753 MkII type

7530-07532

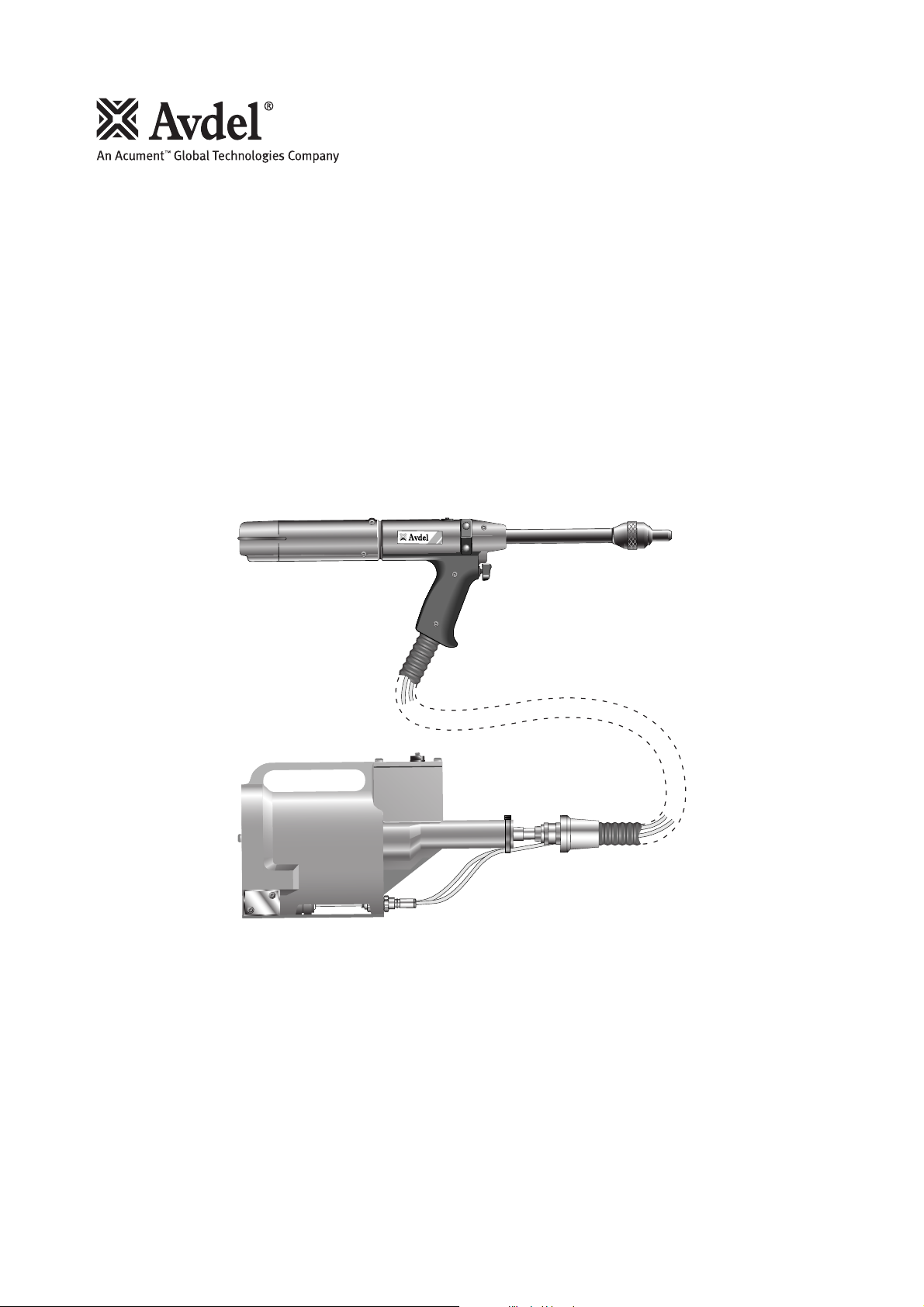

Hydro-Pneumatic Power Tool

Druckluftgerät

Outil oléo-pneumatique

Attrezzo oleopneumatico

Instruction Manual

Manuel d’instructions

Betriebsanleitung

Manuale d’instruzione

0753

TYPE

3

Contents

Safety Rules 4

Specifications

Specification for 0753 MkII Type Tool 5

Specification for 07531 Intensifier 5

Intent of Use 6

Tool Dimensions 7

Putting into Service

Air Supply 8

Mechanical Cursors 9

Cursor 10

Loading and Re-loading the Tool 10-11

Operating Procedure 11

Mandrel Follower Springs Identification 12

and Orientation

Nose Assemblies

Nose Jaws 13

Selecting a Nose Jaw 14

Nose Jaw Selection Tables 15-16

Mandrels and Mandrel Follower Springs 17

Chobert®and Grovit®Selection Tables 17-18

Briv®Selection Tables 19-20

Mandrel Head Types and 'P' Length 20

Avlug®, Avsert®, Avtronic®and Rivscrew

®

21

Selection Tables

Servicing the Tool

Daily / Weekly 22

Moly Lithium Grease EP 3735 Safety Data 22

Service Kit 23

Maintenance

Dismantling 07530-02200 MkII 24-25

Dismantling 07532-02200 MkII 26-27

General Assembly and Parts List 07530-02200 MkII 28-29

General Assembly and Parts List 07532-02200 MkII 30-31

Intensifier 07531-02200 32-33

Pilot valve 07005-00590 Spares Information 34-35

Priming

Oil Details 36

Hyspin VG 32 and AWS 32 Oil Safety Data 36

Priming Procedure 36

Fault Diagnosis

Symptom, Possible Cause & Remedy 37

Français 41

Deutsch 79

Italiano 117

Avdel policy is one of continuous product development and improvement and we reserve the right to change the specification of any product without prior notice.

Warranty

Avdel installation tools carry a 12 month warranty against defects caused by faulty

materials or workmanship, the warranty period commencing from the date of delivery

confirmed by invoice or delivery note.

The warranty applies to the user/purchaser when sold through an authorised outlet,

and only when used for the intended purpose. The warranty is invalidated if the

installation tool is not serviced, maintained and operated according to the instructions

contained in the Instruction and Service Manuals.

In the event of a defect or failure, and at its sole discretion, Avdel undertakes only to

repair or replace faulty components.

4

Safety Rules

1 Do not use outside the design intent.

2 The Hand Tool and Intensifier have been tested as separate items and combined. They must only be used together and under no

circumstances for any other purposes.

3 Do not use equipment with this tool/machine other than that recommended and supplied by Avdel.

4 Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by Avdel or

their representatives, shall be the customer’s entire responsibility. Avdel will be pleased to advise upon any proposed modification.

5 The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and function

by trained competent personnel. Any dismantling procedure shall be undertaken only by personnel trained in Avdel procedures. Do not

dismantle this tool/machine without prior reference to the maintenance instructions. Please contact Avdel with your training requirements.

6 The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation. In the U.K. the “Health and

Safety at Work etc. Act 1974” applies. Any question regarding the correct operation of the tool/machine and operator safety should be

directed to Avdel.

7 The precautions to be observed when using this tool/machine must be explained by the customer to all operators.

8 Always disconnect the airline from the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

9 Do not operate a tool/machine that is directed towards any person(s) or the operator.

10 Always adopt a firm footing or a stable position before operating the tool/machine.

11 Ensure that vent holes do not become blocked or covered and that hoses are always in good condition.

12 The operating pressure shall not exceed 7 bar (100 lbf/in

2

).

13 The combination of fastener, mandrel, hole size and sheet thickness shall be in accordance with Avdel Specifications.

14 Do not operate the tool if it is not fitted with a complete nose assembly unless specifically instructed otherwise.

15 When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against fastener

ejection, should a fastener be placed ‘in air’. We recommend wearing gloves if there are sharp edges or corners on the application.

16 Take care to avoid entanglement of loose clothes, ties, long hair, cleaning rags etc. in the moving parts of the tool which should be kept

dry and clean for best possible grip.

17 When carrying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent startup.

18 Excessive contact with hydraulic oil should be avoided. To minimize the possibility of rashes, care should be taken to wash thoroughly.

This instruction manual must be read with particular attention to the following safety rules, by any person

installing, operating, or servicing this tool.

IMPORTANT

While a small amount of wear and marking will naturally occur through normal and correct use of mandrels, they must

be regularly examined for excessive wear and marking, with particular attention to the head diameter, the tail jaw

gripping area of the shank or heavy pitting of the shank and any mandrel distortion. Mandrels which fail during use

could forcibly exit the tool. It is the customer's responsibility to ensure that mandrels are replaced before any

excessive levels or wear and always before the maximum recommended number of placings. Contact your Avdel

representative who will let you know what that figure is by measuring the broach load of your application with a

calibrated test tool. These tools can also be purchased under Part Number 07900-09080, supplied with all necessary

information for testing in this manual.

Specification for 0753 Mk II Type Tool

Specification for 07531 Intensifier

Specifications

5

Air Pressure Minimum - Maximum 5-7 bar (70-100 lbf/in2)

Free Air Volume Required @ 5.1 bar /75 lbf/in

2

2.6 litres (0.09 ft3)

Stroke Minimum 30.0 mm (1.18 in)

Pull Force @ 5.5 bar /80 lbf/in

2

3.89 kN (875 lbf)

Cycle time Approximately 1 second

Noise Level Less than 70 dB(A)

Weight Pistol 1.2 kg (2.64 lb)

Vibration Less than 2.5 m/s2(8 ft/s2)

Air Pressure Minimum - Maximum 5-7 bar (70-100 lbf/in2)

Intensification Ratio 32:1

English

6

Intent of Use

The pneumatic 0753 MkII type tool is designed to place Avdel®speed fasteners (except 1/16” Avlug®) making it ideal for batch or flowline assembly in a wide variety of applications throughout all industries.

The Hand Tool and Intensifier have been tested as separate items and combined. They must only be used together and for no other

purposes. Refer to "Putting into Service" on page 8 for connection details.

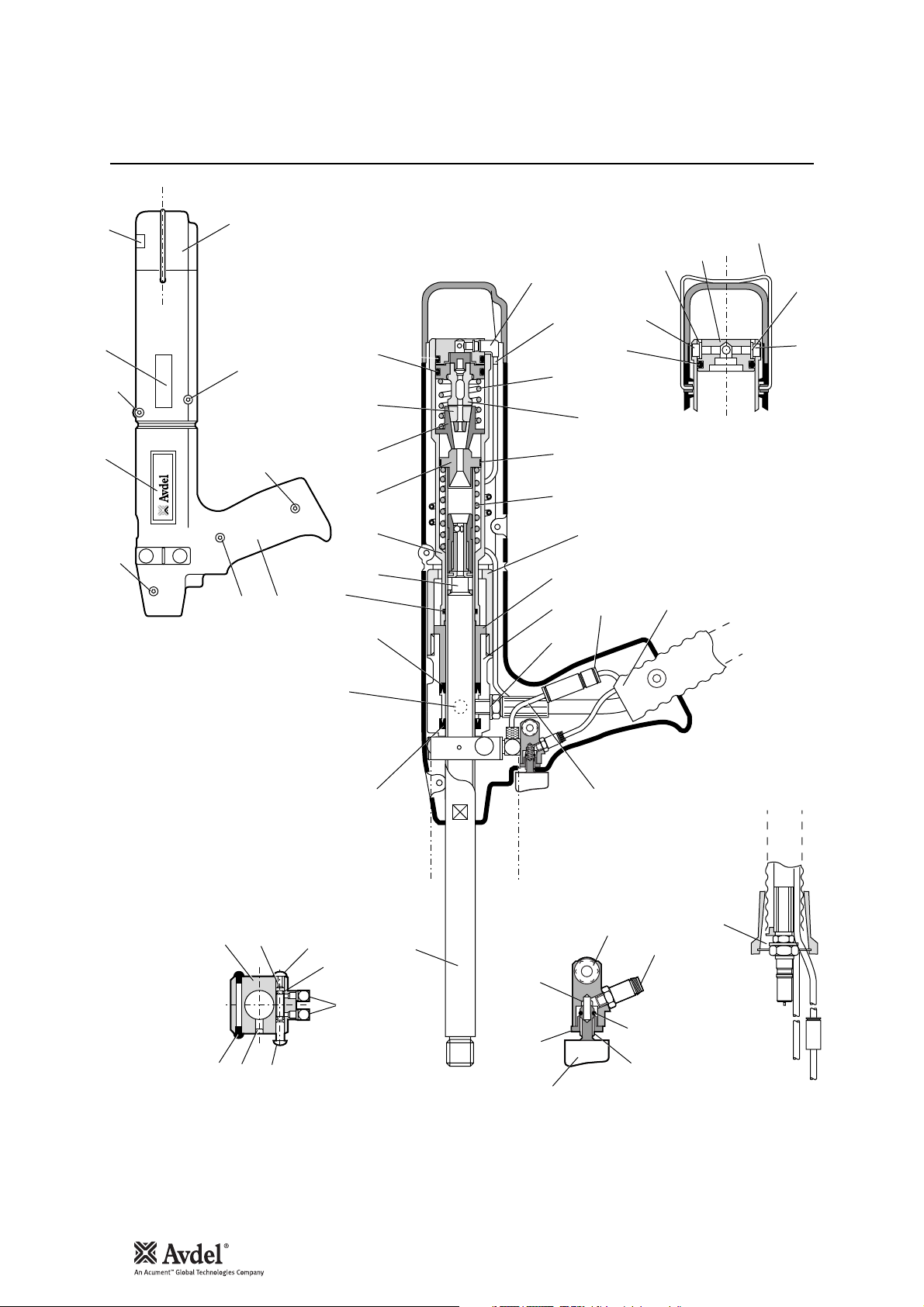

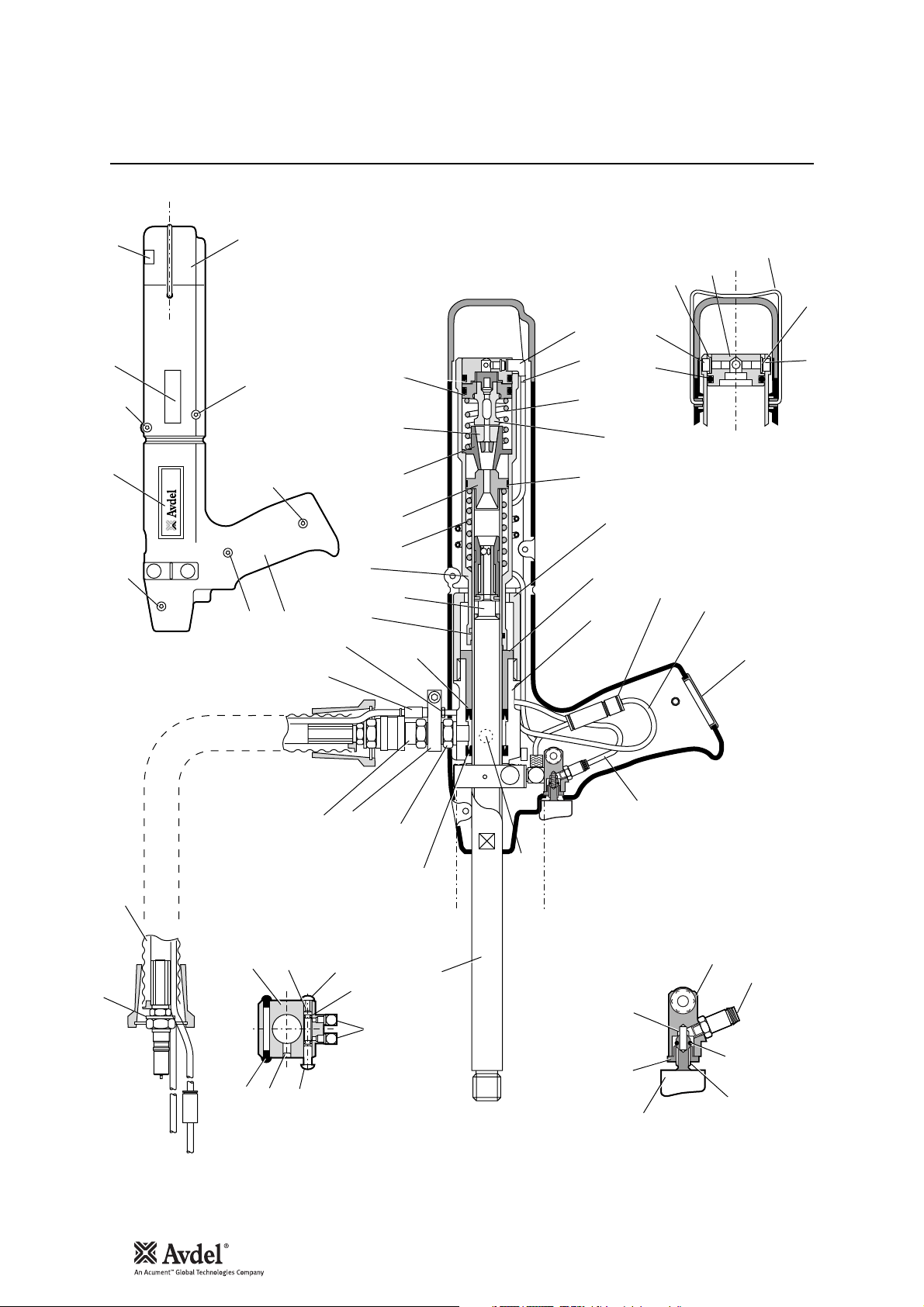

Both models, the 07530 MkII and 07532 MkII are hand-held lightweight tools. Their only difference lies in the location of the hose entry.

The top entry on the 07532 MkII tool allows suspension from an added mounting plate, see drawing opposite. Part numbers are shown

to order a complete tool including the intensifier and all hoses but no nose equipment.

The pistol number for the 07530 MkII model is 07530-02200 and is 07532-02200 for the 07532 MkII model. See the general

assemblies on pages 28-31.

Both models will place the same fasteners and both will place most repetition fasteners, as shown in the table below.

Both models make use of the same nose equipment. Reference must be made to the Nose Equipment section of the manual when

selecting compatible components for the type and size of fastener used in your application (see pages 13-21). Nose jaw dimensions

are shown on page 14.

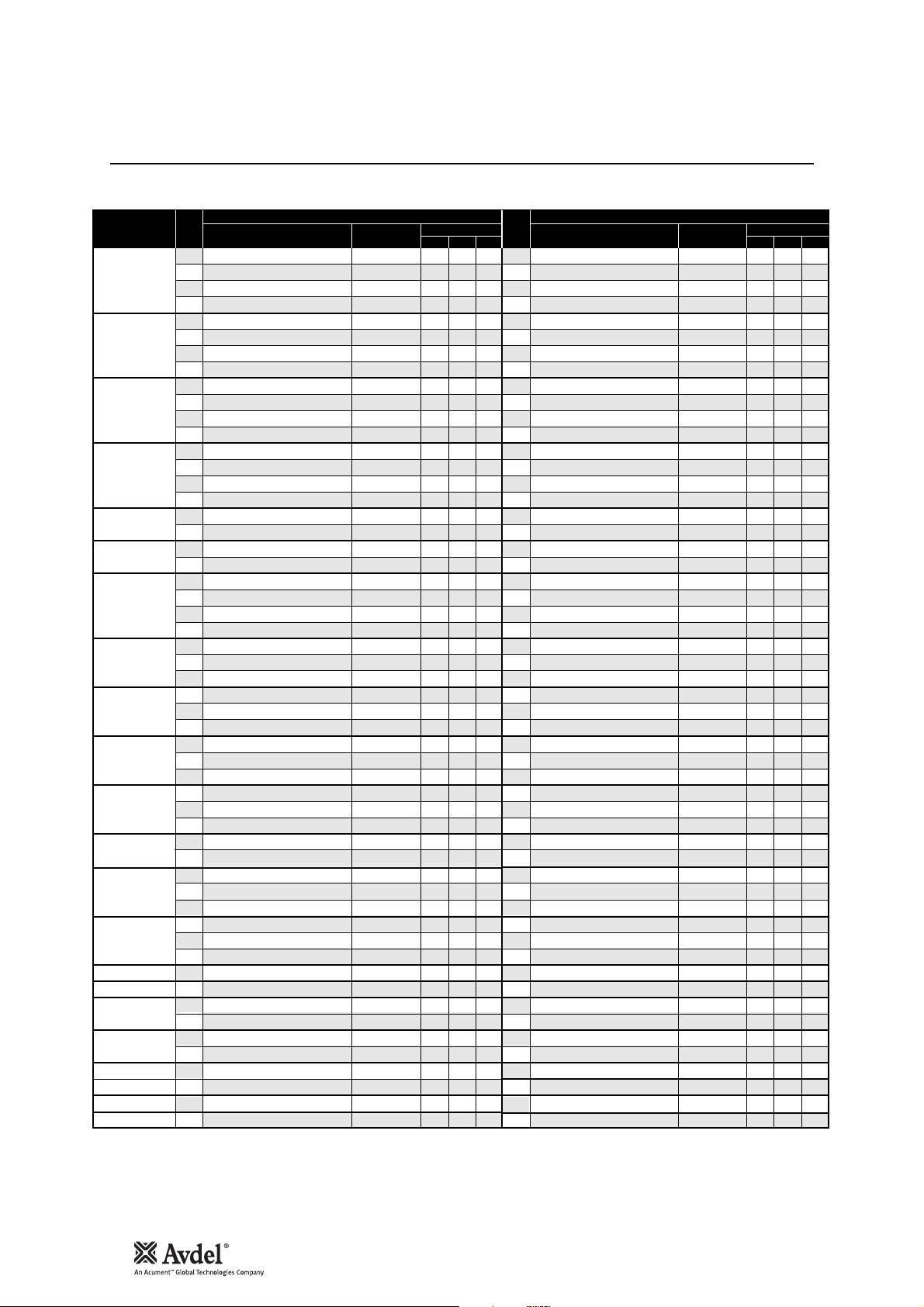

FASTENER NAME

AVLUG

BRIV

®

®

®

®

®

®

®

CHOBERT

GROVIT

RIVSCREW

AVTRONIC

AVSERT

FASTENER SIZE

3

/32"

5

1

/8"

/32"

3

●●●●●

●●●●

●●

●●●●

/16"

1

/4"

2.5mm

2.8mm

4mm3.5mm3mm

6mm

M2.5

4-40

UNC

●

● ● ● ●

●

● ●

M3

6-32

UNC

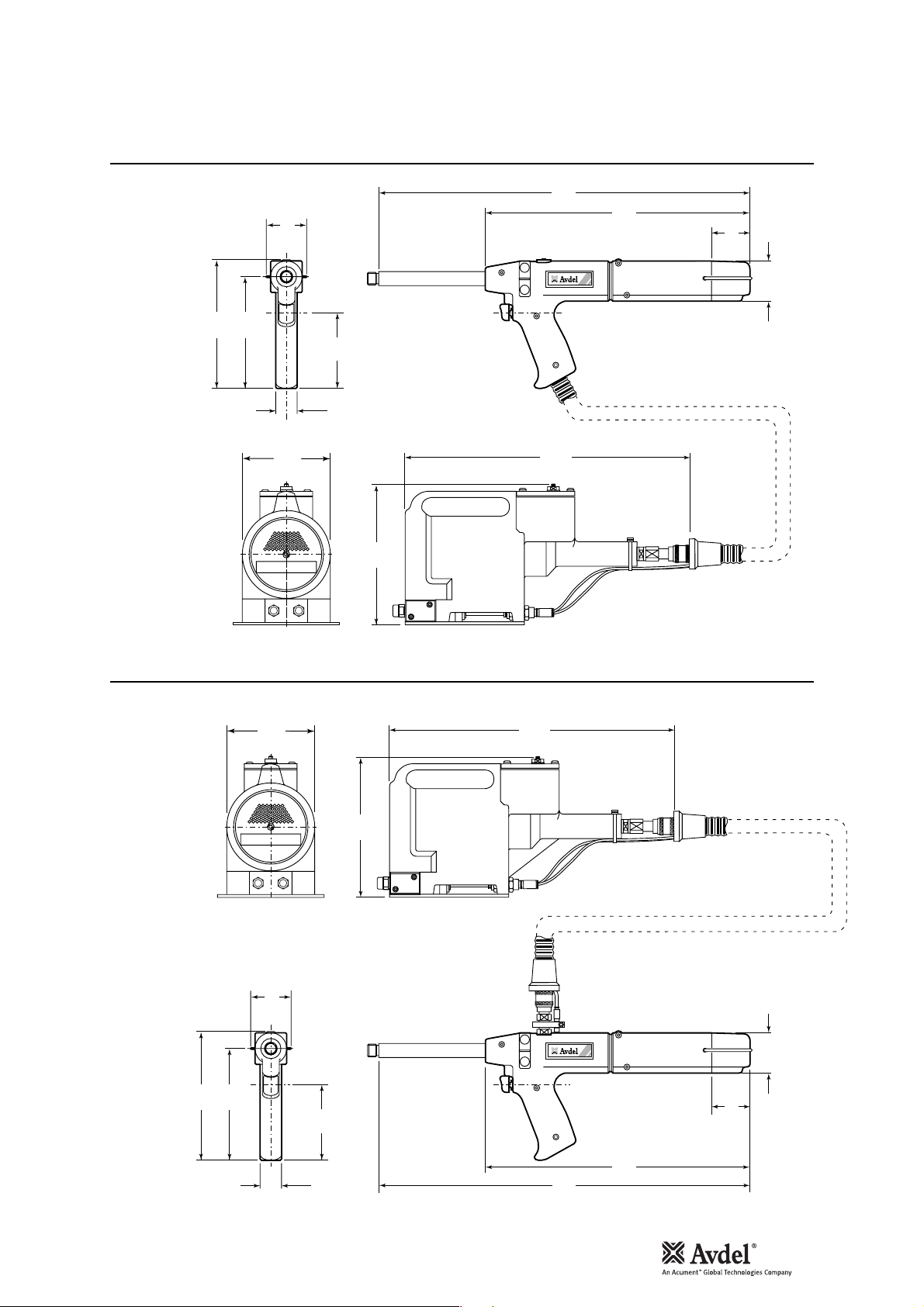

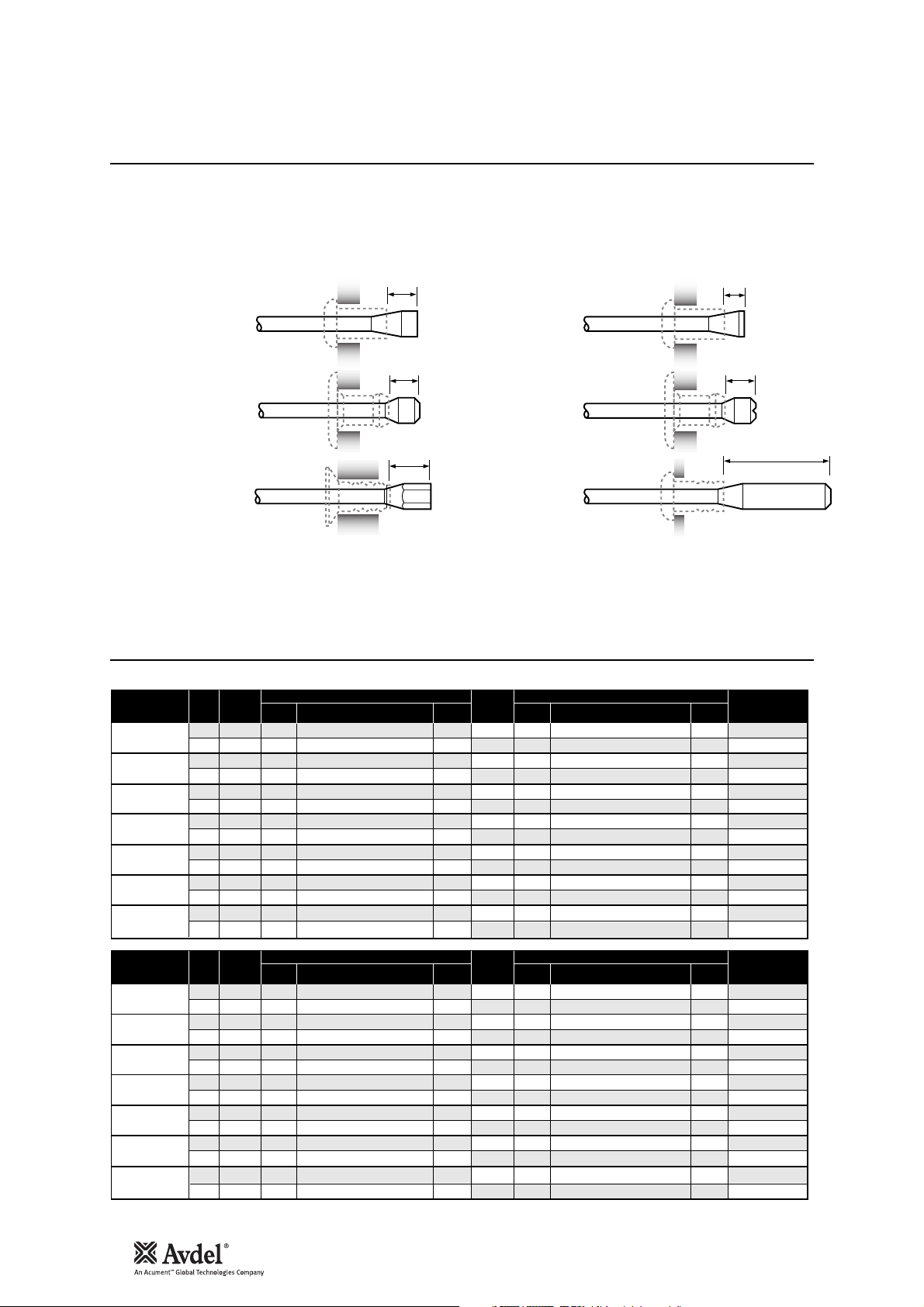

Tool Dimensions - 07530 MkII Model

Tool Dimensions - 07532 MkII Model

Intent of Use

7

Part Number 07530-02100

Part Number 07532-02100

Dimensions shown in bold are millimetres. Other dimensions are in inches.

English

163

140

6.41

5.51

60

2.36

130

5.12

98

3.85

28

1.10

200

7.87

475

18.70

420

16.54

0753

338

13.30

50

1.96

51

2

130

5.12

200

7.87

60

2.36

163

140

6.41

5.51

98

3.85

420

16.54

0753

50

1.96

51

2

28

1.10

475

18.70

338

13.30

8

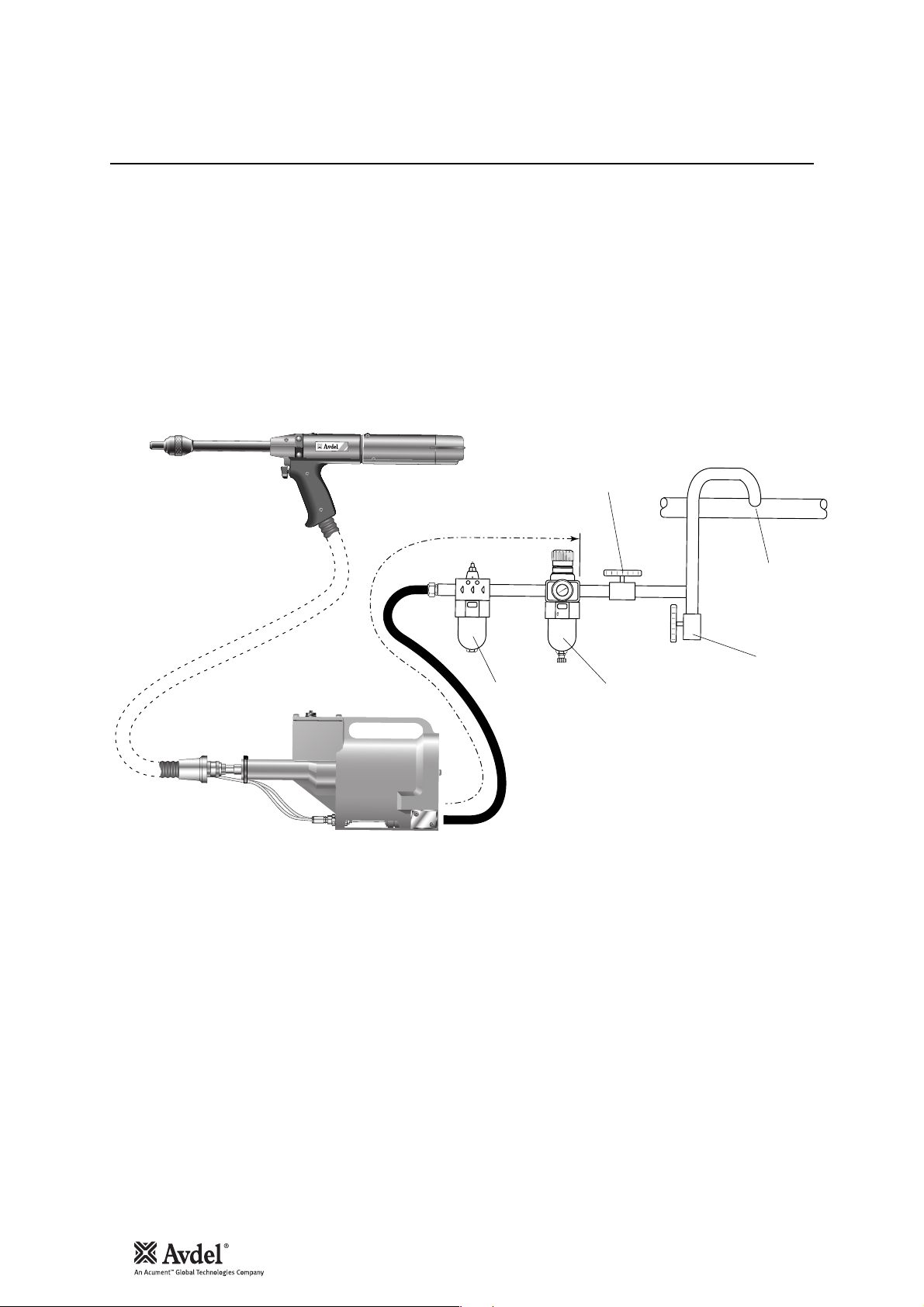

Air Supply

Putting into Service

All tools are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators and

automatic oiling/filtering systems on the main air supply. To ensure maximum tool life and minimum tool maintenance they should be fitted

within 3 metres of the tool (see diagram below).

Air supply hoses should have a minimum working effective pressure rating of 150% of the maximum pressure produced in the system or 10

bar, whichever is the highest. Air hoses should be oil resistant, have an abrasion resistant exterior and should be armoured where operating

conditions may result in hoses being damaged. All air supply hoses MUST have a minimum bore diameter of 6.4 millimetres or

1

/4 inch.

Read daily servicing details page 22.

Follow the steps below when connecting the tool to the intensifier and main air supply:

• Push the end of the large hydraulic hose from the tool into the quick release connector on the end of the intensifier.

• On the front face of the intensifier:

• Push the blue pneumatic (4mm OD) line into the reducer fitting which is located in the left hand bulkhead connector.

• Push the black pneumatic (4mm OD) line into the plastic collet of the right hand bulkhead connector.

• Fit a pneumatic hose between the male connector at the rear of the intensifier and main air supply.

TYPE

0753

(USED DURING MAINTENANCE

OF FILTER/REGULATOR

OR LUBRICATION UNITS)

STOP COCK

M

U

M

I

X

A

M

S

E

R

T

E

M

3

10

8

6

12

4

14

2

16

0

TAKE OFF POINT

FROM MAIN SUPPLY

MAIN SUPPLY

DRAIN POINT

LUBRICATOR

PRESSURE REGULATOR

AND FILTER

(DRAIN DAILY)

9

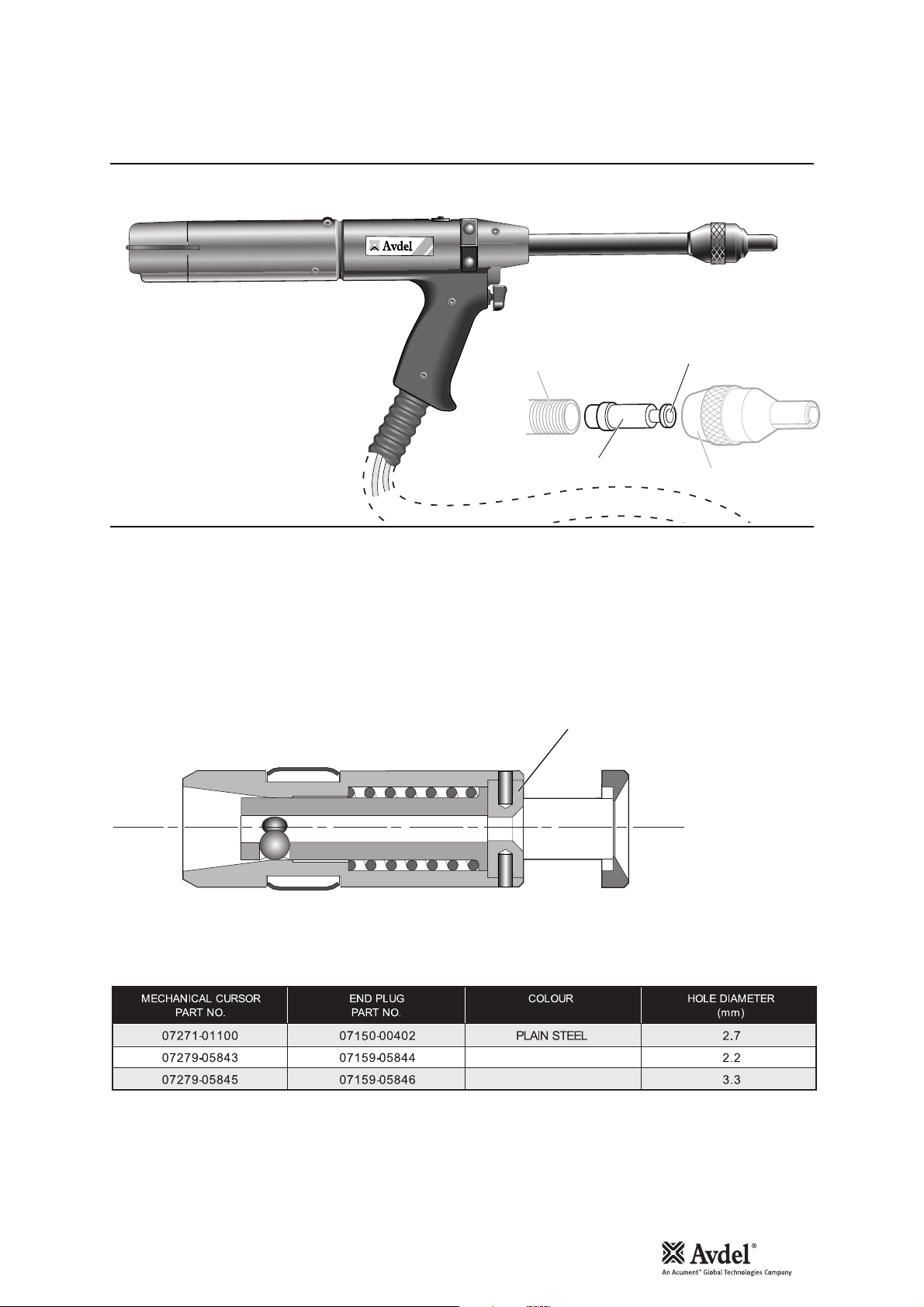

Mechanical Cursors

Putting into Service

For reference there are three different mechanical cursor types:

• 07271-01100 Used for Standard mandrels and 5/32” Disposable mandrels

• 07279-05843 Used for 1/8” Disposable mandrels

• 07279-05845 Used for 3/16” Disposable mandrels

The difference in the above assemblies is the internal diameter of the End Plug.

These are colour coded see below:

END PLUG

English

0753

TYPE

TOOL

BARREL

CURSO

R

SPRIN

LOADED EN

G

D

NOS

E

JAW

S

GOLD

SILVER

10

Loading and Reloading the Tool

Cursor

Putting into Service

While the cursor will be fitted the correct way round when the tool is supplied, we recommend that you check its orientation before

fitting the nose equipment. The sprung loaded, slightly concave, end of the cursor should point towards the front of the tool as shown

in the illustration.

When fitted the correct way round, the cursor will easily slide out of the barrel when a mandrel is pushed into its centre then pulled

back.

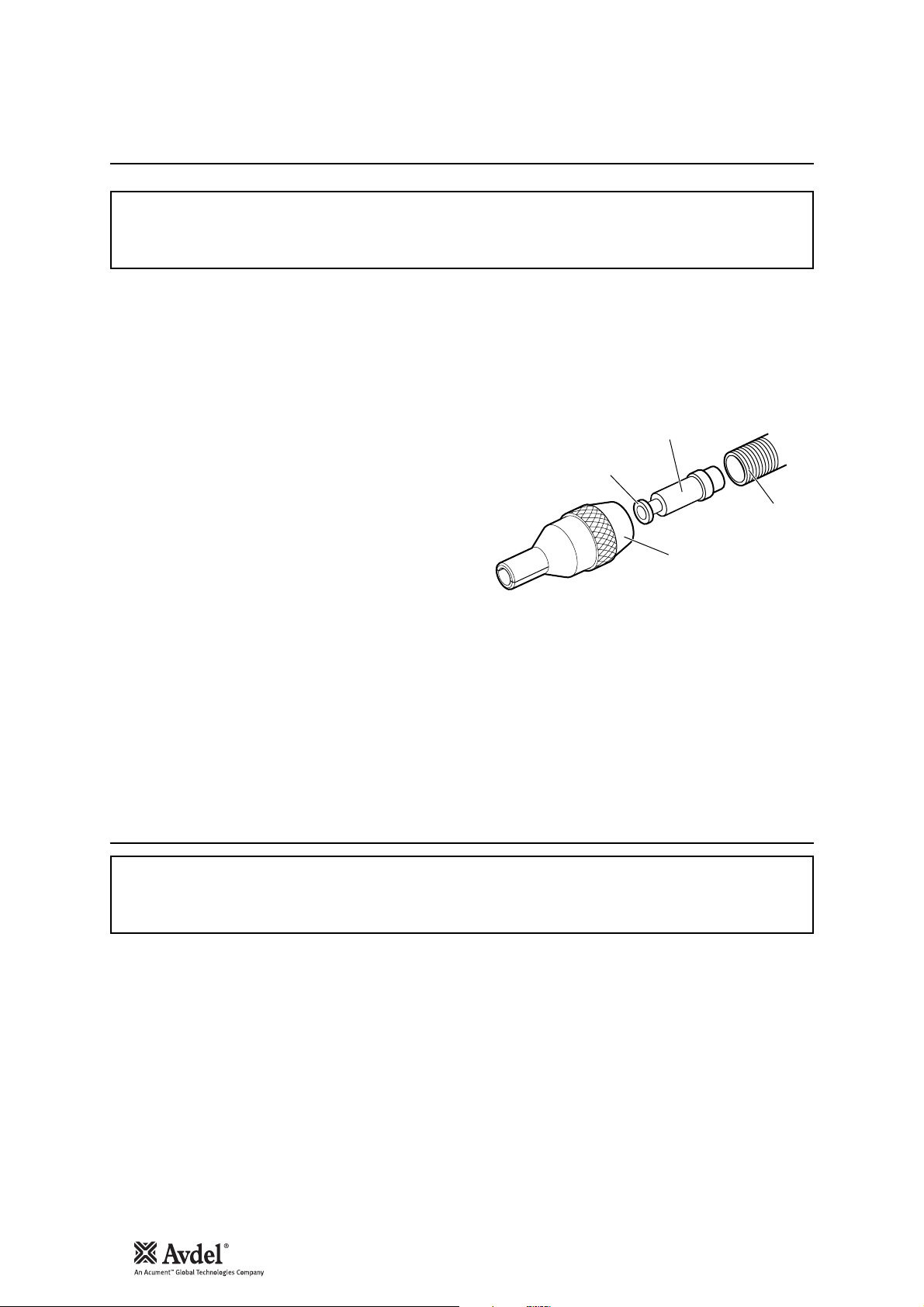

To reverse the orientation of the cursor, follow these steps:

Item numbers in bold refer to the general assembly and parts list for

the 07530-02200 MkII type on pages 28-29. For the 07532-02200

MkII type, the procedure is the same but the part numbers must be

taken from the general assembly and parts list on pages 30-31.

• Remove the clip 47 and slide off end cap 38.

• Using an Allen Key, remove one cap head screw 44 ensuring that

any trapped air is exhausted. remove the second cap head screw

44.

• Pull out rear plug 46.

• Pull out tail jaw piston assembly 14 together with jaws 9.

• Lift out spring 13 and jaw housing 8.

• Insert a mandrel into the hole in the rear end of barrel 25 until it protrudes through the front of the barrel, then pull out the mandrel

and cursor together through the front.

• Reassemble components in reverse order.

• Insert Mechanical Cursor Assembly 5 into the front of the barrel, correct way round.

When ordering a complete tool or system you will normally be supplied with all the nose equipment required for the fastener to be

placed.

To identify nose equipment components or to select the correct elements, read the nose equipment section, on pages 13-21.

If you have been supplied with a nose jaw, mandrels and mandrel follower springs proceed with loading the tool and fitting the nose

equipment as shown overleaf.

IMPORTANT

If fitted incorrectly, the cursor will not allow feeding of the fasteners.

IMPORTANT

The procedure for loading the tool and for fitting the nose equipment to the tool is integral.

Item numbers in bold refer to the general assembly and parts list for the 07530-02200 MkII type on pages 28-29. For the 07532-02200 MkII

type, the procedure is the same but the part numbers must be taken from the general assembly and parts list on pages 30-31.

SPRING

LOADED END

CURSOR

TOOL

BARREL

NOSE

JAWS

11

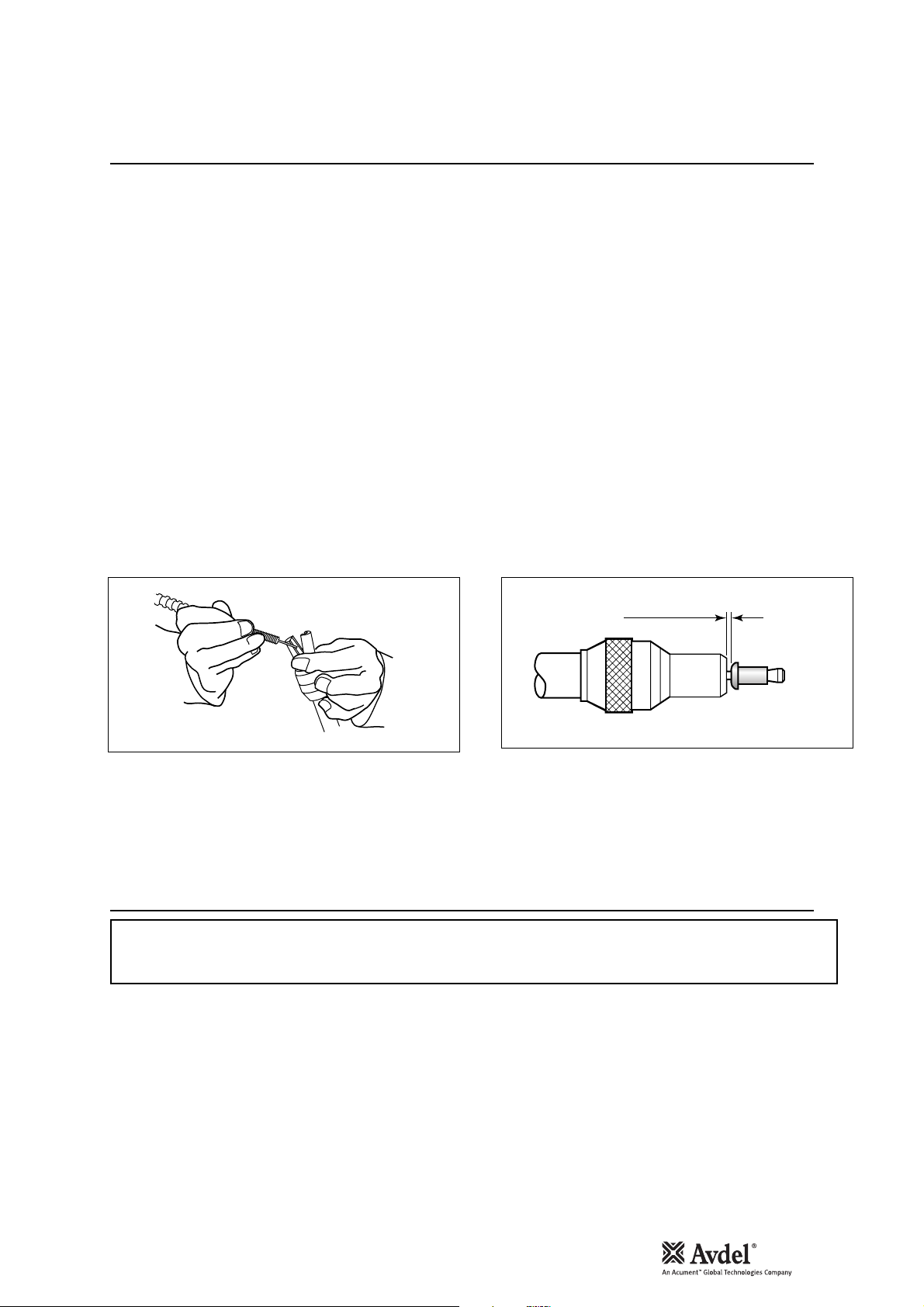

Putting into Service

Loading the Tool

• Connect the air supply to the tool.

• Open tail jaws 9 which grip the mandrel, by switching off the tail jaw switch (items 26 and 30).

• Screw selected nose jaws onto barrel 25 of the tool.

n Insert a mandrel into the tail end of the fasteners through the paper pod.

• Slide the mandrel follower spring onto the mandrel ensuring correct orientation, as shown in the table on page 12.

• Gripping the tail end of the mandrel, tear off the paper pod from around the fasteners.

• Open the nose jaws either by rotating the outer ring on Cam operated jaws or by pushing outwards on the jaw ends, as illustrated

below left.

• Insert the previously assembled mandrel, mandrel follower spring and fasteners into the nose jaws until the first fastener to be placed

is protruding from the nose jaw.

• Close the nose jaws and adjust so that the first fastener protrudes by 1.5mm - 3mm (

1

/16” to 1/8”), as shown in the illustration

below right.

• Close the tail jaws to ensure the mandrel is gripped, by switching on the tail jaw switch (items 26 and 30).

• Push the fastener, protruding from the nose jaws, fully into the application holes ensuring that the tool is held square.

• Operate the trigger without releasing - the mandrel head is pulled through the fastener, forming the fastener into the application.

• Remove the tool.

• Release the trigger. The next fastener will be automatically presented through the nose jaws, ready for placing.

Reloading the Tool

• Open tail jaws 9 of tool.

• Open the nose jaws and pull the empty mandrel and mandrel follower spring out of the tool.

• Reload the tool by following the above instructions, starting at stage n.

IMPORTANT

You must check that the cursor orientation and the nose equipment are correct before attempting to operate the tool.

Item numbers in bold refer to the general assembly and parts list for the 07530-02200 MkII type on pages 28-29. For the 07532-02200 MkII

type, the procedure is the same but the part numbers must be taken from the general assembly and parts list on pages 30-31.

Operating Procedure

English

1.5mm - 3mm

1

(

/16" - 1/8")

12

Putting into Service

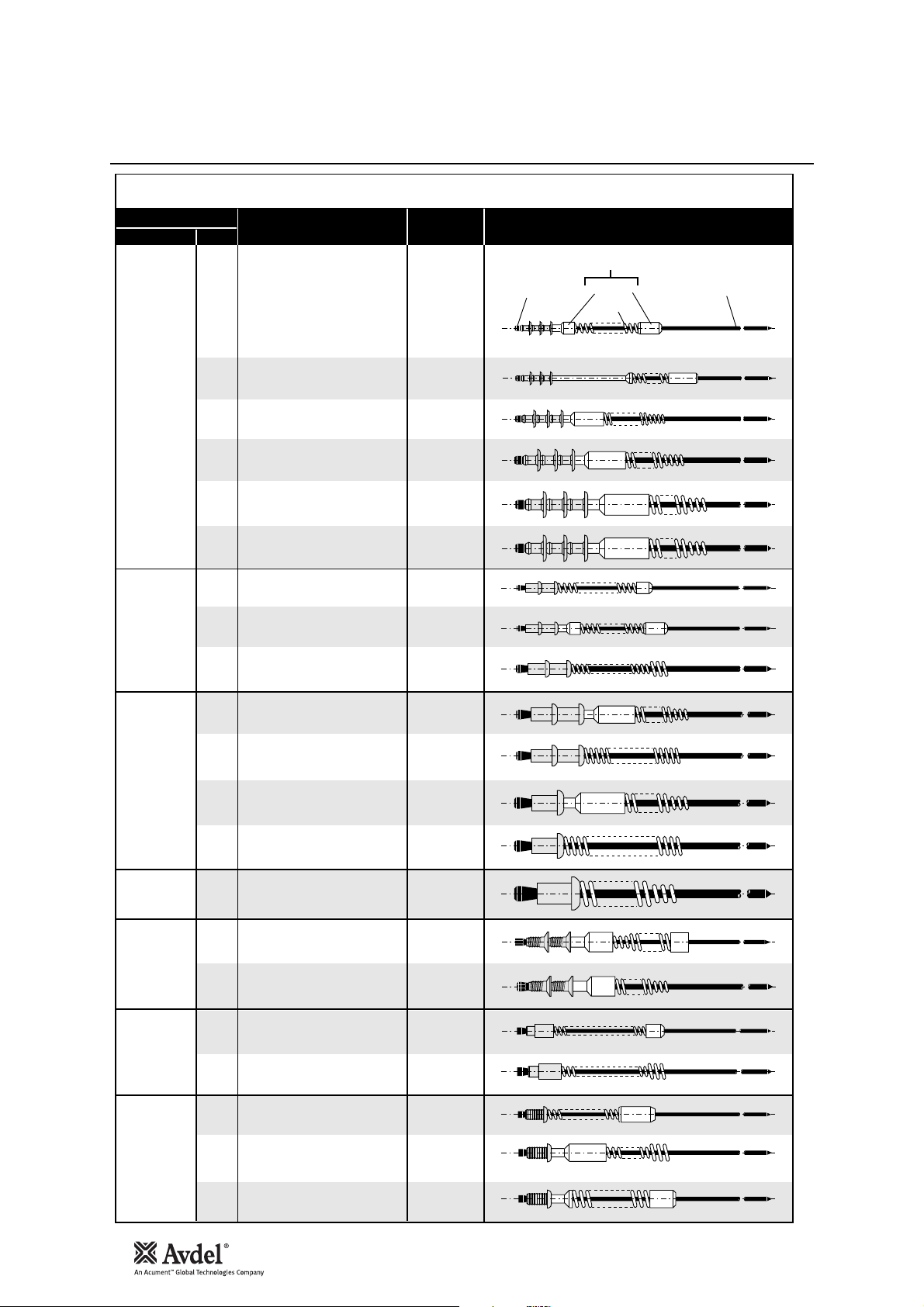

3

/16"

3

/32"

3

/32"

5

/32"

5

/32"

3

/16"

3

/16"

3mm

6 x 32

UNC

2.5mm

4 x 40

UNC

3

/32"

3

/32"

1

/8"

1

/4"

1

/8"

2.8mm

2.5mm

2.8mm

3mm

3.5mm

4mm

2.8mm

CHOBERT

®

AVLUG

®

GROVIT

®

CHOBERT

®

GROVIT

®

CHOBERT

®

RIVSCREW

®

BRIV

®

AVSERT

®

AVTRONIC

®

MANDREL HEAD

FERRULE

MANDREL FOLLOWER SPRING

SPRING

MANDREL

STANDARD TAPERED

ALL

ALL

ALL

ALL EXCEPT

STANDARD TAPERED,

LIMITED ACCESS

ALL EXCEPT

LIMITED ACCESS

STANDARD TAPERED,

LIMITED ACCESS

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

LIMITED ACCESS

5

/32"

FASTENER

SIZENAME

NOSE JAW

(SEE NOSE EQUIPMENT SECTION)

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL EXCEPT

3rd

OVERSIZE

3rd

OVERSIZE

ALL EXCEPT

2nd

OVERSIZE

2nd

OVERSIZE

ALL

ALL

ALL

ALL

ALL

ALL

ALL

MANDREL

SIZE

MANDREL FOLLOWER SPRINGS IDENTIFICATION AND ORIENTATION

MANDREL/MANDREL FOLLOWER SPRING

AND FASTENER ASSEMBLY

LIMITED ACCESS &

LIMITED ACCESS CAM OPERATED

STANDARD

ALL

EXCEPT 3rd

OVERSIZE

6mm

ALL ALL

13

Nose Jaws

Nose Assemblies

IMPORTANT

To avoid complete dismantling of the tool it is essential to check the orientation of the cursor before fitting

the nose equipment to the tool. See ‘CURSOR’ section on page 10.

It is essential that the correct nose equipment is fitted to the tool to ensure both effective placing of the

fastener and SAFE operation of the tool. READ THE SAFETY INSTRUCTIONS page 4 carefully.

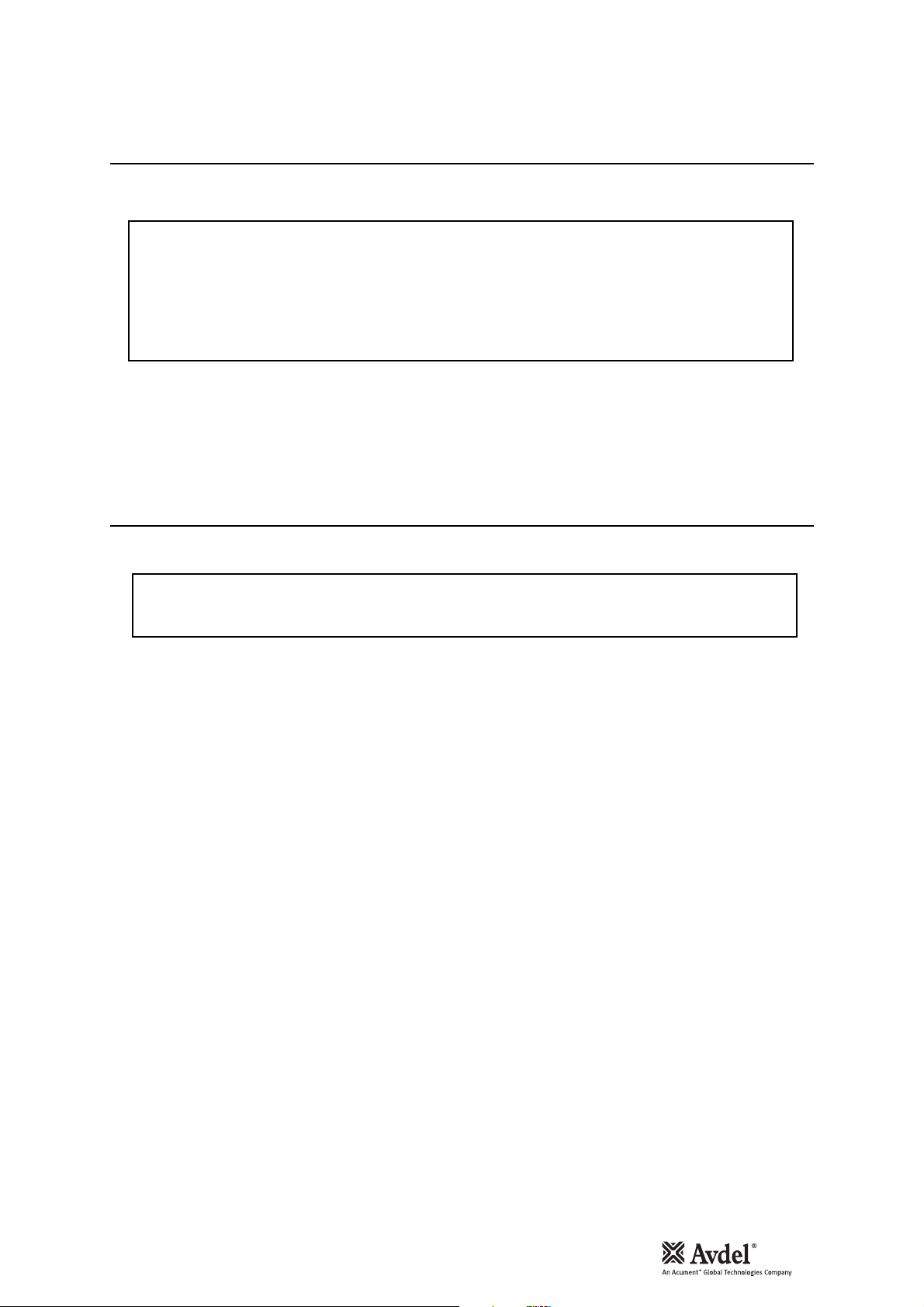

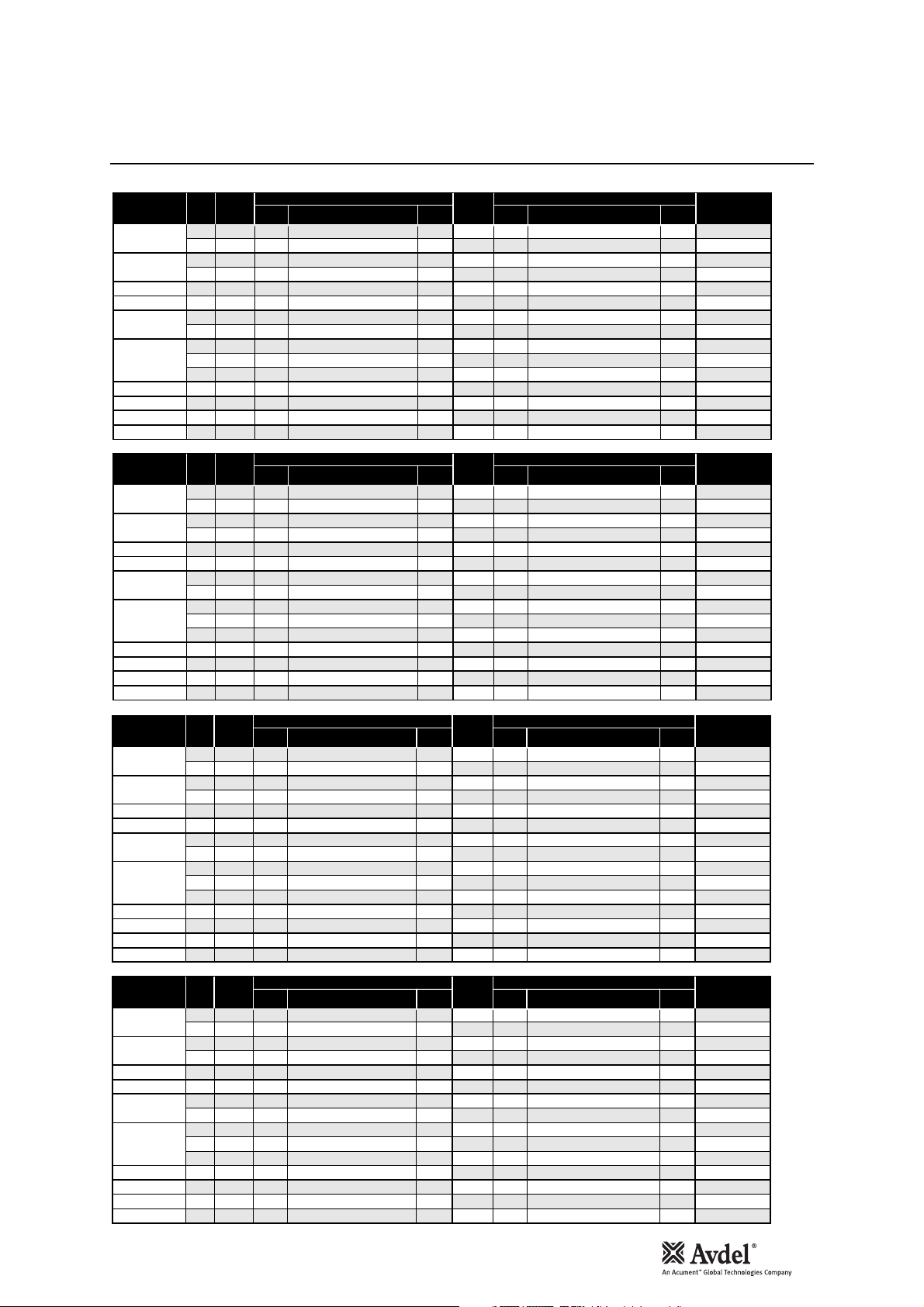

On speed fastening tools such as 0753 MkII type, the nose equipment always consists of three elements: a nose jaw, a mandrel and a

mandrel follower spring. All three items are matched to the fastener being placed and to the hole size in the application.

To identify the correct combination of nose equipment to fit your tool first select a nose jaw by reading the section below then read the

mandrel section to select part numbers both for the mandrel itself and for the mandrel follower spring. Mandrels and mandrel follower

springs are illustrated on page 12.

To fit the nose equipment, follow the ‘Loading the Tool’ procedure page 11.

Nose Jaws can be categorised into 7 different basic shapes as illustrated opposite, even though internal dimensions will vary

according to the fastener it is intended for. Exact dimensions referring to the letters in the illustrations opposite are indicated in the

‘Nose Jaw Selection Tables’ on pages 15-16.

For a particular shape, there may be several options of end form giving access benefits or fastener placing enhancement.

Flat

• Normal end form of all nose jaws.

• Suitable on all applications with no access restrictions.

Universal

• Designed for use with universal head Chobert

®

fasteners.

• Can also be used with Briv

®

fasteners to obtain the highest possible clench. Note this reduces the maximum grip range of the

Briv®fastener by approximately 0.015” (0.4mm).

Recessed

• For use with Briv

®

fasteners ONLY.

• It gives a higher clench than a flat end form but less than a universal end form, with no reduction of the grip range of the fastener.

Tapered

• Available as shown in the ‘Nose Jaw Selection Tables’.

• Allows greater accessibility than a flat end form and places the same range.

Head Forming

• For use with Rivscrew

®

fasteners ONLY.

• Deforms the head of the fastener to achieve good clench.

IMPORTANT

The wrong nose jaw could result in an incorrectly placed fastener or incorrect clench.

English

14

Selecting a Nose Jaw

Nose Assemblies

Available in 4 different end forms to place all

fasteners (except Rivscrew). Suitable on

applications with no or little access restriction.

• List the name, size and material of the fastener to be placed.

• Look for this fastener in the first column of the nose jaw selection tables on page 15

if you use imperial measurements and on page 16 if you use metric units.

• Looking right across the table, take note of which nose jaws are available. ONLY

those shown are available.

• Select which is most suitable for your application by referring to the respective nose

jaw drawing. If your application has no access restriction, you should select the

standard shape with a flat end form with or without a cam.

Available as shown in NOSE JAW SELECTION TABLE.

Allows access into very restrictive applications.

Available as shown in NOSE JAW SELECTION TABLE overleaf. Equivalent functions to the Standard and Limited Access above with the

addition of a cam to ease and speed up the nose jaw opening thus the pod reloading procedure.

Available as shown in NOSE JAW SELECTION TABLE.

Allows more penetration into applications

with restricted access.

Mandrels must be curved by hand to follow

the shape of the jaw.

Available to place most of the fasteners.

Allows more penetration into applications

with no other access restriction.

Dimensions shown in bold are millimetres. Other dimensions are in inches.

28.6

1.125

STANDARD

33.5

1.32

'B'

'E'

'D'

LONG

28.6

1.125

33.5

1.32

'D'

UNIVERSALFLAT

'B'

'E'

RECESSED

LONG CURVED

'B'

'F'

33.5

1.32

28.6

1.125

RIVET

Ø

mm in.

1

/8 .620 15.7

5

/32 .690 17.5

3

/16 .720 18.3

'F'

'D'

'E'

FLAT RECESSED

UNIVERSALFLAT

RECESSED TAPERED

LIMITED ACCESS

'B'

20.5

0.81

41.4

1.63

'D'

FLAT

'E'

STANDARD CAM OPERATED

'B'

28.6

1.25

'D'

HEAD FORMING (HF)

FLAT

34

1.34

'E'

LONG CAM OPERATED

34

1.34

28.6

1.25

FLAT

LIMITED ACCESS CAM OPERATED

'B'

28.6

1.25

'D'

'E'

37.1

1.46

'B'

'E'

'D'

FLAT

15

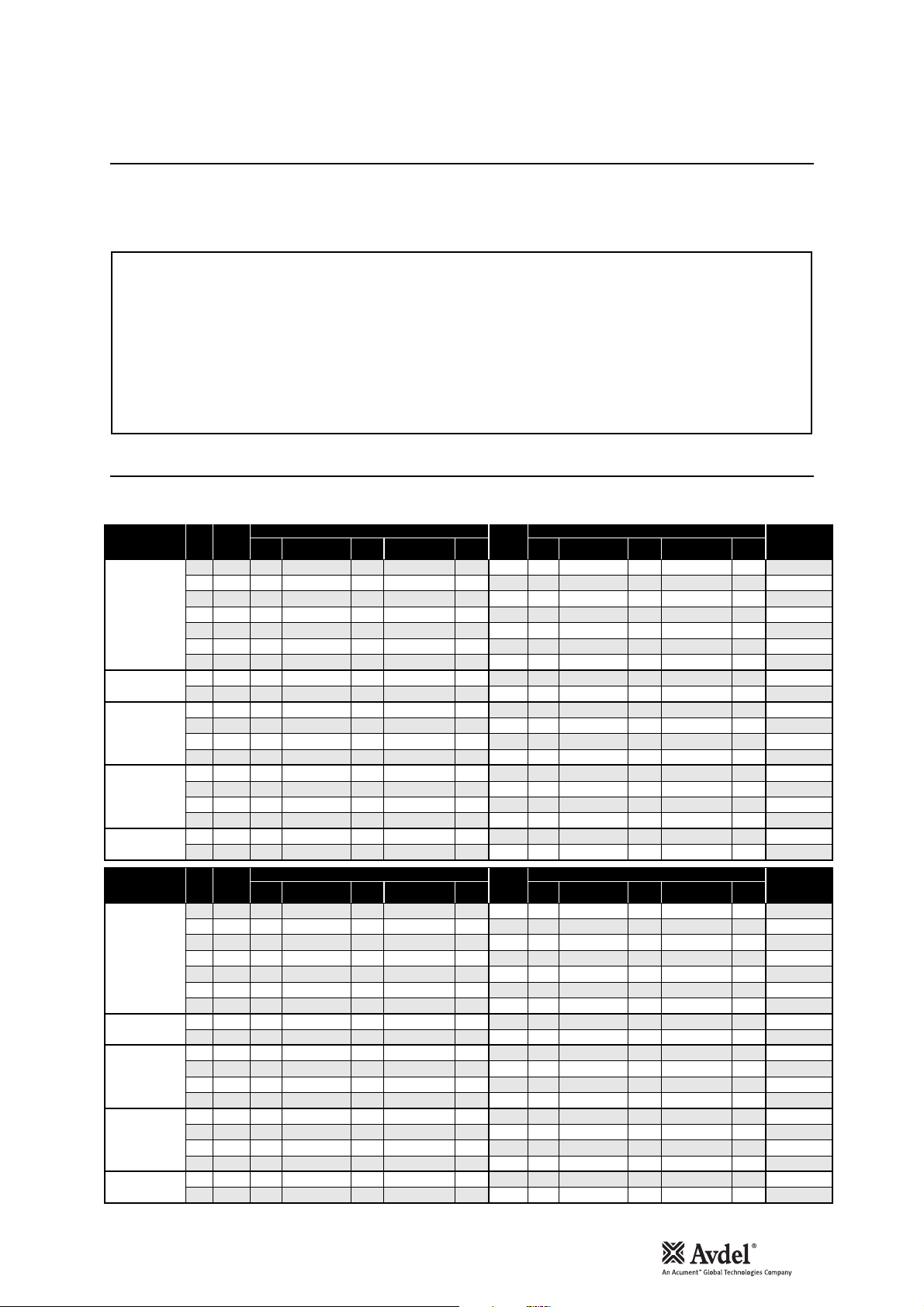

Nose Jaw Selection - Imperial

Nose Assemblies

The ‘REF Nº’ column cross references with the ‘REF Nº’ columns in the mandrel section. It identifies both the mandrel and mandrel

follower spring required for a particular nose jaw with a specific fastener.

# These nose jaws are suitable for placing Chobert®rivets with a Universal Head Form. When used on the equivalent size of Briv®, the

highest possible clench is achieved. Note when using Briv

®

fasteners, the maximum grip is reduced by approximately 0.015" (0.4mm).

possible clench is achieved. Note that when using Briv fasteners, the maximum grip is reduced by approximately 0.015” (0.4 mm).

English

FASTENER

3/32" CHOBERT®

& GROVIT

1/8" CHOBERT®

& GROVIT

5/32" CHOBERT®

& GROVIT

3/16" CHOBERT®

& GROVIT

1/4" CHOBERT®

3/32" BRIV®

Brass only

1/8" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

St.Steel only

3/16" BRIV®

Al. Alloy,

Brass, Steel

3/16" BRIV®

St.Steel only

6mm BRIV®

Al. Alloy, Steel

3/32" AVLUG®

1/8" AVLUG®

2.5mm, 4-40 UNC

AVSERT®

3.0mm, 6-32 UNC

AVSERT®

2.5mm AVTRONIC®

2.8mm AVTRONIC®

2.8mm RIVSCREW®

3.0mm RIVSCREW®

3.5mm RIVSCREW®

4.0mm RIVSCREW®

REF.

Nº

1

STD. CAM OPERATED - FLAT

1

2

4

5

5

6

6

7

7

8

8

9

9

10

10

11

12

13

14

15

15

16

16

LONG CURVED - RECESSED

17

18

18

19

20

20

21

22

22

23

24

24

25

26

27

STD. CAM OPERATED - FLAT

27

28

29

STD. CAM OPERATED - FLAT

29

30

31

32

33

34

35

37

STD. CAM OPERATED - HF

38

STD. CAM OPERATED - HF

39

STD. CAM OPERATED - HF

40

STD. CAM OPERATED - HF

41

TYPE AND

END FORM

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

STANDARD - TAPERED

LIMITED ACCESS

STANDARD - FLAT

STANDARD - TAPERED

LONG - RECESSED

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STD. CAM OPERATED

LONG CAM OPERATED

STANDARD - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

STANDARD - FLAT

STANDARD - FLAT

LONG - FLAT

STANDARD - FLAT

LONG - FLAT

NOSE JAW

07150-03003

07170-04500

07170-03103

07150-04003

07150-03004

07170-03104

07150-04004

07150-05004

07150-03005

07150-03105

07150-04005

07150-05005

07150-03006

07150-03106

07150-04006

07150-05006

07150-03008

07150-04008

07170-03103

07274-01000

07150-03004

07170-03104

07170-03204

07170-03304

07150-03005

07150-04005

07150-05005

07150-03005

07150-04005

07150-05005

07150-03006

07150-04006

07150-05006

07150-03006

07150-04006

07150-05006

07170-05600

07170-05700

07150-03003

07170-04500

07150-05003

07150-03004

07170-04600

07150-05004

07150-03003

07150-03004

07150-03003

07150-04003

07271-05600

07271-05900

07271-03000

07271-03000

07271-03500

07271-04000

PART Nº

DIMENSIONS

'D' 'E''B'

1.30

.36

1.30

.36

1.30

.36

2.30

.41

1.18

.41

1.19

.41

2.18

.41

2.12

.41

1.30

.48

1.30

.44

2.30

.48

2.23

.48

1.18

.56

1.18

.56

2.30

.56

2.21

.56

1.18

.64

2.18

.64

1.30

.36

1.07

.22

1.18

.41

1.19

.41

2.18

.41

2.12

.41

1.30

.48

2.30

.48

2.23

.48

1.30

.48

2.30

.48

2.23

.48

1.18

.56

2.30

.56

2.21

.56

1.18

.56

2.30

.56

2.21

.56

1.21

.64

2.19

.64

1.30

.36

1.30

.36

2.28

.41

1.18

.41

1.18

.41

2.12

.41

1.30

.36

1.18

.41

1.30

.36

2.30

.41

1.30

.36

2.30

.41

1.18

.41

1.18

.41

1.18

.41

1.18

.41

.16

.16

.16

.16

.20

.20

.20

.20

.24

.24

.24

.24

.33

.33

.33

.33

.39

.39

.15

.16

.20

.20

.30

.30

.24

.24

.24

.24

.24

.24

.33

.33

.33

.33

.33

.33

.52

.52

.16

.16

.16

.20

.20

.20

.16

.20

.16

.16

.16

.16

.24

.24

.24

.25

REF.

Nº

# STANDARD - UNIVERSAL

1

LTD. ACCESS CAM OPERATED

1

3

4

5

5

6

6

7

7

8

8

9

9

10

10

11

12

14

-

15

16

16

-

17

18

18

19

20

20

21

22

22

23

24

24

25

26

27

28

29

30

30

-

32

33

-

36

-

-

-

-

-

LONG CURVED - FLAT

# STANDARD - UNIVERSAL

STD. CAM OPERATED - FLAT

# LONG - UNIVERSAL

LONG CAM OPERATED - FLAT

# STANDARD - UNIVERSAL

STD. CAM OPERATED - FLAT

# LONG - UNIVERSAL

LONG CAM OPERATED - FLAT

# STANDARD - UNIVERSAL

STD. CAM OPERATED - FLAT

# LONG - UNIVERSAL

LONG CAM OPERATED - FLAT

STD. CAM OPERATED - FLAT

LONG CAM OPERATED - FLAT

LTD. ACCESS CAM OPERATED

STANDARD - RECESSED

LONG CURVED - FLAT

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - FLAT

STANDARD - TAPERED

STANDARD - TAPERED

LONG CAM OPERATED - FLAT

STD. CAM OPERATED - FLAT

LTD. ACCESS CAM OPERATED

LTD. ACCESS CAM OPERATED

TYPE AND

END FORM

LIMITED ACCESS

-

LONG - FLAT

-

LONG - FLAT

LONG - FLAT

-

LONG - FLAT

-

-

-

-

-

-

-

NOSE JAW

07150-03203

07177-03003

07274-01000

07150-05003

07150-03204

07170-04600

07150-04204

07170-05000

07150-03205

07170-04700

07150-04205

07170-05100

07150-03206

07170-04800

07150-04206

07170-05200

07170-04900

07170-05300

07177-03003

07170-03004

07150-04004

07150-05004

07170-03005

07170-03205

07170-03305

07170-03005

07170-03205

07170-03305

07170-03006

07170-03206

07170-03306

07170-03006

07170-03206

07170-03306

07170-05800

07170-05900

07150-03103

07150-04003

07170-03104

07150-04004

07170-05000

07170-04600

07271-08000

07271-08100

PART Nº

-

-

-

-

-

-

-

-

-

-

DIMENSIONS

'D' 'E''B'

1.33

.36

1.18

.20

1.07

.22

2.28

.41

1.22

.41

1.18

.41

2.22

.41

2.18

.41

1.35

.48

1.30

.48

2.35

.48

2.30

.48

1.24

.56

1.18

.56

2.39

.56

2.30

.56

1.18

.64

2.18

.64

1.18

.20

-

-

1.20

.41

2.18

.41

2.12

.41

-

-

1.32

.48

2.30

.48

2.23

.48

1.32

.48

2.30

.48

2.23

.48

1.20

.56

2.30

.56

2.21

.56

1.20

.56

2.30

.56

2.21

.56

1.21

.64

2.19

.64

1.30

.36

2.30

.41

-

-

1.19

.41

2.18

.41

2.18

.41

-

-

1.18

.41

1.18

.41

-

-

1.18

.40

-

-

-

-

-

-

-

-

-

-

.24

.16

.16

.16

.32

.20

.30

.20

.41

.24

.42

.24

.47

.33

.48

.33

.39

.39

.16

.30

.20

.20

.41

.41

.41

.41

.41

.41

.47

.47

.47

.47

.47

.47

.52

.52

.16

.16

.20

.20

.20

.20

.16

.16

-

-

-

-

-

16

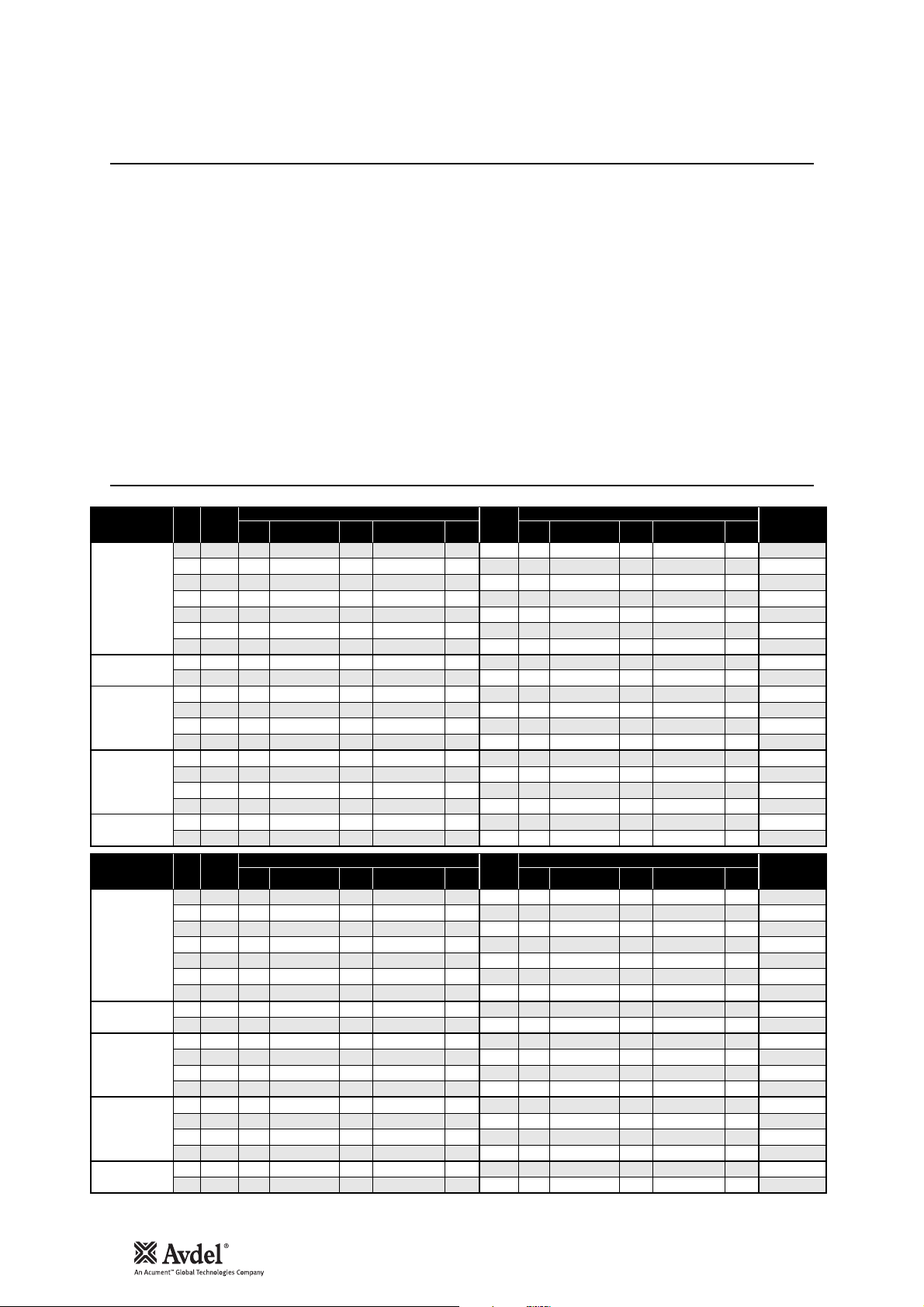

Nose Jaw Selection - Metric

Nose Assemblies

# These nose jaws are suitable for placing Chobert®rivets with a Universal Head Form. When used on the equivalent size of Briv®, the

highest possible clench is achieved. Note that when using Briv

®

fasteners, the maximum grip is reduced by approximately 0.015" (0.4mm).

possible clench is achieved. Note that when using Briv fasteners, the maximum grip is reduced by approximately 0.015” (0.4 mm).

FASTENER

3/32" CHOBERT®

& GROVIT

1/8" CHOBERT®

& GROVIT

5/32" CHOBERT®

& GROVIT

3/16" CHOBERT®

& GROVIT

1/4" CHOBERT®

3/32" BRIV®

Brass only

1/8" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

St.Steel only

3/16" BRIV®

Al. Alloy,

Brass, Steel

3/16" BRIV®

St.Steel only

6mm BRIV®

Al. Alloy, Steel

3/32" AVLUG®

1/8" AVLUG®

2.5mm, 4-40 UNC

AVSERT®

3.0mm, 6-32 UNC

AVSERT®

2.5mm AVTRONIC®

2.8mm AVTRONIC®

2.8mm RIVSCREW®

3.0mm RIVSCREW®

3.5mm RIVSCREW®

4.0mm RIVSCREW®

REF.

Nº

1

STD. CAM OPERATED - FLAT

1

2

4

5

5

6

6

7

7

8

8

9

9

10

10

11

12

13

14

15

15

16

16

LONG CURVED - RECESSED

17

18

18

19

20

20

21

22

22

23

24

24

25

26

27

27

STD. CAM OPERATED - FLAT

28

29

29

STD. CAM OPERATED - FLAT

30

31

32

33

34

35

37

38

STD. CAM OPERATED - HF

39

STD. CAM OPERATED - HF

40

STD. CAM OPERATED - HF

41

STD. CAM OPERATED - HF

TYPE AND

END FORM

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

STANDARD - TAPERED

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

STANDARD - TAPERED

LIMITED ACCESS

STANDARD - FLAT

STANDARD - TAPERED

LONG - RECESSED

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG - FLAT

LONG CURVED - FLAT

STD. CAM OPERATED

LONG CAM OPERATED

STANDARD - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

LONG CURVED - FLAT

STANDARD - FLAT

STANDARD - FLAT

STANDARD - FLAT

LONG - FLAT

STANDARD - FLAT

LONG - FLAT

NOSE JAW

07150-03003

07170-04500

07170-03103

07150-04003

07150-03004

07170-03104

07150-04004

07150-05004

07150-03005

07150-03105

07150-04005

07150-05005

07150-03006

07150-03106

07150-04006

07150-05006

07150-03008

07150-04008

07170-03103

07274-01000

07150-03004

07170-03104

07170-03204

07170-03304

07150-03005

07150-04005

07150-05005

07150-03005

07150-04005

07150-05005

07150-03006

07150-04006

07150-05006

07150-03006

07150-04006

07150-05006

07170-05600

07170-05700

07150-03003

07170-04500

07150-05003

07150-03004

07170-04600

07150-05004

07150-03003

07150-03004

07150-03003

07150-04003

07271-05600

07271-05900

07271-03000

07271-03000

07271-03500

07271-04000

PART Nº

DIMENSIONS

33.02

9.14

33.02

9.14

33.02

9.14

58.42

10.41

29.97

10.41

30.23

10.41

55.37

10.41

53.85

10.41

33.02

12.19

33.02

11.18

58.42

12.19

56.64

12.19

29.97

14.22

29.97

14.22

58.42

14.22

56.13

14.22

29.97

16.26

55.37

16.26

33.02

9.14

27.18

5.59

29.97

10.41

30.23

10.41

55.37

10.41

53.85

10.41

33.02

12.19

58.42

12.19

56.64

12.19

33.02

12.19

58.42

12.19

56.64

12.19

29.97

14.22

58.42

14.22

56.13

14.22

29.97

14.22

58.42

14.22

56.13

14.22

30.65

16.33

55.65

16.33

33.02

9.14

33.02

9.14

57.91

10.41

29.97

10.41

29.97

10.41

53.85

10.41

33.02

9.14

29.97

10.41

33.02

9.14

58.42

10.41

33.02

9.14

58.42

10.41

29.97

10.41

29.97

10.41

29.97

10.41

29.97

10.41

REF.

4.06

4.06

4.06

4.06

5.08

5.08

5.08

5.08

6.10

6.10

6.10

6.10

8.38

8.38

8.38

8.38

9.91

9.91

3.81

4.06

5.08

5.08

7.62

7.62

6.10

6.10

6.10

6.10

6.10

6.10

8.38

8.38

8.38

8.38

8.38

8.38

13.14

13.14

4.06

4.06

4.06

5.08

5.08

5.08

4.06

5.08

4.06

4.06

4.06

4.06

6.10

6.10

6.10

6.35

Nº

1

1

3

4

5

5

6

6

7

7

8

8

9

9

10

10

11

12

14

-

15

16

16

-

17

18

18

19

20

20

21

22

22

23

24

24

25

26

27

28

-

29

30

30

-

32

33

-

36

-

-

-

-

-

'D' 'E''B'

TYPE AND

END FORM

# STANDARD - UNIVERSAL

LTD. ACCESS CAM OPERATED

LIMITED ACCESS

LONG CURVED - FLAT

# STANDARD - UNIVERSAL

STD. CAM OPERATED - FLAT

# LONG - UNIVERSAL

LONG CAM OPERATED - FLAT

# STANDARD - UNIVERSAL

STD. CAM OPERATED - FLAT

# LONG - UNIVERSAL

LONG CAM OPERATED - FLAT

# STANDARD - UNIVERSAL

STD. CAM OPERATED - FLAT

# LONG - UNIVERSAL

LONG CAM OPERATED - FLAT

STD. CAM OPERATED - FLAT

LONG CAM OPERATED - FLAT

LTD. ACCESS CAM OPERATED

-

STANDARD - RECESSED

LONG - FLAT

LONG CURVED - FLAT

-

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - RECESSED

LONG - RECESSED

LONG CURVED - RECESSED

STANDARD - FLAT

LONG - FLAT

STANDARD - TAPERED

LONG - FLAT

-

STANDARD - TAPERED

LONG - FLAT

LONG CAM OPERATED - FLAT

-

STD. CAM OPERATED - FLAT

LTD. ACCESS CAM OPERATED

-

LTD. ACCESS CAM OPERATED

-

-

-

-

-

NOSE JAW

07150-03203

07177-03003

07274-01000

07150-05003

07150-03204

07170-04600

07150-04204

07170-05000

07150-03205

07170-04700

07150-04205

07170-05100

07150-03206

07170-04800

07150-04206

07170-05200

07170-04900

07170-05300

07177-03003

07170-03004

07150-04004

07150-05004

07170-03005

07170-03205

07170-03305

07170-03005

07170-03205

07170-03305

07170-03006

07170-03206

07170-03306

07170-03006

07170-03206

07170-03306

07170-05800

07170-05900

07150-03103

07150-04003

07170-03104

07150-04004

07170-05000

07170-04600

07271-08000

07271-08100

PART Nº

-

-

-

-

-

-

-

-

-

-

DIMENSIONS

33.78

9.14

29.97

5.08

27.18

5.59

57.91

10.41

30.99

10.41

29.97

10.41

56.39

10.41

55.37

10.41

34.29

12.19

33.02

12.19

59.69

12.19

58.42

12.19

31.50

14.22

29.97

14.22

60.71

14.22

58.42

14.22

29.97

16.26

55.37

16.26

29.97

5.08

-

30.48

10.41

55.37

10.41

53.85

10.41

-

33.53

12.19

58.42

12.19

56.64

12.19

33.53

12.19

58.42

12.19

56.64

12.19

30.48

14.22

58.42

14.22

56.13

14.22

30.48

14.22

58.42

14.22

56.13

14.22

30.65

16.33

55.65

16.33

33.02

9.14

58.42

10.41

-

30.23

10.41

55.37

10.41

55.37

10.41

-

29.97

10.41

29.97

10.41

-

29.97

10.16

-

-

-

-

-

'D' 'E''B'

6.10

4.06

4.06

4.06

8.13

5.08

7.62

5.08

10.41

6.10

10.67

6.10

11.94

8.38

12.19

8.38

9.91

9.91

4.06

-

-

7.62

5.08

5.08

-

-

10.41

10.41

10.41

10.41

10.41

10.41

11.94

11.94

11.94

11.94

11.94

11.94

13.14

13.14

4.06

4.06

-

-

5.08

5.08

5.08

-

-

5.08

4.06

-

-

4.06

-

-

-

-

-

-

-

-

-

-

17

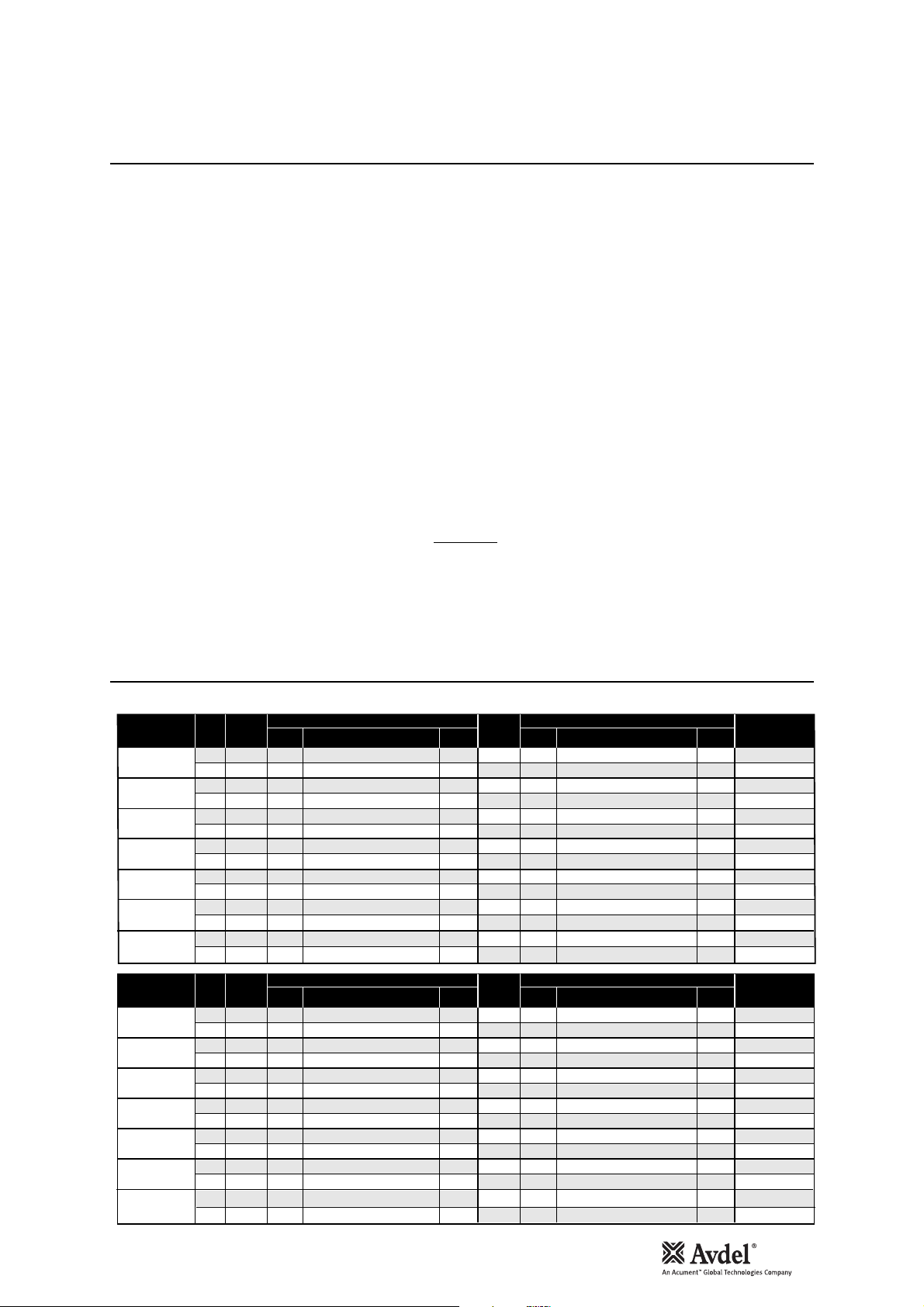

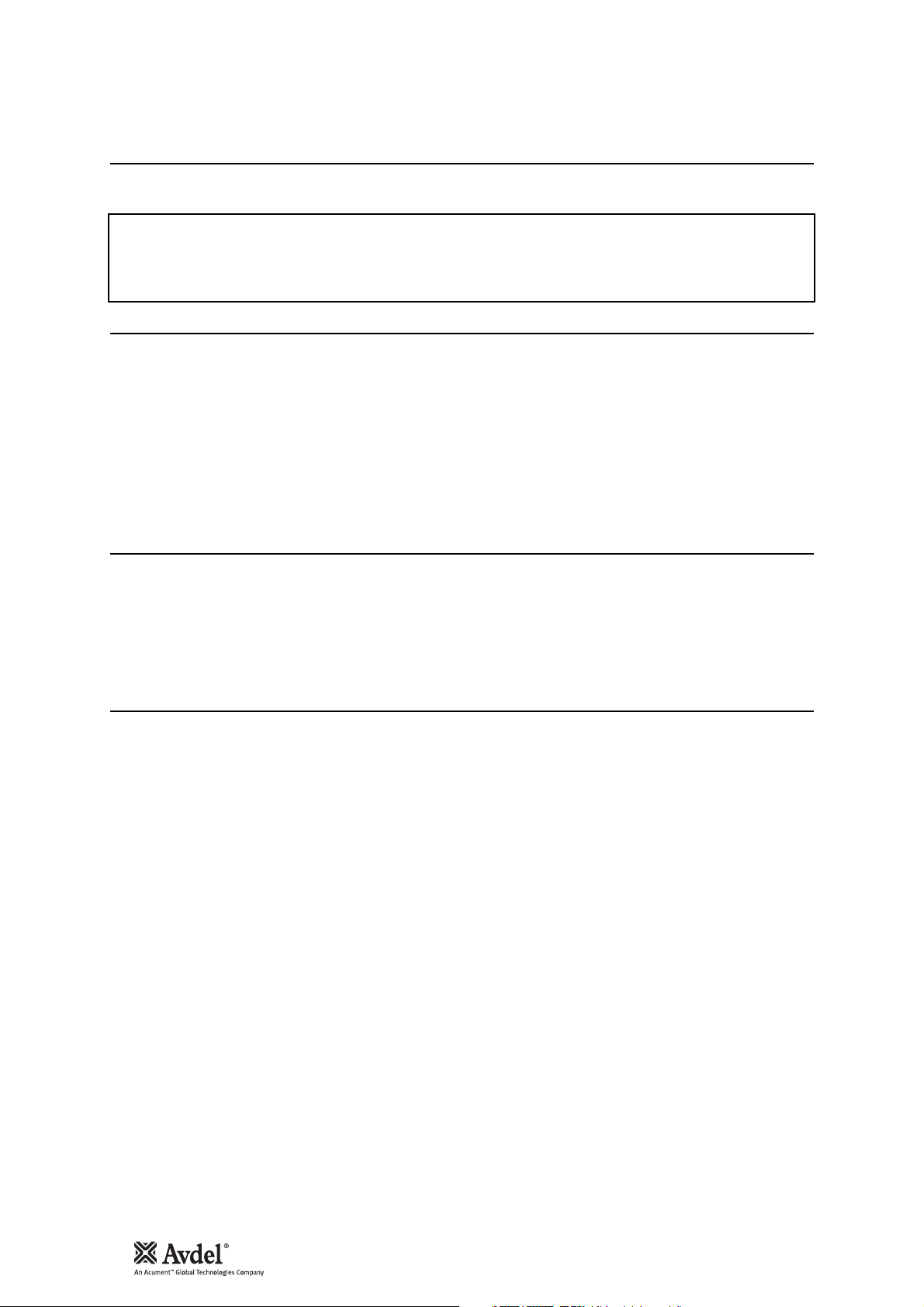

Mandrels and Mandrel Follower Springs

Chobert® and Grovit® - Imperial

Nose Assemblies

Mandrels and mandrel follower springs, illustrated on page 12 need to be selected to suit the fastener type and size as well as the size

of the hole in the application. Use of the wrong mandrel could increase the risk of breakage and the wear of the mandrel head.

Feeding problems could occur if the wrong mandrel follower spring is used.

For mandrel or mandrel follower spring selection, follow instructions on page 19.

IMPORTANT

READ THE SAFETY INSTRUCTIONS page 4 carefully.

While a small amount of wear and marking will naturally occur through normal and correct use of mandrels, they

must be regularly examined for excessive wear and marking, with particular attention to the head diameter, the

tail jaw gripping area of the shank or heavy pitting of the shank and any mandrel distortion. Mandrels which fail

during use could forcibly exit the tool. It is the customer’s responsibility to ensure that mandrels are replaced

before any excessive levels of wear and always before the maximum recommended number of placings. Contact

your Avdel representative who will let you know what that figure is by measuring the broach load of your

application with our calibrated measuring tool. These tools can also be purchased under part number 07900-

09080, supplied with all necessary information for testing.

# S/R: Short Reach Mandrel. See page 19-20 for explanation.

English

FASTENER

3/32" CHOBERT®

& GROVIT®

1/8" CHOBERT®

& GROVIT®

5/32" CHOBERT®

& GROVIT®

3/16" CHOBERT®

& GROVIT®

1/4" CHOBERT®

FASTENER

3/32" CHOBERT®

& GROVIT®

1/8" CHOBERT®

& GROVIT®

5/32" CHOBERT®

& GROVIT®

3/16" CHOBERT®

& GROVIT®

1/4" CHOBERT®

REF.

Nº

10

10

11

12

REF.

Nº

1

1

2

2

3

3

4

5

6

7

7

8

8

9

9

10

10

11

12

HOLE

HEAD

SIZE

.0725

AS REC.

1

-

1

.0725

AS REC.

2

-

2

.0725

AS REC.

3

-

3

.0725

AS REC.

4

AS REC.

5

AS REC.

6

AS REC.

7

-

7

AS REC.

8

-

8

AS REC.

9

-

9

AS REC.

AS REC.

AS REC.

HOLE

HEAD

SIZE

+.0035

+.0035

+.0035

+.0035

+.010

+.010

+.015

-

+.015

-

-

+.024

-

+.024

-

-

STANDARD MANDREL - GREEN

MANDREL

Ø

PART Nº

07150-06003

-

-

-

.088

.088

.107

-

.107

-

.132

-

.132

.184

.184

Ø

.076

.076

.076

.076

.098

.098

.122

.122

-

.156

.156

-

-

-

07150-06003

-

07150-06003

07150-07003

07150-06004

07150-07004

07150-06005

07150-07005

07150-06006

07150-07006

07150-06008

07150-07008

2ND OVERSIZE MANDREL - BLUE

MANDREL

PART Nº

07150-06103

07150-06103

07150-06103

07150-07103

07150-06204

07150-07204

07150-06205

07150-07205

-

07150-06206

07150-07206

-

-

P

MAX.

.166

.166

.166

.166

.216

.216

.244

.244

.247

.247

.268

.268

MAX.

.185

.185

.185

.185

.268

.268

.320

.320

.372

.372

-

-

-

-

-

-

-

P

-

-

-

-

-

-

-

-

-

# S/R MANDREL

PART Nº

07150-08003

-

07150-08003

-

07150-08003

07150-09003

07150-08004

07150-09004

07150-08005

07150-09005

07150-08006

07150-09006

07150-08008

07150-09008

# S/R MANDREL

PART Nº

-

-

-

-

-

-

07150-08204

07150-09204

07150-08205

07150-09205

-

07150-08206

07150-09206

-

-

P

MAX.

.071

-

.071

-

.071

.071

.090

.090

.100

.100

.102

.102

.110

.110

P

MAX.

-

-

-

-

-

-

.110

.110

.130

.130

-

.150

.150

-

-

HOLE

SIZE

+.0015

+.0035

+.0015

+.0035

+.0015

+.0035

+.0035

+.004

+.004

+.008

-

+.008

-

+.014

-

+.014

+.012

+.012

HOLE

SIZE

-

-

-

-

-

-

+.014

+.014

+.025

+.025

-

-

-

-

-

-

1ST OVERSIZE MANDREL - YELLOW

MANDREL

HEAD

PART Nº

Ø

07150-06303

.074

.076

07150-06303

.074

.076

07150-06303

.074

.076

.076

07150-06104

.092

07150-07104

.092

07150-06105

.115

07150-07105

.115

07150-06106

.146

07150-07106

.146

07150-06108

.196

07150-07108

.196

3RD OVERSIZE MANDREL - RED

MANDREL

HEAD

PART Nº

Ø

-

-

-

-

-

-

07150-06304

.102

07150-07304

.102

07150-06305

.132

07150-07305

.132

-

-

-

-

-

-

MAX.

-

-

-

-

-

-

-

-

MAX.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

P

# S/R MANDREL

.174

-

.174

-

.174

-

.237

.237

.284

.284

.320

.320

.330

.330

P

# S/R MANDREL

-

-

-

-

-

-

.288

.288

.372

.372

-

-

-

-

-

-

PART Nº

-

07150-08103

-

07150-08103

07150-08103

07150-09103

07150-08104

07150-09104

07150-08105

07150-09105

07150-08106

07150-09106

07150-08108

07150-09108

PART Nº

-

-

-

-

-

-

07150-08304

07150-09304

07150-08305

07150-09305

-

-

-

-

-

-

P

MAX.

-

.078

-

.078

.078

.078

.098

.098

.116

.116

.130

.130

.134

.134

P

MAX.

-

-

-

-

-

-

.118

.118

.150

.150

-

-

-

-

-

-

SPRING

PART Nº

07150-06803

07150-06803

07170-06873

07170-06873

07170-06903

07170-06903

07150-07803

07150-06804

07150-07804

07170-06875

-

07170-07875

-

07170-06876

-

07170-07876

07150-06808

07150-07808

SPRING

PART Nº

07150-06803

07170-06873

07170-06903

07150-07803

07150-06804

07150-07804

07170-06875

07150-06805

07170-07875

07150-07805

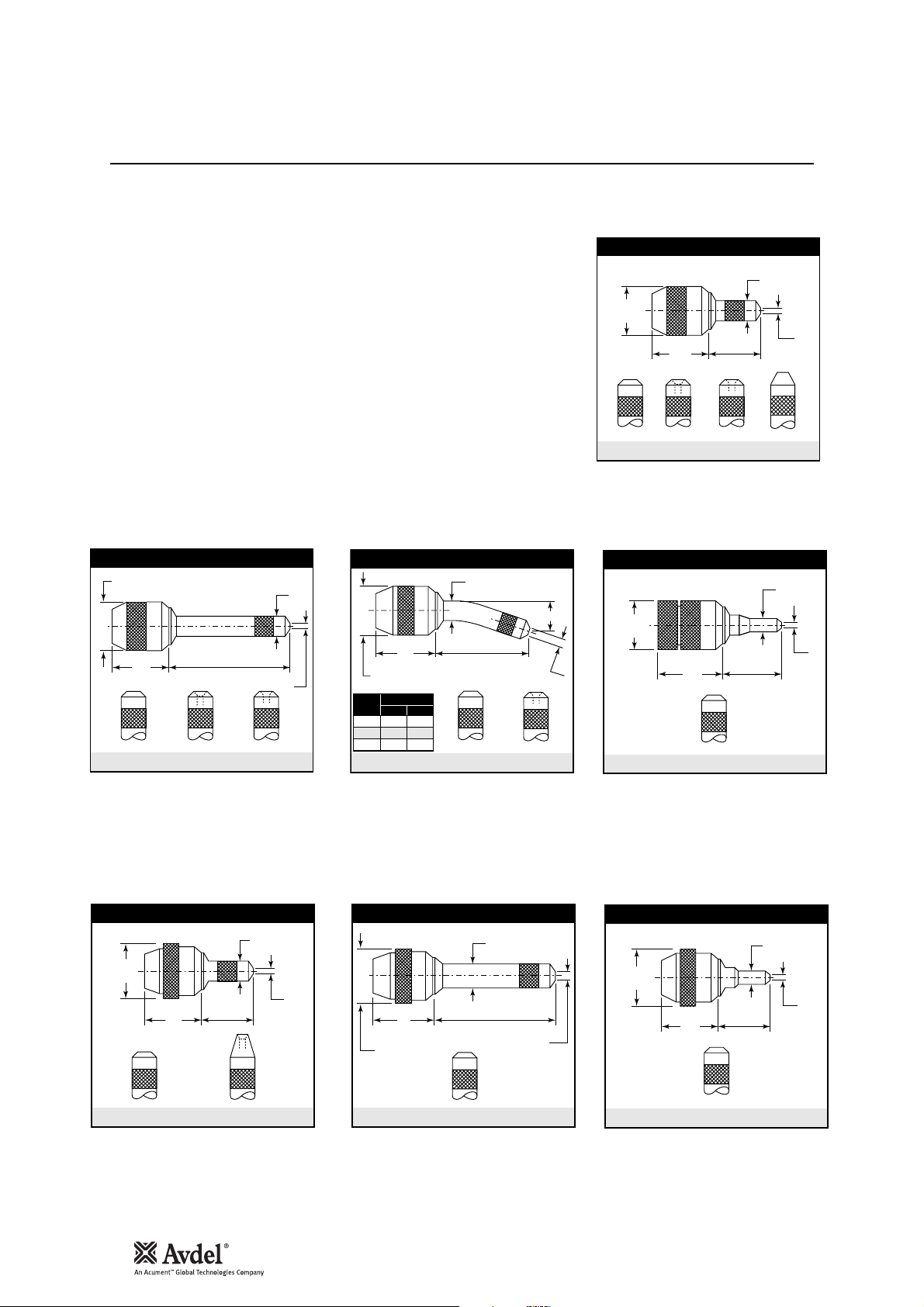

07150-06806

07150-07806

-

-

18

Nose Assemblies

Tables below left and right and over the next four pages list part numbers of all mandrels and mandrel follower springs available per

fastener or group of fasteners, i.e. for Chobert

®

and Grovit®on these pages.

While fastener sizes are always shown in their specified units, each table has been produced twice to offer dimensions in imperial units

on the left-hand page then in metric units on the right-hand page. These 'Mandrel Selection' tables cross-reference with the 'Nose Jaw

Selection' tables on pages 15-16 through the ‘Ref. Nº’ column.

It is the diameter of the head at the end of a mandrel which when pulled through controls the expansion of the fastener body.

While there are different head shapes to suit different types of fasteners (see illustration on page 20), progressive head sizes are

needed to reflect manufacturing tolerances on the diameter of the hole in your application so that the fastener always expands

sufficiently to fill the hole.

Too large a mandrel head would overstress the mandrel and mandrels which fail during use could forcibly exit the tool.

Selection tables are arranged into four 'mandrel size' sections, ranging from 'standard’ to '3rd oversize', each being colour coded as

per the end of the mandrel heads themselves.

# S/R: Short Reach Mandrel. See page 19-20 for explanation.

Chobert® and Grovit® - Metric

FASTENER

3/32" CHOBERT®

& GROVIT®

1/8" CHOBERT®

& GROVIT®

5/32" CHOBERT®

& GROVIT®

3/16" CHOBERT®

& GROVIT®

1/4" CHOBERT®

FASTENER

3/32" CHOBERT®

& GROVIT®

1/8" CHOBERT®

& GROVIT®

5/32" CHOBERT®

& GROVIT®

3/16" CHOBERT®

& GROVIT®

1/4" CHOBERT®

REF.

Nº

1

1

2

2

3

3

4

5

6

7

7

8

8

9

9

10

10

11

12

REF.

Nº

10

10

11

12

1

1

2

2

3

3

4

5

6

7

7

8

8

9

9

HOLE

SIZE

AS REC.

-

AS REC.

-

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

HOLE

SIZE

+.09

-

+.09

-

+.09

-

+.09

+.25

+.25

+.38

-

+.38

-

-

+.60

-

+.60

-

-

HEAD

HEAD

STANDARD MANDREL - GREEN

MANDREL

Ø

PART Nº

1.84

07150-06003

-

1.84

-

1.84

-

1.84

2.24

2.24

2.72

-

2.72

-

3.35

-

3.35

-

4.67

4.67

Ø

1.93

-

1.93

-

1.93

-

1.93

2.49

2.49

3.10

-

3.10

-

-

3.96

-

3.96

-

-

-

07150-06003

-

07150-06003

07150-07003

07150-06004

07150-07004

07150-06005

07150-07005

07150-06006

07150-07006

07150-06008

07150-07008

2ND OVERSIZE MANDREL - BLUE

MANDREL

PART Nº

07150-06103

07150-06103

07150-06103

07150-07103

07150-06204

07150-07204

07150-06205

07150-07205

-

07150-06206

07150-07206

-

-

P

# S/R MANDREL

MAX.

4.22

-

4.22

-

4.22

-

4.22

5.49

5.49

6.20

-

6.20

-

6.27

-

6.27

-

6.81

6.81

P

# S/R MANDREL

MAX.

4.70

-

4.70

-

4.70

-

4.70

6.81

6.81

8.13

-

8.13

-

-

9.45

-

9.45

-

-

PART Nº

07150-08003

-

07150-08003

-

07150-08003

07150-09003

07150-08004

07150-09004

07150-08005

07150-09005

07150-08006

07150-09006

07150-08008

07150-09008

PART Nº

-

-

-

-

-

-

07150-08204

07150-09204

07150-08205

07150-09205

-

07150-08206

07150-09206

-

-

P

MAX.

1.80

-

1.80

-

1.80

-

1.80

2.29

2.29

2.54

-

2.54

-

2.59

-

2.59

-

2.79

2.79

P

MAX.

2.79

2.79

3.30

3.30

3.81

3.81

HOLE

SIZE

+.04

+.09

+.04

+.09

+.04

+.09

+.09

+.10

+.10

+.20

-

+.20

-

+.35

-

+.35

+.30

+.30

HOLE

SIZE

-

-

-

-

-

-

-

-

-

-

-

-

-

+.35

+.35

-

+.63

-

-

+.63

-

-

-

-

-

-

-

-

-

-

-

1ST OVERSIZE MANDREL - YELLOW

MANDREL

HEAD

Ø

1.88

1.93

1.88

1.93

1.88

1.93

1.93

2.34

2.34

2.92

-

2.92

-

3.71

-

3.71

-

4.98

4.98

HEAD

Ø

-

-

-

-

-

-

-

2.59

2.59

-

3.35

-

3.35

-

-

-

-

-

-

PART Nº

07150-06303

07150-06303

07150-06303

07150-06104

07150-07104

07150-06105

07150-07105

07150-06106

07150-07106

07150-06108

07150-07108

3RD OVERSIZE MANDREL - RED

MANDREL

PART Nº

07150-06304

07150-07304

07150-06305

07150-07305

MAX.

-

-

-

-

-

-

-

-

MAX.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

P

# S/R MANDREL

4.42

-

4.42

-

4.42

-

-

6.02

6.02

7.21

-

7.21

-

8.13

-

8.13

-

8.38

8.38

P

# S/R MANDREL

-

-

-

-

-

-

-

7.32

7.32

-

9.45

-

9.45

-

-

-

-

-

-

PART Nº

-

07150-08103

-

07150-08103

07150-08103

07150-09103

07150-08104

07150-09104

07150-08105

07150-09105

07150-08106

07150-09106

07150-08108

07150-09108

PART Nº

-

-

-

-

-

-

07150-08304

07150-09304

07150-08305

07150-09305

-

-

-

-

-

-

P

MAX.

1.98

1.98

1.98

1.98

2.49

2.49

2.95

2.95

3.30

3.30

3.40

3.40

P

MAX.

3.00

3.00

3.81

3.81

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

07150-06803

07150-06803

07170-06873

07170-06873

07170-06903

07170-06903

07150-07803

07150-06804

07150-07804

07170-06875

07170-07875

07170-06876

07170-07876

07150-06808

07150-07808

07150-06803

07170-06873

07170-06903

07150-07803

07150-06804

07150-07804

07170-06875

07150-06805

07170-07875

07150-07805

07150-06806

07150-07806

SPRING

PART Nº

-

-

-

-

SPRING

PART Nº

-

-

-

-

-

-

-

19

Briv® - Imperial

Nose Assemblies

For mandrel or mandrel follower spring selection, follow instructions above.

To find the correct part number of a mandrel for a particular application, read the instructions below after you have gathered the following

information as per example alongside. Answers for the example are shown in

grey italic.

FASTENER NAME

example Chobert

®

FASTENER SIZE

1

/8”

DATASHEET

Series 1125

APPLICATION HOLE SIZE

0.1335”

CLEARANCE BEHIND APPLICATION

Infinite

‘REF.Nº’ FROM NOSE JAW SELECTION TABLE

5 (standard flat)

• Subtract the minimum hole size recommended (AS REC.) in the fastener datasheet from the actual application hole size.

-example: 0.005.

• Turn to the page with the ‘Mandrel Selection’ table for your fastener, selecting either the imperial or the metric dimensions table

(pages 17-21).

-example: page 17.

• Staring with the ‘Standard Mandrel - Green’ section, find your fastener size in the left-hand column.

-example 1/8” Chobert®& Grovit®.

• If you selected a nose jaw which place you fastener, you should now be able to find a line within your fastener section with the same ‘Ref

No.’ as that from the ‘Nose Jaw Selection’ table.

-example: 5.

This is your line ‘Ref. No.’ in which you will find both your mandrel and

mandrel follower spring part number. This line continues into the second half of the table for the ‘2nd’ and ‘3rd’ oversize mandrels.

• Scan along the line to the ‘hole size’ columns and select which ever is the nearest or equal to the figure calculated in step one. You may

now read the mandrel part number next to the ‘hole size’.

-example: 07150-06104

• For Chobert

®

and Grovit®only, most mandrels are also available in a ‘short reach’ version (see illustration on page 20). Short reach

mandrels are used to minimise the possibility of the mandrel head contacting a read obstruction. This would result in the underside of the

fastener head not seating properly on the application surface, causing a lack on clench in the joint.

• Whichever size mandrel you settle on, you will also need to check the ‘P’ figure against that mandrel is adequate. ‘P’ is the clearance

required for the mandrel head at the back of the application IN ADDITION

to the length of the fastener protruding through the application,

as shown in the illustration on page 20.

• You may now read the corresponding mandrel follower spring part number in the right-hand column of the table.

-example: 07150-06804.

In all cases, satisfactory clenching of the joint should be assessed particularly if the size of the hole in your application is very close to the next

oversize hole condition, when it will be safe to select the greater size of mandrel to obtain a higher clench. REMEMBER that this will increase

the broach load and reduce the mandrel life.

English

FASTENER

3/32" BRIV®

Brass only

1/8" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

St.Steel only

3/16" BRIV®

Al. Alloy,

Brass, Steel

3/16" BRIV®

St.Steel only

6mm BRIV®

Al. Alloy, Steel

FASTENER

3/32" BRIV®

Brass only

1/8" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

St.Steel only

3/16" BRIV®

Al. Alloy,

Brass, Steel

3/16" BRIV®

St.Steel only

6mm BRIV®

Al. Alloy, Steel

REF.

Nº

13

14

15

16

17

18

19

20

21

22

23

24

25

26

REF.

Nº

13

14

15

16

17

18

19

20

21

22

23

24

25

26

HOLE

SIZE

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC

AS REC

HOLE

SIZE

+.008

+.008

+.010

+.010

+.010

+.010

-

+.010

+.010

-

+.010

+.010

STANDARD MANDREL - GREEN

HEAD

Ø

.072

.072

.092

.092

.110

.110

.120

.120

.141

.141

.153

.153

.179

.179

2ND OVERSIZE MANDREL - BLUE

HEAD

Ø

.079

.079

.102

.102

.120

.120

-

.151

.151

-

.189

.189

MANDREL

PART Nº

07150-06013

07150-06013

07271-06414

07271-07414

07150-06015

07150-07015

07170-06805

07170-07805

07150-06016

07150-07016

07170-06806

07170-07806

07150-06018

07150-07018

MANDREL

PART Nº

07150-06213

07150-06213

07271-06614

07271-07614

07150-06215

07150-07215

07150-06216

07150-07216

07150-06218

07150-07218

HOLE

P

SIZE

MAX.

.119

+.004

.119

+.004

.120

+.005

.120

+.005

.136

+.005

.136

+.005

.126

+.005

.126

+.005

.157

+.005

.157

+.005

.150

+.005

.150

+.005

.165

+.005

.165

+.005

HOLE

P

SIZE

MAX.

.126

.126

.133

.133

.149

.149

-

.170

.170

-

.177

.177

-

-

-

-

-

-

-

-

-

+.012

+.012

-

-

-

-

-

-

1ST OVERSIZE MANDREL - YELLOW

HEAD

Ø

.076

.076

.097

.097

.115

.115

.125

.125

.146

.146

.158

.158

.184

.184

HEAD

Ø

-

-

-

-

-

-

-

.153

.153

-

-

-

-

MANDREL

PART Nº

07150-06113

07150-06113

07271-06514

07271-07514

07150-06115

07150-07115

07170-06825

07170-07825

07150-06116

07150-07116

07170-06826

07170-07826

07150-06118

07150-07118

3RD OVERSIZE MANDREL - RED

MANDREL

PART Nº

-

-

-

-

-

-

-

07150-06316

07150-07316

-

-

-

-

MAX.

.123

.123

.126

.126

.142

.142

.132

.132

.164

.164

.156

.156

.171

.171

MAX.

.173

.173

P

P

-

-

-

-

-

-

-

-

-

-

-

-

SPRING

PART Nº

07170-06873

07170-06903

07150-06814

07150-07814

07170-06875

07170-07875

07170-06875

07170-07875

07170-06876

07170-07876

07170-06876

07170-07876

07150-06846

07150-07846

SPRING

PART Nº

07170-06873

07170-06903

07150-06814

07150-07814

07170-06875

07170-07875

-

07170-06876

07170-07876

-

07150-06846

01750-07846

20

Mandrel Head Types and ‘P’ Length

Briv® - Metric

Nose Assemblies

Mandrels for stainless steel Briv®are easily identifiable by a ‘V’ cut in the end of the mandrel heads.

When using curved nose jaws, mandrels have to be bent by hand to match the curvature of the nose jaw, thus ensuring good feed of

fasteners.

CHOBERT®, GROVIT®,

AVSERT®, AVTRONIC®

BRIV®

RIVSCREW®

REF.

FASTENER

3/32" BRIV®

Brass only

1/8" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

St.Steel only

3/16" BRIV®

Al. Alloy,

Brass, Steel

3/16" BRIV®

St.Steel only

6mm BRIV®

Al. Alloy, Steel

FASTENER

3/32" BRIV®

Brass only

1/8" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

Al. Alloy,

Brass, Steel

5/32" BRIV®

St.Steel only

3/16" BRIV®

Al. Alloy,

Brass, Steel

3/16" BRIV®

St.Steel only

6mm BRIV®

Al. Alloy, Steel

Nº

13

14

15

16

17

18

19

20

21

22

23

24

25

26

REF.

Nº

13

14

15

16

17

18

19

20

21

22

23

24

25

26

HOLE

SIZE

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC

AS REC

HOLE

SIZE

+.20

+.20

+.25

+.25

+.25

+.25

-

+.25

+.25

-

+.25

+.25

STANDARD MANDREL - GREEN

HEAD

Ø

1.83

1.83

2.34

2.34

2.79

2.79

3.05

3.05

3.58

3.58

3.89

3.89

4.54

4.54

HEAD

Ø

2.01

2.01

2.59

2.59

3.05

3.05

3.84

3.84

4.79

4.79

-

-

-

-

MANDREL

PART Nº

07150-06013

07150-06013

07271-06414

07271-07414

07150-06015

07150-07015

07170-06805

07170-07805

07150-06016

07150-07016

07170-06806

07170-07806

07150-06018

07150-07018

2ND OVERSIZE MANDREL - BLUE

MANDREL

PART Nº

07150-06213

07150-06213

07271-06614

07271-07614

07150-06215

07150-07215

07150-06216

07150-07216

07150-06218

07150-07218

P

SHORT REACH

(CHOBERT® &

GROVIT® ONLY)

P P

BRIV®

(STAINLESS STEEL)

P

AVLUG®

HOLE

P

SIZE

MAX.

3.02

+.10

3.02

+.10

3.05

+.13

3.05

+.13

3.45

+.13

3.45

+.13

3.20

+.13

3.20

+.13

3.99

+.13

3.99

+.13

3.81

+.13

3.81

+.13

4.18

+.13

4.18

+.13

HOLE

P

SIZE

MAX.

3.20

3.20

3.38

3.38

3.78

3.78

-

-

4.32

4.32

-

-

4.49

4.49

-

-

-

-

-

-

-

-

-

+.30

+.30

-

-

-

-

-

-

1ST OVERSIZE MANDREL - YELLOW

HEAD

Ø

1.93

1.93

2.46

2.46

2.92

2.92

3.18

3.18

3.71

3.71

4.01

4.01

4.67

4.67

HEAD

Ø

-

-

-

-

-

-

-

-

3.85

3.85

-

-

-

-

MANDREL

PART Nº

07150-06113

07150-06113

07271-06514

07271-07514

07150-06115

07150-07115

07170-06825

07170-07825

07150-06116

07150-07116

07170-06826

07170-07826

07150-06118

07150-07118

3RD OVERSIZE MANDREL - RED

MANDREL

PART Nº

-

-

-

-

-

-

-

07150-06316

07150-07316

-

-

-

-

P

MAX.

3.12

3.12

3.20

3.20

3.61

3.61

3.35

3.35

4.17

4.17

3.96

3.96

4.34

4.34

P

MAX.

4.39

4.39

-

-

-

-

-

-

-

-

-

-

-

-

P

SPRING

PART Nº

07170-06873

07170-06903

07150-06814

07150-07814

07170-06875

07170-07875

07170-06875

07170-07875

07170-06876

07170-07876

07170-06876

07170-07876

07150-06846

07150-07846

SPRING

PART Nº

07170-06873

07170-06903

07150-06814

07150-07814

07170-06875

07170-07875

07170-06876

07170-07876

07150-06846

07150-07846

P

-

-

-

-

21

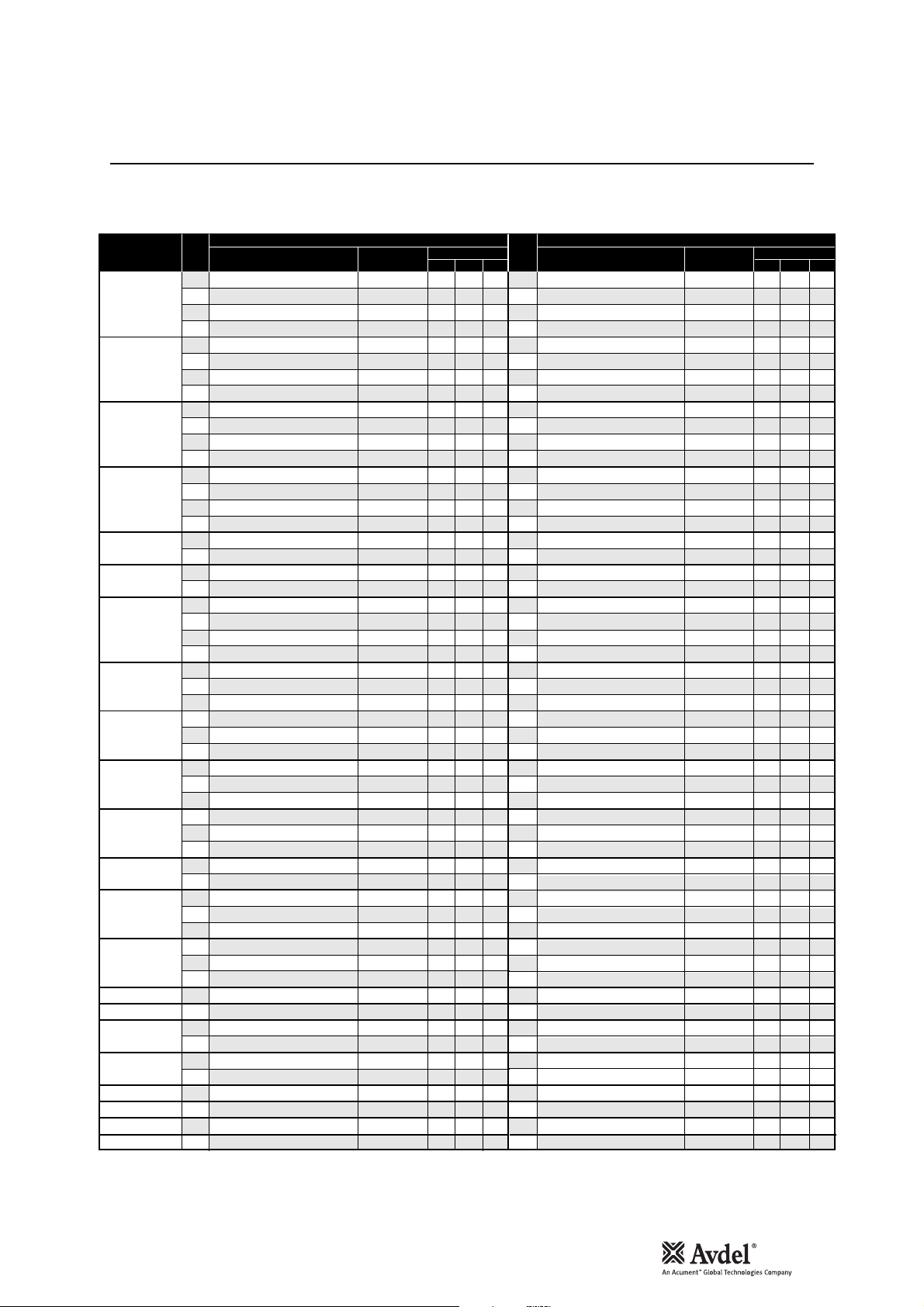

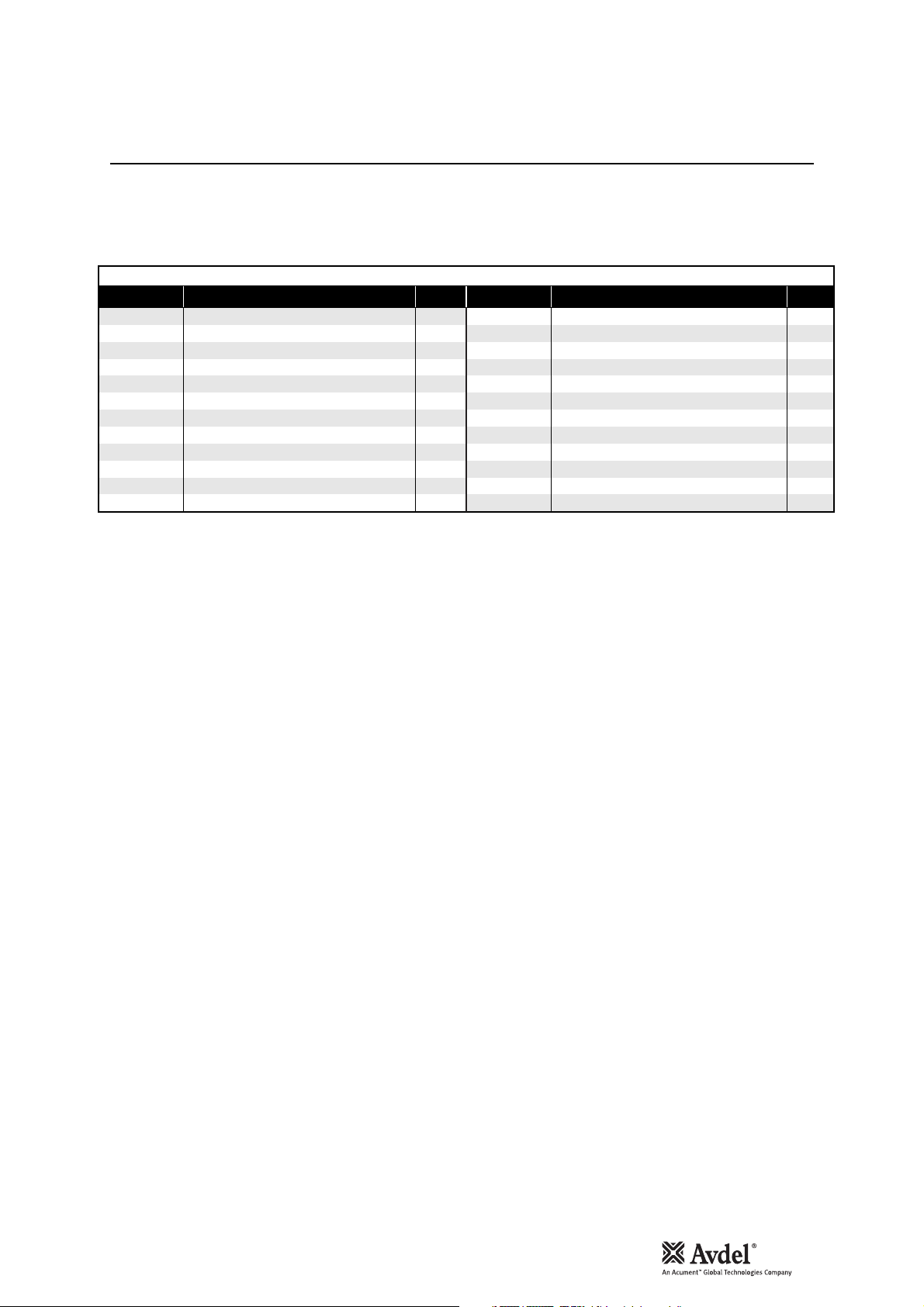

Avlug®, Avsert®, Avtronic® & Rivscrew® - Imperial & Metric

Nose Assemblies

For mandrel or mandrel follower spring selection, follow instructions on page 19.

FASTENER

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

P

MAX.

SPRING

PART Nº

STANDARD MANDREL - GREEN

HOLE

SIZE

1ST OVERSIZE MANDREL - YELLOW

3/32" AVLUG®

1/8" AVLUG®

2.5mm AVTRONIC®

2.8mm AVTRONIC®

2.8mm RIVSCREW®

3.0mm RIVSCREW®

3.5mm RIVSCREW®

4.0mm RIVSCREW®

2.5mm, 4-40 UNC

AVSERT®

3.0mm, 6-32 UNC

AVSERT®

.353

.353

.593

.593

.145

.185

.140

.140

.150

.150

.150

.127

.127

.132

.150

MANDREL

PART Nº

07150-06603

07150-07603

07150-06604

07150-07604

07150-06003

07150-06004

07170-06025

07170-07025

07170-06028

07170-06028

07170-07028

07271-06030

07271-06030

07271-06035

07271-06140

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

AS REC.

HEAD

Ø

.076

.076

.098

.098

.0725

.088

.070

.070

.079

.079

.079

* .065

* .065

* .0825

* .103

P

MAX.

HOLE

SIZE

.478

.368

-

-

-

.140

.140

.150

.150

.150

-

-

-

-

MANDREL

PART Nº

07150-06703

07150-07703

-

-

-

07170-06125

07170-07125

07170-06128

07170-06128

07170-07128

-

-

-

-

+.005

+.003

-

-

-

+.003

+.003

+.003

+.003

+.003

-

-

-

-

HEAD

Ø

.081

.079

-

-

-

.073

.073

.082

.082

.082

-

-

-

-

07150-06803

07150-07803

07150-06804

07150-07804

07150-06803

07150-06804

07150-06803

07150-07803

07170-06528

07170-06873

07170-07528

07271-06630

07271-06630

07271-06635

07271-06640

FASTENER

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

P

MAX.

SPRING

PART Nº

2ND OVERSIZE MANDREL - BLUE

HOLE

SIZE

3RD OVERSIZE MANDREL - RED

3/32" AVLUG®

1/8" AVLUG®

2.5mm AVTRONIC®

2.8mm AVTRONIC®

2.8mm RIVSCREW®

3.0mm RIVSCREW®

3.5mm RIVSCREW®

4.0mm RIVSCREW®

2.5mm, 4-40 UNC

AVSERT®

3.0mm, 6-32 UNC

AVSERT®

-

-

-

-

-

.140

.140

.150

.150

.150

-

-

-