Page 1

Hang for easy reference.

®

Monarch

®

1115

®

Labeler

Operating Instructions

TC1115OI Rev. BE 12/07 ©2006 Paxar Americas, Inc.

a subsidiary of Avery Dennison Corp. All rights reserved.

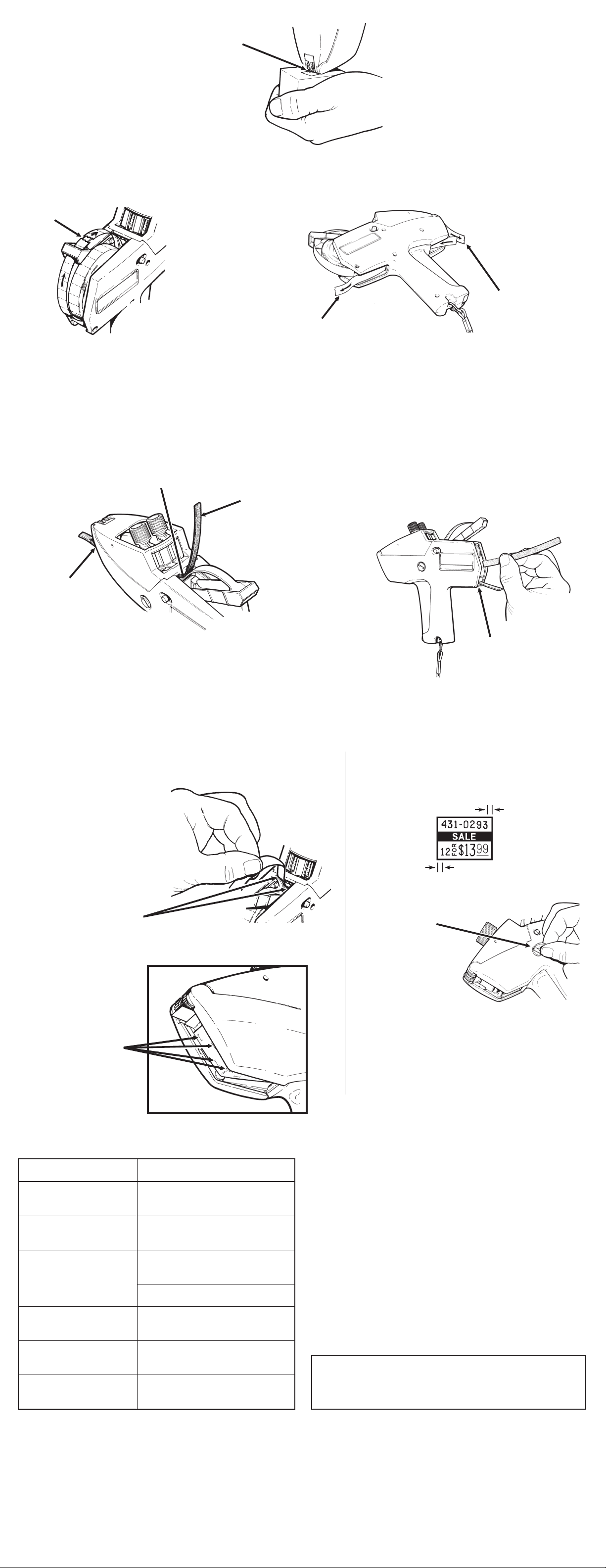

LOADING LABELS

Slide label roll between hubs.

1

Discard first fourteen labels

and backing paper.

Hub

Pull backing paper to the end of the

4

operating lever, separating labels from

backing paper.

2

wheels until about twelve labels come out.

Brake

Wheels

LOADING LABELS & SETTING PRINT BANDS

Squeeze operating lever and feed

label strip over spring and under brake

Label Exit

Operating

Lever

Feed label strip up under plate until

3

label roll until loop is removed.

5

strip as shown.

two labels come out. Rewind

Label Exit

Plate

Loop

Tear backing paper evenly

between cuts, close to the end of the

Discarded

Labels

Hold labeler upside down and while

6

squeezing operating lever, feed

backing paper into slot. Squeeze operating

lever eight times until backing paper comes

through the rear exit.

Slot

Backing

Paper Exit

Backing

Paper

If backing paper does not become

7

taut and exit at rear: Turn labeler

upside down, squeeze operating lever and

pull backing paper out of slot. Repeat

steps, 4, 5, and 6.

SETTING PRINT BANDS

Pull the knob until the

1

indicators point to

the desired band.

Turn the knob untill the indicators

2

point to desired character or blank.

Set all bands and push the knob

3

in all the way.

INKING

Move two latch buttons toward

1

label roll and swing top cover

away from print head.

Top Cover

Knob

Blank Print

Positions

Fold a piece of scrap backing

2

paper.

Indicator

Print a sample label to insure

4

information is correct.

If the character prints UPSIDE

5

DOWN, turn the band until you can

read the characters correctly. The desired

character may be coated with ink.

Insert folded backing paper

3

between ink roll and carrier.

Pull to snap old ink roll free.

Latch

Button

Cut off end of ink roll package.

4

Using package to protect fingers,

slide carrier into package and snap new ink roll

into carrier.

Cap

End

Carrier

Snap top cover closed.

5

INKING

Page 2

OPERATION

Squeeze and release operating lever.

1

Pull labeler to apply label.

3

(Gentle wiping motion.) DO NOT POUND labeler when

Black

Rollers

Place black rollers on item to

2

be labeled.

applying labels.

REMOVING SUPPLIES

Tear label strip at label roll as

1

shown and pull label roll from

between hubs.

Tear

MAINTENANCE

With label roll removed, check

1

label track and backing paper

track for stray labels.

Brake

Wheels

Tear backing paper strip.

2

Pull label strip from labeler.

Pull Strip

Clear label track by squeezing

2

operating lever and feeding label

removal strip under brake wheels and out

front of labeler.

Removal

Strip

Squeeze and release operating

3

lever until backing paper is free

to be pulled out.

Tear Backing

Paper

To clear backing paper track:

3

a. Insert label removal strip in end of

track to loosen stray labels.

b. Insert label removal strip as

shown, using corner to remove stray

labels.

Front

Exit

End of

Track

OPERATION, REMOVING SUPPLIES & MAINTENANCE

LUBRICATION PRINT ADJUSTMENT

If adhesive buildup occurs, lubricate as shown

with labels loaded.

Monarch lubricant is recommended.

Print location is correct when extreme

1

right-hand and left-hand characters are located

as shown.

Approx. 1/16 inch (1.6 mm)

Approx. 1/16 inch (1.6 mm)

Lubricate:

One drop each side of label

chute between spring and

backing paper.

Lubricate:

One drop each spot on

backing paper (total of

four drops). Spread

with finger.

DO NOT OVER

LUBRICATE!

TROUBLESHOOTING

Trouble Remedy

Place small coin in feedwheel button slot.

2

Feedwheel

Button Slot

Push feedwheel button IN COMPLETELY

3

and turn slightly clockwise if print is too far left or

slightly counterclockwise if print is too far right.

Adjustment made without completely depressing button

are temporary.

Repeat steps 2 and 3 until print is correctly

4

located.

Characters not printing.

Bands not inked.

Labels feed slowly or

hesitantly.

Labels will not feed. Reload per instructions. Use

Print incorrectly located. Follow Print Adjustment

Printing smeared or

distorted.

Printing too light. Squeeze operating lever harder

Check ink roll per Inking

instructions.

Follow Lubrication and

Maintenance Instructions.

correct supplies.

Follow Maintenance instructions.

instructions.

Print several labels (15 to 25) to

use up excess ink.

during operation.

Visit www.paxar.com for sales, service, supplies, information, and telephone

numbers of our locations throughout the world.

Warranties

Product warranty statements may vary from country to

country. Please contact the authorized PAXAR/Monarch

representative in your country for details.

TOLL FREE:

1-800-543-6650 (In the U.S.A.)

1-800-263-4650 (In Canada)

LUBRICATION, PRINT LOCATION, & TROUBLESHOOTING

Loading...

Loading...