Autonics M4Y SERIES Instruction Manual

DRW170 80 1AB

Autonics

DIGITAL PANEL METER

M4Y SERIES

I N S T R U C T I O N M A N U A L

Thank you for choosing our Autonics products.

Please read the following safety considerations before use.

Safety Considerations

※

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

Failure to follow these instructions may result in serious injury or death.

Warning

Failure to follow these instructions may result in personal injury or product damage.

Caution

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause

serious injury or substantial economic loss. (e.g. nuclear power control, medical

equipment, ships, vehicles, railways, aircraft, combustion apparatus, safety equipment,

crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fire, personal injury, or economic loss.

2. Install on a device panel to use.

Failure to follow this instruction may result in electric shock or fire.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock or fire.

4. Check 'Connections' before wiring.

Failure to follow this instruction may result in fire.

5. Do not disassemble or modify the unit.

Failure to follow this instruction may result in electric shock or fire.

Caution

1.

When connecting the power/measurement input, use AWG 24(0.20mm2) to AWG 15(1.65mm2)

cable and tighten the terminal screw with a tightening torque of 0.98 to 1.18N.m.

Failure to follow this instruction may result in re or malfunction due to contact failure.

2. Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

3. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or re.

4. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity,

direct sunlight, radiant heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

5. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

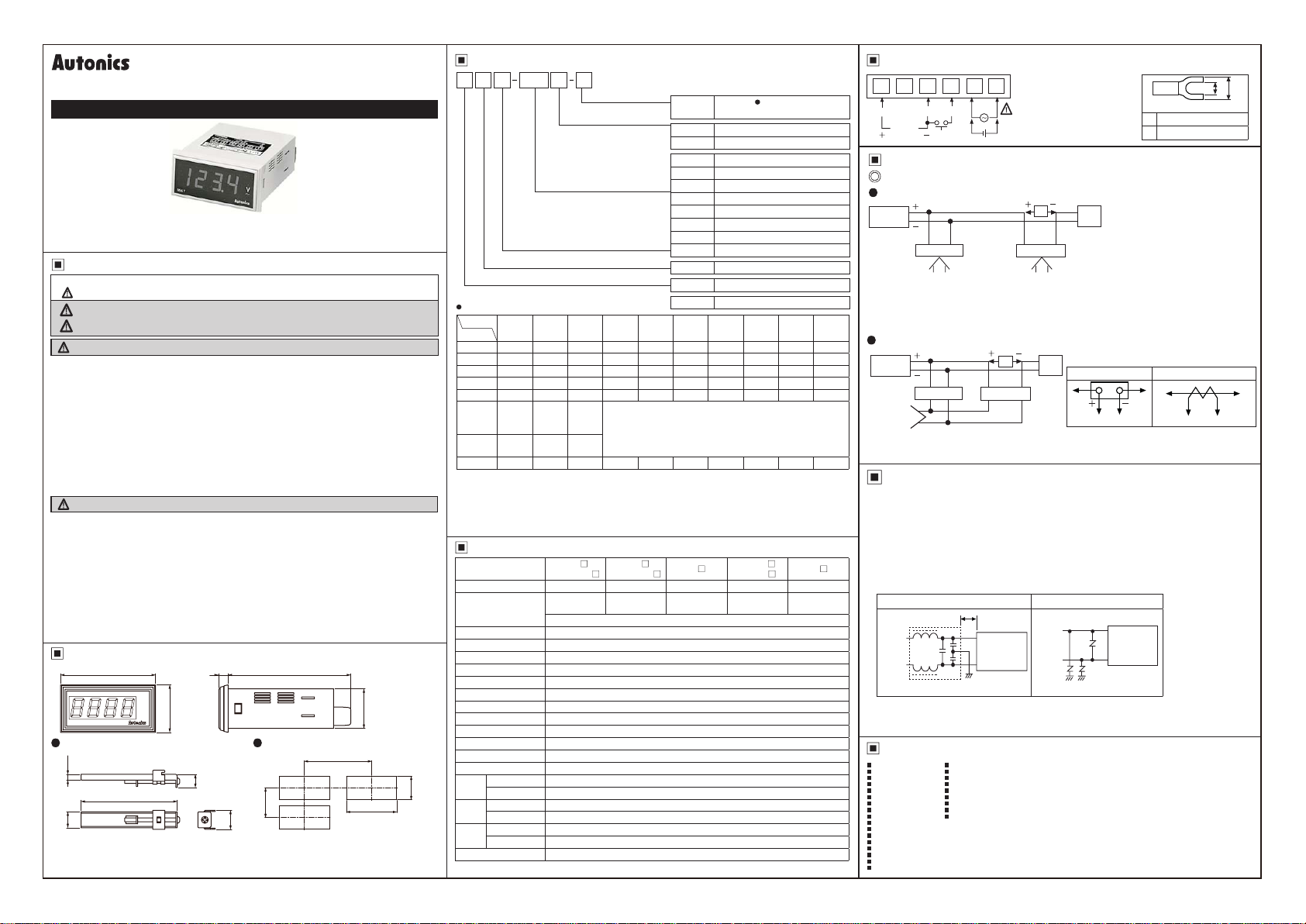

Dimensions

00

72

36

Bracket Panel cut-out

4.4

73

12

※

The above specications are subject to change and some models may be discontinued

without notice.

※

Be sure to follow cautions written in the instruction manual and the technical

descriptions (catalog, homepage).

10

14.5

937

Min. 91

Min. 40

30

68

0 7

0

(unit: mm)

0

+ 05

31.5

Ordering Information

00

MAVY R4 4

-

LD

AC measuring method

Measurement input /

display scale

Measurement input

Refer to "

range"

I

•

Number

I

No-mark Average value (AVG)

R

Root mean suare value (RMS)

I

I I

DV DC voltage

DA

Measurement function (input)

DC current

AV AC voltage

AA AC current

W AC Power

T Rotation (tachometer)

S

Size

Digit

Item

※

1: 1-5VDC mearsurement input is option.

Measurement input range

•

Input

No-mark

Function

I~

DV

DA

AV(R)

AA(R)

1

※

W

2

※

T(R)

2

※

S(R)

DI 1999

※

1: Use the transducer. This specification is based on the transducer with 0-10VDC output.

When the output of transducer is DC4-20mA or 1-5VDC, please use the scaling meter.

※

2: Use the tacho generator. This specification is based on the tacho generator with 0-10VDC

or 0-10VAC output.

※

When "

and then check the cables.

Specications

00

Model

Measurement function

Max. allowable input

Max.display range 1999

Power supply 100-240VACᜠ 50/60Hz (option: 24-70VDCᜡ)

Power consumption DC input: 2W, AC input: 4VA

Display method 7-segment LED display (red) (character height: 14mm)

Display accuracy DC input: F.S.±0 2%rdg ±1-digit, AC input: F.S.±0.5%rdg ±1-digit

Sampling cycle 300ms

A/D conversion method

Response time 2 sec (0 to 1999)

Sampling time 2 5 times/sec

Insulation resistance Over 100MΩ (at 500VDC megger)

Dielectric strength 2000VAC 50/60Hz for 1 minute

Noise immunity ±1kV the square wave noise (pulse width:1㎲) by the noise simulator

Mechanical 0.75mm amplitude at frequency of 10 to 55Hz in each X, Y, Z direction for 1hour

Vibra

-tion

Malfunction 0 5mm amplitude at frequency of 10 to 55Hz in each X, Y, Z direction for 10 min

Mechanical 300m/s² (approx. 30G) in each X, Y, Z direction for 3times

Shock

Malfunction 100m/s² (approx. 10G) in each X, Y, Z direction for 3times

Ambient temp. -10 to 50℃, storage: -25 to 65

Environ

-ment

Ambient humi. 35 to 85%RH, storage: 35 to 85%RH

Unit weight Approx. 144g

※

Environment resistance is rated at no freezing or condensation.

1 2 3 4 5 6 7 8 XX

-

199.9mV 1.999V 19.99V 199.9V 300V

-

199.9㎂ 1.999mA 19.99mA 199.9mA 1.999A 19.99A 199.9A 1999A

-

199.9mV 1.999V 19.99V 199.9V

-

19.99mA 199.9mA 1.999A 19.99A 199.9A 1999A

-

199.9W 1.999kW 19.99kW 199.9kW

-

1999rpm 1999rpm

1999

m/min

- - - - - - - -

" or "

1999

`999

M4Y-DVM4Y-AV(R)-

DC, AC voltage DC, AC current Power

Max. 400VAC

Max. 300VDC

150% for each input specication (at 400VACᜠ: 120%)

Dual slope intergal method

1: 0-10VDC

2: 0-10VAC

DX: DC input option

1999

AX: AC input option

m/min

" is flashes with a certain measurement input, disconnect power supply

M4Y-DA-

□ □

M4Y-AA(R)-

□

Max. AC 5A

ᜠ

Max. DC 2A

ᜡ

M4Y-W-

□

Max. 10VDC

℃

Speed (speed meter)

DI

DC4-20mA (scaling meter)

Y DIN W72×H36mm

4 1999 (3½-digit)

M Meter

I

I

- - -

-

400V

- -

M4Y-T(R)M4Y-S(R)-

Rotation

Max. 10VDC

ᜡ

max. 10VAC

- -

□

□

, speed

ᜡ

ᜠ

- - - -

□

M4Y-DI-

Scaling

,

DC4-20mA

Option

Option

Option

Option

Option

Option

□

※

Connections

Use terminals of size

specied below.

1 2 3 4 5 6

HOLD

LOW

HI

I

INPUT

SOURCE: 100-240VAC 50/60Hz

- +

24-70VDC (option)

<Forked>

a Min. 3.5mm

b Max. 7 0mm

Connections of Applications

Simultaneous connection of voltmeter and ammeter

For DC power supply

+

Power of

the load

1

※

DC power supply 1

※

1: Compared to measurement input range, higher measuring voltage needs a multiplier and

lower measuring voltage needs a shunt.

※

When using voltmeter and ammeter simultaneously, connect the separated power supply each.

※

(-) terminal of the power and (-) terminal of measurement input are shorted.

For AC power supply

•

Power of

the load

AC power

supply

※

1: When measuring higher current than measurement input, use a shunt for DC current and

a current transformer (CT) for AC current.

Cautions during Use

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. 5VDC power supply should be insulated and limited voltage/current or Class 2, SELV power

supply device.

3. Install a power switch or circuit breaker in the easily accessible place for supplying or

disconnecting the power.

4. Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line filter or varistor at power

line and shielded wire at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency

noise.

Connection with the line lter Connection with the varistor

110/

220VAC

5. This unit may be used in the following environments.

Indoors (in the environment condition rated in 'Specifications')

①

Pollution degree 2

③

Major Products

00

Photoelectric Sensors Temperature Controlers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors

Door Side Sensors Counters

Area Sensors

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse (Rate) Meters

Rotary Encoders

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (F ber, Co₂, Nd YAG)

Laser Welding/Cutting System

LOW LOW

HI HI

Voltmeter

LOW LOW

HI HI

Voltmeter

,-_::-_-_-_-_-_-------H

'---------------•

Ammeter

Install the ine fiter close

to the panel meter

HI

'

Panel meter

'

LOW

Earth ground

■

■

SSRs/Power Controllers

■

■

Timers

■

■

■

Display Units

■

■

※

1

A

Ammeter

DC power supply 2

※

1

A

Load

Shunt

I;ID

110/

220VAC

Ill

Load

HI LOW

Panel meter

LOW

/II

Current transformer (CT)

HI

②

④

Altitude max. 2,000m

Installation category II

a

HI LOW

DRW170 80 1AB

b

Loading...

Loading...