Avdel 07551 Instruction Manual

I n s t r u c t i o n M a n u a l

Threaded Insert Power Tool

Pass onto user to read and keep for reference

07551

AVDEL policy is one of continuous development. Specifications shown in this document may be subject to changes which

may be introduced after publication. For the latest information always consult Avdel.

AIR PRESSURE Minimum - Maximum 5 - 8 bar 70 - 120 lbf/in

2

FREE AIR VOLUME REQUIRED @ 5 bar / 75 lbf/in

2

480 litres/min 17 ft3 /min

MOTOR SPEED @ 75 lb/in

2

minimum 950 RPM

CYCLE TIME Approximately 4 seconds

NOISE LEVEL 80 dB(A)

WEIGHT Without nose equipment 1.55 kg 3.4 lb

VIBRATION Less than 2.5 m/s

2

8 ft/s

2

S P E C I F I C A T I O N S F O R 0 7 5 5 1 T O O L

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

Fault Diagnosis Table 16

Fitting/Servicing/Components 8-9

Regular Servicing 10

Maintenance 11-13

General Assembly & Parts List 14-15

C

O N T E N T S

1

S A F E T Y

General 2

Specific to 07551 Tool 3

F A U L T D I A G N O S I S

N O S E A S S E M B L I E S

S E R V I C I N G

Air Supply 6

Operating Procedure 6

Clutch Adjustment - Accessories 7

P U T T I N G I N T O S E R V I C E

General 4

I N T E N T O F U S E

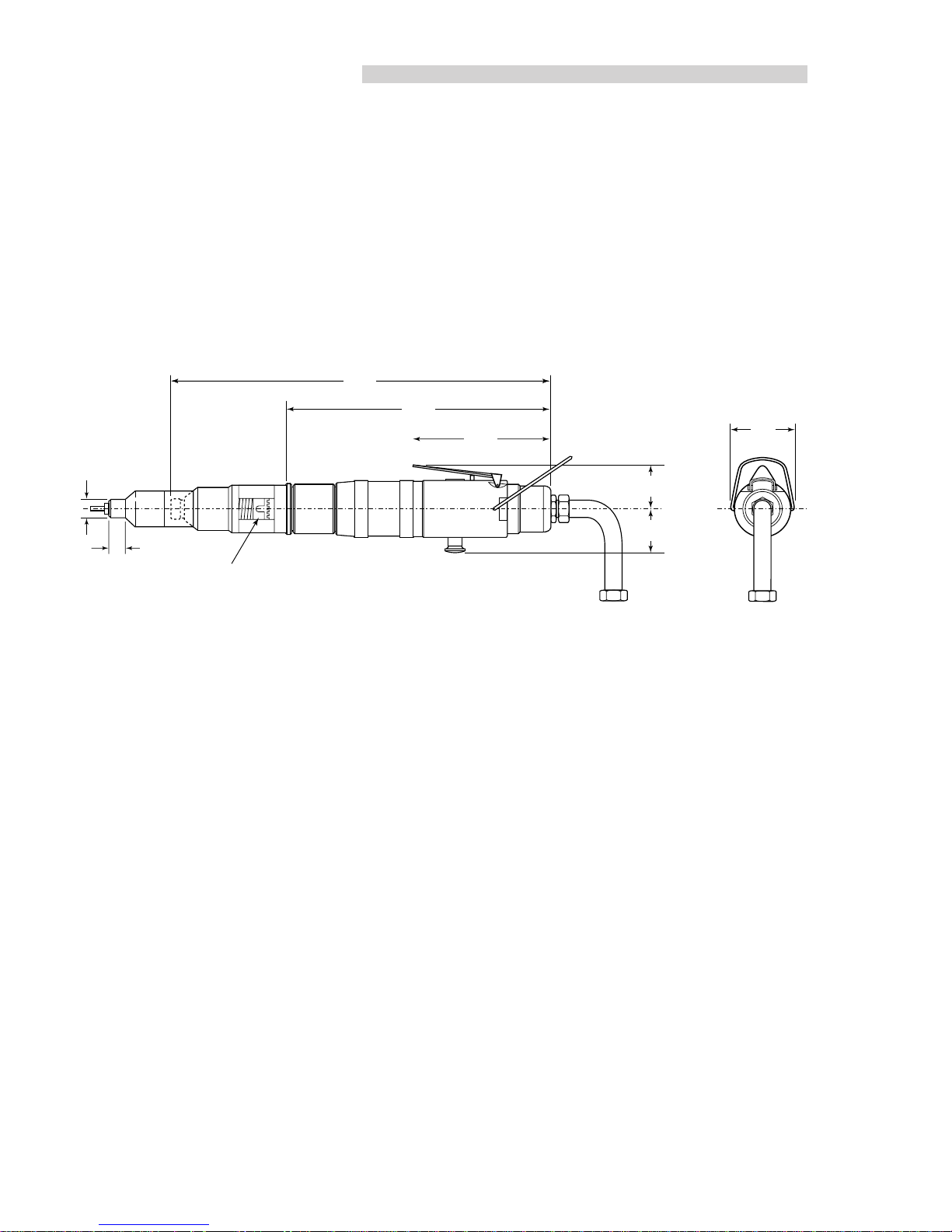

Tool Dimensions / Selection 4-5

S

A F E T Y

2

This instruction manual must be read with particular attention to the following safety rules,

by any person installing, operating, or servicing this tool.

DO NOT USE OUTSIDE THE DESIGN INTENT.

DO NOT USE EQUIPMENT WITH THIS TOOL/MACHINE OTHER THAN THAT

RECOMMENDED AND SUPPLIED BY AVDEL.

ANY MODIFICATION UNDERTAKEN BY THE CUSTOMER TO THE TOOL/MACHINE,

NOSE ASSEMBLIES, ACCESSORIES OR ANY EQUIPMENT SUPPLIED BY AVDEL OR THEIR

REPRESENTATIVES, SHALL BE THE CUSTOMER'S ENTIRE RESPONSIBILITY. AVDEL WILL BE

PLEASED TO ADVISE UPON ANY PROPOSED MODIFICATION.

THE TOOL/MACHINE MUST BE MAINTAINED IN A SAFE WORKING CONDITION AT

ALL TIMES AND EXAMINED AT REGULAR INTERVALS FOR DAMAGE AND FUNCTION BY

TRAINED COMPETENT PERSONNEL. ANY DISMANTLING PROCEDURE SHALL BE

UNDERTAKEN ONLY BY PERSONNEL TRAINED IN AVDEL PROCEDURES. DO NOT DISMANTLE

THIS TOOL/MACHINE WITHOUT PRIOR REFERENCE TO THE MAINTENANCE INSTRUCTIONS.

CONTACT AVDEL WITH YOUR TRAINING REQUIREMENTS.

THE TOOL/MACHINE SHALL AT ALL TIMES BE OPERATED IN ACCORDANCE WITH

RELEVANT HEALTH AND SAFETY LEGISLATION. IN THE U.K. THE “HEALTH AND SAFETY AT

WORK ETC. ACT 1974” APPLIES. ANY QUESTION REGARDING THE CORRECT OPERATION

OF THE TOOL/MACHINE AND OPERATOR SAFETY SHOULD BE DIRECTED TO AVDEL.

THE PRECAUTIONS TO BE OBSERVED WHEN USING THIS TOOL/MACHINE MUST BE

EXPLAINED BY THE CUSTOMER TO ALL OPERATORS.

ALWAYS DISCONNECT THE AIRLINE FROM THE TOOL/MACHINE INLET BEFORE

ATTEMPTING TO ADJUST, FIT OR REMOVE A NOSE ASSEMBLY.

DO NOT OPERATE A TOOL/MACHINE THAT IS DIRECTED TOWARDS ANY PERSON(S).

ENSURE THAT VENT HOLES DO NOT BECOME BLOCKED OR COVERED AND THAT

HOSES ARE ALWAYS IN GOOD CONDITION.

3

In addition to the general safety rules opposite, the following specific safety points must also

be observed:

THE OPERATING PRESSURE SHALL NOT EXCEED 8 BAR - 120 LBF/IN2.

DO NOT OPERATE THE TOOL WITHOUT FULL NOSE EQUIPMENT IN PLACE.

WHEN USING THE TOOL, THE WEARING OF SAFETY GLASSES IS REQUIRED BOTH BY

THE OPERATOR AND OTHERS IN THE VICINITY TO PROTECT AGAINST FASTENER

PROJECTION, SHOULD A FASTENER BE PLACED ‘IN AIR’. WE RECOMMEND WEARING

GLOVES IF THERE ARE SHARP EDGES OR CORNERS ON THE APPLICATION.

TAKE CARE TO AVOID ENTANGLEMENT OF LOOSE CLOTHES, TIES, LONG HAIR,

CLEANING RAGS ETC. IN THE MOVING PARTS OF THE TOOL WHICH SHOULD BE KEPT DRY

AND CLEAN FOR BEST POSSIBLE GRIP.

WHEN CARRYING THE TOOL FROM PLACE TO PLACE KEEP HANDS AWAY FROM THE

TRIGGER/LEVER TO AVOID INADVERTENT START UP.

ALWAYS ADOPT A FIRM FOOTING OR A STABLE POSITION BEFORE OPERATING THE

TOOL AND BE AWARE OF A TORQUE REACTION ON THE HANDS WHEN THE TOOL IS

OPERATING, PARTICULARLY DURING THE REVERSING SEQUENCE. GRIP THE TOOL FIRMLY

TO BE ABLE TO COUNTER THE TORQUE REACTION, BUT NOT TOO TIGHTLY.

KEEP HANDS AWAY FROM THE ROTATING DRIVE SCREW AND THE NOSE END OF

THE TOOL. IF A FASTENER BECOMES JAMMED ON THE DRIVE SCREW, SHUT OFF THE AIR

SUPPLY AND DRAIN THE SUPPLY LINE TO THE TOOL BEFORE ATTEMPTING TO DISLODGE IT.

THE TOOL IS NOT ELECTRICALLY INSULATED.

THIS TOOL IS NOT DESIGNED FOR USE IN COMBUSTIBLE OR EXPLOSIVE

ATMOSPHERES.

The pneumatic 07551 type tool is designed to place Avdel threaded inserts at high speed making it ideal for batch or flow-line assembly

in a wide variety of applications throughout all industries.

Use the selection table opposite to select a complete tool which will be fitted with the correct nose assembly for the threaded insert

selected. ‘A’ and ‘B’ dimensions will help you assess the accessibility of your application.

It is also possible to order the base tool only (part number 07551-00400). For details of nose assemblies see pages 8 and 9.

4

I

N T E N T O F U S E

Dimensions shown in bold are millimetres.

Other dimensions are in inches.

A

B

299

11.75

299

11.75

216

8.50

117

4.60

41

1.63

33

1.31

44

1.75

TORQUE

ADJUSTING

APERTURE

Loading...

Loading...