Page 1

Autodesk® Mechanical Desktop

®

User’s Guide

6

20507-010000-5020A May 3, 2001

Page 2

Copyright © 2001 Autodesk, Inc.

This publication, or parts thereof, may not be reproduced in any form, by any method, for any purpose.

AUTODESK, INC. MAKES NO WARRANTY, EITHER EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, REGARDING THESE MATERIALS AND MAKES

SUCH MATERIALS AVAILABLE SOLELY ON AN “AS-IS” BASIS.

IN NO EVENT SHALL AUTODESK, INC. BE LIABLE TO ANYONE FOR SPECIAL, COLLATERAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN CONNECTION WITH OR ARISING OUT OF PURCHASE OR USE OF THESE MATERIALS. THE SOLE AND EXCLUSIVE

LIABILITY TO AUTODESK, INC., REGARDLESS OF THE FORM OF ACTION, SHALL NOT EXCEED THE PURCHASE PRICE OF THE

MATERIALS DESCRIBED HEREIN.

Autodesk, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication,

and may not reflect the product at all times in the future.

The following are registered trademarks of Autodesk, Inc., in the USA and/or other countries: 3D Plan, 3D Props, 3D Studio, 3D Studio MAX, 3D

Studio VIZ, 3DSurfer, ActiveShapes, ActiveShapes (logo), Actrix, ADE, ADI, Advanced Modeling Extension, AEC Authority (logo), AEC-X, AME,

Animator Pro, Animator Studio, ATC, AUGI, AutoCAD, AutoCAD Data Extension, AutoCAD Development System, AutoCAD LT, AutoCAD Map,

Autodesk, Autodesk Animator, Autodesk (logo), Autodesk MapGuide, Autodesk University, Autodesk View, Autodesk WalkThrough, Autodesk World,

AutoLISP, AutoShade, AutoSketch, AutoSurf, AutoVision, Biped, bringing information down to earth, CAD Overlay, Character Studio, Design

Companion, Design Your World, Design Your World (logo), Drafix, Education by Design, Generic, Generic 3D Drafting, Generic CADD, Generic

Software, Geodyssey, Heidi, HOOPS, Hyperwire, Inside Track, Kinetix, MaterialSpec, Mechanical Desktop, Multimedia Explorer, NAAUG, ObjectARX,

Office Series, Opus, PeopleTracker, Physique, Planix, Powered with Autodesk Technology, Powered with Autodesk Technology (logo), RadioRay,

Rastation, Softdesk, Softdesk (logo), Solution 3000, Tech Talk, Texture Universe, The AEC Authority, The Auto Architect, TinkerTech, VISION*, WHIP!,

WHIP! (logo), Woodbourne, WorkCenter, and World-Creating Toolkit.

The following are trademarks of Autodesk, Inc., in the USA and/or other countries: 3D on the PC, 3ds max, ACAD, Advanced User Interface, AEC

Office, AME Link, Animation Partner, Animation Player, Animation Pro Player, A Studio in Every Computer, ATLAST, Auto-Architect, AutoCAD

Architectural Desktop, AutoCAD Architectural Desktop Learning Assistance, AutoCAD Learning Assistance, AutoCAD LT Learning Assistance, AutoCAD

Simulator, AutoCAD SQL Extension, AutoCAD SQL Interface, Autodesk Animator Clips, Autodesk Animator Theatre, Autodesk Device Interface,

Autodesk Inventor, Autodesk PhotoEDIT, Autodesk Software Developer’s Kit, Autodesk Streamline, Autodesk View DwgX, AutoFlix, AutoPAD,

AutoSnap, AutoTrack, Built with ObjectARX (logo), ClearScale, Colour Warper, Combustion, Concept Studio, Content Explorer, cornerStone Toolkit,

Dancing Baby (image), Design 2000 (logo), DesignCenter, Design Doctor, Designer’s Toolkit, DesignProf, DesignServer, DWG Linking, DWG

Unplugged, DXF, Extending the Design Team, FLI, FLIC, GDX Driver, Generic 3D, gmax, Heads-up Design, Home Series, i-drop, Kinetix (logo),

Lightscape, ObjectDBX, onscreen onair online, Ooga-Chaka, Photo Landscape, Photoscape, Plasma, Plugs and Sockets, PolarSnap, Pro Landscape,

QuickCAD, Reactor, Real-Time Roto, Render Queue, SchoolBox, Simply Smarter Diagramming, SketchTools, Sparks, Suddenly Everything Clicks,

Supportdesk, The Dancing Baby, Transform Ideas Into Reality, Visual LISP, Visual Syllabus, VIZable, Volo, and Where Design Connects.

All other brand names, product names or trademarks belong to their respective holders.

ACIS Copyright © 1989-2001 Spatial Corp.

Third Party Software Program Credits

Anderson, et. al. LAPACK Users’ Guide, Third Edition. Society for Industrial and Applied Mathematics, 1999.

Portions Copyright © 1991-1996 Arthur D. Applegate. All rights reserved.

Typefaces from the Bitstream ® typeface library copyright 1992.

Cypress Enable™, Cypress Software, Inc.

dBASE is a registered trademark of Ksoft, Inc.

Portions licensed from D-Cubed Ltd. DCM-2D and CDM are a trademark of D-Cubed Ltd. DCM-2D Copyright D-Cubed Ltd. 1989-2001.

CDM Copyright D-Cubed Ltd. 1998-2001.

SPEC is a registered trademark of Associated Spring/Barnes Group, Inc.

Portions of this software are based on the work of the Independent JPEG Group.

InstallShield™ 3.0. Copyright © 1997 InstallShield Software Corporation. All rights reserved.

Licensing Technology Copyright © C-Dilla Ltd. UK 1996, 1997, 1998, 1999, 2000, 2001.

MD5C.C - RSA Data Security, Inc., MD5 message-digest algorithm Copyright © 1991-1992, RSA Data Security, Inc. Created 1991. All

rights reserved.

International CorrectSpell™ Spelling Correction System © 1995 by Lernout & Hauspie Speech Products, N.V. All rights reserved.

LUCA TCP/IP Package, Portions Copyright © 1997 Langener GmbH. All rights reserved.

Copyright © 1997 Microsoft Corporation. All rights reserved.

Microsoft® HTML Help Copyright © Microsoft Corporation 2001.

Microsoft® Internet Explorer 5 Copyright © Microsoft Corporation 2001. All rights reserved

Microsoft® Windows NetMeeting Copyright © Microsoft Corporation 2001. All rights reserved

Objective Grid ©, Stingray Software a division of Rogue Wave Software, Inc.

Typefaces from Payne Loving Trust © 1996. All rights reserved.

PKWARE Data Compression Library ©, PKWARE, Inc.

SMLib © 1998-2000, IntegrityWare, Inc., GeomWare, Inc., and Solid Modeling Solutions, Inc.

Use, duplication, or disclosure by the U. S. Government is subject to restrictions as set forth in FAR 12.212 (Commercial Computer

Software-Restricted Rights) and DFAR 227.7202 (Rights in Technical Data and Computer Software), as applicable.

All Rights Reserved

Autodesk Trademarks

Third Party Trademarks

GOVERNMENT USE

12345678910

Page 3

Contents

Part I Getting Started with Autodesk® Mechanical Desktop® .1

Chapter 1 Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

What is Autodesk Mechanical Desktop?. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Making the Transition from AutoCAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Migrating Files from Previous Releases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Data Exchange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 Modeling with Autodesk® Mechanical Desktop®. . . . . . . . . . . . . . . 7

Mechanical Desktop Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 3 The User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mechanical Desktop Today. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mechanical Desktop Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Assembly Modeling Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Part Modeling Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mechanical Desktop Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Desktop Browser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Issuing Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4 Documentation and Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Printed and Online Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mechanical Desktop Printed Manual . . . . . . . . . . . . . . . . . . . . . . . . 28

AutoCAD Printed Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Online Installation Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

AutoCAD 2002 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

iii

Page 4

Mechanical Desktop Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Updating Help Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Product Support Assistance in Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Updating the Support Assistance Knowledge Base. . . . . . . . . . . . . . .31

Learning and Training Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Internet Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Part I Autodesk® Mechanical Desktop® Tutorials. . . . . . . . . . 33

Chapter 5 Using the Tutorials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

How the Tutorials are Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Accessing Mechanical Desktop Commands. . . . . . . . . . . . . . . . . . . . . . . . .37

Positioning the Desktop Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Backing up Tutorial Drawing Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Chapter 6 Creating Parametric Sketches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Basic Concepts of Parametric Sketching . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Sketching Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Creating Profile Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Creating Text Sketch Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Creating Open Profile Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Creating Closed Profile Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Using Default Sketch Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Using Custom Sketch Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Using Nested Loops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Creating Path Sketches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Creating 2D Path Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Creating 3D Path Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Creating Cut Line Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Creating Split Line Sketches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Creating Break Line Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Chapter 7 Constraining Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Basic Concepts of Creating Constraints. . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Constraining Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Constraining Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

iv | Contents

Page 5

Applying Geometric Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Showing Constraint Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Replacing Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Applying Dimension Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Creating Profile Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Adding Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appending Sketches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Modifying Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Using Construction Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Creating Profile Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Adding Project Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Adding Parametric Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Constraining Path Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Controlling Tangency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Chapter 8 Creating Sketched Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Basic Concepts of Sketched Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

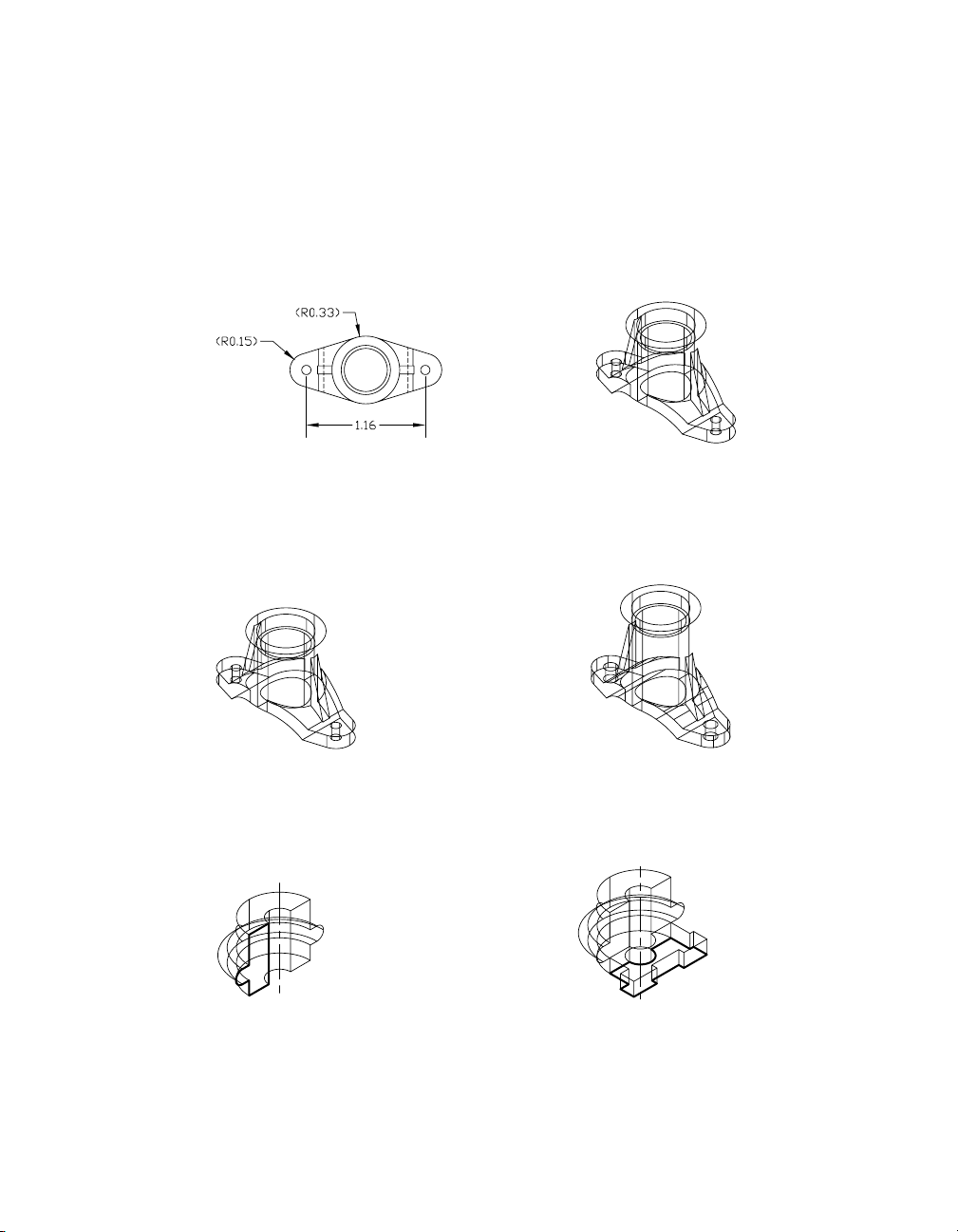

Creating Extruded Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Extruding Closed Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Editing Extruded Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Extruding Open Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Creating Rib Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Creating Thin Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Creating Emboss Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Editing Emboss Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Creating Loft Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Creating Linear Lofts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Creating Cubic Lofts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Editing Loft Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Creating Revolved Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Editing Revolved Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Creating Face Splits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Editing Face Splits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

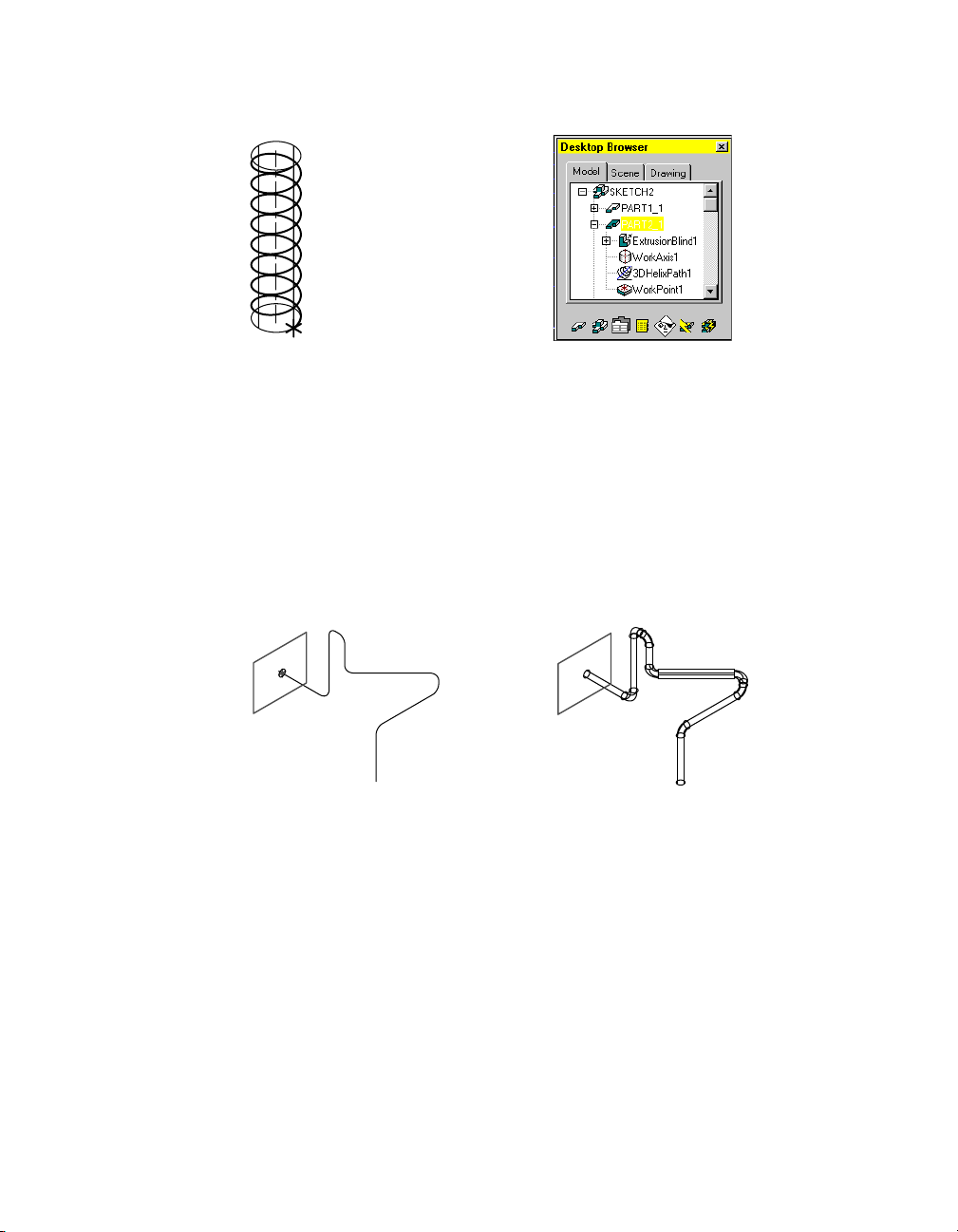

Creating Sweep Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Creating 2D Sweep Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Creating 3D Sweep Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Editing Sweep Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Creating Bend Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Editing Bend Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Contents | v

Page 6

Chapter 9 Creating Work Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Basic Concepts of Work Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Creating Work Planes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Editing Work Planes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Creating Work Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Editing Work Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Creating Work Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

Editing Work Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Chapter 10 Creating Placed Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Basic Concepts of Placed Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Creating Hole Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

Creating Thread Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Editing Hole Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

Editing Thread Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

Creating Face Drafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

Editing Face Drafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

Creating Fillet Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Editing Fillet Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

Creating Chamfer Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Editing Chamfer Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

Creating Shell Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Editing Shell Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210

Creating Surface Cut Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

Editing Surface Cut Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .213

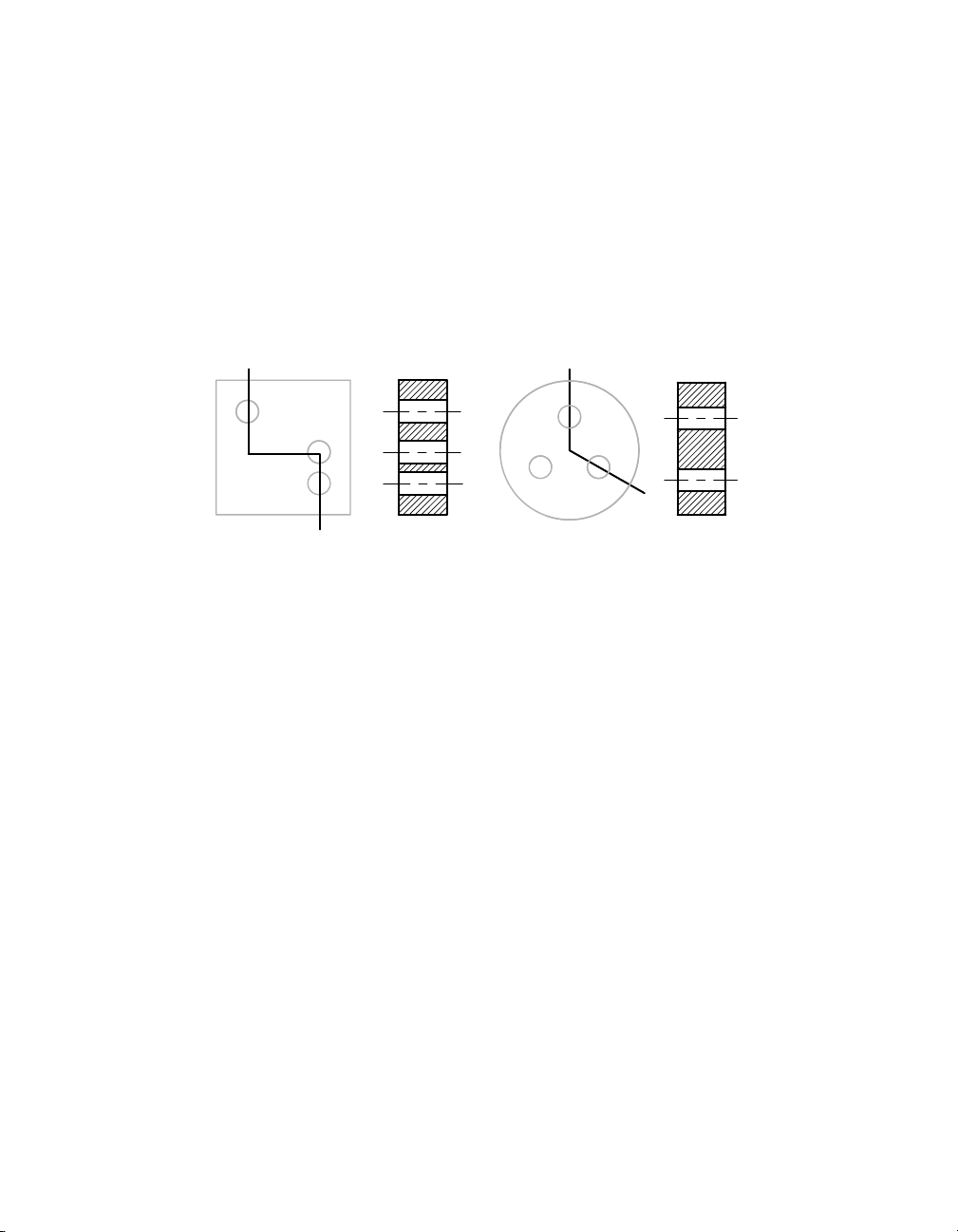

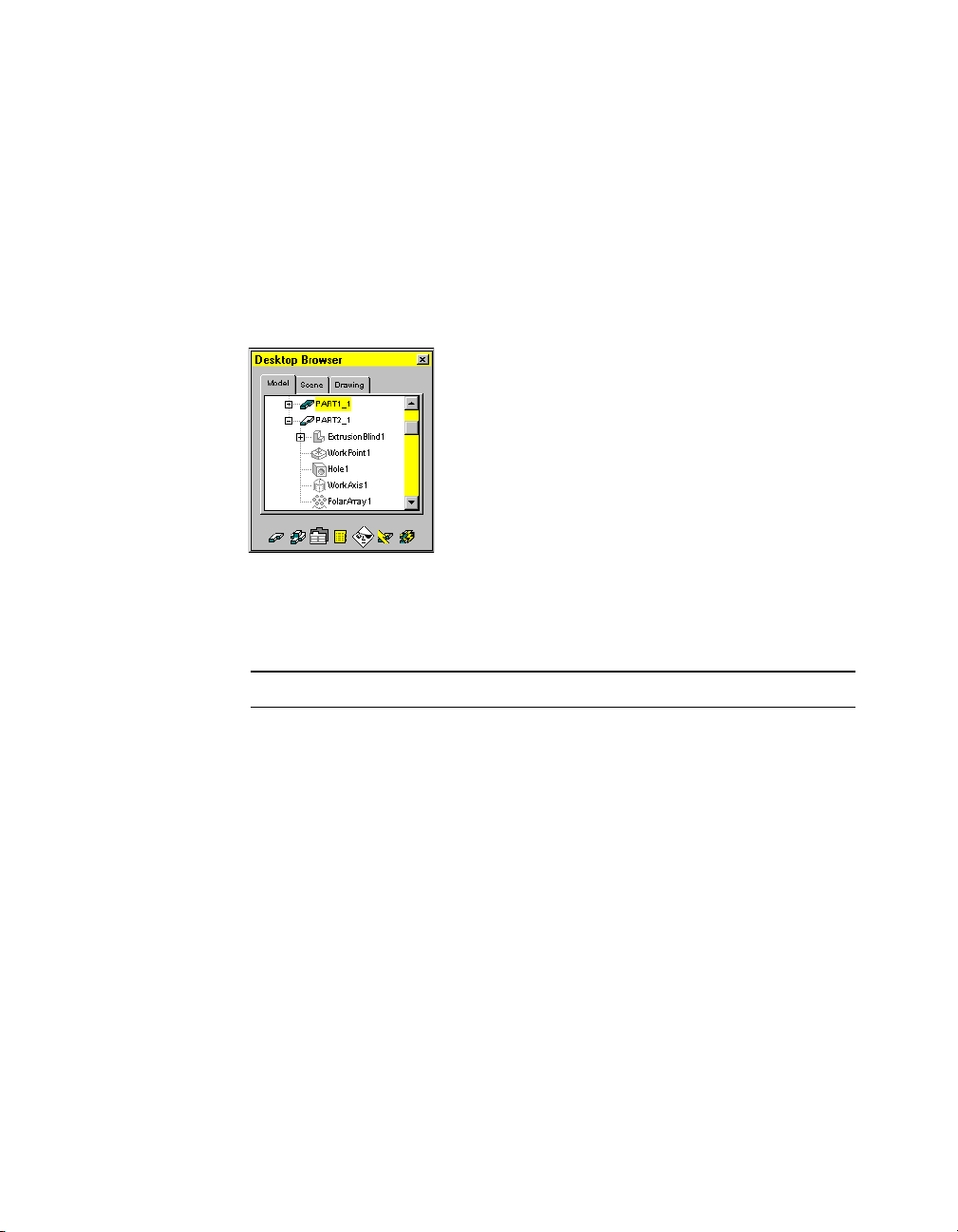

Creating Pattern Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .214

Editing Pattern Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

Editing Array Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

Creating Copied Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Editing Copied Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Creating Combined Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Editing Combined Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Creating Part Splits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Editing Part Splits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .231

Chapter 11 Using Design Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

Basic Concepts of Design Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

Preparing The Drawing File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

vi | Contents

Page 7

Using Design Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Active Part Design Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Global Design Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Creating Active Part Design Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Assigning Design Variables to Active Parts . . . . . . . . . . . . . . . . . . . . . . . . 242

Modifying Design Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Working with Global Design Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Chapter 12 Creating Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Basic Concepts of Creating Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Creating Base Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Sketching Base Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Creating Work Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Defining Sketch Planes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Creating Extruded Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Constraining Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Dimensioning Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Creating Constraints Between Features. . . . . . . . . . . . . . . . . . . . . . 276

Editing Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Extruding Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Creating Revolved Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Creating Symmetrical Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Constraining Sketches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Refining Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Shading and Lighting Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Chapter 13 Creating Drawing Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Basic Concepts of Creating Drawing Views . . . . . . . . . . . . . . . . . . . . . . . 309

Planning and Setting Up Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Creating Drawing Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Cleaning Up Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Hiding Extraneous Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Moving Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Hiding Extraneous Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Enhancing Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Changing Dimension Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Creating Reference Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Creating Hole Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Creating Centerlines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Creating Other Annotation Items . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Modifying Drawing Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

Exporting Drawing Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Contents | vii

Page 8

Chapter 14 Creating Shells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .346

Basic Concepts of Creating Shells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .347

Adding Shell Features to Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .347

Using Replay to Examine Designs . . . . . . . . . . . . . . . . . . . . . . . . . .348

Cutting Models to Create Shells . . . . . . . . . . . . . . . . . . . . . . . . . . . .350

Editing Shell Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .352

Adding Multiple Wall Thicknesses . . . . . . . . . . . . . . . . . . . . . . . . . .354

Managing Multiple Thickness Overrides . . . . . . . . . . . . . . . . . . . . .358

Chapter 15 Creating Table Driven Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .362

Basic Concepts of Table Driven Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . .363

Setting Up Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .364

Displaying Part Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .366

Editing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .367

Resolving Common Table Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .369

Suppressing Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .371

Working with Two Part Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .377

Creating Drawing Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .379

Cleaning Up the Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .384

Displaying Dimensions as Parameters . . . . . . . . . . . . . . . . . . . . . . .384

Hiding Extraneous Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .385

Moving Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .387

Enhancing Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .390

Creating Power Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .390

Creating Hole Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .393

Pasting Linked Spreadsheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .396

Chapter 16 Assembling Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400

Basic Concepts of Assembling Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .401

Starting Assembly Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .402

Using External Parts in Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .403

Assembling Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .406

Constraining Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .407

Using the Desktop Browser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .414

Getting Information from Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . .417

Checking for Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .417

Calculating Mass Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .418

Creating Assembly Scenes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .420

viii | Contents

Page 9

Creating Assembly Drawing Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Editing Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Editing External Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Editing External Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

Editing Assembly Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 438

Chapter 17 Combining Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Basic Concepts of Combining Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

Working in Single Part Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 446

Creating Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Creating Toolbody Part Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Working with Combine Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 458

Creating Relief Toolbodies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

Combining Toolbodies with Spacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Adding Weight Reduction Holes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

Adding Weight Reduction Extrusions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

Adding Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 474

Chapter 18 Assembling Complex Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 477

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

Basic Concepts of Complex Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Starting the Assembly Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

Creating Local and External Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

Applying Assembly Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

Creating New Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

Creating Subassemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 494

Defining and Activating Subassemblies. . . . . . . . . . . . . . . . . . . . . . 494

Using External Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

Instancing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 496

Completing Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

Applying Assembly Constraints. . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

Restructuring Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 504

Analyzing Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 506

Editing Mechanical Desktop Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

Reloading External References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

Assigning Mass Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 510

Calculating Mass Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 511

Reviewing Assembly Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 513

Creating Exploded Assembly Scenes . . . . . . . . . . . . . . . . . . . . . . . . 513

Using Tweaks and Trails in Scenes. . . . . . . . . . . . . . . . . . . . . . . . . . 515

Creating Assembly Drawing Views . . . . . . . . . . . . . . . . . . . . . . . . . 518

Contents | ix

Page 10

Creating Bills of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .522

Customizing BOM Databases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .523

Working with Part References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .525

Adding Balloons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .527

Placing Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .529

Finishing Drawings for Plotting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .531

Chapter 19 Creating and Editing Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . 533

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .534

Basic Concepts of Creating Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . .535

Working with Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .536

Creating Motion-Based Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .538

Revolved Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .538

Extruded Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .539

Swept Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .540

Creating Skin Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .546

Ruled Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .546

Trimmed Planar Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .554

Lofted Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .555

Creating Derived Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .559

Blended Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .559

Offset Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .563

Fillet and Corner Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .565

Editing Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .569

Adjusting Adjacent Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .569

Joining Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .570

Trimming Intersecting Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . .571

Trimming Surfaces by Projection . . . . . . . . . . . . . . . . . . . . . . . . . . .573

Chapter 20 Combining Parts and Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . 575

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .576

Basic Concepts of Combining Parts and Surfaces . . . . . . . . . . . . . . . . . . .577

Using Surface Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .577

Creating Surface Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .579

Attaching Surfaces Parametrically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .582

Cutting Parts with Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .584

Creating Extruded Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .586

Creating Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .598

Creating Features on a Work Plane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

Modifying Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .609

Finishing Touches on Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .611

x | Contents

Page 11

Chapter 21 Surfacing Wireframe Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 613

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 614

Basic Concepts of Surfacing Wireframe Models . . . . . . . . . . . . . . . . . . . . 615

Discerning Design Intent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 615

Identifying Logical Surface Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . 616

Identifying Base Surface Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 617

Using Trimmed Planar Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . 619

Choosing a Surfacing Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 620

Verifying Surfacing Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 623

Surfacing Wireframe Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 624

Creating Trimmed Planar Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 626

Joining Surfaces on Complex Shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 634

Creating Swept and Projected Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . 645

Creating Complex Swept Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 655

Using Projection to Create Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 661

Using Advanced Surfacing Techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . 665

Viewing Completed Surfaced Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 669

Chapter 22 Working with Standard Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 671

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 672

Tutorial at a Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 673

Basic Concepts of Standard Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 673

Inserting Through Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 674

Using Cylinder Axial Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . 674

Using Cylinder Radial Placement . . . . . . . . . . . . . . . . . . . . . . . . . . 677

Inserting Screw Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 681

Chapter 23 Creating Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 689

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 690

Tutorial at a Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 691

Basic Concepts of the Shaft Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . 691

Using the Shaft Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 692

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 692

Creating Shaft Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 693

Adding Threads to Shafts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 695

Adding Profile Information to Shafts . . . . . . . . . . . . . . . . . . . . . . . 697

Editing Shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 698

Adding Standard Parts to Shafts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 701

Displaying and Shading 3D Views. . . . . . . . . . . . . . . . . . . . . . . . . . 705

Contents | xi

Page 12

Chapter 24 Calculating Stress on 3D Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 707

Key Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .708

Tutorial at a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .709

Basic Concepts of 3D FEA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .709

Using 3D FEA Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .710

Performing Finite Element Analyses. . . . . . . . . . . . . . . . . . . . . . . . .710

Defining Supports and Forces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .711

Calculating and Displaying the Result . . . . . . . . . . . . . . . . . . . . . . .715

Desktop Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .720

Part Modeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .721

Part Modeling ➤ New Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .721

Part Modeling ➤ New Sketch Plane . . . . . . . . . . . . . . . . . . . . . . . . .722

Part Modeling ➤ 2D Sketching. . . . . . . . . . . . . . . . . . . . . . . . . . . . .722

Part Modeling ➤ 2D Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . .725

Part Modeling ➤ Profile a Sketch . . . . . . . . . . . . . . . . . . . . . . . . . . .726

Part Modeling ➤ Sketched Features . . . . . . . . . . . . . . . . . . . . . . . . .727

Part Modeling ➤ Placed Features . . . . . . . . . . . . . . . . . . . . . . . . . . .727

Part Modeling ➤ Work Features . . . . . . . . . . . . . . . . . . . . . . . . . . . .727

Part Modeling ➤ Power Dimensioning . . . . . . . . . . . . . . . . . . . . . .728

Part Modeling ➤ Edit Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .728

Part Modeling ➤ Update Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .728

Part Modeling ➤ Part Visibility . . . . . . . . . . . . . . . . . . . . . . . . . . . .729

Part Modeling ➤ Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .729

Toolbody Modeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .730

Toolbody Modeling ➤ New Toolbody . . . . . . . . . . . . . . . . . . . . . . .730

Toolbody Modeling ➤ Part Catalog . . . . . . . . . . . . . . . . . . . . . . . . .730

Toolbody Modeling ➤ 3D Toolbody Constraints . . . . . . . . . . . . . .731

Toolbody Modeling ➤ Power Manipulator . . . . . . . . . . . . . . . . . . .731

Toolbody Modeling ➤ Check Interference. . . . . . . . . . . . . . . . . . . .731

Toolbody Modeling ➤ Toolbody Visibility . . . . . . . . . . . . . . . . . . .732

Assembly Modeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .732

Assembly Modeling ➤ New Subassembly. . . . . . . . . . . . . . . . . . . . .733

Assembly Modeling ➤ Assembly Catalog. . . . . . . . . . . . . . . . . . . . .733

Assembly Modeling ➤ 3D Assembly Constraints. . . . . . . . . . . . . . .733

Assembly Modeling ➤ Assign Attributes . . . . . . . . . . . . . . . . . . . . .734

Assembly Modeling ➤ Power Manipulator . . . . . . . . . . . . . . . . . . .734

Assembly Modeling ➤ Mass Properties. . . . . . . . . . . . . . . . . . . . . . .734

Assembly Modeling ➤ Assembly Visibility. . . . . . . . . . . . . . . . . . . .734

xii | Contents

Page 13

Surface Modeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 735

Surface Modeling ➤ AutoSurf Options . . . . . . . . . . . . . . . . . . . . . . 735

Surface Modeling ➤ Swept Surface . . . . . . . . . . . . . . . . . . . . . . . . . 736

Surface Modeling ➤ Loft U Surface . . . . . . . . . . . . . . . . . . . . . . . . . 736

Surface Modeling ➤ Blended Surface. . . . . . . . . . . . . . . . . . . . . . . . 736

Surface Modeling ➤ Flow Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . 737

Surface Modeling ➤ Object Visibility . . . . . . . . . . . . . . . . . . . . . . . 737

Surface Modeling ➤ Surface Display . . . . . . . . . . . . . . . . . . . . . . . . 737

Surface Modeling ➤ Stitches Surfaces . . . . . . . . . . . . . . . . . . . . . . . 738

Surface Modeling ➤ Grip Point Placement . . . . . . . . . . . . . . . . . . . 738

Surface Modeling ➤ Lengthen Surface . . . . . . . . . . . . . . . . . . . . . . 738

Surface Modeling ➤ Extract Surface Loop . . . . . . . . . . . . . . . . . . . . 739

Surface Modeling ➤ Edit Augmented Line . . . . . . . . . . . . . . . . . . . 739

Surface Modeling ➤ Wire Direction . . . . . . . . . . . . . . . . . . . . . . . . 739

Scene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 740

Scene ➤ New Scene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 740

Scene ➤ Scene Visibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 741

Drawing Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 741

Drawing Layout ➤ Power Dimensioning . . . . . . . . . . . . . . . . . . . . 742

Drawing Layout ➤ Drawing Visibility. . . . . . . . . . . . . . . . . . . . . . . 744

Mechanical View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 744

Mechanical View ➤ Zoom Realtime . . . . . . . . . . . . . . . . . . . . . . . . 745

Mechanical View ➤ 3D Orbit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 745

Mechanical View ➤ Sketch View. . . . . . . . . . . . . . . . . . . . . . . . . . . 746

Mechanical View ➤ Restore View #1. . . . . . . . . . . . . . . . . . . . . . . . 746

Mechanical View ➤ Toggle Shading/Wireframe . . . . . . . . . . . . . . . 747

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 749

Contents | xiii

Page 14

xiv

Page 15

Part I

Getting Started

with Autodesk

Mechanical Desktop

Part I provides information for getting started with your Mechanical Desktop 6 software. It

includes information to help in the transition from AutoCAD

from previous releases. It explains the user interface and the basics of modeling in the

different work environments in Mechanical Desktop.

In addition, Part I provides a guide to both the print and online documentation that you

®

®

®

and the migration of files

received with your Mechanical Desktop software. Information about training courseware

and Internet resources are also included.

1

Page 16

2 |

Page 17

Welcome

In This Chapter

1

This chapter provides an overview of the capabilities of

®

Autodesk

about the transition from AutoCAD

and the migration of files from previous releases with the

Mechanical Desktop Migration Assistance.

Mechanical Desktop® 6 software. You learn

®

, data exchange,

About Mechanical Desktop

■

■ Making the transition from

AutoCAD

■ Migrating files from previous

releases

3

Page 18

What is Autodesk Mechanical Desktop?

Mechanical Desktop is a powerful and easy-to-use 3D parametric modeler

used in mechanical design. Built on AutoCAD 2002, the Mechanical Desktop

6 design software package includes:

■ AutoCAD Mechanical 6 with the power pack (2D Parts and Calculations)

■ Mechanical Desktop 6 with the power pack (Mechanical Desktop 6, 3D

Parts and Calculations)

■ AutoCAD 2002

When you start Mechanical Desktop 6, you have the option to run it with or

without the power pack.

The Mechanical Desktop software provides design tools to

■ Create parts from sketched and placed features

■ Combine parts and toolbodies

■ Build assemblies and subassemblies

■ Define scenes for drawing views

■ Set up drawing sheets and views

■ Annotate drawings for final documentation

■ Manage and reuse design data

■ Migrate and edit legacy solids data

Productivity and collaboration tools in Mechanical Desktop enable you to

improve workflows and comply with company practices.

Web tools are provided in a design portal called the Today page. From the

Today page, you can

■ Start a new drawing or open an existing drawing

■ Access symbol libraries

■ Communicate to design team members through a Web page you create

from a template provided

■ Link directly to design information on the Web

■ Link directly to Autodesk Web pages

For more information about the Today page, see “Mechanical Desktop

Today” on page 14.

4 | Chapter 1 Welcome

Page 19

Making the Transition from AutoCAD

Mechanical Desktop 6 is built on AutoCAD 2002 and uses many of the tools

you may already be familiar with. Because Mechanical Desktop is a parametric

modeling program, exercise care in using standard AutoCAD commands.

In the sketching stage, you can use any AutoCAD command to create the

geometry for your sketch. You can use AutoCAD drawing and editing tools

to edit sketch geometry after it has been consumed by a feature.

In general, follow these rules:

■ Use Mechanical Desktop dimensions. AutoCAD dimensions are not

parametric and cannot control the size, shape, or position of Mechanical

Desktop parts and features.

■ Use sketch planes and work planes to control the UCS orientation. Using

the AutoCAD

your part.

■ Do not use the command EXPLODE. Exploding a part deletes the part

definition from a Mechanical Desktop drawing.

■ Use the Assembly Catalog or the Browser to insert external part files into

drawings and externalize part files. Using the AutoCAD

XREF, and XBIND commands could corrupt Mechanical Desktop data.

■ Use the Mechanical Desktop drawing view commands to create drawing

views. The AutoCAD

of your parts.

UCS command does not associate the current plane with

INSERT, WBLOCK,

MVIEW command does not create associative views

Migrating Files from Previous Releases

In Mechanical Desktop 6, you can add more than one part to a part file for

creating combined parts. The first part becomes the part definition, while all

other parts become unconsumed toolbodies. You combine toolbodies with

each other and the first part to create a complex part.

To migrate parts from a part file that contains more than one part and was

created before Mechanical Desktop Release 2, you need to follow specific

procedures. See "Running the Desktop File Migration Utility" in the Autodesk

Mechanical Products Installation Guide on the product CD.

The File Migration Tool (FMT) is a component of Mechanical Desktop

Migration Assistance, an independent Visual Basic (not VBA) application

located on your product CD. The FMT migrates multiple files from previous

releases of Mechanical Desktop to the current format. You can install

Mechanical Desktop Migration Assistance during or after the installation of

your Autodesk mechanical product.

Making the Transition from AutoCAD | 5

Page 20

To install the Mechanical Desktop Migration Assistance from your product CD

1 Hold down the

drive. This prevents Setup from starting automatically.

2 In the file tree of the CD-ROM drive, navigate to the Migrate folder and click

setup.exe.

3 Respond to the directions in the Mechanical Desktop Migration Assistance

installation dialog boxes.

NOTE For more information about installing the Migration Assistance and

running the FMT, see "Mechanical Desktop Migration Assistance" in the

Autodesk Mechanical Products Installation Guide on your product CD.

Data Exchange

During your design process, you may want to complement Mechanical

Desktop with other computer-aided design (CAD) software. Mechanical

Desktop 6 includes the STEP translator and the IGES Translator. The Standard

for the Exchange of Product Model Data (STEP) is International Standards

Organization (ISO) 10303. The Initial Graphics Exchange Specification

(IGES) is the ANSI standard for data exchange between CAD systems and is

supported by many CAD vendors.

SHIFT key while you insert the product CD into the CD-ROM

The IGES Translator is compliant with the most recent version of IGES and

related standards. It supports both the United States Department of Defense

Continuous Acquisition and Life-cycle Support initiative (CALS) and the Japanese Automotive Manufacturers Association subset of IGES (JAMA).

Besides creating and maintaining a flexible CAD tool environment, the

Translator preserves the investment you have made in previous designs

developed with other CAD systems.

The Translator supports the following types of design objects:

■ 2D and 3D wireframe geometry

■ Ruled, parametric, and NURBS surfaces

■ Mechanical Desktop and AutoCAD native solids, and IGES boundary

representation solids (B-rep).

For more information, see STEP and IGES in the Mechanical Desktop Help.

6 | Chapter 1 Welcome

Page 21

Modeling with Autodesk®

Mechanical Desktop

This chapter describes the basic concepts of mechanical

design with Autodesk Mechanical Desktop software,

including fundamentals of parametric design.

If you understand the underlying concepts in this chap-

ter, you can become proficient in using the Mechanical

Desktop software.

®

In This Chapter

Mechanical Desktop basics

■

■ Mechanical Desktop work

environments

2

7

Page 22

Mechanical Desktop Basics

g

Mechanical Desktop is an integrated package of advanced 3D modeling tools

and 2D drafting and drawing capabilities that helps you conceptualize,

design, and document your mechanical products.

You create models of 3D parts, not just 2D drawings.

You use these 3D parts to create 2D drawings and 3D assemblies.

2D drawin

Mechanical Desktop, a dimension-driven system, creates parametric models.

Your model is defined in terms of the size, shape, and position of its features.

You can modify the size and shape of your model, while preserving your

design intent.

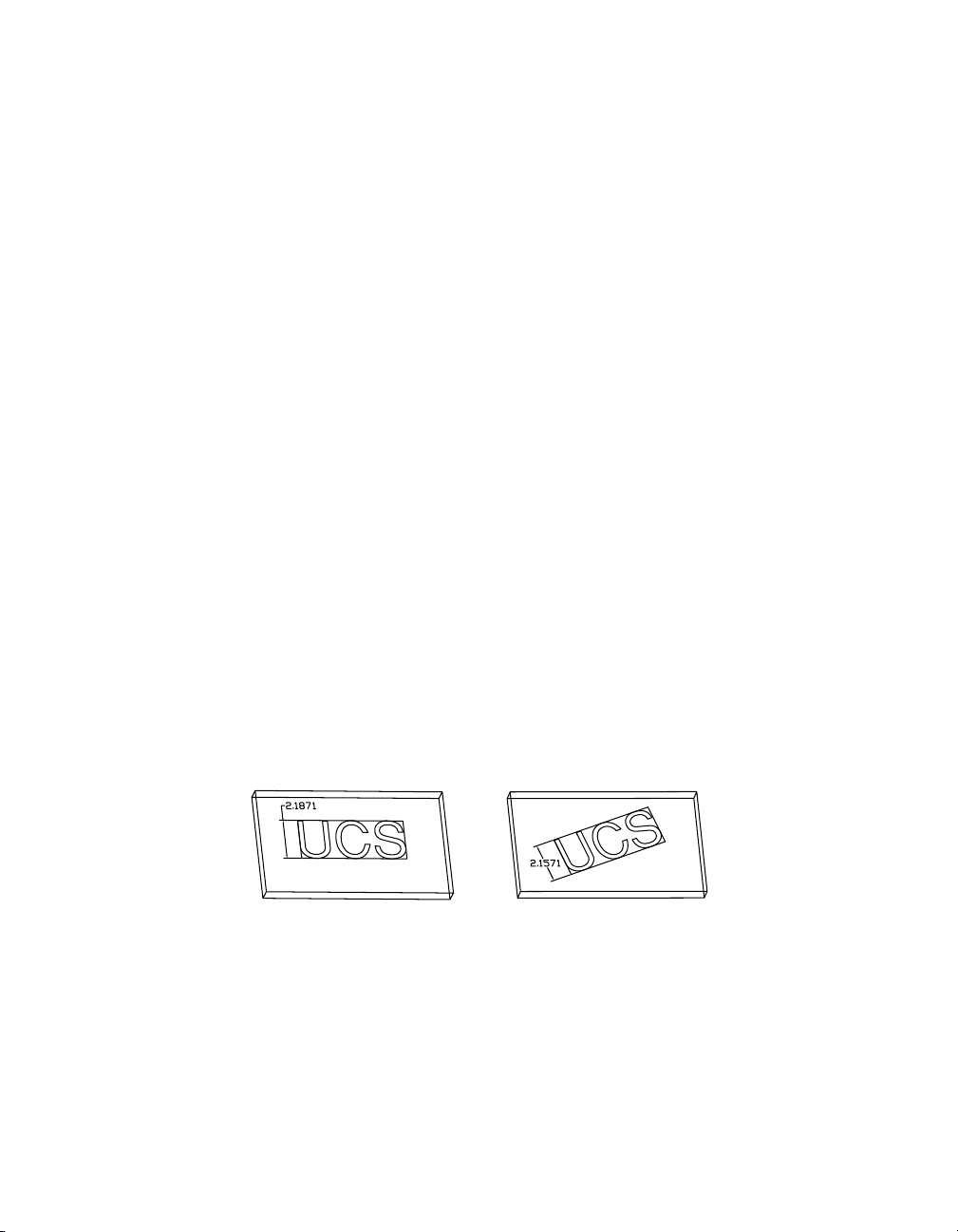

original part revised part

You build parts from features—the basic shapes of your part.

Building blocks like extrusions, lofts, sweeps, bends, holes, fillets, and chamfers are parametrically combined to create your part.

3D part

revolved feature

extruded feature

8 | Chapter 2 Modeling with Autodesk Mechanical Desktop

Page 23

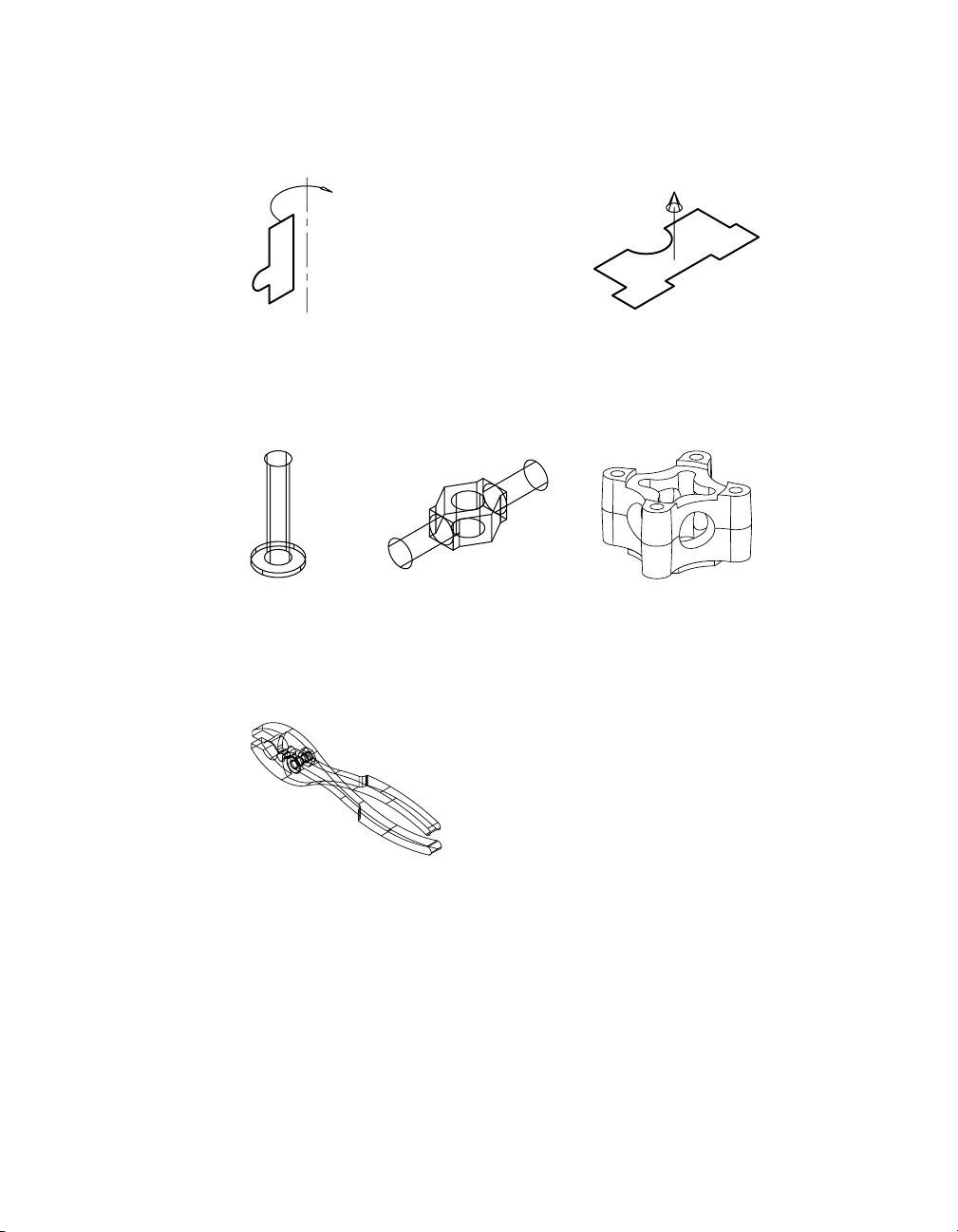

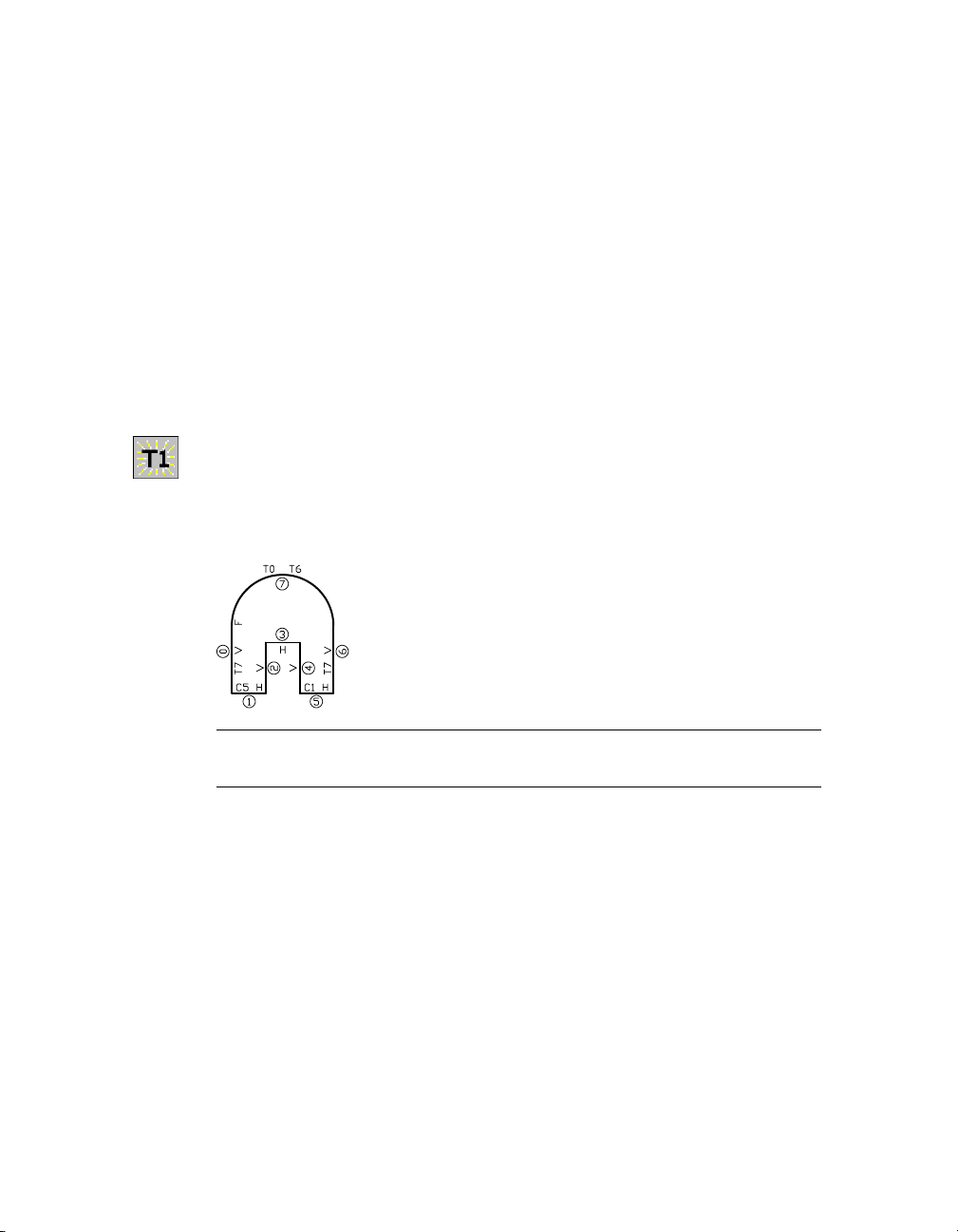

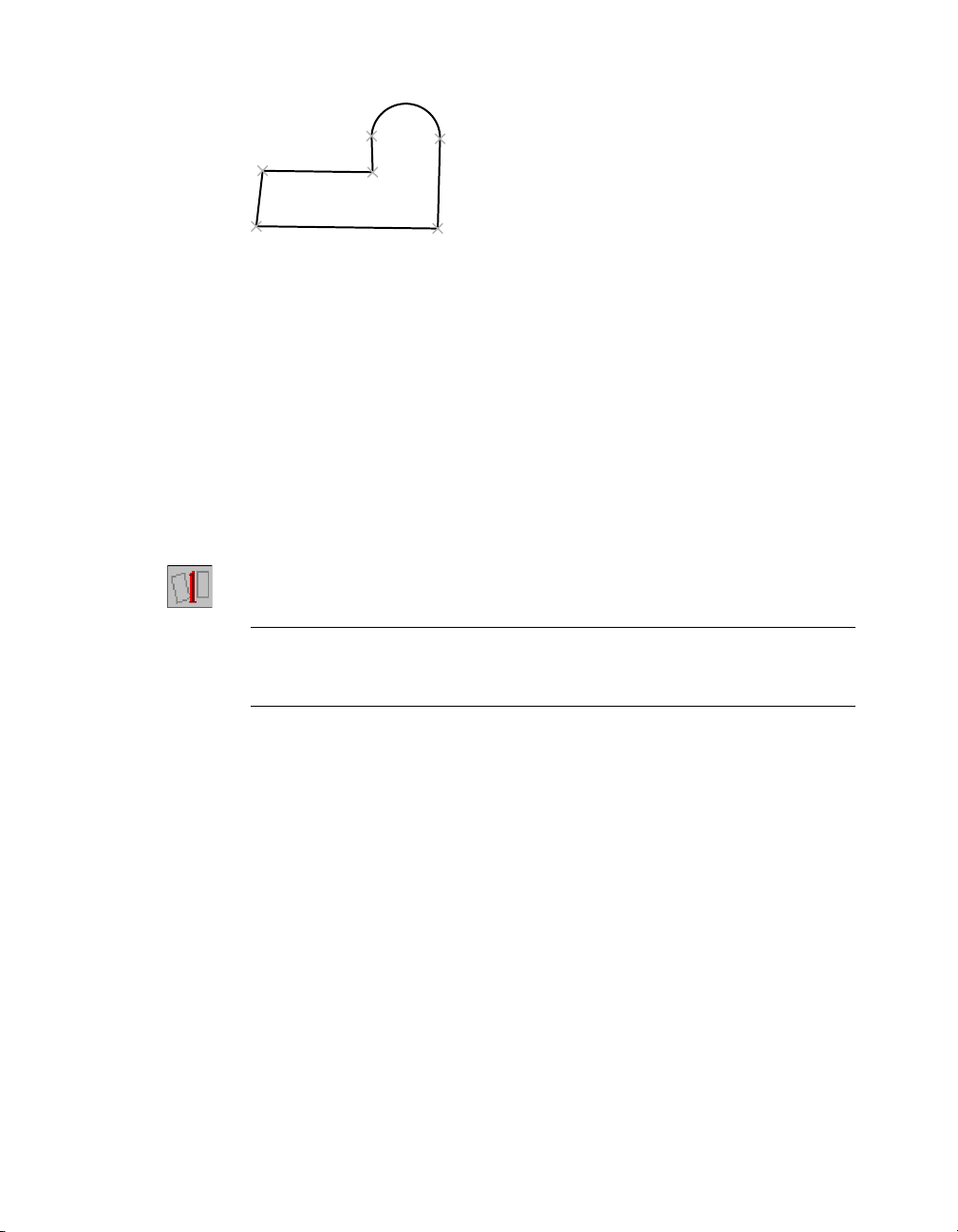

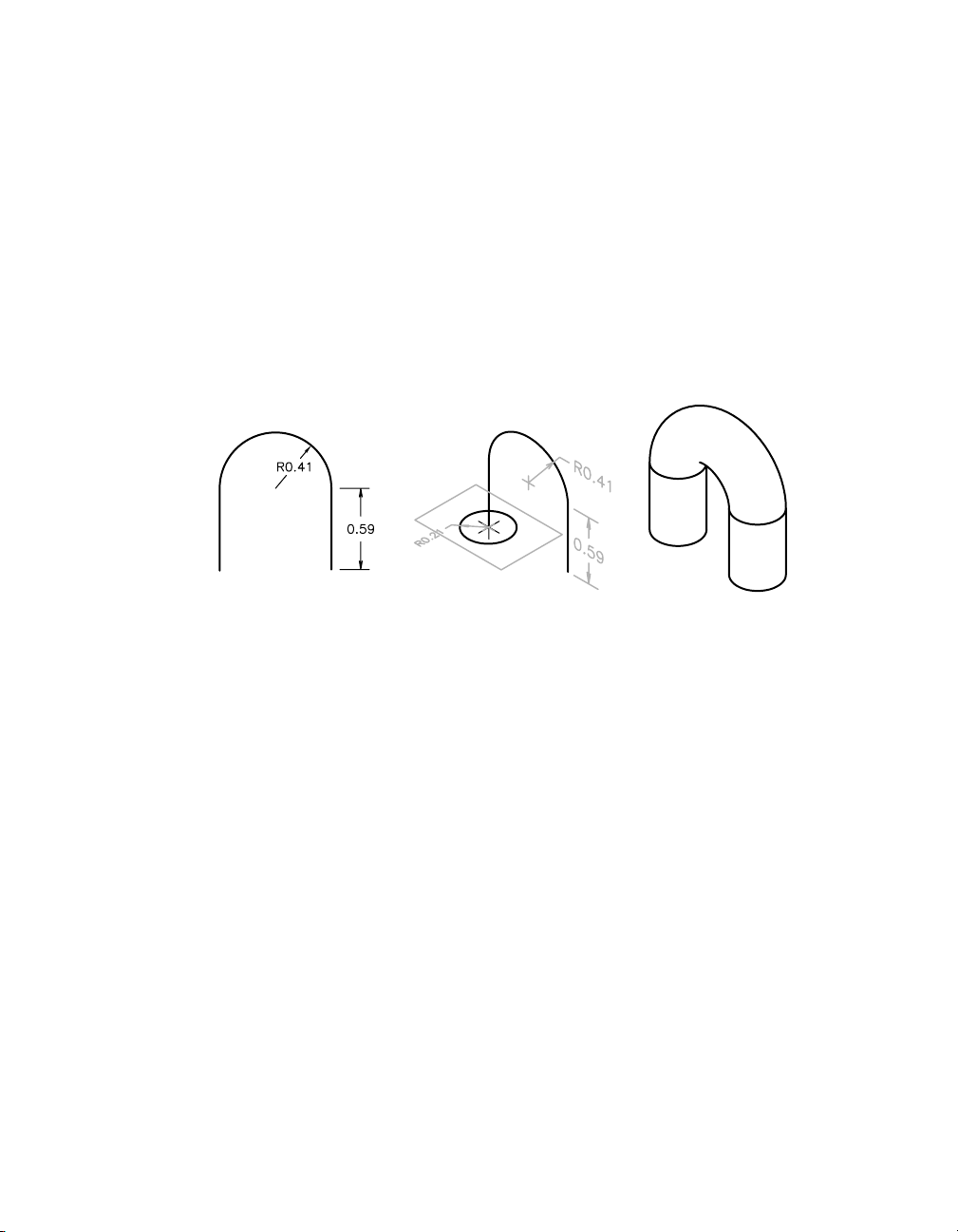

You create most features from sketches.

Sketches can be extruded, revolved, lofted, or swept along a path to create

features.

sketch for revolved feature

sketch for extruded feature

You work in the Part Modeling environment to create single parts.

In this environment, only one part can exist in a drawing. Additional parts

become unconsumed toolbodies for the purpose of creating a combined part.

Use part files to build a library of standardized parts.

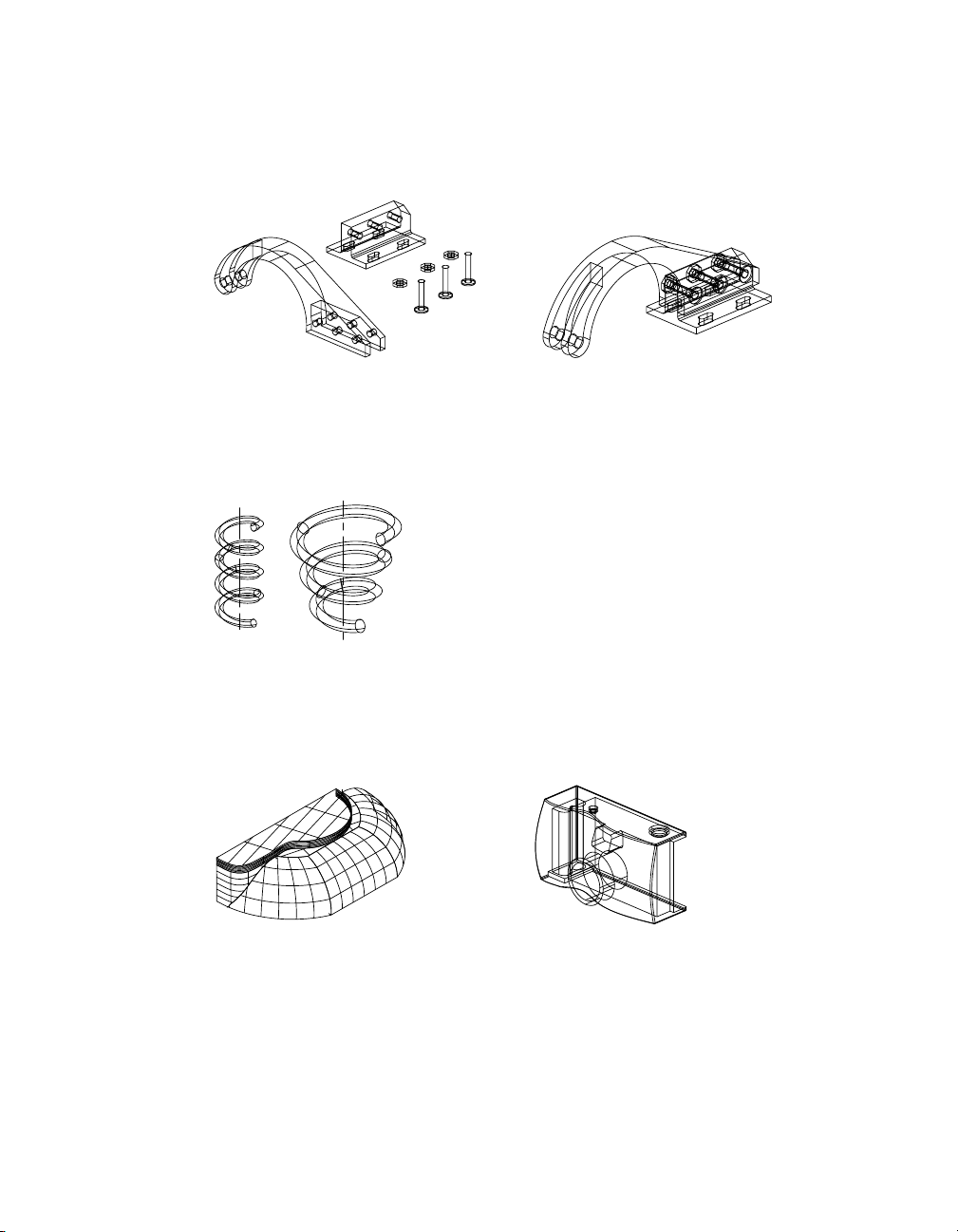

examples of single part files

You work in Assembly Modeling to create multiple parts and assemblies.

In this environment, any number of parts can exist in one drawing. Parts can

be externally referenced from part and assembly files, or localized in the

assembly drawing.

assembly file containing four external part files

Mechanical Desktop Basics | 9

Page 24

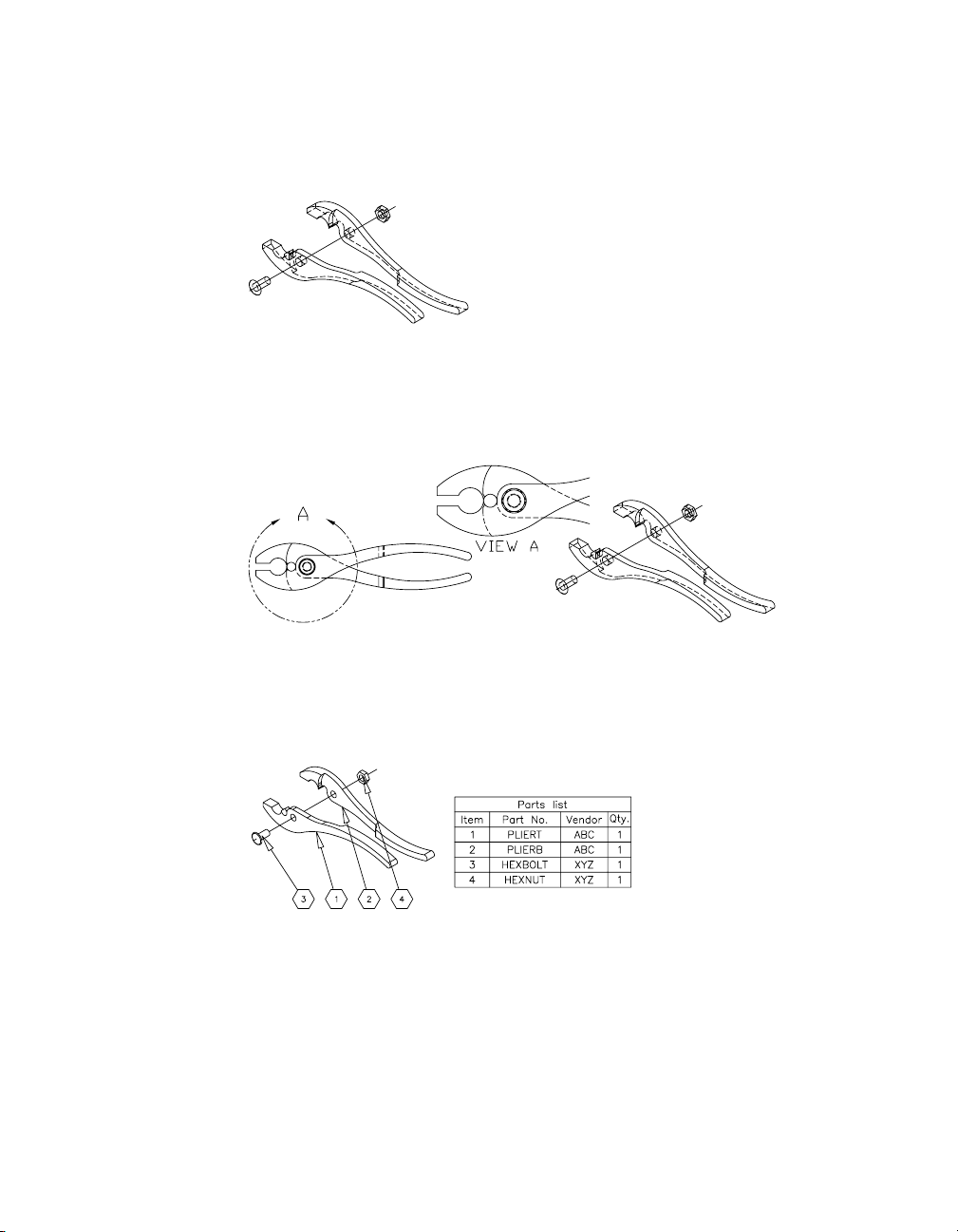

Individual parts can be fit together to create subassemblies and assemblies.

Assembly files contain more than one part. Parts are fit together using assembly constraints to define the positions of the individual parts that make up

your final product.

individual parts in an assembly file

completed assembly

For standard parts, you can define different versions using a spreadsheet.

Instead of a large library of parts that differ only in size, like springs, bolts,

nuts, washers, and clamps, you can create one part and define different versions of that part in a spreadsheet that is linked to your drawing.

table driven part versions

You can also create 3D surface models.

Surface modeling is useful in the design of stamping dies, castings, or injection molds. You can also use surfaces to add to or cut material from a solid

part to create hybrid shapes.

surfaces used to create a part

surface cut applied to a part

10 | Chapter 2 Modeling with Autodesk Mechanical Desktop

Page 25

You can create scenes to define how your design fits together.

To better conceptualize the position of the parts in your assembly, you define

scenes using explosion factors, tweaks, and trails that illustrate how your

design is assembled.

exploded scene

You can create base, orthogonal, isometric, section, and detail views.

To document your design, drawing views can be created from scenes, parts,

or groups of selected objects. Any design changes are automatically updated

in these drawing views.

parametric drawing views

Add annotations and additional dimensions to finalize your documentation.

After you have created drawing views, finalize your design by adding balloons, bills of material, notes, reference dimensions, and mechanical

symbols.

annotations added to drawing

Mechanical Desktop Basics | 11

Page 26

12

Page 27

The User Interface

In This Chapter

3

When you start the Autodesk® Mechanical Desktop® 6

software, a page called the Today window is displayed.

This chapter provides an overview of the options on the

Today window to help manage your work, collaborate

with others, and link to information on the Web.

Information about the work environments and the user

interface are included to help you get started using the

Mechanical Desktop software.

The Today window

■

■ Work environm e nts

■ Mechanical Desktop interface

■ Working in the Browser

■ Methods for issuing commands

13

Page 28

Mechanical Desktop Today

The first time you open the Mechanical Desktop 6 program, the Today window

is displayed on top of the program interface, along with instructions about how

to use it. The Today feature is a powerful tool that makes it easy to manage drawings, communicate with design teams, and link directly to design information.

In the Today Window, you can expand the following options for access to the

the services you require.

My Workplace Connect directly to files on your computer and your local

network.

My Drawings Open existing drawings, create new ones, or access

symbol libraries.

Bulletin Board Post your own Web page with links to block libraries, CAD

standards, or other folders and directories on your

company network. CAD managers can use the Bulletin

Board to communicate with their design teams. An HTML

bulletin board template is provided.

The Web Connect directly to the Internet.

Autodesk

Point A

You can close the Today Window and use the File menu to create new drawings or open existing drawings.

To reopen Today, in the Assist menu choose Mechanical Desktop Today.

If you prefer not to see the Today Window when you start Mechanical

Desktop, you can turn it off in Assist ➤ Options ➤ System ➤ Startup.

Link directly to design information and tools such as

Buzzsaw.com on the Web. Use the units converter, link to

Autodesk Web sites, and much more.

Login and create your free account. Customize the

information in Autodesk Point A for your specific needs.

14 | Chapter 3 The User Interface

Page 29

Mechanical Desktop Environments

Mechanical Desktop has two working environments: Assembly Modeling

and Part Modeling.

Assembly Modeling Environment

This is the environment Mechanical Desktop uses when you start the

program or create a new file by using File ➤ New. Any number of parts and

subassemblies can coexist in the same drawing.

The advantages of the Assembly Modeling environment are

■ More than one part can be created in the same drawing.

■ Individual part files, and other assemblies or subassemblies, can be exter-

nally referenced or localized and used to build a complex assembly.

■ Different versions of a part can be displayed in the same file.

■ Scenes containing explosion factors, tweaks, and trails can be created.

There are three modes in the Assembly Modeling environment: Model,

Scene, and Drawing.

Model Mode

In Model mode, you create as many parts as you need. Parts may be local or

externally referenced. Create subassemblies and save them for use in larger

assemblies. Build assemblies from any number of single part files, subassemblies, and assemblies. You can also generate a BOM (Bill of Material) database

so a list of parts can be placed in your final drawing.

Scene Mode

In Scene mode, you set explosion factors for your assembled parts and create

tweaks and trails. These settings govern how your drawing views represent

your assemblies.

Drawing Mode

In an assembly file, you can place balloons to reference the parts in your

assembly. You can create a parts list with as much information as you need

to define your parts. To illustrate how parts in an assembly fit together, you

can create base views on exploded scenes.

Mechanical Desktop Environments | 15

Page 30

Part Modeling Environment

To begin a new drawing in the Part Modeling environment, choose File ➤

New Part File. Only one part may exist in the drawing. If you add more parts,

they automatically become unconsumed toolbodies. You use toolbodies to

create complex combined parts.

The advantages of the Part Modeling environment are

■ A library of standard parts can be created for use in assembly files.

■ The interface is streamlined to allow only those commands available in a

part file.

■ File sizes are minimized because the database doesn’t need additional

assembly information.

There are two modes in the Part Modeling environment: Model and Drawing.

Model Mode

In Model mode, you build and modify your design to create a single parametric part. The part takes the name of the drawing file.

Drawing Mode

In Drawing mode, you define views of your part and place annotations for

documentation. You can also create a parts list and balloons to reference a

combined part and its toolbodies.

16 | Chapter 3 The User Interface

Page 31

Mechanical Desktop Interface

When you open a new or existing drawing in Mechanical Desktop 6, four

toolbars and the Desktop Browser are displayed.

■ The Mechanical Main toolbar provides quick access to select commands

from the AutoCAD Standard and the Object Properties toolbars, some

Mechanical Desktop commands, and the Web. Icons are available for

direct links to Mechanical Desktop Today window and Web tools such as,

Point A, Streamline, RedSpark, MeetNow, Publish to Web, and eTransmit.

■ The Desktop Tools toolbar acts as a toggle, giving you quick access to Part

Modeling, Assembly Modeling, Scenes, and Drawing Layout.

■ The Part Modeling toolbar is the default, but, when you use the Desktop

Tools toolbar or the Desktop Browser to switch modes, the toolbar repre-

senting the mode you have chosen is displayed.

■ The Mechanical View toolbar is designed to give you full control over how

you view your models, including real-time pan, zoom, dynamic 3D

rotation, and shading commands.

■ The Desktop Browser is docked at the left side of the screen.

Desktop Tools toolbar

Mechanical Main toolbar

Help

Mechanical View toolbar

Desktop Browser

Part Modeling toolbar

Mechanical Desktop Interface | 17

Page 32

There are four main toolbars controlled by the Desktop Tools toolbar: Part

Modeling, Assembly Modeling, Scene, and Drawing Layout.

Part Modeling

Assembly Modeling

Scene

Drawing Layout

If you begin a drawing in the Part Modeling environment, the Desktop Tools

toolbar changes to display three buttons that control the Part Modeling,

Toolbody Modeling, and Drawing Layout toolbars.

Part Modeling

Toolbody Modeling

Drawing Layout

In addition to controlling the Mechanical Desktop toolbars, the Desktop

Tools toolbar switches between Part, Toolbody/Assembly, Scene, and

Drawing modes.

For a complete description of Mechanical Desktop toolbars, see appendix A,

“Toolbar Icons.”

Desktop Browser

When you start Mechanical Desktop 6, the Desktop Browser is displayed in

the default position at the left of your screen.

Docking the Desktop Browser

Right-click the gray area at the top of the Browser for a context menu of docking

controls. You can turn the following Browser docking options on and off.

Allow Docking With Docking on, you can drag a corner of the Browser to

change its shape and size, and you can drag the Browser

to a new location on your screen.

To return the Browser to its default position, turn on

Allow Docking, and double-click the Browser title bar.

18 | Chapter 3 The User Interface

Page 33

AutoHide With AutoHide on, choose Collapse to minimize the

Browser. When you move the cursor over and off of the

Browser, it expands and collapses.

Choose Right or Left to hide the Browser off a side of the

screen. When you move your cursor to the corresponding

edge of the screen, the Browser is displayed. Move the

cursor off the Browser, and it is hidden again.

To turn AutoHide off, in the Browser docking menu

choose AutoHide ➤ Off.

Hide Hides the Browser entirely. To restore it, in the Desktop

menu choose View ➤ Display ➤ Desktop Browser.

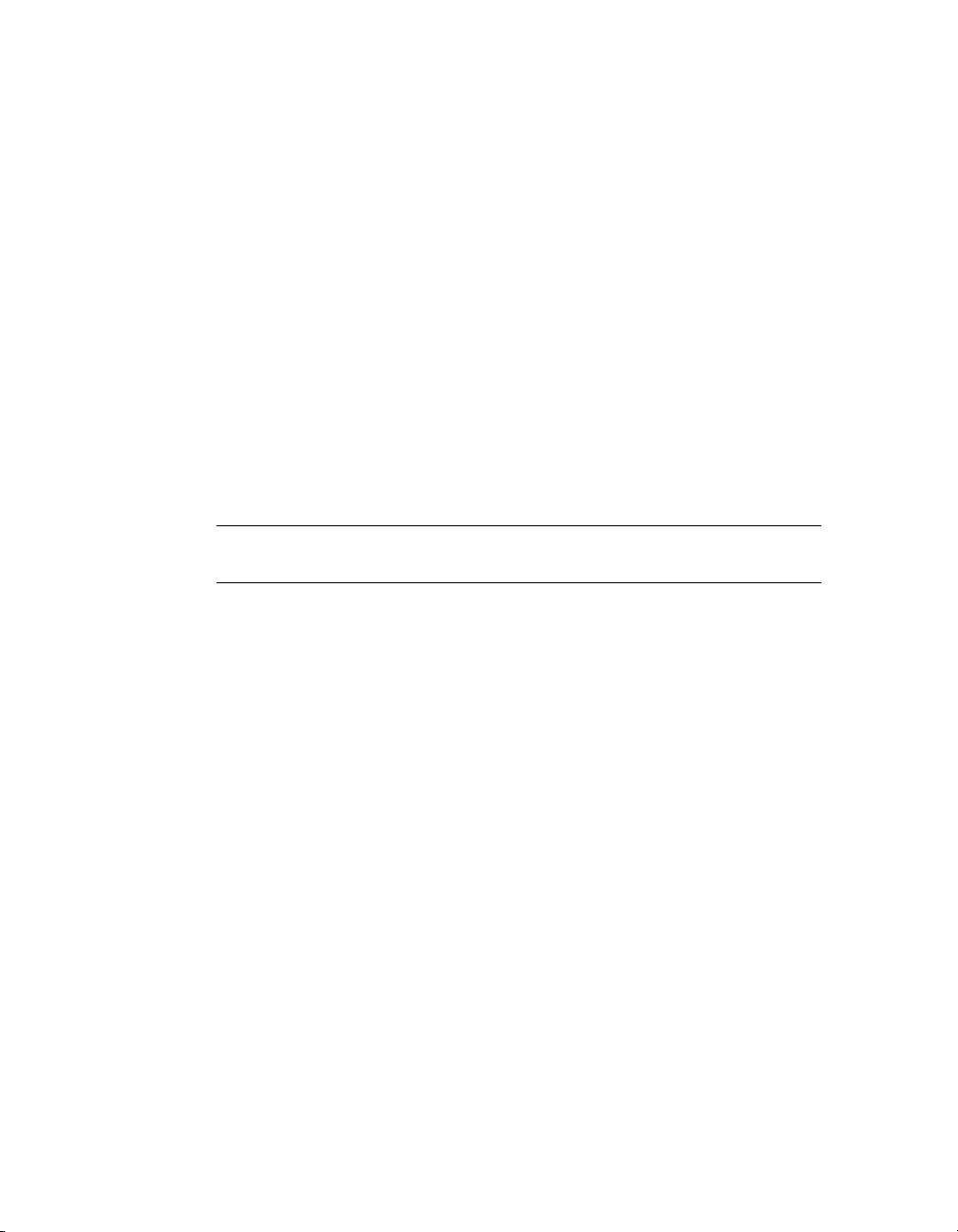

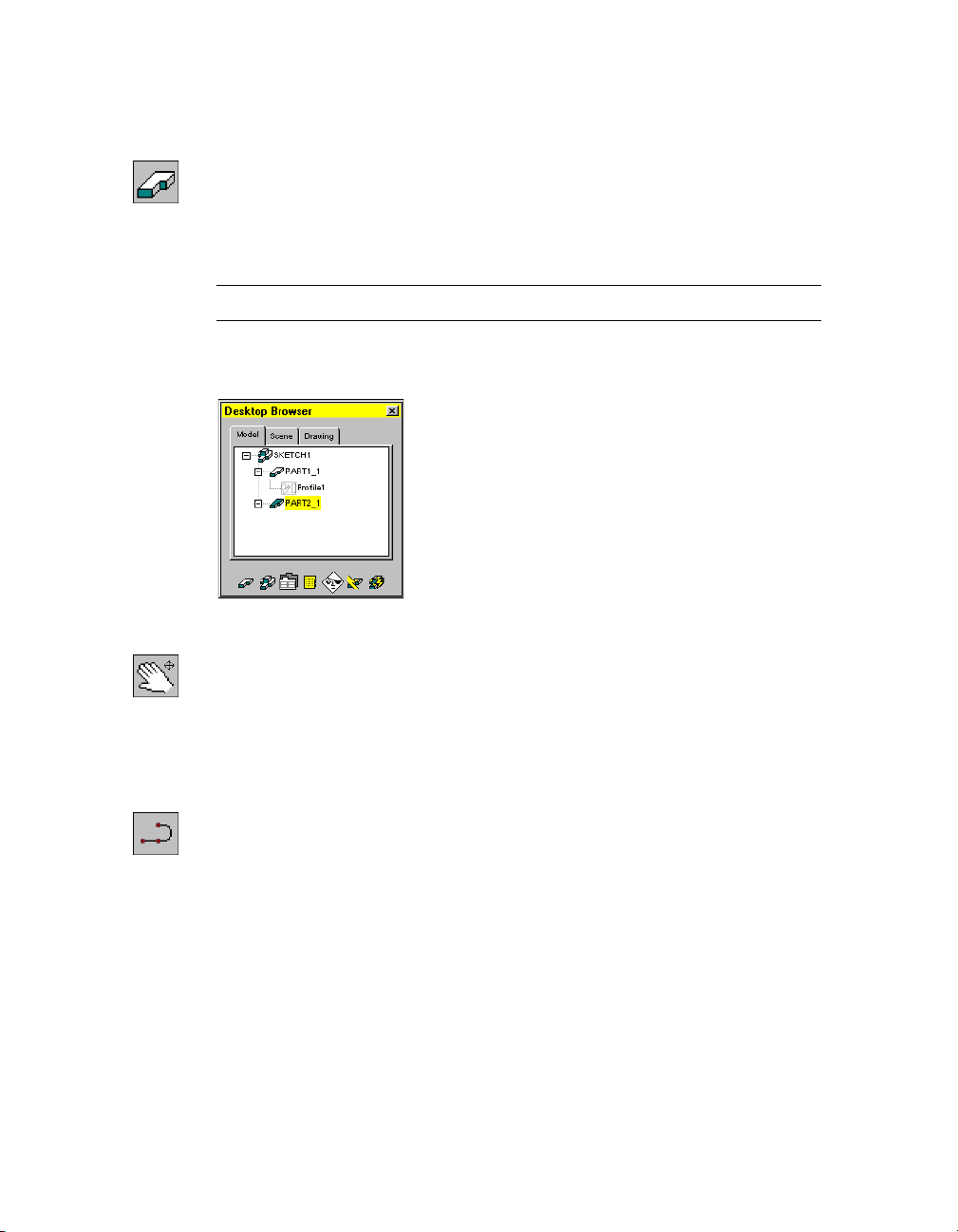

Working with the Desktop Browser

When you begin, Mechanical Desktop starts a new drawing in the Assembly

Modeling environment. The assembly is named for the current file.

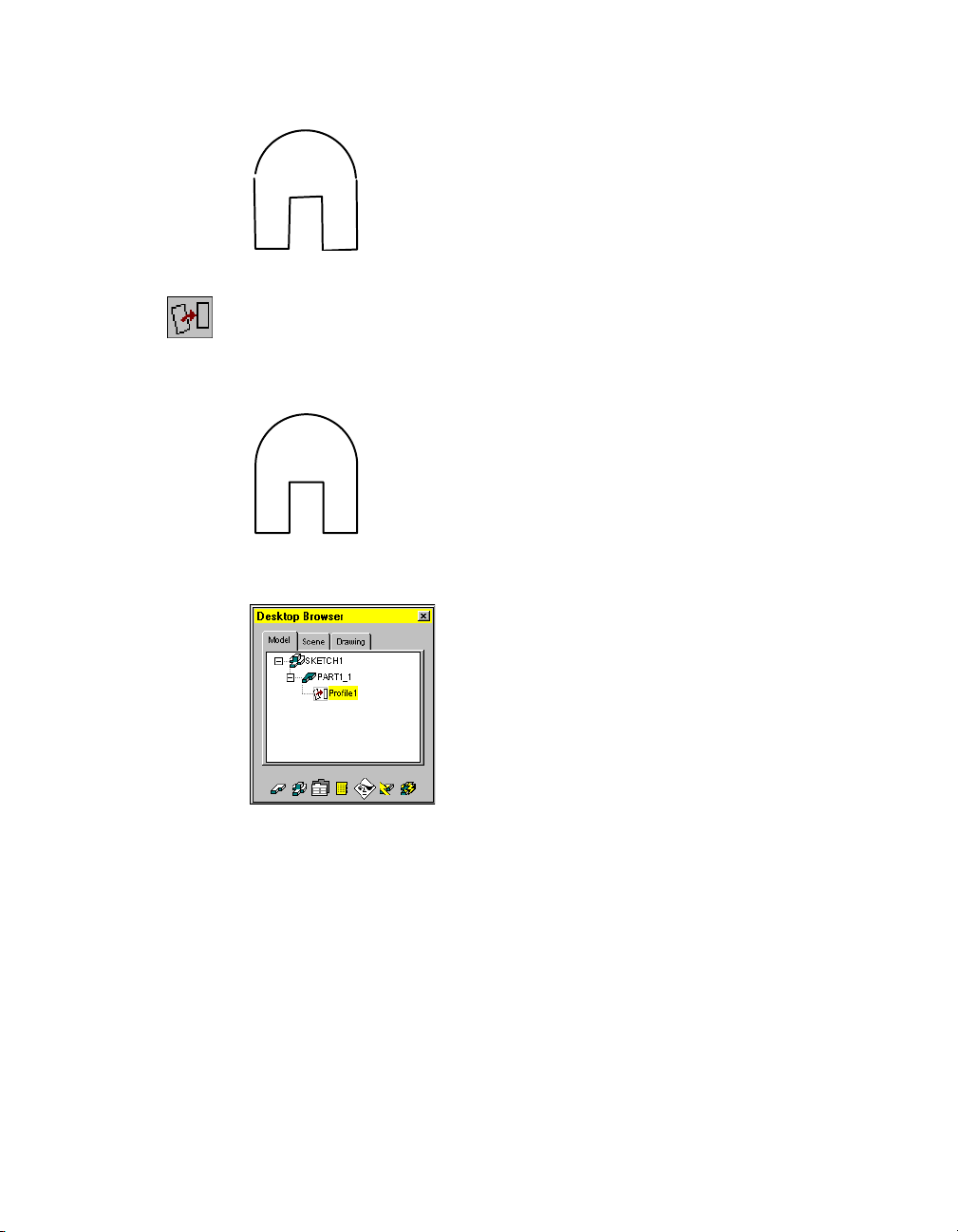

When you create the first sketch, a part is automatically named, numbered,

and represented in the Browser. Because the first thing you create is a sketch,

it is nested under the part. As these objects are created, they are displayed

automatically in a hierarchy.

In the Browser, you can show as much or as little detail as you wish. When

there is more information, a plus sign is shown beside an object. You click

the plus sign to reveal more levels.

Mechanical Desktop Interface | 19

Page 34

You collapse levels by clicking the minus sign beside an object, or collapse

the entire hierarchy by right-clicking the assembly name and choosing

Collapse from the menu.

When you start a new drawing in the Part Modeling environment, or open

an existing part file, the Desktop Browser contains two tabs: Model and

Drawing. In the Assembly Modeling environment, the Browser contains

three tabs: Model, Scene, and Drawing. You can choose the tabs at the top of

the Browser window to navigate from one mode to another.

Part Modeling environment

Icons at the bottom of the Browser provide quick access to frequently-used

commands.

Assembly Modeling environment

Using the Browser in Part Modeling

When you are working in the Part Modeling environment, the Browser

contains two tabs: Model and Drawing.

Model Mode in Part Modeling

In Model mode, seven icons are displayed at the bottom of the Browser.

The two at the left are quick filters. These filters are available so that you can

control the visibility of features and assembly constraints in the Browser

when you are creating combined parts.

20 | Chapter 3 The User Interface

Page 35

The first icon, the Part filter, controls the display of assembly constraints

attached to a part and its toolbodies. If the Part filter is selected, only the

features of your part and its toolbodies are visible in the Browser. If it is not

selected, assembly constraints are also visible.

The second icon is the Assembly filter. If you select this filter, only assembly

constraints that are attached to your part and its toolbodies are visible.

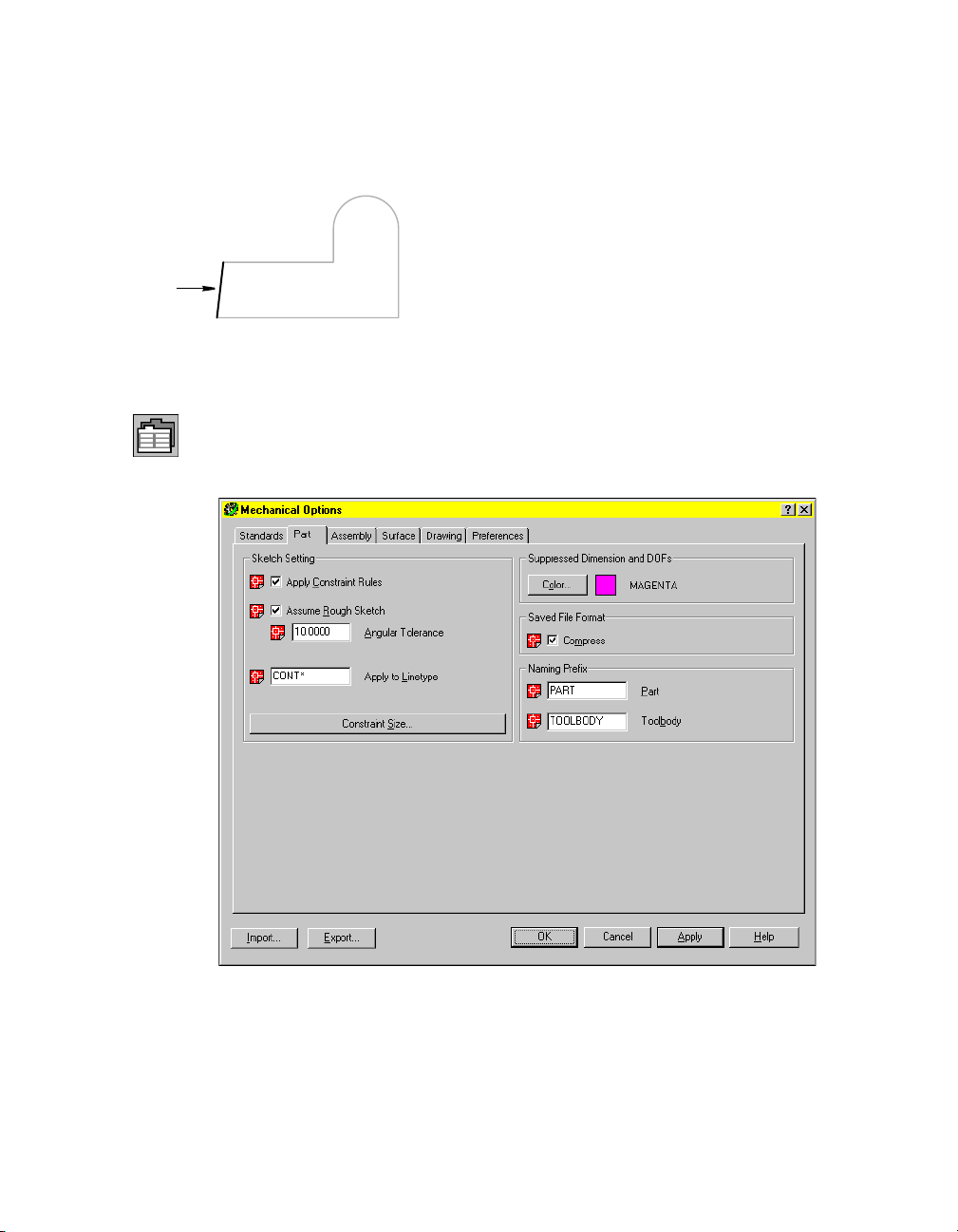

The third icon accesses the Desktop Options dialog box where you control

the settings for your part, surfaces, drawing views, and miscellaneous desktop

preferences.

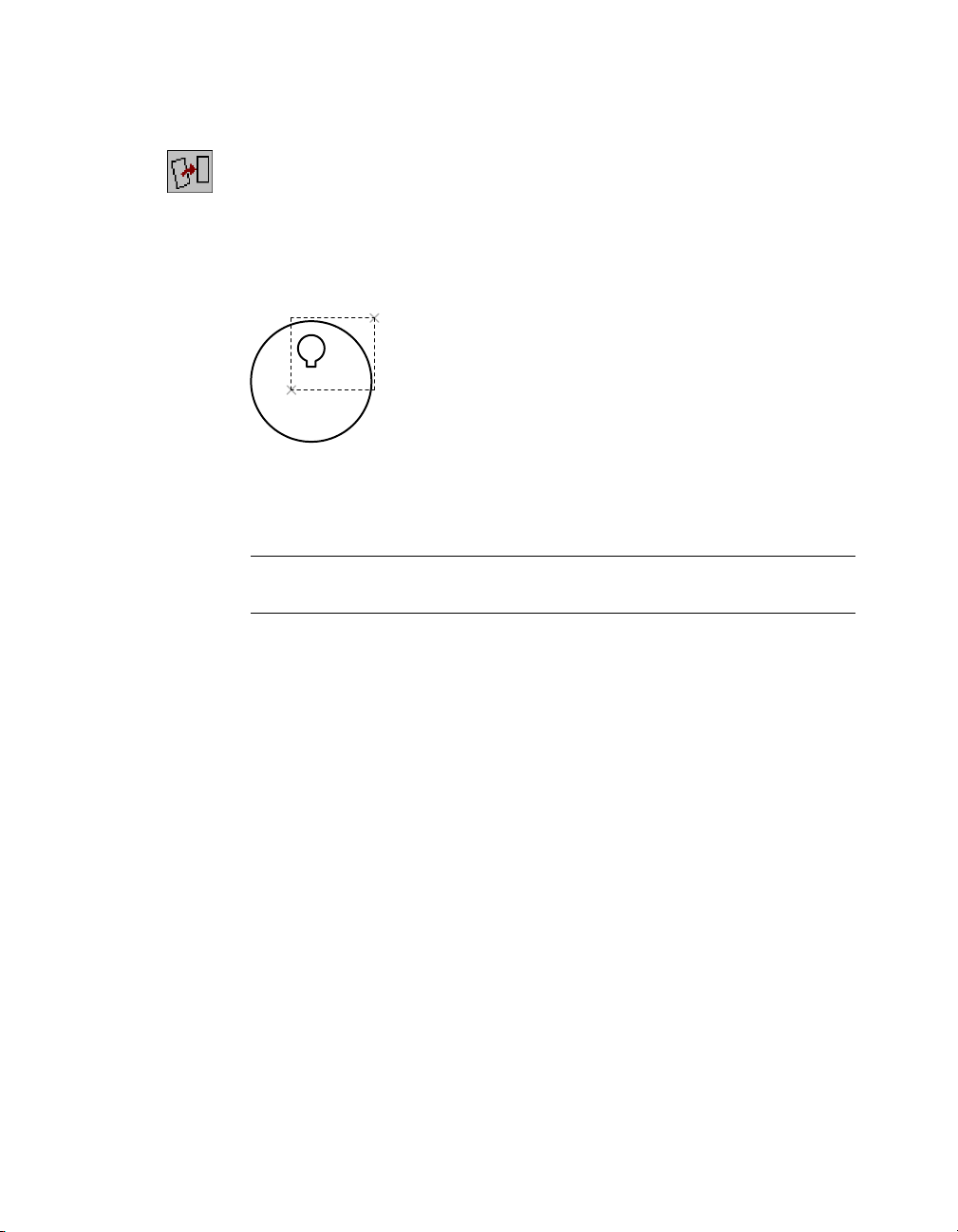

The middle icon provides immediate access to the Part Catalog. You use the

Part Catalog to attach and localize external part files, and instance external

and local parts in your current file for the purpose of creating combined parts.

The fifth icon opens the Desktop Visibility dialog box where you control the

visibility of your part, toolbodies, and drawing objects. The sixth icon

updates your part after you have made changes to it, and the last icon

updates assembly constraints if you are working with a combined part.

Drawing Mode in Part Modeling

In Drawing mode, six icons are displayed at the bottom of the Browser.

The first two icons on the left are toggles to control automatic updating of

your drawing views or part. The last four icons access desktop options,

control visibility, and manually update your drawing views or part.

Mechanical Desktop Interface | 21

Page 36

Using the Browser in Assembly Modeling

In the Assembly Modeling environment, the Browser displays three tabs:

Model, Scene, and Drawing. With these tabs, you can create multiple parts,

assemblies, scenes, BOMs, and documents, and you can reorder assemblies.

You can localize and externalize parts in the Browser without opening the

Assembly Catalog.

Model Mode in Assembly Modeling

Model mode in the Assembly Modeling environment has the same icons at

the bottom of the Browser as Model mode in the Part Modeling environment.

Because you are working in the Assembly environment, these icons provide

more functionality.

The first icon is the Part filter which you use to control the display of the

features that make up your parts. If the Part filter is selected, only part

features are visible in the Browser. If it is not selected, assembly constraints

are also visible.

The second icon is the Assembly filter. When you select this filter, only the

assembly constraints attached to your parts are visible.

The third icon opens the Mechanical Options dialog box. From this dialog

box you can manage your settings and standards for parts, assemblies,

surfaces, drawings, shaft generators, calculations, standard parts, and various

desktop preferences.

The middle icon provides access to the Assembly Catalog, a powerful interface for attaching and localizing external part and assembly files as well as

instancing both external and local parts in your current assembly.

The fifth icon controls the visibility of parts, assemblies, drawing entities, layers,

and linetypes. The sixth icon updates the active part after you have made

changes to it, and the last icon updates the active assembly or subassembly.

22 | Chapter 3 The User Interface

Page 37

Scene Mode in Assembly Modeling

In Scene mode, three icons are displayed at the bottom of the Browser.

The first icon accesses Desktop Options, where you can control the settings

for scenes. The second icon accesses Desktop Visibility, where you can

control the visibility of your parts, assemblies, and individual drawing

objects. The last icon updates the active scene.

Drawing Mode in Assembly Modeling

In Drawing mode, six icons perform the same functions as those in Drawing

mode in the Part Modeling environment.

Mechanical Desktop Interface | 23

Page 38

Issuing Commands

You can issue commands in several ways:

■ Select an option from a right-click menu in the Desktop Browser.

■ Select an option from a right-click menu in the active screen area of your

drawing.

■ Select a toolbar icon.

■ Select an option from a pull-down menu.

■ Enter the command name on the command line.

■ Use an abbreviation of the command, called an accelerator key, on the

command line.

Using Command Menus in the Desktop Browser

Many of the commands in Mechanical Desktop can be accessed using the

Browser menus. The Browser has two types of menus. One you activate by

right-clicking an existing object in the Browser. The other you activate by

right-clicking the Browser background. Options that are not available are gray.

The type of object you select with a right-click determines the menu displayed.

The mode you are in, Model, Scene, or Drawing, when you right-click the

Browser background determines the menu displayed.

24 | Chapter 3 The User Interface

Page 39

Using Context Menus in the Graphics Area

In addition to the Browser menus, context-sensitive menus are available in

the graphics area during the modeling process. When you start Mechanical

Desktop, the Part menu is available in the graphics area. You can toggle

between the Part and Assembly menus as you build your models. When you

are in Scene mode, the Scene menu is available. In Drawing mode, you can

toggle between the Drawing and Annotate menus.

Using Toolbars

Toolbars have icons to represent frequently-used commands, settings, and

environments. You can choose an icon instead of selecting a command from

a menu or entering its name on the command line. When you pause with

the mouse selection arrow on an icon, the command action is shown at the

bottom of the screen. A tooltip also appears under the cursor. Click the left

mouse button to select the command.

Some icons have a subtoolbar (flyout) with related icons. If the icon has a

small arrow in the lower right corner, drag the mouse to reveal the additional

icons, and then select one.

To hide a toolbar, click the button in its upper right corner. To unhide it,

right-click any toolbar. In the pop-up menu, select the toolbar to redisplay.

The toolbar is automatically redisplayed.

To reorient the Mechanical Desktop toolbars to their default positions,

choose View ➤ Toolbars ➤ Desktop Express (Left). If you prefer the toolbars

at the right of your screen, choose Desktop Express (Right).

You may want to view larger toolbar icons. To do so, right-click any toolbar

and choose Customize. Select Large Buttons at the bottom left of the Toolbars

dialog box.

If you choose Large Buttons and then dock the toolbars in the screen header

area above the command line or at either side of the screen, some icons may

not be visible. In that case, you can drag the toolbar onto the screen.

Mechanical Desktop Interface | 25

Page 40

Using Pull-down Menus

To select a menu option, or access a submenu, hold down the left mouse

button while you navigate through the menu. When you find the command

you want to use, release the mouse button.

You can also access menu commands by using the keyboard. Hold down

while selecting the underlined letter of the menu option. For example, to

AMPROFILE from the keyboard, press ALT, then P, S, P.

select

ALT

Selecting Command Options from Dialog Boxes

Many commands have options within dialog boxes. As the term dialog box

suggests, you interact by selecting options to make a particular setting active,

display a list from which to choose an option, or enter a specific value. If a

command has a dialog box, it is displayed when you access the command,

regardless of whether you did so on the command line or from a menu or

toolbar icon.

When you need information about a dialog box you are working with, click

the Help button located in the dialog box.

NOTE If the Mechanical Desktop dialog boxes do not display, on the

command line enter CMDDIA, and change the system variable to 1.

Using the Command Line

You can access a command or system variable directly by entering its name

on the command line. Many experienced users prefer this method because it

is faster than using menus. Some experienced users are familiar with specifying command options from the command line and prefer to turn off the

display of dialog boxes.