TM Series

2/4-CH Modular Type, PID Control Temperature Controller

Features

● Multi-channel (4-channel: TM4 / 2-channel: TM2) input and output control

● High-speed sampling cycle (4-channel: 100 ms / 2-channel: 50 ms)

● Module connection and expansion with expansion connectors

- Communication between modules

- No additional power supply wiring

- Expandable up to 31 units (124-channel / 62-channel)

● Simultaneous heating and cooling control function

● Isolated input channels (dielectric strength: 1000 VAC)

● Switch between current output and SSR drive output (TM2- 2C models)

● SSR drive output (SSRP function) control options: ON/OFF control, cycle control, phase control

● Parameter conguration via PC (USB and RS485 communication)

- DAQMaster software included (comprehensive device management software)

-

Communication converter sold separately: SCM-WF48 (Wi-Fi to RS485·USB wireless communication converter),

SCM-US48I (USB to RS485 converter), SCM-38I (RS232C to RS485 converter),

SCM-US (USB to serial converter)

● Easy wiring and maintenance with various connectors:

sensor input connector, control output connector, power/communication connector

● Heater disconnect alarm function (CT input)

- Current transformer (CT) sold separately: CSTC-E80LN, CSTC-E200LN, CSTS-E80PP

● Various input types and temperature ranges

Please read “Safety Considerations”

in the instruction manual before using.

Manual

● Visit our website (www.autonics.com) to download user manual and communication manual.

● User manual describes for specications and function, and communication manual describes for RS485 communication

(Modbus RTU protocol) and parameter address map data.

Comprehensive Device Management Program

● DAQMaster is comprehensive device management program for convenient management of parameters and multiple

device data monitoring.

● Visit our website (www.autonics.com) to download user manual and comprehensive device management program.

Item Minimum requirements

System IBM PC compatible computer with Intel Pentium Ⅲ or above

Operations

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS-232 serial port (9-pin), USB port

Ordering Information

Microsoft Windows 98/NT/XP/Vista/7/8/10

(DAQMaster)

< DAQMaster screen >< Computer specication for using software >

TM 4 N 2 R B

Module type

Control output

Power supply

Option I/O

Channels

Item

※

The expansion module does not supply power/comm. terminal. Order it with the basic module.

B Basic module

E Expansion module

2CH

4CH

2 24VDC

2CH

4CH N RS485 comm. output

2 2-channel

4 4-channel

TM Multi-channel modular temperature controller

R Relay output

C Current or SSR drive output selectable

R Relay output

S SSR drive output

CT input, Digital input (DI-1, DI-2),

2

Alarm output 1+2, RS485 comm. output

CT input, Digital input (DI-1, DI-2),

4

Alarm output 1+2+3+4, RS485 comm. output

※

1

J-52

2/4-CH Modular Type, PID Control

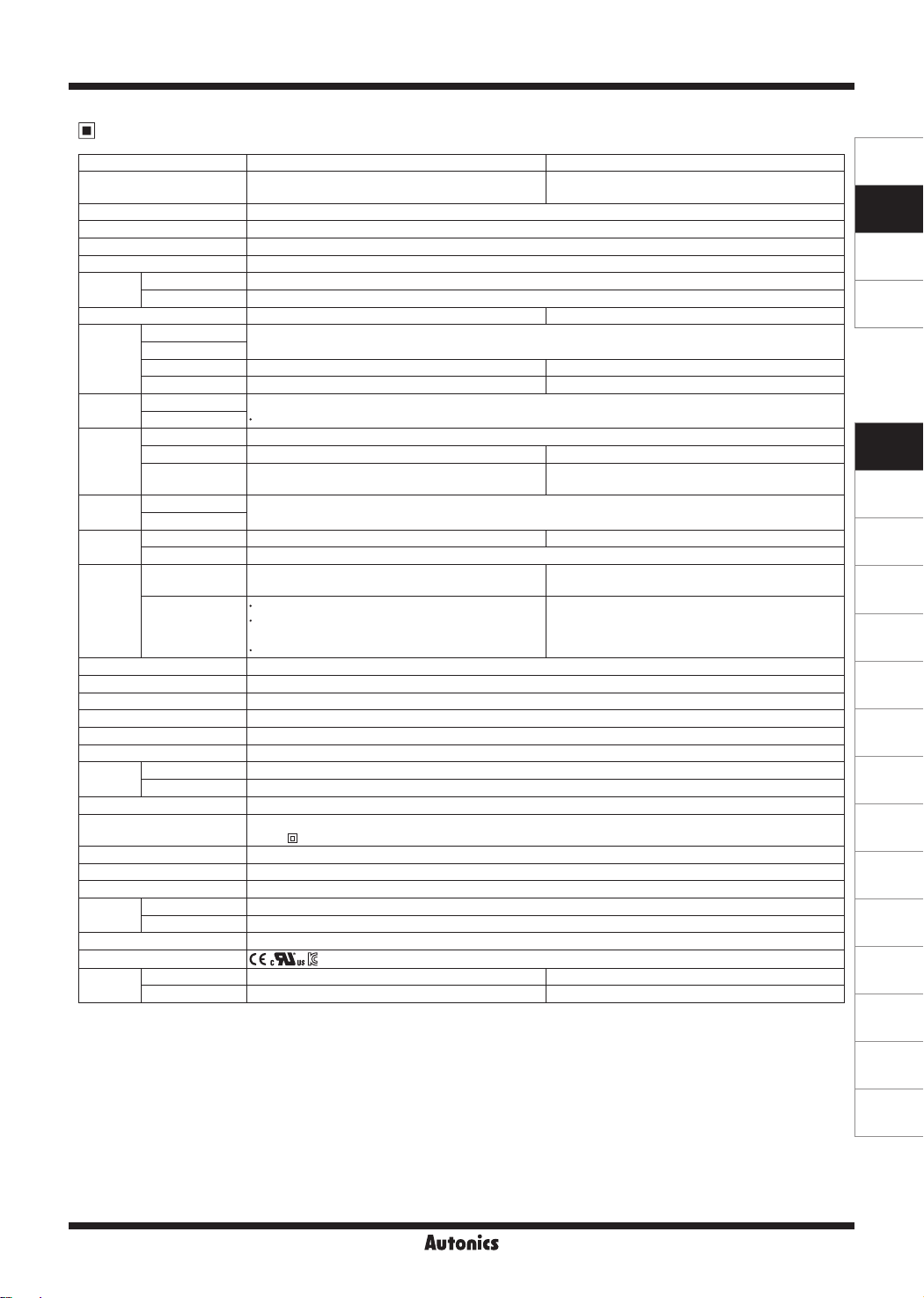

Specifications

Series

No. of channels

Power supply 24VDC

Permissible voltage range 90 to 110% of rated voltage

Power consumption Max. 5W (for max. load)

Display method None- parameter setting and monitoring is available at external devices (PC, PLC, etc.)

Input type

Thermocouple K(CA), J(IC), E(CR), T(CC), B(PR), R(PR), S(PR), N(NN), C(TT), G, (TT), L(IC), U(CC), Platinel II

RTD JPt100Ω, DPt100Ω (permissible line resistance max. 5Ω)

Sampling period 50ms (2 channel synchronous sampling) 100ms (4 channel synchronous sampling)

Thermocouple

Measured

accuracy

RTD

CT input ±5% F.S. ±1-digit max.

Current output ±1.5% F.S. ±1-digit max.

Inuence

of temp.

Thermocouple

※

2

RTD

Relay 250VACᜠ 3A, 30VDCᜡ 3A, 1a

Control

output

Control

method

Option

output

SSR Max. 12VDCᜡ ±3V 30mA Max. 22VDCᜡ ±3V 30mA

Current

Heating, Cooling

Heating&Cooling

Alarm 250VACᜠ 3A 1a

Communication RS485 communication output (Modbus RTU method)

CT input

Option

input

Digital input

Hysteresis 1 to 100℃/℉ (0.1 to 100℃/℉) variable

Proportional band (P) 0.1 to 999.9℃/

Integral time (I) 0 to 9999 sec

Derivative time (D) 0 to 9999 sec

Control period (T) 0.1 to 120.0 sec (only for relay output, SSR drive output)

Manual reset 0.0 to 100.0%

Relay

life cycle

Mechanical Min. 10,000,000 operations

Electrical Min. 100,000 operations (250VAC 3A resistance load)

Insulation resistance Over 100MΩ (at 500VDC megger)

Insulation type

Dielectric strength 1,000VAC 50/60Hz for 1 min (between input terminals and power terminals)

Vibration 0.75mm amplitude at frequency of 5 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Noise immunity ±0.5kV the square wave noise (pulse width: 1㎲) by the noise simulator

Environment

Ambient temp. -10 to 50℃, storage: -20 to 60

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

Accessories Expansion connector: 1, Power/Comm. connector: 1 (only for basic module)

Approval

Weight

※

1: In case of thermocouple K, J, E, T, N, it is below -100℃ and L, U, Platinel II, it is below ±2℃ ±1-digit.

Expansion module Approx. 208g (approx. 143g) Approx. 231g (approx. 166g)

Basic module Approx. 217g (approx. 152g) Approx. 239g (approx. 174g)

※

3

In case of thermocouple B, display accuracy cannot be ensured under 400℃.

In case of thermocouple R, S, it is below 200℃ and C, G, it is max. 3℃ ±1-digit.

※

2: Applied when it is for out of room temperature (23±5℃) range.

※

3: The weight includes packaging. The weight in parentheses is for unit only.

※

Environment resistance is rated at no freezing or condensation.

TM2 TM4

2-channel

(insulated each channel-dielectric strength 1,000VAC)

4-channel

(insulated each channel-dielectric strength 1,000VAC)

ᜡ

※

1

(PV ±0.5% or ±1℃, select the highter one) ±1-digit max.

-

-

(PV ±0.5% or ±2℃, select the highter one) ±1-digit max. (TC input max. -100℃ is within ±5℃)

TC B, R, S, C, G, L, U: (PV ±0.5% or ±5℃, select the highter one) ±1-digit max.

Selectable DC 4-20mA or DC 0-20mA

(load resistance max. 500Ω)

-

ON/OFF control, P, PI, PD, PID control

-

0.0-50.0A (primary current measurement range)

※

CT ratio=1/1000

-

Contact input: ON max. 1kΩ, OFF min. 100kΩ

Solid-state input: ON residual voltage max. 1.5VDCᜡ,

OFF leakage current max. 0.1mA

-

Outow current: Approx. 0.5mA per input

℉

Double insulation or reinforced insulation

(mark: , dielectric strength between the measuring input part and the power part: 1kV)

℃

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-53

TM Series

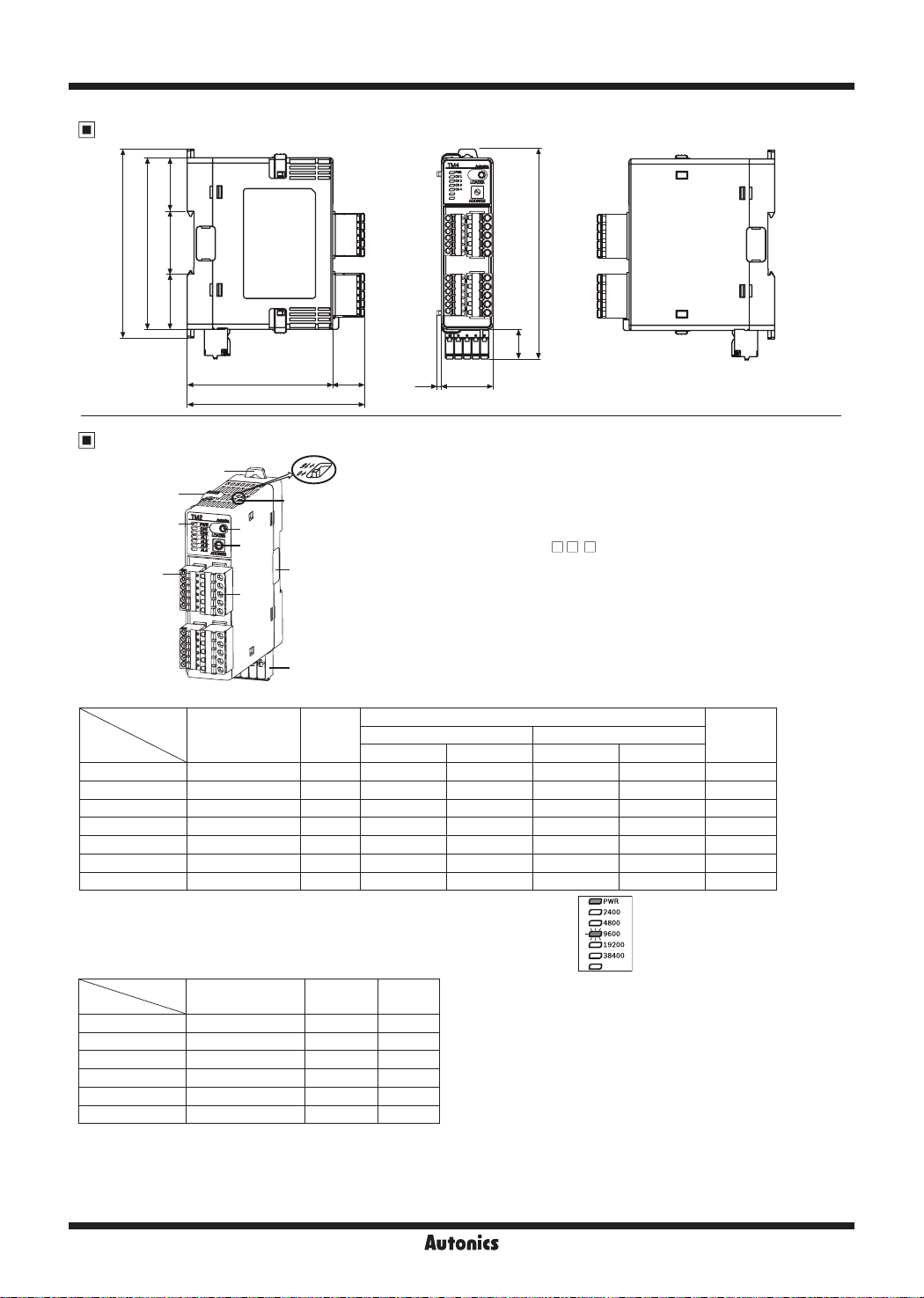

Dimensions

110

100

36.6 31.232.2

7

10

3

1

Control

output

※

4

※

5

-

18.6

2.9

30

1. Sensor input connector

2. Control output connector

3. Power/Comm. terminal

[only for basic module (TM - 2 B)]

Suppling power to basic/expansion modules and communicating with over

1 module(s).

4. PC loader port

It is the PC loader port for serial communication between one module

and PC to set parameter and monitoring by DAQMaster. Use this for

connecting SCM-US (USB to serial converter, sold separately).

※

When using PC loader port (connecting SCM-US), communication via

power/comm. terminal is blocked and monitoring is not available.

Alarm output

N.O. (Normally Open) N.C. (Normally Closed)

OFF (OPEN) ON (CLOSE) OFF (CLOSE) ON (OPEN)

- - - -

- - - -

- - - -

OFF ON OFF ON OFF

OFF ON OFF ON OFF

OFF ON OFF ON OFF

OFF ON OFF ON OFF

84.8

103.4

Unit Description

9

8

5

4

6

1

2

5. Indicators

●TM2 Series

Status

Indicator

PWR (green)

Initial power ON

※

3

ON ON

CH1 (red) Flash (2,400bps) ON

CH2 (red) Flash (4,800bps) ON

AL1 (yellow) Flash (9,600bps) ON

AL2 (yellow) Flash (19,200bps) ON

AL3 Flash (38,400bps)

AL4

※

1: When power is supplied initially, the set communication speed LED flashes for 5 sec.

- -

※

17.3

122.3

Autotuning

ON

Flash

Flash

(unit: mm)

※

2

●TM4 Series

Status

Indicator

PWR (green)

※

3

Initial power ON

ON ON ON

Control

※

1

output

CH1 (red) Flash (2,400bps) ON Flash

CH2 (red) Flash (4,800bps) ON Flash

CH3 (red) Flash (9,600bps) ON Flash

CH4 (red) Flash (19,200bps) ON Flash

Flash (38,400bps)

6. Communication address setting switch (SW1):

7. Communication address group switch (SW2):

8. Lock switch:

9. Rail Lock:

10. END cover

Used for fixing modules at top and bottom.

Used for installing at DIN rail or using bolts.

: Remove it when connecting each module to connect an expansion connector.

- -

Set the communication address.

When setting the communication address over 16, select +16.

J-54

Autotuning

※

※

2: The auto-tuning CH LED flashes for 1 sec in turn.

2

※

3: The PWR LED flashes during communication for 1 sec in turn.

※

4: Turns ON when CH1 control method is heating & cooling control

and cooling output occurs.

(disable AL1 setting)

※

5: Turns ON when CH2 control method is heating & cooling control

and cooling output occurs.

(disable AL2 setting)

2/4-CH Modular Type, PID Control

Connections and Block Diagram

TM2 Series

CURRENT

0.0A-50.0A

DIGITAL

INPUT

CH1 IN

CH2 IN

CH3 IN

CH4 IN

※

: Available for

single module

DI-1

DI-2

CH1 IN

TC

CH2 IN

TC

TM4 Series

Port A

A

B

B'

TC

RTD

A

B

B'

RTD

TC

A

B

B'

TC

RTD

A

B

B'

RTD

TC

CT1

CT2

RTD

RTD

1

2

3

4

5

6

7

8

9

10

11

12

A

B

B'

A

B

B'

ADC

ADC

ADC

ADC

ADC

1

2

ADC

3

4

5

6

7

ADC

8

9

10

11

ADC

12

CONTROL

CIRCUIT

RS485

CIRCUIT

1 2 3 4 5

A B

RS485

Serial

CONTROL

CIRCUIT

RS485

POWER

CIRCUIT

CIRCUIT

1 2 3 4 5

N.C

A B

RS485

N.C

POWER

CIRCUIT

SOURCE

24VDC

SOURCE

24VDC

OUTPUT

CIRCUIT

OUTPUT

CIRCUIT

OUTPUT

CIRCUIT

13

14

15

16

17

18

19

20

21

22

13

14

15

16

17

18

19

20

21

22

SSR OUT1

V

22VDC ±3V

30mA Max.

SSR OUT2

V

22VDC ±3V

30mA Max.

SSR OUT3

V

22VDC ±3V

30mA Max.

SSR OUT4

22VDC ±3V

V

30mA Max.

SCM-US (USB to Serial converter)

SSR OUT1

12VDC ±3V

30mA Max.

RELAY AL1 OUT

250VAC 3A 1a

RELAY AL2 OUT

250VAC 3A 1a

SSR OUT2

12VDC ±3V

30mA Max.

RELAY AL3

250VAC 3A 1a

RELAY AL4

250VAC 3A 1a

※

RELAY AL3/4 is available only for TM2-42 model.

RELAY OUT1

250VAC 3A 1a

30VDC 3A 1a

RELAY OUT2

250VAC 3A 1a

30VDC 3A 1a

RELAY OUT3

250VAC 3A 1a

30VDC 3A 1a

RELAY OUT4

250VAC 3A 1a

30VDC 3A 1a

SCM-38I

(RS232C to RS485 converter)

CURRENT OUT1

DC0/4-20mA

Load 500Ω Max.

CURRENT OUT2

DC0/4-20mA

Load 500Ω Max.

※

RELAY OUT1

250VAC 3A 1a

30VDC 3A 1a

RELAY OUT2

250VAC 3A 1a

30VDC 3A 1a

Use crimp terminals of size specied below.

a

c

<Crimp terminal>

Terminal number a b c

1 to 12 10

13 to 22 10

RS232C

b

(unit: mm)

Max. 1.7 Max. 3.7

Max. 2.1 Max. 4.2

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

※

Port B

: Available for

single/multi module

1 2 3 4 5

RS485 A (+)

RS485 B (-)

N

- +

.

C

SOURCE

24VDC 5W

※

This connector is

available only for

standard model

(TM

SCM-US48I

(USB to RS485 converter)

SCM-WF48

(Wi-Fi/RS485, USB wireless

communication converter)

B).

PC

<RS485 communication support external device>

PLC

GP/LP

J-55

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TM Series

Installation

● Connector connection

Control output

Sensor input

connector

Power / Comm. connector

(only for basic module:

TM - 2 B

Bolt inserting

●

①

connector

● Multi module connection

④

③

②

③

TM - 2 E

(expansion module)

M4 Bolt

③

①

②

TM - 2 B

(basic module)

Remove each module’s END covers.

①

(do not remove at the ends of END covers)

Connect expansion connectors between modules.

②

Push each modules. (max. 30 units)

③

Push the lock switch to lock direction.

④

※

Supply adequate power for power input specications and overall capacity.

(Max. power when connecting 31 modules:

31 units×5W=155W)

M4 Bolt

TM - 2 E

(expansion module)

⑤

①

①

Pull each Rail Lock switch up and down.

DIN rail Installation

●

[Installation method]

①

Put the top edge of the rail Lock

on the top edge or the DIN rail.

②

Push the module body in while

pressing down.

※

Install the units vertically.

110

②

②

Insert the bolts to fix.

(Tightening torque is 0.5N·m to 0.9N·m.)

①

②

[Removal method]

①

Press down the module body.

②

Pull the module body forward.

①

②

※

Use end plates (sold separately, not available from Autonics) to

x rmly.

END PLATE

J-56

2/4-CH Modular Type, PID Control

Input Sensor Type and Temperature Range

Input sensor No. Dot Display Input range (℃) Input range (℉)

K(CA)

J(IC)

E(CR)

T(CC)

B(PR) 8 1 B(PR) 0 to 1800 32 to 3272

Thermocouple

R(PR) 9 1 R(PR) 0 to 1750 32 to 3182

S(PR) 10 1 S(PR) 0 to 1750 32 to 3182

N(NN) 11 1 N(NN) -200 to 1300 -328 to 2372

※

C(TT)

※

G(TT)

L(IC)

U(CC)

Platinel II 18 1 PLII 0 to 1400 32 to 2552

JPt 100Ω

RTD

DPt 100Ω

※

1: C(TT): Same as existing W5(TT).

※

2: G(TT): Same as existing W(TT).

※

Default: K(CA).H

Error Display

Status

Indicators

PWR (red) ON

CH (red)

※

1

Disconnected input sensors Out of temperature range

Flash (for 0.5 sec in turn)

Comm. output (decimal) Outputs '31000' Outputs '30000 (high-limit)', '-30000 (low-limit)'

DAQMaster Displays 'OPEN' Displays 'HHHH (high-limit)', 'LLLL (low-limit)'

※

1: The applied CH LED indicator flashes.

0 1 K(CA).H -200 to 1350 -328 to 2462

1 0.1 K(CA).L -200.0 to 1350.0 -328.0 to 2462.0

2 1 J(IC).H -200 to 800 -328 to 1472

3 0.1 J(IC).L -200.0 to 800.0 -328.0 to 1472.0

4 1 E(CR).H -200 to 800 -328.0 to 1472

5 0.1 E(CR).L -200.0 to 800.0 -328.0 to 1472.0

6 1 T(CC).H -200 to 400 -328 to 752

7 0.1 T(CC).L -200.0 to 400.0 -328.0 to 752.0

1

12 1 C(TT) 0 to 2300 32 to 4172

2

13 1 G(TT) 0 to 2300 32 to 4172

14 1 L(IC).H -200 to 900 -328 to 1652

15 0.1 L(IC).L -200.0 to 900.0 -328.0 to 1652.0

16 1 U(CC).H -200 to 400 -328 to 752

17 0.1 U(CC).L -200.0 to 400.0 -328.0 to 752.0

19 1 JPt100.H -200 to 600 -328 to 1112

20 0.1 JPt100.L -200.0 to 600.0 -328.0 to 1112.0

21 1 DPt100.H -200 to 600 -328 to 1112

22 0.1 DPt100.L -200.0 to 600.0 -328.0 to 1112.0

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

J-57

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TM Series

Communication Setting

It is for parameter setting and monitoring via external devices (PC, PLC, etc.).

Interface

Comm. protocol Modbus RTU Comm. distance Max. 800m

Connection type RS485 Comm. speed 2400, 4800, 9600 (default), 19200, 38400 bps

Application standard Compliance with EIA RS485 Start bit 1-bit (xed)

Max. connection 31 units (address: 01 to 31) Data bit 8-bit (xed)

Synchronous method Asynchronous Parity bit None (default), Odd, Even

Comm. method Two-wire half duplex Stop bit 1-bit, 2-bit (default)

※

It is not allowed to set overlapping communication address at the same communication line.

Use twisted pair wire for RS485 communication.

Application of system organization

RS232C/

USB/Wi-Fi

Comm.

converter

Computer

※

It is recommended to use Autonics communication converter; SCM-WF48 (Wi-Fi to RS485·USB wireless communication

ON

RS485

B(-)

OFF

A(+)

Terminating resistance

(100 to 120Ω)

A(+) B(-) A(+) B(-) A(+) B(-)

RS485

DEVICE

#1

RS485

DEVICE

#2

RS485

DEVICE

#30

B(-)

A(+)

RS485

DEVICE

#31

converter, sold separately), SCM-US48I (USB to RS485 converter, sold separately), SCM-38I (RS232C to RS485

converter, sold separately).

Please use twisted pair wire, which is suitable for RS485 communication, for SCM-WF48, SCM-US48I and SCM-38I.

Communication Address Setting

Set the communication address by the communication address setting switch (SW1) and Communication address group switch (SW2).

When setting as 0, it does not operate communication.

(setting range: 01 to 31, factory default: [SW1] 1, [SW2] +0)

SW1

SW2

+0

+16

+0

+16

Caution for Communication Address Setting

When changing communication address via the Power/Comm. terminal, resupply the power.

0 1 2 3 4 5 6 7 8 9 A B C D E F

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Sold Separately

Communication converter

SCM-WF48

(

Wi-Fi to RS485·USB wireless

communication converter)

J-58

SCM-US48I

(USB to RS485 converter)

SCM-38I

(RS232C to RS485 converter)

SCM-US

(USB to Serial converter)

Sold Separately

Current transformer (CT)

CSTC-E80LN

Ø23.3

Ø7

7

15026.5

10.5

CSTC-E200LN

Ø37.1

Ø13

10

13.5

CSTS-E80PP

21.4

15.4

0.5

Ø6

725.4

K (black)

L (white)

K (black)

L (white)

15040.8

2.9

2/4-CH Modular Type, PID Control

F=50Hz

100Ω

10Ω

Max. load current: 80A (50/60Hz)

※Max. load current for TM Series

is 50A.

Current ratio: 1/1000

Wire wounded resistance: 31Ω±10%

F=50Hz

100Ω

10Ω

Max. load current: 200A (50/60Hz)

※Max. load current for TM Series

is 50A.

Current ratio: 1/1000

Wire wounded resistance: 20Ω±10%

F=50Hz

100Ω

10Ω

3

(unit: mm)

3

(unit: mm)

4.5

10

Ta=25

℃

1

3.8

0.1

0.01

OUTPUT IN VOLTS RMS (V)

0.001

0.1

1 10 100 1000

SENSED CURRENT IN AMPS RMS (Io)

10

Ta=25

℃

1

0.1

0.01

OUTPUT IN VOLTS RMS (V)

0.001

0.1 1 10 100 1000

SENSED CURRENT IN AMPS RMS (Io)

10

Ta=25

℃

1

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

10.5

40.2

31

Ø3.4

※

Do not supply primary current in case that CT output is open. High voltage will be generated in CT output.

※

The current for above CTs is 50A same but inner hole sizes are different. Please use this for your environment.

2.7

0.01

OUTPUT IN VOLTS RMS (V)

0.001

10

(unit: mm)

0.1 1 10 100 1000

SENSED CURRENT IN AMPS RMS (Io)

Max. load current: 80A (50/60Hz)

※

Max. load current for TM Series

is 50A.

Current ratio: 1/1000

Wire wounded resistance 31Ω±10%

Display units (DS/DA-T Series)

DS/DA-T Series

(RS485 communication input type display unit)

0.1

DS16- T

※

Connect RS485 communication input type display unit (DS/DA-T Series) and TM Series, the display unit displays present value of the

device without PC/PLC.

DS22/DA22- T

DS40/DA40- T DS60/DA60- T

J-59

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TM Series

Proper Usage

Simple failure diagnosis

● LED indicators flash (for 0.5 sec in turn), or external

device displays OPEN.

● Check input sensor setting.

● Disconnect the power and check the input connection.

● If input is connected, disconnect the input wiring

from the temperature controller and short the + and -

terminals. Power the temperature controller and check

if the external device displays the room temperature. If

it does not display the room temperature and continues

to display HHHH or LLLL, the controller is broken.

Please contact our technical support. (input type is

thermocouple)

● Output does not operate normally.

● Check that CH indicators for control output operates

normally.

● If CH indicators for control output does not operates,

check the parameter settings.

● If CH indicators for control output operates, remove

the control output connector and check the output.

● External device receives no-response or abnormal

data.

● Check the communication converter (SCM-WF48 or

SCM-US48I, SCM-38I, SCM-US, sold separately).

● Do not install communication converter line and AC

power supply lines.

● Use different communication converter power and

temperature controller power.

● Indicates damage to internal chip by strong noise.

Please contact our technical support. Locate the

source of the noise device countermeasures.

● Communication does not work between TM and

external device

● Check the communication converter power and

connections.

● Check the communication settings.

● Check the temperature controller and external device

connections.

Cautions during use

● Follow instructions in 'Cautions during Use'. Otherwise, It

may cause unexpected accidents.

● Check the polarity of the terminals before wiring the

temperature sensor.

For RTD temperature sensor, wire it as 3-wire type, using

cables in same thickness and length.

For thermocouple (CT) temperature sensor, use the

designated compensation wire for extending wire.

● Keep away from high voltage lines or power lines to

prevent inductive noise.

In case installing power line and input signal line closely,

use line filter or varistor at power line and shielded wire

at input signal line.

Do not use near the equipment which generates strong

magnetic force or high frequency noise.

● Do not apply excessive power when connecting or

disconnecting the connectors of the product.

● Install a power switch or circuit breaker in the easily

accessible place for supplying or disconnecting the

power.

● Do not use the unit for other purpose (e.g. voltmeter,

ammeter), but temperature controller.

● When changing the input sensor, turn off the power first

before changing.

After changing the input sensor, modify the value of the

corresponding parameter.

● 24VDC power supply should be insulated and limited

voltage/current or Class 2, SELV power supply device.

● Do not overlapping communication line and power line.

Use twisted pair wire for communication line and connect

ferrite bead at each end of line to reduce the effect of

external noise.

● Make a required space around the unit for radiation of

heat.

For accurate temperature measurement, warm up the

unit over 20 min after turning on the power.

● Make sure that power supply voltage reaches to the

rated voltage within 2 sec after supplying power.

● Do not wire to terminals which are not used.

● Install DIN rail vertically from the ground.

● This unit may be used in the following environments.

Indoors (in the environment condition rated in

①

'Specifications')

Altitude max. 2,000m

②

Pollution degree 2

③

Installation category II

④

J-60

Loading...

Loading...