TMH Series

-|Transparent setting guide|-

Multi-Channel Modular Type High Performance

Temperature Controller

Feature

[Common]

Easy maintenance with separated body/base parts

No communication and power supply for expansion modules required using module connectors: Up to 32 modules

PC parameter setting via PC (USB cable and RS485 communication):

Supports comprehensive device management program (DAQMaster)

Communication converter, sold separately: SCM-US (USB/Serial converter),

※

SCM-38I (RS232C/RS485 converter), SCM-US48I (USB/RS485 converter),

SCM-WF48 (Wi-Fi/RS485.USB wireless communication converter),

EXT-US (converter cable)

[TMH2/4 Series (control module)]

One module supports multi channels (2 channels/4 channels) for

input/output control : connecting TMH2/4, up to 32 modules

(2 channels: 64 channels/4 channels: 128 channels)

High-speed sampling with 50ms and ±0.3% measuring accuracy

Simultaneous heating/cooling control and auto/manual control

for high-performance control

Selectable current output or SSR drive output

Each channel insulated (dielectric strength 1,000VAC)

CT input terminal for measuring load current

※

(※CT, sold separately: CSTC-E80LN, CSTC-E200LN, CSTS-E80PP)

Multi input/Multi range

[TMHA (analog input/output option module)]

4 channels, multi input/multi range/transmission output (DC0-20mA or 4-20mA)

Each channel insulated (dielectric strength 1,000VAC)

High-speed sampling with 50ms and ±0.3% measuring accuracy

[TMHE (digital input/alarm output option module)]

Digital input (8 types)/Alarm output (8 types)

[TMHCT (CT input option module)]

8 CT inputs

CT input status indicators

[TMHC (communication module)]

Connection expansion to master devices (PC, PLC, etc) with

TMH2/4 (control module) and TMHA/E/CT (option module) (up to 16 modules)

One module connects up to 32 control/option modules

(16 control modules and 16 option modules)

PLC ladderless (RS422/RS485), Ethernet communication supported

Please read “Safety Considerations”

in the instruction manual before using.

Manuals

For the detail information and instructions, please refer to the user manual and the user manual for communication, and

be sure to follow cautions written in the technical descriptions (catalog, website).

Visit our website (www.autonics.com) to download manuals.

User manual describes for specications and function, and communication manual describes for RS485 communincation

(protocol Modbus RTU) and parameter address map data.

J-32

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

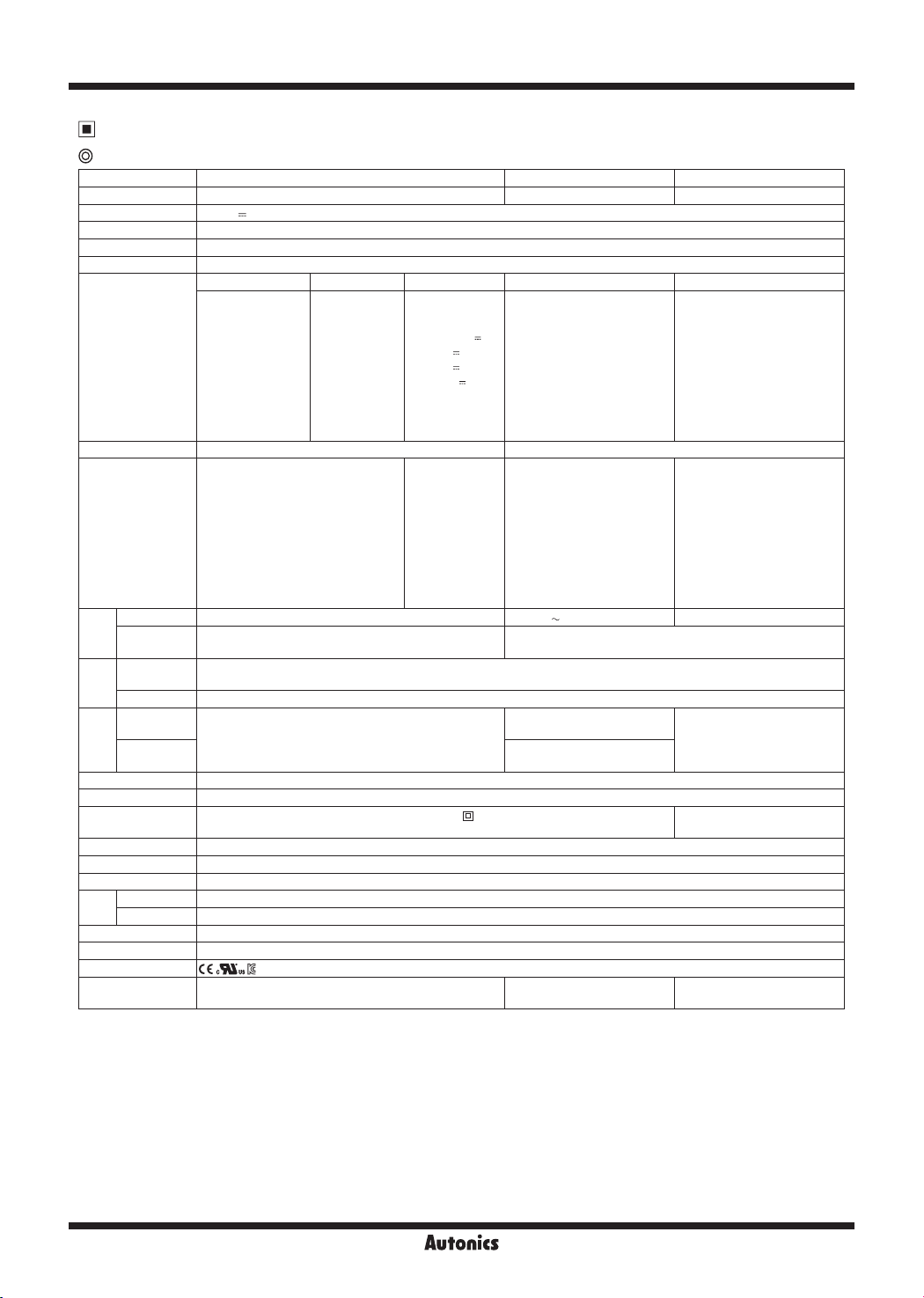

Ordering Information

Control module

2 4 2 R BTMH

Module

type

Control output

Power supply

Input/Output option

Channels

Item

1: Since the expansion module is not supplied with power/comm. terminal. Order it with the basic module.

※

B

E

R

C

2

2CH

4CH N

2

4

TMH

Basic module

Expansion module

1

※

Relay output

Selectable current or SSR drive output

24VDC

CT input, digital input (DI-1/2),

2

alarm output 1/2, RS485 comm. output

CT input, digital input (DI-1/2),

4

alarm output 1/2/3/4, RS485 comm. output

CT input, RS485 comm. output

2 channels

4 channels

Advanced Multi-Channel Modular Temperature Controller

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

Option module

Type Analog input/output Digital input, alarm output CT input

Model TMHA-42AE TMHE-82RE TMHCT-82NE

Input

Output

Temperature sensor/

Analog input 1 to 4

Transmission output

(0/4-20mA) 1 to 4

Digital input 1 to 8 CT input 1 to 8

Alarm output 1 to 8

-

Communication module

Type PLC ladderless communication Ethernet communication

Model TMHC-22LE TMH-22EE

COM1

(Master,

Communication

PLC)

COM2

(Master,

Group)

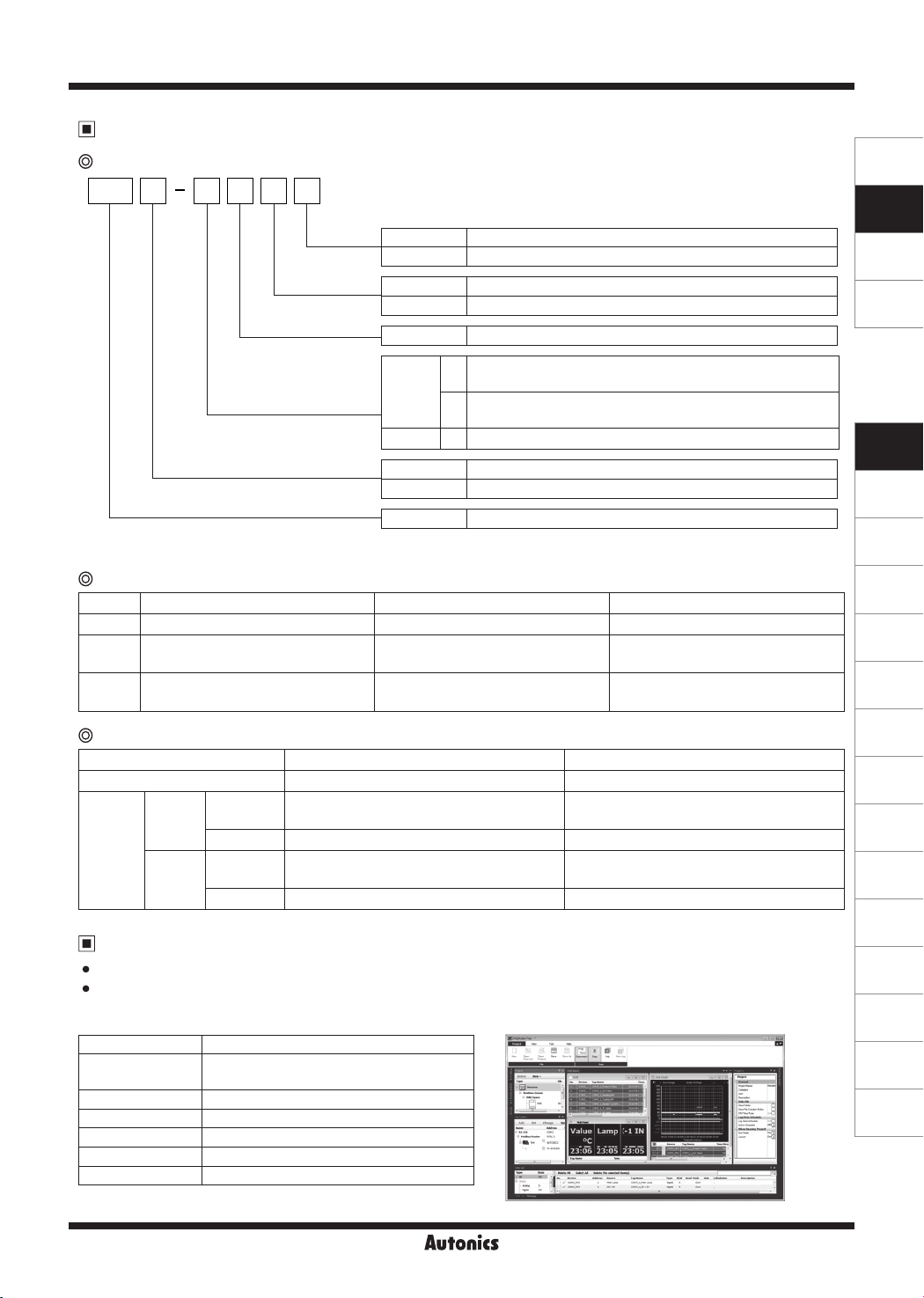

Comprehensive Device Management Program

DAQMaster is comprehensive device management program. It is available for parameter setting, monitoring.

Visit our website (www.autonics.com) to download user manual and comprehensive device management program.

< Computer specication for using software >

Item Minimum requirements

System

Operating system Microsoft Windows 98/NT/XP/Vista/7/8/10

Memory 256MB or more

Hard disk More than 1GB of free hard disk space

VGA 1024×768 or higher resolution display

Others RS-232 serial port (9-pin), USB port

Connection

method

RS422, RS485 Ethernet

Protocol Modbus RTU, PLC ladderless comm. Modbus TCP

Connection

method

RS422, RS485 Ethernet

Protocol Modbus RTU Modbus TCP

(DAQMaster)

< DAQMaster screen >

IBM PC compatible computer with Intel

Pentium Ⅲ or above

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-33

TMH Series

-|Transparent setting guide|-

Max. 32 units

Terminal resistance

Internal

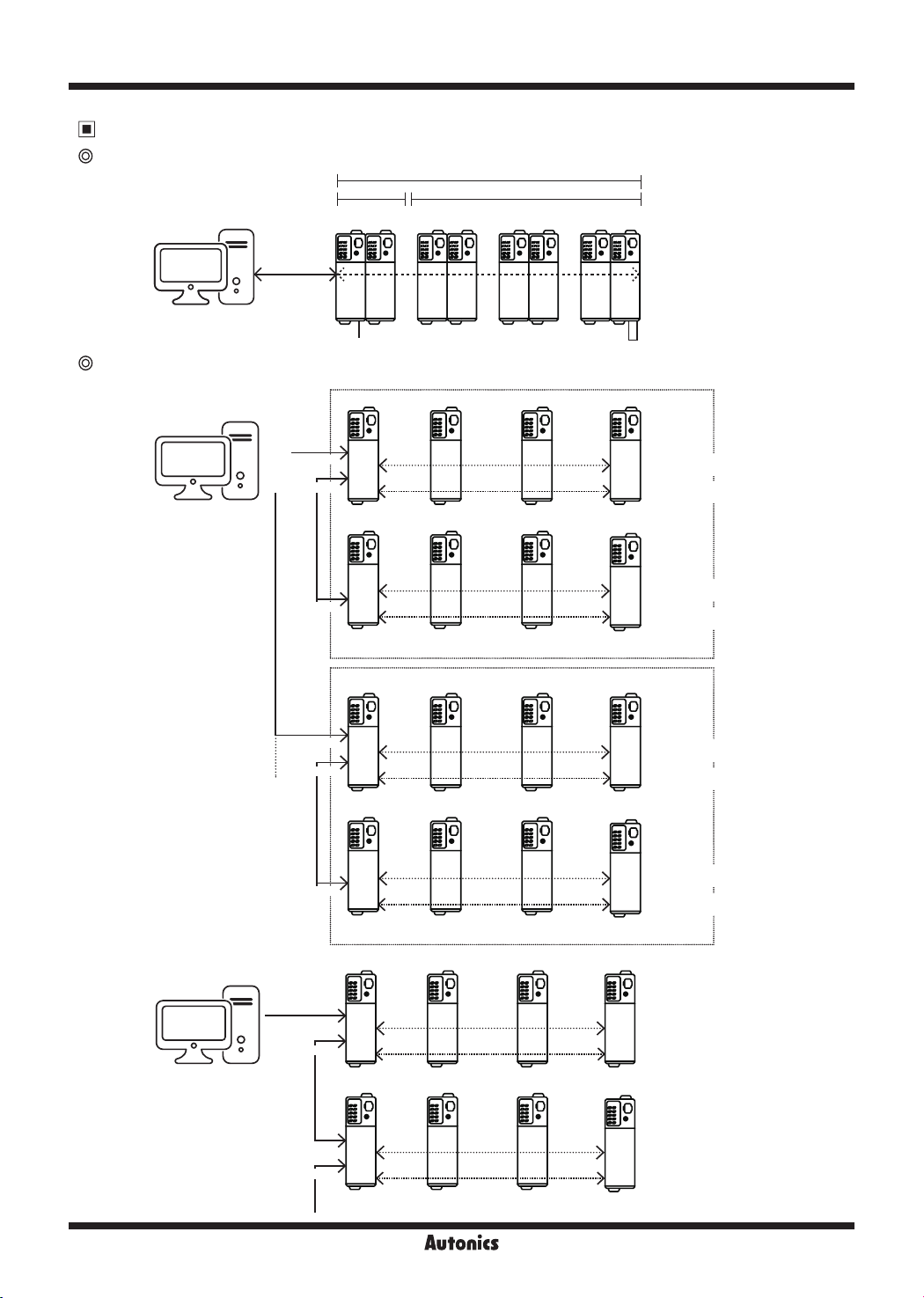

Connection Examples

TMH2/4, TMHA, TMHE, TMHCT inter-working configuration example

Address

range:

External

comm.

Master

(PC, PLC, HMI)

TMHC configuration example

● PLC ladderless communication

Master

Master

(PC, PLC, HMI)

(PC, PLC, HMI)

1. When using TMHC,

※

in case connecting

only TMHC to Master

(PC, PLC, etc.),

communication

address of TMHC

and TMH2/4 Series

control module can be

duplicated. However,

in case connecting

both TMHC and

TMH2/4 Series control

module to Master,

communication

address must not be

duplicated.

(If the TMHC and TMH

modules communicate

Max. connection:

4 group

with Master at

the same time, a

communication error

may occur.)

● Ethernet communication

Group1

Port 1

Port 2

Group2

Max. 16 units

TMH2/4

1 to 32

24VDC

TMHC TMH2/4

COM1

COM2

TMHC TMH2/4

COM2

Max. connection: 4 TMHC per a group

TMHC

COM1

COM2

TMHC

COM2

Max. connection: 4 TMHC per a group

TMHC TMH2/4

TMH2/4

TMH2/4

TMHA

33 to 48

Max. 16 units

※1

※1

※1

※1

※1

TMHE

49 to 64

TMHA/E/CT

TMHA/E/CT

TMHA/E/CT

TMHA/E/CT

TMHA/E/CT

TMHCT

65 to 80

※

※

comm.

Internal comm. of

control module

Internal comm. of

comm. module

Internal comm. of

control module

Internal comm. of

comm. module

Internal comm. of

control module

Internal comm. of

comm. module

Internal comm. of

control module

Internal comm. of

comm. module

※

Internal communication:

Receiving/Sending data

between TMH2/4 and

TMHA/E/CT

External communication:

Communication with

Master for controlling

Each module is

available to monitoring

at DAQMatser via PC

loader

COM1

COM2

Master

Master

(PC, PLC, HMI)

(PC, PLC, HMI)

Max. connection:

16 TMHC

COM2

J-34

TMHC TMH2/4

Internal comm. of

control module

Internal comm. of

comm. module

※1

TMHA/E/CT

Internal comm. of

control module

Internal comm. of

comm. module

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

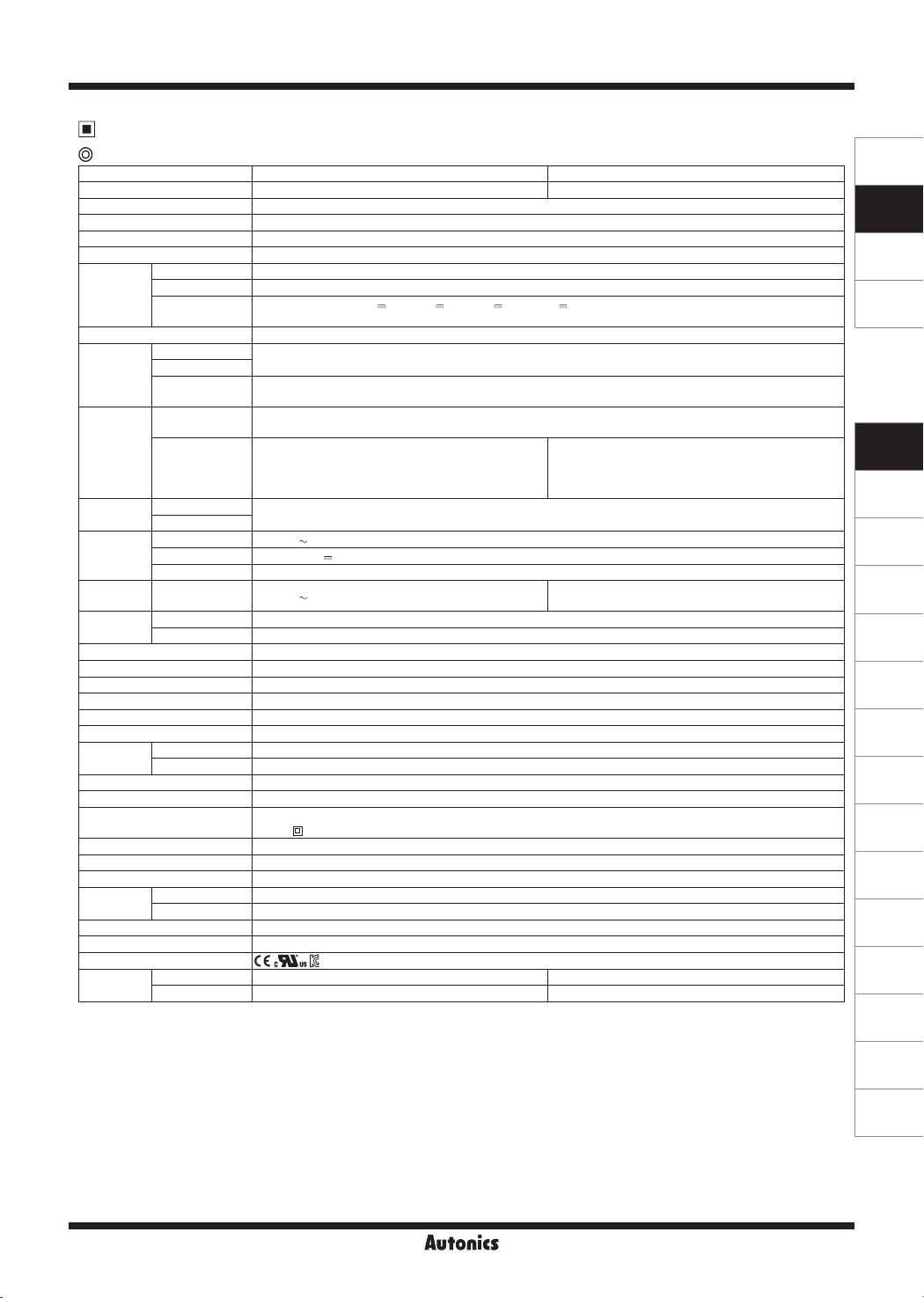

Specifications

Control module

Series TMH2 TMH4

No. of channels 2 channels 4 channels

Power supply 24VDC

Permissible voltage range 90 to 110% of rated voltage

Power consumption Max. 5W (for max. load)

Display method None- parameter setting and monitoring is available at external devices (PC, PLC, etc.)

Thermocouple K(CA), J(IC), E(CR), T(CC), B(PR), R(PR), S(PR), N(NN), C(TT), G(TT), L(IC), U(CC), Platinel II

Input type

RTD

Analog

Sampling cycle 50ms (2 channel or 4 channel synchronous sampling)

Thermocouple

Measured

accuracy

RTD

Analog

※

1

CT input

Option input

Digital input

Control

method

Control

output

Option

output

Communication

Heating, Cooling

Heating&Cooling

Relay 250VAC

SSR Max. 12VDC

※

3

Current

Alarm 250VAC

Comm. terminal RS485 (Modbus RTU protocol)

PC loader TTL (Modbus RTU protocol)

Hysteresis RTD/Thermocouples: 1 to 100℃/℉ (0.1 to 100.0℃/℉), analog: 1 to 100 digit

Proportional band (P) RTD/Thermocouples: 1 to 999℃/℉ (0.1 to 999.9℃/℉), analog: 0.1 to 999.9 digit

Integral time (I) 0 to 9999 sec

Derivative time (D) 0 to 9999 sec

Control period (T) Relay output: 0.1 to 120.0 sec, SSR output: 1.0 to 120.0 sec

Manual reset 0 to 100% (0.0 to 100.0% )

Relay

life cycle

Mechanical Min. 10,000,000 operations

Electrical Min. 100,000 operations (250VAC 3A resistance load)

Memory retention Approx. 10 years (non-volatile semiconductor memory type)

Insulation resistance 100MΩ (at 500VDC megger)

Insulation type

Dielectric strength 1,000VAC 50/60Hz for 1 min (between input terminals and power terminals)

Vibration 0.75mm amplitude at frequency of 5 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Noise immunity ±0.5kV the square wave noise (pulse width: 1㎲) by the noise simulator

Environment

Ambient temp. -10 to 50℃, storage: -20 to 60

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

Protection structure IP20 (IEC standard)

Accessories Expansion connector: 1, module lock connector: 2

Approval

Weight

※

1: Connecting 1 or more expansion module can vary measurement accuracy about ±1℃, regardless of the number of connected

※

2: At room temperature (23℃±5℃)

Expansion module

expansion module.

Basic module Approx. 250.8g (approx. 177.7g) Approx. 250.4g (approx. 177.3g)

※

4

• Thermocouple K, J, N, E below -100℃, L, U, PLII and RTD Cu50Ω, DPt50Ω: (PV ±0.3% or ±2℃, higher one) ±1-digit

• Thermocouple C, G and R, S below 200℃: (PV ±0.3% or ±3℃, higher one) ±1-digit

• Thermocouple B below 400℃: there is no accuracy standards.

Out of room temperature range

• RTD Cu50Ω, DPt50Ω: (PV ±0.5% or ±3℃, higher one) ±1-digit

• Thermocouple R, S, B, C, G: (PV ±0.5% or ±5℃, higher one) ±1-digit

• Others blow -100℃: within ±5

※

3: If the control output is set to current output, the heater current value monitoring function through the CT input terminal of the control

module is not available.

※

4: The weight includes packaging. The weight in parenthesis is for unit only.

※

Environment resistance is rated at no freezing or condensation.

ᜡ

DPt100Ω, JPt100Ω, DPt50Ω, Cu100Ω, Cu50Ω, Nikel 120Ω 3-wire type (permissible line resistance max. 5Ω)

• Voltage: 0-100mVDC , 0-5VDC , 1-5VDC , 0-10VDC

• Current: 0-20mA, 4-20mA

※

• At room temperature (23℃±5℃): (PV ±0.3% or ±1℃, higher one) ±1-digit

2

• Out of room temperature range: (PV ±0.5% or ±2℃, higher one) ±1-digit

• At room temperature (23℃±5℃): ±0.3% F.S. ±1-digit

• Out of room temperature range: ±0.5% F.S. ±1-digit

0.0-50.0A (primary current measurement range) ※CT ratio=1/1000

Measured accuracy: ±5% F.S. ±1-digit

• Connect input: ON - max. 1kΩ, OFF - min. 100kΩ

• Solid-state input: ON - max. residual voltage 0.9V,

OFF - max. leakage current 0.5mA

-

• Outow current : approx. 0.3mA per input

ON/OFF control, P, PI, PD, PID control

3A 1a

±3V 20mA

Selectable DC 4-20mA or DC 0-20mA (load resistance max. 500Ω)

3A 1a

-

Double insulation or reinforced insulation

, dielectric strength between the measuring input part and the power part: 1kV)

(mark:

℃

Approx. 245.7(approx. 172.6g) Approx. 245.1g(approx. 172.2g)

℃

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-35

TMH Series

-|Transparent setting guide|-

Specifications

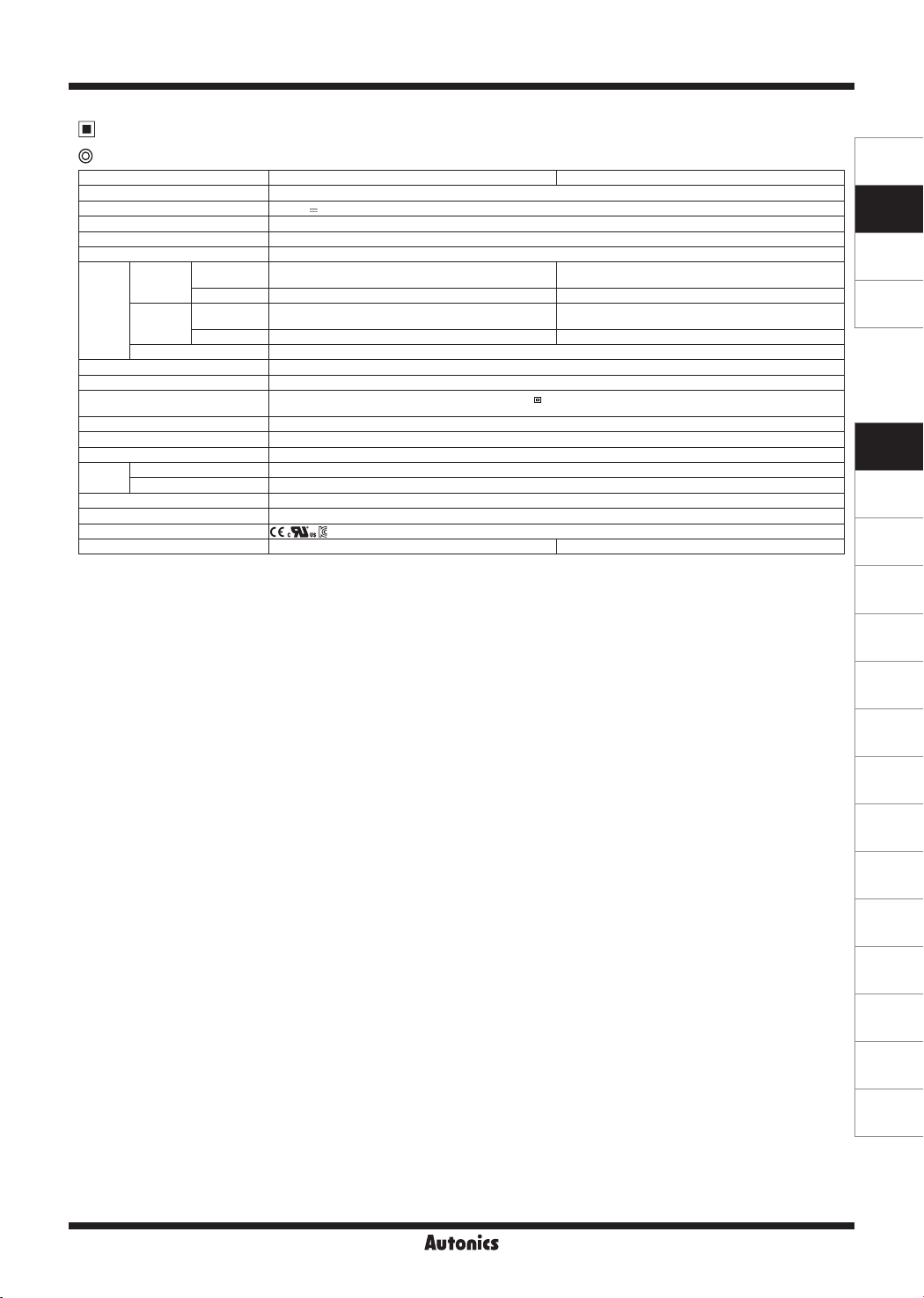

Option module

Model TMHA-42AE TMHE-82RE TMHCT-82NE

No. of channels 4 channels 8 points 8 points

Power supply

Permissible voltage range

Power consumption Max. 5W (for max. load)

Display method None- parameter setting and monitoring is available at external devices (PC, PLC, etc.)

Input type

Sampling cycle 50ms (4CH synchronous sampling)

Measured

accuracy

Output

Comm.

Relay

life

cycle

Memory retention Approx. 10 years (non-volatile semiconductor memory type)

Insulation resistance Over 100MΩ (500VDC megger)

Insulation type

Dielectric strength 1,000VAC 50/60Hz for 1 min (between power source terminal and input terminal)

Vibration 0.75mm amplitude at frequency of 5 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Noise immunity Square shaped noise by noise simulator (pulse width 1㎲) ±0.5kV R-phase, S-phase

Environment

Protection structure IP20 (IEC standard)

Accessories Expansion connector: 1, module lock connector: 2

Approval

Weight

※

1: Voltage of power supply/communication terminal placed in the backside of TMH2/4 Series (basic control module)

※

2: In case of TMHA, connecting 1 or more expansion module can vary measurement accuracy about ±1℃, regardless of the number of

※

3: At room temperature (23℃±5℃)

Out of room temperature range

• RTD Cu50Ω, DPt50Ω: (PV ±0.5% or ±3℃, higher one) ±1-digit

• Thermocouple R, S, B, C, G: (PV ±0.5% or ±5℃, higher one) ±1-digit

• Others blow -100℃: within ±5

※

4: The weight includes packaging. The weight in parenthesis is for unit only.

※

Environment resistance is rated at no freezing or condensation.

※

1

24VDC

90 to 110% of rated voltage

Thermocouple RTD Analog Digital CT

DPt100Ω,

K(CA), J(IC), E(CR),

T(CC), B(PR), R(PR),

S(PR), N(NN), C(TT),

G(TT), L(IC), U(CC),

Platinel II

• At room temperature (23℃±5℃):

(PV ±0.3% or ±1℃, higher one)

※

3

※

2

Alarm

Transmission

Comm.

terminal

PC loader TTL (Modbus RTU protocol)

Mechanical

Electrical

Ambient temp.

Ambient humi.

※

4

connected expansion module.

• Thermocouple K, J, N, E below -100℃, L, U, PLII and RTD Cu50Ω, DPt50Ω:

(PV ±0.3% or ±2℃, higher one) ±1-digit

• Thermocouple C, G and S below 200℃: (PV ±0.3% or ±3℃, higher one) ±1-digit

• Thermocouple B below 400℃: there is no accuracy standards.

±1-digit

• Out of room temperature range:

(PV ±0.5% or ±2℃, higher one)

±1-digit

-

DC 4-20mA or DC 0-20mA

(load resistance max. 500Ω)

RS485 (Modbus RTU protocol)

-

Double insulation or reinforced insulation (mark:

measuring input part and the power part : 1kV)

-10 to 50℃, storage: -20 to 60

35 to 85%RH, storage: 35 to 85%RH

Approx. 233.8g (approx. 160.7g)

JPt100Ω,

DPt50Ω, Cu100Ω,

Cu50Ω, Nikel

120Ω 3-wire type

(permissible line

resistance max.

5Ω per line)

℃

• Voltage:

0-100mVDC ,

0-5VDC ,

1-5VDC ,

0-10VDC

• Current: 0-20mA,

4-20mA

• At room

temperature

(23℃±5℃):

±0.3% F.S.

±1-digit

• Out of room

temperature

range:

±0.5% F.S.

±1-digit

℃

• Connect input:

ON - max. 1kΩ,

OFF - min. 100kΩ

• Solid-state input:

ON - max. residual voltage 0.9V,

OFF - max. leakage current

0.5mA

• Outow current :

approx. 0.3mA per input

-

-

250VAC 3A 1a

-

Min. 10,000,000 operations

Min. 100,000 operations

(250VAC 3A resistance load)

, dielectric strength between the

Approx. 239g

(approx. 165.9g)

0.0-50.0A

(primary current measurement

range)

※

CT ratio=1/1000

±5% F.S. ±1-digit

-

-

-

Approx. 220.6g

(approx. 147.5g)

J-36

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

Specifications

Communication module

Model TMHC-22LE TMHC-22EE

Communication port COM1/2

Power supply

Permissible voltage range 90 to 110% of rated voltage

Power consumption Max. 5W (for max. load)

Display method

Comm.

Memory retention Approx. 10 years (non-volatile semiconductor memory type)

Insulation resistance Over 100MΩ (500VDC megger)

Insulation type

Dielectric strength 1,000VAC 50/60Hz for 1 min (between power source terminal and input terminal)

Vibration

Noise immunity

Environ

-ment

Protection structure IP20(IEC standard)

Accessories Expansion connector: 1, module lock connector: 2

Approval

Weight

1:

※

2: The weight includes packaging. The weight in parenthesis is for unit only.

※

Environment resistance is rated at no freezing or condensation.

※

※1

24VDC

None- parameter setting and monitoring is available at external devices (PC, PLC, etc.)

COM1

(Master,

PLC)

COM2

(Master,

Group)

Connection

method

RS485/RS422 Ethernet

Protocol Modbus RTU, PLC ladderless comm. Modbus TCP

Connection

method

RS485/RS422 Ethernet

Protocol Modbus RTU Modbus TCP

PC loader TTL (Modbus RTU protocol)

Double insulation or reinforced insulation (mark: , dielectric strength between the measuring input part

and the power part : 1kV)

0.75mm amplitude at frequency of 5 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Square shaped noise by noise simulator (pulse width 1㎲) ±0.5kV R-phase, S-phase

Ambient temp. -10 to 50℃, storage: -20 to 60℃

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

※2

approx. 219g (approx. 147g) approx. 200g (approx. 129g)

Voltage of power supply/communication terminal placed in the backside of TMH2/4 Series (basic control module)

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-37

TMH Series

-|Transparent setting guide|-

CT1

Error Display

Status

Indicator

PRW ON (red) ON (green)

※

3

CH

※

1: Input error: input value is below the input range (LLLL) / input value exceeds input range (HHHH) / input sensor wire is

Input error

Flash (red) Flash (red)

down or input sensor is disconnected (OPEN).

※

2: Remote SV error: communication error of Remote SV master and internal communication / input of master channel is

LLLL/HHHH/OPEN when the channel is subjected to display PV.

※

3: An indicator of relative channel flashes.

After main cause of the error is solved, error status is cleared and the device is returned to the normal operation

automatically

Dimensions

● Rail Lock position:

mounting with bolts

30 30

12

2-Ø4.1

※

1

Remote SV error

● Rail Lock position:

mounting on DIN Rail

※

2

(unit: mm)

100

109

119

100

110

85

Unit Description

Control module

8

3

7

9

10

1. Input/Output terminal

4

1

[Front/Side/Top]

5

6

11

2

9

10

For specific information about terminal formation,

please refer to '▣ Connections and Isolated Block Diagram'.

2. Power/Comm. terminal [basic module only]

Supplies power to both basic control/expansion module and communicates with one or more module.

3. CT input terminal

When using the CT input terminal, remove the rubber cap and connect CT in the same

direction with right image.

Connect CT with CICT4-

When connecting CT connector and CT input terminal,

※

(CT connector cable, sold separately).

align the concave part (凹) and the convex part (凸).

8

2

[Bottom]

Back

35mm

DIN RAIL

CT4

CT3

CT2

J-38

Front

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

Control module

4. Indicator

4

1

[Front/Side/Top]

3

8

7

9

5

6

10

11

2

10

9

8

2

[Bottom]

●TMH2 Series

Status

Indicator

LED 1 LED 2

PWR (green)

※

3

Initial

power ON

※

1

CH1 (red) ON Flash

LED 1

CH2 (red) ON Flash

(red) ON

(red) ON

Control

output

ON ON

※

4

※

5

(yellow) Flash (4,800bps) Module comm. status

AL1 (yellow) Flash (9,600bps)

AL2 (yellow) Flash (19,200bps)

LED 2

AL3 (yellow) Flash (38,400bps)

AL4 (yellow) Flash (115,200bps)

- -

- -

- -

- -

●TMH4 Series

Indicator

LED 1 LED 2

Status

Initial power ON

※

PWR (green)

3

CH1 (red) ON Flash

LED 1

CH2 (red) ON Flash

-

※

1

Control

output

ON ON

CH3 (red) ON Flash

CH4 (red) ON Flash

(yellow) Flash (4,800bps) Module comm. status

(yellow) Flash (9,600bps)

(yellow) Flash (19,200bps)

LED 2

(yellow) Flash (38,400bps)

(yellow) Flash (115,200bps)

※

1: At the moment when power is on, the indicator of set communication speed flashes for 5 sec.

※

2: Indicator of the channel, which is in the process of auto-tuning, flashes at 1 sec interval.

※

3: When communicating with external device, PWR indicator flashes.

※

4: Turns on, when CH1 outputs cooling control in the heating&cooling control method.

※

5: Turns on, when CH2 outputs cooling control in the heating&cooling control method.

※

6: Displays communication status in control output, auto-tuning or operating RUN mode.

- -

- -

- -

- -

Alarm output

Auto

N.O.(Normally Open) N.C. (Normally Closed)

※

2

tuning

OFF (OPEN) ON (CLOSE)

OFF (CLOSE)

OFF

OFF

※

6

OFF ON OFF ON

OFF ON OFF ON

OFF ON OFF ON

OFF ON OFF ON

※

Auto tuning

2

※

6

ON (OPEN)

ON: normal / flash: abnormal / OFF: not communicating

5. PC loader port: PC loader port supports serial communication between single module and PC.

It needs EXT-US (converter cable)+SCM-US (USB/Serial converter, sold separately) for communicating.

6. Communication address setting switch (SW1): Set the communication address.

If changing the communication address by setting switch, use the flat head driver which is 2mm size or plastic driver. If

not, it may cause product damage.

7. Communication address group switch (SW2): When setting the communication address over 16, select +16.

8. Rail lock: Rail lock helps installing the device to DIN rail or with bolts.

9. Lock lever: Lock lever holds module body and base tightly.

10. Module lock connecter hole: When connect modules, insert module lock connector in the hole in order to enhance

coherence between modules.

11. END cover: When connect modules, remove END cover in order to connect expansion connector.

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-39

TMH Series

-|Transparent setting guide|-

Option module

5

5

7

2

1

3

4

8

6

7

6

7

1. Input/Output terminal

[Front/Side/Top]

For specific information about terminal formation, please refer to '

Connections and Isolated Block Diagram'.

2. Indicator

●TMHA [analog input/output module]

Indicator

LED 1 LED 2

LED 1

Status

PWR (green)

CH1 (red)

CH2 (red)

CH3 (red)

CH4 (red)

Initial power ON

※

2

-

※

1

Internal comm. Transmission output

ON ON

-

-

-

(yellow) Flash (4,800bps) Module comm. status

(yellow) Flash (9,600bps) ON (CH1)

(yellow) Flash (19,200bps) ON (CH2)

LED 2

(yellow) Flash (38,400bps) ON (CH3)

(yellow) Flash (115,200bps) ON (CH4)

●TMHE [digital input, alarm output module]

Status

Initial power ON

※

1

Internal comm.

Indicator

※

2

ON ON

-

-

-

-

-

LED 1 LED 2

LED 1

PWR (green)

CH1 (red)

CH2 (red)

CH3 (red)

CH4 (red)

(yellow) Flash (4,800bps) Module comm. status

AL5 (yellow) Flash (9,600bps)

AL6 (yellow) Flash (19,200bps)

LED 2

AL7 (yellow) Flash (38,400bps)

AL8 (yellow) Flash (115,200bps)

-

-

-

-

●TMHCT [CT input module]

Indicator

LED 1 LED 2

LED 1

Status

Initial power ON

※

PWR (green)

2

(red) ON (40.1 to 50.0A)

(red) ON (30.1 to 40.0A)

-

※

1

CT input

※

4

ON ON

(red) ON (20.1 to 30.0A)

(red) ON (10.1 to 20.0A)

(yellow) Flash (4,800bps) Module comm. status

(yellow) Flash (9,600bps) ON (40.1 to 50.0A)

LED 2

(yellow) Flash (19,200bps) ON (30.1 to 40.0A)

(yellow) Flash (38,400bps) ON (20.1 to 30.0A)

(yellow) Flash (115,200bps) ON (10.1 to 20.0A)

3. PC loader port: PC loader port supports serial communication between single module and PC.

It needs EXT-US (converter cable)+SCM-US (USB/Serial converter, sold separately) for communicating.

4. Communication address setting switch (SW1): Set the communication address.

If changing the communication address by setting switch, use the flat head driver which is 2mm size or plastic driver. If not, it may cause

product damage.

5. Rail lock: Rail lock helps installing the device to DIN rail or with bolts.

6. Lock lever: Lock lever holds module body and base tightly.

7. Module lock connecter hole:

When connect modules, insert module lock connector in the hole in order to enhance coherence between modules.

8. END cover: When connect modules, remove END cover in order to connect expansion connector.

[Bottom]

ON

ON

ON

ON

※

3

-

-

-

-

Alarm output

N.O.(Normally Open) N.C. (Normally Closed)

OFF

(OPEN)

ON

(CLOSE)

OFF

(CLOSE)ON(OPEN)

OFF ON OFF ON

OFF ON OFF ON

OFF ON OFF ON

OFF ON OFF ON

※

3

OFF ON OFF ON

OFF ON OFF ON

OFF ON OFF ON

OFF ON OFF ON

※

1: At the moment when power is on, the indicator

Internal

comm.

-

-

-

-

※

3

-

-

-

-

of set communication speed flashes for 5 sec.

※

2: When communicating with external device,

PWR indicator flashes.

※

3

: Displays internal communication status between

modules.

ON: normal / flash: abnormal / OFF: not

communicating

※

4

: The indicator corresponding to the certain

setting value of CT input flashes according to

the parameter

[CT Input Value Indication Lamp

LED 1: CT Input Value Indication Lamp1 / LED 2:

CT Input Value Indication Lamp2

].

J-40

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

Communication module

5

6

6

SENSORS

8

2

1

3

4

9

7

8

7

8

1. Communication port

[Front/Side/Top]

Communication ports are varied by model specification.

Please refer to '

Connections and Isolated Block Diagram' for more detail information.

2. Indicator

●TMHC-22LE [RS422/RS485 ladderless communication module]

Status

Indicator

Initial power ON

PWR Flash (4,800bps) Flash (green)

LED 1 LED 2

LED1

(red)

(red)

(red)

(red)

Flash (9,600bps) Flash (TMH2/4)

Flash (19,200bps) Flash (TMHA)

Flash (38,400bps) Flash (TMHE)

Flash (115,200bps) Flash (TMHCT)

(yellow) Flash (4,800bps)

(yellow) Flash (9,600bps)

LED2

(yellow) Flash (19,200bps)

(yellow) Flash (38,400bps)

(yellow) Flash (115,200bps)

※

1: At the moment when power is on, the indicator of set communication speed flashes for 5 sec.

※1

Internal comm. Connection PLC ladderless comm.

-

- -

- -

- -

- -

-

-

-

-

-

ON Flash

ON (TMH2/4)

ON (TMHA)

ON (TMHE)

ON (TMHCT)

●TMHC-22EE [Ethernet communication module]

Status

Indicator

PWR(green)

LED1

(red)

(red)

LED 1 LED 2

(red)

(red)

(yellow)

(yellow)

LED2

(yellow)

(yellow)

(yellow)

Initial power ON Internal comm. Connection

ON Flash (external device)

-

-

-

-

-

Flash (TMH2/4)

Flash (TMHA)

Flash (TMHE)

Flash (TMHCT)

ON

-

Sequence-ashing

vertically for 5 sec

-

-

-

-

-

-

-

Flash (Ethernet

comm.)

ON (TMH2/4)

ON (TMHA)

ON (TMHE)

ON (TMHCT)

3. PC loader port: PC loader port supports serial communication between single module and PC. It needs EXT-US (converter cable)+SCMUS (USB/Serial converter, sold separately) for communicating.

4. Communication address setting switch (SW1): Set the communication address.

If changing the communication address by setting switch, use the flat head driver which is 2mm size or plastic driver. If not, it may cause

product damage.

5. Communication mode switch (SW2): Select communication mode between RS485 and RS422. (TMHC-22LE only)

6. Rail lock: Rail lock helps installing the device to DIN rail or with bolts.

7. Lock lever: Lock lever holds module body and base tightly.

8. Module lock connecter hole: When connect modules, insert module lock connector in the hole in order to enhance coherence between

modules.

9. END cover: When connect modules, remove END cover in order to connect expansion connector.

[Bottom]

Flash (red, Reading)

(Sending)

-

-

-

-

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

J-41

(X)

Field Network

Devices

TMH Series

-|Transparent setting guide|-

CT1

CT4

Connections and Isolated Block Diagram

Use terminals of size specied below.

※

b

a

<Round>

a

b

<Forked>

a Min. 3.0mm Min. 3.0mm

b Max. 5.8mm Max. 5.8mm

Control module

●CT input terminal on the top ● Power/Comm. terminal on the back

※

When use the CT input terminals,

remove the robber cap.

※

Connect CT with CICT4-□(CT connector cable,

sold separately).

●TMH2 Series

CH1

RELAY OUT1: 250VAC 3A 1a

CURRENT OUT1:

DC0/4-20mA Load 500Ω

SSR OUT1:

12VDC ±3V 20mA Max.

CH2

RELAY OUT2: 250VAC 3A 1a

CURRENT OUT2:

DC0/4-20mA Load 500Ω

SSR OUT2:

12VDC ±3V 20mA Max.

+

㎃

-

+

㎃

-

+++

V

---

V

TC

㎃

+

-

TC

㎃

RTD

+++

---

RTD

A

B

B'

V

A

B

B'

+

V

-

Back

[basic module only]

24VDC

+

-

CT3

CT2

Front

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

DIGITAL

INPUT 1

RELAY AL1 OUT1

250VAC 3A 1a

RELAY AL2 OUT1

250VAC 3A 1a

DIGITAL

INPUT 2

RELAY AL3 OUT1

250VAC 3A 1a

RELAY AL4 OUT1

250VAC 3A 1a

●TMH4 Series

CH1

+++++

㎃

V

-----

RELAY OUT1:

250VAC 3A 1a

CURRENT OUT1:

DC0/4-20mA Load 500Ω

SSR OUT1:

12VDC ±3V 20mA Max.

CH2

㎃

V

RELAY OUT2:

250VAC 3A 1a

CURRENT OUT2:

DC0/4-20mA Load 500Ω

SSR OUT2:

12VDC ±3V 20mA Max.

A

1

B

2

B'

TC

㎃

+

-

TC

㎃

3

RTD

4

+

+

V

-

-

5

A

6

B

7

B'

8

RTD

9

+

+

V

-

-

10

RS485

(A+)

11

12

13

14

15

16

17

18

19

20

RS485

(B-)

-

+

B'

B

A

RTD

-

+

B'

B

A

RTD

V

V

S.G

RELAY OUT3:

250VAC 3A 1a

-

CURRENT OUT3:

㎃

DC0/4-20mA Load 500Ω

+

SSR OUT3:

12VDC ±3V 20mA Max.

----V

+++++

TC

RELAY OUT4:

250VAC 3A 1a

-

CURRENT OUT4:

㎃

DC0/4-20mA Load 500Ω

+

SSR OUT4:

12VDC ±3V 20mA Max.

-

V

+

TC

㎃

CH3

㎃

CH4

Option module

●TMHA [analog input/output module] ●TMHE [digital input, alarm output module]

CH1

+

㎃

V

-

CURRENT OUT1

DC0/4-20mA

Load 500Ω

+++

---

RTD

㎃

B

B'

+

-

A

A

CH2

+

㎃

V

-

CURRENT OUT2

DC0/4-20mA

Load 500Ω

B

+

B'

-

RTD

+

㎃

-

J-42

11

1

2

3

4

5

6

7

8

9

10

-

㎃

+

12

B'

13

B

A

RTD

B'

B

A

RTD

+++

TC

-

㎃

+

TC

14

15

16

17

18

19

20

CURRENT OUT3

DC0/4-20mA

Load 500Ω

---

-

㎃

V

+

CH3

CURRENT OUT4

DC0/4-20mA

Load 500Ω

-

-

㎃

V

+

+

CH4

DIGITAL

INPUT 1

DIGITAL

INPUT 2

DIGITAL

INPUT 3

DIGITAL

INPUT 4

DIGITAL

INPUT 5

DIGITAL

INPUT 6

DIGITAL

INPUT 7

DIGITAL

INPUT 8

11

1

12

2

13

3

14

4

15

5

16

6

17

7

18

8

19

9

20

10

RELAY AL1 OUT

250VAC 3A 1a

RELAY AL2 OUT

250VAC 3A 1a

RELAY AL3 OUT

250VAC 3A 1a

RELAY AL4 OUT

250VAC 3A 1a

RELAY AL5 OUT

250VAC 3A 1a

RELAY AL6 OUT

250VAC 3A 1a

RELAY AL7 OUT

250VAC 3A 1a

RELAY AL8 OUT

250VAC 3A 1a

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

●TMHCT [CT input module]

1

CT INPUT 1

CT INPUT 2

CT INPUT 3

CT INPUT 4

Communication module

●TMHC-22LE

RS485(A+)

RS485(B-)

SG

RS485 (A+)

RS485 (B-)

SG

CT

2

3

4

CT

5

6

CT CT

7

8

9

CT

10

[RS422/RS485 ladderless communication module]

RS422 R(A)

RS422 R(B)

RS422 T(B)

RS422 T(A)

RS422 R(A)

RS422 R(B)

RS422 T(B)

RS422 T(A)

1

2

SG

3

COM1

4

5

6

7

SG

8

COM2

9

10

11

CT INPUT 5

CT

SENSORS

12

13

14

CT INPUT 6

CT

CONTROLLERS

MOTION DEVICES

15

16

CT INPUT 7

SOFTWARE

17

18

19

CT INPUT 8

CT

20

●TMHC-22EE [Ethernet communication module]

11

12

Ethernet Port 1

13

14

15

Ethernet Port 2

16

17

18

SPEED

LINK/ACT

SPEED

LINK/ACT

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

19

20

(Q)

Converters

Sold Separately

Communication converter

SCM-WF48

( Wi-Fi to RS485·USB wireless

communication converter)

SCM-US

(USB to Serial converter)

SCM-US48I

(USB to RS485 converter)

EXT-US

(converter cable)

SCM-38I

(RS232C to RS485 converter)

J-43

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TMH Series

-|Transparent setting guide|-

Sold Separately

Current transformer (CT)

CSTC-E80LN

10.5

CSTC-E200LN

13.5

CSTS-E80PP

Ø6

21.4

15.4

0.5

Ø23.3

Ø7

7

Ø37.1

Ø13

10

725.4

K (black)

L (white)

15026.5

K (black)

L (white)

15040.8

2.9

3

(unit: mm)

3

(unit: mm)

4.5

3.8

10

Ta=25

℃

1

0.1

0.01

OUTPUT IN VOLTS RMS (V)

0.001

10

0.1

0.01

OUTPUT IN VOLTS RMS (V)

0.001

SENSED CURRENT IN AMPS RMS (Io)

10

1 10 100 1000

0.1

SENSED CURRENT IN AMPS RMS (Io)

Ta=25

℃

1

0.1 1 10 100 1000

Ta=25

℃

1

F=50Hz

100Ω

10Ω

F=50Hz

100Ω

10Ω

F=50Hz

100Ω

10Ω

Max. load current: 80A (50/60Hz)

※Max. load current for TMH Series

is 50A.

Current ratio: 1/1000

Wire wounded resistance:

31Ω±10%

Max. load current: 200A (50/60Hz)

※Max. load current for TMH Series

is 50A.

Current ratio: 1/1000

Wire wounded resistance:

20Ω±10%

10.5

40.2

Ø3.4

※

Do not supply primary current in case that CT output is open. High voltage will be generated in CT output.

※

The current for above CTs is 50A same but inner hole sizes are different. Please use this for your environment.

31

2.7

10

(unit: mm)

CT connector cable

CICT4-1 (cable length: 1m)

CICT4-3 (cable length: 3m)

When connecting CT connector and CT input terminal, align the concave part (凹) and the convex part (凸).

※

J-44

0.1

0.01

OUTPUT IN VOLTS RMS (V)

0.001

0.1 1 10 100 1000

SENSED CURRENT IN AMPS RMS (Io)

Pin number Cable color CT connection

1 Brown CT2/4

2 Blue CT2/4

3 White CT1/3

4 Black CT1/3

Max. load current: 80A (50/60Hz)

※

Max. load current for TMH Series

is 50A.

Current ratio: 1/1000

Wire wounded resistance

31Ω±10%

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

②

Installation

1. Separating base terminal block

3. Mounting with bolts

①

M4 Bolt

②

SENSORS

CONTROLLERS

MOTION DEVICES

②

①

Push the lock lever at the bottom of the module.

①

Pull the body of the module and open up.

②

※

When connecting base terminal block, align the upper

concave part (凹) of the body and the upper convex part

(凸) of the base. If the upper parts are not align correctly, it

may damage to the inner connector.

2. Connection between modules

TMH - 2 B

(basic module)

TMH - 2 E

(expasion module)

TMH - 2 E

(expasion module)

①

②

③

④ ⑤ ⑥

Remove END cover of each module

①

(except END cover of the rst and last module).

Insert expansion connector.

②

Put all together tightly (max. 31 units).

③

Insert module lock connector.

④

Push module lock connector and insert in lock connector

⑤

hole of another module on the side.

Push module lock connector to the lock direction.

⑥

※

Supply adequate power for power input specications

and overall capacity.

(Max. power when connecting 32 modules:32×5W=160W)

①

Pull the rail lock at the top and bottom of the module.

①

Insert bolts and x it on rail lock.

②

(xing torque is 0.5 to 0.9N.m.)

4. Mounting on DIN rail

4.1 Installing

①

②

Hang the top rail lock to DIN rail.

①

Push and press the module to down direction.

②

4.2 Removing

①

②

Press the module down.

①

Pull the module body forward.

②

※

Use end plates (sold separately, not available from

Autonics) to x rmly.

END PLATE

※

Install the module vertically.

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

Expansion

connector

Module lock

connector

J-45

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TMH Series

-|Transparent setting guide|-

Input Type and Range

Input type

K(CA)

J(IC)

E(CR)

T(CC)

Thermocouple

RTD

Analog

B(PR) 1 B(PR) 0 to 1800 32 to 3272

R(PR) 1 R(PR) 0 to 1750 32 to 3182

S(PR) 1 S(PR) 0 to 1750 32 to 3182

N(NN) 1 N(NN) -200 to 1300 -328 to 2372

C(TT) 1 C(TT) 0 to 2300 32 to 4172

G(TT) 1 G(TT) 0 to 2300 32 to 4172

L(IC)

U(CC)

Platinel II 1 PLII 0 to 1390 32 to 2534

Cu 50Ω 0.1 CU 50 -200.0 to 200.0 -200.0 to 392.0

Cu 100Ω 0.1 CU 100 -200.0 to 200.0 -200.0 to 392.0

JIS

standard

DIN

standard

Nickel 120Ω 1 NI12 -80 to 260 -112 to 500

Voltage

Current

JPt 100Ω 1 JPt100.H -200 to 650 -328 to 1202

JPt 100Ω 0.1 JPt100.L -200.0 to 650.0 -328.0 to 1202.0

DPt 50Ω 0.1 DPt50.L -200.0 to 600.0 -328.0 to 1202.0

DPt 100Ω 1 DPt100.H -200 to 650 -328 to 1202

DPt 100Ω 0.1 DPt100.L -200.0 to 650.0 -328.0 to 1202.0

0 to 10V

0 to 5V

1 to 5V

0 to 100mV

0 to 20mA

4 to 20mA

Decimal

point

1 K(CA).H -200 to 1350 -328 to 2463

0.1 K(CA).L -200.0 to 1350.0 -328.0 to 2463.0

1 J(IC).H -200 to 800 -328 to 1472

0.1 J(IC).L -200.0 to 800.0 -328.0 to 1472.0

1 E(CR).H -200 to 800 -328 to 1472

0.1 E(CR).L -200.0 to 800.0 -328.0 to 1472.0

1 T(CC).H -200 to 400 -328 to 752

0.1 T(CC).L -200.0 to 400.0 -328.0 to 752.0

1 L(IC).H -200 to 900 -328 to 1652

0.1 L(IC).L -200.0 to 900.0 -328.0 to 1652.0

1 U(CC).H -200 to 400 -328 to 752

0.1 U(CC).L -200.0 to 400.0 -328.0 to 752.0

-

-

-

-

-

-

Display Temperature range(℃) Temperature range(℉)

AV1 0 to 1000

AV2 0 to 5000

AV3 1000 to 5000

AMV1 0 to 1000

AMA1 0 to 2000

AMA2 400 to 2000

J-46

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

Functions

1. Analog input special function

In case of analog input, it displays the applied measured value of the set special function.

1) Linear

It applies low-limit scale and high-limit scale to low-limit input value and high-limit input value and displays this values.

E.g.) In case of input type: 0-10V, low-limit input value: 0V, high-limit input value: 10V, low-limit scale: 0, high-limit scale:

1000, present input value is 2V and the display value is 200.

2) Root

In case of voltage, current (shunt) input, this mode is used when input value is calculated by Root(

display value. Dierential pressure signal of dierential pressure ow meter is calculated Root( ) for the to-be measured

ux. This function is used to measure ux by input value.

E.g.) In case of input type: 0-10V, low-limit input value: 0V, high-limit input value: 10V, low-limit scale: 0, high-limit scale:

1000, present input value is 2V and the display value is 447.

3) Square

In case of voltage, current (shunt) input, this mode is used when input value is calculated by square for the desired

display value.

E.g.) In case of input type: 0-10V, low-limit input value: 0V, high-limit input value: 10V, low-limit scale: 0, high-limit scale:

1000, present input value is 2V and the display value is 40.

2. Remote SV

SV setting is available to set using PV or SV of the other module/channel not the direct setting of the module/channel.

Set the other module’s (RSV Master) address, channel, and the target value (PV or SV).

Control module

Internal communication

) for the desired

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

Selectable Master PV/SV Selectable Master PV/SV

Remote SV

Local SV

Master channel

(CH1)

Control Control Control

Remote SV

Local SV

RSV using channel

(CH2)

Remote SV

Local SV

RSV using channel

(CH3)

Input Input Input

E.g.) RSV function is available when PV of TMHA (address 33, channel 1) is used for SV of TMH2(address 1, channel 3).

Set RSV Master setting of TMH2. RSV Master address: 33, RSV Master channel: 1, RSV Master channel target: PV

TMH2

Address: 1

CH 3

TMHA

Address: 33

CH 1

Device A

Heater B

SV

PV

Analog input

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-47

TMH Series

-|Transparent setting guide|-

3. Alarm

Alarm output (Alarm) is output terminal and alarm (Event) is for alarm setting by each channel.

One channel is available to set total 4 alarms (Event 1 to 4).

One alarm consists of alarm mode, option, set value, hysteresis, delay time, output address, and channel settings, etc.

● Using TMHE Option module alarm output

TMH2/4 is connectable to TMHE option module. (according to address setting)

TMH4 does not have built-in alarm and TMHE option module outputs alarm when alarm condition occurs by internal

communication.

Several alarm (Event 1 to 4) is selectable as one alarm output and AND/OR operation is selectable at TMHE.

4. CT input value indicators channel

The indicator of TMHCT turns ON by the input value of CT.

Indicator

LED 1 LED 2

LED 1

LED 2

Set at LED 1: CT Input Value Indication Lamp1 / LED 2: CT Input Value Indication Lamp2 of TMHC.

Status

PWR (green) ON

(red) ON (40.1 to 50.0A)

(red) ON (30.1 to 40.0A)

(red) ON (20.1 to 30.0A)

(red) ON (10.1 to 20.0A)

(yellow)

(yellow) ON (40.1 to 50.0A)

(yellow) ON (30.1 to 40.0A)

(yellow) ON (20.1 to 30.0A)

(yellow) ON (10.1 to 20.0A)

CT input

-

5. User parameter group

At DAQMaster, user parameter group of each module, TMH2/4/A/E/CT/C, is available to set.

This function is able to set the frequently used parameters to the user parameter group, so you can quickly and easily set

the parameter settings.

In addition, the parameters set to the user group are configured sequentially and consecutively in TMHC, so it can

improve efficiency of communication to the master device via batch read/write process.

For more information, refer to the user manual for communication.

Visit our website (www.autonics.com) to download the DAQMaster program and the manuals.

J-48

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

Communication Setting

It is for parameter setting and monitoring via external devices (PC, PLC, etc.).

In case of TMHC, set COM1/2 both.

Interface

Protocol

Connection

method

Maximum

connection

Synchronization type Asynchronous

Communication method Two-wire half duplex

Communication eective range Max. 800m

Communication speed 4800, 9600 (default), 19200, 38400, 115200 bps

Response time 5 to 99ms (default: 20ms)

Start bit 1-bit (xed)

Data bit 8-bit (xed)

Parity bit None (default), Odd, Even

Stop bit 1bit, 2bit (default)

Mac address [Ethernet comm. module: TMHC-22EE]

After connecting Ethernet module (TMHC-22EE), can check Mac address in ‘Property - Mac address’ item.

For more details as like method of module connection, refer to the user manual for TMH.

Mac address is the network address for Ethernet communication.

※

DIP switch configuration [PLC ladderless comm. module: TMHC-22LE]

After separating base terminal block, set communication speed, stop bit, PLC connection and protocol by using a internal

DIP switch. (Default: All switches OFF(congure via PC))

※ When connecting PLC, apply setting value to COM1 only.

TMH2/4/TMHA/TMHE/TMHCT/ Modbus RTU

TMHC

-22LE Modbus RTU, PLC ladderless comm.

-22EE Modbus TCP

TMH2/4/TMHA/TMHE/TMHCT/ RS485

TMHC

TMH2/4

-22LE RS422, 485

-22EE Ethernet

32unit (address: 01 to 32)

(in case connecting TMHC module: 16 units (address: 01 to 16))

TMHA/TMHE/TMHCT Each module 16 units

TMHC 16 control modules and 16 option modules per 1 TMHC module

DIP SW1 DIP SW2

OFF

ON

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

- SW1

1

2

OFF OFF Comm. parameter setting

OFF ON 19200bps

ON

OFF

ON ON 115200bps

Comm. speed

38400bps

- SW2

1

2 3 4

OFF OFF OFF OFF Comm. parameter setting

OFF OFF OFF ON MODBUS(RTU) protocol

OFF ON OFF

OFF

OFF OFF ON ON LS GLOFA-GM Series special protocol

OFF ON OFF OFF LS XGT/XGB Series special protocol

OFF ON OFF ON

OFF ON ON OFF

OFF ON ON ON OMRON SYSMAC Series special protocol

PLC connection and Protocol

LS MASTER-K Series special protocol

MITSUBISHI MELSEC Series special protocol

Q/QnACPU common command (1401/0401)

MITSUBISHI MELSEC Series special protocol

ACPU common Command (WW/WR)

3

Stop bit

4

OFF OFF Comm. parameter setting

OFF ON Stop bit: 1bit

OFF

ON

ON ON

Stop bit: 2bit

-

J-49

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

TMH Series

-|Transparent setting guide|-

Communication Setting

Application of system organization

RS232C/

USB/Wi-Fi

Comm.

converter

Computer

※

It is recommended to use Autonics communication converter; SCM-WF48 (Wi-Fi to RS485·USB wireless communication

converter, sold separately), SCM-US48I (USB to RS485 converter, sold separately), SCM-38I (RS232C to RS485

converter, sold separately).

Please use twisted pair wire, which is suitable for RS485 communication, for SCM-WF48, SCM-US48I and SCM-38I.

ON

RS485

B(-)

OFF

A(+)

Communication address setting

Set the communication address with the communication address setting switch (SW1). (default: [SW1] 1)

SW

Module

TMH4/2

TMHC 16 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

TMHA 48 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

TMHE 64 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63

TMHCT 80 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79

※

When using TMHC, in case connecting only TMHC to Master (PC, PLC, etc.), communication address of TMHC and

TMH2/4 Series control module can be duplicated. However, in case connecting both TMHC and TMH2/4 Series control

module to Master, communication address must not be duplicated. (If the TMHC and TMH modules communicate to

Master at the same time, a communication error may occur.)

0 1 2 3 4 5 6 7 8 9 A B C D E F

+0

16 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

+16

+0

32 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

+16

Caution for communication interface setting

When changing the setting value related to communication interface, reboot the device for normal operation.

Terminating resistance

(100 to 120Ω)

A(+) B(-) A(+) B(-) A(+) B(-)

RS485

DEVICE

#1

RS485

DEVICE

#2

RS485

DEVICE

#30

B(-)

A(+)

RS485

DEVICE

#31

J-50

Multi-Channel Modular Type High Performance

-|Transparent setting guide|-

Proper Usage

Cautions during use

Follow instructions in ‘Cautions during Use’. Otherwise, It may cause unexpected accidents.

Check the polarity of the terminals before wiring the temperature sensor.

For RTD temperature sensor, wire it as 3-wire type, using cables in same thickness and length.

For thermocouple (CT) temperature sensor, use the designated compensation wire for extending wire.

Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line filter or varistor at power line and shielded wire at input

signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

Do not apply excessive power when connecting or disconnecting the connectors of the product.

Install a power switch or circuit breaker in the easily accessible place for supplying or disconnecting the power.

Do not use the unit for other purpose (e.g. voltmeter, ammeter), but temperature controller.

When changing the input sensor, turn off the power first before changing.

After changing the input sensor, modify the value of the corresponding parameter.

Power supply should be insulated and limited voltage/current or Class 2, SELV power supply device.

Do not overlapping communication line and power line.

Use twisted pair wire for communication line and connect ferrite bead at each end of line to reduce the effect of external

noise.

Make a required space around the unit for radiation of heat.

For accurate temperature measurement, warm up the unit over 20 min after turning on the power.

Mounting multiple devices in any way other than the specied mounting method may cause heat to build up inside,

which will shorten their service life. If there is a possibility of the ambient temperature rising to a temperature above the

specied temperature range, take steps, such as installing fans, to cool the device. Be sure that the cooling method in not

cooling just the terminal block. If only the terminal block is cooled, measurement errors may occur.

Make sure that power supply voltage reaches to the rated voltage within 2 sec after supplying power.

Do not wire to terminals which are not used.

Install DIN rail vertically from the ground.

This unit may be used in the following environments.

Indoors (in the environment condition rated in ‘Specifications’)

①

Altitude max. 2,000m

②

Pollution degree 2

③

Installation category II

④

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

J-51

Loading...

Loading...