DRW171430BA

KRN100

Pressure Transmitter

TPS20 SERIES

I N S T R U C T I O N M A N U A L

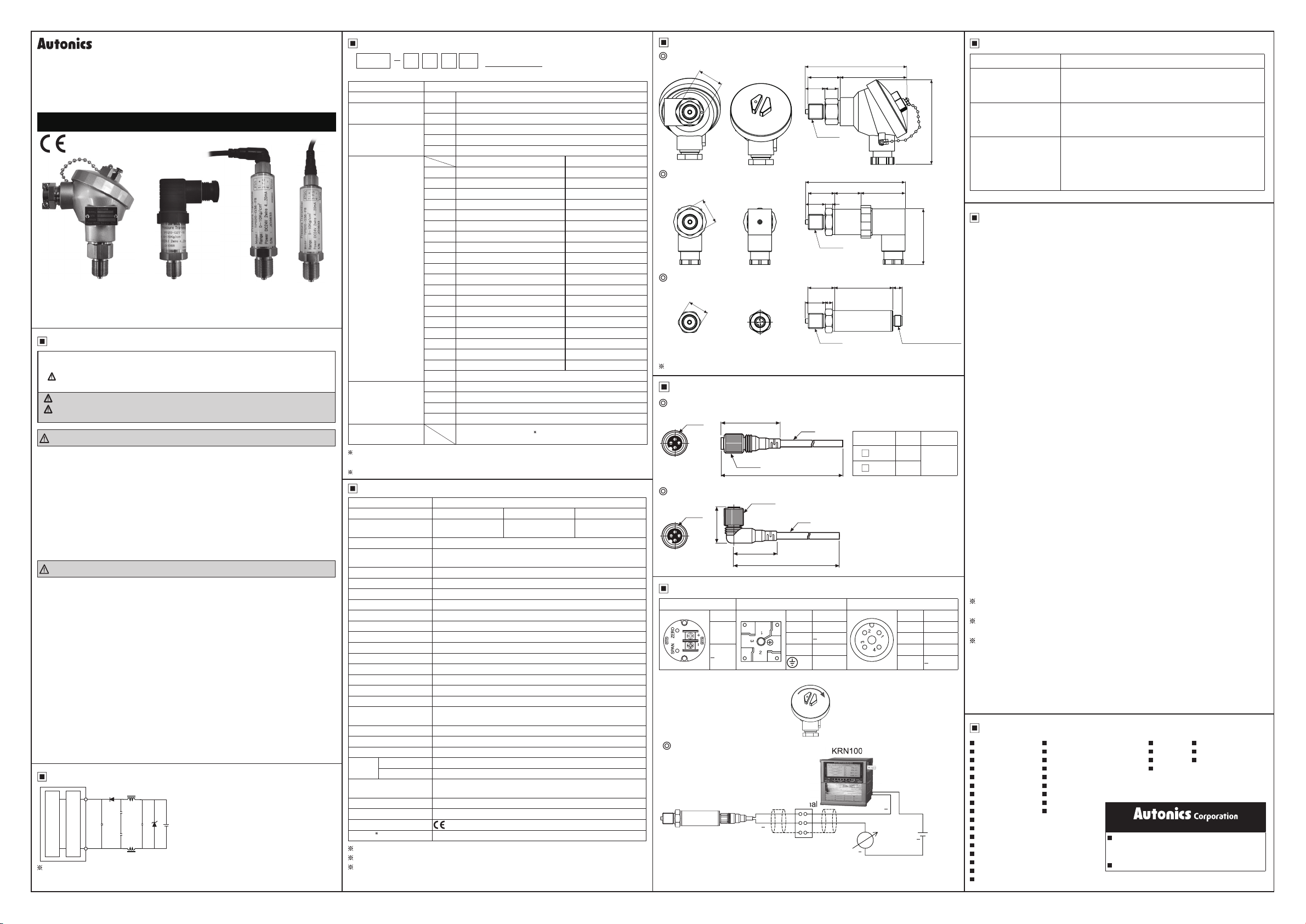

Head type DIN connector type Connector cable type

Please read the following safety considerations before use.

Safety Considerations

※

Please observe all safety considerations for safe and proper product

operation to avoid hazards.

symbol represents caution due to special circumstances in which hazards

※

may occur.

Warning

Caution

damage.

Warning

1. Fail-safe device must be installed when using the unit with machinery that

may cause serious injury or substantial economic loss. (e.g. nuclear

power control, medical equipment, ships, vehicles, railways, aircraft,

combustion apparatus, safety equipment, crime/disaster prevention

devices, etc.)

Failure to follow this instruction may result in personal injury, fi re, or economic loss.

2. Do not use the unit where fl ammable or explosive gas, humidity, direct

sunlight, radiant heat, vibration and impact may be present.

Failure to follow this instruction may result in fi re or explosion.

3. Do not disassemble or modift the unit. Please contact us if necessary.

Failure to follow this instruction may result in fi re.

Caution

1. Do not apply beyond rated pressure.

Failure to follow this instruction may result in product damage.

2. Use the unit within the rated specifi cations.

Failure to follow this instruction may result in fi re or shortening the life cycle of the

unit.

3. Fix the cable through the cable connection part.

Do not turn the cable of the unit.

Failure to follow this instruction may result in product damage.

4. Keep dust and wire residue from fl owing into the unit.

Failure to follow this instruction may result in burn out of the unit.

5. Check the polarity of the measurement terminals before wiring the unit.

Failure to follow this instruction may result in burn out of the unit.

6. Please contact us for using the unit to the corrosive detergent.

Failure to follow this instruction may result in shortening the life cycle of the unit

or product damage.

7. Do not use water or oil-based detergent when cleaning the unit. Use dry

cloth to clean the unit.

Failure to follow this instruction may result in or fi re.

Connections

Main Circuit

The above specifications are subject to change and some models

may be discontinued without notice.

Thank you for choosing Autonics product.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product

(brown) +V

+

15-35VDC

-

Current amplifi er

(blue) GND

Ordering Information

TPS20

G 1 5

F8

(0 to 5kgf/cm

① ② ③ ④ ⑤ ⑥

Description

①Item

②Measurement

presssure

TPS20 Pressure Transmitter

G Gauge pressure

A Absolute pressure

1 Head type

③Cable

2 DIN connector type

3 Connector cable type

Gauge pressure Absolute pressure

1 0 to 0.2kgf/cm

2 0 to 0.5kgf/cm

3 0 to 1kgf/cm2 0 to 1kgf/cm2

4 0 to 2kgf/cm

5 0 to 7kgf/cm

2

2

6 0 to 10kgf/cm

7 0 to 20kgf/cm

8 0 to 35kgf/cm2 0 to 35kgf/cm2

9 0 to 70kgf/cm

④Pressure range

A 0 to 100kgf/cm

C 0 to 200kgf/cm2

F 0 to 300kgf/cm2

H 0 to 350kgf/cm2

M -760mmHg to 0kgf/cm2

O -760mmHg to 1kgf/cm2

Q -760mmHg to 7kgf/cm2

V -760mmHg to 10kgf/cm2

X -760mmHg to 20kgf/cm2

Y -760mmHg to 35kgf/cm

Z Others

P2 PT 1/2 (with adapter)

⑤Pressure port

P8 PT 3/8 (with adapter)

F8 PF 3/8 (Standard)

ZZ Others

⑥User pressure

range

User pressure range

1: Write the desired pressure range and it is the default of user pressure range.

(

Select "Z" at ④Pressure range)

For ordering cable, order as CID3-2, CID3-5, CLD3-2, CLD3-5.(Sold seperately)

2

)

2

2

-

-

0 to 2kgf/cm2

0 to 7kgf/cm

2

2

0 to 20kgf/cm

2

2

0 to 10kgf/cm2

-

-

-

-

-

-

-

-

-

-

2

-

1

2

2

Specifi cations

Series TPS20

Pressure type Gauge pressure Absolute pressure

Rated pressure range

0 to

0.2 to 350 kg/cm

0 to

2

1.0 to 35 kg/cm

Max. pressure range 300% of max. span

Measured materials

Liguid, Gas, Oil (except corrosive environment of

Stainless steel type 316)

Power supply 15-35VDCᜡ

Permissible voltage range

90 to 110% of rated voltage

Current consumption Max. 50mA

Response time Max. 100 ms

Protection circuit Reverse polarity protection circuit

Current output DC4-20 mA

Linearity ±0.3% F.S.(-10 to 50 ℃), ±0.5%F.S.(50 to 70 ℃)

Hysteresis ±0.3% F.S.

Temp. Zero Shift ±0.03% F.S.

Temp. Span Shift ±0.03% F.S. (at 25 ℃)

Load resistance Max. 600 Ω

Insulation resistance Over 100MΩ (at 500VDC megger)

Dielectric strength 500VAC 50/60Hz for 1 minute

Vibration

Shock 95m/s

1.5mm amplitude at frequency of 10 to 55Hz(for 1 min) in

each X, Y, Z direction for 2hours

2

Tightening torque Industrial plug over 5N

Pressure port PF 3/8(standard), PT 3/8, PT 1/2

Environment

Materials

Ambient temp.

Ambient humid.

-10 to 70 ℃, storage: -10 to 70 ℃

5 to 95% RH, storage: 5 to 95% RH

Sealing, Diaphragm, Connection: Stainless steel type 316,

O-ring: fl uoro rubber

Connection +, Case structure Drip-proof structure

Approval

1

Weight

Approx. 350 g (approx. 320 g) (based on head type)

1: The weight includes packaging. The weight in paranthesis is for unit only.

F.S.(Full Scale): It is rated pressure range.

Environment resistance is rated at no freezing or condensation.

Compound pressure

-760 mmHg to

2

0 to 30 kg/cm

2

Dimensions

Head type

24

106

34 71

21 14

G3/8

DIN connector type

104

31 28 42

21

27

8

G3/8

Connector cable type

22

31 62 10

21

8

G3/8

M12 Connector

The standard pressure port for above is G3/8.

Connection Cable (sold separately)

CID3-2 / CID3-5

M12

40

Ø5

Model L(m) Meterial

C

C

D3-2 2

D3-5 5

CLD3-2 / CLD3-5

M12

Ø14.8

L(m)

Ø14.8

Ø5

27.5

32

L(m)

Connections

Head type DIN connector type Connector cable type

Pin Pin Function Pin Function

+

※

In case of head type, remove the top cover

Example of external connections

TPS20

1 + 1 +

2

3 N.C 3 F.G.

F.G. 4

.

KRN100

Terminal

+

+

DC4-20mA

Power 24VDC load 600Ω

Output DC4-20mA 2 wire

2 N.C

+

+

(unit: mm)

84

46.5

(unit: mm)

PVC

24VDC

Troubleshooting

Error Troubleshooting

Check the power supply.

No outputs

Check the polarity (+, -) when wiring cable.

Check the connection part.

Abnormally fl uctuating

output

Check the power supply.

Check the supplied pressure.

Check the pressure line.

Check the power supply.

Out of zero point output

value

Check the load resistive value of current output type

for a receiver is over 600Ω.

Check the measuring point and transmission distance.

Check the line resistance is below 600Ω.

Cautions during Use

1. When installing the unit on pipe line, use the hexagon part of connections not

to turn the unit with a pipe wrench. Do not use the unit with strong vibrations.

2. The unit is manufactured with precisely. If you drop or shock the unit, it may

lose the function. Please treat the unit carefully.

3. Store the unit at the place without moisture, dust, and vibration.

4. This product which does not have drive part at sensing part does not need to

repair it. Even though inside of pressure pipe is normally clean, it needs to take

maintenance once a year as below instructions.

① Check the broken status of outside.

② Check the pressure slot, cleanliness inside, and corrosion state.

③ Short each terminal and check the insulation resistance between the case

and power. (at 100VDC, over 10MΩ)

④ Check zero, span adjustment and linearity by pressure standards.

5. When removing a sensor for maintenance, follow the below instructions.

① Replace an O-ring which is used once.

② Be sure that diaphragm part is not damaged.

6. In case of head type for connecting the power, use a crimp terminal.

(M3.5, Max. 7.2mm)

7. The connection of this unit should be separated from the power line and high

voltage line in order to prevent inductive noise.

8. Install a power switch or a circuit breaker to supply or cut off the power.

9. Connect the power with the crimp terminals.

10. Switch or circuit breaker should be installed nearby users for convenient

control.

11. Do not use the unit near the high frequency instruments (high frequency

welding machine & sewing machine, large capacity SCR controller).

12. The unit cannot be repaired due to disassembled structure.

13. The unit is fi xed with bolt and nut at the both sides of case.

Do not press excessive load (approx. 300kg/cm

2

), or it may cause damage to

the unit.

14. Do not pull the cables with over 30N of tension force.

15. Tighten the cable connection part fi rmly not to enter water to the cable.

16. Installation environment.

① Indoor / Outdoor

② Altitude max. 2,000 m

③ Pollution degree 2

④ Installation category II

We are not responsible for any damages and claims for careless.

Must read the cautions for your safety and using.

If there are any problems with the unit, contact the head offi ce or A/S

center.

Failure to follow these instructions may result in product damage.

Major Products

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse(Rate) Meters

Rotary Encoders Display Units

Connectors/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System(Fiber, Co₂, Nd: YAG)

Laser Welding/Cutting System

HEADQUARTERS:

18, Bansong-ro 513beon-gil, Haeundae-gu, Busan,

South Korea, 48002

TEL: 82-51-519-3232

E-mail: sales@autonics.com

Recorders Thyristor Units

Indicators Pressure Transmitters

Converters Temperature Transmitters

Controllers

http://www.autonics.com

DRW17143 0B A

Loading...

Loading...