Autopilot PPC10 Installation And User Manual

PPC10

Pool/Spa Control System

Installation and User Guide

2 Commander PPC-CON - PPC-REM Installation Guide

Important Safety Instructions

All electrical work must be performed by a licensed electrician and conform to all national, state,

and local codes. When installing and using this electrical equipment, basic safety precautions

should always be followed, including the following:

DANGER: To reduce the risk of injury, do not remove the suction fittings of your spa or hot tub.

Never operate a spa or hot tub if the suction fittings are broken or missing. Never replace a

suction fitting with one rated less than the flow rate marked on the equipment assembly.

WARNING: Prolonged immersion in hot water may induce hyperthermia. Hyperthermia occurs

when the internal temperature of the body reaches a level several degrees above the normal

body temperature of 98.6°F. The symptoms of hyperthermia include dizziness, fainting,

drowsiness, lethargy, and an increase in the internal temperature of the body. The effects of

hyperthermia include: 1) unawareness of impending danger; 2) failure to perceive heat; 3)

failure to recognize the need to exit spa; 4) physical inability to exit spa; 5) fetal damage in

pregnant women; 6) unconsciousness resulting in a danger of drowning.

WARNING: To Reduce the Risk of Injury —

• The water in a spa should never exceed 104°F (40°C). Water temperatures between 100°F

(38°C) and 104°F (40°C) are considered safe for a healthy adult. Lower water temperatures are

recommended for young children and when spa use exceeds 10 minutes.

• Since excessive water temperatures have a high potential for causing fetal damage during

the early months of pregnancy, pregnant or possibly pregnant women should limit spa water

temperatures to 100°F (38°C).

• Before entering a spa or hot tub, the user should measure the water temperature with an

accurate thermometer since the tolerance of water temperature-regulating devices varies.

• The use of alcohol, drugs, or medication before or during spa or hot tub use may lead to

unconsciousness with the possibility of drowning.

• Obese people and people with history of heart disease, low or high blood pressure,

circulatory system problems, or diabetes should consult a physician before using a spa.

• People using medication should consult a physician before using a spa or hot tub since some

medication may induce drowsiness while other medication may affect heart rate, blood

pressure, and circulation.

WARNING: Risk of electric shock – Install the control center at least five (5) feet (152.4cm)

from the inside wall of the pool and/or hot tub using non-metallic plumbing. Canadian

installations must be at least three (3) meters from the water.

WARNING: Failure to heed the following may result in permanent injury or death:

Risk of electric shock – Disconnect all AC power when insatalling or servicing this system.

Copyright © 2010 AquaCal AutoPilot, Inc.

Safety 3

• Children should not use spas or hot tubs without adult supervision.

• Do not use spas or hot tubs unless all suction guards are installed to prevent body and hair

entrapment.

• People using medications and/or having an adverse medical history should consult a

physician before using a spa or hot tub.

• People with infectious diseases should not use a spa or hot tub.

• To avoid injury, exercise care when entering or exiting the spa or hot tub.

• Do not use drugs or alcohol before or during the use of a spa or hot tub to avoid

unconsciousness and possible drowning

• Pregnant or possibly pregnant women should consult a physician before using a spa or hot

tub.

• Water temperature in excess of 100°F (38°C) may be injurious to your health.

• Before entering a spa or hot tub measure the water temperature with an accurate

thermometer.

• Do nut use a spa or hot tub immediately following strenuous exercise.

• Prolonged immersion in a spa or hot tub may be injurious to your health.

• Do not permit any electric appliance (such as a light, telephone, radio, or television) within 5

feet (1.5m) of a spa or hot tub.

• The use of alcohol, drugs or medication can greatly increase the risk of fatal hyperthermia in

hot tubs and spas.

• Water temperature in excess of 100°F (38°C) may be hazardous to your health.

WARNING: To reduce the risk of electrical shock, connect the grounding terminal in the

metal enclosure to the grounding terminal of your electric service or supply panel with a

continuous copper conductor having green insulation and one that is equivalent in size to the

circuit conductors supplying this equipment. In addition, a second wire connector should be

bonded with a no. 8 AWG (4.115mm) copper wire to any metal ladders, water pipes, or other

metal within five (5) feet (1.52m) of the tub.

WARNING: A ground-fault circuit-interrupter must be provided if this device is used to control

underwater lighting fixtures. The conductors on the load side of the ground-fault circuitinterrupter shall not occupy conduit, boxes or enclosures containing other conductors unless

the additional conductors are also protected by a ground-fault circuit-interrupter. Refer to

local codes for complete details.

Copyright © 2010 AquaCal AutoPilot, Inc.

4 Commander PPC-CON - PPC-REM Installation Guide

Contents

Important Safety Instructions ........................................................................................................... 2

Section 1: System Overview .........................................................................................................8

Additional Detail on Key Components .........................................................................................9

Handheld Controller (PPC-REM) ................................................................................................. 9

24-Volt Valve Actuator (PPC-ACT) ............................................................................................... 9

Water Temperature Sensor (PPC-WTR) ........................................................................................9

Optional — Freeze (Air Temperature) Sensor (PPC-AIR) ...............................................................9

24-Volt Valve/Pump Switch (PPC-ACTC) ...................................................................................10

24-Volt Valve/Pump Swtich with Enclosure (PPC-ACTE) ............................................................ 10

80 Amp Bus PE Outdoor Enclosure (PPC-80CP) ........................................................................10

Section 2: Plumbing Examples ....................................................................................................11

For Pool and Spa Combo Installations ........................................................................................ 11

For Booster Pump Pool Cleaner Installations...............................................................................11

For Non-Booster Pump Pool Cleaner Installations.......................................................................12

For Separate Pool and Spa Combo Installations .......................................................................... 12

Section 3: Installing and Wiring the PPC-CON Receiving Device ..............................................13

Ratings ....................................................................................................................................... 13

Wiring Instructions ..................................................................................................................... 14

Power Connections ...............................................................................................................14

Upper Terminal Connections ................................................................................................. 15

Installation Instructions ......................................................................................................... 15

List of Wiring Diagrams .........................................................................................................16

Variable-Speed Pumps ...............................................................................................................17

240V Variable-Speed Pump ................................................................................................... 17

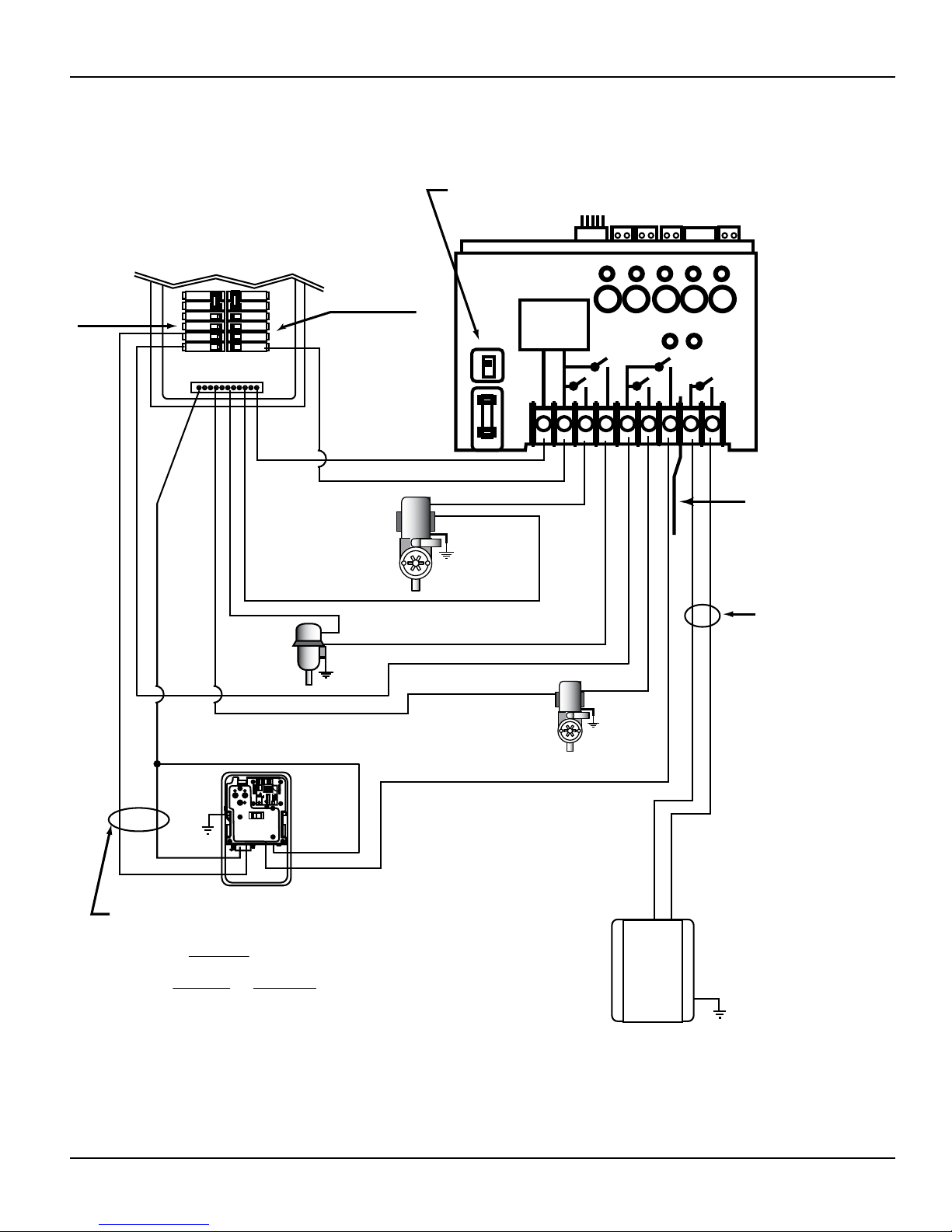

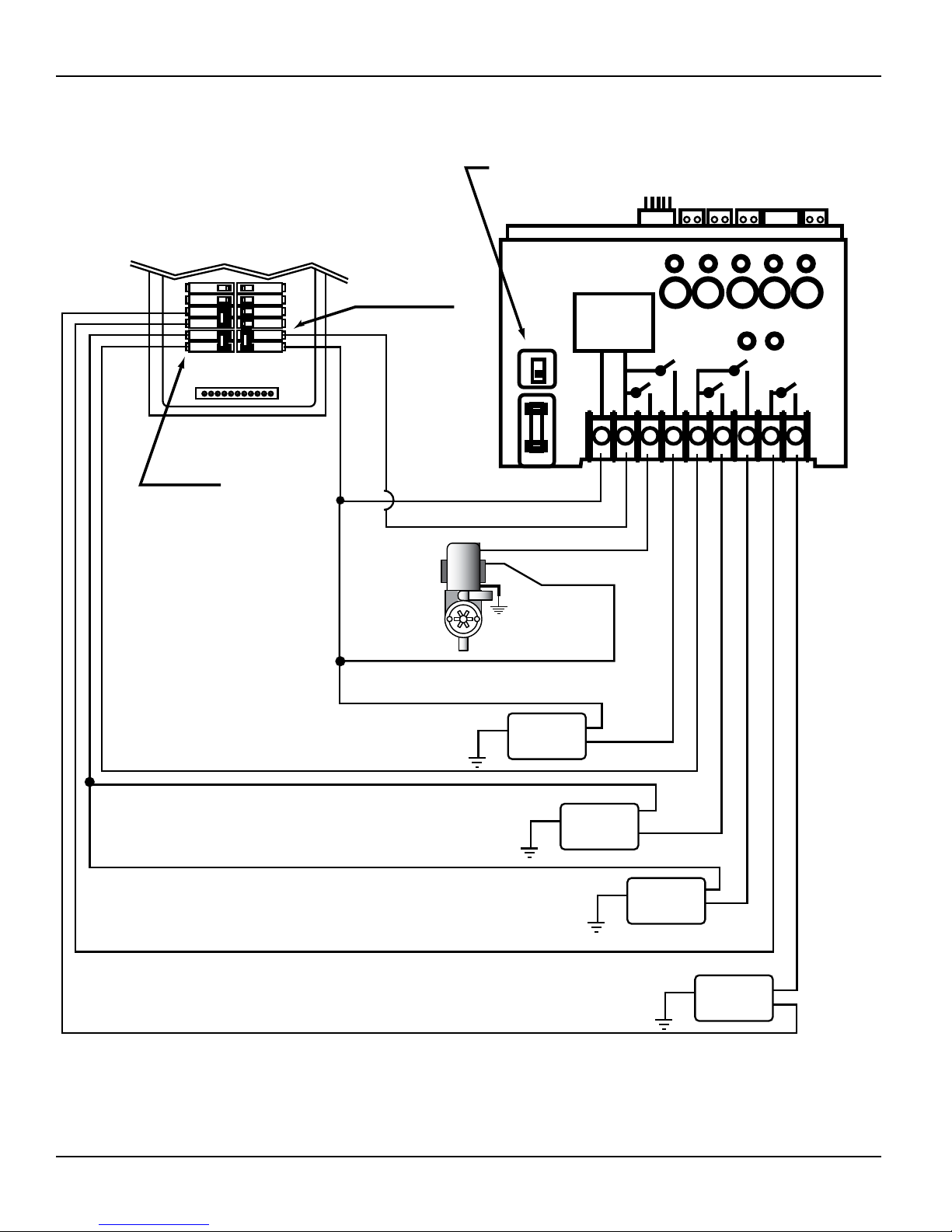

1-Speed Pumps ..........................................................................................................................18

120V 1-speed pump .............................................................................................................. 18

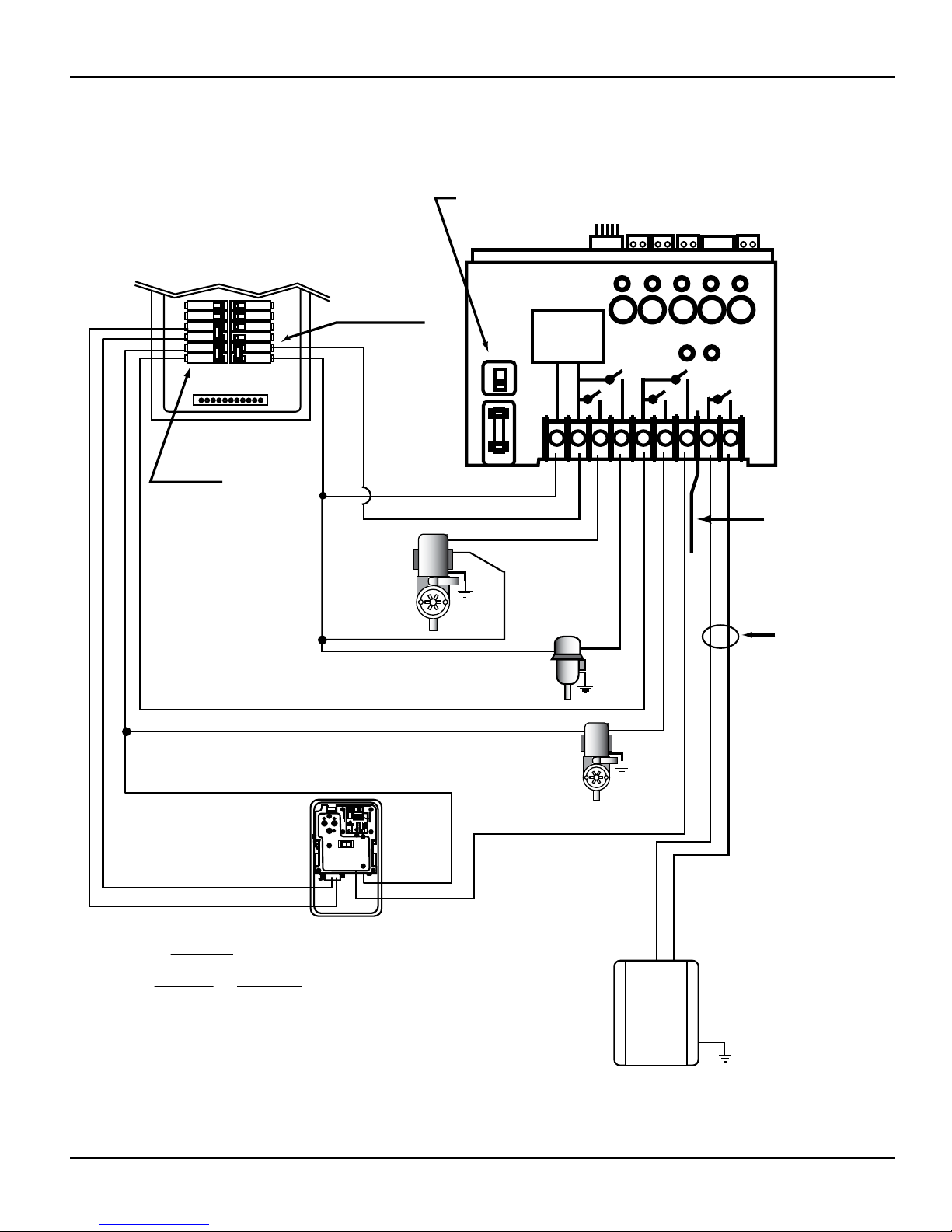

120V 1-speed pump + any four 120 VAC auxiliary equipment ..............................................19

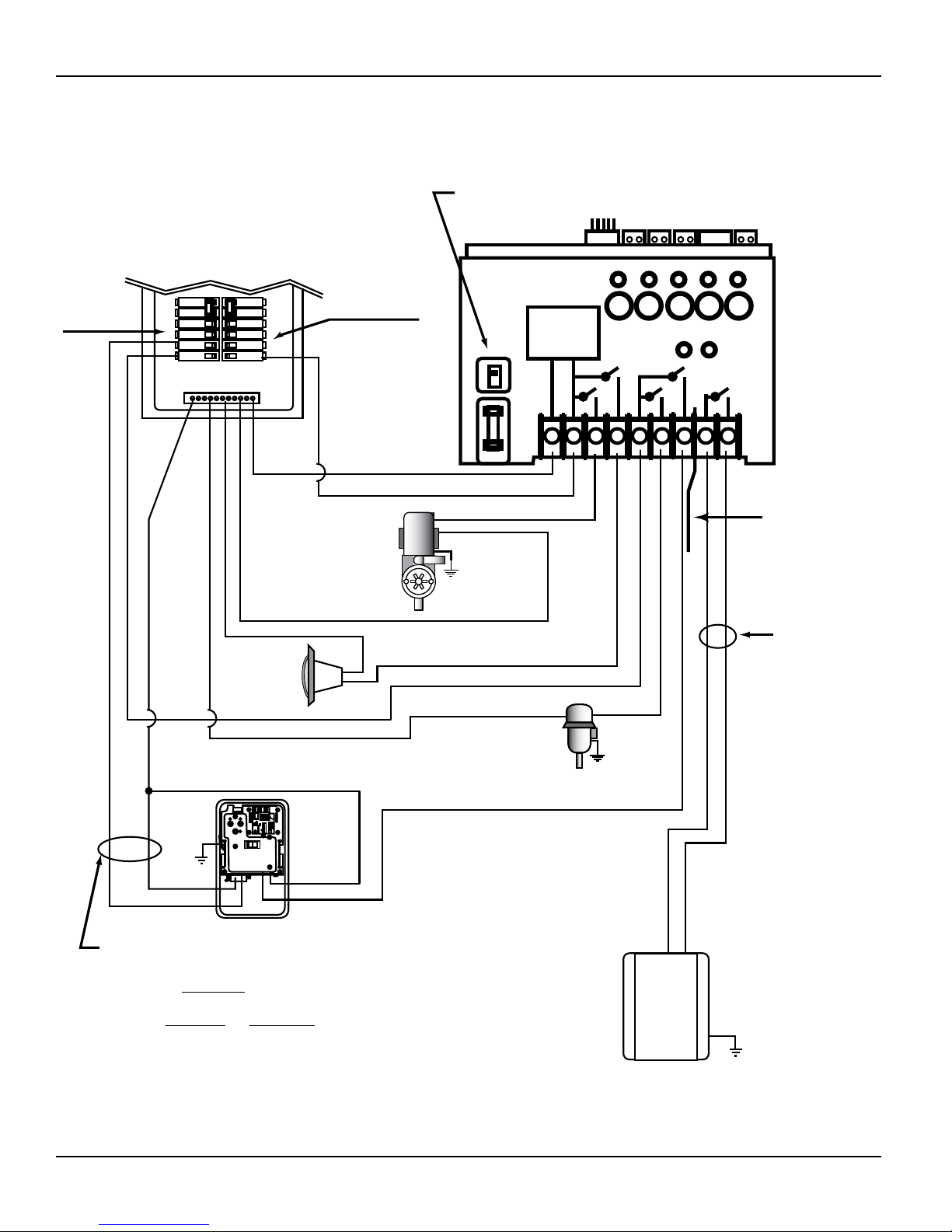

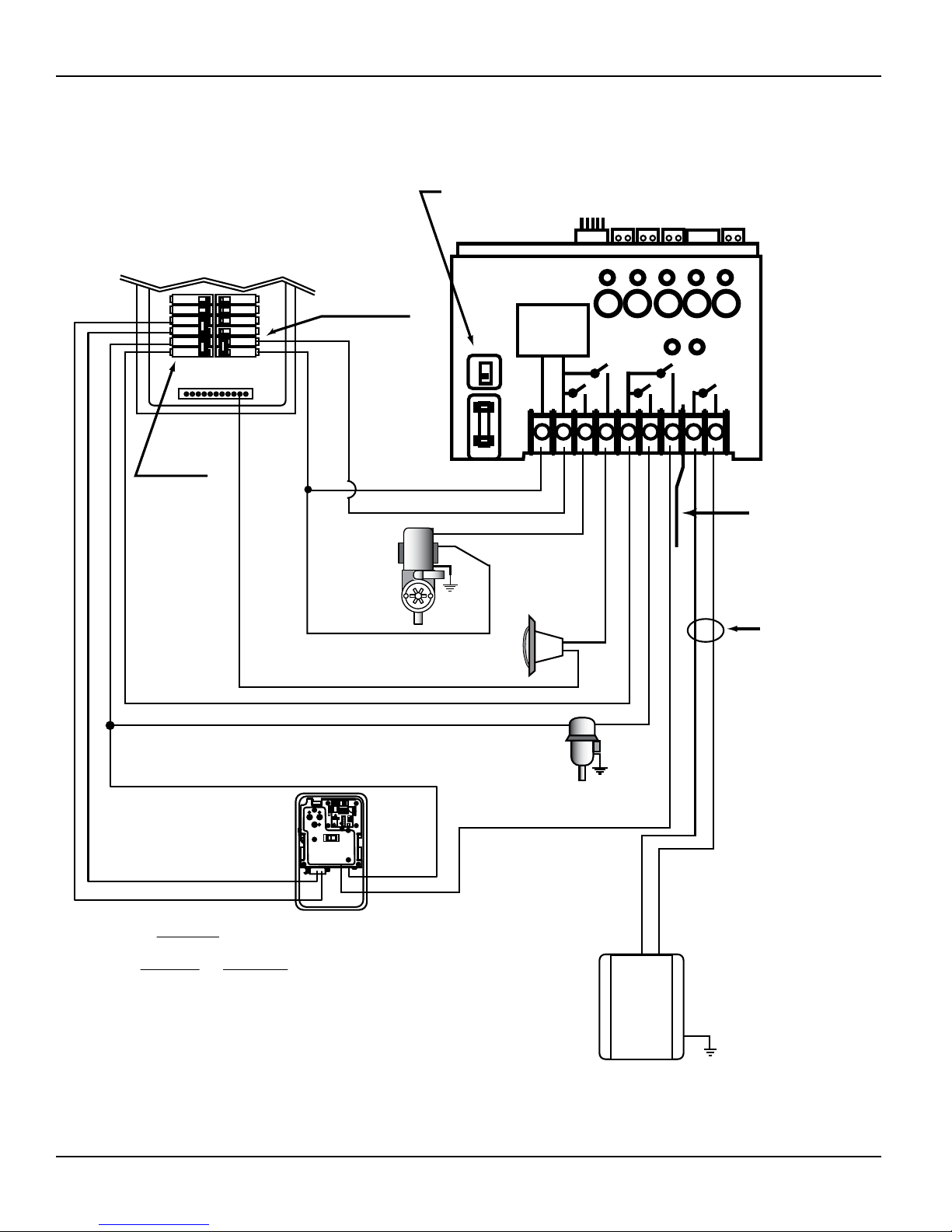

120V 1-speed pump + 120 VAC blower or lights + 120V booster pump +

120V actuator + heater .................................................................................................... 20

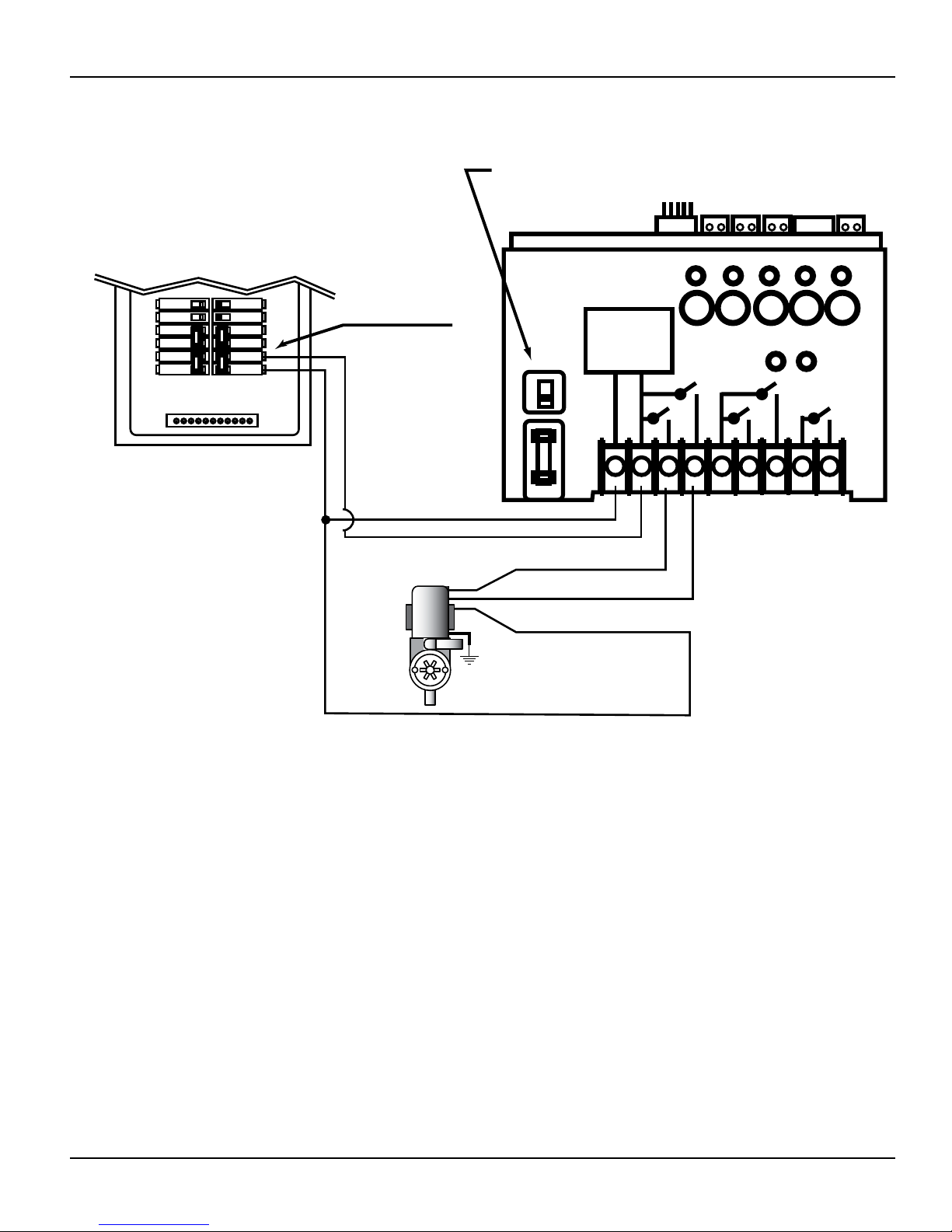

120V 1-speed pump + 120V blower + 120V lights + 120V actuator + heater ........................ 21

240V Pumps ..............................................................................................................................22

240V 1-speed pump .............................................................................................................. 22

240V 1-speed pump + any four 240 VAC auxiliary equipment ..............................................23

240V 1-speed pump + 240V blower + 240V booster pump + 240V actuator + heater ........... 24

240V 1-speed pump + 120V lights + 120V blower + 240V actuator + heater ........................ 25

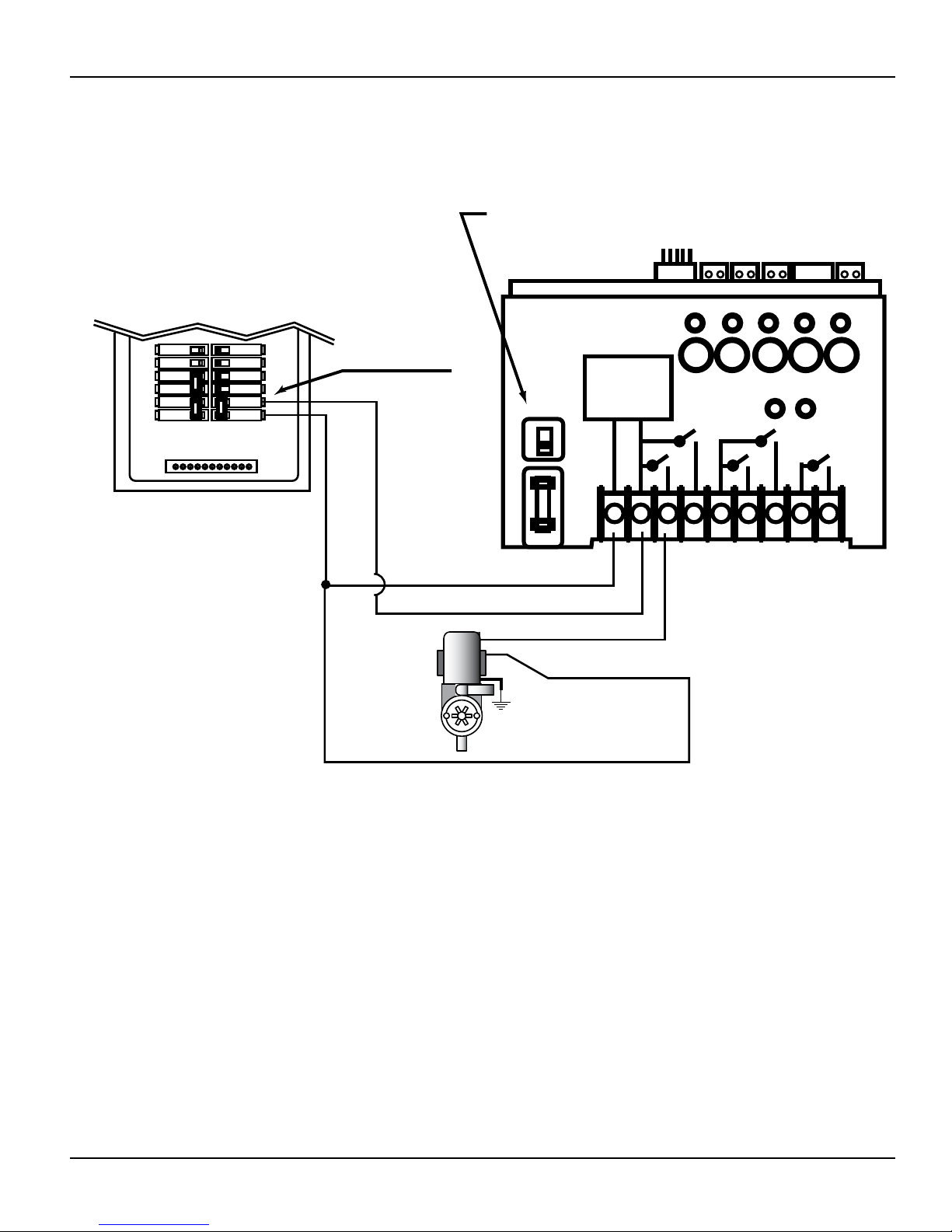

240V 2-Speed Pump .............................................................................................................26

240V 2-speed pump + any three 240VAC auxiliary equipment .............................................27

240V 2-Speed pump + any 3 120 VAC auxiliary equipment ..................................................28

240V 2-Speed pump + 240V Booster Pump + 240V Actuator + Heater ................................29

240V 2-speed pump + 120V lights + 240V blower + heater .................................................. 30

240V 2-speed pump + 240V blower + 240V actuator + heater .............................................. 31

Copyright © 2010 AquaCal AutoPilot, Inc.

Contents 5

240V 2-speed pump + 240V booster pump + 240V blower + heater ..................................... 32

240V 2-speed pump + 240V booster pump + 120V light + heater ......................................... 33

240V 2-speed pump + 240V booster pump + other 120 VAC equipment + heater .................34

Low-Voltage Wiring ...................................................................................................................35

Water Temperature Sensor ..................................................................................................... 35

Freeze/Air Temperature Sensor ............................................................................................... 35

Communications to a Variable-Speed Pump .........................................................................36

Motorized Valve Actuator Connection and Synchronizing .....................................................36

Heater Connection ..................................................................................................................... 37

Connection for AquaCal Heat Pump ......................................................................................37

Connection for Jandy Heaters ................................................................................................38

Connection for Raypak Heaters .............................................................................................39

Connection for Hayward Heaters ..........................................................................................39

Connection for Pentair Heater ...............................................................................................40

Connection for Sta-Rite / Pentair Heater with DDTC ..............................................................40

Section 4: Programming the PPC-REM Handheld Controller ...................................................... 41

Overview ................................................................................................................................... 41

Creating a Network Connection between the Handheld Controller and

the PPC-CON Receiving Device ........................................................................................... 41

Deleting Any Existing Programming ....................................................................................... 41

Linking the Handheld Controller to the PPC-CON Receiving Device .....................................43

Configuring for a 1-Speed or 2-Speed Pump ...............................................................................44

Calibrating Pool, Spa and Air Temperature Settings ..................................................................... 44

Configuring for a Booster (Cleaner) Pump ..................................................................................45

Configuring the Heater Control and Fireman Switch Time Interval .............................................. 46

Setting the Time of Day ..............................................................................................................47

Setting Up Schedules .................................................................................................................47

Configuring the Freeze Temperature (optional) ...........................................................................48

Configuring for a Variable Speed Pump (optional) ......................................................................49

Testing Z-Wave Reception ..........................................................................................................50

Moving the Antenna to a Better Location ...............................................................................50

Labeling for the PE653 Screen ...............................................................................................51

Labeling for the Z-Wave Screen ............................................................................................. 51

Labeling for the Variable-Speed Pump Screen ........................................................................ 51

Sample Schedule Planning Sheet ................................................................................................ 52

Schedule Planning Worksheet ....................................................................................................53

Sample Schedule Planning Sheet for Variable Speed Pump .........................................................54

Schedule Planning Worksheet for Variable Speed Pump ............................................................. 55

Section 5: Everyday Use of the Handheld Controller ................................................................. 56

Setting the Default Primary Screen .............................................................................................56

Controlling the PPC-CON Receiving Device ..............................................................................57

Operating Programmed Functions .........................................................................................57

Changing between Pool and Spa ...........................................................................................57

Copyright © 2010 AquaCal AutoPilot, Inc.

6 Commander PPC-CON - PPC-REM Installation Guide

Setting Pool and Spa Temperatures.........................................................................................58

Controlling a Variable-Speed Pump ............................................................................................ 58

Naming the Speeds ...............................................................................................................58

Changing Pump Speeds ......................................................................................................... 59

Controlling Z-Wave Devices ......................................................................................................59

Changing Batteries in the Handheld Controller ..........................................................................60

Manually Turning Equipment On and Off ..............................................................................60

Section 6 : Advanced Features ...................................................................................................61

Configuring Two or More Handheld Controllers ........................................................................61

Changing a Secondary Remote Control into a Primary Control .................................................63

Including the PPC-REM Controller into a non-Commander (other manufacturer’s) network. ...... 64

Section 7 : Programming for Use with Z-Wave Home Control Devices .....................................65

Deleting Any Existing Programming ..........................................................................................65

Including Z-Wave Devices into the Network ............................................................................. 66

Including the PPC-CON Receiver onto a non-Commander remote controller ............................66

Adding Z-Wave Devices to Scenes for Everyday Control ...........................................................67

Renaming a Scene ....................................................................................................................68

Removing Z-Wave Devices from Scenes ................................................................................... 69

Removing Z-Wave Devices from a Network ..............................................................................69

Setting Up Z-Wave Associations with Capable Devices ............................................................70

Removing Z-Wave Devices from an Association ......................................................................72

Section 8: Checking Out and Verifying the System .....................................................................73

Section 9: Troubleshooting .........................................................................................................77

Section 10: Appendix ................................................................................................................81

Glossary of Z-Wave Terminology ................................................................................................81

FCC Statement ...........................................................................................................................82

Section 11: Warranty Registration ............................................................................................. 83

Copyright © 2010 AquaCal AutoPilot, Inc.

7

Notes

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

Copyright © 2010 AquaCal AutoPilot, Inc.

8 Commander PPC-CON - PPC-REM Installation Guide

Section 1:

System Overview

The AutoPilot Pool Pilot Commander PPC10 Wireless Control System brings wireless control to a

new level of simplicity and affordability. The following features make the system distinctive:

• Easy to Use — with simple, push button controls and a clear, easy-to-read display panel

• Everything You Need — includes the functionality and control called for in nearly every

installation.

• Dependable — with Z-Wave

inexpensive repeaters that plug into available electrical outlets to help extend the RF signal

range of the entire system. Z-Wave technology eliminates intermittent signal problems

experienced with many other systems.

• Cost Efficiency — a superior system, easier to install and maintain, with better

dependability, and at a cost that’s competitive with any other system available.

The standard configuration for the Commander PPC10 Pool/Spa Wireless Control System

configuration is shown in Figure 1-1. You can order individual components for a custom

configuration or system as indicated.

Receiving Device (PPC-CON)

®

technology that lets you expand your system with

Two-wire connection (RS485) for

control of variable-speed motors

Antenna can be remotely located

using a Standard Cat 5 Ethernet

cable with RJ45 plugs.

Internal selector switch for

120 / 240 VAC operation

Spare 0.10 Amp Fuse

Offers timer capability and can

control up to five preprogrammed

configurable circuits.

Handheld Controller (PPC-REM).

Additional units can be ordered

separately.

Terminals for two-wire

connections to remote

temperature sensors

Weatherproof outdoor enclosure

can be mounted directly to an

existing enclosure.

Approved snap-in wiring

separator for use with low

voltage heater control circuit

Metal indoor/outdoor enclosure

provides for easy and secure

mounting and a large space for

conduit wire connections.

Figure 1-1

Copyright © 2010 AquaCal AutoPilot, Inc.

Z-Wave is a registered trademark of

Sigma Designs and/or its subsidiaries.

Additional Detail on Key Components

Handheld Controller (PPC-REM)

The main function of the Handheld Controller is to transmit user commands

to the PPC-CON Receiving Device and/or Z-Wave home control devices,

and to display the status of the installed equipment.

The unit floats if thrown in the pool or spa, is water-submersible, shock

resistant, and requires three (3) AA batteries. Expected battery life is about

one year in typical use.

When the components of a specific system are linked together into a

network, unique network ID codes supplied by the PPC-REM prevent

unauthorized use of the system by neighboring systems.

24-Volt Valve Actuator (PPC-ACT)

Designed with quality in mind, AutoPilot’s 24-volt valve actuators

provide reliable control of 2-way and 3-way diverter valves for pool/

spa combinations and water features. The water flow can be altered

for specific applications through the adjustable cam, which rotates

diverter valves to multiple degree settings. The cam settings can be

easily adjusted by simply removing the lid. These valve actuators are

compatible with all pool/spa valves currently offered in the industry and

will retrofit into all pool/spa control systems.

One: System Overview 9

• 24VAC Input Voltage

• Automates compatible diverter valves for

pool/spa combos

• Adjustable cam rotates diverter valves to

multiple degree settings

• Designed to operate most 2-way and 3-way diverter valves

• Shipping Weight - 3 lbs. (1.4 kg)

• Agency Approval - CSA/C-US

Water Temperature Sensor (PPC-WTR)

The AutoPilot Water Sensor (PPC-WTR) monitors both pool and spa water

temperature, depending on the position of the diverter valves. Installation is

necessary for the thermostatic control to work. The sensor can be ordered

separately.

Optional — Freeze (Air Temperature) Sensor (PPC-AIR)

Add the Freeze or Air Temperature Sensor (PPC-AIR) to installations where

below-freezing outdoor temperatures are a concern.

Copyright © 2010 AquaCal AutoPilot, Inc.

10 Commander PPC-CON - PPC-REM Installation Guide

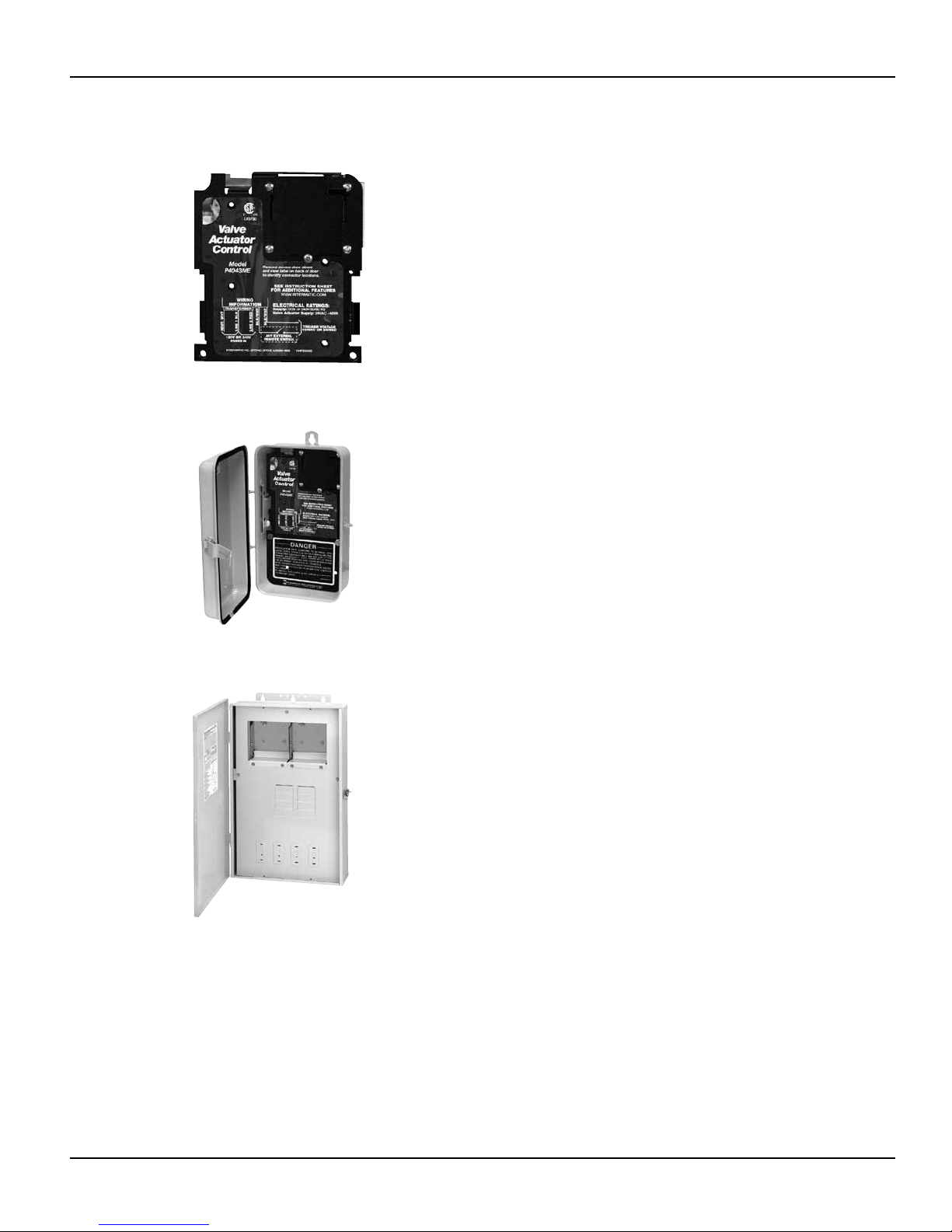

24-Volt Valve/Pump Switch (PPC-ACTC)

Designed as part of the Commander system and for aftermarket

and retrofit applications, the PPC-ACTC unit snaps into almost any

Intermatic enclosure and controls the 24 volt supply for up to three

valve actuators. For this installation, if an enclosure must be added, we

recommend PPC-CASE.

• 120 or 208-240 input voltage

• Controls up to three valve actuators

• Agency approval – CSA/C-US

• Valve Actuator Supply: 24VAC 40VA

24-Volt Valve/Pump Switch with Enclosure (PPC-ACTE)

PPC-ACTE includes the PPC-ACTC with a raintight enclosure for new

installations or those that do not have an existing Intermatic timeclock

housing already in place.

• 120 or 208-240 input voltage

• Controls up to three valve actuators

• Agency approval – CSA/C-US

• Valve Actuator Supply: 24VAC 40VA

80 Amp Bus PE Outdoor Enclosure (PPC-80CP)

One empty 22”x14”x4.25” PE Outdoor Enclosure with 80 Amp Bus.

The PPC-ACTC can be mounted inside this enclosure and can house 8

circuit breakers.

Copyright © 2010 AquaCal AutoPilot, Inc.

Section 2:

Plumbing Examples

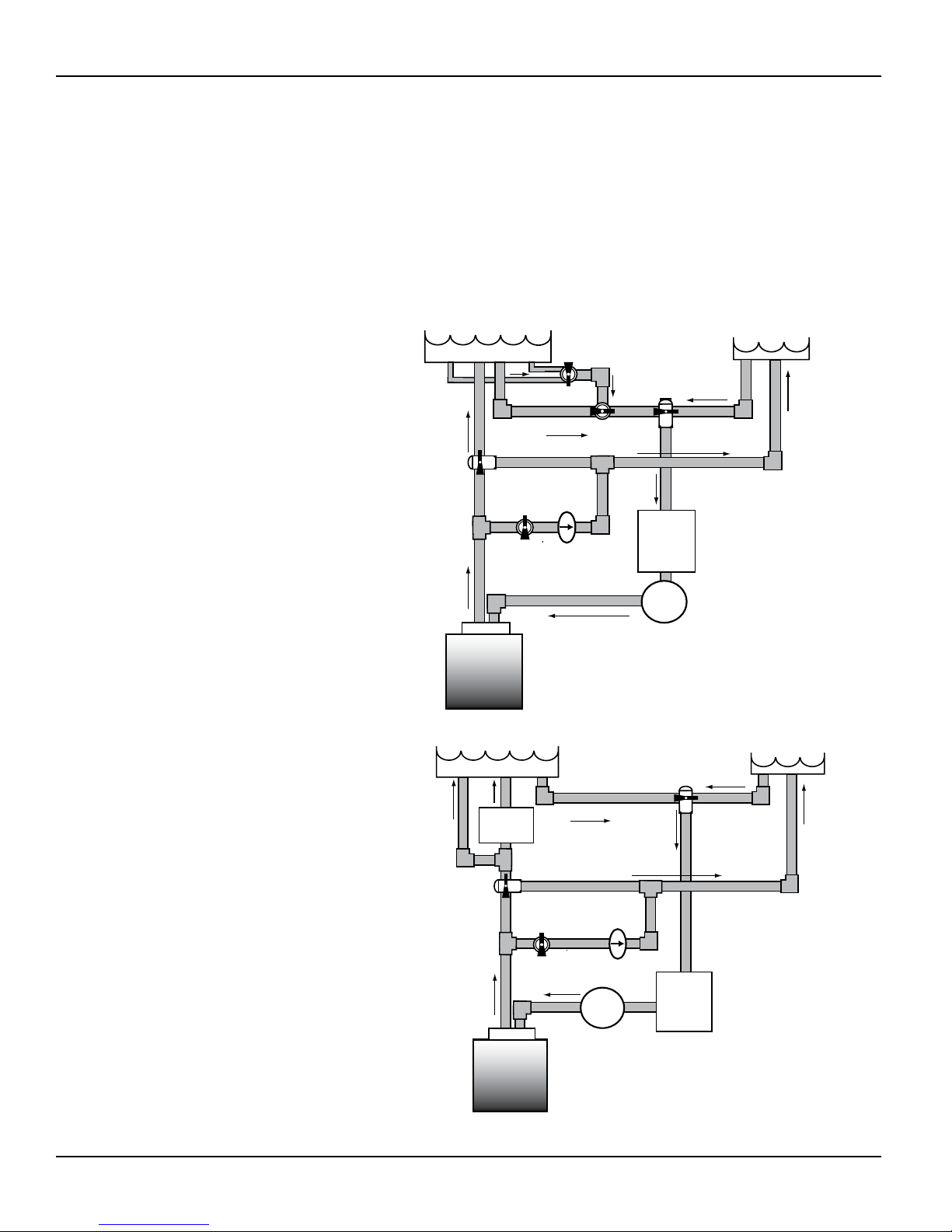

The following diagrams show several plumbing and wiring examples of installations for pool and

spa that share a single filter pump, filter, and heater. If you are installing a pool only or spa only,

these diagrams will not apply.

Two: Plumbing and Wiring Examples 11

For Pool and Spa

Combo Installations

For Booster Pump Pool

Return

Pool

Heater

Pool

Intake

Check

Valve

Spa

Make-up

Spa

Skimmers

Return

Intake

Filter

Pump

Filter

Spa

Cleaner Installations

Return

Copyright © 2010 AquaCal AutoPilot, Inc.

Booster

Pump

Heater

Intake

Spa Make-up

Check

Valve

Filter

Intake

Return

Filter

Pump

12 Commander PPC-CON - PPC-REM Installation Guide

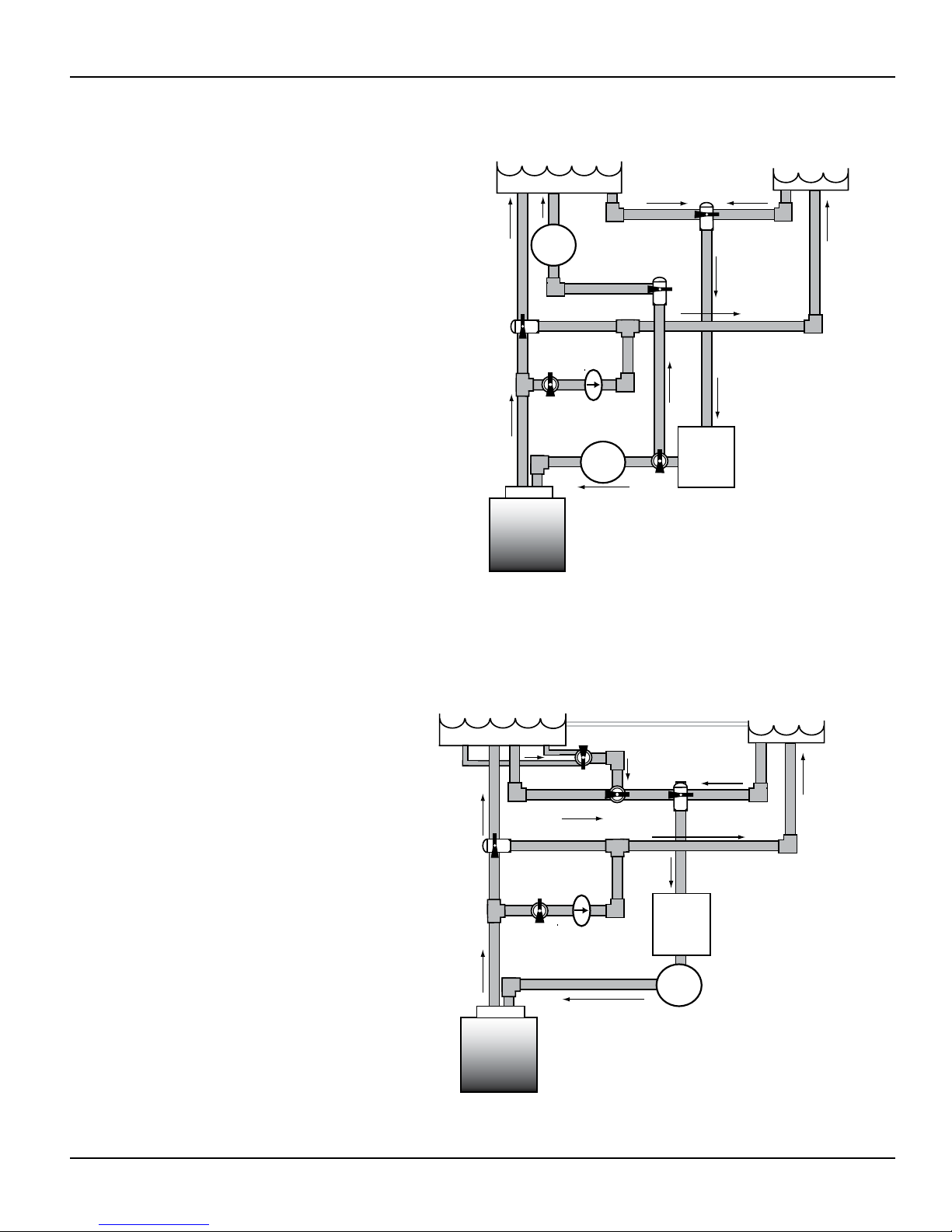

For Non-Booster Pump

Pool Cleaner Installations

Return

Heater

Pool

Energy

Filter

Spa

Make-up

Check

Valve

Filter

Intake

Filter

Pump

Intake

Spa

Return

For Separate Pool

and Spa Combo

Installations

If you do not have an overflow spa, you

must always include an equalizer line to

prevent the possibility of pumping the pool

into the spa.

Return

Pool

Heater

Intake

Check

Valve

Spa

Make-up

Equalizer Line

Skimmers

Spa

Return

Intake

Filter

Pump

Filter

Copyright © 2010 AquaCal AutoPilot, Inc.

Three: PPC-CON Receiving Device Installation 13

3 4 5 6 7 8 921

120 V

240 V

INCLUDE

Section 3:

Installing and Wiring the PPC-CON

Receiving Device

• To avoid fire, shock, or death, turn off power at circuit breaker and test that power is off before wiring.

• Read instructions completely before installation and retain for future reference.

• Observe all national and local electrical and safety codes.

• Disconnect power when servicing or changing loads.

• Alterations or modifications to the device will void the warranty.

• For outdoor locations, rain-tight or wet location conduit hubs that comply with the requirements of UL 514B

Conduit, Tubing, and Cable Fittings, must be used.

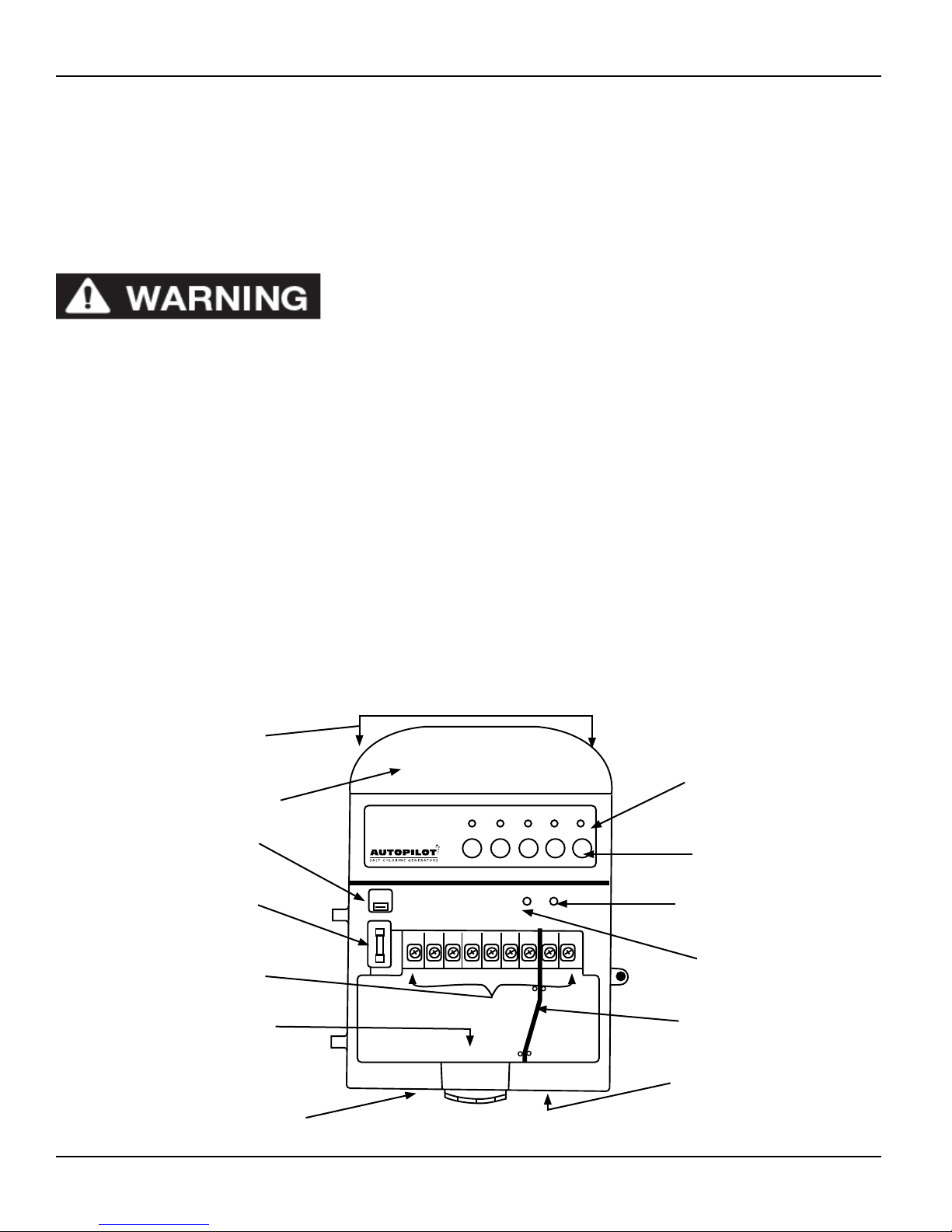

Ratings

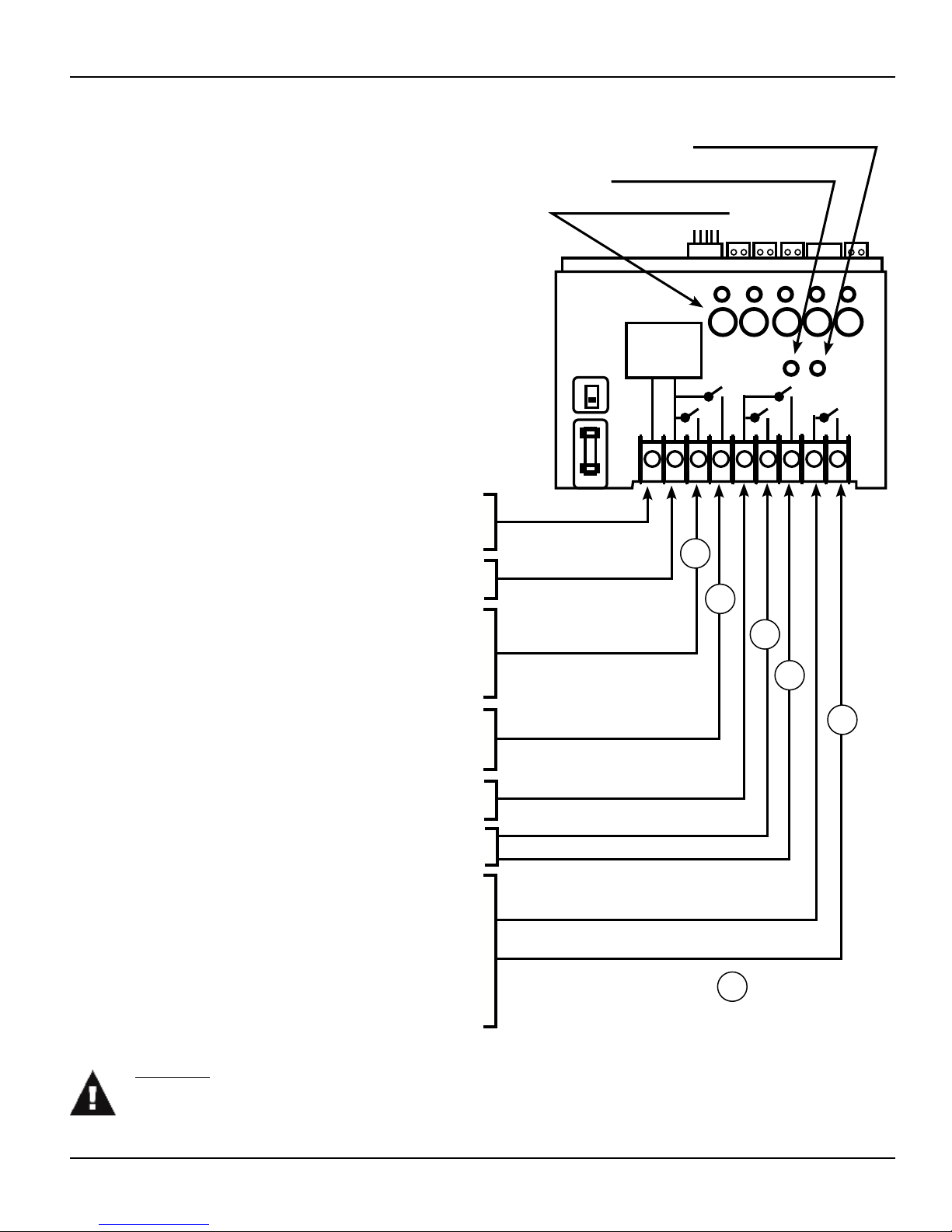

Antenna Section

Locking Screws

•

Antenna Section

120 / 240 VAC Selector Switch

(250 VAC - 0.1 A)

Wiring Terminals

Controller Power In:

• 120/240VAC, 50/60Hz - 5W MAX.

Contact Ratings:

Load 1

• 120/240 VAC

• 20A Resistive

• 17 Full load A, 80 Lock Rotor A

• 5A Tungsten or Ballast

Fuse

Loads 2-5

• 120/240 VAC

• 15A Resistive

• 10 Full load A, 60 Lock Rotor A

• 5A Tungsten or Ballast

Load ON indicator

(Green LEDs)

Circuit ON/OFF Switches

AC Power & Status

indicator (Red)

Include/Exclude Switch

Connection Bushing and Hub

AC Power

Conduit opening

Threaded Conduit

Low Voltage Divider

(removable)

Low Voltage Knockout

Figure 3-1 (PPC-CON Receiving Device)

Copyright © 2010 AquaCal AutoPilot, Inc.

14 Commander PPC-CON - PPC-REM Installation Guide

Wiring Instructions

Power Connections

• 1- Speed Pump: Must be powered from

Terminal 3.

• 2-Speed Pump: Must be powered from

Terminal 3 for High-Speed and Terminal 4 for

Low-Speed.

• Booster Pump: Must be powered from

Terminal 6.

• Actuator Control: Must be powered from

Terminal 7.

• Heater Control: Must be Terminals 8 & 9.

• The metal enclosure must be ground bonded

in compliance with national, state and local

codes.

Terminal 1 must always be Neutral when using

120 VAC power.

Terminal 1 must be L2 when using 240 VAC.

Terminal 2 must always be Hot or L1 for both

120 VAC and 240 VAC.

Terminal 3 must always be connected to the Hot

terminal of the pump.

Terminal 3 must always be connected to the

HIGH SPEED terminal of a 2-speed pump.

AC POWER & STATUS indicator

Manual ON/OFF Switches

CONTROL

120V

240V

POWER IN & CONTROL

POWER SUPPLY

LOAD 1

INCLUDE/EXCLUDE switch

1 2 3 4 5

POWER

SUPPLY

1 2 3 4 5 6 7 8 9

1

2

3

4

Terminal 4 must always be connected to the

LOW SPEED terminal of a 2-speed pump when

using a 2-speed motor.

Terminal 5 is the input supply for both terminals

6 & 7. This terminal is rated at 15 A. maximum.

Terminals 6 & 7 are function selectable with a

maximum combined rating of 15 A.

Terminal 8 is the input supply for terminal 9.

The load is rated at 15 A. maximum.

Terminals 8 & 9 can be used for low voltage

provided the Low Voltage Divider is used to

separate the Low Voltage conductors from Line

Voltage conductors. Low voltage conductors

must exit the cabinet through a separate

opening. (See Figure 3-1)

Figure 3-2 PPC-CON Master Control Center Power Terminal identification

CAUTION: The PPC-CON is a control device and NOT a safety disconnect. A proper sized fused

disconnect or breaker of no more than 125 Amp capacity must be provided in the power supply circuit.

Proper gauge wire should be based on local code requirements of amperage and wire length.

Copyright © 2010 AquaCal AutoPilot, Inc.

LOAD 2

POWER IN

LOAD 3

LOAD 4

POWER IN

1

5

LOAD 5

= Circuit number

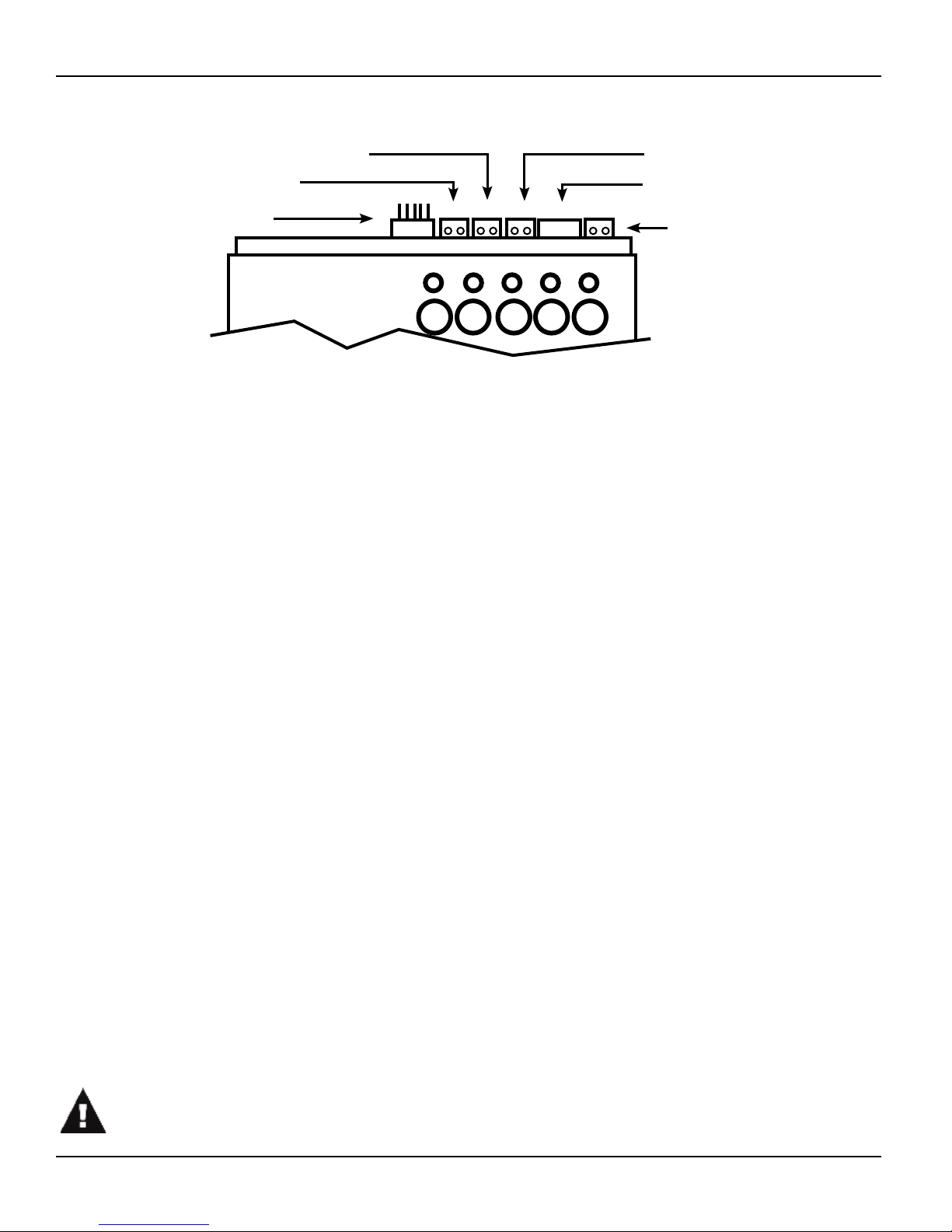

Upper Terminal Connections

Three: PPC-CON Receiving Device Installation 15

Air Sensor (PPC-AIR)

Local Antenna Connector

Installation Instructions

1. To avoid fire, shock, or death, turn off power at circuit breaker and test that power is off

before wiring.

2. Select a location for the installation that is near the pool/spa equipment; at least five (5) feet

distance or more from either the pool or spa and at least five (5) feet above ground level. The

PPC-CON must be mounted in a vertical (upright) position on the top of the enclosure.

3. Select the knockouts to be used. Remove the inner 1/2” knockout by inserting a flathead

screw driver in the slot and carefully punch the knockout loose and remove the slug. If a

3/4’ knockout is required, remove the outer ring with pliers after removing the 1/2” knockout.

Smooth the edge with a file if required.

Water Sensor (PPC-WTR)

Figure 3-3 PPC-CON Master Control Center Upper Terminal identification

Solar Sensor (PPC-WTR)

Remote Antenna Connector

Serial Connection (RS485)

NOTE: Observe polarity when

connecting pump manufacturer’s

cable to the Serial connection.

1 2 3 4 5

4. Place the metal enclosure in the desired mounting location and mark the three mounting

holes. Install the top screw first and then hang the enclosure by the keyhole. Then install the

bottom screws, tightening all screws for a secure mounting.

5. Install electrical conduit as needed to comply with all national and local electrical and safety

codes.

6. If a low voltage circuit or a heater control circuit is to be used, remove the low voltage

knockout from the PPC-CON enclosure.

7. Install electrical conduit as required by national, state and local codes.

8. Bond the enclosure in accordance with your state and local codes. Where required, connect

a No. 8 AWG solid copper wire to the enclosure using Bonding Lug (Intermatic part number

156T11047A). Connect the bonding wire to an approved earth ground.

9. Identify and install all wires necessary to complete the installation. Allow a length of

approximately 18” of each wire at the metal enclosure for required connections of junctions.

10. Connect wiring for circuits as required. Refer to the diagrams in this section for wiring

suggestions for specific equipment combinations. All splices and wire nut connections

should be in the metal enclosure, not in the PPC-CON enclosure.

11. Check and tighten all connections and circuits.

12. Apply power.

THE METAL ENCLOSURE MUST BE CLOSED AND SECURED WITH A LOCK OR TY-WRAP.

Copyright © 2010 AquaCal AutoPilot, Inc.

16 Commander PPC-CON - PPC-REM Installation Guide

List of Wiring Diagrams

Variable-Speed Pumps

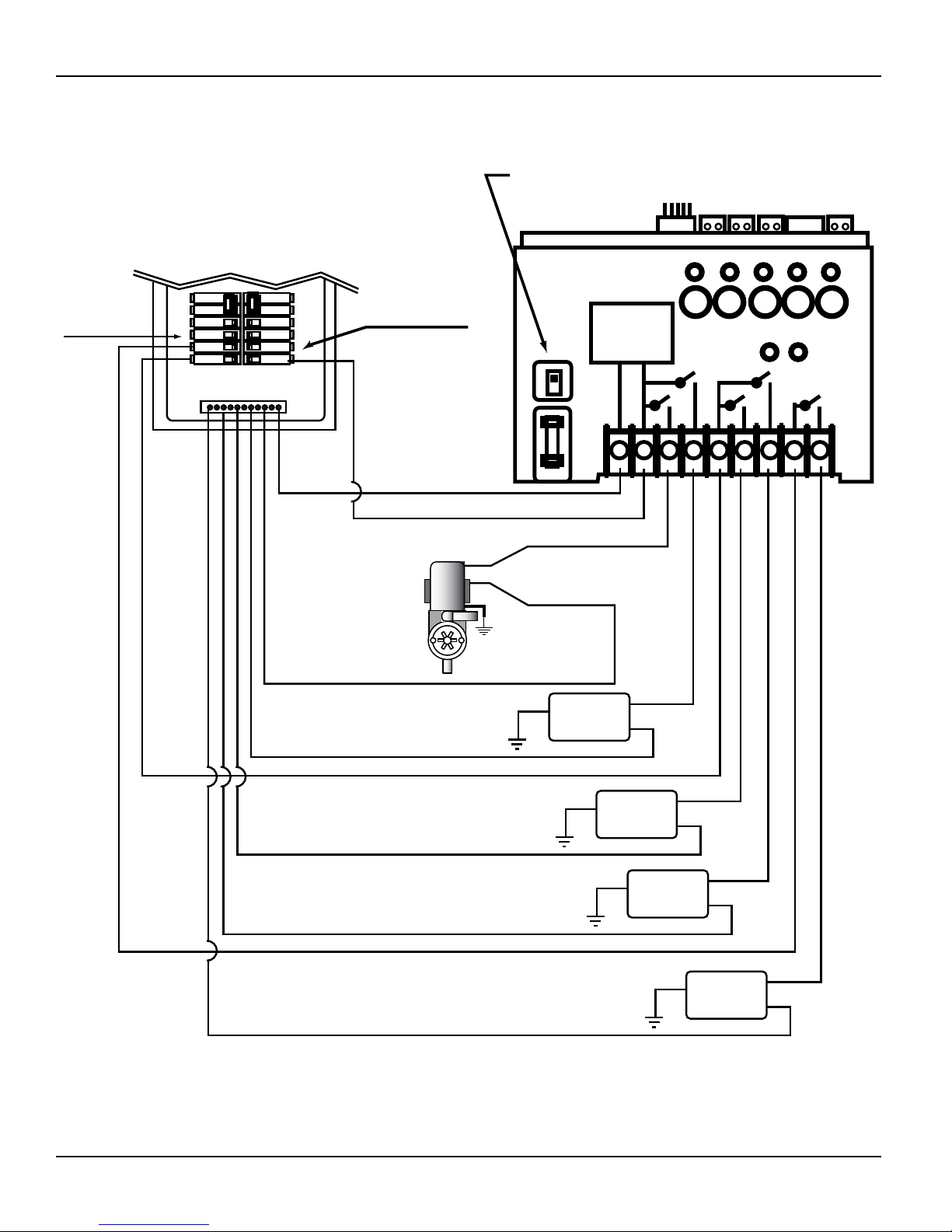

240V Variable-Speed Pump ......................................................................................................... Figure 3-4

One-Speed Pumps

120V 1-Speed Pump ................................................................................................................... Figure 3- 5

120V 1-Speed pump + any 4 120 VAC auxiliary equipment ........................................................ Figure 3- 6

120V 1-Speed pump + 120V Blower or Lights + 120V Booster Pump + 120V Actuator + Heater Figure 3-7

120V 1-Speed pump + 120V Lights + 120V Blower + 120V Actuator + Heater ........................... Figure 3-8

240V 1-Speed Pump ................................................................................................................... Figure 3-9

240V 1-Speed pump + any 4 240 VAC auxiliary equipment ........................................................ Figure 3-10

240V 1-Speed pump + 240V Blower + 240V Booster Pump + 240V Actuator + Heater ............... Figure 3-11

240V 1-Speed pump + 120V Lights + 120V Blower + 240V Actuator + Heater ........................... Figure 3-12

Two-Speed Pumps

240V 2-Speed Pump ................................................................................................................... Figure 3-13

240V 2-Speed pump + any 3 240 VAC auxiliary equipment ........................................................ Figure 3-14

240V 2-Speed pump + any 3 120 VAC auxiliary equipment ........................................................ Figure 3-15

240V 2-Speed pump + 240V Booster Pump + 240V Actuator + Heater ....................................... Figure 3-16

240V 2-Speed pump + 120V Lights + 240V Blower + Heater ...................................................... Figure 3-17

240V 2-Speed pump + 240V Blower + 240V Actuator + Heater .................................................. Figure 3-18

240V 2-Speed pump + 240V Booster pump + 240V Blower + Heater ......................................... Figure 3-19

240V 2-Speed pump + 240V Booster pump + 120V Light + Heater ............................................. Figure 3-20

240V 2-Speed pump + 240V Booster pump + other 120 VAC equipment + Heater ..................... Figure 3-21

Copyright © 2010 AquaCal AutoPilot, Inc.

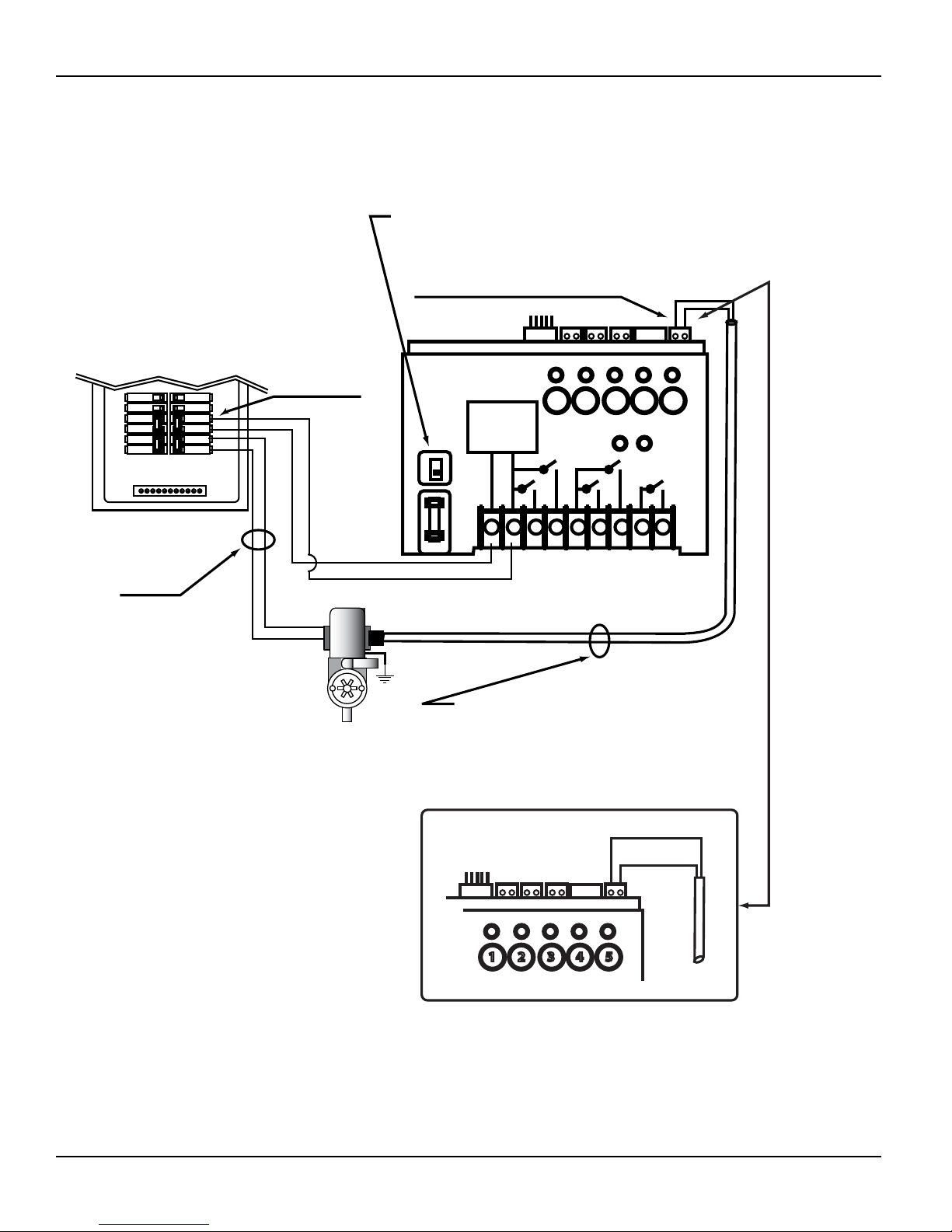

Variable-Speed Pumps

240V Variable-Speed Pump

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

2-pole Breaker

NEUTRAL BUS

Three: PPC-CON Receiving Device Installation 17

Make sure that voltage selector switch is in 240V

position before applying power to Terminals 1 & 2

NOTE:

The cable is Polarity Sensitive. Wires must be

connected as shown below for proper operation.

RECEIVER

POWER

SUPPLY

120V

240V

1 2 3 4 5

240 VAC

Pump

1

Jacketed Cable with Twist-lock Connector

supplied by pump manufacturer.

240 VAC

Variable Speed Pump

All IntelliFlo® & IntelliPro® VS & VF Pumps *

CABLE CONNECTION

1 2 3 4 5

2 3 4 5 6 7 8 9

POLARITY

GREEN

YELLOW

1-Speed Pumps

* IntelliFlo and IntelliPro are registered trademarks of Pentair Water Pool and Spa, Inc.

Figure 3-4

Copyright © 2010 AquaCal AutoPilot, Inc.

18 Commander PPC-CON - PPC-REM Installation Guide

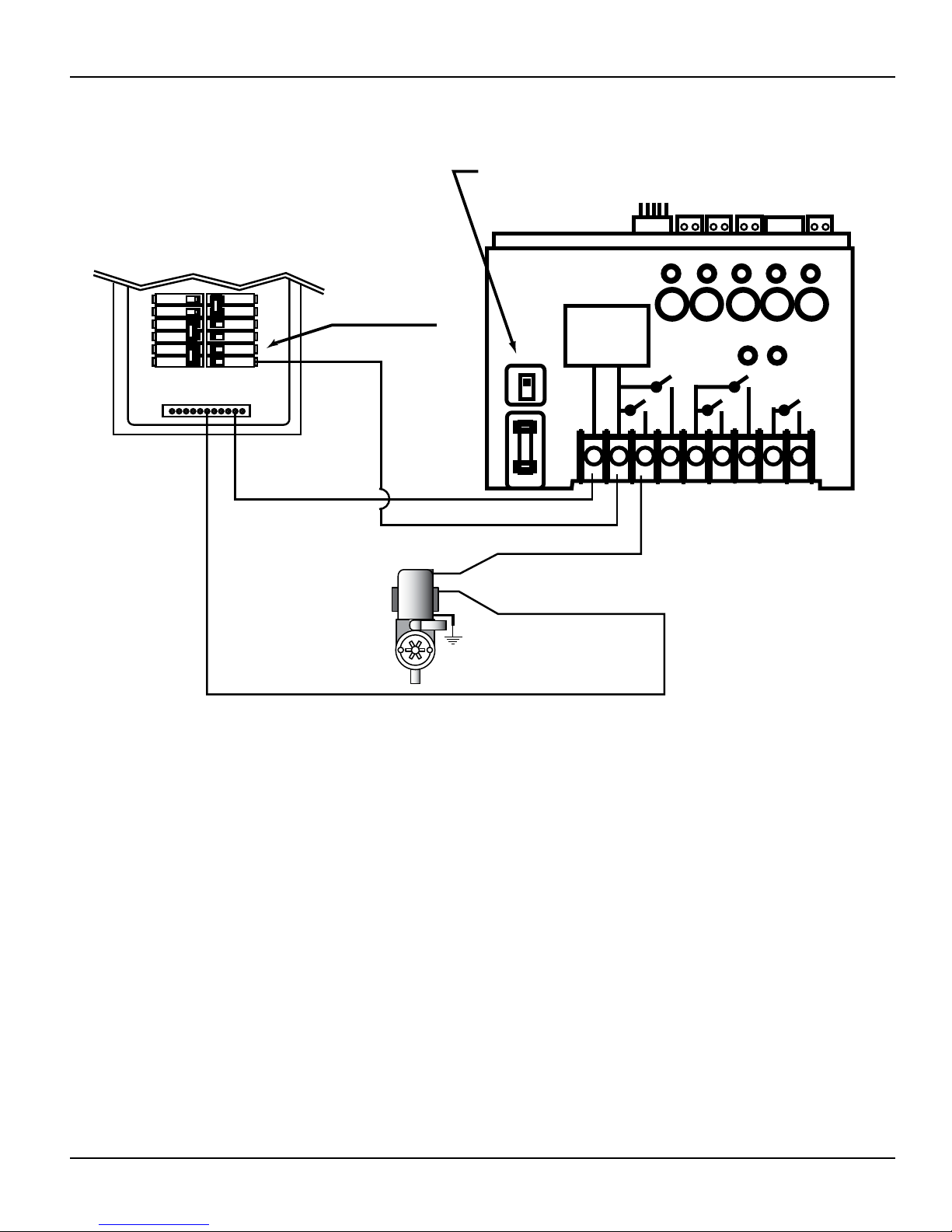

120V 1-speed pump

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

Make sure that voltage selector switch is in 120V

position before applying power to Terminals 1 & 2

NEUTRAL BUS

Single pole

120 VAC

1-Speed

Pump

# 1 Button

Breaker

RECEIVER

120V

240V

HOT

# 1 Button

NEUTRAL

1 2 3 4 5

POWER

SUPPLY

1

2 3 4 5 6 7 8 9

Figure 3-5

Copyright © 2010 AquaCal AutoPilot, Inc.

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

1-pole

Breakers

15 A. Max.

Three: PPC-CON Receiving Device Installation 19

120V 1-speed pump + any four 120 VAC auxiliary equipment

Make sure that voltage selector switch is in 120V

position before applying power to Terminals 1 & 2

1-pole Breaker

RECEIVER

POWER

SUPPLY

1 2 3 4 5

NEUTRAL BUS

NOTE: The combined load on Terminals 6 & 7

120 VAC

1-Speed

NEUTRAL

Pump

# 1 Button

120 VAC

must NOT exceed 15 amps Resistive.

120 VAC

120V

240V

HOT

Aux.

# 2 Button

1 2 3 4 5 6 7 8 9

# 1 Button

Aux.

# 3 Button

Aux.

# 4 Button

120 VAC

Aux.

# 5 Button

120 VAC

Figure 3-6

Copyright © 2010 AquaCal AutoPilot, Inc.

20 Commander PPC-CON - PPC-REM Installation Guide

120V 1-speed pump + 120 VAC blower or lights + 120V booster pump

+ 120V actuator + heater

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

1-pole

Breakers

15 A. Max.

NEUTRAL BUS

1-pole Breaker

120 VAC

1-Speed

Pump

# 1 Button

Make sure that voltage selector switch is in 120V

position before applying power to Terminals 1 & 2

1 2 3 4 5

Divider provided

120V

240V

HOT

NEUTRAL

RECEIVER

POWER

SUPPLY

1 2 3 4 5 6 7 8 9

# 1 Button

must be installed

for Heater circuit.

NOTE:

Low Voltage

120 VAC

Blower

# 2 Button

The combined load on Terminals 6 & 7

must NOT exceed 15 amps Resistive.

RELAY 1

RELAY 2

VALVES

WHITE

BLK

BLK/WHT

BLK/WHT

120 VAC Actuator Power

Actuator model PPC-ACTC must be installed in a

separate enclosure, either an existing Intermatic

timeclock or PPC-80CP. Or PPC-ACTE may be used

which includes its own enclosure. Refer to

Actuator installation instructions for additional

wiring instructions.

NOTE:

120 VAC

Actuator Control

# 4 Button

NOTE:

Refer to Heater manufacturer’s

installation instructions for

Heater installation and setup

120 VAC

Booster

Pump

# 3 Button

HEATER

# 5 Button

NOTE:

Wires must exit

through separate

opening from line

voltage wires. Use

shutter bushing

provided.

Heater Enable Circuit

(24 VAC Typical) MUST

connect to Terminals 8 & 9

on PPC-CON and to

Fireman’s Switch on the

Heater

Figure 3-7

Copyright © 2010 AquaCal AutoPilot, Inc.

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

1-pole

Breakers

15 A. Max.

Three: PPC-CON Receiving Device Installation 21

120V 1-speed pump + 120V lights + 120V blower + 120V actuator +

heater

Make sure that voltage selector switch is in 120V

position before applying power to Terminals 1 & 2

1 2 3 4 5

NOTE:

Low Voltage

Divider provided

must be installed

for Heater circuit.

NEUTRAL BUS

1-pole Breaker

120 VAC

1-Speed

Pump

# 1 Button

120V

240V

HOT

NEUTRAL

RECEIVER

POWER

SUPPLY

1 2 3 4 5 6 7 8 9

# 1 Button

120 VAC

Lights

# 2 Button

The combined load on Terminals 6 & 7

must NOT exceed 15 amps Resistive.

RELAY 1

RELAY 2

VALVES

WHITE

BLK

BLK/WHT

BLK/WHT

120 VAC Actuator Power

Actuator model PPC-ACTC must be installed in a

separate enclosure, either an existing Intermatic

timeclock or PPC-80CP. Or PPC-ACTE may be used

which includes its own enclosure. Refer to

Actuator installation instructions for additional

wiring instructions.

NOTE:

120 VAC

Actuator Control

# 4 Button

NOTE:

Refer to Heater manufacturer’s

installation instructions for

Heater installation and setup

120 VAC

Blower

# 3 Button

HEATER

# 5 Button

NOTE:

Wires must exit

through separate

opening from line

voltage wires. Use

shutter bushing

provided.

Heater Enable Circuit

(24 VAC Typical) MUST

connect to Terminals 8 & 9

on PPC-CON and to

Fireman’s Switch on the

Heater

Figure 3-8

Copyright © 2010 AquaCal AutoPilot, Inc.

22 Commander PPC-CON - PPC-REM Installation Guide

240V Pumps

240V 1-speed pump

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

2- pole

Breaker

NEUTRAL BUS

Make sure that voltage selector switch is in 240V

position before applying power to Terminals 1 & 2

1 2 3 4 5

RECEIVER

POWER

SUPPLY

120V

240V

2 3 4 5 6 7 8 9

1

240 VAC

1-Speed

Pump

# 1 Button

L1

L2

Figure 3-9

Copyright © 2010 AquaCal AutoPilot, Inc.

240V 1-speed pump + any four 240 VAC auxiliary equipment

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

NEUTRAL BUS

2- pole

Breaker

2- pole

Breaker

Three: PPC-CON Receiving Device Installation 23

Make sure that voltage selector switch is in 240V

position before applying power to Terminals 1 & 2

RECEIVER

POWER

SUPPLY

120V

240V

1 2 3 4 5 6 7 8 9

1 2 3

4 5

240 VAC

1-Speed

Pump

# 1 Button

NOTE:

The combined load on Terminals 6 & 7

must NOT exceed 15 amps Resistive.

240 VAC

240 VAC

Aux.

# 2 Button

240 VAC

L1

L2

Aux.

# 3 Button

Aux.

# 4 Button

240 VAC

Figure 3-10

Copyright © 2010 AquaCal AutoPilot, Inc.

Aux.

# 5 Button

24 Commander PPC-CON - PPC-REM Installation Guide

240V 1-speed pump + 240V blower + 240V booster pump + 240V

actuator + heater

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

Make sure that voltage selector switch is in 240V

position before applying power to Terminals 1 & 2

NEUTRAL BUS

2- pole

Breakers

240 VAC

1-Speed

Pump

# 1 Button

NOTE:

The combined load on Terminals 6 & 7

must NOT exceed 15 amps Resistive.

240 VAC

Actuator Control

# 4 Button

BLK

RELAY 1

RELAY 2

VALVES

240 VAC Actuator Power

RED

Actuator model PPC-ACTC must be installed in a

separate enclosure, either an existing Intermatic

timeclock or PPC-80CP. Or PPC-ACTE may be used

which includes its own enclosure. Refer to

Actuator installation instructions for additional

wiring instructions.

2- pole

Breaker

BLK/WHT

BLK/WHT

RECEIVER

POWER

SUPPLY

120V

240V

1 2 3 4 5 6 7 8 9

L1

L2

240 VAC

Blower

# 2 Button

240 VAC

Booster

# 3 Button

NOTE:

Refer to Heater manufacturer’s

installation instructions for

Heater installation and setup

1 2 3 4 5

NOTE:

Low Voltage

Divider provided

must be installed

for Heater circuit.

NOTE:

Wires must exit

through separate

opening from line

voltage wires. Use

shutter bushing

provided.

Heater Enable Circuit

(24 VAC Typical) MUST

connect to Terminals 8 & 9

on PPC-CON and to

Fireman’s Switch on the

Heater

HEATER

# 5 Button

Figure 3-11

Copyright © 2010 AquaCal AutoPilot, Inc.

240V 1-speed pump + 120V lights + 120V blower + 240V actuator +

heater

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

NEUTRAL BUS

2- pole

Breakers

2- pole

Breaker

Three: PPC-CON Receiving Device Installation 25

Make sure that voltage selector switch is in 240V

position before applying power to Terminals 1 & 2

RECEIVER

POWER

SUPPLY

120V

240V

1 2 3 4 5 6 7 8 9

1 2 3 4 5

240 VAC

1-Speed

Pump

# 1 Button

NOTE:

The combined load on Terminals 6 & 7

must NOT exceed 15 amps Resistive.

240 VAC

Actuator Control

# 4 Button

BLK

RELAY 1

RELAY 2

VALVES

240 VAC Actuator Power

RED

Actuator model PPC-ACTC must be installed in a

separate enclosure, either an existing Intermatic

timeclock or PPC-80CP. Or PPC-ACTE may be used

which includes its own enclosure. Refer to

Actuator installation instructions for additional

wiring instructions.

L1

L2

240 VAC

Blower

# 3 Button

BLK/WHT

BLK/WHT

NOTE:

Refer to Heater manufacturer’s

installation instructions for

Heater installation and setup

120VAC

Lights

# 2 Button

NOTE:

Low Voltage

Divider provided

must be installed

for Heater circuit.

NOTE:

Wires must exit

through separate

opening from line

voltage wires. Use

shutter bushing

provided.

Heater Enable Circuit

(24 VAC Typical) MUST

connect to Terminals 8 & 9

on PPC-CON and to

Fireman’s Switch on the

Heater

HEATER

# 5 Button

Figure 3-12

Copyright © 2010 AquaCal AutoPilot, Inc.

26 Commander PPC-CON - PPC-REM Installation Guide

240V 2-Speed Pump

Select Breaker to match wire size

and load requirement. Observe

maximum control circuit capacity.

Make sure that voltage selector switch is in 240V

position before applying power to Terminals 1 & 2

NEUTRAL BUS

2-pole Breaker

HIGH

LOW

COMMON

240 VAC

2-Speed

Pump

RECEIVER

1 2 3 4 5

POWER

SUPPLY

120V

240V

1 2 3 4 5 6 7 8 9

# 1 Button

# 2 Button

Figure 3-13

Copyright © 2010 AquaCal AutoPilot, Inc.

Loading...

Loading...