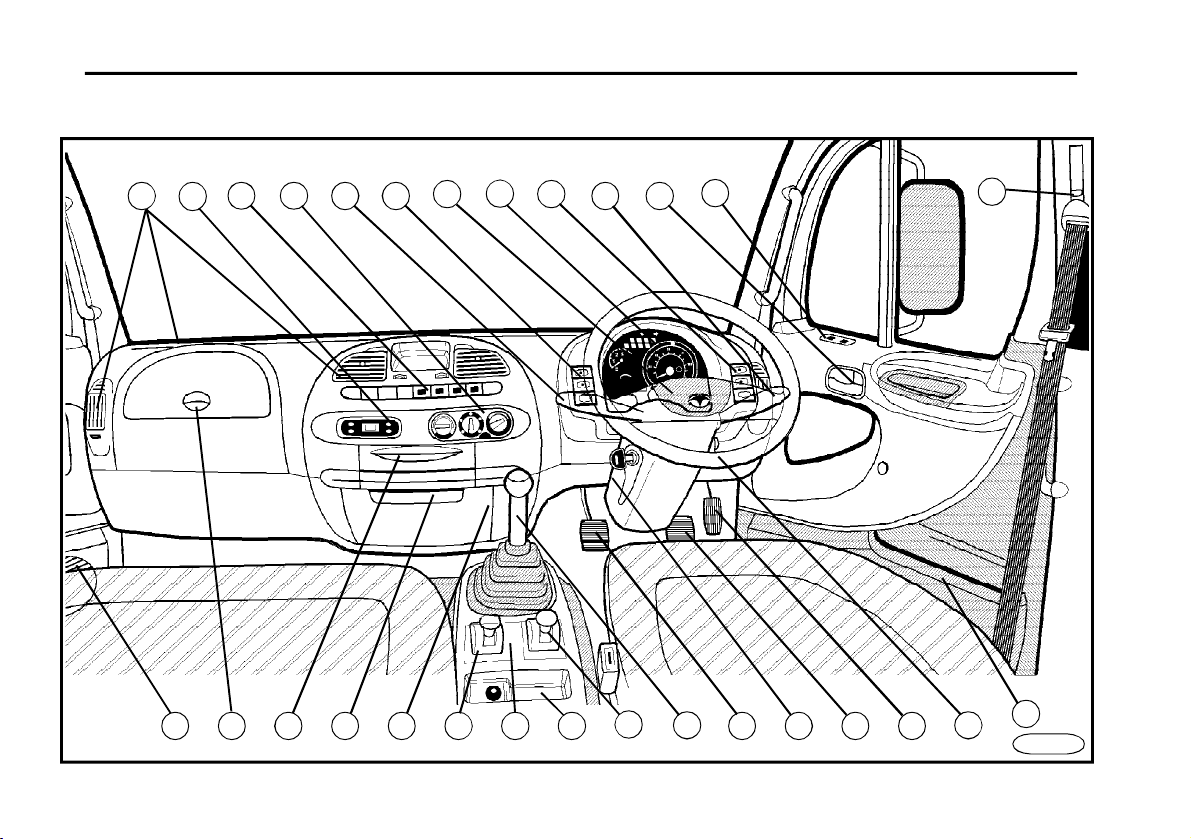

D E S C R I P T I O N

Compartment

12

25

20

FN0010

6

5

9

7

26 19 20 16 15 14 27 22 21 23 24

18

8

2 4

17

3

1 11

13

10

28

4

D E S C R I P T I O N

1 Combined change-over switch

-flash lamps

-position lamps

-low-beam headlamps

-high-beam headlamps

2 Combined change-over switch

-windscreen wiper control

-windscreen washer control

-exhaust brake

3 Controls

-front fog lamps

-rear fog lamps

4 Controls

-warning lamps

-rear-view mirror heating

5 Controls

-auxiliary drive

-differential lock

-truck superstructure illumination

-air conditioner

-cruise control (ISBe)

-cruise control - ON/OFF (ISBe)

-cruise control - SET/RESET (ISBe)

6 Measurement instruments and indicator lights

7 Digital clock

8 Heating control

9 Controlled air outlet

*

*

*

*

10Window winder

11Door open and lock

12Switchbox

13Parking brake

14Headlamp adjustment

15Rear-view mirror adjustment

16Gear-shift lever

17Horn

18Loudspeaker

19Ashtray

20Storage compartment

21Steering-wheel inclination control lever

22Clutch pedal

23Driving brake pedal

24Accelerator pedal

25Safety belt height adjustment

26Storage compartment (with cover *), fuse box

27Plug socket / cigarette lighter

28Plug socket 12 V

*

*

*

*

5

D E S C R I P T I O N

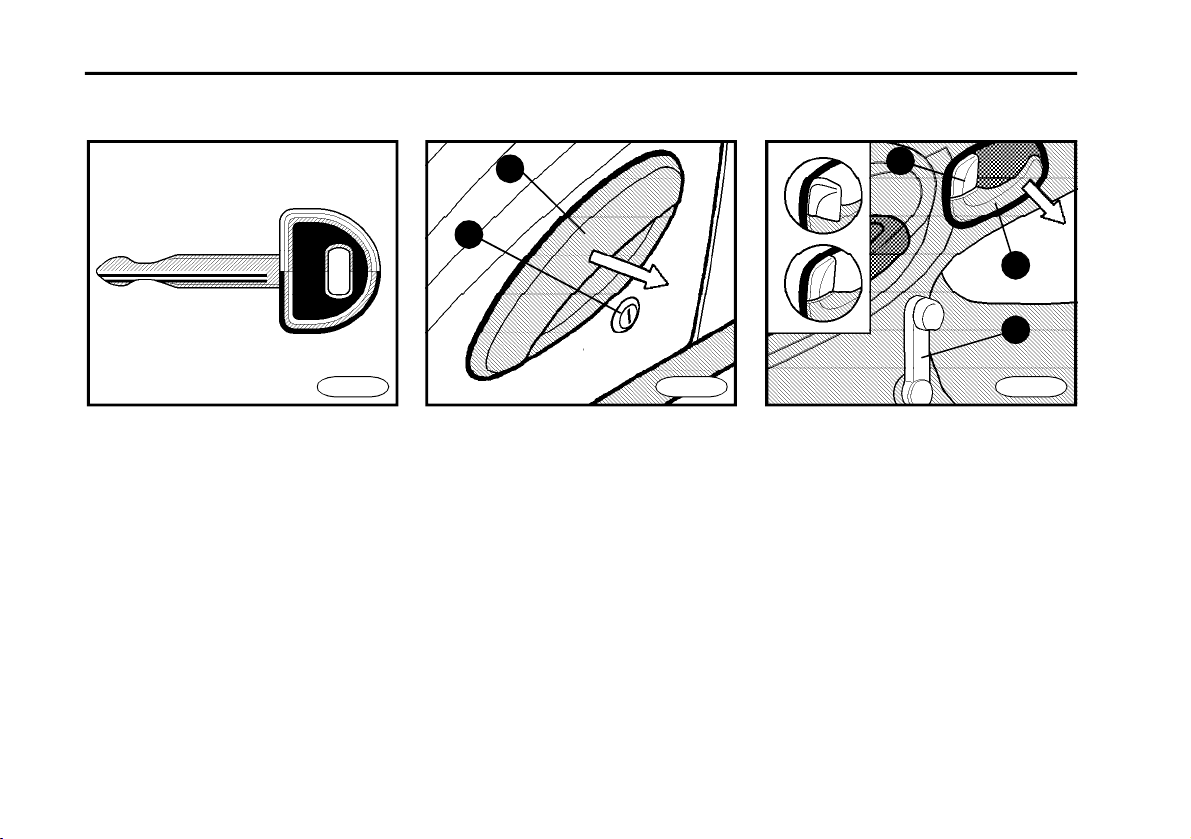

Keys

n Two keys are delivered - it is advised

to hide one of them outside vehicle as a

spare key.

n A label is fastened to keys where key

number is stamped. It is advised to hide

it outside vehicle and record the number.

n When vehicle is equipped with re-

cording speedometer, key for opening it

is delivered with vehicle.

Door

2

1

FN0030FN0020 FN0040

Exterior side

It is possible to lock and unlock both

doors by means of key from exterior

side. Key is inserted into lock (item 1).

Grasping the door handle (item 2) and

pulling outside results in door opening.

Unlocking - Insert the key, turn the key

90° counter clockwise and back to the

basic position, where the key can be

removed.

Locking - Insert the key, turn the key

slightly clockwise and back to the basic

position.

A

B

inner side

n (item 4)

A - Unlocked door

B - Locked door (Door locked this way

cannot be opened from both exterior

and inner side).

n Pulling lever (item3) door is opened

from inner side.

n Turning winder handle (item 5) re-

sults in window opening and vice versa.

4

3

5

6

D E S C R I P T I O N

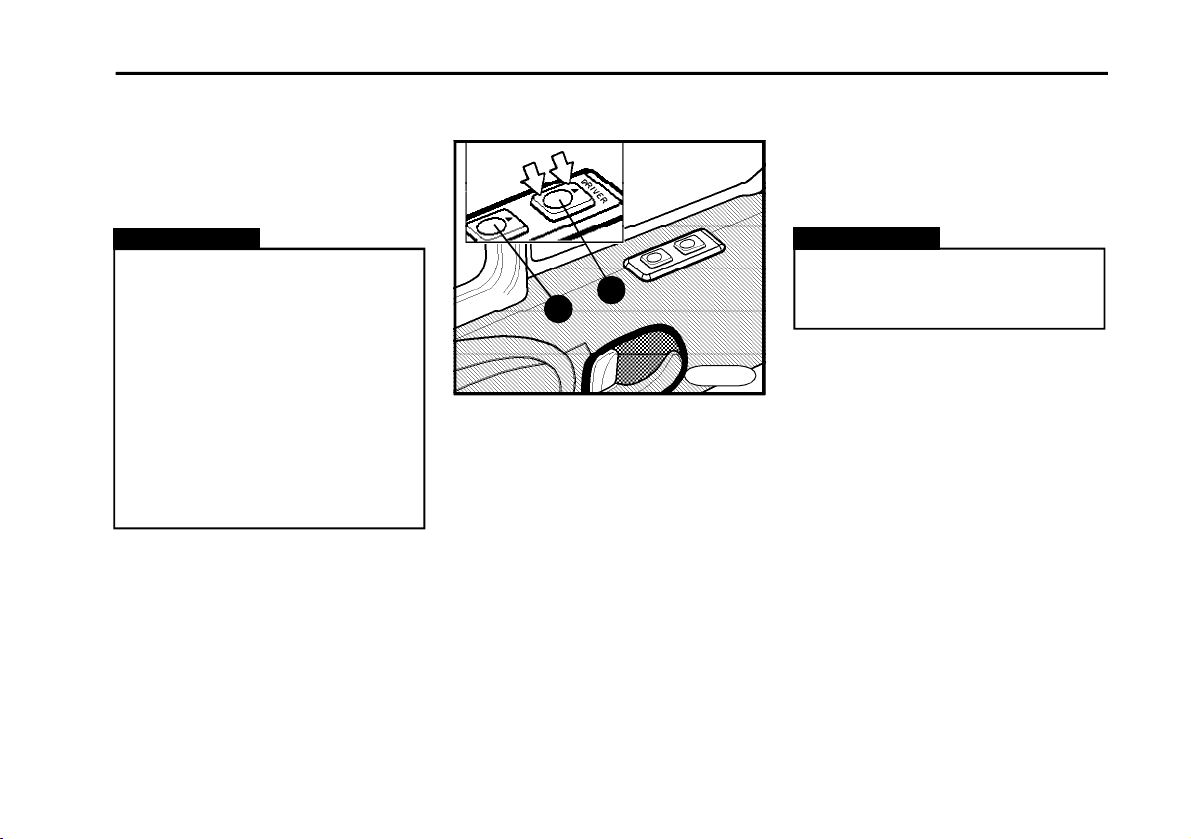

Central door lock

Central door lock is possible to lock or

unlock from driver‘s side both doors.

Warning!!

n Before leaving vehicle, always

remove ignition key from switchbox.

n It is necessary to take care of

closing rear and side doors of vantype truck and it is not permitted to

transport such cargo that disables proper door closing. If vantype truck damage occur due to

improper rear or side door closing

manufacturer exclude the truck

from warranty.

*

Electric window winder

1

2

n It is possible to wind windows only

when key is in position ON.

n Winding operates for the time of

pressing the button.

n Controls are placed on upper part of

doors.

n Both windows can be controlled from

the place of driver.

n Right side window can be controlled

from the place of front seat passenger.

n Control (item 1) - for window on driv-

er‘s side.

n Control (item 2) - for window on front

seat passenger‘s side.

*

FN0050

n Pressing of rocker switch front side

results in opening window, pressing the

other side window is closed.

Warning!

Take care of grip - mechanism is

able to create such force that could

result in injury.

7

D E S C R I P T I O N

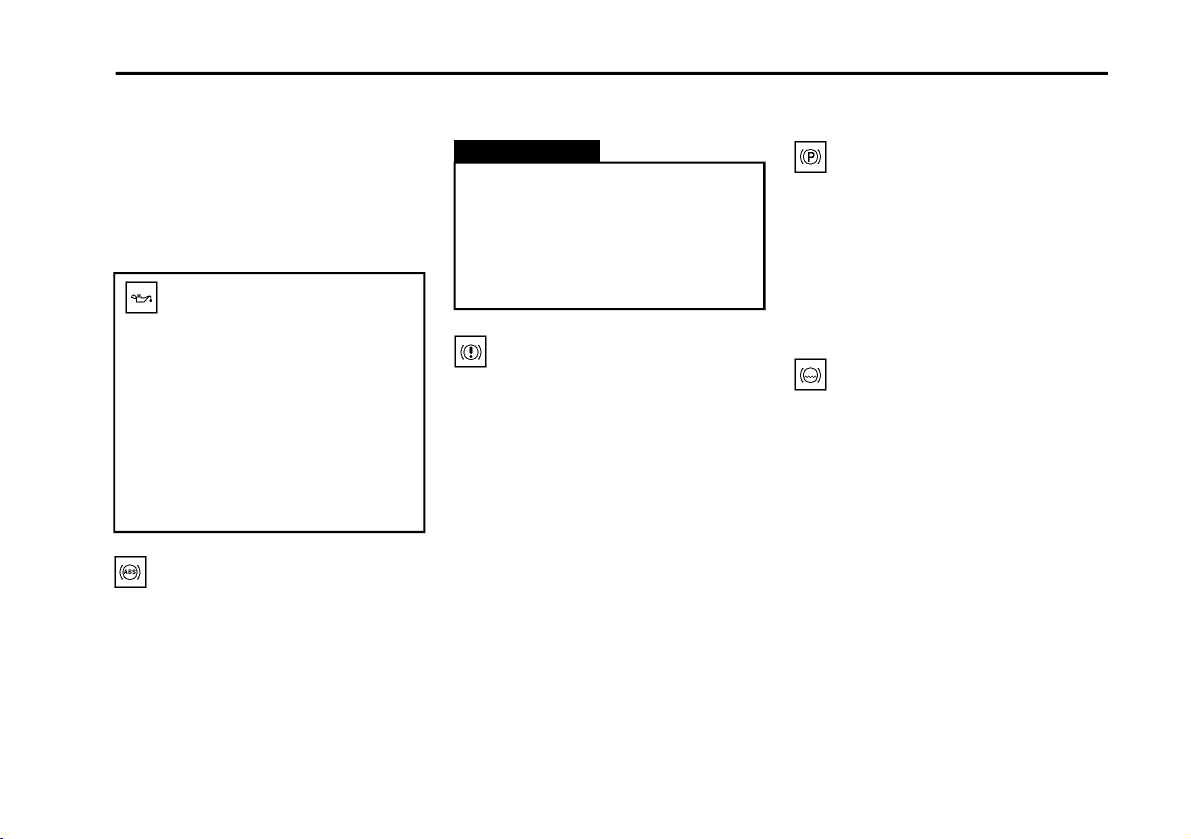

Instrument panel - indicators

!D432

7

2

4

3

5

1 Recording speedometer

2 Engine revolution indicator

3 Pressure gauge of brake system

circuit I.

4 Pressure gauge of brake system

circuit II.

8

1

86

5 Fuel reserve indicator, reserve

6 Coolant temperature indicator,

7 Indicator lamp block I.

8 Indicator lamp block II.

9 Indicator lamp block III.

9

fuel indicator lamp

indicator lamp

FN0065

Indicator lamps

FN0070

Direction indicator lamp

n According to switched on flasher light

control, left or right indicator lamp flashes.

n Shorter time interval of flashing indi-

cates damage of flasher lamp bulb (it is

necessary to replace burnt bulb immediately).

High-beam headlamps

It glows when high-beam headlamps

are switched on.

Battery charging

n It glows when ignition is switched on,

after engine starting it should be

switched off.

D E S C R I P T I O N

n When indicator lamp is not switched

off or it starts glowing during driving, it is

necessary to stop vehicle and engine

and proceed according to chapter Mal-

functions and their repair.

Engine lubrication

(only D432)

n It glows when key is in position ON,

after engine starting it should be switched

off.

n When indicator lamp is not switched

off or it starts glowing (shine through)

during driving, it is necessary to stop

vehicle and engine and proceed according to chapter Malfunctions and their repair.

ABS (vehicle)

n It glows when key is in position ON

(for check of diode function), after short

time interval it should be switched off.

n When indicator lamp is not switched

off after short time interval or it starts

glowing during driving, it is necessary to

stop vehicle and proceed according to

chapter Malfunctions and their repair.

Warning!

The indicator lamp may start shine

throughin irregular intervals with

low light intensity. This shining

through does not indicate failure,

bur it is caused by continuous inspection of ABS control unit.

Brake system failure

n It glows when key is in position ON (for

check of diode), after short time interval

it should be switched off.

n When indicator lamp is not switched

off after short time interval or it starts

glowing during driving, it is necessary to

stop vehicle and proceed according to

chapter Malfunctions and their repair.

Parking brake

n It glows when parking brake is ap-

plied and when air pressure is lower.

n When it glows, it isn‘t possible to

move off or when it starts glowing during

driving, it is necessary to stop vehicle

and proceed according to chapter Mal-

functions and their repair.

Minimum level of braking

fluid

n It glows when key is in position ON (for

check of diode function), after short time

interval it should be switched off.

n When indicator lamp is not switched

off after short time interval or it starts

glowing during driving, it is necessary to

stop vehicle and proceed according to

chapter Malfunctions and their repair.

9

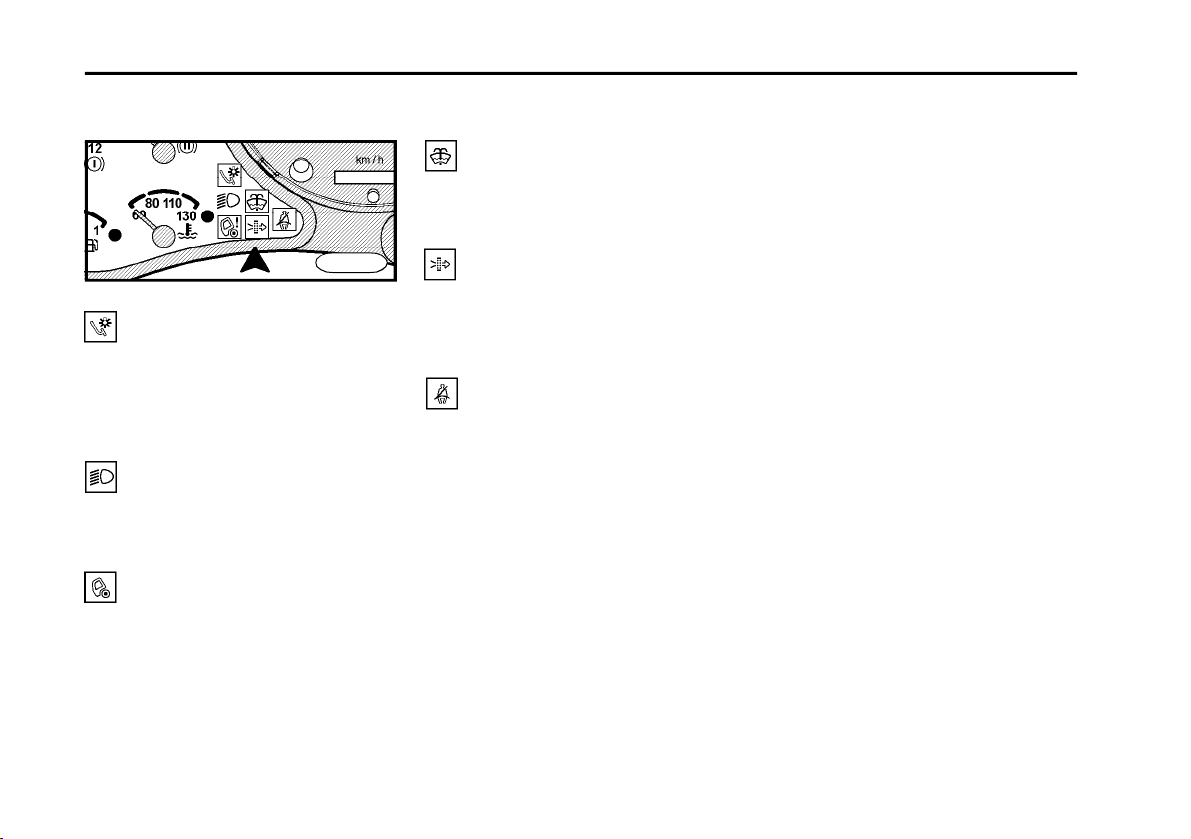

D E S C R I P T I O N

Minimum washer fluid

level

It glows in the case of washer fluid small

quantity.

*

FN0080

Brake lamp

n It glows when brake lamp bulb is

burnt.

n It is necessary to replace the faulty

bulb.

Low-beam headlamps

It glows when low-beam headlamps

are switched on.

Tilting of cab

It glows when the cab is improperly fixed

in rear support (it is necessary to repair

at once).

10

Air cleaner (clogged)

n It glows in case of clogged air filter.

n It ai necessary to replace air filter

element.

Safety belt

Necessity of safety belt fastening is

noticed.

*

D E S C R I P T I O N

FN0090

Exhaust brake

It glows when exhaust brake operates

(only D432, 422).

Differential lock

It glows when differential lock is activated.

Cargo area tipping

It glows when cargo area is tipped.

Auxiliary drive

It glows when auxiliary drive is activated.

Reverse lamp

It glows when reverse gear is engaged.

*

*

Flasher lights of trailer

n It glows when flasher lights are acti-

vated and trailer is towed.

n Shorter time interval of flashing indi-

cates damage of flasher lamp bulb (it is

necessary to replace burnt bulb immediately)

Engine – stop

ISBe

n It glows when switchbox is in posi-

tion "ON" (for checking operation)

After short time if must go out.

n It glows in a case of serious defect of

engine.

n If it will not go out after short interval,

or if it will glow during drive, you must

stop vehicle and follow chapter "Mal-

functions and their remedy".

Engine-warning.

ISBe

n It glows when switchbox is in posi-

tion "ON" (for checking operation)

After short time if must go out.

n It glows in a case of mistake or defect

of engine component.

If it will not go out after short interval or if

*

it will glow during drive, you must stop

vehicle and follow chapter "Malfunc-

tions and their remedy".

Glowing plugs

It glows after turning ignition key in

switchbox to position „ON“. For ISBe

only at lower evoironmental temperatures. After switching off, it is possible to

start engine.

Engine – maintenance

ISBe

n It glows when the switchbox is in

position ”ON” (for checking operation).

After short time if must go out.

n It glows in a case of necessary main-

tenance (exchange of oil.

n If it will not go out after short interval,

or if it flickers or if it will glow during drive,

you must stop vehicle and follow chapter "Malfunctions and their remedy".

11

D E S C R I P T I O N

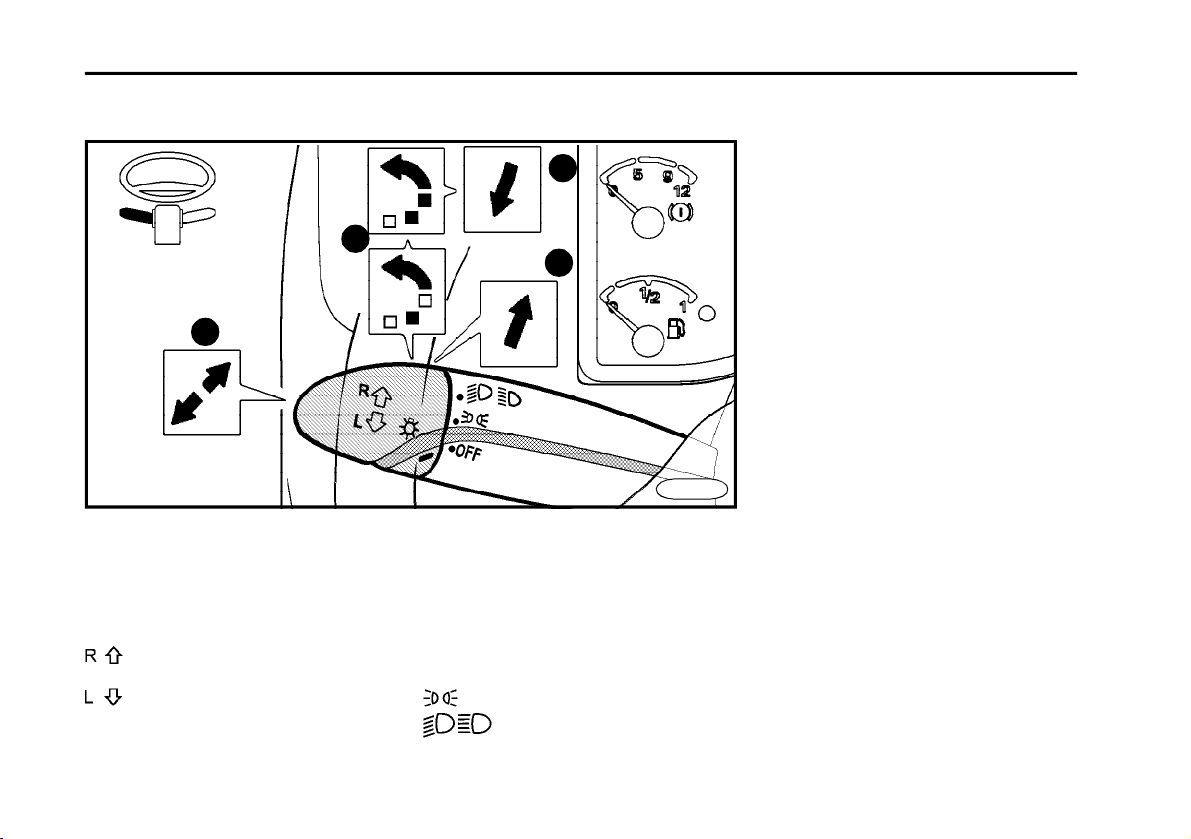

Combined switch over switch

2

1

1 Flasher lamps

Flasher lamps are active when key is in

position ON. They are set by vertical

movement, perpendicular to steering

wheel centreline.

right flasher lamps - shift control

lever upward

left flasher lamps - shift control

lever downward

12

2 Position lamps and low beam

headlamps

They are switched on by turning tip of

control lever.

Lamps that have their symbol aligned

with notch shine

OFF Lamps are switched off

3

4

FN0100

Position lamps are switched on

Low beam headlamps are

switched on (alternatively

main beam headlamps)

n Audible signal indicates open doors

and burning lights.

3Low and high beam switch

over

n To switch on high beam headlamp,

press control lever in direction from steering wheel (high beam is indicated by

indicator lamp).

n Switching over is performed by pull-

ing control lever to original position.

4 Headlamp flasher

n Pull slightly control lever to steering

wheel (high beam indicator lamp are

switched on).

n Lamps glow for the time of holding

the lever.

5 Windscreen washer

n Wiper and washer are active when

key is in position ON.

n Washer is switched on by pressing

to the end of control lever. Washer pump

is activated for the time of pressing the

switch.

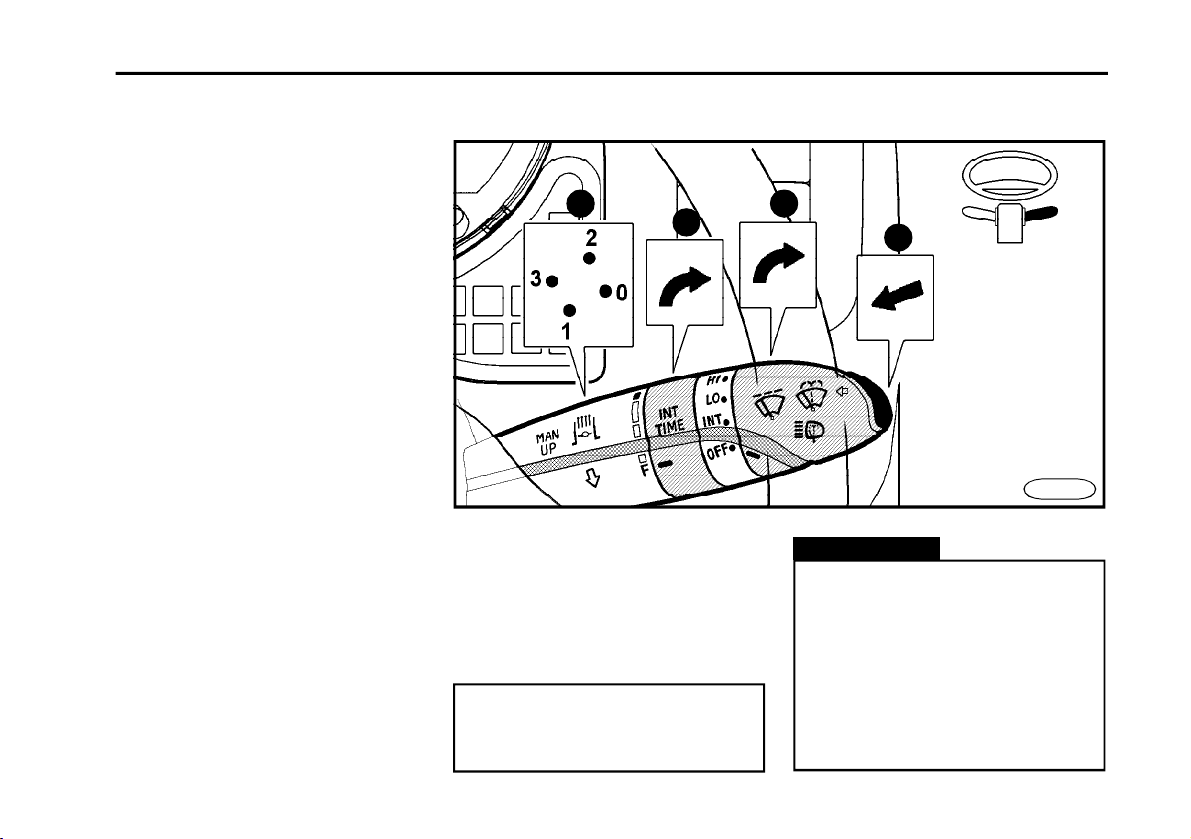

6 Windscreen wiper

It is switched on by turning the end of

control lever:

OFF Wiper is switched off

INT Position for selection of pulsating

wiper time interval (in this position

it is possible to select arbitrary in

terval that is gradually controlled

by rotary ring (item 7).

LO Slow and uninterrupted wiping.

HI Fast and uninterrupted wiping.

7 Selector of pulsating wiping

interval

Interval is the shortest in position F,

turning of ring increases the interval.

D E S C R I P T I O N

8

7

6

5

FN0110

8 Exhaust brake

Position 0 - push combined switch in

direction from driver forwards and downwards - the engine brake is switched off.

Position 1 -pull the switch in direction to

driver backwards and downwards - the

engine brake is is on during operation

of break pedal.

Position 2 - push the switch in direction

from driver forwards andupwards - the

engine brake is on after too sening

*

accelerator pedal (at revolutions higher

than idle speed).

Position 3 - pull the switch in direction to

driver backwards and upwards - the

engine brake is on after loosening accelerator pedal or during operation of

break pedal as well.

It is recommended to engage &

disengage the engine brake at least

once a week - engine brake service-life is extended in this way.

Warning!

n By actuating the accelerator pedal - the engine brake is disengaged

automatically from its action.

n Action of the engine brake is

signalled by a warning lamp.

n Signalling by the warning lamp

depends on action of the engine

brake, not at all on the switch position.

13

D E S C R I P T I O N

Controls

1

2

1Auxiliary drive

n It is engaged when vehicle is motion-

less when engine speed is low for about

6s.

n When engine is running, it is neces-

sary to press clutch pedal.

n Engaged drive is indicated by indica-

tor lamp.

8

7

*

11109

6

5

2Differential lock engaging

n It is engaged when vehicle is motion-

less when engine speed is low for about

6s.

n Use only for the time necessary to

overcome more severe driving conditions.

n Engaged lock is indicated by indica-

tor lamp.

3

4

FN0125

Warning!

It is possible to engage items 1. and

2. only under air pressure higher

than 0.55 MPa - otherwise engaging

isn‘t reliable.

It is recommended to engage &

disengage the differential lock at

least once a week - differential lock

service-life is extended in this way

(it is effective especially for the

EATON final drives).

3 Warning lights

n Indicated by lamp, placed in control.

n It is possible to switch on even when

ignition is switched off.

4Outside rear-view mirror

heating

It is indicated by bulb in control.

Warning!

Allow heating to operate for needful time.

14

D E S C R I P T I O N

5Rear fog lamps

n It is possible to switch rear fog lamps

on only when low beam, high beam or

front fog lamps are switched on.

n Owing to dazzle effect they are al-

lowed to use under fog, heavy rain and

snow conditions.

n It is indicated by bulb in control.

6Front fog lamps

n Fog lamps shine when position

lamps and low or high beam lamps are

switched on.

n It is indicated by bulb in control.

7Cargo space illumination

It is indicated by bulb in control.

8Air conditioner

n Cooling device operates only when

engine is running.

n Air conditioner does not operate, when

rotary switch of blower is in off position.

n Signalled by bulb in control.

*

*

9Reset / coast

ISBe

n It resets speed, adjusted on cruise

control.

n It is possible by this switch to reduce

revolution of engine during drive or with

P.T.O..

10 Cruise control switch

ISBe

n It is used for switch ON cruise control

or P.T.O..

11 Set / accelerate

ISBe

n It sets real speed to memory of cruise

control.

It is possible to increase revolution of

engine during driving or using P.T.O..

n During diagnostic testing, of switch

pressing will set next defect code.

FN0135

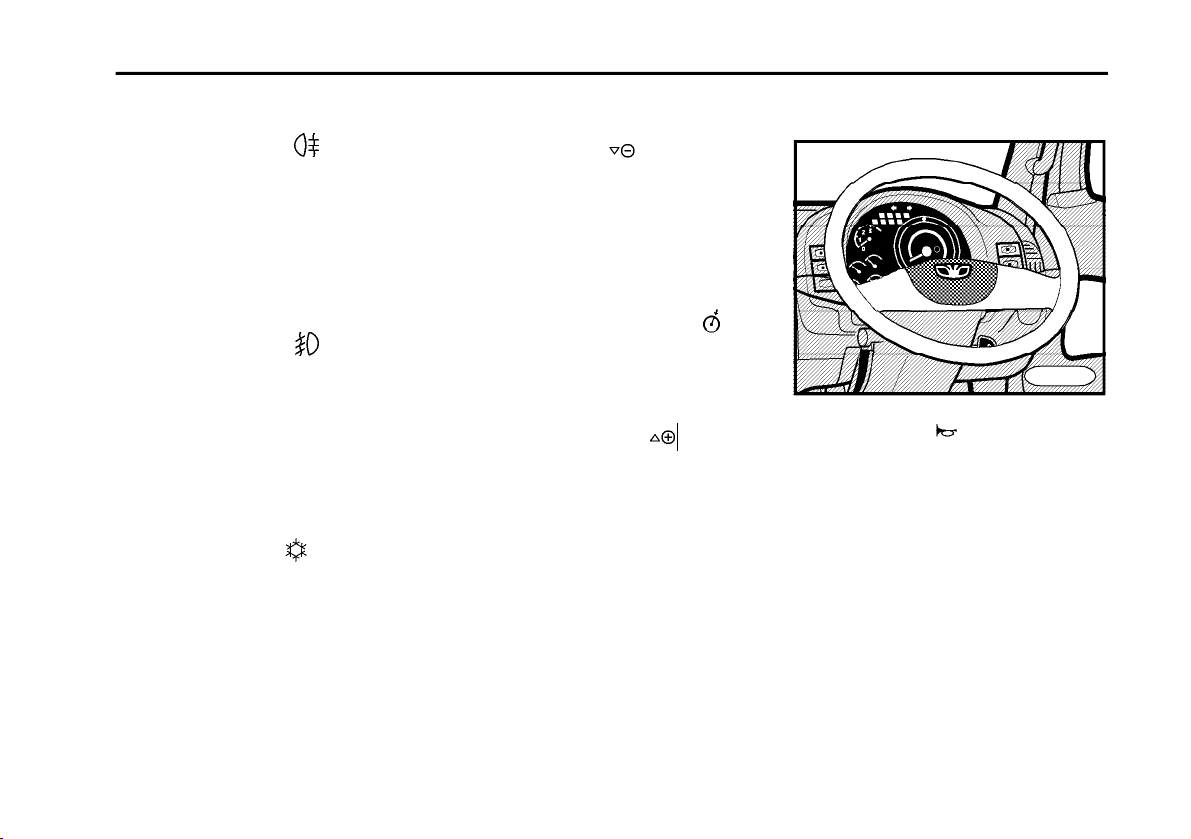

Acoustic horn

Control of acoustic horn is located in the

centre of steering wheel.

15

D E S C R I P T I O N

Cruise control

ISBe

FN0136

n Cruise control keeps adjusted speed

(engine revolution during driving or using P.T.O.) without using accelerator pedal.

n Three control elements in central

panel of dashboard are used.

n Cruise control begins operation

above approx. 48 km/h, using P.T.O. up

to 48 km/h (optional).

Adjustment of cruise control

n Press ”Cruise control” switch ON.

n Reach required speed and than

press shortly switch ”Set/accelerate”:

Now the speed is adjusted in memory

and the engine will keep this speed

without using accelerator pedal.

n It is possible to increase speed by

accelerator pedal . After releasing pedal, the speed of the vehicle will be influenced again by the cruise control (of

course, ”Cruise control (main)” switch

must be in the ON position.

n All functions will be cancelled after

actuating clutch pedal, brake pedal or

by switching ”Cruise control” switch to

OFF position. Operation of cruise control will be restored by short pressing of

switch ”Reset / coast” it means that it is

not necessary to adjust cruise control

again.

Adjustment of P.T.O. revolutions

at parking of vehicle.

n Adjustment of P.T.O. revolutions when

the truck is at stand still.

n Press switch "Cruise control".

n Increase revolutions by pressing

"Set / accelerate" switch (range of adjustable revolutions is 950 - 3000 rev./

min.). By holding switch, revolutions in

crease continuously. By pressing

switch, revolutions increasle by steps

(approx. 25 rev./min.).

n By pressing switch "Reset / coast",

1200 rev./min. will be set automatically.

Warning!

n If cruise control is not used,

”Cruise control” switch must be in

the OFF position.

n Speed of the vehicle can be influenced by climbing or by weight of

load . Therefore use cruise control

only during driving on level ground

or when differences of landscape

elevation are only small.

16

Diagnostic sockets

4

3

D E S C R I P T I O N

1 Socket for ABS diagnostics

2 Socket for engine diagnostics

ISBe

2

3 Switch of engine diagnostics

ISBe

4 Fuse box for voltage changer

(fuses 2x 5A)

1

n Diagnostic sockets are placed un-

der package compartment in the instrument panel.

n Access is facilitated after removing

bottom of the package compartment

that is loosened by rotating two turnable

holders (rotation direction is marked on

the cover).

FN0132

17

D E S C R I P T I O N

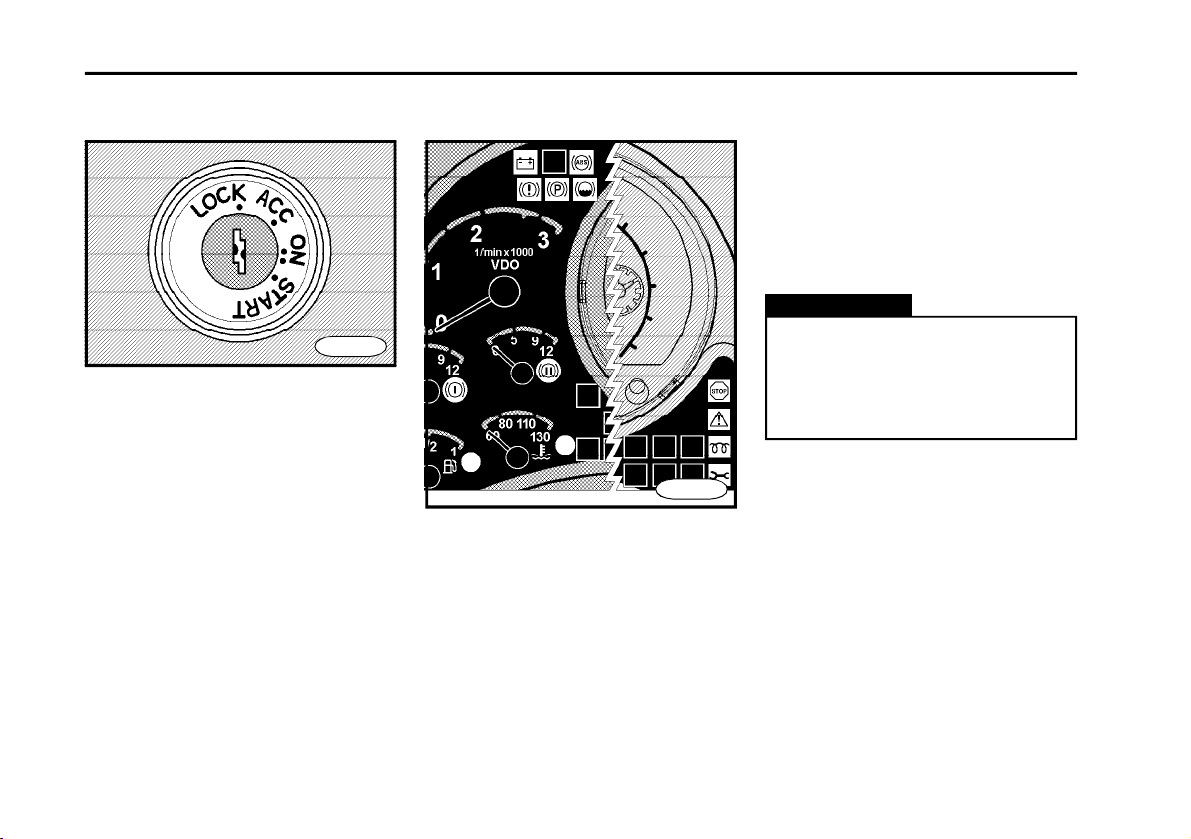

Switchbox and steering lock

FN0140

Switching positions

n Position "LOCK"

Only in this position, it is possible to

insert and remove ignition key. Merely

recording speedometer, electric clock

or radio are connected. Only in this position, steering wheel shaft is automatically locked.

n Position "ACC"

Steering is unlocked, electric circuits

that are connected through switchbox

are without voltage. After switching over

from position "ON" to this position, en-

gine is stopped.

18

FN015cu

n Position "ON"

Following indicator lamps glow: (see

fig.)–battery charging,

only D432)

, brake system malfunction,

(engine lubrication

parking brake, minimum level of brake

liquid, glowing plugs, ABS, coolant temperature, fuel reserve. In the case of

engine ISBe, also following indicator

lamps glow:engine–stop, engine–

warning, engine–maintenance. After few

seconds,only following indicator lamps

remain to glow: battery charging,

lubrication only D432)

, possibly glowing

(engine

plugs. After glowing indicator lamp will

go out, engine is ready to start. Electrical

circuits, connected to switchbox, are

under voltage.

Warning!

If after short time any indicator

lamp, which is tested only itself,

will glow, it is necessary to follow

Chapter "Malfunction and their remedy".

n Position "START"

The engine can start only if gears are

disengaged, without using accelerator

pedal. Position is not locked. For restarting, turn back ignition key to position "ACC" - that prevents from restarting of running engine that could result in

starter motor damage.

Warning!

n Function of switchbox is assured

when battery master switch is on.

n Do not switch off battery master

switch or disconnect battery terminals when engine is running to

prevent alternator or some electric device damage.

D E S C R I P T I O N

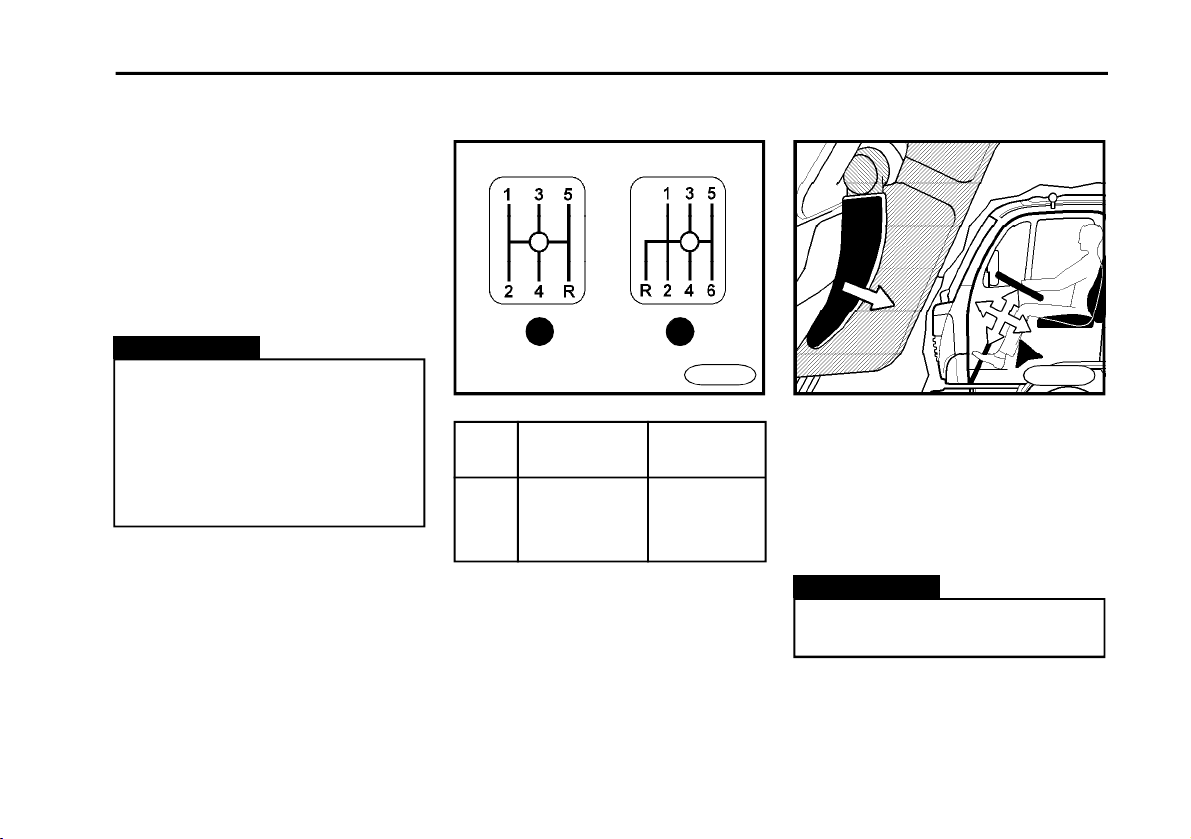

Gear-shifting lever Steering-wheel inclina-

tion adjustment

1

Position Gearbox type Number of

1 ZF S5-42 5

2 ZF 6 S 850 6

2

gears

FN0160

FN0170

n Release steering wheel pulling con-

trol lever in direction to yourself and

adjust steering wheel position to required position.

n After adjustment, press control lever

in forward direction up to stop.

Gear changing is performed mechanically by means of gear shifting lever,

when clutch pedal is depressed.

Warning!

To adjust steering wheel during

drive isn‘t acceptable.

19

D E S C R I P T I O N

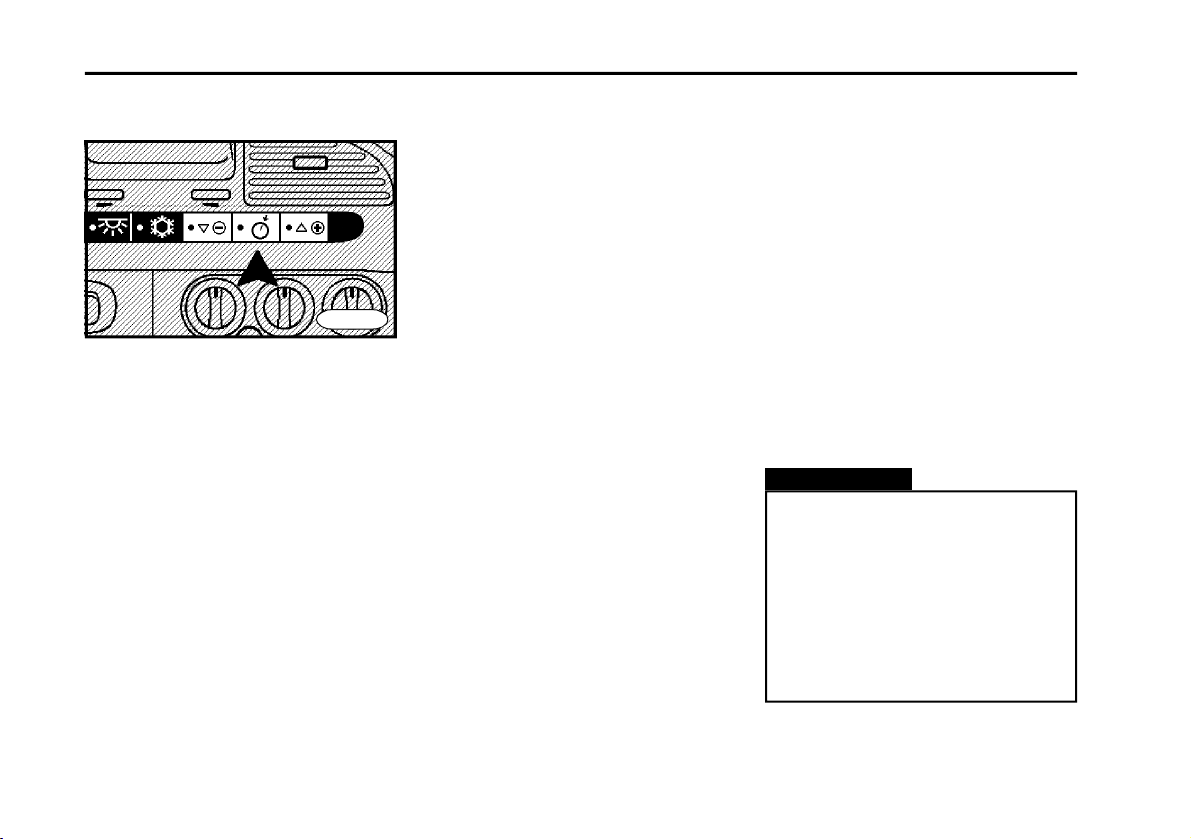

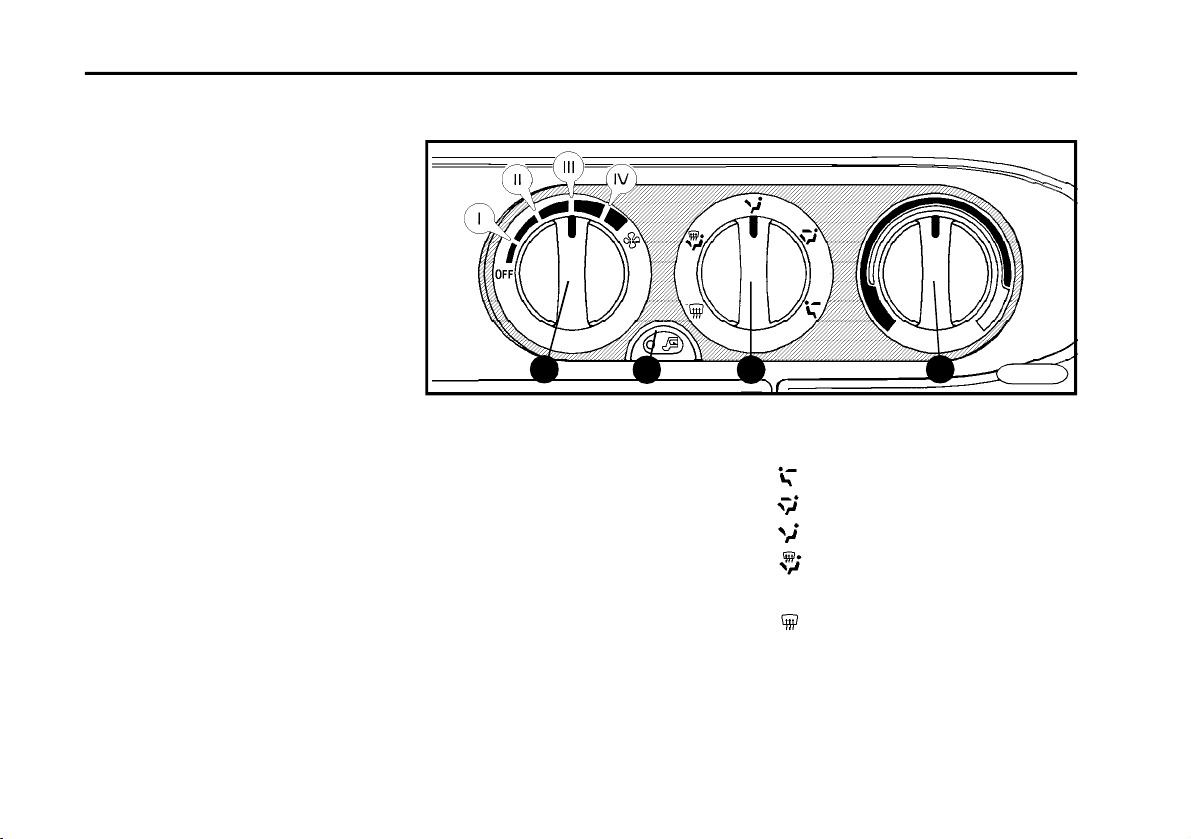

Heating and ventilation

n The truck cabin is heated by a hot

water heating. It is possible to use it

after coolant is heated up in the

cooling&heating water circuit after the

engine is started.

n Heating is controlled and regulated

by turning of heating controls located

on instrument panel.

n Heating valve control (item 3) regu-

lates quantity of water flowing through

heating element and so temperature

of outlet air (when turning to red field,

hot air is produced and vice versa).

n Control (item 1) regulates fan speed

and so quantity of air that comes through

the system. Speed is adjustable in four

steps.

n Air flow direction control (item 2) en-

ables to select direction of air outlet

(The way of cab heating).

n Button (item 4) switches on or off

mode of circulating air in cab.

n Rib inclination (item 5) of air outlet

can change angle of air flow. Quantity of

air flowing from individual vent hole can

be controlled by wheels (item 6).

24

1Heating fan control

2Air flow direction control

to heads of crew

to legs and heads of crew

to legs of crew

to legs, windscreen and side

windows

to windscreen and side windows

3Heating valve control - temperature

regulation of outlet air.

4Mode of circulating air.

31

FN0185

20

D E S C R I P T I O N

5

6

Removing hoarfrost and bedewed windows

n (item 1) up to stop to position IV.

n (item 3) to the left up to stop.

n (item 2) turn to position .

n Close vent holes by control wheels.

Removing icing from

windscreen

n (item 1) up to stop to position IV.

n (item 3) to the left up to stop.

n (item 2) turn to position .

n Switch mode of air circulation,

n Close vent holes by control wheels.

5

5

Maintaining windows in status

without bedew under higher

humidity.

When windows are constantly bedewed (e.g. in rain), it is necessary:

n (item 1) to position II or III.

n (item 2) turn to position .

n (item 3) if necessary to area of heating.

Ventilation

n (item 1) to required position.

n (item 3) to the right stop.

n (item 2) turn to position

Pleasant heating

n (item 1) to position II or III.

5

66

FN0195

n (item 3) to required heating output.

n (item 2) turn to position .

Maximum heating

n (item 1) to position IV.

n (item 2) turn to position

n (item 3) to the left up to stop.

n Switch on mode of circulating air.

Warning!

Heating output is dependent on coolant temperature. Maximum heating output is obtained after heating

engine to operation temperature.

21

D E S C R I P T I O N

Air conditioner*

6

7

n Air conditioner is combined cooling

and heating equipment.

n Cooling unit of air conditioner cools

air and removes moisture out of air.

n Cooling device operates only when

engine is running.

6 7

5

2

Controls

n Air conditioner is switched on (off) by

control (item 1) designated with symbol (indicated by bulb located in

control). n Air conditioner doesn‘t

operate when rotary switch is in off

position.

n Control of heating valve (item 4) reg-

ulates temperature of inlet air (turning

to red field - hot air and vice versa). It is

possible to use it even when air conditioner is switched on.

n Control (item 2) regulates fan speed

and so quantity of air passed through

2

3

6

4

system. Speed of air flow is adjustable

in four steps.

n Control of air flow direction (item 2)

enables to select direction of air outlet

(way of cab heating)

n Button (item 5) switches on (off)

mode of air circulation in cab (indicated

by bulb located in control).

n Travel of air outlet fins (item 6) can

change angle of air flow. Air quantities

regulated by wheels (item 7).

7

FN0195

6

22

Optimal cooling

n (item 1) to requested position (posi-

tions II and III are optimal)

n (item 3) up to stop to the right, tem-

perature can be regulated according to

need by means of turning to the left.

n (item 2) turn to position

n Press switch with symbol (bulb

in control glows)

n In this mode, exterior air is sucked

and cooled.

2

Maximum cooling

n Close all windows

n (item 1) to position IV

n (item 3) up to stop to the right

n (item 2) turn to position

n Press control with symbol . (bulb

in control starts to glow)

n Switch mode of air circulation on

31

FN0185

D E S C R I P T I O N

Warning!

It isn‘t recommended to smoke

when air circulation in cab mode is

on.

Warning!

n If vehicle is parked on direct

sun, open windows before switching on of air conditioner.

n It is recommended to operate

air conditioner at least once a

week - it extends life of air conditioner.

23

D E S C R I P T I O N

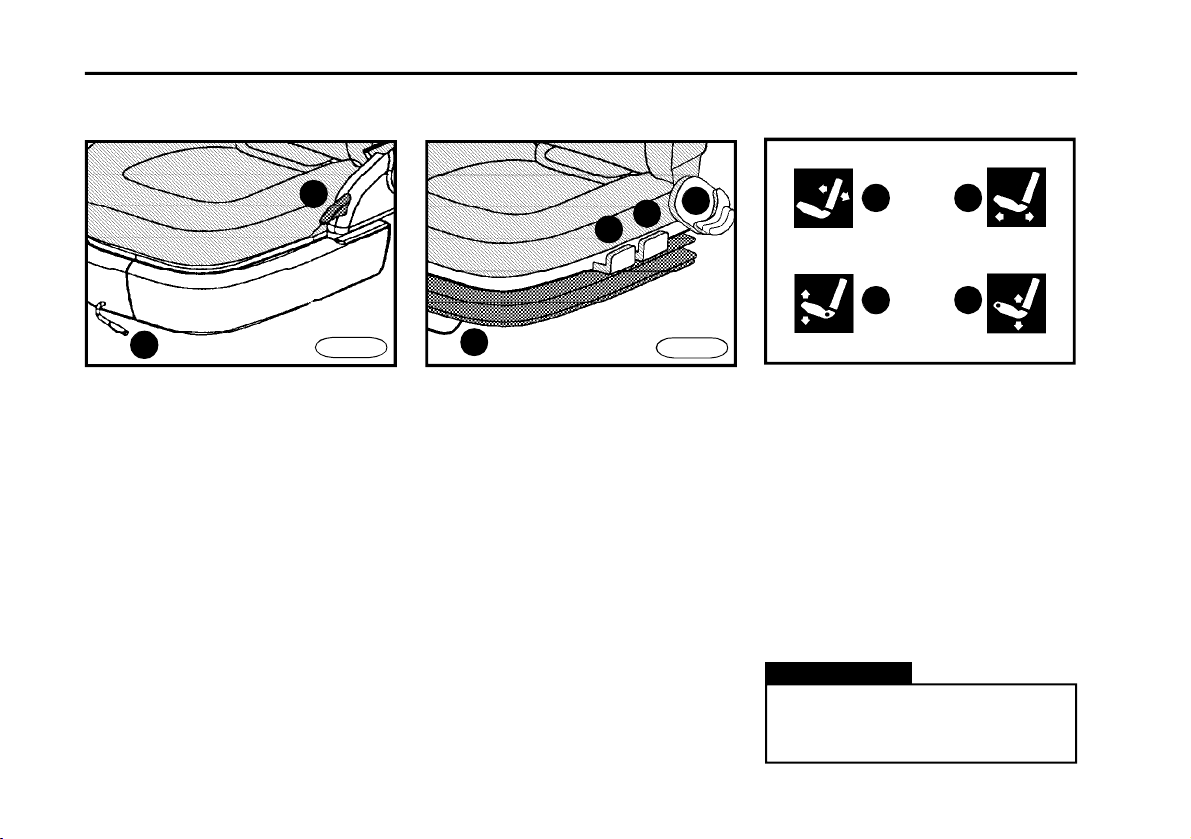

Seats

1

2

Adjustment of seat backrest

inclination (a)

Tilting of seat backrest backwards is

performed by control lever (item 1) lifting and pressing to backrest in backward direction.Tilting of seat backrest

forwards is performed by control lever

(item 1) lifting and slight pressing to

backrest in backward direction and consequential release of backrest that automatically tilts forwards. The backrest

is secured by releasing the small lever.

Adjustment in longitudinal

direction (b)

n Longitudinal shift is released by pull-

ing control lever (item 2) upwards and

24

FN0200

1

4

3

2

then it is possible to adjust seat to

required position. The seat is released

by releasing the small lever.

n Seat should be adjusted so that driv-

er can safely control pedals.

Adjustment of seat squab

incline (c) and height (d) on

the driver´s pneumatically

sprung seat

n Front part of seat is adjustable by

lever (item 3).

n Rear part of seat is adjustable by

lever (item 4).

n Regulation in upward direction is

performed in released status.

*

FN0210

a b

c d

Proper adjustment of seats

n Backrest should be adjusted so that

driver could hold steering wheel in its

highest point by slightly wrinkled hands.

n Quick and safe manipulation with

necessary controls that are important

for driving must be secured.

n It must result in free holding of body

for maximal protective effect of safety

belts.

Warning!

For precautionary reasons, driver‘s seat is allowed to adjust only

when vehicle stops.

Headrests

FN0220

n Headrests are height-adjustable.

n For height adjustment of headrest,

press stop in direction to back wall.

n Adjust headrest so that its position

recommends to physical dimensions

of driver‘s figure.

D E S C R I P T I O N

Warning!

n Good adjustment of headrest effectively supports nape during rear

impact.

n For precautionary reasons, driver‘s headrest is allowed to adjust

only when vehicle stops.

25

D E S C R I P T I O N

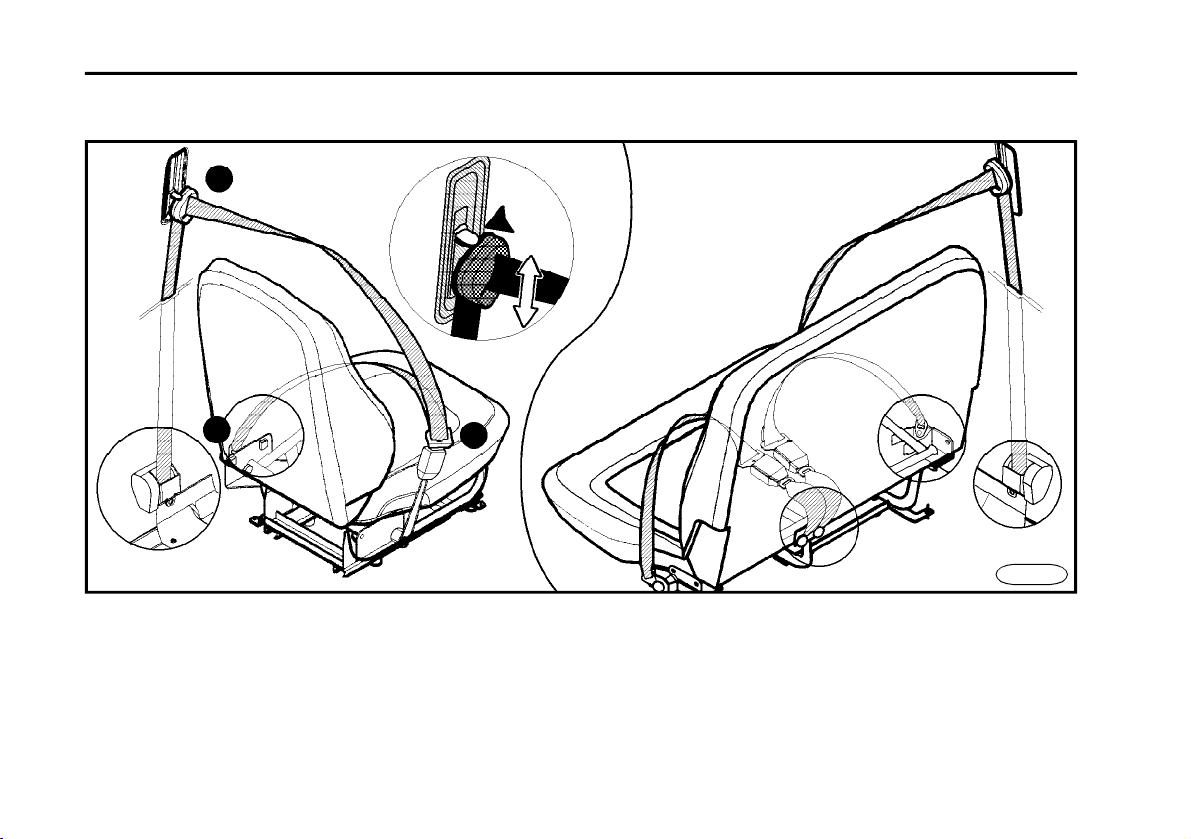

Safety belts

FN0230

n The truck cabin is equipped with pre-

loaded three-point seat belts of outward seats.

26

n The middle seat features two-point

seat belt with mechanical adjustment.

n Safety belts are used as passenger

protection in case of accident.

n Safety belts must be used during

each drive - even in city traffic.

D E S C R I P T I O N

Use of safety belts

n Necessity to use safety belts is sig-

nalled by relevant indicator lamp*.

n Take safety belt catch and slowly

draw over thorax and pelvis.

n The belt must fit tightly to centre of

shoulder and pelvis.

n When the belt is during pulling out

locked, release it and let it wind back

and than pull it out again.

n Insert catch into belt lock that corre-

sponds to the seat.The belt is properly

fixed after snap into lock.

n The belt is released after pressing

red lock stopper.

Height-adjustment of safety

belts

*

n Due to height adjustable upper bear-

ing of belt, it is possible to adapt belt

best way to physical dimensions of figure.

n For height-adjustment, press button

in downward direction, turn upper belt

bearing in direction to yourself (upwards) and adjust to requested position.

Warning!

n Belt must not lie over rigid or

easy fractured objects that could

be e.g. in your clothing, in pockets.

n Safety belts that went through

accident or they are damaged must

be unconditionally replaced by new

belts.

n Take care of the belt not to be

twisted and to lie over pelvis and at

least over soft parts of body.

n Maximum effect can be reached

with proper seating position in cab.

n One seat belt is allowed to bind

only one person.

n Maintain safety belts clean (dirt

influences on winding mechanism).

For cleaning, it is recommended to

use soft soap solution.

n When safety belt is damaged,

let it replaced.

27

D E S C R I P T I O N

Rear view mirrors

n Vehicles are equipped with heated

rear view mirrors.

n Heating is switched on by control

that is placed on instrument panel and

it is indicated by indicator lamp placed

directly on control.

n Heating is used for necessary time.

Warning!

n For safety reasons, mirrors

must be adjusted before drive.

n It is necessary to pay attention

of judgement about size and distance of vehicle or another objects

that are visible in side convex mirror (objects look smaller and they

are displayed more distant then it

is in reality.

Rear view mirror remote

control

n Turn control to select between left

and right mirror.

To the left - left mirror - position A.

To the right - right mirror - position B.

n Requested position of mirror is

reached by skewing of four-position

control.

*

A

B

FN0240

28

D E S C R I P T I O N

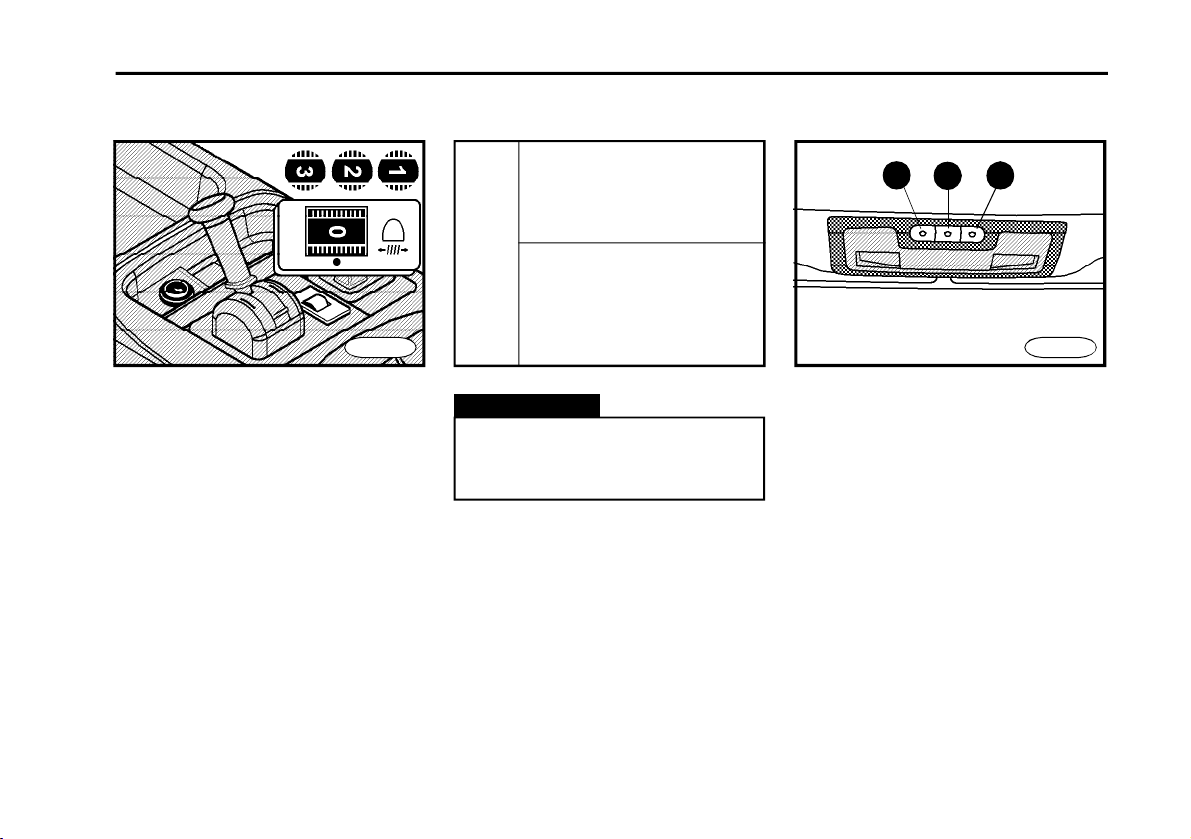

Headlamps inclination adjustment

K 1 2 3

N 1 2 3

L 1 2

FN0255 FN0260

n Regulation wheel changes head-

lamp inclination.

n Basic adjustment is performed with

vehicle without cargo load (notch of

adjustment control aligned with nought).

n Payloads of given version are men-

tioned in table Weights and weight on

axles.

E 1 2

Warning!

It is obligatory for driver to adjust

headlamps inclination according

to actual vehicle load with cargo.

Percentage of payload

30% 50% 70% 100%

Cab interior illumination

1

2 3

n Ceiling light bulbs are switched on

by controls located directly on lamp.

n Controls (item1) and (item 2) switch

on (off) illumination of driver‘s side.

n Control (item 3) switches on (off)

illumination of front-seat passenger ‘s

side.

29

D E S C R I P T I O N

Digital clock

n Button „HOUR“ adjusts individual

hours.

n Button „MIN“ adjusts individual min-

utes.

n Button „SET“ clears minutes to whole

hours.

n Button „DISPLAY“ illuminates clock

when switchbox is in position „LOCK“.

Clock is illuminated for time of button

holding.

*

FN0270

Socket / cigarette

lighter

A

n Socket (pos. A) may be used for con-

nection of cigarette lighter or additional

current consumer having 24V supply.

To use the socket * (pos. B) for current

consumers having 12 V supply

n Cigarette lighter is switched on by

pressing to extension piece. After of

heating of heating element in lighter,

extension piece springs up. Remove

heated lighter and use it immediately

(element quickly looses heat energy).

Warning!

n During manipulation with lighter

take a good care of burn.

n When lighter does not spring up

after about 30 seconds, it is necessary

to remove it to prevent heat damage.

B

FN0280

Sun visors

FN0295

n Sun visors are located above wind-

screen in ceiling panel.

n They can be lowered according to

need.

n Adjust sun visors to protect against

bedazzlement.

30

Loading...

Loading...