TPS30 Series

Non-indicating Pressure Transmitters

Features

• Robust build allows high or low pressure measurement in high

and low temperature environments.

: high pressure (0 to 60MPa), low pressure (0 to 2 MPa)

: temperature range (-40 to 125℃) (may vary by model)

• For diverse applications including packaging machines, heavy

machinery, factories, and shipbuilding.

• Pressure measurement of any gas, liquid, or oil.

• 316L stainless steel diaphragm for high corrosion resistance.

• Compact size allows easy installation in tight or limited spaces.

• 1ms high-speed response rate.

• Analog output: Voltage (1-5 VDC), Current (DC 4-20 mA)

• Built-in reverse polarity protection circuit.

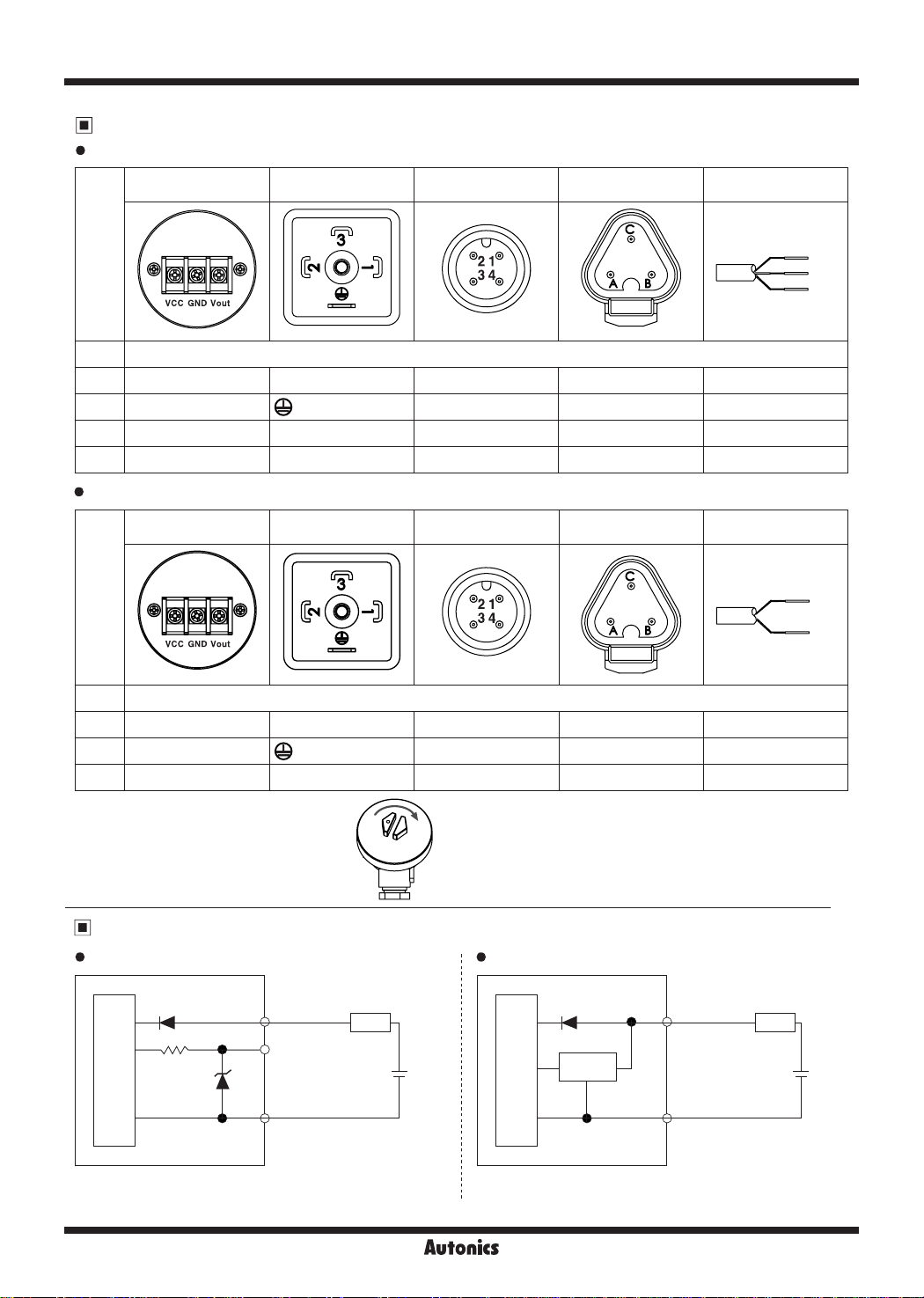

Various connector types

•

: cable type, DIN43650-A connector type,

DT04-3P connector type, M12 connector type, head type.

• Available thread sizes: G3/8, G1/4, R1/2

Protection structure: IP67 (IEC standard)

•

(except DIN43650-A connector type: IP65)

Please read “Safety Considerations”

in the instruction manual before using.

=I

&:,____

___

____.I

CE:

Cable type DIN43650-A

connector

type

connector

type

M12

connector

type

Head typeDT04-3P

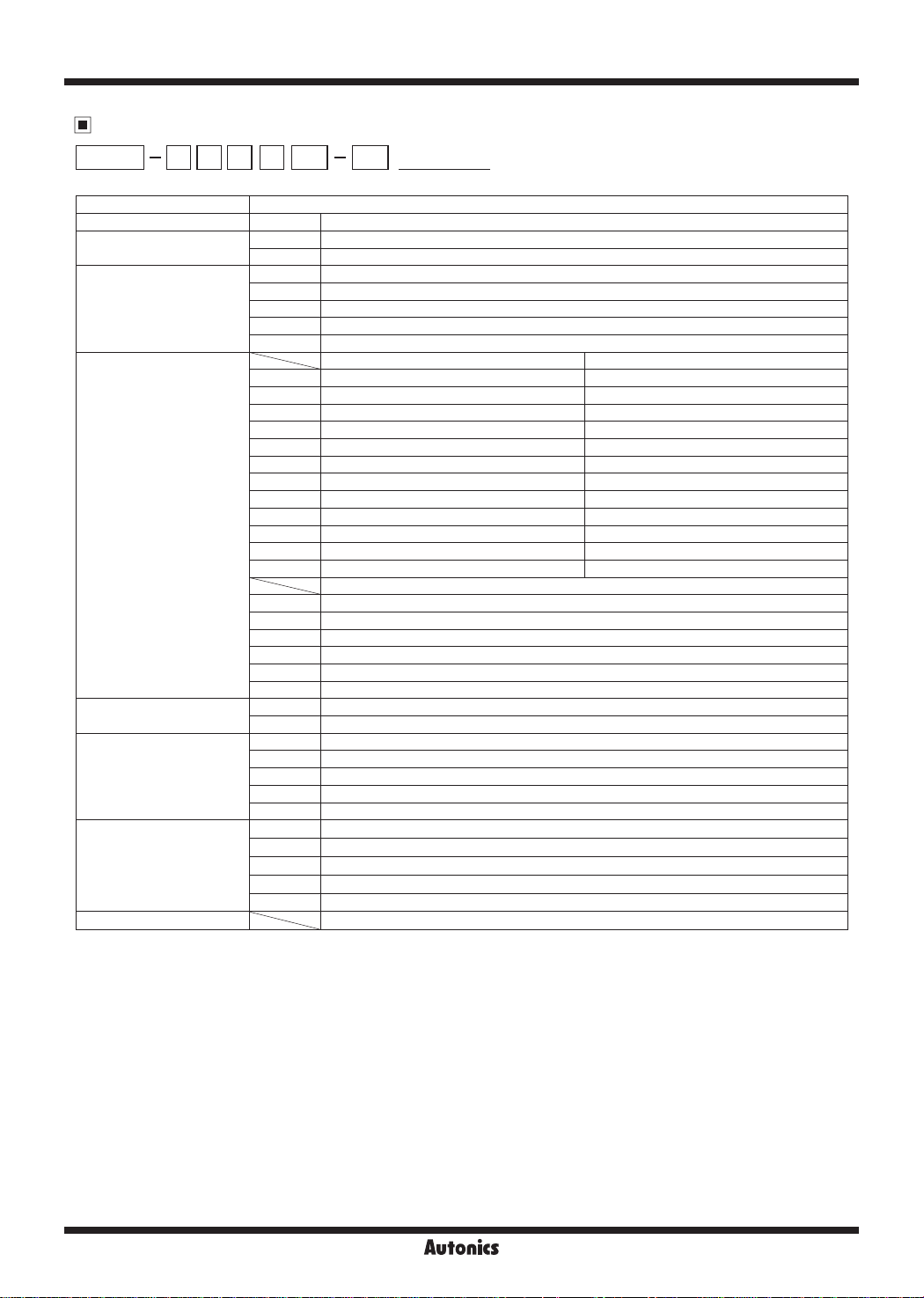

Example of External Connections

KRN100 (100mm hybrid recorder)

TPS30

+

-

Terminal

I'

I'

'I 'I

+

-

+ +

-

DC4-20mA

Power 24VDC load 600Ω

Output DC4-20mA 2 wire

24VDC

-

G-60

Autonics

Non-indicating Pressure Transmitters

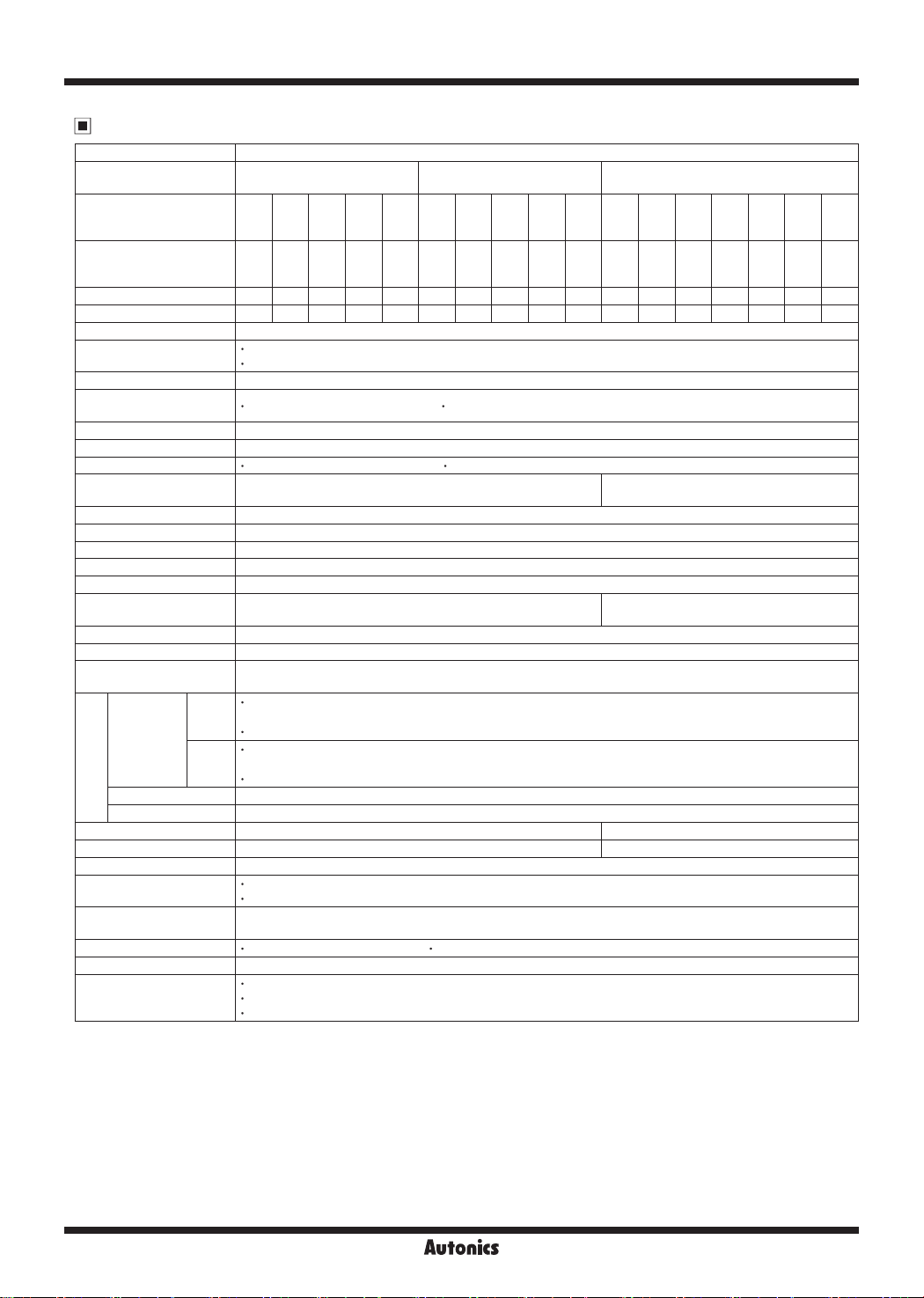

Ordering Information

~I-

①

G 2 9 V G8 00TPS30

□□□□□-□--

② ③ ④ ⑤ ⑥ ⑦ ⑧

Description

①

Item

②

Measurement pressure

TPS30 Non-indicating Pressure Transmitters

G Gauge pressure, sealed gauge pressure

A Absolute pressure

1 Head type

2 DIN43650-A connector type

③

Cable

3 M12 connector type

4 DT04-3P connector type

5 Cable type

Gauge pressure Absolute pressure

3 0 to 0.1MPa 0 to 0.1MPa

---------

4 0 to 0.2MPa 0 to 0.2MPa

5 0 to 0.7MPa 0 to 0.7MPa

6 0 to 1MPa 0 to 1MPa

7 0 to 2MPa 0 to 2MPa

※

2

④

Pressure range

8

※

2

9

※

2

A

※

2

B

※

2

C

※

2

D

※

2

E

0 to 3.5MPa

0 to 5MPa

0 to 10MPa

0 to 20MPa

0 to 40MPa

0 to 50MPa

0 to 60MPa

Sealed gauge pressure

F -0.1 to 0MPa

---------

G - 0 .1 to 0 .1M Pa

H -0.1 to 0.7MPa

J -0.1 to 1MPa

K -0.1 to 2MPa

Z Others

⑤

Output type

V Voltage (1-5VDC) output

A Current (DC4-20mA) output

G8 G3/8 (PF)(EN387)

G4 G1/4 (PF)(EN387)

⑥

Pressure port

R2 R1/2 (PT)(DIN3852)

N4 NPT1/4 (DIN3852)

※

3

ZZ

Others (option)

00 Not used

⑦

Option

(connector cable)

※

2I "I" type 2m

2L "L" type 2m

4

5I "I" type 5m

5L "L" type 5m

⑧

User pressure range User pressure range

※

1: The pressure is sealed gauge pressure. The unit is sealed structure. It is based on atmospheric pressure 101.3kPa (1.013bar).

※

2: G1/4 is the standard pressure port. For the other pressure ranges, G3/8, R1/2 are standard pressure ports.

※

The option ports are sold separately. In case of large amount ordering, contact he Autonics for manufacturing the requested pressure port.

3:

※

4: Only for M12 connector type.

※

5: Write the desired pressure range and it is the default of user pressure range.

-----..........

(0 to 0.5MPa)

※

1

※

5

※

1

-

-

-

-

-

-

-

(select "Z" at ④Pressure range)

G-61

TPS30 Series

Specifications

Series TPS30

Pressure type

Rated pressure range (MPa)

Expanded analog output

range (MPa)

Max. pressure range (MPa) 0.6 0.6 3 3 3 0.6 0.6 3 3 3 10 20 50 80 120 120 120

Burst pressure (MPa) 0.6 0.6 3 3 3 0.6 0.6 3 3 3 15 30 75 120 160 160 160

Measured materials Liquid, gas, oil (inappropriate to corrosion environment for stainless steel 316L)

Power supply

Permissible voltage range 90 to 110% of rated voltage

Current

consumption

Response time Max. 1ms

Protection circuit Reverse polarity protection circuit

Output type Voltage output type: 1-5VDCᜡ Current output type: DC4-20mA

Compensation

temperature

Accuracy Max. ±0.5% F.S. (including linearity, hysteresis, reproducibility)

Linearity Max. ±0.2% F.S.

Hysteresis Max. ±0.2% F.S.

Temp. Zero Shift Max. ±0.1% F.S./10℃ (standard), max. ±0.25% F.S./10℃ (ma x .)

Temp. Span Shift Max. ±0.1% F.S./10℃ (standard), max. ±0.25% F.S./10℃ (ma x .)

Temperature

characteristics

Load resistance Current output type: max. 700Ω (supplying 24VDC)

Dielectric strength 500VAC 50/60Hz for 1 minute

Insulation

resistance

Ambient

temp.

Environment

Ambient humidity 35 to 85%RH

Fluid temp. -40 to 125

Vibration 10g, 20 to 2,000Hz 20g, 20 to 2,000Hz

Shock 100g/ 6ms 50 0g /1ms

Tightening torque Max. 10N.m

Protection

structure

Material

Connection Voltage output type: +, -, Vout Current output type: +, Approval

※

2

Weight

※

1: The sensor is sealed structure. It is based on atmospheric pressure 101.3kPa (1.013bar).

※

2: The weight includes packaging. The weight in parenthesis is for unit only.

※

Environment resistance is rated at no freezing or condensation.

Gauge pressure,

absolute pressure

0 to

0 to

0 to

0.1

0.2

0 to

0 to

0.11

0.22

Voltage output type: 8-36VDCᜡ (ripple P-P: max. 10%)

Current output type: 11-36VDCᜡ (ripple P-P: max. 10%)

Voltage output type: max. 20mA Current output type: max. 30mA

-10 to 80

℃

-

Over 100MΩ (at 500VDC megger)

Head type, DIN43650-A connector type, M12 connector type, DT04-3P connector type: -40 to 125℃,

Voltage

storage: - 40 to 125℃

output

Cable type: -40 to 80℃, storage: - 40 to 80

Head type, DIN43650-A connector type, M12 connector type, DT04-3P connector type: -40 to 85℃,

Current

storage: - 40 to 125℃

output

Cable type: -40 to 80℃, storage: - 40 to 80

℃

Head type, M12 connector type, DT04-3P connector t ype, cable type: IP67 (IEC standard)

DIN43650-A connector type: IP65 (IEC standard)

Stainless steel 316L (head par t of head t ype: aluminium diecasting), connector: polybutylene terephthalate

G30, water-proof rubber: silicon

ᜢ

Head type: approx. 330g (approx. 250g)

DIN43650-A connector type, M12 connector type, DT04-3P connector type: approx. 130g (approx. 50g)

Cable type: approx. 200g (approx. 120g)

0.7

0 to

0.77

0 to 10 to

0 to

1.1

Sealed gauge pressure

- 0.1

- 0.1

to

0

- 0.1

to

0.01

to

0.1

- 0.1

to

0.1 2

2

0 to

2.2

- 0.1

to

0.7

- 0.1

to

0.78

℃

℃

- 0.1

to

1

- 0.1

to

1.11

※

1

Gauge pressure

- 0.1

0 to

to

3.5

2

- 0.1

0 to

to

3.85

2.21

0 to 80

-25 to 100℃: max. ±1.5% F.S.

-40 to 125℃: max. ±2.5% F.S.

0 to 100 to 200 to 400 to 500 to

0 to 5

0 to

0 to 110 to 220 to 440 to 550 to

5.5

℃

60

66

G-62

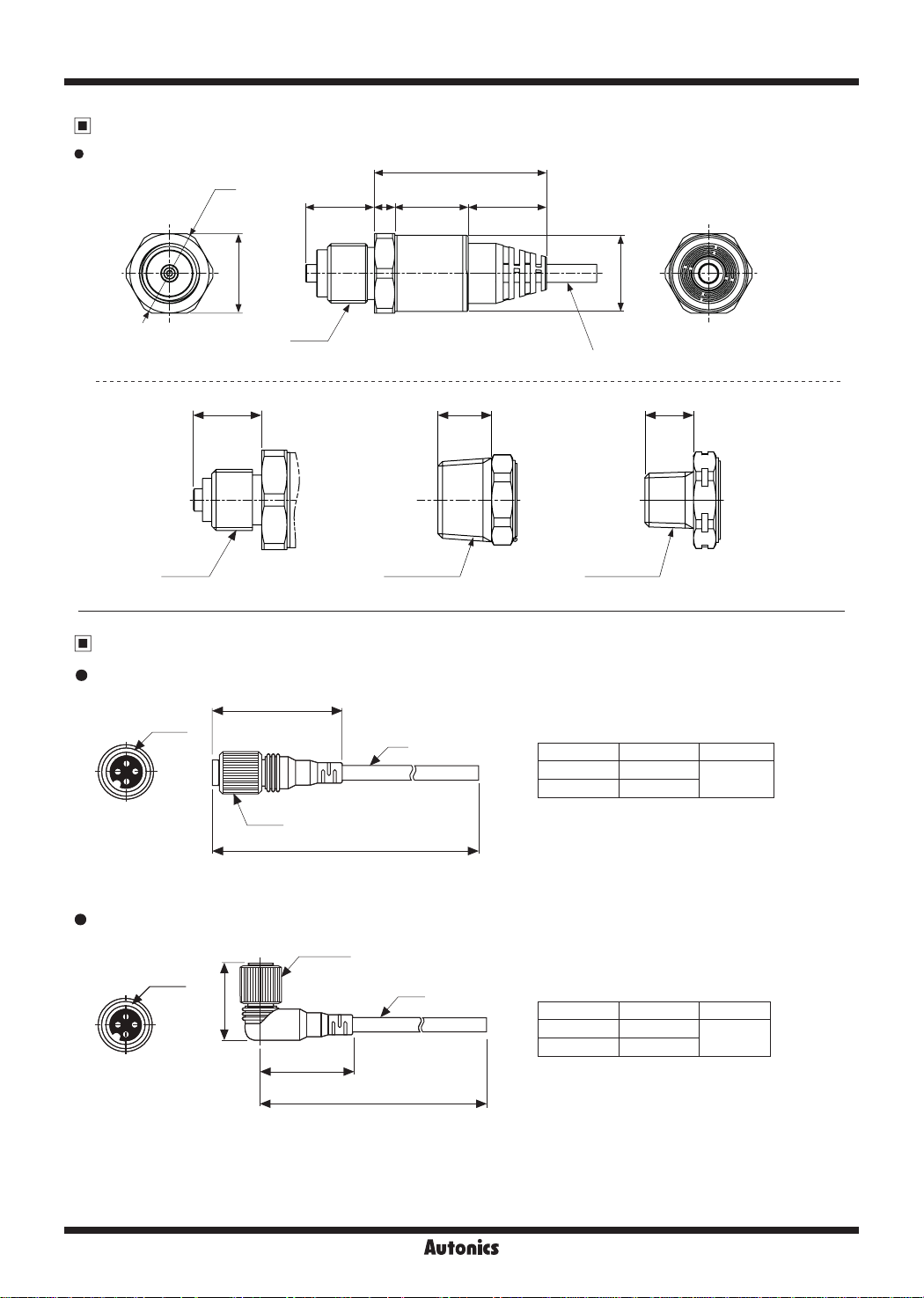

Non-indicating Pressure Transmitters

Dimensions

Head type

•

22

DIN43650-A connector type

•

Ø24

22

- .

※1

G3/8

(EN837)

(unit: mm)

115

19 8214.2

5 6

90

※

1

G3/8

(EN837)

□27

24.4

63.2

·

33.2

1

-

. a

:1

46.5

5 6

19

:T

---

DIN43650-A

connector

M12 connector type

•

Ø24

22

DT04-3P connector type

•

Ø24

22

19 20.3

5.6

※

1

G3/8

(EN837)

5 6

19 18.8 19

※

1

G3/8

(EN837)

35.9

46.8

10

Ø21

M12

connector

DT04-3P

connector

@

I

3.4

Ø21

0

Connector: CS-DT3P,

sold separately

Autonics

G-63

TPS30 Series

Dimensions

Cable type

※

1: Pressure port

G1/4

(EN837)

Ø24

15

(unit: mm)

47.6

5.6

19

22

※

1

G3/8

(EN837)

20.3 21.7

R1/2

(DIN3852)

14.3

Ø21

Ø5, 2m

12

NPT1/4

(DIN3852)

Connection Cable (Sold Separately)

~

CID3-2/CID3-5

•

•

CLD3-2/CLD3-5

•

M12

M12

1

◄

I.

40

Ø5

Ø14.8

L(m)

Ø14.8

Ø5

27.5

u

•

32

I:

L(m)

2 I

.I

•

Model L(m) Material

CID3-2 2

CID3-5 5

※

Only for M12 connector.

Model L(m) Material

CLD3-2 2

CLD3-5 5

I

PVC

PVC

(unit: mm)

G-64

Autonics

Connectors

Voltage output type

Head type

Non-indicating Pressure Transmitters

DIN43650-A

connector type

M12 connector type

DT04-3P

connector type

Cable type

Pin

type

Func.

Pin

+ + 1 1 A Brown

- -

Vout Vout 2 4 B Black

N.C

-

Current output type

•

Head type

Pin

type

Func.

Pin

+ + 1 1 A Brown

- -

N.C Vout 2, 3 2, 4 B

※

In case of head type, remove the top cover

3 2

DIN43650-A

connector type

.

3 C Blue

- -

M12 connector type

3 C Blue

DT04-3P

connector type

Cable type

-

Brown

Black

Blue

Brown

Blue

Connections

Voltage (1-5VDC) output type

•

Main Circuit

※

Cable color is only for cable type.

(brown) VCC

(black) Voltage

(1-5VDC) Output

(blue) GND

LOAD

+

8-36VDC

Autonics

Current (DC4-20mA) output type

(brown) VCC

Current

amplier

Main Circuit

(blue) GND

LOAD

+

11-36VDC

G-65

TPS30 Series

Troubleshooting

Error Troubleshooting

No outputs

Abnormally uctuating output

Out of zero point output value

Proper Usage

• Follow instructions in 'Cautions during Use'. Otherwise, It may cause unexpected accidents.

• 8-36VDC, 11-36VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply

device.

• When installing the unit on pipe line, use the hexagon part of connections not to turn the unit with a pipe wrench. Do not

use the unit with strong vibrations.

• Store the unit at the place without moisture, dust, and v bration.

• This product which does not have drive part at sensing part does not need to repair it. Even though inside of pressure

pipe is normally clean, it needs to take maintenance once a year as below instructions.

① Check the broken status of outside.

② Check the pressure slot, cleanliness inside, and corrosion state.

③ Short each terminal and check the insulation resistance between the case and power.

• When removing a sensor for maintenance, follow the below instructions.

①Replace an O-ring which is used once.

②Be sure that diaphragm part is not damaged.

• Switch or circuit breaker for suppling or cutting o the power should be installed nearby users for convenient control.

• The unit cannot be repaired due to disassembled structure.

• The unit is xed with bolt and nut at the both sides of case.

Do not press excessive load (approx. 300kg/cm²), or it may cause damage to the unit.

• This unit may be used in the following environments.

① Indoor / Outdoor (in the environment condition rated in 'Specications')

② Altitude max. 2,000 m

③ Pollution Degree 2

④ Installation Category II

Check the power supply.

Check the polarity (+, -) when wiring the cable.

Check the connection part.

Check the power supply.

Check the supplied pressure.

Check the pressure line.

Check the power supply.

Check the load resistive value of current output type for a receiver is over 700Ω.

(when supplying 24VDC)

Check the measuring point and transmission distance.

Check the line resistance is below 700Ω.

G-66

Loading...

Loading...