Autonics MD5 Series Catalog Page

MD5 Series

Model

MD5-HD14

MD5-HF14

MD5-HF14-AO

MD5-HF28

MD5-ND14

Power supply

20-35VDC

※

1

100-220VACᜠ 50/60Hz

20-35VDC

※

1

Allowable voltage range

90 to 110% of the rated voltage

Max. current consumption

※

2

3A5A3A

RUN current

※

3

0.4-1.4A/Phase

1.0-2.8A/Phase

0.5-1.5A/Phase

STOP current

27 to 90% of RUN current (set by STOP current switch)

25 to 75% of RUN

current volume)

Drive method

Bipolar constant current pentagon drive

Basic step angle

0.72˚/step

Resolution

1, 2, 4, 5, 8, 10, 16, 20, 25, 40, 50, 80, 100, 125, 200, 250-division (0.72 to 0.00288/Step)

1, 2-division (0.72, 0.36 /step)

Min. 1

Min. 10㎲ (CW, CCW),

Min. 1ms (HOLD OFF)

50% (CW, CCW)

Below 130ns (CW, CCW)

[H]: 4-8VDCᜡ, [L]: 0-0.5VDC

7.5-14mA (CW, CCW), 10-16mA (HOLD OFF, DIVISION SELECTION, ZERO OUT)

※

4

Max. 500kHz (CW, CCW)

Input resistance

270Ω (CW, CCW),

390Ω (HOLD OFF, DIVISION SELECTION),

10Ω (ZERO OUT)

270Ω (CW, CCW),

390Ω (HOLD OFF),

10Ω (ALARM)

270Ω (CW, CCW),

10Ω (ZERO OUT)

Insulation resistance

Over 100MΩ (at 500VDC megger, between all terminals and case)

Dielectric strength

1000VAC 50/60Hz for 1min (between all terminals and case)

Noise immunity

±500V the square wave

noise (pulse width: 1μs)

by the noise simulator

±2kV the square wave noise (pulse wid h: 1μs) by the noise simulator

±500V the square wave

)

by the noise simulator

Vibration

Mechanical

1.5mm amplitude at frequency 5 to 60Hz (for 1 min) in each X, Y, Z direc ion for 2 hours

Malfunction

1.5mm amplitude at frequency 5 to 60Hz (for 1 min) in each X, Y, Z direc ion for 10 min

Environment

0 to 40℃,

storage: -10 to 60℃

0 to 50

0 to 40℃,

storage: -10 to 60℃

Ambient humi.

35 to 85%RH, storage: 35 to 85%RH

Approval

ᜢ

ᜢ ᜧ

ᜢ ᜧ

Weight

Approx. 327.5g

(approx. 220g)

Approx. 840g

(approx. 680g)

Approx. 820g

(approx. 660g)

Approx. 1.35kg

(approx. 1.2kg)

Approx. 183g

(approx. 130g)

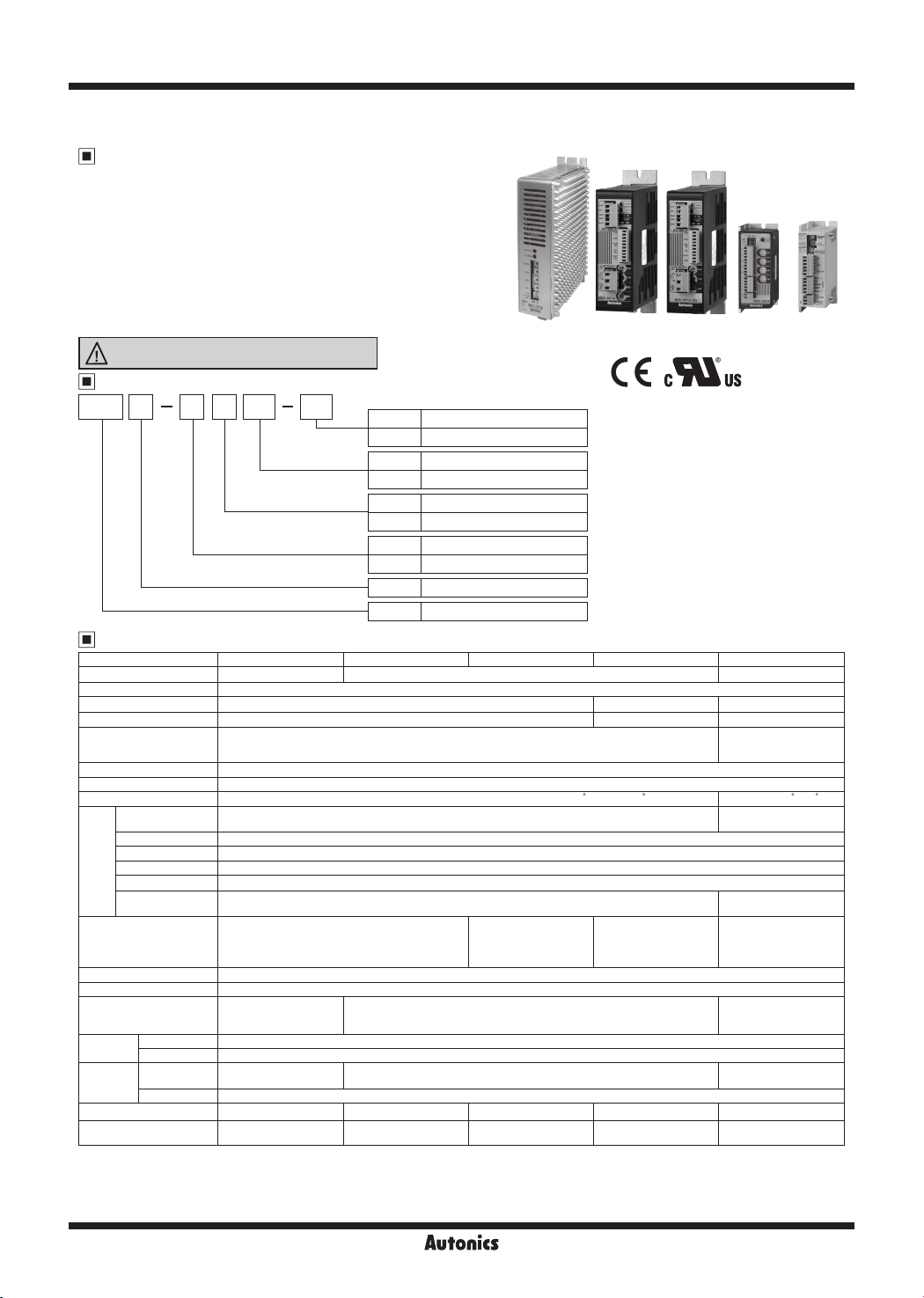

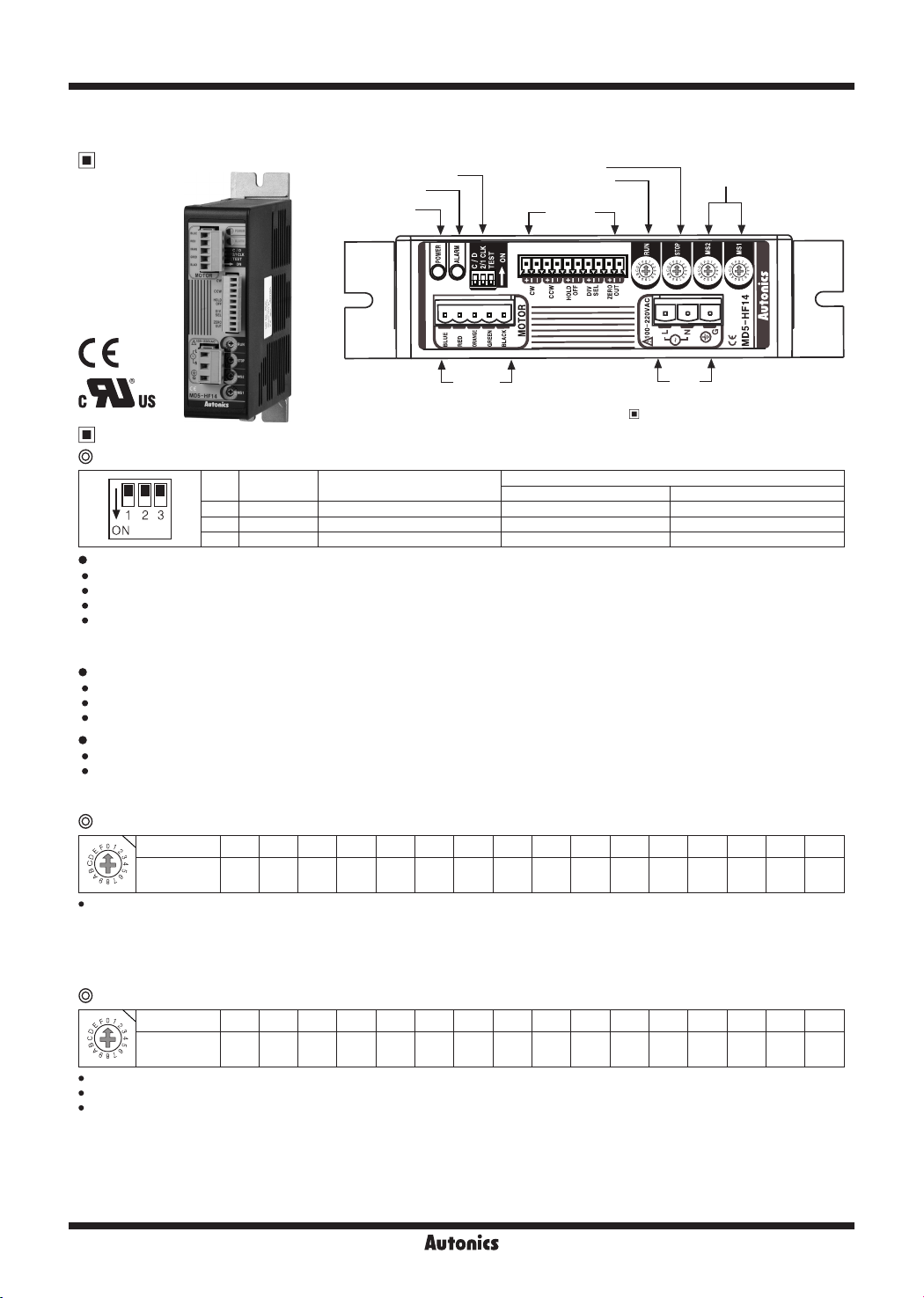

Small, Light, High Speed & Torque 5-Phase Stepper Motor Driver

Features

● Bipolar constant pentagon drive method

● Includes auto current down and self-diagnosis function

● Low speed rotation and high accuracy controlling with

microstep-driving (MD5-HD14, MD5-HF14, MD5-HF14-AO,

MD5-HF28)

[Max. resolution 250 division: In case of 5-phase stepper motor of

which basic step angle is 0.72°, it enables to control up to 0.00288°

per pulse and it requires 125,000 pulses per rotation.]

● Photocoupler input insulation method to minimize the

eects from external noise

Please read “Safety Considerations”

in the instruction manual before using.

Ordering Information

MD 145 H F

Step type (resolution)

Motor phase

Item

※

1: Except MD5-ND14

Specifications

~

RUN current

Power supply

ᜡ

No mark Zero point excitation output

Output

AO Alarm output

14 1.4A/Phase

28 2.8A/Phase

D 20-35VDC

F 100-220VAC

H Micro step (250-division)

N Normal Step

5 5-phase

MD Motor Driver

I

I

※

1

MD5-HF14

※

※

※

※

MD5-HF14-AO

(only for MD5-HF14(-AO),

MD5-HF28 model)

KR-55MC can be replaced with MD5-HD14.

KR-5MC can be replaced with MD5-ND14.

MD5-MF14 can be replaced with MD5-HF14.

KR-505G can be replaced with MD5-HF28.

I

MD5-HF28

I

MD5-HD14

ᜡ

MD5-ND14

Pulse wid h

Duty rate

Rising/Falling ime

Pulse input voltage

Pulse input current

Input pulse

characteristic

Max. input pulse

frequency

※

5

㎲ (CW, CCW), Min. 1ms (HOLD OFF)

I

Ambient temp.

※

6

1: When using over 30VDC power supply, torque characteristics are improved but the driver temperature raise. The unit should be installed at the well ventilation

※

environment.

2: Based on ambient temperature 25℃, ambient humidity 55%RH.

※

3: RUN current varies depending on the input RUN frequency and max. RUN current at the moment varies also varies depending on the load.

※

4: In case of MD5-HF14-AO, MD5-ND14, there are no DIVISION SELECTION, ZERO OUT function.

※

5: Max. input pulse frequency is max. frequency to be input and is not same as max. pull-out frequency or max. slewing frequency.

※

6: The weight includes packaging. The weight in parenthesis is for unit only.

※

AA-4

℃, storage: -10 to 60℃

I

I

I

Autonics

I

I

current (set by STOP

Max. 50kHz (CW, CCW)

390Ω (HOLD OFF,

DIVISION SELECTION),

390Ω

(CW, CCW, HOLD OFF)

noise (pulse width: 1μs

I

ᜢ ᜧ ᜢ

I

I

Environment resistance is rated at no freezing or condensation.

※

I

I

I

I

5-Phase Stepper Motor Driver (1.4A/Phase, DC Power)

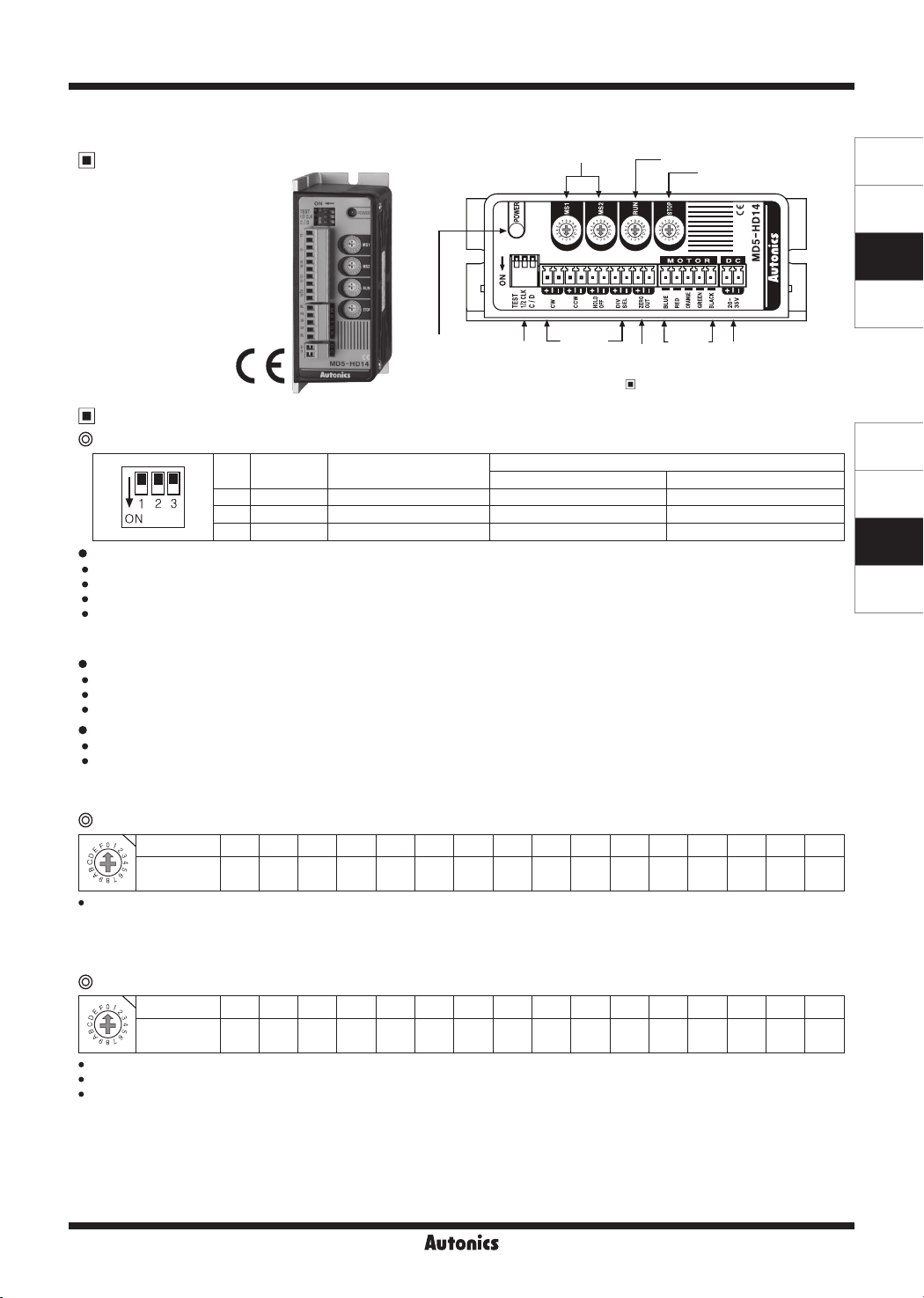

5-Phase Micro Stepper Motor Driver [MD5-HD14]

Unit Description

Resolution switch

RUN current switch

STOP current switch

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

Input

terminal

Refer to

※

Motor

Zero

connection

output

terminal

'

Specifications'

Power

terminal

.

Power indicator

Functions

~

@

Function selection DIP switch

No. Name Function

l~!~~~--------r--~

TEST

•

Self diagnosis function is for motor and driver test.

•

This function makes the motor rotate with 30rpm in full step. Rotation speed varies with resolution settings.

•

Rotation speed = 30rpm/resolution

•

In 1-pulse input method, it rotates to CCW, and in 2-pulse input method, it rotates to CW.

•

※

Be sure that the TEST switch is OFF before supplying the power.

If the TEST switch is ON, he motor operates immediately and it may be dangerous.

1/2 CLK

•

1/2 CLK switch is to select pulse input method.

•

1-pulse input method: CW → operating rotation signal input, CCW → rotation direction signal input ([H]: CW, [L]: CCW)

•

2-pulse input method: CW → CW rotation signal input, CCW → CCW rotation signal input.

•

C/D (auto current down)

•

This function is to reduce the current provided for motor automatically for preventing severe motor's heat when motor stops.

•

If motor RUN pulse is not applied, the current provided for motor reduces as the set STOP current.

•

※

Be sure that when motor RUN current is reduced, the stop torque of motor also reduced.

※

Set the STOP current by the STOP current switch.

Setting RUN current

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

Current

1,

Setting RUN current is for the current provided for motor when the motor runs.

•

※

※

※

※

1,

Setting STOP current is for the current provided for motor when the motor stops for preventing severe motor's heat.

•

This setting is applied when using C/D (current down) function.

•

Setting value of STOP current is percentage (%) ratio of the set RUN current.

•

E.g.) Set RUN current as 1.4A and STOP current as 40%.

※

※

※

(A/Phase)

®J I I I I I I I I I I I I I I I I I

When RUN current is increased, RUN torque of the motor is also increased.

When RUN current is set too high, the heat is severe.

Set RUN current wi hin the range of motor's rated current according to its load.

Change RUN current only when the motor stops.

Setting STOP current

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

% 27 31 36 40 45 50 54 58 62 66 70 74 78 82 86 90

w,

J I I I I I I I I I I I I I I I I I

STOP current is set as 1.4A×0.4=0 56A

When STOP current is decreased, STOP torque of the motor is also decreased.

When STOP current is set too low, the heat is lower.

Change STOP current only when the motor stops.

I

.-----I---,------------,--------

1 TEST Self diagnosis function 30rpm rotation Not use

2 1/2 CLK Pulse input method 1-pulse input method 2-pulse input method

3 C/D Auto current down Not use Use

0.4 0.5 0.57 0.63 0.71 0.77 0.84 0.9 0.96 1.02 1.09 1.15 1.22 1.27 1 33 1.4

Function

selection

DIP switch

Switch position

ON OFF (default)

(Y)

Closed Loop

Stepper System

(Z)

Stepper Motors

(AA)

Drivers

(AB)

Motion

Controllers

Autonics

AA-5

MD5 Series

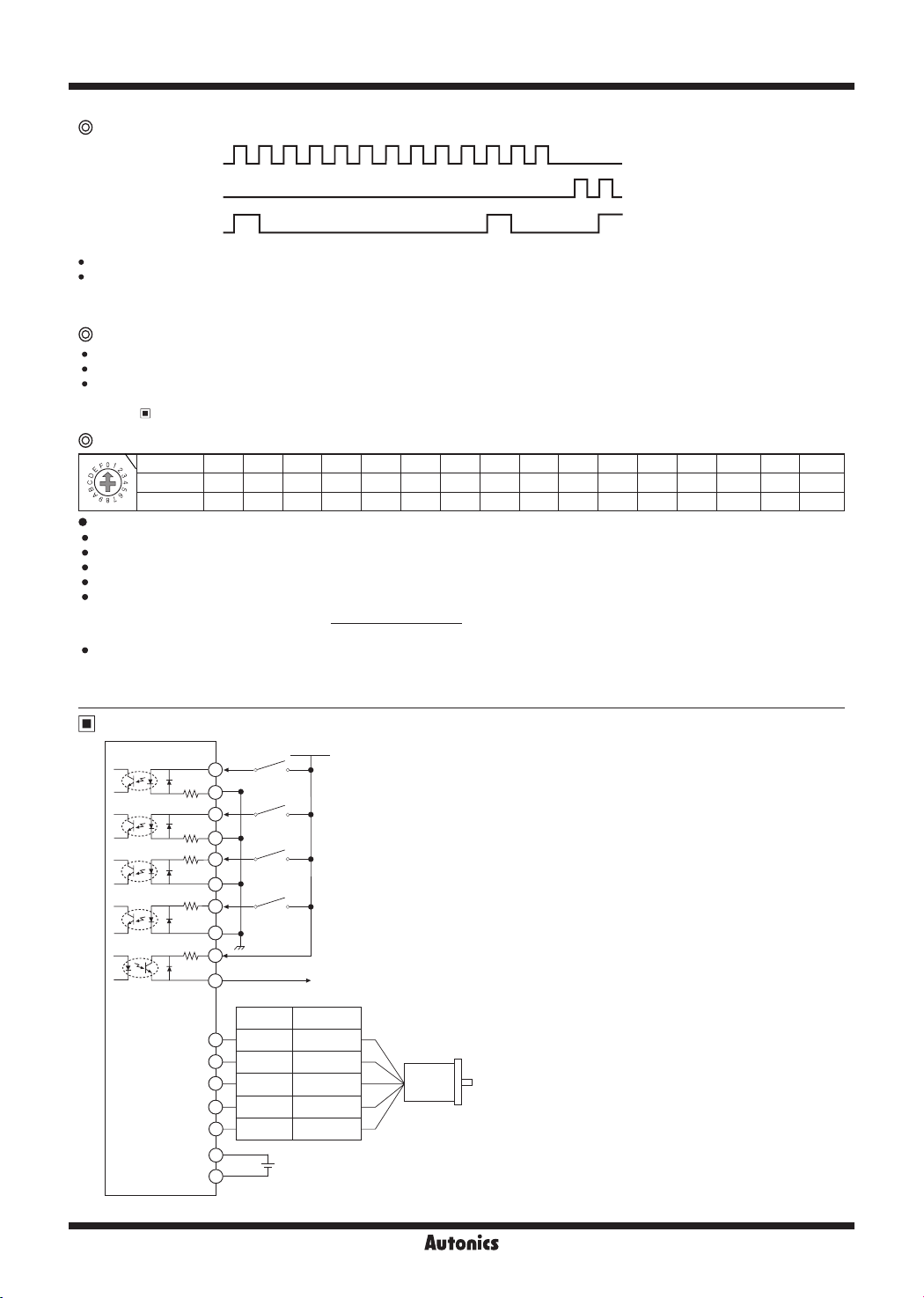

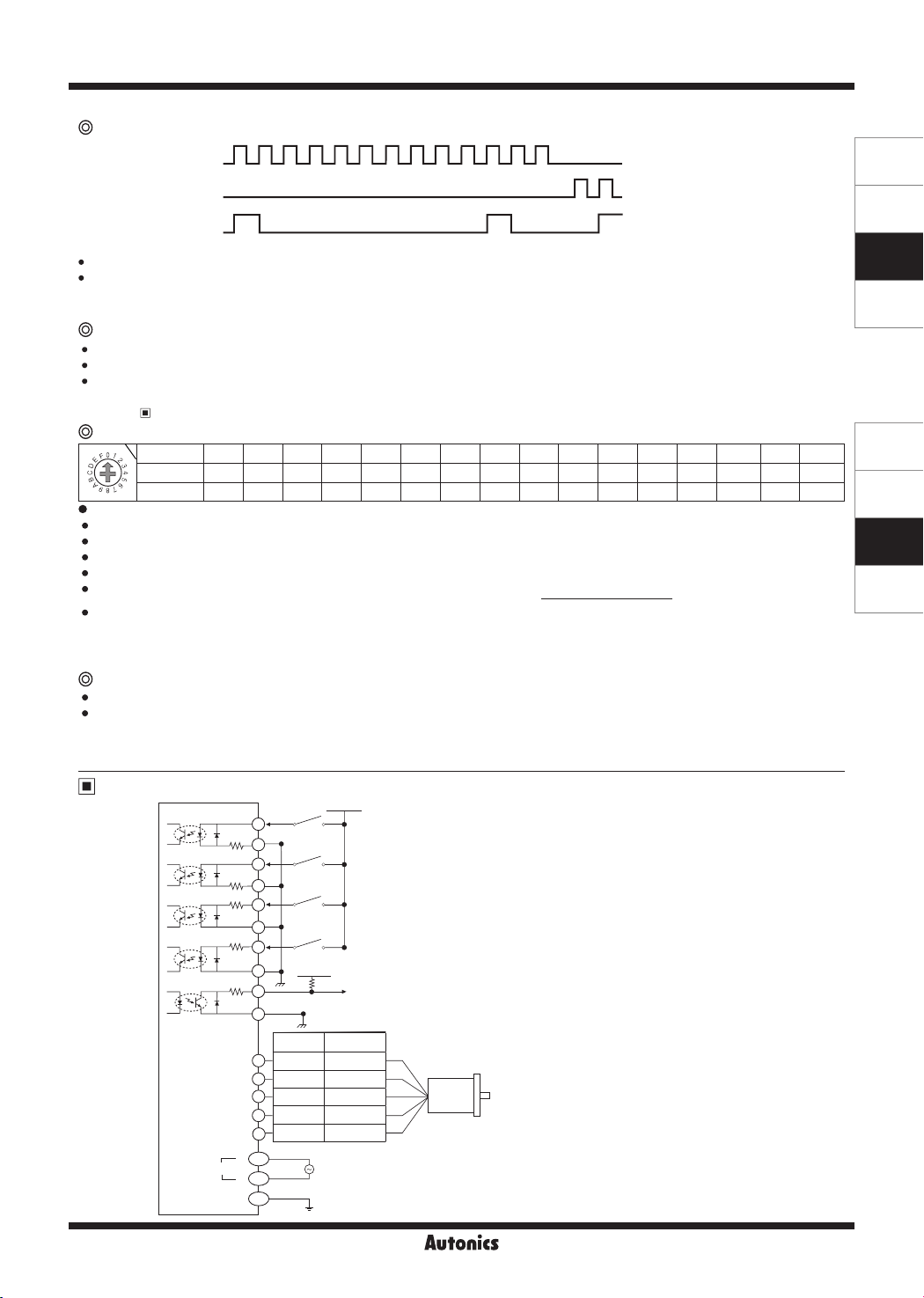

Zero point excitation output signal (ZERO OUT)

CW Pulse

CCW Pulse

ZERO OUT

This output indicates the initial step of excitation order of stepper motor and rota ion position of motor axis.

•

This signal outputs every 7.2° of rotation of the motor axis regardless of resolu ion.

•

(50 outputs per 1 rotation of the motor.)

E.g.) Full step: outputs one time by 10 pulses input, 20-division: outputs one time by 200 pulses input.

@

HOLD OFF function

This signal is for rotating motor's axis using external force or used for manual positioning.

•

When hold off signal maintains over 1ms as [H], motor excitation is released.

•

When hold off signal maintains over 1ms as [L], motor excita ion is in a normal status.

•

※

Must stop the motor for using this function.

※

Refer to '

~

@

Setting Microstep (microstep: resolution)

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

1,

1 • I I I I I I I I I I I I I I I I

The MS1, MS2 switches is for resolution setting.

Select MS2 or MS2 by DIVISION SELECTION signal ([L]: MS1, [H]: MS2)

Select the step angle (motor rota ion angle per 1 pulse).

The set step angle is dividing basic step angle (0.72°) of 5-phase stepper motor by setting value.

The calculation formula of divided step angle is as below.

•

When using geared type motor, the angle is step angle divided by gear ratio.

•

※

Resolution 1 2 4 5 8 10 16 20 25 40 50 80 100 125 200 250

@J I

Step angle 0.72° 0 36° 0.18° 0.144° 0 09° 0 072° 0 045° 0.036°

Setting Resolution (same as MS1, MS2)

Step angle / gear ratio = Step angle applied gear

E.g) 0.72° / 10 (1:10) = 0.072°

Must stop the motor before changing the resolution.

ON

OFF

ON

OFF

ON

nn====~-n:__:fln

OFF

0 0 01 1 12 23 4 5 6 7 8 9

I/O Circuit and Connections'.

Set step angle =

Basic step angle (0.72°)

Resolution

,______________,

0 0288°

0.018°

0.0144°

0 009°

0.0072° 0 00576° 0 0036° 0.00288°

I/O Circuit and Connections

~~])~_?::-

[Signal]

JE>

""?-;;·

·•,

3----··

A;·-

..

J---·

-·

L.......J...__

[Motor]

BLUE

RED

ORANGE

GREEN

BLACK

[Power]

~-==-------

1

270Ω

2

3

270Ω

4

5

390Ω

6

7

390Ω

8

9

10Ω

10

1

2

3

4

5

1

2

+5VDC

CW

CCW

HOLD

OFF

DIVISION

SELECTION

GND

ZERO OUT

Pentagon

connection

Blue Gray+Red

Red Yellow+Black

Orange

Green Brown+Green

Black Blue+Purple

Standard

connection

Orange+White

+

Power

20-35VDC

-

※

CW

2-pulse input method (CW rota ion signal input)

1-pulse input method (operating rotation signal input)

※

CCW

2-pulse input method (CCW rotation signal input)

1-pulse input method (rotation direction signal input)

→ [H]: CW, [L]: CCW

※

HOLD OFF

Control signal for motor excitation OFF

→ [H]: Motor excitation OFF

※

DIVISION SELECTION

Division selection signal

→ [L]: Operated by MS1 setting resolution

[H]: Operated by MS2 setting resolution

※

ZERO OUT

Zero point excitation output signal → Zero point status ON

※

If the power for driving pulse from external is over

than +5VDC, please connect resistor at the outside.

(input power max. 24VDC, input current 10-20mA)

Motor

※

This connection cable color is only for Autonics motors.

It may different cable color when using other motors.

AA-6

Autonics

5-Phase Stepper Motor Driver (1.4A/Phase, DC Power)

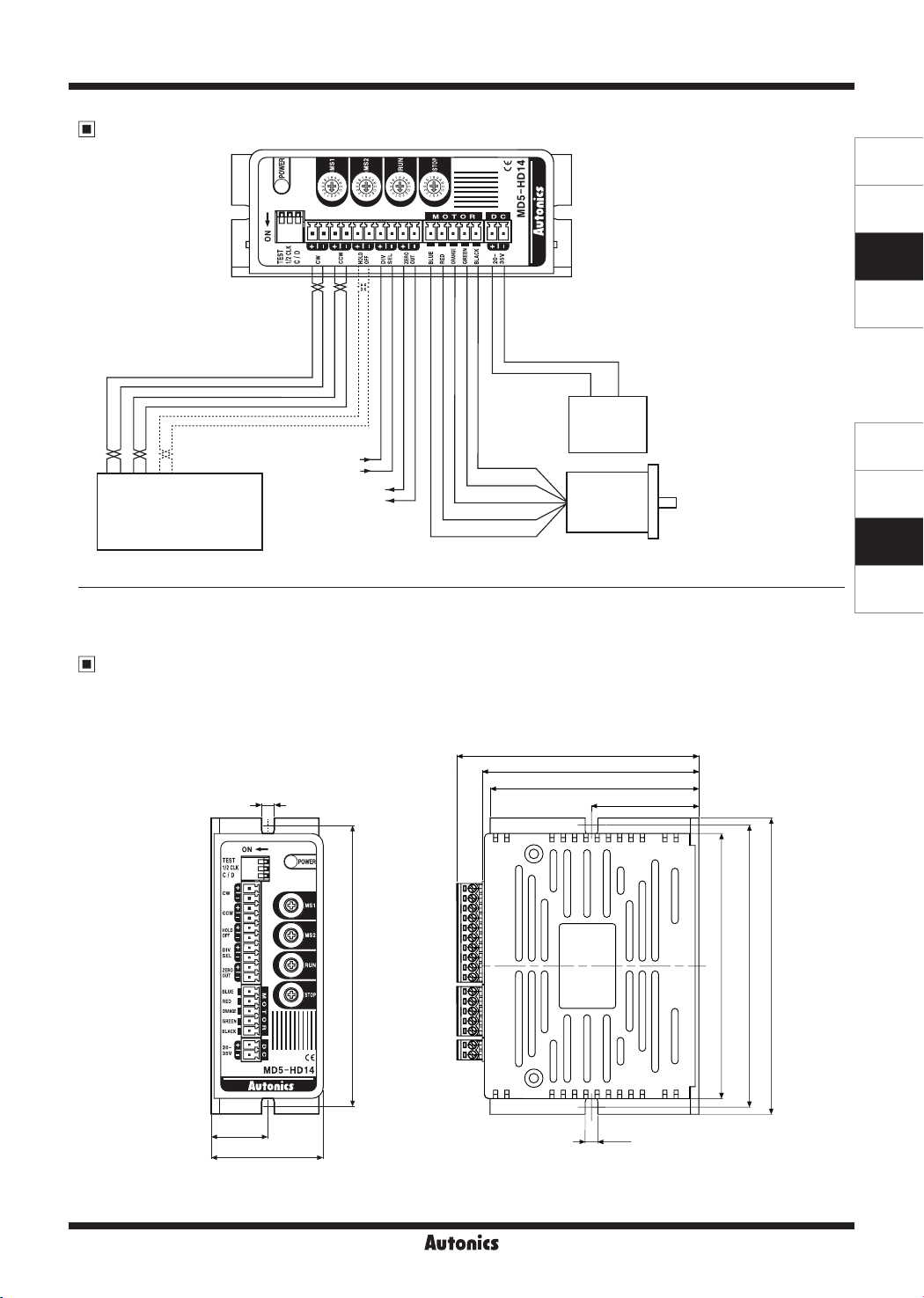

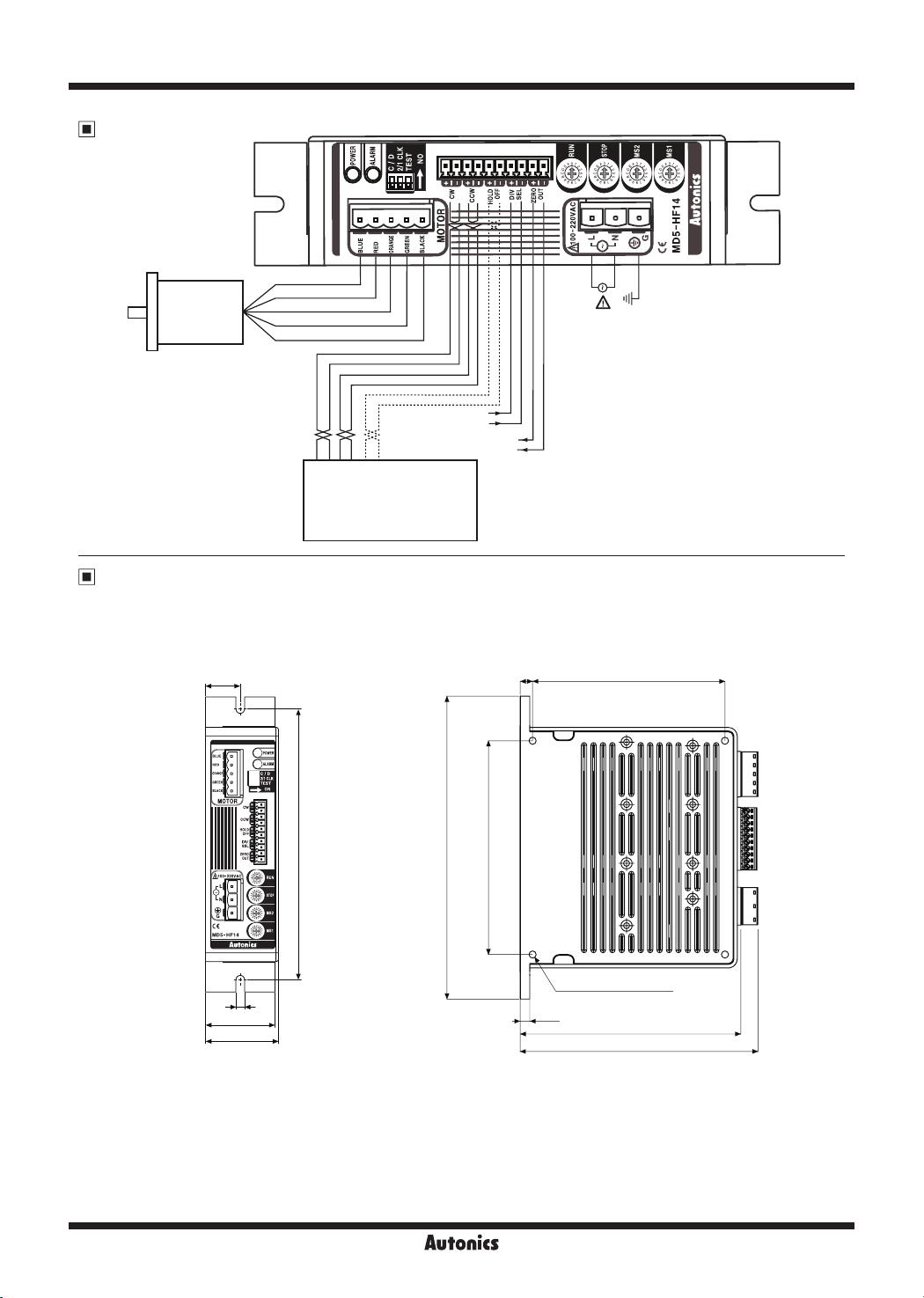

Connections

.

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(Y)

Closed Loop

Stepper System

(Z)

Stepper Motors

(AA)

Drivers

(AB)

Motion

Controllers

CW+

l

=r··---------------------------------------------------

CW-

1

CCW-

CCW+

HOLD OFF+

Controller

HOLD OFF-

User

Division selec ion

signal

Zero point

excitation

output signal

_v~

"'"

- C

= :c

='

++-

POWER

20-35VDC

+

-

-

Black

Green

Orange

Red

Blue

Motor

※

In case of standard connection,

refer to 'Stepper Motors'

section

Dimensions

~

20

4.5

MD5-HD14

39.5

(unit: mm)

86

76.5

74

38

100

(€

4.5

94

100

105

Autonics

AA-7

MD5 Series

5-Phase Micro Stepper Motor Driver [MD5-HF14]

Unit Description

Function selection DIP switch

Alarm indicator (red)

Power indicator

STOP current switch

RUN current switch

Input

terminal

Resolu ion

switch

CE:

a,®

c~us

Functions

~

@

Function selection DIP switch

l-

!~~~

r-=:

TEST

Self diagnosis function is for motor and driver test.

This function makes the motor rotate with 30rpm in full step. Rotation speed varies with resolution settings.

Rotation speed = 30rpm/resolution

In 1-pulse input method, it rotates to CCW, and in 2-pulse input method, it rotates to CW.

•

※

Be sure that the TEST switch is OFF before supplying the power.

If the TEST switch is ON, he motor operates immediately and it may be dangerous.

2/1 CLK

•

2/1 CLK switch is to select pulse input method.

•

1-pulse input method: CW → operating rotation signal input, CCW → rotation direction signal input ([H]: CW, [L]: CCW)

•

2-pulse input method: CW → CW rotation signal input, CCW → CCW rotation signal input.

•

C/D (auto current down)

•

This function is to reduce the current provided for motor automatically for preventing severe motor's heat when motor stops.

•

If motor RUN pulse is not applied, the current provided for motor reduces as the set STOP current.

•

※

Be sure that when motor RUN current is reduced, the stop torque of motor also reduced.

※

Set the STOP current by the STOP current switch.

@

Setting RUN current

1,

~J I

. I I I I I I I I I I I I I I I I

Setting RUN current is for the current provided for motor when the motor runs.

※

When RUN current is increased, RUN torque of the motor is also increased.

※

When RUN current is set too high, the heat is severe.

※

Set RUN current wi hin the range of motor's rated current according to its load.

※

Change RUN current only when the motor stops.

,:

--:-•

No. Name Function

1 TEST Self diagnosis function 30rpm rotation Not use

2 2/1 CLK Pulse input method 1-pulse input method 2-pulse input method

I I I

===------1::::::::t::==±:=~======~±==I

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

Current

(A/Phase)

3 C/D Auto current down Not use Use

0.4 0.5 0.57 0.63 0.71 0.77 0.84 0.9 0.96 1.02 1.09 1.15 1.22 1.27 1 33 1.4

Motor

connection

terminal

※

Refer to '

Switch position

ON OFF (default)

~~I

Power

terminal

Specifications'.

00

~~1

@

Setting STOP current

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

1,

: : I I I I I I I I I I I I I I I I

Setting STOP current is for the current provided for motor when the motor stops for preventing severe motor's heat.

This setting is applied when using C/D (current down) function.

Setting value of STOP current is percentage (%) ratio of the set RUN current.

※

※

※

AA-8

% 27 31 36 40 45 50 54 58 62 66 70 74 78 82 86 90

~J I

E.g.) Set RUN current as 1.4A and STOP current as 40%.

STOP current is set as 1.4A×0.4=0.56A

When STOP current is decreased, STOP torque of the motor is also decreased.

When STOP current is set too low, the heat is lower.

Change STOP current only when the motor stops.

Autonics

5-Phase Stepper Motor Driver (1.4A/Phase, AC Power)

Zero point excitation output signal (ZERO OUT)

CW Pulse

CCW Pulse

ZERO OUT

This output indicates the initial step of excitation order of stepper motor and rota ion position of motor axis .

•

This signal outputs every 7.2° of rotation of the motor axis regardless of resolu ion.

•

(50 outputs per 1 rotation of the motor.)

E.g.) Full step: outputs one time by 10 pulses input, 20-division: outputs one time by 200 pulses input.

@

HOLD OFF function

This signal is for rotating motor's axis using external force or used for manual positioning.

•

When hold off signal maintains over 1ms as [H], motor excitation is released.

•

When hold off signal maintains over 1ms as [L], motor excita ion is in a normal status.

•

※

Must stop the motor for using this function.

※

@

1,

1 • I

Setting Resolution (same as MS1, MS2)

The MS1, MS2 switches is for resolution setting.

Select MS2 or MS2 by DIVISION SELECTION signal ([L]: MS1, [H]: MS2)

Select the step angle (motor rota ion angle per 1 pulse).

The set step angle is dividing basic step angle (0.72°) of 5-phase stepper motor by setting value.

The calculation formula of divided step angle is as follow.

•

When using geared type motor, the angle is step angle divided by gear ratio.

•

※

@

Overheat: When the temperature of driver base is over 80

•

Overcurrent: When overcurrent occurs due to motor damage by burn, driver damage, or error, the alarm indicator (red) turns ON and the

•

※

I!]

Refer to '

Setting Microstep (microstep: resolution)

Switch No. 0 1 2 3 4 5 6 7 8 9 A B C D E F

Resolution 1 2 4 5 8 10 16 20 25 40 50 80 100 125 200 250

mJ I

Step angle 0.72° 0 36° 0.18° 0.144° 0 09° 0 072° 0 045° 0.036°

Step angle / gear ratio = Step angle applied gear

E.g) 0.72° / 10 (1:10) = 0.072°

Must stop the motor before changing the resolution.

Alarm indication

motor becomes HOLD OFF.

Turn OFF the power and remove the causes of alarm. Re-supply the power and the alarm indicator turns OFF and the driver is normal

operation.

I/O Circuit and Connections

ON

OFF

ON

OFF

ON

nn=====~n_:__:fln

OFF

0 0 01 1 12 23 4 5 6 7 8 9

I/O Circuit and Connections'.

----+----+--I

[Signal]

1

CW

2

3

CCW

4

5

HOLD

OFF

6

7

DIVISION SELECTION

+5VDC

8

9

ZERO OUT

10

Pentagon

connection

1

Blue Gray+Red

Red Yellow+Black

2

3

Orange

Green Brown+Green

4

Black Blue+Purple

5

AC

AC

G

[Power]

270Ω

270Ω

390Ω

390Ω

10Ω

[Motor]

BLUE

RED

ORANGE

GREEN

BLACK

Power

L

N

,______________,

0 0288°

0.018°

0.0144°

0 009°

I I I I I I I I I I I I I I

Basic step angle (0.72°)

Resolution

※

CW

2-pulse input method (CW rotation signal input)

1-pulse input method (operating rota ion signal input)

※

CCW

2-pulse input method (CCW rotation signal input)

1-pulse input method (rotation direction signal input)

→ [H]: CW, [L]: CCW

※

HOLD OFF

Control signal for motor excitation OFF

→ [H]: Motor excitation OFF

※

DIVISION SELECTION

Division selec ion signal

→ [L]: Operated by switch MS1

[H]: Operated by switch MS2

※

ZERO OUT

Zero point excitation output signal → Zero point status ON

※

If the power for driving pulse from external is over

than +5VDC, please connect resistor at the outside.

(input power max. 24VDC, input current 10-20mA)

+5VDC

2kΩ

Standard

connection

Orange+White

100-220VAC

50/60Hz

GND

Set step angle =

, the alarm indicator (red) turns ON and motor stops with holding the excision.

℃

Motor

※

This connection cable color is only for Autonics motors.

It may different cable color when using other motors.

0.0072° 0 00576° 0 0036° 0.00288°

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(Y)

Closed Loop

Stepper System

(Z)

Stepper Motors

<---------

(AA)

Drivers

(AB)

Motion

Controllers

Autonics

AA-9

MD5 Series

Connections

Motor

※

In case of standard connection,

refer to 'Stepper Motors' section.

Blue

Red

Orange

Green

Black

CW-

CW+

Division selection

Zero point excitation

: :

CCW-

CCW+

HOLD OFF-

HOLD OFF+

signal

output signal

User

Controller

F.G.

100-220VAC 50/60Hz

+

-

+

-

Dimensions

(unit: mm)

20

7

'

CJ

r-

'--'

108

♦

.

~

II.'../

n

I

156

170

120

I

n

I

I

--cJ,_

L::::1

\_

5

40

42

~i-----

5.4

,.-

-

4-M4 Tap Depth: 8

122

133.5

n H

□

'

□

0

AA-10

Autonics

Loading...

Loading...