Avanti DOLPHIN A-V164 Original Instructions Manual

AVANTI SERVICE LIFT

Installation and Maintenance Manual

Model Service Lift DOLPHIN A-V164

Original instructions

®

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 1 6/11/2018 2:03:51 PM

Certificate of Dolphin A-V164

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 2 6/11/2018 2:03:51 PM

Date of publication:

1st CE Edition: 09/2017

Revision 4: 11/06/2018

Manufacturer:

AVANTI Wind Systems A/S

Rønnevangs Allé 6

3400 Hillerød Denmark

P: +45 4824 9024

F: +45 4824 9124

E: info@avanti-online.com

I: www.avanti-online.com

Sales & Service:

Australia Avanti Wind Systems PTY LTD P: +61 (0) 3 9585 1852 3 9585

China Avanti Wind Systems P: +86 21 5785 8811

Denmark Avanti Wind Systems A/S P: +45 4824 9024

Germany Avanti Wind Systems GmbH P: +49 (0) 41 21-7 88 85 – 0

Spain Avanti Wind Systems SL P: +34 976 149 524

UK Avanti Wind Systems Limited P: +44 0 1254 399923

USA Avanti Wind Systems, Inc P: +1 (262) 641 9101

India Avanti Wind Systems India (P) Ltd P: +91 95 00 173 492

Brazil Avanti Brasil Sistema Eólicos LTDA P: +55 85 9 9955-0090

Manufactured Under Process Patent NO.8,499,896.

® Registered in Europe

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 3 6/11/2018 2:03:51 PM

Page

1. Limited warranty................................................................5

2. Introduction....................................................................6

2.1 Observations ............................................................... 6

2.2 Symbols ...................................................................6

2.3 Cautions ....................................................................7

2.4 Terms and definitions .........................................................7

3. Installation ....................................................................8

3.1 WTG integration requirements ..................................................8

3.2 Cautions ...................................................................9

3.3 Freight kit ..................................................................9

3.4 Electrical connections ....................................................... 9

3.4.1 Power cable............................................................10

3.4.2 Guard locking system ...................................................10

3.5 Guiding, traction and safety wire ropes..........................................10

3.5.1 Top platform ...........................................................10

3.5.2 Bottom platform .......................................................10

3.6 Wire rope fix. ...............................................................12

3.7 Danger zone sticker..........................................................13

3.8 Rescue guide ...............................................................13

3.9 Inspection before first use ................................................... 13

4. Maintenance ..................................................................14

4.1 Recommended planning ......................................................14

4.2 Alternative planning..........................................................14

4.3 Cautions ...................................................................15

4.4 Daily inspection .............................................................15

4.5 Annual inspection ...........................................................16

4.5.1 Cabin .................................................................16

4.5.2 Traction hoist ..........................................................16

4.5.3 Fall arrest device .......................................................16

4.5.4 Traction, safety and guiding wire ropes .....................................16

4.5.5 Guiding system.........................................................18

4.5.6 Electrical cables ........................................................18

4.5.7 Overload check and adjustment ...........................................18

4.5.8 Information signs and documents..........................................18

4.6 Repairs ....................................................................18

4.7 Ordering spare parts ........................................................18

Appendix A: Adjustment of the overload limiter ........................................19

Appendix B: Inspection Checklist....................................................21

Appendix C: Inspection Log Sheet ...................................................25

Appendix D: AVANTI lift anchor . .....................................................29

Contents

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 4 6/11/2018 2:03:51 PM

5

Maintenance and Installation Manual

1)

Avanti service lift (“Product”)

Avanti Wind Systems A/S warrants that commencing from the date of shipment to the

Customer and continuing for a period of the

longer of 365 days thereafter, or the period set

forth in the standard AVANTI warranty, the

Product1) described in this Manual will be free

from defects in material and workmanship

under normal use and service when installed

and operated in accordance with the provisions

of this Manual.

This warranty is made only to the original user

of the Product. The sole and exclusive remedy

and the entire liability of Avanti under this

limited warranty, shall be, at the option of

Avanti, a replacement of the Product (including

incidental and freight charges paid by the

Customer) with a similar new or reconditioned

Product of equivalent value, or a refund of the

purchase price if the Product is returned to

Avanti, freight and insurance prepaid. The

obligations of Avanti are expressly conditioned

upon return of the Product in strict accordance

with the return procedures of Avanti.

This warranty does not apply if the Product (i)

has been altered without the authorization of

Avanti or its authorized representative; (ii) has

not been installed, operated, repaired, or

maintained in accordance with this Manual or

other instructions from Avanti; (iii) has been

subjected to abuse, neglect, casualty, or

negligence; (iv) has been furnished by Avanti to

Customer without charge; or (v) has been sold

on an “AS-IS” basis.

Except as specifically set forth in this Limited

Warra nty,

ALL EXPRESS OR IMPLIED CONDITIONS,

REPRESENTATIONS AND WARRANTIES,

INCLUDING, BUT NOT LIMITED TO, ANY

IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, NON-INFRINGEMENT,

SATISFACTORY QUALITY, COURSE OF DEALING, LAW, USAGE OR TRADE PRACTICE ARE

HEREBY EXCLUDED TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE LAW

AND ARE EXPRESSLY DISCLAIMED BY

AVANTI. IF, PURSUANT TO ANY APPLICABLE

LAW, TO THE EXTENT AN IMPLIED WARRANTY CANNOT BE EXCLUDED AS PROVIDED IN

THIS LIMITED WARRANTY, ANY IMPLIED

WARRANTY IS LIMITED IN TIME TO THE SAME

DURATION AS THE EXPRESS WARRANTY

PERIOD SET FORTH ABOVE. BECAUSE SOME

STATES DO NOT PERMIT LIMITATIONS ON

THE DURATION OF IMPLIED WARRANTIES,

THIS MAY NOT APPLY TO A GIVEN CUSTOMER. THIS LIMITED WARRANTY GIVES CUSTOMER SPECIFIC LEGAL RIGHTS, AND

CUSTOMER MAY HAVE OTHER LEGAL

RIGHTS UNDER APPLICABLE LAWS.

This disclaimer shall apply even if the express

warranty fails of its essential purpose.

In any cases of dispute the English original shall

be taken as authoritative.

1. Limited Warranty

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 5 6/11/2018 2:03:51 PM

6

AVANTI Service Lif t for Wind Turbines

2.2 Symbols

2.1 Observations

2. Introduction

Only trained people may use this lift.

This manual must be available to staff at all times during installation, maintenance and operation.

Additional copies are available from the manufacturer upon request.

This manual, including, but not limited to, measurements, procedures, components, descriptions, instructions, recommendations and requirements, is subject to change without prior notice. Please check Avanti

website/manuals for the latest revisions of the manuals.

Any additional cost related to or arising from any changes in the manuals does not entitle Customer to any

form of compensation or other legal remedies.

The pictures and sketches in this manual may not reflect the product aesthetics, colours,

arrangement precisely. This has no impact on the function or safety.

!

STOP

!

Symbol Signal word Meaning Possible injury if not observed

Safety instructions

DANGER!

IMMEDIATE or

possibly imminent

danger:

Death or severe injury!

DANGER!

IMMEDIATE or

possibly imminent

danger of hazardous

voltage:

Death or severe injury!

CAUTION! Potentially hazardous

situation:

Light injury or material damage.

Additional instructions

ATTENTION!

Potentially dangerous

situation:

Damage to equipment or workplace

IMPORTANT!

Useful tips for optimum

working procedure

None

Reference to written

specification/documentation

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 6 6/11/2018 2:03:52 PM

7

Maintenance and Installation Manual

2.3 Cautions

Use and daily inspection of the service lift shall only

be performed by person who has gone through the

relevant training associated with the Avanti service

lift use and daily inspection and is in possession of a

valid (non expired) certificate for the task.

Installation and maintenance of the service lift shall

only be performed by Certified technicians.

Personnel must be at least 18 years of age.

The staff must be familiar with the relevant accident

prevention instructions and must have received

proper training in these.

Personnel are obliged to read and understand this

User’s Manual.

Personnel shall wear PFPE (safety helmet, full body

harness, shock absorber, lanyard and slider) at all

times.

A copy of the User’s Manual must be handed out

to the personnel and must always be available for

reference.

If more than one person is entrusted with one of

the above tasks, the employer shall appoint a

supervisor in charge of the operation.

Self-locking nuts must be used at all times. The

screw must extend from the nut by at least half

of the thread diameter. The nut may not be used once

it has become possible to loosen by hand!

If any damage or faults are found during operation,

or if circumstances arise which may jeopardize

safety: immediately interrupt the work in progress

and notify the supervisor or employer!

All tests/repairs of electrical installations may only

be performed by a certified technician.

All repairs to the traction, braking and supporting

systems may only be performed by a certified technician.

If any supporting parts are repaired or replaced,

the operational safety of the system must be tested

and verified by a certified technician.

Only original fault-free parts may be used.

Use of non-original parts will render the manufacturer’s warranty void and any type approval invalid.

No modification, extension or reconstruction of the

service lift is allowed without the manufacturer’s prior

written consent.

No warranty is provided against damage resulting

from reconstruction or modification of equipment or

use of non-original parts which are not approved by

the manufacturer.

Service lift must be inspected by a certified technician before first use.

Service lift must be inspected at least once a year

by a certified technician. In case of high operating

frequency or severe conditions of use, more frequent

inspection is required.

Service lift is designed for a lifetime of 25 years with

an operating frequency of approximately 10h/year

(250 h in total).

Service lift may not be used by persons who are

under the influence of alcohol or drugs which may

jeopardize working safety.

The service lift shall not be used in case of fire in the

tower.

Service lift shall ONLY be used when the turbine is

not generating power.

All wind farm site specific rules must be followed.

Service lift shall not be used during inclement weather, including wind speeds over 25 m/s (55.5 mph).

Avoid injury – follow all instructions!

Owner must verify the need for third party service lift inspections with the local

authority and comply with the standards

specified.

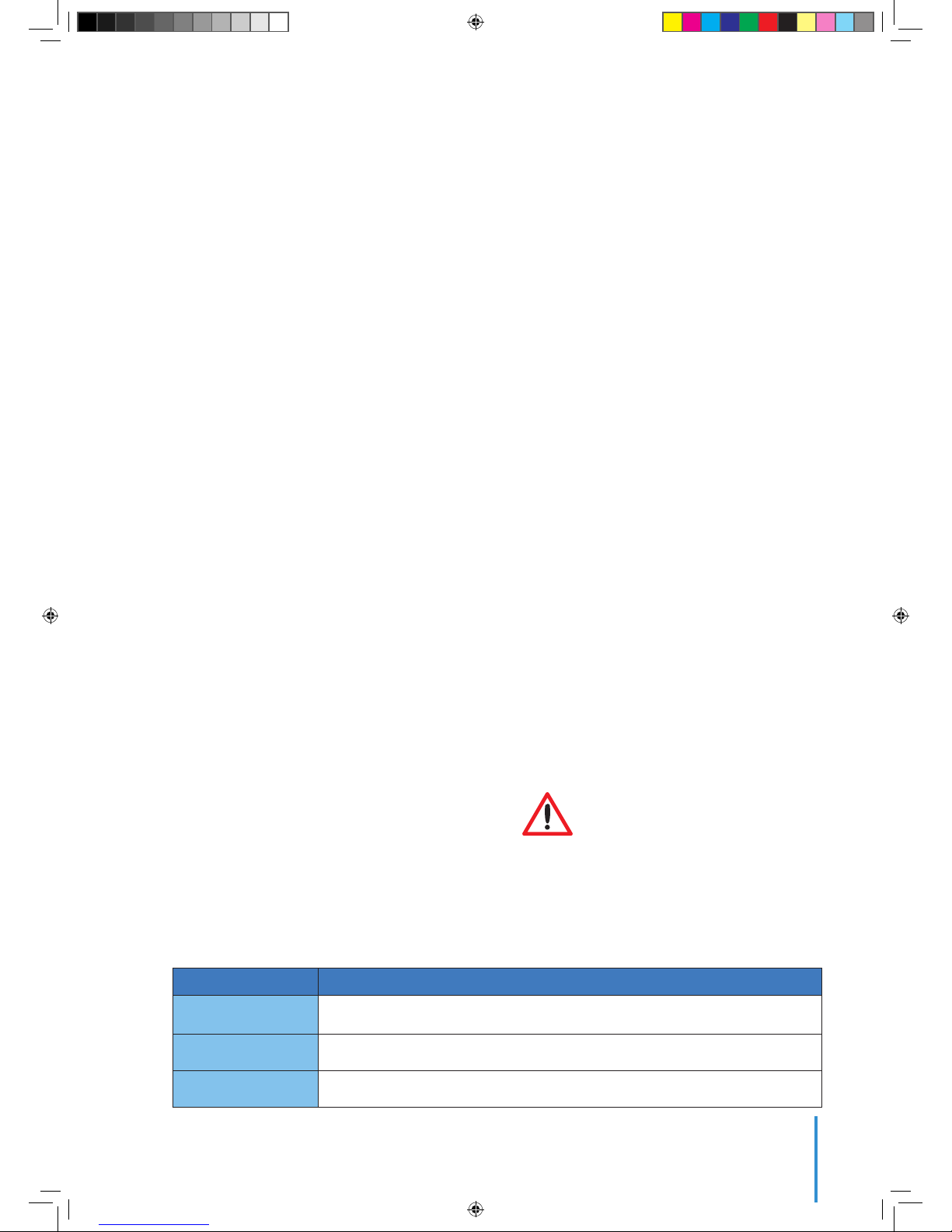

2.4 Terms and definitions

Terms Definitions

Certified technician

Person who has gone through the relevant training associated with the scheduled task from Avanti

or from a cer tified trainer and is in possession of a valid (non expired) certificate for the task.

User

Person who has gone through the relevant training associated with the Avanti service lift

use and daily inspection and is in possession of a valid (non expired) certificate for the task.

Manual descent

Action performed to descend the lift at a controlled speed without power supply by manually

opening the hoist electromagnetic brake. (Also manual no-power descent)

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 7 6/11/2018 2:03:52 PM

8

AVANTI Service Lif t for Wind Turbines

3. Installation

3.1 WTG integration requirements

WTG

component

General integration requirements

Service lift Dolphin A-V164

Power supply Ty pe 3 Phase + PE + N

1)

Voltage (50 Hz) 400 V/ 690 V

Voltage (60 Hz) 400 V/ 690 V

Fuses 16 A

Protection According to EN

602 04-1

Platforms Minimum clearance

around service lift

50 mm

2)

Evacuation

way

Means of evacuation

shall be provided

with a maximum

distance of

1100 mm

Platform

fences

Minimum height 110 0 m m

Compliant to

requirements of

standard

EN 14122-3

Fence door interlock system

Trapped key or

guard locking

Hoistway Maximum total

travel height

See note (3)

Maximum angle

between hoistway

and vertical axis

±5,3º

Top b e am Forces capable to

withstand

Upon request

from AVANTI

1) Note: Neutral applies only to 40 0 V.

2) Note: Up to a minimum value of 40 mm. af ter evaluation

and approval by Avanti

3) Note: With all options: 135 m. / Standard design: 160 m.

Depending on travel path, dimensions may need to be

larger in order to avoid collisions of travelling cable pulley

with platforms. Other dimensions are possible upon

request and design verification by AVANTI.

The WTG manufacturer shall put in place any other

means necessary to ensure the safe use of the service

lift according to AVANTI recommendations and its own

risk assessment for the integration that shall include

items which are not under AVANTI´s scope.

In the event of installation procedure divided into two

different stages and extension of travel path is needed

(e.g.: offshore configuration):

There is a first assembled onsite at harbor stage were

some of the lift components are preassembled by the

tower manufacturer. All the wire ropes have to be

tightened at provisional bottom platform and the extra

length coiled up in a secure manner to prevent damages

in them since they have to be used for the final extension. Half bushings must be installed to protect wire

ropes (traction, safety and guiding) before travelpath

extension.

The assembly of the tower to the offshore foundation

extending the operation of the service lift to the transition

piece (TP) will be undertaken in the second stage.

In this second stage, TP bottom platform will be the final

low travel end of the lift, and therefore when the tower is

located over the TP, the Control Box previously mounted

on first stage provisional bottom platform will be

disassembled and re-mounted on the TP Bottom

Platform.

When the travel path of the cabin is extended to TP

bottom platform, travelling cable and wire ropes need to

be longer, for this reason, these are previously ready

coiled on the first stage.

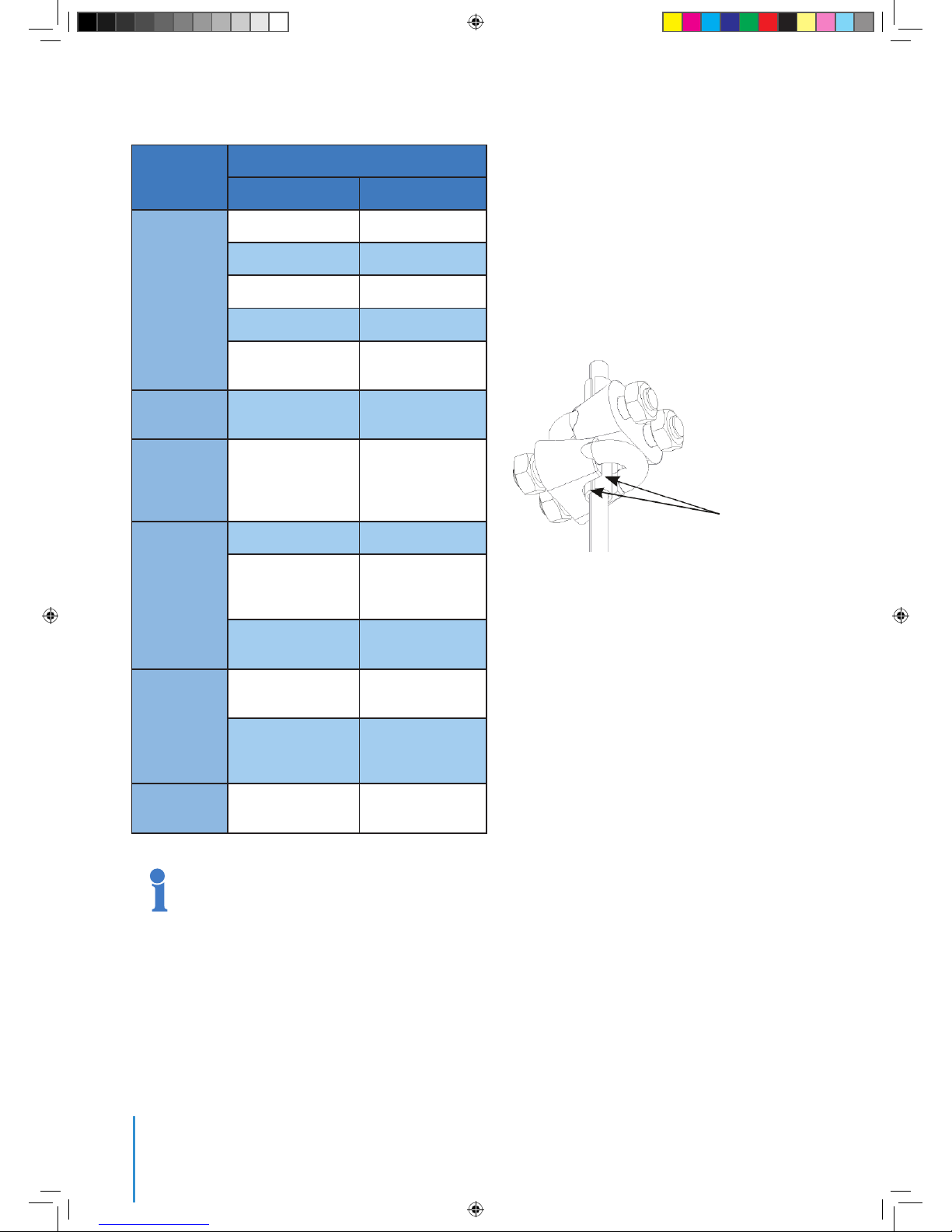

Half bushings

AT00014349_Dolphin A-V164_Maintenance and Installation Manual E01R03.indd 8 6/11/2018 2:03:52 PM

Loading...

Loading...