Page 1

,QVWDOODWLRQIRU$GMXQFWVDQG3HULSKHUDOV

IRU$YD\D0XOWL9DQWDJH6RIWZDUH

Release 1.2

555-233-116

Issue 4

October 2002

Page 2

Copyright 2002, Avaya Inc.

All Rights Reserved

Notice

Every effort was made to ensur e that the in forma tion in th is docume nt

was complete and accurate at the time of printing. However, information is subject to change.

Preventing Toll Fraud

“Toll fraud” is the unauthorized use of your telecommunications system by an unauthorized party (for example, a person who is not a corporate employee, agent, subcontractor, or is not working on your

company's behalf). Be aw a re that there may be a risk of toll fraud

associated with your system and that, if toll fraud occurs, it can result

in substantial additional charges for your telecommunications services.

Avaya Fraud Intervention

If you suspect that you are being victimized by toll fraud and you need

technical assistance or suppor t, in the U ni ted States and Canada, call

the Technical Service Center's Toll Fraud Intervention Hotline at

1-800-643-2353.

How to Get Help

For additional support telephone numbers, go to the Avaya Web site:

http://www.avaya.com/support/

If you are:

• Within the United States, click Escalatio n Lists, which includes

escalation phone numbers within the U SA .

• Outside the United States, click Escalation Lists then click Glo-

bal Escalation List, which includes phone numbers for the

regional Centers of Excellence.

Providing Telecommunications Security

Telecommunications security (of voice, data, and/or video communications) is the prevention of any type of intrusion to (that is, either

unauthorized or malicious access to or use of) your company's telecommunications equi pm ent by some party.

Your company's “t elecommunications equipme n t ” includes both this

Avaya product and any other voice/data/video equipment that could be

accessed via this Avaya product (that is, “networked equipment”).

An “outside party” is an yone who is not a corporate employee, age n t ,

subcontractor, or is not working on your company's behalf. Whereas, a

“malicious party” is anyone (in cl uding someone who may be otherwise authorized) who accesses your telecommunications equipment

with either malicious or mischievous intent.

Such intrusions may be either to/through synchronous (time-multiplexed and/or circuit-based) or asynchronous (character-, message-, or

packet-based) equipment or interfaces for reasons of:

• Utilization (of capabilities special to the accessed equipment)

• Theft (such as, of intellectual property, financial assets, or toll

facility acces s )

• Eavesdropping (privacy invasions to humans)

• Mischief (troubling, but appare ntl y in noc uous, tampering)

• Harm (such as harmful tampering, data loss or alteration,

regardless of motive or intent)

Be aware that there may be a ri sk of unauthorized intrusions associated with your system and/or its networked equipment. Also realize

that, if such an intrusion should oc cur, it could result in a variety of

losses to your company (including but not limited to, human/data privacy, intellectual property, material assets, financial resources, labor

costs, and/or legal costs).

Responsibility for Your Company’s Telecommunications Security

The final responsibility for securi ng both this system and its net-

worked equip men t rests with you - Avaya’s customer system adminis-

trator, your telecommunications peers, and your managers. Base the

fulfillment of your responsibility on acquired knowledge and

resources from a variety of sources incl udi ng but not limited to:

• Installation documents

• System administration docum en ts

• Security documents

• Hardware-/software-based security tools

• Shared information between you and your peers

• Telecommunications security experts

To prevent intrusions to your telecommunications equipment, you and

your peers should carefully pro gra m a nd c onfi gure:

• Your Avaya-provided telecommunications systems and their

• interfaces

• Your Avaya-provided software applications, as well as their

• underlying hardware/software platforms and interface s

• Any other equipment ne tworked to your Avaya products.

Voice Over Inte rn et Protocol ( VoIP)

If the equipment supports Voice over Internet Protocol (VoIP) facilities, you may experience c ert ai n compromises in performance, reliability and security, even when the equipm e n t performs as warranted.

These compromises may become more acute if you fail to follow

Avaya's recommendations for configuration, operation an d use of the

equipment. YOU ACKNOWLEDGE THAT YOU ARE AWARE OF

THESE RISKS AND THA T YOU HAVE DETERMINED THEY

ARE ACCEPTABLE FOR YOUR APPLICATION OF THE EQUIPMENT. YOU ALSO ACKNOWLEDGE THAT, UNLESS

EXPRESSLY PROVIDED IN ANOTHER AGREEMENT, YOU

ARE SOLELY RESPONSIBLE FOR (1) ENSURING THAT YOUR

NETWORKS AND SYSTEMS ARE ADEQUATELY SECURED

AGAINST UNAUTHORIZED INTRUSION AND (2) BACKING

UP YOUR DATA AND FILES.

Standards Compliance

Avaya Inc. is not responsible for any radio or television interference

caused by unauthorize d m odifications of this equipment or the substitution or attachment of connecti n g cables and equipment other than

those specif ied by Avaya Inc. The co rr ecti on o f i nt erf eren ce c aus ed b y

such unauthorized modifi ca t ions, substitution or attachment will be

the responsibility of the user. Pursuant to Part 15 of the Federal Communications Commission (FCC) Rules, the user is cautioned that

changes or modifications not expressly approved by Avaya Inc. could

void the user’s author ity to operate this equip ment.

Product Safety Standards

This product complies with and co nf o r ms to the fo llowing international Product Safety standards as applicable:

Safety of Information T echnology Equipment, IEC 60950, 3rd Edition

including all relevant national deviations as listed in Compliance with

IEC for Electrical Equipment (IECEE) CB-96A.

Safety of Information Technology Equipment , CAN/CSA-C22.2

No. 60950-00 / UL 60950, 3r d Edition

Page 3

Safety Requirements for Custome r Equipment, ACA Technical Standard (TS) 001 - 1997

One or more of the following Mexican national standards, as applicable: NOM 001 SCFI 1993, NOM SCFI 016 1993, NOM 019 SCFI

1998

The equipment describe d i n thi s document may contain Class 1

LASER Device(s). These devices comply with the following standards:

EN 60825-1, Edition 1. 1, 19 98-01

21 CFR 1040.10 and CFR 1040 .11.

The LASER devices o perate within the following parameters:

• Maximum power output: -5 dBm to -8 dB m

• Center Wavelength: 1310 nm to 1360 nm

Luokan 1 Laserlaite

Klass 1 Laser Apparat

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation exposures. Contact your Avaya representative for more laser product information.

Electromagnetic Compatibility (EM C) Standards

This product complies with and conforms to the following international EMC standards and all relevant national deviations:

Limits and Methods of Measurement of Radio Interference of Information Technology Equipment, CISPR 22:1997 and EN55022:1998.

Information Technology Equipment – Immunity Characteristics –

Limits and Methods of Measurement, CISPR 24:1997 and

EN55024:1998, including:

• Electrostatic Discharge (ESD) IEC 61000-4-2

• Radiated Immunity IE C 61000-4-3

• Electrical Fast Transient IEC 61000-4-4

• Lightning Effects IEC 61000-4-5

• Conducted Immunity IEC 61000-4-6

• Mains Frequency Magnetic Field IEC 61 000-4-8

• Voltage D ips and Variations IEC 61000-4-11

• Powerline Harmonics IEC 61000-3-2

• Voltage Flu ct ua ti ons a nd Fli c ker IEC 61000-3-3

Federal Communications Commission Statement

Part 15:

For MCC1, SCC1, G600, and C M C 1 M edia Gateways:

Note: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Pa rt 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipm e n t is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Oper ation of this

equipment in a r esidential area is likely to ca us e harmful interference in which case the user will be required to correct the interference at his own expense.

For the G700 Media Gateway:

Note: This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against h a r m ful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. However, there is no guarantee that radio interference will not occur in a particular installation. I f th is equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off

and on, the user is enc ou raged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

Part 68: Answer-Supervision Signaling. Allowing this equipment to

be operated in a manner that does not provide proper answer-supervision signaling is in violation of Part 68 rules. Thi s equi pm e nt returns

answer-supervision signals to the pub lic sw it c hed network when:

• answered by the called station,

• answered by the attendant, or

• routed to a recorded announcement that can be administered by

the customer premises equipment (CPE) user.

This equipment returns an sw er-supervision signals on all direct

inward dialed (DID) calls forward ed back to the public swi tched telephone network. Permissible ex ce pt ion s are :

• A call is unanswered.

• A busy tone is received.

• A reorder tone is received.

Avaya attests that this registered equipment is capable of providing

users access to int erstate providers of operato r services th rough the use

of access codes. Modification of this equipment by call aggregators to

block access dialing codes is a vi ol ation of the Telephone Operator

Consumers Act of 1990.

For MCC1, SCC1, G600, and CMC1 Media Gateways:

This equipmen t comp l ies with P art 68 of t he F CC rul es . On the r ear of

this equipment is a label that contains, among other information , th e

FCC registration number and ringer equivalence number (REN) for

this equipment. If req uest ed, this information must be provided to the

telephone compan y.

For the G700 Media Gateway:

This equipment complie s with Part 68 of th e FCC rules and the

requirements adopted by the ACTA. Located prominently on this

equipment is a label that contains, among other information, a product

identifier in the format US:AAAEQ##TXXXX. The digi ts represented

by ## are the ringer eq uivalence number (REN) without a decimal

point (for example, 03 is a REN of 0.3). If requested, this number must

be provided to the telephone company.

The REN is used to determine the qua nt it y of de vices which may be

connected to the telephone line. Excessive RENs on the telephone line

may result in devices not ringing in response to an incoming call. In

most, but not all areas, the sum of REN s should not exceed 5.0. To be

certain of the num ber of devices that may be connect ed to a line, as

determined by the total RENs, contact the local telephone company.

REN is not required for some t ype s of analog or digital facilities.

Page 4

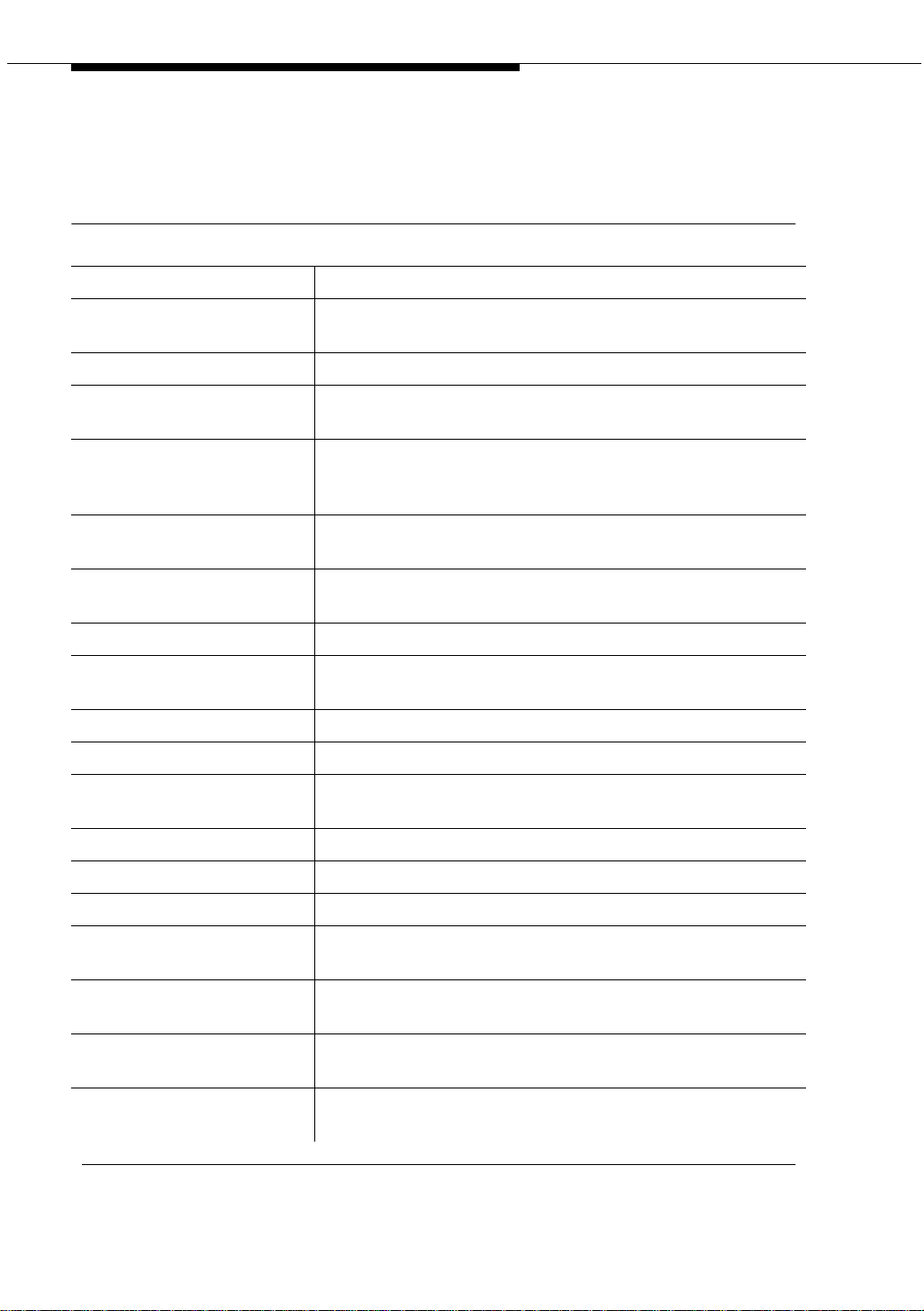

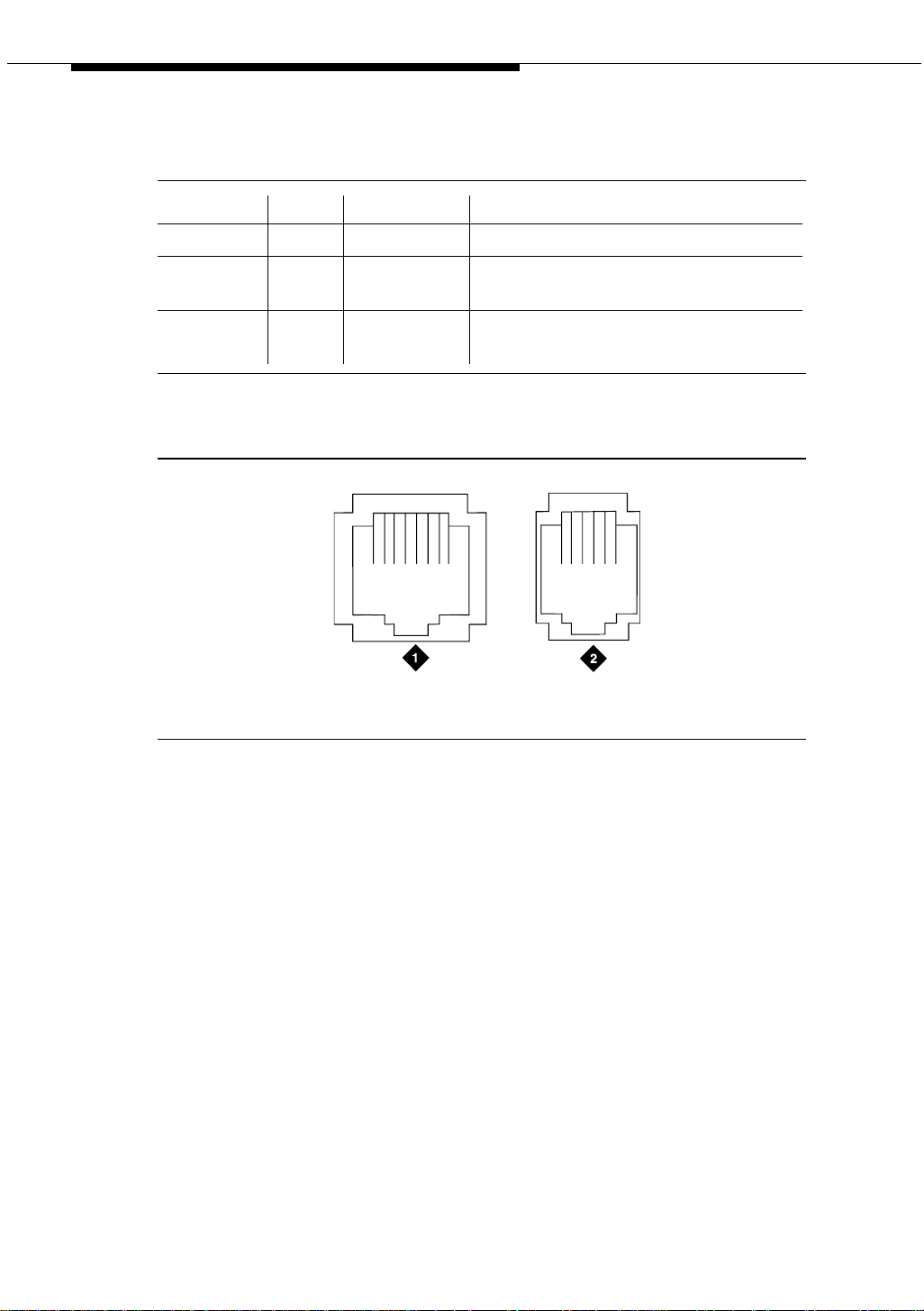

Means of Conne ct i o n

Connection of this equipment to the telephone network is shown in the

following tables.

For MCC1, SCC1, G600, and C M C 1 M edia Gateways:

Manufacturer’s Port

Identifier

FIC Code SOC/REN/

A.S. Code

Network

Jacks

Off/On premises station OL13C 9.0F RJ2GX,

RJ21X,

RJ11C

DID trunk 02RV2-T 0.0B RJ2GX,

RJ21X

CO trunk 02GS2 0.3A RJ21X

02LS2 0.3A RJ21X

Tie trunk TL31M 9.0F RJ2GX

Basic Rate Interface 02IS5 6.0F, 6.0Y RJ49C

1.544 digital interface 04DU9-BN 6.0F RJ48C,

RJ48M

04DU9-IKN 6.0F RJ48C,

RJ48M

04DU9-ISN 6.0F RJ48C,

RJ48M

120A3 channel servic e unit 04DU9-DN 6.0Y RJ48C

A plug and jack used to connect this equipment to the premises wiring

and telephone network mu st co mply with the applicable FCC Part 68

rules and requirements adopted by the ACTA. A compliant telephone

cord and modular plug is pro vided with this product. It is designed to

be connected to a compatible modular jack that is also compliant. It is

recommended that repairs be performed by Avaya certified technicians.

The equipment cannot be used on public coin phone service provided

by the telephone company. Connection to party line service is subject

to state tariffs. Contact the state public util ity commission, public service commission or corpor ation commission for information.

This equipment, if it use s a tel e phone receiver, is hearing aid compatible.

Canadian Department of Communications (DOC) Interference

Information

For MCC1, SCC1, G600, and CMC1 Media Gateways:

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil nu mérique de la classe A est conforme à la norme

NMB-003 du Canada.

For the G700 Media Gateway:

This Class B digital apparatus com pl ie s wit h Ca nadian ICES-003.

For the G700 Media Gate w ay:

Manufacturer’s Port

Identifier

FIC Code SOC/REN/

A.S. Code

Network

Jacks

Ground Start CO trunk 02GS2 0.5A RJ11C

DID trunk 02RV2-T AS.0 RJ11C

Loop Start CO trunk 02LS2 0.5A RJ11C

1.544 digital interface 04DU9-BN 6.0Y RJ48C

04DU9-DN 6.0Y RJ48C

04DU9-IKN 6.0Y RJ48C

04DU9-ISN 6.0Y RJ48C

Basic Rate Interface 02IS5 6.0F RJ49C

If the terminal equipment (for example, the MultiVantage

™ Solution

equipment) causes harm to the telephone network, the telephon e company will notify you in advance that temporary discontinuance of service may be required. But if a dvance notice is not practical, the

telephone company will notify the customer as soon as possible. Also,

you will be advised of your right to file a complaint with the FCC if

you believe it is necessary.

The telephone company may make changes in its facilities, equipment,

operations or procedures tha t co uld affect the operation of the equipment. If this happens, the telephone company will provide advance

notice in order for you to make necessary modifications to maintain

uninterrupted service.

If trouble is experienced w i th t his equipment, for repair or warranty

information, plea se contact the Technical Service Center at

1-800-242- 2121 or contact your local Avaya representative. If the

equipment is causing ha rm to the telephone network, the telephone

company may request tha t you disconnect the equipment until the

problem is re s olved.

Cet appareil nu mérique de la classe B est conforme à la norme

NMB-003 du Canada.

This equipment meets t he ap plic able Ind ustr y Canad a Terminal Equipment Technical Specifications. This is confirmed by the r egistration

number. The abbreviation, IC, before the registration number signifies

that registration was performed based on a Declaration of Conformity

indicating that Industry Can ada technical specifications were met. It

does not imply that Industry Canada app roved the equipment.

DECLARATIONS OF CONFORMITY

United States FCC Part 68 Supplier’s Declaration of Conformity

(SDoC)

Avaya Inc. in the United States of America hereby certifies that the

equipment describe d in thi s document and bearing a TIA TSB-168

label identification number complies with the FCC’s Rules and R egu -

lations 47 CFR Part 68, and the Administrative Council on Terminal

Attachments (ACTA) adopted technical criteria.

Avaya further asserts that Avaya handset-equipped terminal equipment described in this docu m ent complies with Paragraph 68.316 of

the FCC Rules and Regulations defining Hearing Aid Compatibility

and is deemed co mpatible with hearing aids.

Copies of SDoCs signed by the Responsible Par ty in the U. S. can be

obtained by contacting your local sales representative and are available on the following Web site:

http://www.avaya.com/support/

All MultiVantage

™ system products are compli ant with FCC Part 68,

but many have been registered with the FCC before the SDoC process

was available. A list of all Avaya registered products may be found at:

http://www.part68.org/

by conducting a search using “Avaya” as man u fa cturer.

Page 5

European Union Declarations of Conformity

Avaya Inc. declares that the equipment specified in this document

bearing the “CE” (Conformité Europeénne) ma rk conforms to the

European Union Radio and Telecommunications Terminal Equipment

Directive (1999/5/EC), including the Electromagnetic Compatibility

Directive (89/336/EEC) and Low Voltage Directive (73/23/EEC). This

equipment has been certified to meet CTR3 Basic Rate Interface (BRI)

and CTR4 Primary Rate Interface (PRI) and subsets thereof in CTR12

and CTR13, as applic able.

Copies of these Declaratio ns of Conformity (DoCs) can be obtained

by contacting your local sale s representative and are available on the

following Web site:

http://www.avaya.com/support/

Japan

For MCC1, SCC1, G600, and C M C 1 M edia Gateways:

This is a Class A product based on the standard of the Voluntary Control Council for Interferen ce by Information Tec hnology Equipment

(VCCI). If this equipment is used in a domestic environment, radio

disturbance may occur, in which case, the user may be required to take

corrective act ions.

For the G700 Media Gate w ay:

This is a Class B product based on the stan dard of the Voluntary Control Council for Interferen ce by Information Tec hnology Equipment

(VCCI). If this equipment is used in a domestic environment, radio

disturbance may occur, in which case, the user may be required to take

corrective act ions.

To order copies of this and other documents:

Call: Avaya Publications Center

Write: Globalware Solutions

E-mail: totalware@gwsmail.com

Voice 1.800.457.1235 or 1.207.866.6701

FAX 1.800.457.1764 or 1.207.626.7269

200 Ward Hill Avenue

Haverhill, MA 01835 USA

Attention: Avaya Account Management

Page 6

Page 7

Contents

About this book 15

■ Overview 15

■ Conventions used in this book 18

Systems and circuit packs 19

Admonishments 19

Physical di mensions 20

■ Antistatic protection 20

■ Remove/install circuit packs 20

■ Security 21

■ Standards compliance 21

■ LASER product 22

■ Trademarks 22

■ How to get this book on the Web 22

■ How to get help 23

■ Tell us what you think 23

1 909A/B universal coupler 25

2 Auxiliary power supplies 29

■ Local auxiliary power supply 30

■ Applications that require auxiliary power 30

■ Sources of auxiliary local power 31

■ Required safety precautions 31

■ 1145B power supply 32

Circuit protection 32

Mountings 33

Installing the wall mounting 33

Installing the 1146 power distribution unit 35

Installing the expanded power distribution unit 36

Powering up and testing AC and DC power 38

Issue 4 October 2002 7555-233-116

Page 8

Contents

Wire the 1146 power distribution unit 39

Replacing the batteries 40

Storing the batteries in inactive units 40

Repairing short circuits and resetting red LEDs 40

■ 1151A and 1151A2 power supplies 40

Desk mounting 42

Wall mounting 42

Standards compliance 42

3 Extenders for 2-wire DCP endpoints 43

■ 2-wire DCP endpoints 43

■ DCP extender, stand alone 45

■ DCP extender, rack mount 46

4 Data modules and asynchronous data units 47

■ Understanding RS-232 communications 48

■ Installation procedure 49

■ Obtain required equipment 50

■ Set hardware options 50

Setting 7400A data module hardware options 50

Setting 7400B data module hardware options 52

■ Connect data modules 54

Connecting a single data module 55

Connecting multiple data modules to the system 56

■ Administer the data modules 95

■ Asynchronous data units (ADU) 98

555-233-1168 Issue 4 October 2002

Page 9

Contents

5 External modems 99

■ Hardware required when configuring modems 99

■ Paradyne COMSPHERE 3715 100

Configuring the 3715 for CMS 100

Configuring the 3715 for modem pooling 100

■ Paradyne COMSPHERE 3810 Plus and 3811 Plus 101

Configuring the 3810 Plus and 3811 Plus modems 101

■ Paradyne COMSPHERE 3910 101

Configuring the 3910 for CMS 102

■ U.S. Robotics modems 109

Configuring U.S. Robotics modems 109

■ Multi-Tech MT5634ZBA-USB 110

Configuring the MT5634ZBA-USB modem 110

■ Administration 110

6 Printers 113

■ Connecting printers using TCP/IP 113

Task list 113

Administering adjunct parameters 114

Using the downloadable reliable session-layer

protocol (RSP) tool 115

7 DEFINITY LAN gateway system 117

■ What is the DEFINITY LAN gateway? 117

How the DLG application works 117

How is the DLG application is packaged 118

The MAPD DLG 118

The co-resident DLG 119

Switch-based connectivity — co-resident DLG 119

Issue 4 October 2002 9555-233-116

Page 10

Contents

8 Terminal server installation 121

■ Overview 121

■ Installing and administering the terminal server 122

Administering the IOLAN+ 124

Potential failure scenarios and repair actions 131

■ Administering IP node names 131

■ Administering IP services 132

9 DS1/T1 CPE loopback jack 135

■ Installing a loopback jack 135

With a smart jack 135

Without a smart jack 136

■ Administering the loopback jack 137

■ Loopback testing with a smart jack 137

Testing the DS1 span from the ICSU to the loopback jack 137

Testing the DS1 span from the smart jack to the

network interface termination or fiber multiplexer (MUX) 143

Testing the DS1 span from the loopback jack to

the smart jack 143

■ Testing a loopback jack without a smart jack 151

Configurations using fiber multiplexers 156

10 ISDN converters and adapters 157

■ Converters for single-carrier cabinets 158

PRI-to-DASS and PRI-to-DPNSS converters 158

PRI-to-BRI converter 159

■ Converters for multi-carrier cabinets 160

PRI-to-DASS and PRI-to-DPNSS converters 160

PRI-to-BRI converter 161

555-233-11610 Issue 4 October 2002

Page 11

Contents

11 Stratum 3 clock 163

■ Set clock options 163

Cabling the Stratum 3 clock 165

Stratum 3 clock wiring installation procedure 167

12 Busy tone disconnect equipment for

non-U.S. installations 171

13 Call detail recording (CDR) option settings 173

■ Connecting CDR equipment 173

■ Using other equipment as the CDR output devices 174

■ Sources of administration information 174

■ Connecting a CDR device 174

Task list 174

Administering CDR parameters 174

■ Using the downloadable reliable

session-layer protocol (R SP ) tool 176

14 DEFINITY INADS 179

Analog loopback 179

Administration 181

Partner installation 181

INADS connection with power fail transfer 182

INADS connection without power fail transfer 184

PARTNER administration 185

DEFINITY ECS administration 186

Installation test (all installations) 187

■ Connectivity for INADS on S8700 and S8300 media servers 187

Example of an ART script file 187

Issue 4 October 2002 11555-233-116

Page 12

Contents

15 Malicious call trace 189

16 Music-on-hold 191

■ For MCC1, SCC1, CMC1, and G600 Media Gateways 191

Registered music source 192

Nonregistered music source 192

■ For G700 Media Gateways 194

17 Paging and announcement equipment 197

■ Background information 197

IP configurations 198

Configuration using the S8700 Media Server in a

multi-connect configuration controlling a G700

Media Gateway 198

S8700 Media Server in a multi-connect configuration networked

with a S8300 Media Server in a G700 Media Gateway and a

DEFINITY CSI 199

Configuration using the S8700 Media Server with IP connect 200

■ Loudspeaker paging for MCC1, SCC1,

CMC1, or G600 Media Gateways 201

Loudspeaker paging without paging adapter 202

Loudspeaker paging access without universal coupler 203

Loudspeaker paging with universal coupler 203

■ ESPA radio paging 204

■ External ringing 205

■ Queue warning indicator 205

■ Loudspeaker paging for G700 Media Gateways 206

555-233-11612 Issue 4 October 2002

Page 13

Contents

18 Multimedia communications

products: MMCX, MMCH, ESM 207

■ MASI for MMCX 207

Direction connection 208

Main distribution frame connection 209

■ Wideband endpoints 209

Nonsignaling configuration 209

Signaling configuration 210

■ Multimedia call handling (MMCH) 212

Connect the endpoints 212

Setup and test the MMCH installation 214

Place conversion test call 221

Expansion services module 221

Administration 222

Place test call 223

Troubleshooting 223

19 Property management system (PMS) 225

■ Connecting the property management system (PMS) 225

■ Connecting a terminal and/or journal printer 226

Using data modules 226

Using an asynchronous data unit (ADU)

and a data line circuit pack 227

■ Connecting PMS and printers using TCP/IP 227

Task list 227

Administering adjunct parameters 228

Using the downloadable reliable session-layer protocol tool 229

Issue 4 October 2002 13555-233-116

Page 14

Contents

A Connector and cable pinout charts 231

IN Index 243

555-233-11614 Issue 4 October 2002

Page 15

About this book

This book provides procedures for installing software (adjuncts) and equipment

(peripherals) to Avaya media servers and gateways. Not all adjuncts and

peripherals are addressed in this book. For those adjuncts and peripherals not

addressed, we are supplying other resources for the information.

The information in this book is intended for use by:

Overview

Avaya media servers and gateways can work with a wide range of external

equipment, applications, and peripherals. For the purposes of this book, we define

the terms as follows:

Be aware that some equipment and software work only with certain releases. See

your Avaya representative for the most current compatibility information.

■ Trained field installation and maintenance personnel

■ Technical support personnel

■ Network engineers and technicians

■ Design center personnel

■ Sales associates

■ Business partners

■ Adjuncts are software products that work with the various Avaya servers or

gateways.

■ Peripherals are hardware products that connect directly or remotely to

Avaya m edia servers or gateways.

Issue 4 October 2002 15555-233-116

Page 16

About this book

Table 1 provides a list of current adjuncts and peripherals, and where installation

information exists.

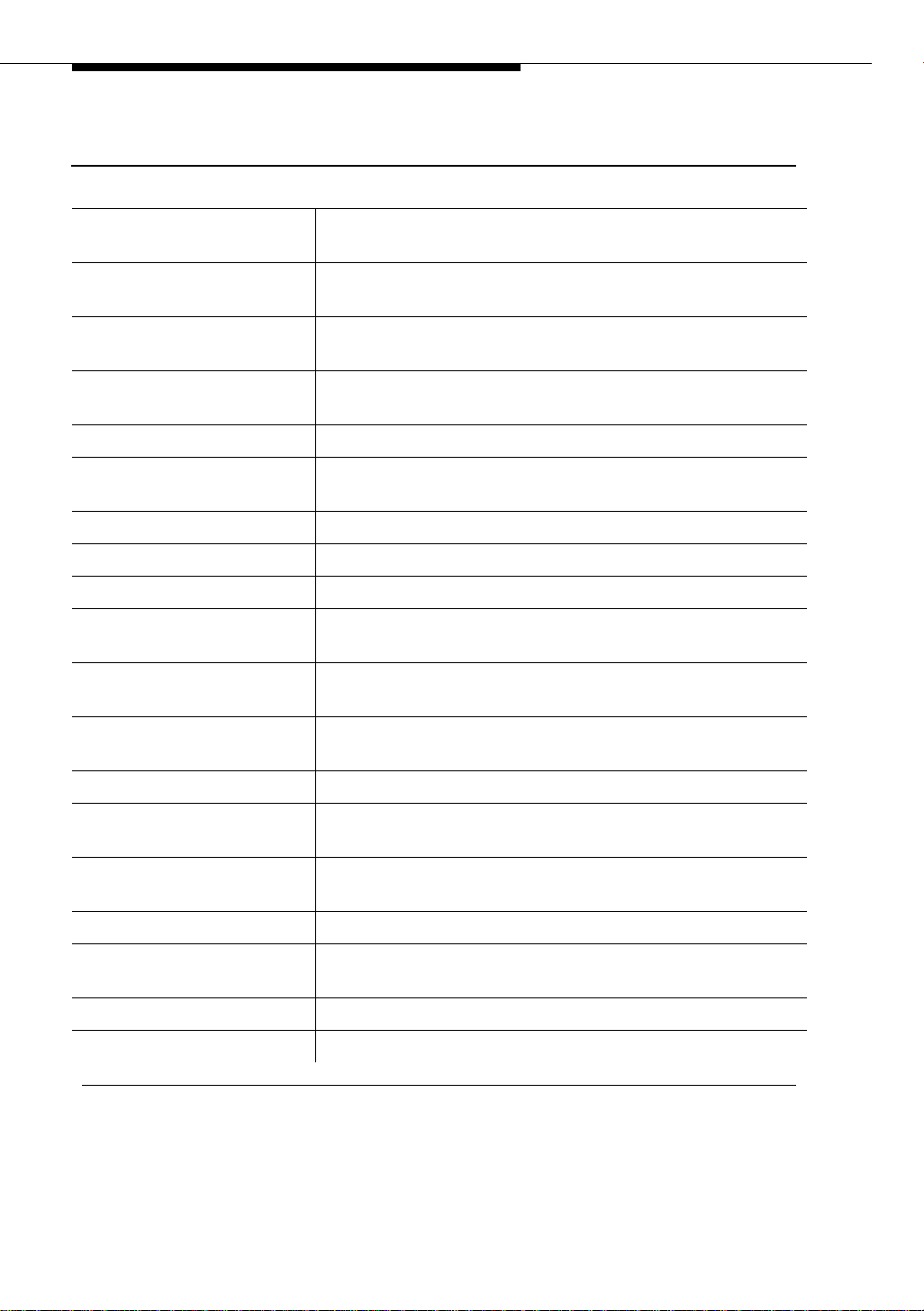

Table 1. Adjuncts and peripherals resource list

Adjunct/Peripheral Resource

909A/B Universal Coupler Chapter 1

AUDIX AUDIX Installat ion

AUDIX Voice Power Installation and Maintenance Guide

Auxiliary Power Suppl ie s Chapter 2

Basic Call Management

System (BCMS) View

Busy Tone Disconnect

Equipment for Non-U.S.

Installations

Call Detail Recording

(CDR) Option Settings

CallVisor ASAI LAN

Gateway

CentreVu Agent CentreVu Agent Installation and Administration

CentreVu Call Management

System (CMS)

CentreVu Explorer CentreVu Explorer User Guide

CentreVu Supervisor CentreVu Supervisor —Installation and Getting Started

Conversant INTUITY CONVERSANT System Customer Assist

Data Modules and ADUs Chapter 4

DCS Connections Chapter 9

DEFINITY INADS Chapter 14

Basic Call Management System (BCMS) Operations

Chapter 12

Chapter 13

CallVisor ASAI DEFINITY LAN Gateway over MAPD

Installation, Administration, and Maintenance

CentreVu Call Management System Software Installation

and Setup

Technical Operations

DEFINITY LAN Gateway

System

DEFINITY Wireless

Personal Comm Mgr.

DS1/T1 CPE Loopback

Jack

Expansion Services Module

(ESM)

16 Issue 4 October 2002

Chapter 7

Interface for the DEFINITY Wireless Business System

Guide

Chapter 9

Chapter 18

Continued on next page

555-233-116

Page 17

Overview

Table 1. Adjuncts and peripherals resource list

Adjunct/Peripheral Resource

External Alerting

Equipment

Internet Call Center CentreVu Internet Solutions Documentation CD-ROM

Internet Telephony

Gateway

Intuity AUDIX

Intuity Interchange INTUITY Interchange System Supporting Documentation

ISDN Converters and

Adapters

Loudspeaker Paging Chapter 17

Malicious Call Trace Chapter 15

Modems, external Chapter 5

Multimedia Call Exchange

MMCX

Multimedia Call Handling

(MMCH)

Multipoint Control Unit

(MCU)/CRS

Chapter 16

Internet Call Center Solution Guide

Internet Telephony Server-Enterprise Hardware Installation

Quick Reference

Internet Messaging for the Intuity AUDIX Multimedia

Messaging System, Installation

Chapter 10

Chapter 18

Chapter 18

MultiPoint Conferencing Unit Installation and Test

Music-on-hold Chapter 16

Paging and Announcement

Equipment

Pollable Storage Unit

(PSU)

Printers Chapter 6

Property Management

System

Stratum 3 Clock Chapter 11

Voice and Data Terminals Chapter 3

Chapter 17

Pollable Storage Unit Installation

Chapter 19

Continued on next page

Issue 4 October 2002

17555-233-116

Page 18

About this book

Conventions used in this book

Become familiar with the following terms and conventions. They help you use this

book with your Avaya MultiVantage™ Software.

■ Commands are printed in bold face as follows: command.

We show complete commands in this book, but you can usually type an

abbreviated version of the command. For example, list configuration

station can be typed as list config sta.

■ Screen displays and names of fields are printed in constant width as

follows: screen display.

A screen is any form displayed on your computer or terminal monitor.

■ Variables are printed in italics as follows: variable.

■ Keys and buttons are printed as follows: KEY.

■ To move to a certain field, you can use the TAB key, arrows, or the ENTER

key (the

ENTER key may appear as the RETURN key on your keyboard).

■ If you use terminal emulation software, you need to determine what keys

correspond to

■ In this book we use the terms “telephone” and “voice terminal” to refer to

ENTER, RETURN, CANCEL, HELP, NEXT PAGE, etc.

phones.

■ We show commands and screens from the newest release of MultiVantage

Software and refer to the most current books. Please substitute the

appropriate commands for your system and refer to the manuals you have

available.

■ If you need help constructing a command or completing a field entry,

remember to use

— When you press

HELP.

HELP at any point on the command line, a list of

available commands appea rs.

— When you press HELP with your cursor in a field on a screen, a list of

valid entries for that field appears.

■ The status line or message line can be found near the bottom of your

monitor display. This is where the system displays messages for you.

Check the message line to see how the system responds to your input.

Write down the message if you need to call our helpline.

■ When a procedure requires you to press ENTER to save your changes, the

screen you were working on clears and the cursor returns to the command

prompt.

The message line shows “command successfully completed” to

indicate that the system accepted your changes.

18 Issue 4 October 2002

555-233-116

Page 19

Conventions used in this book

Systems and circuit packs

■ The word “system” is a general term encompassing all references to an

Avaya m edia server or gateway running MultiVantage Software.

■ The term “ASAI” is synonymous with the newer CallVisor ASAI.

■ Circuit pack codes (for example, TN780 or TN2182B) are shown with the

minimum acceptable alphabetic suffix (like the “B” in the code TN2182B).

Generally, an alphabetic suffix higher than that shown is also acceptable.

However, not every vintage of either the minimum suffix or a higher suffix

code is necessarily accep tab le. A suffix of “P” means that firmware can be

downloaded to that circuit pack.

■ The term “cabinet” refers to the external casing (shell) of an MCC1, SCC1,

CMC1, or G600 Media Gateway. Circuit packs are installed in the cabinet

in a specific carrier (row) and in a specific slot within that carrier.

■ The designation “UUCSSpp” refers to the location (address) of a circuit

pack in cabinet-carrier-slot order. In this address designation, UU is the

cabinet number, C is the carrier letter, SS is the slot number of a specific

circuit pack, and pp (if applicable) is a specific port on the circuit pack. A

sample address for port 4 on a circuit pack on an MCC1 Media Gateway

might look like this: 02A0704.

■ A G700 Media Gateway uses media modules instead of circuit packs. The

Admonishments

Admonishments in this book have the following meanings:

Tip:

Draws attention to information that you may find helpful.

NOTE:

Draws attention to information that you must heed.

!

CAUTION:

Denotes possible harm to softwa re, possible loss of data, or pos si ble service

interruptions.

media module address is designated as XXXVSpp, where XXX is the

administered number of the G700 Media Gateway, VS is the slot n umber of

a specific media module location on the G700 Media Gateway, and pp (if

applicable) is a specific port on the media module. The V is not a variable

and needs to be included in the command exactly where shown. A sample

address for port 4 on an MM711 Media Module on a G700 Media Gateway

might look like this: 002V304. An S8300 Media Server, if installed in a

G700 Media Gateway, must be in location V1.

Issue 4 October 2002

19555-233-116

Page 20

About this book

!

WARNING:

Denotes possible harm to hardware or equipment.

!

DANGER:

Denotes possible harm or injury to your body.

!

SECURITY ALERT:

Indicates when system administration may leave your system open to toll

fraud.

Physical dimensions

■ All physical dimensions in this book are in English units (feet [ft]) followed

by metric (centimeter [cm]) in parenthesis.

■ Wire gauge measurements are in AWG followed by the diameter in

millimeters in parenthesis

Antistatic protection

!

WARNING:

To minimize electrostatic discharge (ESD), always wear an authorized wrist

ground strap. Connect the strap to an approved ground, such as an

unpainted metal surface, before handling circuit packs, media modules, or

any components.

Remove/install circuit packs

!

CAUTION:

Do not remove or install control circuit packs (circuit packs with white labels)

when the power is on in an MCC1 Media Gateway. Damage may occur.

Make sure the power is off before removing or installing control circuit packs.

Port circuit packs (circuit packs with gray labels—older version circuit packs

had purple labels) can be safely removed or installed when the power is on.

Do not remove or install media modules when the power is on in a

G700 Media Gateway. Damage may occur. Make sure the power is off

before removing or installing a media module.

20 Issue 4 October 2002

555-233-116

Page 21

Security

Security

To ensure the greatest security possible, Avaya offers services that can reduce

toll fraud liabilities. Contact your Avaya representative for more security

information.

Login security is an attribute of the MultiVantage Software. Advise customers that

their existing passwords expire 24 hours after the upgrade. Also explain that the

new passwords must conform to strict requirements.

System administrators must keep network addresses confidential. A PPN or any

endpoint masquerading as a PPN on the ATM network can seize that EPN and

control it if that EPN is not already connected to its proper PPN.

Standards compliance

The equipment in this document complies with the following standards (as

applicable):

■ ITU-T (Formerly CCITT)

■ ECMA

■ ETSI

■ IPNS

■ DPNSS

■ National ISDN-1

■ National ISDN-2

■ ISO-9000

■ ANSI

■ FCC Part 15 and Part 68

■ EN55022

■ EN50081

■ EN50082

■ UNI 3.1

■ CISPR22

■ Australia AS3548 (AS/NZ3548)

■ Australia AS3260

■ IEC 825

■ IEC 950

■ UL1459

Issue 4 October 2002

21555-233-116

Page 22

About this book

■ UL 1950

■ CSA C222 Number 225

■ TS001

■ ILMI 3.1

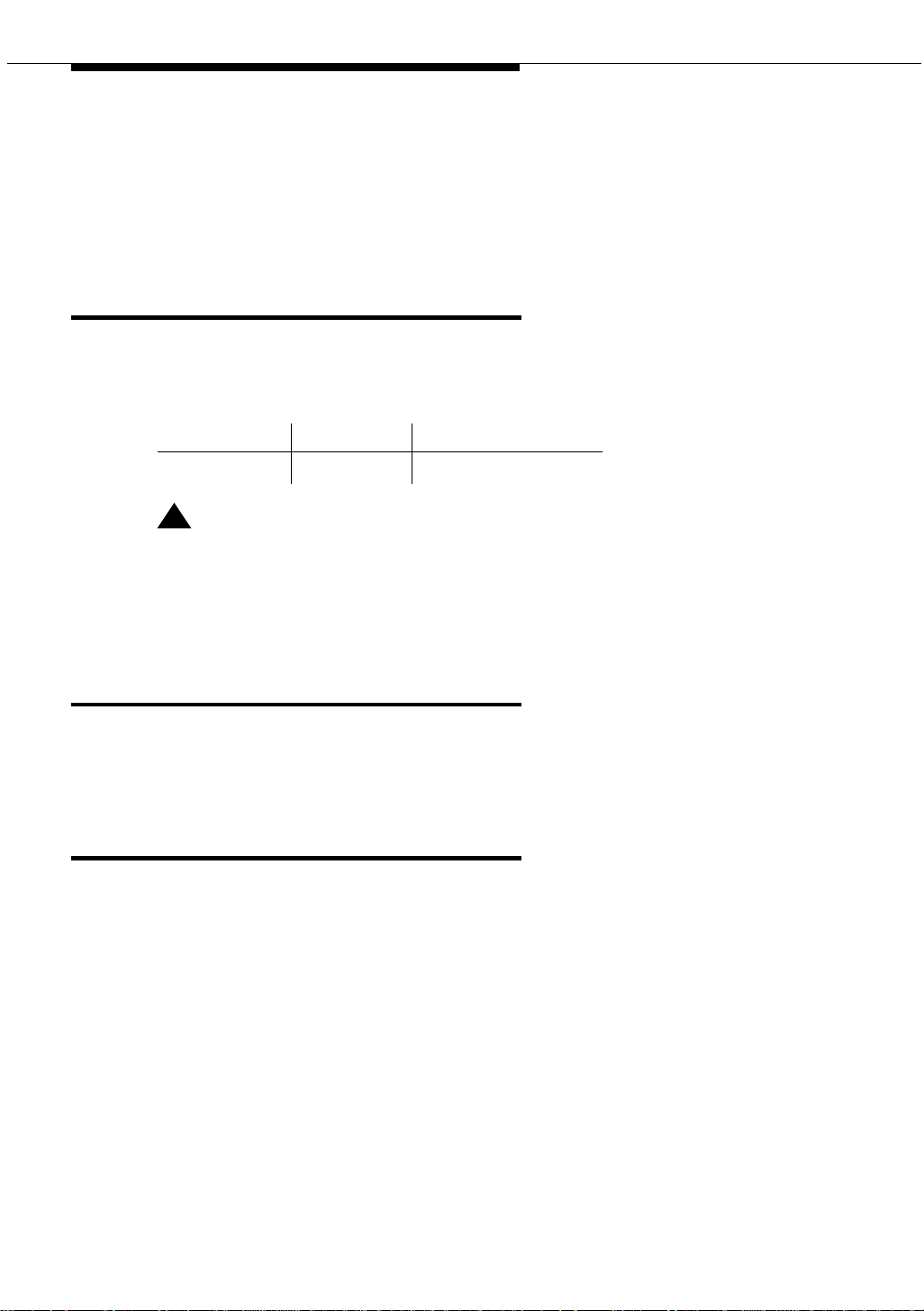

LASER product

The Avaya Media Gateway may contain a Class 1 LASER device (IEC 825 1993)

if single-mode fiber optic cable is connected to a remote expansion port network

(EPN). The LASER device operates within the following parameters:

Power output Wavelength Mode field diameter

-5 dBm 1310 nm 8.8 mm

!

DANGER:

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Contact your Avaya representative for more information.

Trademarks

All trademarks identified by ® or ™ are registered trademarks or trademarks,

respectively, of Avaya, Inc. All other trademarks are the property of their

respective owners.

How to get this book on the Web

If you have internet access, you can view and download the latest version of this

book. To view the book, you must have a copy of Acrobat Reader.

To access the latest version:

1. Access the Avaya Web site at http://www.avaya.com/support/.

2. Click Produc t Document ation.

3. In the Search Product Documentation dialog box, type the ID number of

this book (555-233-116) and click Search.

4. Find the latest issue number, then click the book title.

5. Download this book.

22 Issue 4 October 2002

555-233-116

Page 23

How to get help

How to get help

If you need additional help, the following resources are available. You may need

to purchase an extended service agreement to use some of these resources. See

your Avaya representative for more information.

■ If you are within the United States, go to the Avaya Web site at

http://www.avaya.com/support/ for support telephone numbers. Click

Escalation Lists, which includes escalation phone numbers within specific

regions of the United States.

■ For all international resources, contact your local Avaya authorized dealer

for any additional help and questions.

Tell us what you think

Let us know what you like or don’t like about this book. Although we can’t respond

personally to all your feedback, we promise we will read each response we

receive.

Write to us at: Avaya Inc.

Product Documentation Group

1300 W. 120th St.

Westminster, CO 80234 USA

Fax to: 303-538-1741

Send email to: document@avaya.com

Issue 4 October 2002

23555-233-116

Page 24

About this book

24 Issue 4 October 2002

555-233-116

Page 25

909A/B universal coupler

The 909A/B universal coupler is used with paging and music-on-hold equipment

that is not approved for use with the public network.

NOTE:

The information in this chapter does not apply to the G700 Media Gateway

configurations.

1

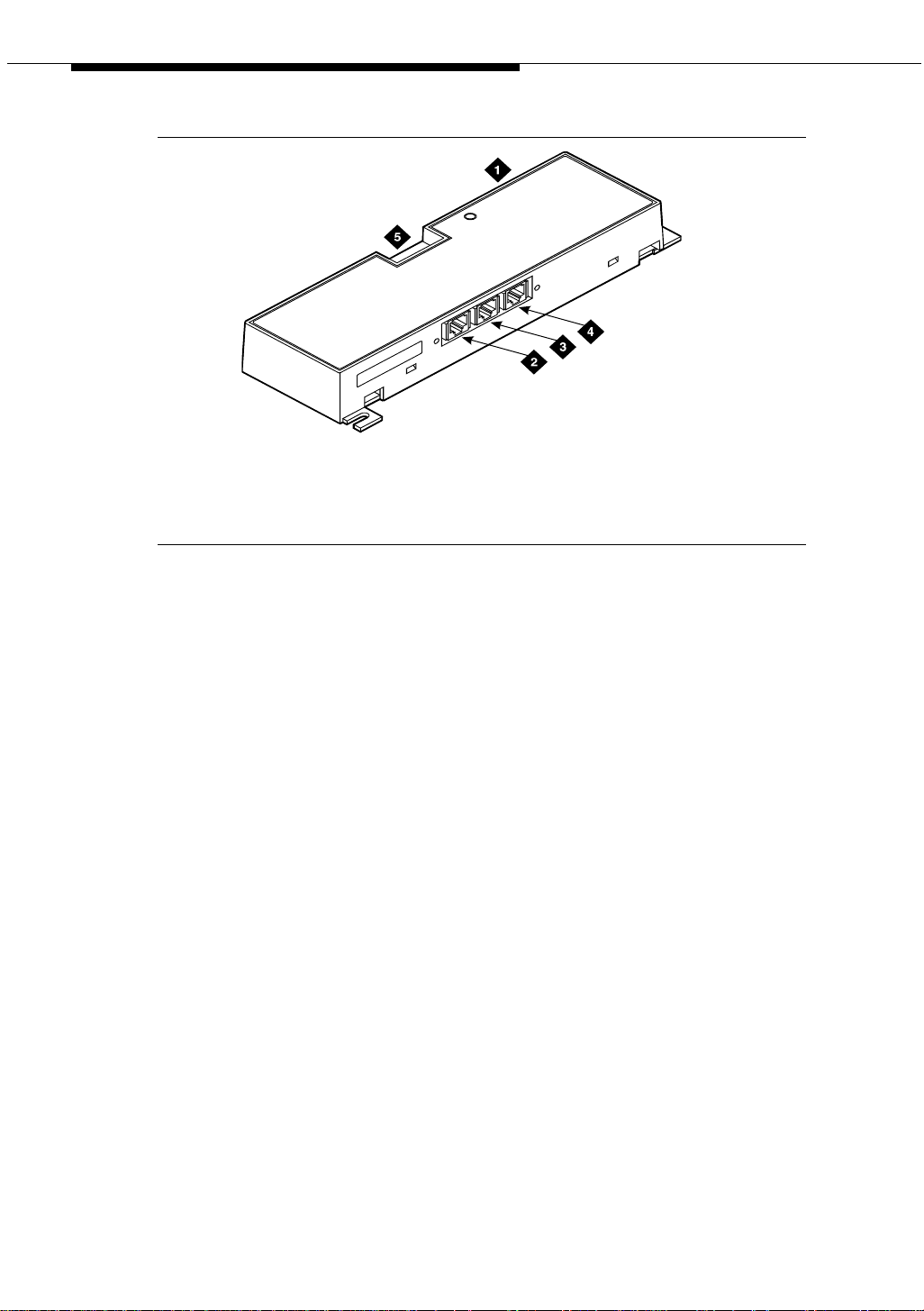

Figure 1 shows a typical 909A/B universal coupler. For additional installation and

switch setting information, refer to 909A/909B Universal Coupler Installation

Instructions.

NOTE:

If the music source is registered by the FCC (in the USA) or an equivalent

body, the 909A/B universal coupler is not required.

Issue 4 October 2002 25555-233-116

Page 26

909A/B universal coupler

1. 909A/B universal coupler

2. J1 8-pin modular jack

3. J2 8-pin modular jack

Figure 1. Typical 909A/B universal coupler

909_brkt KLC 042296

4. J3 7-pin modular jack

5. DIP switch location

The 909A is the direct current (DC) version of the coupler, and cabinet power

supplies -48 VDC power. The 909B is the alternating current (AC) version, and

power is supplied from a separate power supply (such as the KS-22911L2).

The DIP switches on the unit set:

■ Protection/Paging selection — For AUX trunk paging and malicious call

trace, set to C2. Set the switch to C1 for all other applications.

■ Output attenuation (-9 or -15 dBm) — Setting depends on output level of

music source.

■ Output impedance (8 ohms, 1.5 kΩ, and 50 kΩ) —This switch only

requires setting if the Protection/Paging switch is set to C2 and the coupler

is supplying background music to a customer-supplied paging amplifier.

The pinouts for J1, J2, and J3 are provided in Table 2, Table 3, and Table 4. Refer

to these tables when connecting music or paging equipment.

26 Issue 4 October 2002

555-233-116

Page 27

909A/B universal coupler

Table 2. J1 Pin Assignments (System Connections)

Pin Color Designation Description

1 White-Orange — Not Used

2 Orange PG2/BZ2 Seizure control lead, connected to -48 VDC from

the system or from the 909A/B when the protection

paging switch is set to C2, or to -48 VDC on the

909A/B when protection/paging switch is set to C1

3 White-Green PG1/BZ1 Seizure control lead, connected to SZ lead from

the AUX trunk when the protection/paging switch

is set to C2, or to -48 VDC on the 909A/B when the

protection/paging switch is set to C1

4 Blue R Ring lead

5 White-Blue T Tip lead

7 Green BSY2/BY2 Busy/busy-out lead, connected to S1 lead from the

AUX trunk

7 White-Brown BSY1/BY1 Busy/busy-out lead, connected to S lead from the

AUX trunk

8Brown — Not Used

Table 3. J2 Pin Assignments (Accessory Connections)

Pin Color Designation Description

1 White-Orange CMS1/M1 Customer-supplied music source

2 Orange CMS2/M2 Customer-supplied music source

3 White-Green COS1 Remote busy-out control contact closure from

music source

4 Blue CR Customer ring lead

5 White-Blue CT Customer tip lead

7 Green COS2 Remote busy-out control contact closure from

music source

7 White-Brown CBS1/C1 Seizure indication provided to music source

8 Brown CBS2/C2 Seizure indication provided to music source

!

CAUTION:

Do not plug the cable into J3 before all cross-connects are completed.

Damage to the 909A/B universal coupler may occur.

Issue 4 October 2002

27555-233-116

Page 28

909A/B universal coupler

2

Table 4. J3 Pin Assignments (Power Connections)

Pin Color Designation Description

1, 3, 4, & 7 —— Not used

2 Black GRD -48 RET or grou nd le ad fro m sys tem or

5 Yellow -48 VDC -48 VDC from system or from negative

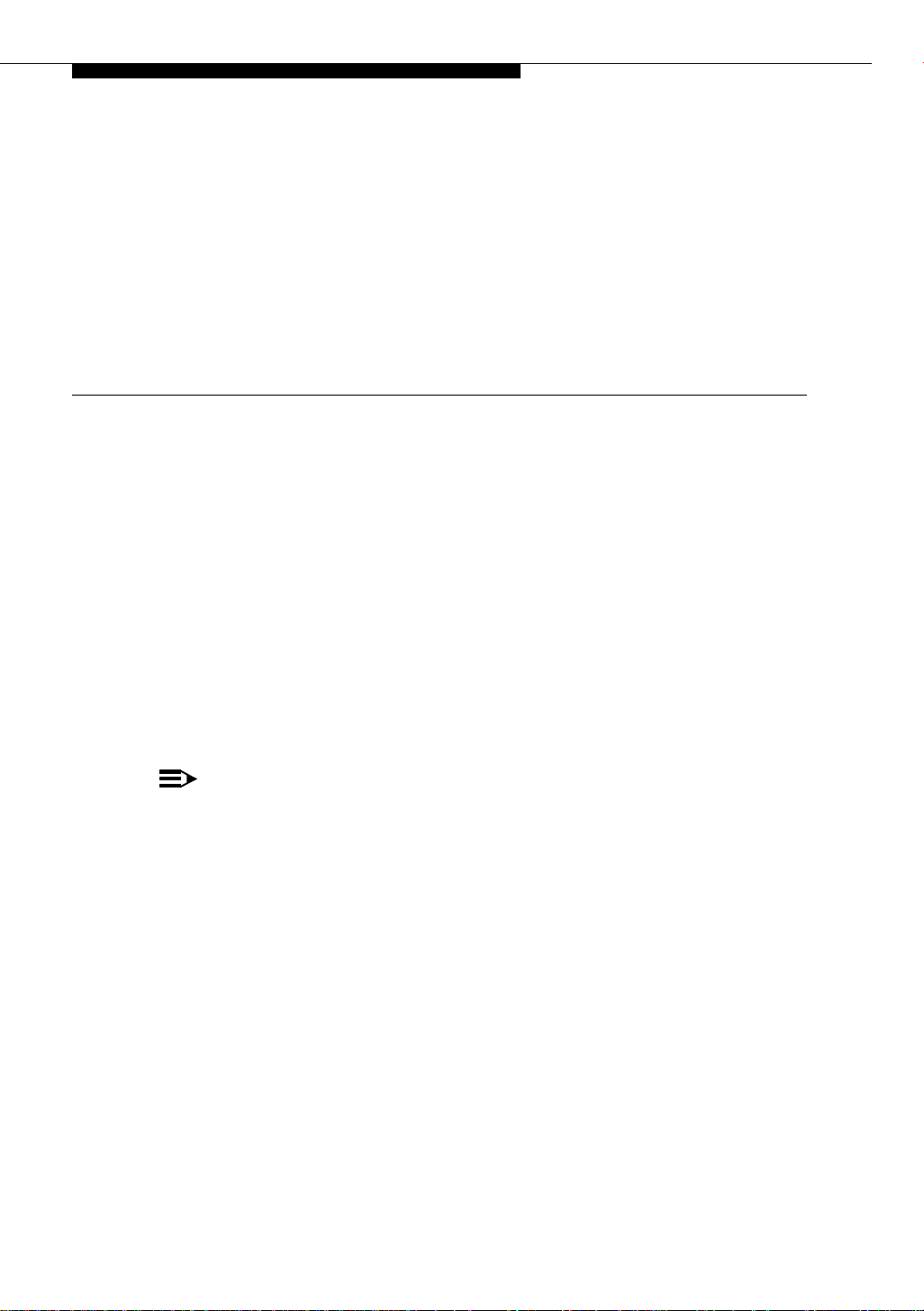

Figure 2 shows the physical locations of the pins for J1, J2, and J3.

from positive lead of power supply

lead of power supply

18

mod_jack RBP 041796

5

1. J1 and J2 8-pin modular jacks 2. J3 7-pin modular jack

Figure 2. Typical modular jack pinout

28 Issue 4 October 2002

555-233-116

Page 29

Auxiliary power supplies

Nonessential features of the attendant console, such as the optional 27B1

selector console as well as DCP terminals, derive their power from an auxiliary

power source. One console can connect to an Avaya DEFINITY

three consoles can connect to each cabinet stack on an Avaya DEFINITY

Server R.

2

®

Server CSI, and

®

Each cabinet can derive auxiliary power from the system and through the auxiliary

cable located in the trunk/auxiliary field. Auxiliary power for a primary attendant

console should be provided through this cable so the console remains fully

operational during short power outages.

NOTE:

The information in the first part of this chapter concerning auxiliary power

supplies for the gateway itself (page 30 through page 40) does not apply to

the G700 Media Gateway.

Information beginning on page 40, ‘‘1151A and 1151A2 power supplies’’,

does apply to a G700 Media Gateway under the following conditions:

■ if a particular endpoint or adjunct uses a 1151A or 1151A2 power

supply, and

■ if that endpoint or adjunct is supported on an S8300/G700.

Please see your Avaya representative for more information.

Issue 4 October 2002 29555-233-116

Page 30

Auxiliary power su pplies

Local auxiliary power supply

Consoles can use either local or phantom power, depending on the distance

between the console and the cabinet. Over short distances, phantom power is

attractive because no additional hardware is necessary—power is supplied using

the telephone circuit itself. For longer distances, you need a local power supply.

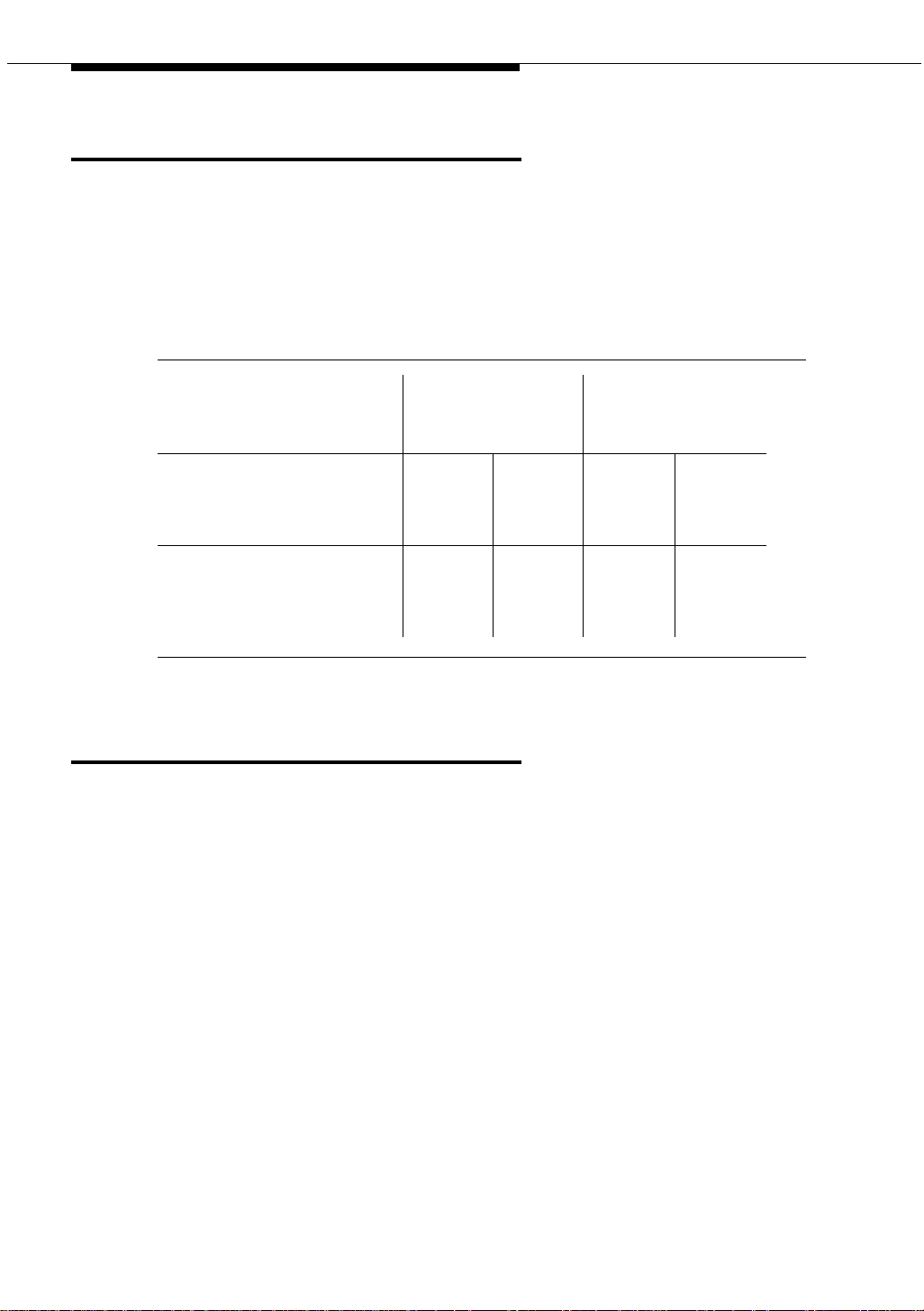

Table 5 shows cabling distances for the 302 attendant console.

Table 5. 302C1 Attendant Console Cabling Distances

24 AWG Wire

(0.27 mm

feet meters feet meters

With selector console:

Phantom-powered 800 244 500 152

Locally powered 5000 1524 3400 1037

Without selector console:

Phantom powered 1400 427 900 274

Locally powered 5000 1524 3400 1037

Applications that require auxiliary power

Auxiliary power (local or bulk) is alway s requi re d for the followi ng:

■ Any 8520 telephone

■ 302-series attendant console

■ Pass ag eWay adapter interfa ce

■ Any 7500-series telephone whether in passive bus, or point to point (one

per BRI port)

■ Any 7500- or 8500-series telephone with an asynchronous data module

■ Any 8510 telephone in passive bus or with an asynchronous data module

(unless the 8510 will not be used to support data or video)

■ Any 7400-series telephone with XM24 expansion module

■ Any 7400-series telephone with adjuncts 7407, 7434 or 7444

■ Any 8400-series telephone with adjuncts 8411 or 8434

■ Any 4600-series IP telephone

■ IP console

2

)

27 AWG Wire

(0.14 mm2)

The 1145B power supply is required for all installations outside the United States.

30 Issue 4 October 2002

555-233-116

Page 31

Sources of auxiliary local power

Sources of auxiliary local power

An attendant console can derive auxiliary power from:

■ A bulk power supply, such as the 1145B

A console’s maximum distance from its 1145B auxiliary powe r source is

800 ft. (244 m) for a 302A1 or 350 ft. (107 m) for a 301B1 and 302C1.

■ 1151A1 or 1151A2 power supply

Required safety precautions

!

DANGER:

When operating power-supply equipment, you must follow basic safety

precautions to reduce the risk of fire, electric shock, and personal injury.

Read and understand all instructions. Follow all warnings and instructions

marked on the products. Follow all the installation instructions when

mounting the product.

Never use a power unit with a power source other than that specified on the

product labels.

Do not try to plug the 3-wire grounding plug into a nongrounding power

outlet. This plug only fits into a grounding power outlet. This is a safety

feature. If you are unable to insert the plug into the outlet, have an electrician

replace the outlet. Do not defeat the safety purpose of the grounding plug.

Do not attach the power supply cord to building surfaces.

Do not overload power outlets.

Do not use this product near water. Do not let anything spill on or into the

unit. Clean only with a dry rag.

Never push objects through openings in the case.

Do not try to disassemble the unit. Return it for repair. Opening or removing

covers may expose you to dangerous voltages. Incorrect reassembly may

cause electric shock when the products are subsequently used.

Power down the unit and refer servicing immediately if the unit is exposed to

water or other liquids, if the unit is dropped or damaged, or if the unit fails to

operate normally.

Never let the operating temperature of the unit exceed the recommended

maximum.

Issue 4 October 2002

31555-233-116

Page 32

Auxiliary power su pplies

!

DANGER:

Do not block or cover the ventilation openings in the case.

Do not let anything rest on the unit.

Do not attempt to recharge batteries. The power unit recharges the batteries

itself. Any other recharging method may cause leaks of corrosive electrolyte

or explosion. Discard discharged batteries as soon as possible. Discharged

batteries are more likely to leak.

Do not store batteries in high temperature areas. Batteries stored in a cold

environment should be protected from condensation during storage and

warming. Batteries should be stabilized at room temperature prior to use

after cold storage. Do not install batteries if the manufacturing date on the

label indicates that the batteries are more than six months old.

1145B power supply

The 1145B power supply powers ISDN/DCP, terminal equipment, adjuncts, and

other customer-supplied external equipment. It supplies -48V, 200 W total and

supports 32 outputs. You can install one ISDN terminal or DCP adjunct per output.

A manual switch on the distribution unit lets the user redirect reserve power to

outputs 1 to 32 so that all outputs get battery reserve power.

An optional 1149 battery and 1146 distribution unit provides uninterruptible -48

VDC power.

!

DANGER:

When operating power-supply equipment, you must follow basic safety

precautions to reduce the risk of fire, electric shock and personal injury.

Read, understand, and follow all warnings and instructions. See ‘‘Required

safety precautions’’ on page 31.

Circuit protection

A thermistor current-limits the maximum output of each output to 12 W, but the

average power per output cannot exceed 7.25 W (200/32 = 7.25). An LED

indicates the status of the thermistor. When the LED is ON, there is a short on the

power pair.

32 Issue 4 October 2002

555-233-116

Page 33

1145B power supply

Mountings

The back-up battery mounts on a top plate. The power supply and distribution

units mount on a bottom plate. The plates are normally wall-mounted.

Installing the wall mounting

See Figure 3.

1. Locate one plate directly below the other with the raised letters right side

up. Be sure that the AC power cord can reach the electrical outlet from the

bottom plate. The power cord is about 7.5 ft. (2 m) long.

NOTE:

Up to 4 power supplies can draw current from one 110- or 230-VAC,

20- or 15-A feeder. Use only unswitched receptacles that are not

shared with other equipment.

2. Secure the wall mounting plates to a 3/4-in. (2-cm) plywood mounting

board using the four 1/2-in. #10 wood screws supplied with the plates.

3. Snap the 1145B power supply onto the bottom wall-mounting plate (no

tools are needed).

4. Connect an insulated 17-AWG #12 (1.2-mm) ground wire (or better)

between the ground lug on the power-supply frame and an approved

ground.

The frame ground screw is located next to the AC receptacle, to the left of

the unit.

5. Write the unit number and connectivity information on the front label, next

to the LEDs.

Issue 4 October 2002

33555-233-116

Page 34

Auxiliary power su pplies

1149 Battery

1145 Power Unit

4

2

On Battery Reserve

Charging Battery

Output Power On

1

3

1146 Power Distribution Unit

1-8

7

5

1-32

6

1. Wall mounting plate

2. Optional battery (1149B shown)

3. 1146 power distribution unit

4. 1145B power unit

Figure 3. 1145B/1146 mounting arrangement

34 Issue 4 October 2002

pcdf1145 KLC 030100

5. Power cable

6. Unswitched outlet (120 VAC, 20 A or 230

VAC, 15 A )

7. Battery backup switch setting

555-233-116

Page 35

1145B power supply

Installing the 1146 power distribution unit

1. Insert and securely tighten the two supplied #8-32 x 1/2-in. shoulder

screws (they have an unthreaded section at the top) into the top holes

designated for 1146 Power Distribution Unit on the bottom plate. Mount the

unit on these two shoulder screws, using the key holes on the back of the

unit.

2. Secure the unit by inserting the #8-32 x 1 in. screw through the bottom of

the unit (just above the wire clips) into the plate and tighten.

3. Set the battery back-up switch option to the 1-32 (down) position to provide

battery back-up to all outputs.

4. Connect the power distribution unit to the power supply with the power

cable. Refer to the power supply’s right-side label to locate the output

power connection.

Installing and wiring the battery

Two types of backup batteries can be used:

Table 6. Back-Up Batteries

Battery Rating

1148B 2.5 amp-hours

1149B 5 amp-hours

To install the battery, proceed as follows.

1. Loosely insert two #10-32 x 1/2-in. shoulder screws in the battery-mounting

holes at the top of the wall mounting plate.

2. Place the keyhole slots in the battery bracket on these two screws. Make

sure the label on the battery is visible.

The battery cord exits from the right side of the bracket.

3. Tighten the screws securely.

4. Plug the battery cord into the right rear receptacle on the power supply.

The right-side label indicates the rear receptacle.

Issue 4 October 2002

35555-233-116

Page 36

Auxiliary power su pplies

Installing the expanded power distribution unit

You can install a second power-distribution unit for additional 8400- and 8500series terminals.

!

CAUTION:

Total power cannot exceed 200 W. Consult the chart below for permissible

terminal installations.

Table 7. Permissible terminal installations (total power < 200 W)

Terminal mix Maximum numbers Notes

7500-series + 8500-series ISDN 24 + 24

7400-series + 8400-series DCP 24 + 24

8400-series DCP 74

7400-series DCP 74 Average power per

terminal must be

less than 3.126 W

Each expanded power distribution unit kit supplies the following items:

■ One power distribution unit

■ One T-cable

■ Two #8-32 x 1/2-in. shoulder screws

■ One #8-32 x 1 in. screw

■ One spacer bracket

See Figure 4 while installing the power distribution unit:

1. Fasten the spacer bracket to the mounting plate with the #8-32 x 1/2-in.

shoulder screws.

The spacer bracket is not shown in the figure. It is behind the top power

distribution unit.

2. Slide the keyhole slots in the power distribution unit over the shoulder

screws.

3. Insert the #8-32 x 1 in. screw through the distribution unit, through the

spacer bracket, and into the plate. Tighten the screw.

The mounting hole is located just above the wire clip.

4. Set the battery back-up switch to the 1-32 (down) position.

5. Power-down the 1145B as described on the label on the side of the unit.

36 Issue 4 October 2002

555-233-116

Page 37

1145B power supply

6

6. Remove the output power cable between the 1145B and the 1147B units.

The cable will not be reused.

7. Connect the P1 connector end of the T-cable to the bottom power

distribution unit.

8. Connect the P2 connector to the top distribution unit.

9. Connect the P3 connector to the 1145B.

10. Power-up the 1145B as described on the label on the side of the unit.

1149 Battery

1145 PowerUnit

On Battery Reserve

Charging Battery

Output Power On

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

-48V -48V

RTN RT N

-48V -48V

RTN RT N

UnitNo.

ConnectedTo:

UnitNo.

ConnectedTo:

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1. Wall-mounting plate

2. Optional 1146 power distribution unit

3. T cable (H600-347-G7)

Figure 4. Expanded power distribution unit

0004_1 PDH 06259

4. Standard 1146 power

distribution unit

5. 1145B power unit

Issue 4 October 2002

37555-233-116

Page 38

Auxiliary power su pplies

Powering up and testing AC and DC power

When you power up the unit or interrupt power to a unit, the unit runs an AC or DC

self test. LEDs on the front panel indicate the status of the power supply. The

followin g table lists the LEDs.

Table 8. Power-supply LEDs

LED Color Meaning

GREEN Power supply is providing power

YELLOW Battery is charging (after at most 20 hours, when the battery has

reached full charge, the YELLOW LED should go out)

RED Power supply is on battery reserve

1. Connect the AC power cord to the power supply , and route the cord to an

appropriate AC outlet using the clips provided on the unit.

NOTE:

A maximum of four power supplies can be powered from one

dedicated 110 VAC, 20-A feeder. Use only unswitched receptacles.

2. Start the AC test by plugging the cord into the outlet.

This powers up the power supply.

3. Check AC operation of the 1145B power supply by monitoring the LEDs:

PASS: GREEN and YELLOW are both lit.

FAIL: either GREEN or YELLOW LED is not lit.

4. If the AC test failed, test the AC outlet, power cord, and connections.

5. If the AC test failed, but power is available and the AC power cord and

connections are good, replace the power unit.

6. Once the AC test passes, activate the DC battery-backup supply by

disconnecting the AC plug.

7. Check DC (battery back-up) operation by monitoring the LEDs.

PASS: RED and GREEN are both lit.

FAIL: either RED or GREEN is not lit.

8. If the DC test fails, check the connections.

9. If the DC test fails but the connections are good, replace the batteries and

retest.

10. If the DC test fails after you replace the batteries, replace the power supply.

11. Once the DC test passes, reconnect AC power to the power supply.

38 Issue 4 October 2002

555-233-116

Page 39

1145B power supply

Wire the 1146 power distribution unit

Wire endpoints to the 1146 while power from the 1145B is on.

1. Install cross-connect jumpers (the label shows polarity) to Pins 7 and 8 of

the appropriate information outlet. Route the wires through the clip

provided on the unit. If a red LED is on, see ‘‘Repairing short circuits and

resetting red LEDs’’ on page 40. Figure 5 shows the co nnec ti ons .

A red LED lights if the associated circuit is connected to shorted wiring or a

shorted terminal.

1

2

11

12

7

4

1. Power supply kit

2. 2.5, 5.0, or 8.0 A hour battery

3. 1146 power distribution unit

4. 1145B power supply

5. Circuits 1-17

6. Circuits 17-32

7. Port circuit

3

14

5

6

14

8

10

9 9

8. Main distribution frame

9. Modular cord

10. AC input

11. Ground wire

12. ISDN/ display system protocol terminal

13. Circuits 1-32

14. Pins 7 and 8 (display terminal power)

13

Figure 5. Typical wiring to a terminal

2. Mark lead destinations, unit number, and connectivity information on the

label next to each connector.

Issue 4 October 2002

39555-233-116

Page 40

Auxiliary power su pplies

Replacing the batteries

To maintain back-up protection and battery reliability, replace batteries every four

years.

Storing the batteries in inactive units

To prevent leakage when the power unit is not in use for several months or more,

remove the batteries and store them separately.

Repairing short circuits and resetting red LEDs

A red LED next to any of the 32 power output connectors indicates a short circuit

in the building wiring or the terminal equipment. To reset the LED:

1. Disconnect the terminal equipment from the wall jack.

2. If the LED goes off, the terminal equipment is faulty. Replace it.

3. If the LED is still lit, find and repair the short circuit in the building wiring.

4. Reconnect the terminal equipment to the wall jack, and re-test.

1151A and 1151A2 power supplies

The 1151A is a standard (no battery backup) power supply unit. The 1151A2 is a

battery backup version of the 1151A. Either power supply can support one

telephone with or without an adjunct.

The 1151A and 1151A2 power supplies can supply local power to ISDN-T 7400-,

7500-, 8400-, and 8500-series voice terminals connected to a system, and to the

DCP 7444 voice terminal or 302C attendant console that need auxiliary power for

its display. The unit can supply power to adjunct equipment such as S201A and

CS201A speakerphones, or a 500A headset adapter attached to any currently

manufactured analog, DCP, or ISDN-T voice terminal equipped with an adjunct

jack.

The power supply has the following specifications:

■ A single output of -48 VDC, 0.4 A.

■ Either a 120 VAC 60-Hz power source (105 to 129 VAC) or a 220/230/240

VAC 50-Hz power source (198 to 274 VAC).

■ Automatic input voltage selection.

■ Output capacity of19.2 W.

■ Maximum loop range of 250 ft. (77 m).

■ Use of 2 modular jacks. PHONE jack pins 7 and 8 (- and +, respectively)

provide power.

40 Issue 4 October 2002

555-233-116

Page 41

1151A and 1151A2 power supplies

The PHONE and LINE jacks are 8-pin female nonkeyed 757-type jacks that can

accept D4, D7, and D8 modular plug cables. Figure 6 shows a 1151A power

supply. The 1151A2 looks similar.

!

DANGER:

When operating power-supply equipment, you must follow basic safety

precautions to reduce the risk of fire, electric shock and personal injury.

Read, understand, and follow all warnings and instructions. See ‘‘Required

safety precaution s’’ on page 31.

!

CAUTION:

Do not locate the unit within 7 in. (15.25 cm) of the floor.

Use the power supply only with telecommunications equipment, indoors,

and in a controlled environment.

pwr_sup1 CJL 051496

Figure 6. Typical 1151A power supply (front)

Issue 4 October 2002

41555-233-116

Page 42

Auxiliary power su pplies

Desk mounting

1. Place the power supply on a flat surface such as a desk.

Wall mounting

1. For wall-mounting, use the keyhole slots on the bottom of the chassis.

Standards compliance

The 1151A and 1151A2 power supplies comply with the UL Standard UL 1459,

second edition.

Table 9. Standards compliance

Complies UL 1459

Certified CSA 22.2

Approved EN7950

Approved CE

42 Issue 4 October 2002

555-233-116

Page 43

Extenders for 2-wire DCP endpoints

This chapter provides information on 2-wire voice and data terminals and digital

communications protocol (DCP) extenders. Extenders provide off-site employees

with the full feature set of the PBX.

3

2-wire DCP endpoints

Wire the tip and ring connections of 2-wire DCP endpoints to a TN2224B digital

line 2-wire circuit pack (or equivalent), similar to the 2-wire analog endpoints for a

TN747B analog line circuit pack.

The TN2224B supports 2-wire DCP sets only (not 4-wire).

The MM712 media module for the G700 Media Gateway is a 2-wire DCP

interface. The G700 Media Gateway supports 2-wire DCP sets only (not 4-wire).

!

CAUTION:

Except for auxiliary power, if necessary, these should be the only

connections to the modular wall jack. Do not bridge or parallel these

telephones.

Table 10 provides the pin-out configuration for 2-wire endpoints.

Issue 4 October 2002 43555-233-116

Page 44

Extenders for 2-wire DCP endpoints

Table 10. Pin-out for 2-wire DCP endpoints

Pin Number Function

1 not used by 2-wire DCP endpoints

2 not used by 2-wire DCP endpoints

3 not used by 2-wire DCP endpoints

4 DCP signal transmission

5 DCP signal transmission

6 not used by 2-wire DCP endpoints

7 auxiliary power -48 VDC (if needed)

8 auxiliary power ground (if needed)

Figure 7 shows a workstation connecting to a data adapter. The line side of the

adapter connects to the TN2181 digital line 2-wire circuit pack through the main

distribution frame (MDF) (to the system cabinet).

1

7

itdata RBP 032896

5

5

Line

3

1. 103A or modular wall jack

2. 2-wire endpoint

3. Data terminal (serial data)

4. Data adapter (such as an 8400B+)

2

Phone

4

I/O

6

5. 4-wire modular cord

6. Serial data cable

7. To TN2181 digital line circuit pack

Figure 7. Typical connections to a 2-wire DCP workstation

44 Issue 4 October 2002

555-233-116

Page 45

DCP extender, stand alone

Wire the circuit pack to the MDF with a 25-pair cable:

1. Wire to the data adapter per local standards.

2. Wire the data terminal and telephone as instructed in the document

accompanying the data adapter.

DCP extender, stand alone

The stand alone extender installs at the work location. See Appendix A, Table 33,

‘‘DCP extender 25-pair cable pinout’’ for cabling information and pin assignments.

NOTE:

2-wire DCP extenders are not currently supported on G700 Media Gateway

configurations.

Figure 8 shows a typical connection from a digital line 2-wire DCP circuit pack

through two DCP extender devices. The DEFINITY Extender Switch Module

System Administrator’s Guide contains additional information.

1. Avaya™ Media Server/Gateway

2. TN2181 or TN2224B circuit pack

3. 25-pair cable

4. DCP extender

5. Main distribution frame (MDF)

6. Pub lic swit ch ed tele pho ne netwo rk (P STN)

Figure 8. Typical DCP extender connections

7. 103A or modular wall jack

8. Modular line cord

9. DCP telephone (Such as 8410D,

8405, or 8434)

10. Remote work location

Issue 4 October 2002

45555-233-116

Page 46

Extenders for 2-wire DCP endpoints

DCP extender, rack mount

Figure 9 shows a typical rack mount (multi-mount) DCP extender. Connections

from either a digital line 17-port 2-wire DCP circuit pack or a digital line 24-port

2-wire DCP circuit pack, are made through two DCP extender devices.

NOTE:

2-wire DCP extenders are not currently supported on G700 Media Gateway

configurations.

h2dferm PDH100796

1. Front of rack mount assembly

2. First circuit pack in slot 1 (“A”)

3. Slot 12 (“L”)

Figure 9. Typical DCP extender connections

4. Rear of rack mount assembly

5. 25-pair connector to the MDF and the digital

6. Power connector

46 Issue 4 October 2002

line circuit packs

555-233-116

Page 47

Data modules and asynchronous data units

Data modules connect peripheral equipment to the Avaya Media Server or

Gateway or the Avaya S8100 Media Server with a CMC1 Media Gateway

(DEFINITY ONE). Data modules convert between the RS-232 communications

protocol used by peripherals and the digital communications protocol (DCP).

4

Possible peripherals include AUDIX adjunct equipment and terminals, serial

printers, customer-supplied terminals and host computers, call detail recording

(CDR) devices, and pooled modems.

NOTE:

Data modules, PGATE boards, printers connected through data modules,

SATs connected through data modules, and anything related to the X.25

connectivity protocol are not supported on the S8300 or S8700 Media

Server platforms.

The following data modules are described in this chapter, and Figure 10 shows

typical data-module connections.

■ 7400A/B/C/D

■ 8400B

■ ExpressRoute 1000

■ Asynchronous data units (ADU).

NOTE:

ISDN data modules, such as the 7500B, are not covered in this book. Refer

to Integrated Services Digital Network (ISDN) 7500B Data Module User’s

Manual, for detailed procedures. ISDN data modules connects DTE and

DCE equipment to the ISDN network using an RS-232 or V.35 interface and

an RS-377 automatic calling unit.

Issue 4 October 2002 47555-233-116

Page 48

Data modules and asynchronous data units

Understanding RS-232 communications

To install a data module, you have to set up the device to work with RS-232

devices.

NOTE:

Data modules, PGATE boards, printers connected through data modules,

SATs connected through data modules, and anything related to the X.25

connectivity protocol are not supported on the S8300 or S8700 Media

Server platforms.

The RS-232 communications protocol defines a communications link as a Data

Communications Equipment (DCE) device and a Data Terminal Equipment (DTE)

device connected by an RS-232 cable. The send and receive pins on DCE

equipment (pins 2 and 3) are reversed on DTE equipment, so that the DCE

transmit pin connects to the receive pin of the DTE and vice versa.

Generally, the term DCE is applied to devices that mediate between customer

equipment and the carrier or network. Such devices include modems, data

modules, and data units. DTE describes devices that provide a user interface for

data communications, such as dumb terminals and PCs. When configured as

DTE, data modules are used for asynchronous modem pooling. When configured

as DCE, data modules are analogous to modems in that they link a device such

as a terminal or PC (DTE) to DEFINITY.

To install a data module correctly, you identify the connected equipment as DCE

or DTE and do one of the following:

■ Configure the modem for a DTE or DCE connection

■ Install a null-modem converter

Detailed instructions are provided for each modem type, beginning on page 49.

48 Issue 4 October 2002

555-233-116

Page 49

Installation procedure

cydfnst RPY 070397

1. 103A connector or modular wall jack

2. 400B2 adapter

3. Rear of data module (7400B Shown)

4. Host computer

5. Data module power supply

6. Electrical outlet

7. Dis play tel eph one

8. S101A speakerphone

Port 2

Phone

Line

Power Port 1

9. Auxiliary power supply for telephone

10. D7AP cord

11. D8W cord

12. Line to display telephone (D8W cord)

13. Data cable (EIA/RS-232)

14. Data-module power cable

15. To MDF and system cabinet

16. Printer

Figure 10. Typical connections to a data module

Installation procedure

To install a typical data module, you perform the following tasks:

1. Obtain required equipment

2. Set hardware options (must be completed before you administer or

physically connect the data module)

3. Connect data modules

4. Administer the data modules (can be completed either before or after you

physically connect the data module)

Issue 4 October 2002

49555-233-116

Page 50

Data modules and asynchronous data units

Obtain required equipment

To physically connect a data module to the system, you need the following parts.

■ 105C/D Isolating Data Interface (if connecting to a DC cabinet).

■ EIA-232-D (RS-232-C) cable with a male connector (for the data module)

and the correct connector for the peripheral equipment.

The cable connects the PC to the data module.

■ Null-modem converter (optional).

■ V.35 cable with correct connectors (not required by all systems).

■ D8W telephone cord.

The cord connects the data module’s LINE jack to the DEFINITY wall jack.

■ DCP telephone and D8W cord (optional).

The D8W cord connects the telephone to the data module’s PHONE jack.

■ Suitable auxiliary power supply if the optional telephone is installed (D7AP

power cord and 400B2 adapter in the US, international power supply, such

as the MSP-1, elsewhere).

You must have access to the administration console of the DEFINITY, either

through a terminal and keyboard or through a PC.

A breakout box for RS-232 interfaces may prove helpful in some cases. The RS232 breakout box helps you to identify the pin configuration of the RS-232

interface on the equipment you are trying to connect.

Set hardware options

Depending on the data module, you may have to set various configuration options

using hardware switches, software commands, or both. You must set the

hardware options before you administer or physically install the data module.

Setting 7400A data module hardware options

Most configuration options are controlled by commands entered on the front panel

of the 7400A. But you have to make hardware changes when you want to set up

the 7400A data-module for use in a modem pool or as a piece of data

communications equipment. In a modem-pool, the data module operates as dataterminal equipment (DTE). In most other applications, it functions as data

communications equipment (DCE). Y ou have to set the correct operating mode for

the data module before you can access the menus for the remaining configuration