DRW170305AD

Autonics

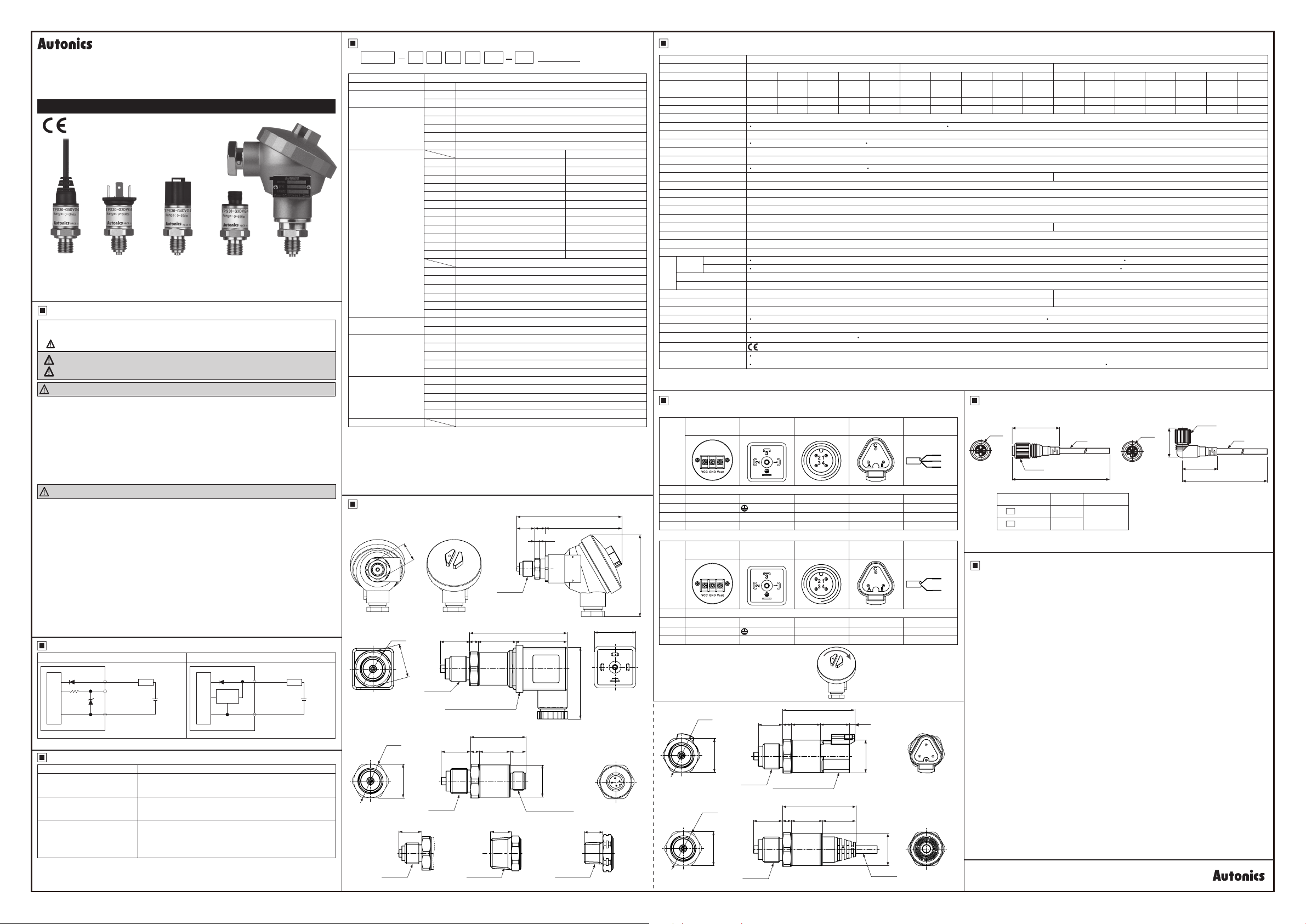

Non-indicating Pressure Transmitters

TPS30 SERIES

I N S T R U C T I O N M A N U A L

Cable type

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid

※

hazards.

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

Warning

1. Fail-safe device must be installed when using the unit with machinery that may

cause serious injury or substantial economic loss. (e.g. nuclear power control,

medical equipment, ships, vehicles, railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in personal injury, re or economic loss.

2. Do not use the unit in the place where ammable/explosive/corrosive gas, high

humidity, direct sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in explosion or re.

3. Do not disassemble or modify the unit.

Failure to follow this instruction may result in re or electric shock."

Caution

1. Do not apply beyond the rated pressure.

Failure to follow his instruction may result in product damage.

2. Use the unit within the rated specications.

Failure to follow his instruction may result in re or product damage.

3. Fix the cable through the cable connection part and do not turn the cable of the

unit.

Failure to follow cause instruction may result in product damage.

4. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow his instruction may result in re or product damage.

5. Check the polarity of the contact before wiring the unit.

Failure to follow his instruction may result in product damage by a re.

6. This product is designed to detect the pressure of noncorrosive uid. Do not use

for corrosive uid.

Failure to follow his instruction may result in product damage.

7. Use a dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow his instruction may result in re.

Connections

Voltage (1-5VDC) output type Current (DC4-20mA) output type

Main Circuit

~

※

Cable color is only for cable type.

Troubleshooting

Error Troubleshooting

~~

No outputs

Abnormally uctuating

output

Out of zero point output

value

※

The above specications are subject to change and some models may be discontinued

without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions

(catalog, homepage).

DIN43650-A

Connector type

DT04-3P

Connector type

M12

Connector type

Head type

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

(brown) VCC

(black) Voltage

(1-5VDC) Output

(blue) GND

LOAD

+

8-36VDC

-

J

Current

amplier

Main Circuit

(brown) VCC

(blue) GND

LOAD

7

~

----==-~------=--

Check the power supply.

Check the polarity (+, -) when wiring he cable.

Check the connection part.

Check the power supply.

Check the supplied pressure.

Check the pressure line.

Check the power supply.

Check the load resistive value of current output type for a

receiver is over 700Ω. (when supplying 24VDC)

Check the measuring point and transmission distance.

Check the line resistance is below 700Ω.

_-

_==.J

+

11-36VDC

-

Ordering Information

TPS30

① ② ③ ④ ⑤ ⑥ ⑦ ⑧

①

Item

②

Measurement

pressure

③

Cable

④

Pressure range

⑤

Output type

⑥

Pressure port

⑦

Option

(connector cable)

User pressure range

⑧

※

1: The pressure is sealed gauge pressure. The unit is sealed structure. t is based on atmospheric

pressure 101.3kPa (1 013bar).

※

2: G1/4 is the standard pressure port.

For the other pressure ranges, G3/8, R1/2 are standard pressure ports.

※

The option ports are sold separately. In case of large amount ordering, contact the Autonics for

3:

manufacturing the requested pressure port.

※

4: Only for M12 connector type.

※

5: Write the desired pressure range and it is the default of user pressure range.

(

select " Z" at ④Pre ssure range)

G 2 9 V

-□□□□□-□

Description

TPS30 Pressure Transmitter

G Gauge pressure, sealed gauge pressure

A Absolute pressure

1 Head type

2 DIN43650-A connector type

3 M12 connector type

4 DT04-3P connector type

5 Cable type

---.......____

3 0 to 0.1MPa 0 to 0.1MPa

4 0 to 0.2MPa 0 to 0.2MPa

5 0 to 0.7MPa 0 to 0.7MPa

6 0 to 1MPa 0 to 1MPa

7 0 to 2MPa 0 to 2MPa

※

2

8

※

2

9

※

2

A

※

2

B

※

2

C

※

2

D

※

2

E

F - 0.1 to 0MPa

------

G - 0.1 to 0.1MPa

H - 0.1 to 0.7MPa

J - 0.1 to 1MPa

K - 0.1 to 2MPa

Z Others

V Voltage (1-5VDC) output

A Current (DC4-20mA) output

G8 G3/8 (PF) (EN837)

G4 G1/4 (PF) (EN837)

R2 R1/2 (PT) (DIN3852)

N4 NPT1/4 (DIN3852)

※

3

ZZ

00 Not used

2I "I" type 2m

2L "L" type 2m

※

4

5I "I" type 5m

5L "L" type 5m

------

G8 00

Gauge pressure Absolute pressure

0 to 3.5M Pa

0 to 5MPa

0 to 10MPa

0 to 20MPa

0 to 40MPa

0 to 50MPa

0 to 60MPa

Sealed gauge pressure

Others (option)

User pressure range

Dimensions

● Head type

22

G3/8

(EN837)

● DIN43650-A connector type

Ø24

·~

● M12 connector type

22

Ø24

.@fil

22

※

1: Pressure port

15

~

G1/4

(EN837)

19

,..---.,..,.

※

1

G3/8

(EN837)

DIN43650-A connector

19

~

※

1

G3/8

(EN837)

24.4

5.6

~_______.,...-

35.9

5.6

20.3 10

o==iir---------'

14 3

-fl

R1/2

(DIN3852)

(0 to 0.5MPa)

-

-

-

-

-

-

1

14.2

33 2

Ø21

5.6

-

115

1

:

-----.

NPT1/4

DIN3852)

(

※

※

5

19 82

※

1

63.2

"l==========,!~B

M12 connector

※

1

(unit: mm)

□27

ffi

46 5

@ i

I

12

~

Specications

Series TPS30

Pressure type Gauge pressure, absolute pressure Sealed gauge pressure

Rated pressure range (MPa)

Expanded analog output

range (MPa)

Max. pressure range (MPa)

Burst pressure (MPa) 0.6 0.6 3 3 3 0.6 0.6 3 3 3 15 30 75 120 160 160 160

Measured materials Liquid, gas, oil

Power supply

Permissible voltage range

Current consumption

Response ime Max. 1ms

Protection circuit Reverse polarity protection circuit

Output type

Compensation temperature

Accuracy Max. ±0.5% F.S. (including linearity, hysteresis, reproducibility)

Linearity Max. ±0.2% F.S.

Hysteresis Max. ±0.2% F.S.

Temp. Zero Shift Max. ±0.1% F.S./10℃ (standard), max. ±0.25% F.S /10℃ (max.)

Temp. Span Shift Max. ±0.1% F.S./10℃ (standard), max. ±0.25% F.S /10℃ (max.)

Temperature characteristics

Load resistance Current output type: max. 700Ω (supplying 24VDC)

Dielectric strength 500VAC 50/60Hz for 1 minute

Insulation resistance Over 100MΩ (at 500VDC megger)

Environ-

Vibration

Shock

Tightening torque Max. 10N.m

Protection structure

Material Stainless steel 316L (head component of head type: aluminium diecasting), connector: Polybutylene terephthalate G30, water-proof rubber: Silicon

Connection

Approval

Weight

※

1: The sensor is sealed structure. It is based on atmospheric pressure 101.3kPa (1.013bar).

※

Environment resistance is rated at no freezing or condensation.

Voltage output

Ambient

I

temp.

I

Current output

Ambient humidity

ment

Fluid temp.

※

2

0 to 0.1 0 to 0.2 0 to 0.7 0 to 1 0 to 2 -0.1 to 0

0 to 0.11 0 to 0.22 0 to 0.77 0 to 1.1 0 to 2.2

0.6 0.6 3 3 3 0.6 0.6 3 3 3 10 20 50 80 120 120 120

Voltage output type: 8-36VDCᜡ (ripple P-P: max. 10%) Current output type: 11-36VDCᜡ (ripple P-P: max. 10%)

90 to 110% of rated voltage

Voltage output type: max. 20mA Current output type: max. 30mA

Voltage output type: 1-5VDCᜡ Current output type: DC4-20mA

-10 to 80℃ 0 to 80℃

-

Head type, D N43650-A connector type, M12 connector type, DT04-3P connector type: -40 to 125℃, storage: -40 to 125℃ Cable type: -40 to 80℃, storage: -40 to 80℃

Head type, D N43650-A connector type, M12 connector type, DT04-3P connector type: -40 to 85℃, storage: -40 to 125℃ Cable type: -40 to 80℃, storage: -40 to 80℃

35 to 85%RH

-40 to 125℃

10g, 20 to 2,000Hz 20g, 20 to 2,000Hz

100g/6ms 500g/1ms

Head type, M12 connector type, DT04-3P connector type, cable type: IP67 (IEC standard) DIN43650-A connector type: IP65 (IEC standard)

Voltage output type: +, -, Vout Current output type: +, -

CE

Head type: approx. 330g (approx. 250g)

DIN43650-A connector type, M12 connector type, DT04-3P connector type: approx. 130g (approx. 50g) Cable type: approx. 200g (approx. 120g)

-0.1 to

0 01

-0.1 to 0.1 -0.1 to 0.7

-0.1 to

0.12

Connector

● Voltage output type

~-------r-~-------,----------,---~

Head type

Pin

type

Function

Pin

+ + 1 1 A Brown

- Vout Vout 2 4 B Black

-

N C

● Current output type

Head type

Pin

90

type

Function

Pin

+ + 1 1 A Brown

- N.C Vout 2, 3 2, 4 B

※

In case of head type, remove the top cover

::

---

● DT04-3P connector type

Ø24

~

● Cable type

:

00

Ø24

22

22

DIN43650-A

connector type

3 2

DIN43650-A

connector type

@

i----

5.6

19

※

1

G3/8

DT04-3P connector

(EN837)

5.6

19

※

1

G3/8

(EN837)

M12 connector

type

3 C Blue

M12 connector

type

3 C Blue

.

DT04-3P

connector type

- -

DT04-3P

connector type

Cable type

Cable type

-

~

-

~-------+j

46.8

18 8 19 3.4

47 6

20.3 21.7

__

Ø21

Connector: CS-DT3P,

sold separately

Ø21

Ø5, 2m

__J

Brown

Black

Blue

Brown

Blue

※

1

-0.1 to 1 -0.1 to 2 0 to 3.5 0 to 5 0 to 10 0 to 20 0 to 40 0 to 50 0 to 60

-0.1 to

-0.1 to

0.78

1.11

※

2: The weight includes packaging. The weight in parentheses is for unit only.

Connection Cable (sold separately)

~

● CID3-2/CID3-5 ● CLD3-2/CLD3-5

M12

Model L(m) Meterial

C D3-2 2

D3-5 5

C

※

Only for M12 connector.

Gauge pressure

-0.1 to

0 to 3.85 0 to 5.5 0 to 11 0 to 22 0 to 44 0 to 55 0 to 66

2.21

I

I

-25 to 100℃: max. ±1.5% F.S. / -40 to 125℃: max. ±2.5% F.S.

I

I

40

Ø5

Ø14 8

L (m)

PVC

M12

27.5

32

Cautions during Use

1. Follow instruc ions in 'Cautions during Use'. Otherwise, It may cause unexpected accidents.

2. 8-36VDC, 11-36VDC power supply should be insulated and limited voltage/current or Class

2, SELV power supply device.

3. When installing the unit on pipe line, use the hexagon part of connections not to turn the

unit with a pipe wrench. Do not use the unit with strong vibrations.

4. Store the unit at he place without moisture, dust, and vibration.

5. This product which does not have drive part at sensing part does not need to repair it. Even

though inside of pressure pipe is normally clean, it needs to take maintenance once a year

as below instructions.

① Check the broken status of outside.

② Check the pressure slot, cleanliness inside, and corrosion state.

③ Short each terminal and check the insula ion resistance between he case and power.

6. When removing a sensor for maintenance, follow he below instructions.

①Replace an O-ring which is used once.

②Be sure hat diaphragm part is not damaged.

7. Switch or circuit breaker for suppling or cut ing o the power should be installed nearby

users for convenient control.

8. The unit cannot be repaired due to disassembled structure.

9. The unit is xed with bolt and nut at he bo h sides of case.

Do not press excessive load (approx. 300kg/cm²), or it may cause damage to the unit.

10.This unit may be used in the following environments.

① Indoor / Outdoor (in the environment condition rated in 'Specica ions')

② Al itude max. 2,000 m

③ Pollu ion Degree 2

④ Installation Category II

(unit: mm)

Ø14.8

Ø5

L (m)

Autonics

Loading...

Loading...