KTC systemKTC system

!!

Leggere il manuale d’uso.

Attenersi alle norme di sicurezza.

Togliere l’alimentazione in caso di apertura.

Read the user manual.

Adhere to safety rules.

Disconnet power source before opening.

Gebrauchsanleitung lesen.

Sicherheitsnormen beachten.

Die Speisespannung muss ausgeschaltet

werden, falls der Empfänger geöffnet wird.

Lire le manuel de l’utilisateur.

Respecter le consignes de sécurité.

Couper l’alimentation avant d’ouvrir le boîtier.

Leer el manual de uso.

Atenerse a las normas de seguridad.

Desconectar la alimentación antes de abrir.

ON

LOW VOLTAGE

SERIAL

NUMBER

TRANSMITTER

!!

Leggere il manuale d’uso.

Attenersi alle norme di sicurezza.

Togliere l’alimentazione in caso di apertura.

Read the user manual.

Adhere to safety rules.

Disconnet power source before opening.

Gebrauchsanleitung lesen.

Sicherheitsnormen beachten.

Die Speisespannung muss ausgeschaltet

werden, falls der Empfänger geöffnet wird.

Lire le manuel de l’utilisateur.

Respecter le consignes de sécurité.

Couper l’alimentation avant d’ouvrir le boîtier.

Leer el manual de uso.

Atenerse a las normas de seguridad.

Desconectar la alimentación antes de abrir.

RECEIVER

SERIAL

NUMBER

Installation, operation and service manual

KTC systemKTC system

INSTALLATION AND OPERATION MANUAL page 1

SERVICE MANUAL page 13

Follow the indications and warnings given by the machine producer regarding the machine controlled by the radio

remote control.

The information contained in this manual considers a representative configuration of the radio remote control:

please find radio remote control real configuration in the technical data sheet (attached to the manual).

If this manual is lost or damaged, ask for a copy from AUTEC. Please specify the serial number of the relative radio

remote control.

Contact AUTEC if any of the instructions and/or warnings given in this manual are not clear.

The information contained in this manual is subject to modification without notice and is not binding.

No parts of this manual may be reproduced by any means without the written permission of AUTEC (including

recording and photocopying).

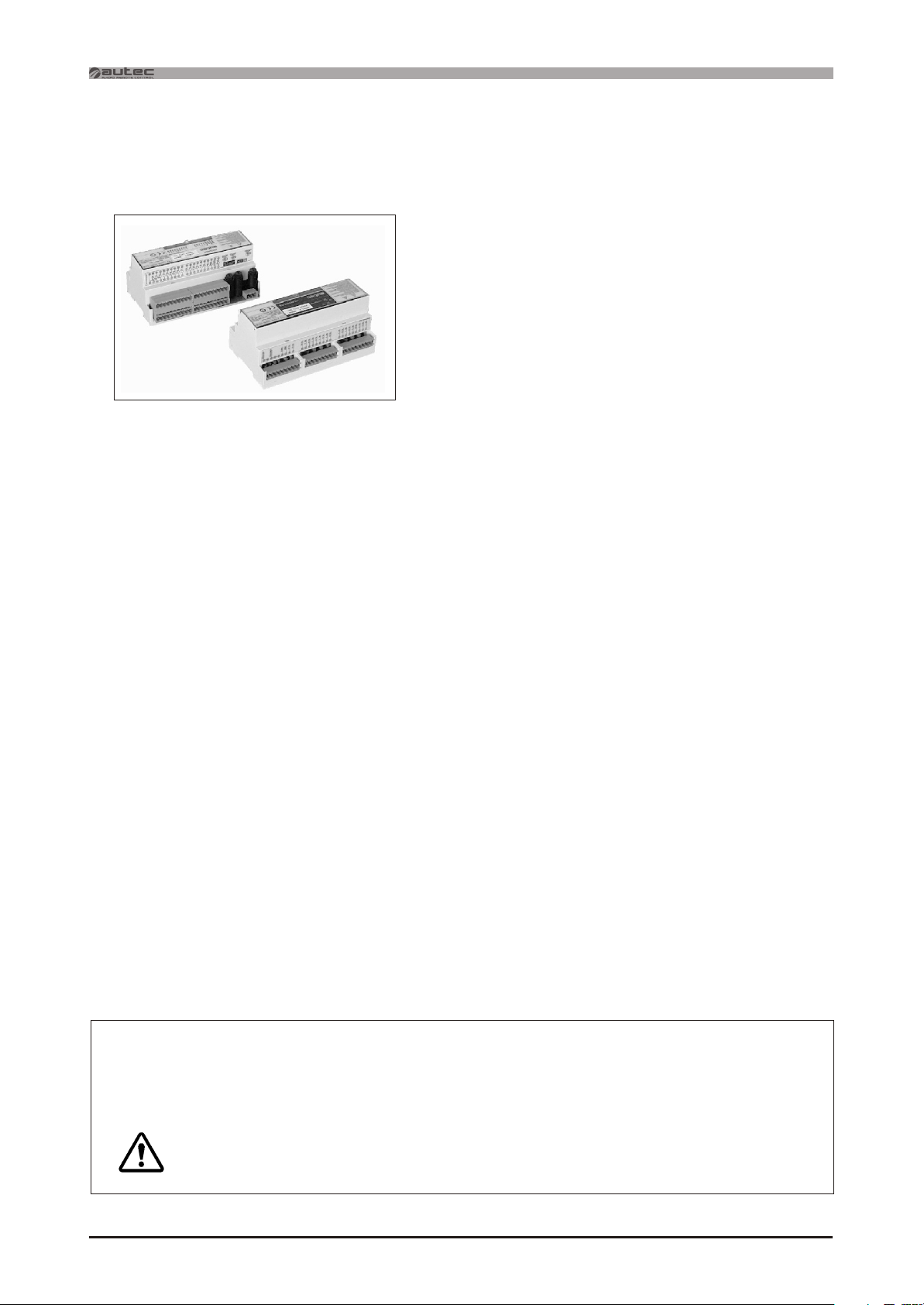

KTC SYSTEM

INSTALLATION AND OPERATION MANUAL

This manual is an integral part of the KTC system (KIT for

TRANSMISSION of COMMANDS). Our objective is to lay down

the basic installation and operational instructions.

BEFORE CARRYING OUT ANY OF THE INSTALLATION

AND OPERATIONAL PROCEDURES IT IS ESSENTIAL TO

READ AND UNDERSTAND ALL OF THE KIT MANUAL

INDEX

Page

1

GENERAL REMARKS

1.1 Conformity 2

1.2 Applications 2

1.3 General warnings 2

2 KTC DESCRIPTION

2.1 3

2.2 3

2.3 Documentation 3

2.4 Transmitting unit 4

2.5 Receiving unit 5

3 INSTALLATION

3.1 Installation warnings 6

3.2 6

3.3 7

3.4 KTC 8

3.5 Connection and wiring 8

4 MAINTENANCE 11

4.1 11

4.2 11

5 TECHNICAL DATA 13

Operational principle

Radio frequencies

Assembly on DIN guide

Antenna installation

composed by more than one transmitting and/or receiving unit

Maintenance warnings

Service Assistance

Conventions

Any pieces of text written in bold should be read very carefully.

This symbol highlights extremely important indications and information which, if not

observed, can create seriously dangerous situations for people or things.

LIKTCNA0 Page 1

1.1 Conformity

Each KTC radio remote control complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

1.2 Applications

Autec cannot be held responsible if the radio remote control is installed on applications

that are different from those permitted

PERMITTED APPLICATIONS:

- Telemetry, signal systems

- Transmission of commands for machines which lift and move material

- Transmission of a safety command

WARNING: Follow the instructions carefully on pages 8,9 and 10

FORBIDDEN APPLICATIONS

- Machines installed in environments where equipment with explosion-proof

characteristics are being used

- Transmission commands for machines which lift and transport people

:

1.3 General warnings

WARNING: Connect the POWER SUPPLY to the KTC only by means of a Safety Transformer

(or corresponding IEC 60204-32 paragraph).

Permission to install and to use the KTC is to be given exclusively to qualified personnel.

All machines must undergo a risk analysis; therefore it is necessary to evaluate, within the limits of this analysis,

if the machine can be radio remote controlled.

The machine producer and/or the person who decides upon radio remote control use and installation is

responsible for this analysis.

Autec cannot be held responsible if the risk analysis is not carried out correctly.

To guarantee correct radio remote control operation, all current regulations regarding safety at work and

accident prevention should be respected. All current user country national laws regarding the use of both the

machine and the radio remote control MUST ALWAYS be respected.

Autec cannot be held responsible if the radio remote control is used in unlawful working conditions.

System must be installed by a licensed technician and in accordance with all relevant local,

state/provincial and federal regulations, including but not limited to NEC, OSHA, CE etc.

Autec will not accept any responsibility if the KTC is:

- installed for applications which are not authorised

- used in working conditions which do not conform to the relevant regulations

- is not installed by qualified personnel

If a fault or breakdown occurs in the KTC, do not use the KTC until the problem has been completely

resolved.

When damaged parts need to be replaced, qualified personnel or service representative have to carry out this

operation using original Autec spare parts.

LIKTCNA0Page 2

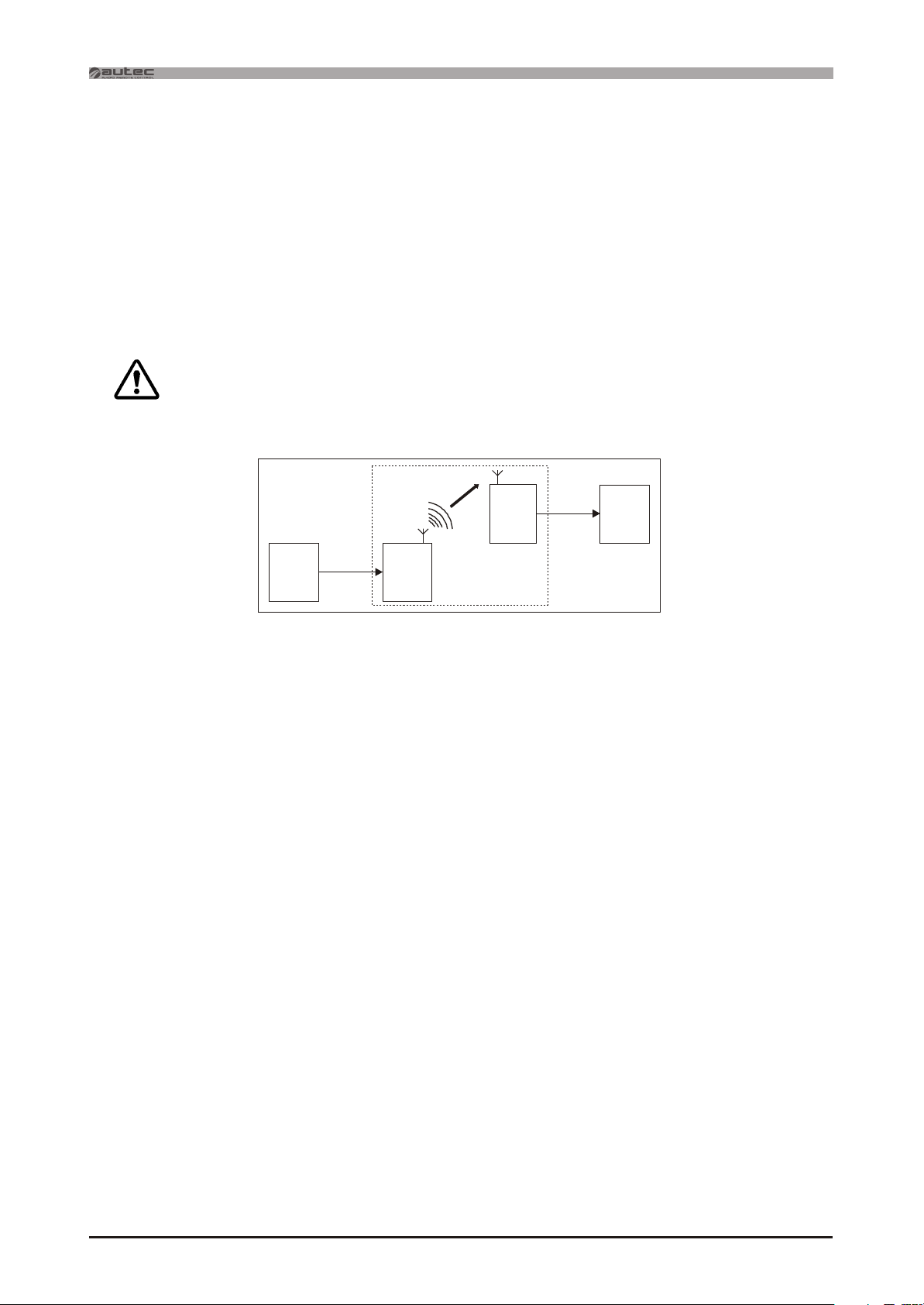

2.1 Operational principle

The KTC system is used to activate commands by remote control (to start up equipment for example) and to

turn on signals ( i.e.: telemetry …).

The KTC consists in a transmitting unit and a receiving unit.

The transmitting unit communicates with the receiving unit by means of a coded radio message which contains

data and address information. The receiving unit can only decode messages sent by the transmitting unit

belonging to the same kit (i.e.: with the same address). This ensures that signals or unwanted commands

cannot be activated. In the event of: interference; an incorrect or interrupted radio transmission, the receiving

unit stops the system autonomously (passive emergency function).

Risk analysis of the equipment or system which uses a KTC , has to take into account that the

radio link may be interrupted, due to electromagnetic disturbance or interference. This will

cause interruption of the KTC system functionality and will require a new start-up sequence.

P

ushbutton

Relays

Output PLC

. . .

KTC operational scheme

Transmitting

INPUT

unit

Receiving

unit

KTC

OUTPUT

R

elays

Lights

Lamps

PLC/PC In

. . .

The transmitting unit is installed where the commands are activated (INPUT) by means of actuators

(pushbutton, relays, output PLC …). The receiving unit is installed where the commands or signals (OUTPUTS)

are controlled (relays, lights, lamps etc..).

Radio frequencies

2.2

The KTC is programmed for use at a certain radio frequency.

The frequencies used fall within the band of frequencies established by American regulations at the time the

KTC was put onto the market.

The band is 902 -928 MHz.

Should it be necessary to install the KTC near other radio equipment, the radio frequencies used by the two

radios must be different (for frequency setting see page 26).

2.3 Documentation

The following minimum documentation is supplied with each radio remote control:

- installation, operation and service manual

- a guarantee certificate

- the radio remote control technical data sheet

Make sure that the following documents have been supplied: if they are not, request them from Autec.

Please specify the radio remote control serial number.

Warranty

The conditions of warranty applicable to the KTC are specified in the " Warranty Certificate".

The radio remote control identification and approval data is given on plates that are on both the transmitting unit

and the receiving unit.

The plates MUST NOT be removed from where they are placed or damaged otherwise the warranty will

be forfeited.

LIKTCNA0 Page 3

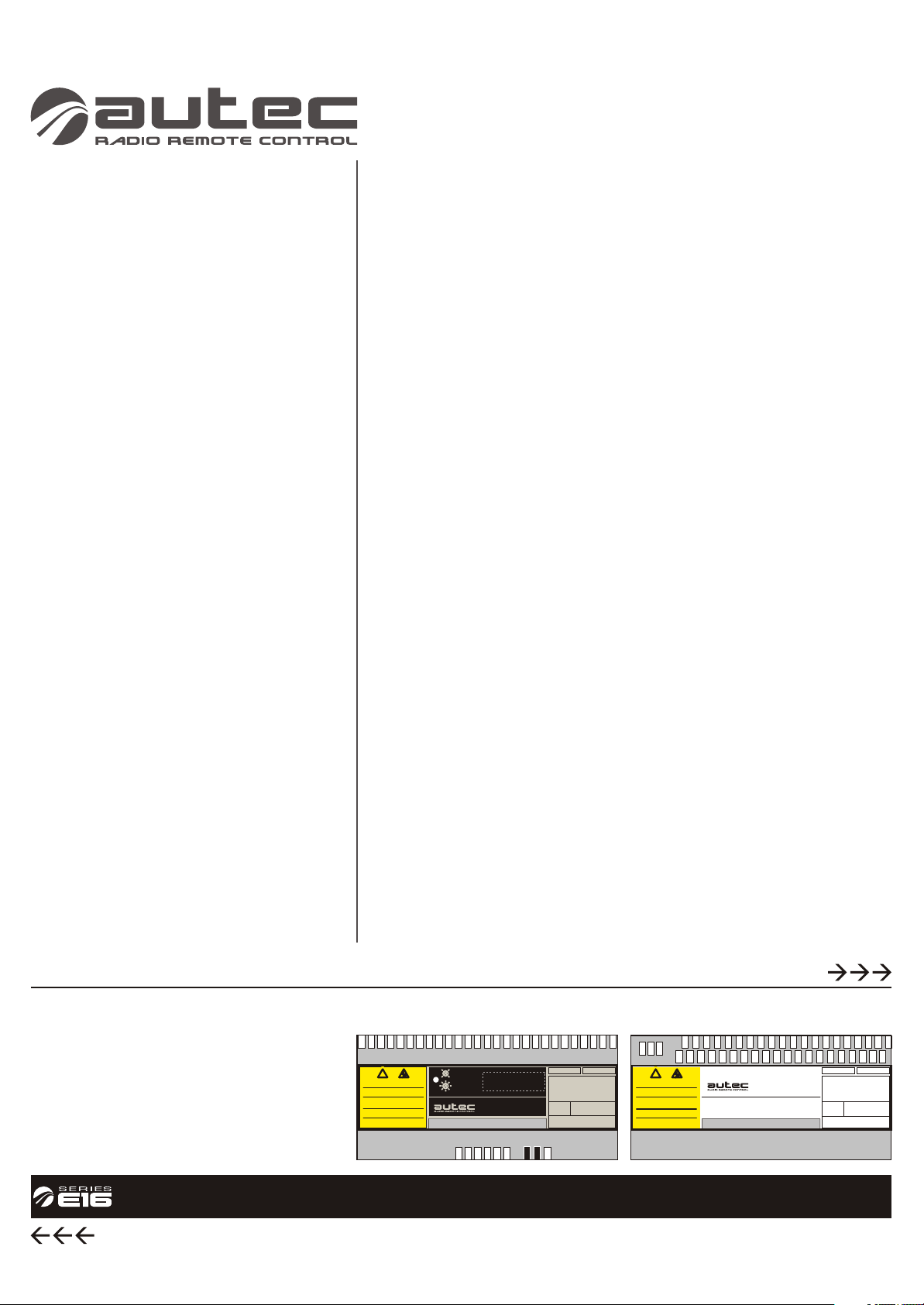

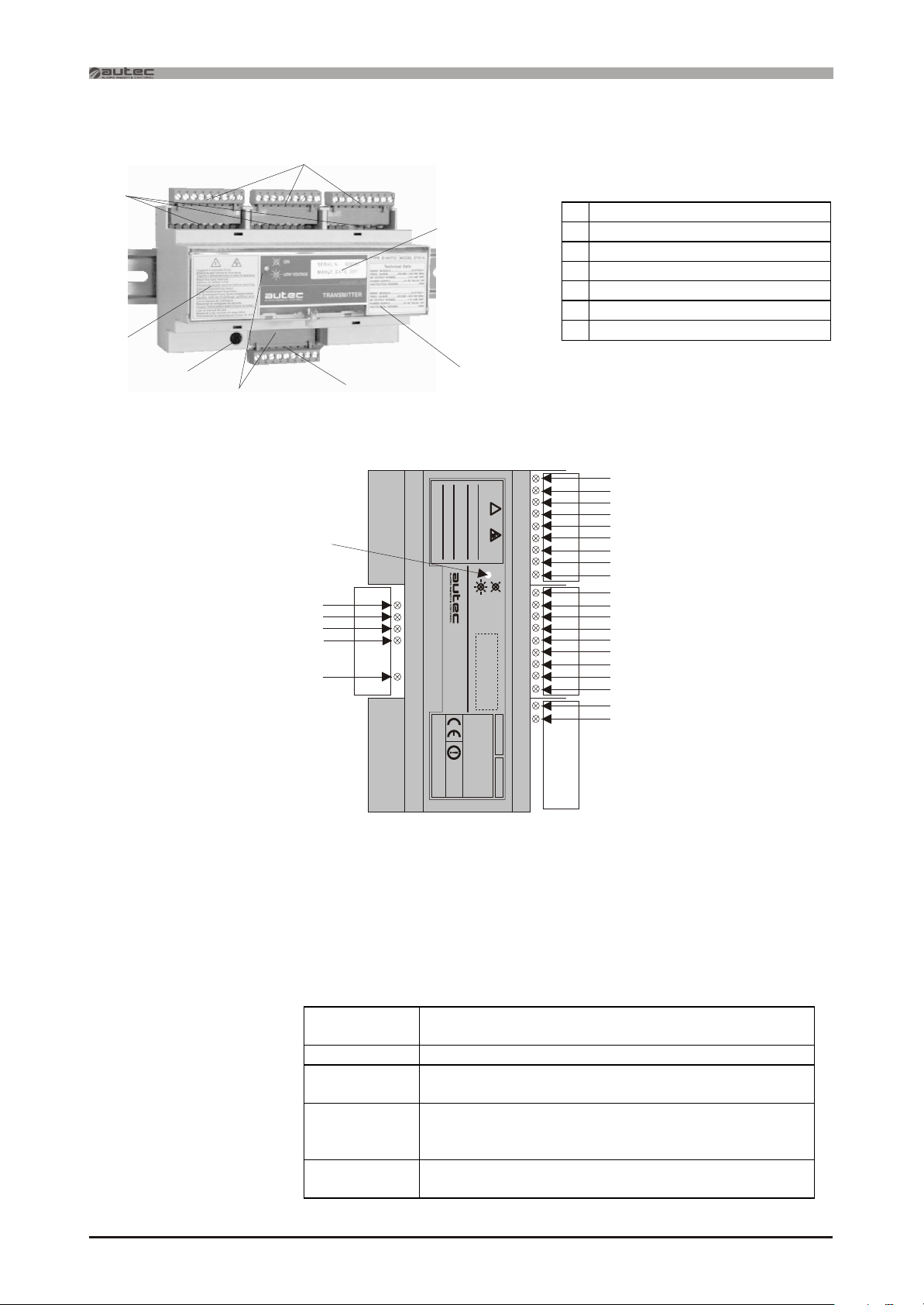

2.4 Transmitting unit

D

E

C

F

G

E

A

B

Light signals

Couper l’alimentation avant d’ouvrir le boîtier.

Togliere l’alimentazione in caso di apertura.

werden, falls der Empfänger geöffnet wird.

Disconnet power source before opening.

Desconectar la alimentación antes de abrir.

Respecter le consignes de sécurité.

Adhere to safety rules.

Attenersi alle norme di sicurezza.

Atenerse a las normas de seguridad.

Die Speisespannung muss ausgeschaltet

Sicherheitsnormen beachten.

Leggere il manuale d’uso.

Read the user manual.

Gebrauchsanleitung lesen.

Lire le manuel de l’utilisateur.

Leer el manual de uso.

!!

State

of the unit

signal

ON

STOP2

SAFETY

START

STOP1

POWER

LOW VOLTAGE

TRANSMITTER

NUMBER

SERIAL

A Power supply terminal block

B Technical data plate

C Identification plate

D Input terminal blocks

E Light signals

F Openable cover

G Antenna connector

RL

1

RL

11

RL

2

RL

12

RL

3

RL

13

RL

4

RL

14

RL

5

RL

15

RL

6

RL

16

RL

7

RL

17

RL

8

RL

18

RL

9

RL

19

RLRL10

20

POWER:

STOP1 e STOP2:

SAFETY:

START:

RL1 - RL20:

State of the unit signal:

indicates that the power supply is present

indicates that the STOP circuit is working correctly

indicates that the SAFETY function is on (it must be on if any of the movement

commands are operational, when the unit is being used to operate or start up

equipment).

indicates that the START function is operational

indicates that the function which corresponds to the command is operational

(see KTC technical data sheet)

indicates the following operating conditions

Signal

Meaning

State

Off The transmitting unit is not transmitting

flashing

flashing

flashing

Slow

Fast

On not

The transmitting unit is transmitting and the power

supply is correct.

The transmitting unit is transmitting but the power supply is not inside the correct voltage range (after about

3,5 minutes the unit will switch off automatically)

Indicates that there are actuators inserted during start

up

LIKTCNA0Page 4

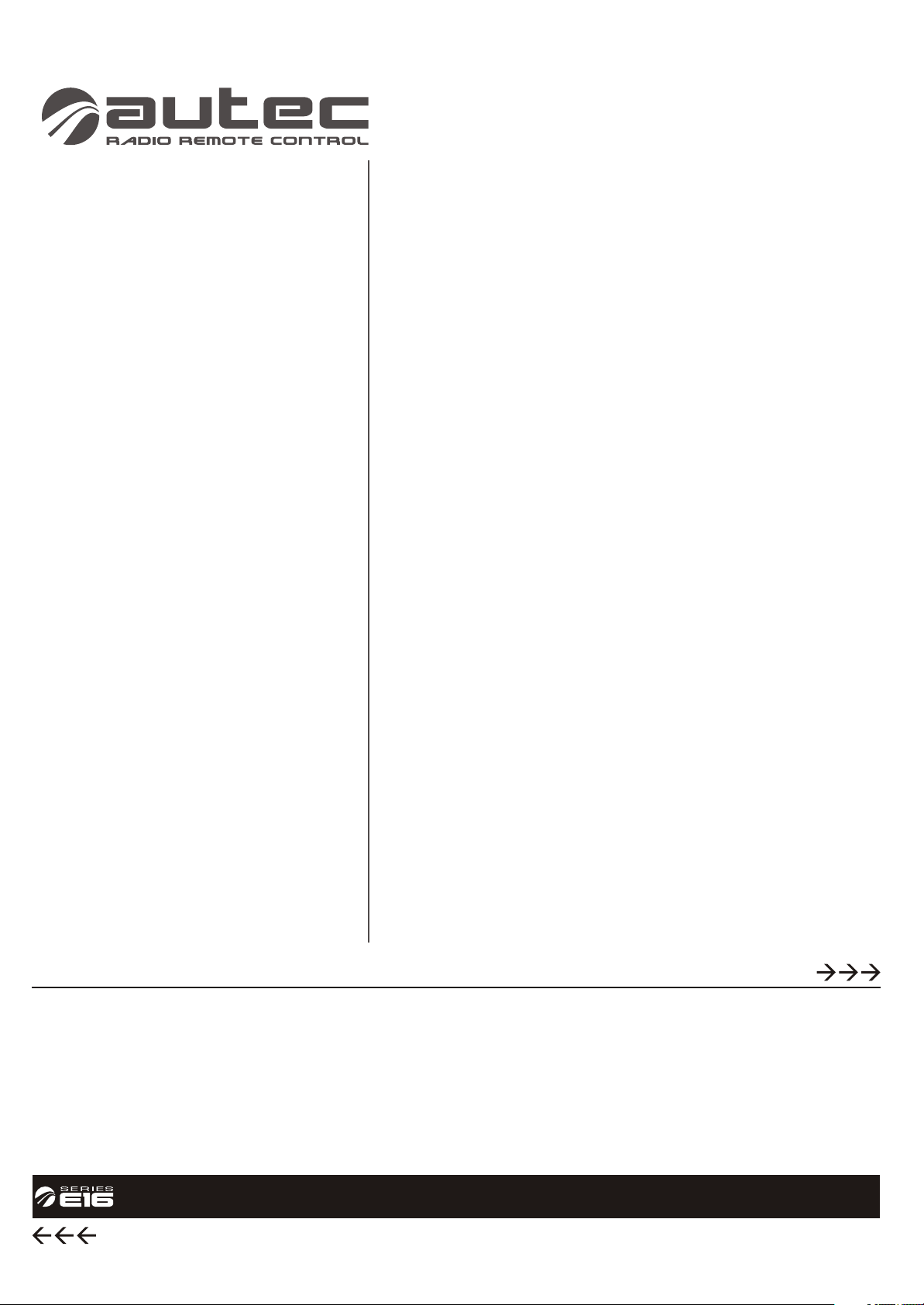

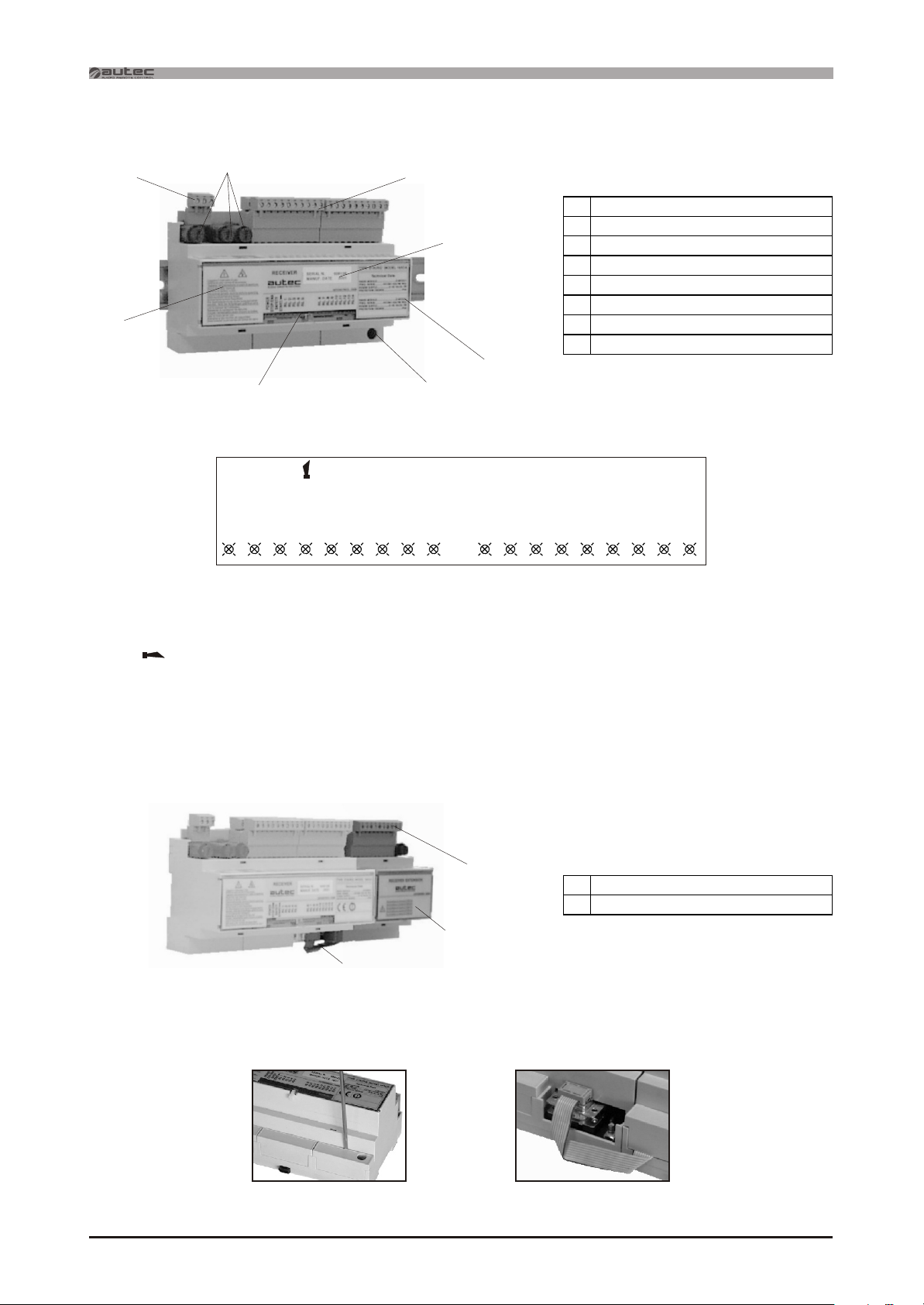

2.5 Receiving unit

A

F

POWER:

STOP/ENABLE:

SAFETY:

START/ :

RL1 - RL14:

H

D

A Power supply terminal block

B Technical data plate

C

C Identification plate

D Output terminal blocks

F Openable cover

G Antenna connector

H Fuses

L Light signals

B

L

G

Light signals

RL 1

RL 2

RL 3

RL 4

POWER

STOP/ENA

START/

SAFETY

RL 5

RL 6

RL 7

RL 8

RL 9

RL 11

RL 10

RL 12

RL 13

RL 14

indicates power supply is on

indicates radio link between the transmitting and the receiving units

Indicates the SAFETY function is activated

indicates the START function is on

indicates that the relay for the corresponding command is activated (see the KTC

technical card)

Additional command unit

Six commands may be added to those already incorporated in the receiving unit, by means of an additional

command unit.

D

D Output terminal blocks

M Connection cable

additional

M

command

unit

To connect the additional command unit to the receiving unit:

- remove the cover on the bottom right (see photo)

- insert the extension connection cable into the connector on the receiving unit (see photo)

LIKTCNA0 Page 5

3.1 Installation warnings

When installing the KTC follow these instructions carefully:

Always RESPECT all laws and regulations and regulations in force in the country where the

installation is carried out.

INSTALL both units either in electrical boards or in casing which guarantees a protection

IP54 or higher (level IP65 is recommended if the cabinet is outdoors)

INSERT, in both units, a switch to open the power supply.

USE a Safety Transformer for the power supply both in the transmitting unit and in the

receiving unit (or corresponding IEC 60204-32 paragraph).

DO NOT by-pass the safety circuits in the KTC and/or in the system in which it is installed.

DO NOT MODIFY, TAMPER WITH OR PERFORATE the KTC units.

CHECK the values given in the "Technical Data" to ensure that

- the power supply voltage in the transmitting and receiving units falls within the range

specified for each unit.

- the electrical current required for all the circuits controlled by the receiving unit are within

the specified range

POSITION both units such that the output terminal blocks be in an upwards direction.

INSTALL both the transmitting and the receiving units far from any components which

generate electromagnetic fields and/or heat (for example transformers, power resistors).

CONNECT the GND terminal to the earth (PE), or to the PEN (PE+N=earth+neutral). In the

latter case the PEN must always be connected to the mains supply earth.

.

of

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN SERIOUS

INJURY OR DEATH TO PERSONNEL AND DAMAGE TO EQUIPMENT.

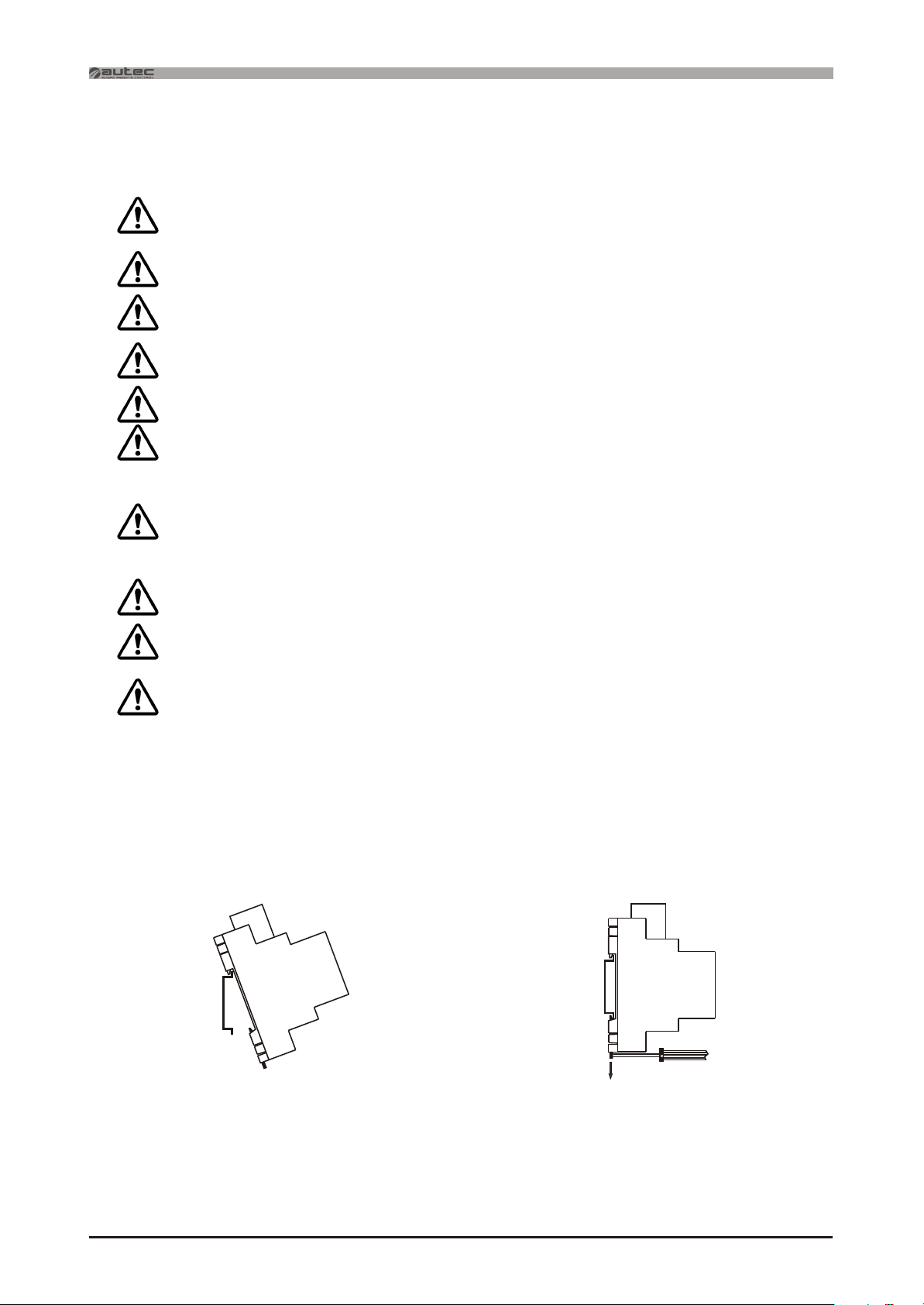

3.2 Assembly on DIN guide

The transmitting and receiving units must only be installed

Hook up the top part of the unit base to the DIN

guide.

Vibrations may interfere with the unit's performance. It is therefore advisable to use anti-vibration systems, when

necessary, to reduce the impact of vibrations on the unit.

on DIN EN 60 715 rail (ex DIN EN 50 022).

Push using a screwdriver to move the hook at the

bottom of the unit down so that the unit fits

perfectly into the DIN guide.

LIKTCNA0Page 6

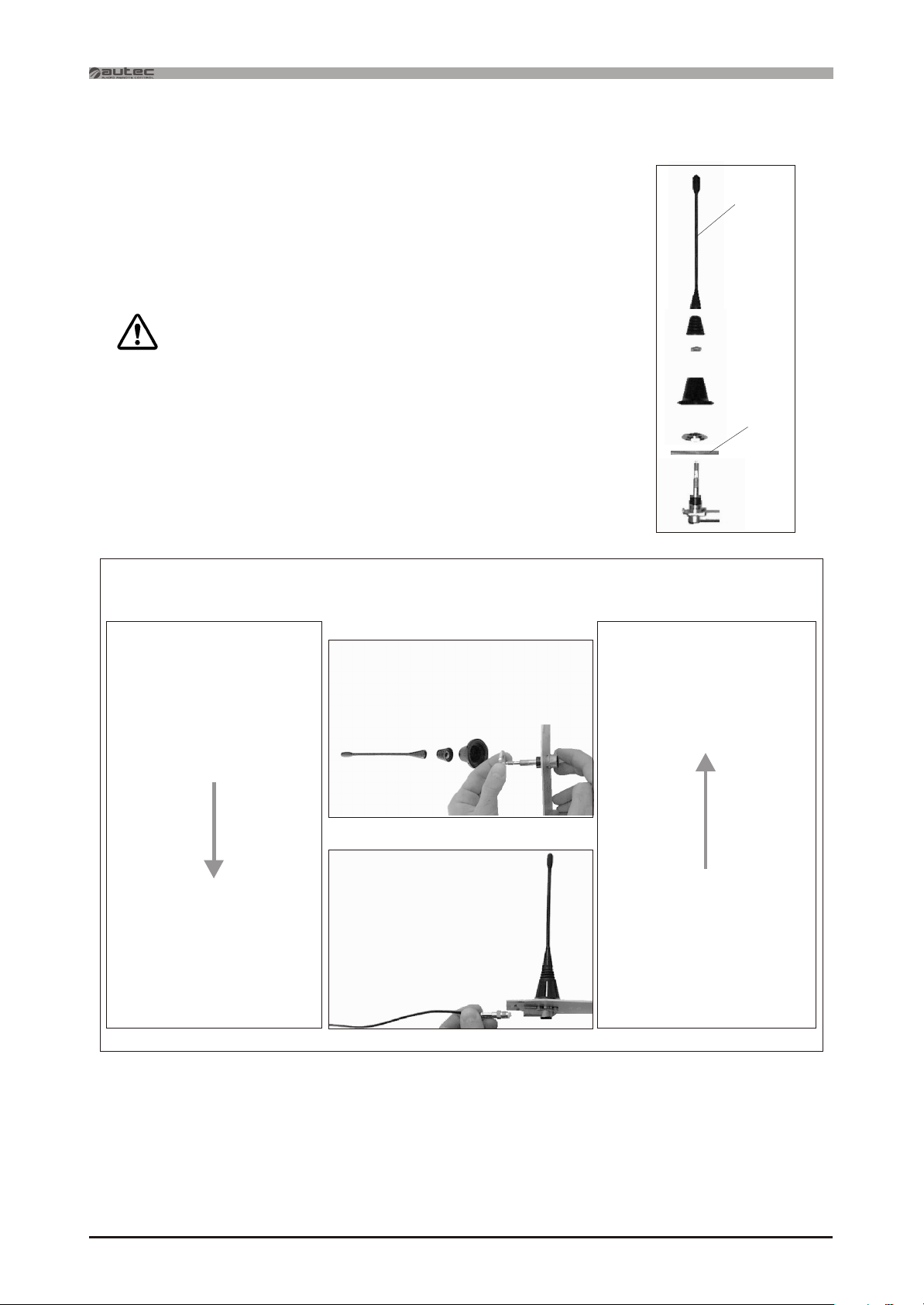

3.3 Antenna installation

Each of the two units requires an antenna. The antenna is not to be installed

on the electrical board.

It is to be installed:

- on a metal assembly surface (clamp, the electrical board ...)

- in such a way as not to be covered by metal structures.

The monopole must not come into contact with metal

parts.

If possible, avoid installing a KTC near antennas of other radio

equipment. Otherwise, take the position of the antenna into

consideration and install the antennas in such a way as to ensure that

both sets work properly (calculate the position, the direction and the

distance of the antenna on the basis of use and the working

environment).

Antenna installation (assembly and disassembly)

monopole

metal

assembly

surface

Assembly Disassembly

1

Assemble the parts of the

antenna on the metal surface

support (for the order see the

previous photo).

2

Insert one part of the cable

into the connector on the

antenna and the other into the

antenna connector (G) on the

unit.

Dismantle the antenna

2

removing it piece by piece from

the metal surface support.

1

Disconnect the unit from the

power supply. Remove the

cable from the connector on

the antenna and from the

antenna connector (G) on the

unit.

LIKTCNA0 Page 7

3.4 KTC composed by more than one transmitting and/or receiving unit

There are also some KTC configurations defined “multiple” which are composed by more than one transmitting

and/or receiving unit. Before using one of these configurations for control a co-ordinate system, it should be

considered in the risk analysis the raccomandations which follow.

The address keys which are used in these multiple configurations must NEVER be used on

other radio remote controls.

KTC WITH MORE THAN ONE TRANSMITTING UNIT

Risk analysis has to take into consideration the fact that more than one control station can command the

equipment (or system) at the same time. In fact,

1) when machines are being commanded (or corresponding IEC 60204-32 paragraph)

2) when the controlled equipment or working site require it,

it is obligatory to:

- use a measures which ensure that only one unit is transmitting at a time

- indicate visually which control station is controlling the receiving unit

KTC WITH MORE THAN ONE RECEIVING UNIT

Risk analysis has to take into consideration the fact that a transmitting unit may command more than one

receiving unit at a time. Consequently, it is necessary to take into consideration the possibility that radio

interference and noise may interrupt the link with one or more radio controlled receiving units, causing the loss

of co-ordinate control behaviour.

3.5 Connection and wiring

To wire up correctly:

- use the terminal block s in the KTC units

- follow the schemes and indications given,

-respect all the regulations regarding electrical panels and relevant national laws..

The person who is carrying out the installation must:

- fill in the attached technical data sheet indicating the wiring and connections to both units

- after wiring and connecting the cable to both units, check that the commands or signals transmitted

correspond to those received

- indicate the date on which the KTC was assembled and tested, on the technical data sheet. Sign and stamp this declaration.

In the transmitting unit the actuator contacts wired to the terminals must not be connected

to the power supply.

WIRING OF TERMINALS IN THE UNITS

V1 and V2: units power supply

Transmission unit Reception unit

Wire directly to the safety transformer.

If the use of the equipment requires it, put in a switch to cut out the

power supply (e.g. a keyswitch selector)

COM and CSZ: Common power supply connection in the transmitting unit

COM CSZ

Wire the COM to all the commands which may be

a source of risk if they are activated when the unit

is switched on.

The CSZ has to be wired to all the commands

which are not a source of risk if they are

activated when the unit is switched on.

Wire directly to the safety

transformer.

LIKTCNA0Page 8

START: The KTC start function

Transmitting unit Receiving unit

Wire the START terminal to a "COM" terminal.

If the use of the equipment requires it, a temporary

switch to switch on the KTC must be used (e.g.

temporary pushbutton).

STOP: KTC safety function (when activated the KTC cuts off)

Transmitting unit Receiving unit

Wire the terminals STOP1 and STOP2 to one of the

"COM" terminals.

If the use of the equipment requires it, insert N.C.

contacts or safety switch (as specified in EN 418) to

activate the function.

SAFETY. Supplementary control function

to protect movement commands

Transmitting unit Receiving unit

Wire the SAFETY terminal to a "COM" terminal. If the

use of the equipment requires it, activate it at the same

time as the commands which need to be protected

(e.g.: all the movement commands, as in the following

illustration).

COM

command A

RL1

RL2

command B

Safety

Wire up the START terminal only if the

transmitting unit has a temporary switch.

Wire up the STOP terminal in series to the

common of the commands.

Wire the SAFETY terminal to those

commands which require protection (the

same commands wired up in the

transmitting unit).

.

NB: the SAFETY contact opens after a 1 sec.

delay

RL1

RL2

Safety

command A

command B

RL1 - RL20: commands

Transmitting unit Receiving unit

RL1 - RL6 and RL11 - RL16

Each of these commands has to be wired up:

- to one of the "COM " terminals, in the event that the

Each of these commands has to be wired to

the appropriate function.

transmitting unit is not to start if a certain command is

on at start up

- to the "CSZ" terminal, in the event that the unit can

start if a certain command is on at start up.

RL7 - RL10 and RL17 - RL20

Each of these commands can be wired up either to the

"COM" or the "CSZ" terminal (if these commands are

activated at start up, the transmitting unit turns on).

Each of these commands has to be wired to

the appropriate function.

ENABLE

Transmitting unit Receiving unit

Not applicable

May be connected when the ENABLE (radio

link on) status is required.

LIKTCNA0 Page 9

Example of wiring for telemetry working applications

KTC

V1

V2

STOP1

STOP2

CSZ

COM

START

. . .

RL1

RL2

V1

V2

STOP

RL1

START

. . .

RL2

Example of wiring for transmission of a safety command working applications

KTC

V1

V2

STOP1

STOP2

CSZ

COM

START

. . .

RL1

RL2

V1

V2

STOP

RL1

START

. . .

RL2

Example of wiring for command transmission working applications

(machines which lift and transport material)

KTC

V1

V2

START

STOP1

STOP2

RL1

CSZ

COM

. . .

. . .

RL2

RL3

COM

SAFETY

V1

V2

STOP

RL1

START

RL2

. . .

RL3

SAFETY

LIKTCNA0Page 10

4.1 Maintenance warnings

During all ordinary and extraordinary maintenance operations carried out on the KTC and

on the system in which it is installed, switch off the power supply to the electrical panel,

both in the transmitting and in the receiving unit.

The transmitting and the receiving units should always be completely shut using the appropriate strip.

Any fault should be repaired by authorised Autec personnel (contact Service), using

original Autec spare parts only.

All control and maintenance interventions carried out on the radio remote control must be verified and recorded

by the person in charge of carrying out maintenance on the machine.

Before carrying out maintenance and/or diagnostics it is recommended to replace the

battery with a charged one and ensure the efficiency of the START key.

Routine maintenance in accordance to the instructions given in this manual is fundamental

for the safe use of the radio remote control.

Read and strictly respect the warnings given in the battery charger manual in order to

lengthen the life of the battery itself.

After each maintenance intervention, always make sure that only the expected

manoeuvres are carried out when the relative commands are sent by the transmitting unit.

ROUTINE MAINTENANCE

The following instructions allow to maintain the radio remote control in a perfect condition, guaranteeing it to

function safely and correctly for a long period.

Special applications may need more specific routine maintenance interventions to be carried out at different

periods.

These instructions do not in any case substitute the norms and laws that regulate work safety, nor do they limit

the responsibility of the purchaser and user of the radio remote control.

All given instructions must be followed correctly each time the machine and the radio remote control are

started.

If irregularities are noted while carrying out routine maintenance, put the "machine+radio

remote control" system out of order, following the indications given (see “Receiving unit

diagnostic”)

Transmitting unit

It is recommended every day to:

1. remove dust or accumulations of other material from the transmitting unit. Never use solvents or

flammable/corrosive materials to clean, and do not use high pressure water cleaners or steam cleaners.

2. store the transmitting unit in clean and dry areas.

3. make sure that the transmitting unit gaskets, joystick bellows, selectors caps and pushbuttons are intact, soft

and elastic

LIKTCNA0 Page 11

4. make sure that the battery seat and the battery contacts are always clean

5. make sure that the transmitting unit are structurally integral

6. make sure that the panel symbols can be easily recognised. If necessary, replace the panel.

7. check identification plate readability and integrity

8. verify the efficiency of the STOP pushbutton before using the radio remote control.

Receiving unit

It is recommended every three months to:

1. remove dust or accumulations of other material from the receiving unit. Never use solvents or

flammable/corrosive materials to clean, and do not use high pressure water cleaners or steam cleaners.

2. make sure that the receiving unit are structurally integral

3. verify the integrity and connection of the internal wiring to the receiving unit

4. make sue that the panel symbols can be easily seen. If necessary, replace the panel.

5. check identification plate readability and integrity

Electrical operation

It is recommended every six months to:

1. make sure that all the relay contacts of the receiving unit operate correctly, controlling contact closing when

the corresponding manoeuvre is enabled and contact opening when the manoeuvre is disabled.

2. verify the correct correspondence between the commands that are sent and the manoeuvres that are carried

out.

3. verify that the contact for the SAFETY relay is open when no movement command has been sent.

External electric conductors

It is recommended every twelve months to:

1. verify integrity along the full length of the cable which connects the receiving unit to the machine.

2. verify the integrity and the electrical connection of the plugs and the connection socket

3. verify and if necessary replace the strips or other fixing systems

4. make sure that the connecting cable has not deteriorated, above all near the cable holder

SPECIAL MAINTENANCE

Any fault should be repaired by authorised Autec personnel (contact Service), using

original Autec spare parts only.

AUTHORIZED SERVICE CENTER

When it is necessary to carry out special maintenance (radio remote control repair and replacement of

damaged or faulty parts), do not contact anyone other than our Authorized Service Center. In order to make the

intervention faster and more reliable, please help us identify the radio remote control correctly and completely

by giving:

- the serial number

- the purchase date (given on the guarantee)

- description of the problem found

- the address and telephone number of the place where the radio remote control is being used

- the name of the person to be contacted

- the name of the company that supplied the radio remote control.

Before speaking with a service technician, it is advisable to make sure that the given instructions have

been followed correctly.

DISPOSAL

When scrapping, entrust the radio remote control to the separate scrap collecting services in the country of

use.

Please pay particular attention when recycling the batteries, applying local rules. Do not throw them away with

domestic trash

LIKTCNA0Page 12

General

Frequency range

Programmable radio channel

Hamming distance

Probability of non-recognition of error

Typical working range

Working temperature

Time of reply to commands

Time of reply to STOP

Passive emergency time

Number of avaible commands

Transmitting unit

Power supply

Antenna

Output power

Time of switching off warning (caused by insufficient power supply)

Housing

Minimum protection grade

Weight

Receiving unit

Power supply

Antenna

Max switching capacity of STOP contacts

Max switching capacity of SAFETY contacts

Max switching capacity of command contacts

Housing

Minimum protection grade

Weight

5 Technical Data

902 - 928 MHz

32

³ 8

< 10 exp-11

100 m

-4°F - +158°F

< 100 ms

< 100 ms

1 second; (opt 0,35 second)

14+start+stop (+6 opt)

9 - 30 Vac/dc (3W)

external with 2,5 metres long cable

meets FCC Part 15 for license-free operation

ca 3,5 min

NORIL ®

IP20

400 g

10 - 30 Vac/dc (7W)

external with 2,5 metres long cable

4A T (250 Vac)

4A T (250 Vac)

4A T (250 Vac)

NORIL ®

IP20

500 g

Additional command unit

Max switching capacity of SAFETY contacts

Max switching capacity of command contacts

Housing

Minimum protection grade

Weight

Transmitting/receiving unit

160 mm

75 mm

110 mm

dimensions

4A T (250 Vac)

4A T (250 Vac)

NORIL ®

IP20

200 g

Additional command unit

dimensions

72 mm

75 mm

110 mm

LIKTCNA0 Page 13

A GENERAL REMARKS

A.1 16

A.2 18

Exploded view of the unit and spare parts

Diagnostic flow chart

KTC SYSTEM

SERVICE MANUAL

This manual is an integral part of the KTC system and aims to

provide the main information required to substitute and

programme the relevant parts.

IT IS ESSENTIAL THAT YOU READ AND UNDERSTAND

ALL OF THE MANUAL BEFORE YOU REPLACE OR

PROGRAMME ANY PARTS OF THE KTC.

It is also advisable to read and understand the

"Installation and operation Manual".

INDEX

Page

B REPLACEMENTS

B.1 20

B.2 21

B.3 22

B.4 22

B.5 Replacement of the case or/and base 23

B.6 24

B.7 25

B.8 25

C PROGRAMMING 26

C.1 27

C.2 28

Opening and closing the unit

Replacement of the transmitting module and/or interface card.

Replacement of the receiving module

Replacement of the programming interface card.

Replacement of the address key.

Replacement of the transmitting unit fuse

Replacement of receiving unit fuses

Programming functions

Programming the operational frequency

Conventions

Any pieces of text written in bold should be read very carefully.

This symbol highlights extremely important indications and information which, if not

observed, can create seriously dangerous situations for people or things.

Substitution and programming of KTC parts should be carried out exclusively by

qualified personnel.

Carefully read the instructions and warnings about the system or the equipment in which the KTC

is installed.

LIKTCNA0

Page 15

Transmitting case

(see B.5)

R0CASS01P03A0

A.1 Exploded view of the unit and spare parts

Exploded view of the transmitting unit

A

A

1

1

0

0

T

T

D

D

L

L

E

E

D

D

MO

MO

1

1

U

U

E

E

aT

a

QT

Q

X

X

t

t

Z

Z

T

T

T

T

H

H

a

a

6

6

U

U

1

1

M

M

E

E

6

6

D

D

0

..

0

..

W

W

l

l

1

1

9

..

9

..

7

7

a

a

..

..

E

E

E

E

P

P

Y

Y

T

D

D

A

A

R

R

R

R

F

F

P

P

AL

AL

I

I

R

R

ER

ER

E

E

S

S

B

B

UM

UM

N

N

TE

TE

T

T

I

I

M

M

S

S

N

N

A

A

TR

le

le

e

e

r

r

e

e

al

al

e

e

i

i

m

m

s

s

li

li

r

r

gg

gg

a

a

e

’

e

’

e

e

l

l

L

L

e

e

e

e

en

en

s

s

r

t

r

t

t

t

u

u

e

e

i

i

A

A

e

e

gl

gl

s

s

h

h

o

o

t

t

T

T

o

o

t

t

d

d

a

a

e

e

t

t

r

r

e

e

e

e

Re

Re

n

n

h

h

n

n

d

d

A

A

co

co

c

s

c

s

i

i

u

u

D

D

a

a

r

r

b

b

rhe

rhe

e

e

G

G

he

he

c

c

p

p

i

i

S

S

S

S

e

e

i

i

D

D

d

d

r

r

e

e

w

w

ire

ire

L

L

e

e

R

R

C

C

t

t

n

n

.

e

.

e

be

be

s

s

lt

.

lt

.

anu

anu

e

e

a

e

a

e

d

d

l

l

r

r

h

h

i

i

m

m

c

c

ru

ru

r

r

w

w

urc

urc

s

s

n.

n.

t

t

y

y

e

o

o

e

t

t

e

n.

e

n.

s

s

g

g

e

s

e

s

e

e

ne

ne

f

s

f

s

r

t

r

t

f

f

e

e

f

f

l

l

a

u

a

u

e

h

e

h

ö

ö

a

a

c

c

g

w

g

w

e

e

a

a

s

s

o

o

g

g

e

e

r.

r.

un

un

p

p

r

r

t

t

b

b

us

us

i

i

ie

ie

e

e

e

e

ît

ît

n

n

m

m

e

e

ng

nl

ng

nl

g

g

bo

bo

ä

a

é.

é.

ä

a

n

n

rm

rm

it

s

it

s

.

.

u

r

u

r

r

r

pf

pf

o

le

le

o

h

h

u

n

u

u

u

n

ir

ir

n

n

m

m

e

c

r

e

c

r

s

t

s

t

v

v

é

é

E

E

a

a

it

it

u

u

r.

r

r.

r

pan

s

pan

s

i

i

is

is

o

o

s

s

e

de

e

de

s

s

s

i

s

i

l

l

l

l

e

e

a

a

f

f

e

e

n,

n,

u

u

e

e

n

n

a

a

m

le

m

le

r

r

le

le

e

e

t

t

c

c

a

a

pe

pe

l’

l’

s

s

r

r

e

e

p

p

u

u

m

m

o

o

el

el

r

r

s

s

e

e

r

r

e

e

e

e

L

L

n

n

e

e

t

t

one

one

c

A

c

A

s

s

e

e

D

D

r

r

’

’

il

il

t

t

de

de

d

d

u

u

ab

t

ab

t

s

s

l’

l’

ad.

ad.

d

d

an

an

e

e

ne

i

ne

i

de

de

v

v

d

d

ig

ig

a

a

s

l

ur

s

l

ur

s

s

g

g

n

n

n

n

o

nte

o

io

nte

io

.

se

.

se

t

t

a

a

c

c

a

o

a

o

e

e

s

s

n

n

nt

d

nt

d

u

u

ó

ó

i

i

s

s

e

e

c

c

a

me

a

me

a

d

a

d

li

li

t

t

m

l

m

l

r

r

o

en

o

en

ua

ua

n

n

n

n

m

m

i

i

a

s

a

s

l

l

a

a

a

a

l

l

a

a

a

a

l

l

r

r

e

e

ta

ta

c

c

.

.

a

a

r

r

tu

tu

r

r

e

e

.

.

p

p

a

a

za

za

i

i

.

.

d

d

ez

o

ez

o

r

r

s

s

o

o

.

.

u

u

u

u

!!

s

s

’

’

c

c

g

g

i

i

a

a

d

d

n

n

s

s

c

c

i

i

i

i

n

n

n

n

d

d

i

i

ale

e

ale

e

e

e

u

u

e

e

p

p

o

o

m

m

an

an

r

r

on

on

i

i

e

e

o

o

r

r

m

m

.

.

n

n

l

l

l

l

az

az

o

o

i

i

t

t

f

f

a

a

TR

.7

.7

c

c

..

..

c

c

4

4

d

d

..

..

i

i

3

/

3

/

20

20

..

..

n

n

P

P

..

..

ac

ac

.I

.I

..

..

h

h

V

V

..

0÷4

..

0÷4

..

..

c

c

..

5

..

5

..

..

0

0

..

..

..

..

.0

e

e

.0

..

..

..

..

÷3

T

÷3

..

..

..

..

33

33

0

0

..

..

..

..

1

1

.4

..

.4

..

..

..

..

..

..

..

..

..

E

E

..

..

..

..

..

..

..

..

..

..

..

..

UL

UL

..

..

..

..

..

..

..

..

D

D

..

..

..

..

..

..

..

..

..

..

O

O

..

..

..

..

M

..

M

..

E

E

GE

GE

..

..

E

E

Y

Y

N

N

IO

IO

A

A

GR

GR

R

R

PPL

PPL

E

E

.

.

U

U

D

D

Q

Q

S

S

E

E

R

R

E

ION

E

ION

T

T

W

W

O

O

EC

EC

T

T

O

O

R

R

P

P

R

R

Address key (see B.6)

F0CHAB00E14D0

Transmitting module

(see B.2)

R0TXCO06E08A0

Transmitting case

and base

(see B.5)

F0BASE00E56A0

Interface card (see B.2)

F0SCIN00E58A0

Antenna (see page 7)

F0ANTE00E34A0

Page 16 LIKTCNA0

Receiving

case

(see B.5)

R0CASS01P01A0

Exploded view of the receiving unit

D

D

e

e

s

s

A

A

c

c

t

t

o

o

e

e

L

L

n

n

n

n

ee

ee

ec

ec

e

e

r

r

s

s

r

r

t

t

C

C

a

a

e

e

e

e

o

r

o

r

l

l

a

a

u

u

l

l

R

ma

R

ma

a

a

p

l

p

l

e

a

e

a

e

e

a

a

s

s

s

s

n

L

n

L

r

r

l

l

p

p

im

im

i

i

n

n

u

u

l

l

r

r

ec

ec

’

’

e

e

a

o

a

o

a

a

e

e

l

l

l

r

l

r

t

t

l

i

l

i

w

w

n

n

m

e

m

e

m

e

m

e

d

d

ta

r

ta

e

r

e

e

e

m

m

e

e

a

l

a

l

r

r

D

D

n

e

n

e

c

s

c

s

d

d

u

u

a

a

t

t

i

i

ó

ó

n

n

a

a

e

e

n

n

g

g

t

t

e

e

u

u

s

s

ri

ri

d

d

d

d

e

e

a

a

d

d

ab

ab

.

.

uv

uv

ri

ri

r

r

r

r

.

i

.

i

r

r

i

i

l

l

t

t

e

e

é

é

.

.

b

b

o

o

î

î

t

t

i

i

e

e

r.

r.

n

n

e

e

t

t

c

c

wi

wi

h

h

r

r

al

al

d

d

t

t

.

.

e

e

t

t

ng

ng

.

D

D

e

e

s

s

A

A

c

c

te

te

o

o

L

L

n

n

ne

ne

e

e

e

e

e

e

c

c

r

r

s

s

r

r

t

t

C

C

a

a

e

e

e

e

o

r

o

r

l

l

a

a

u

u

la

la

R

m

R

m

p

p

l

l

e

a

e

a

a

a

e

e

a

a

s

s

s

s

n

L

n

L

r

r

l

l

p

p

ime

ime

i

i

n

n

u

u

l

l

r

r

e

e

’

’

e

e

a

o

a

o

a

a

c

c

l

l

l

rm

l

rm

t

t

l

i

l

i

we

we

n

n

m

e

e

m

e

e

d

d

t

r

t

r

e

e

m

e

m

e

a

as

a

as

r

l

r

l

D

D

n

e

n

e

c

c

d

d

us

us

a

a

t

t

ió

i

ió

i

e

nu

e

nu

c

a

d

c

d

a

e

e

o.

Si

o

o.

o

n

Si

ti

n

ti

e

n

e

n

S

S

o

n

o

e

n

e

,

s

s

,

c

an

an

g

g

t

t

e

e

u

u

s

s

r

r

i

i

d

d

d

d

e

e

a

a

d

d

a

a

.

.

b

b

r

r

i

i

r

r

r.

r.

i

i

r

r

l

l

e

e

.

.

b

b

o

o

î

î

ti

ti

e

e

r

r

.

.

e

e

t

t

w

w

i

i

rd

rd

a

a

l

l

te

te

.

.

P

P

t

t

S

S

OWE

OWE

T

T

O

O

SA

SA

ST

P

P

g

g

.

.

/

/

R

R

F

F

A

A

E

E

E

E

N

N

RT

RT

RL

RL

T

T

A

A

Y

Y

R

R

/

/ST

L

L

RL

RL

1

1

R

R

2

2

L

R

L

R

3

3

L

L

4

4

5

5

RL

RL

R

R

L

L

R

R

6

6

L

L

R

R

7

7

L

L

8

8

R

R

9

9

l

l

R

1

1

l

l

R

R

0

0

1

1

l

l

Rl

1R

1

1

1

A

Ø

Ø

R

T

T

2

2

13

13Rl

A

A

R

R

N

76

76

-

-

T

T

A

A

6

6

6

6

Ø

ØA

F

F

R

R

A

A

T

T

Y

Y

P

P

E

E

E1

N

G

G

Ø

Ø

U

U

1

1

P

P

MB

MB

Ø

Ø

5

5

S

S

E

E

E

E

R

R

R

R

I

I

A

A

L

L

l

l

1

1

4

4R

P

P

RO

RO

P

P

T

T

O

O

E

E

W

W

C

C

T

T

E

E

REQ

REQ

I

I

R

R

O

O

N

N

S

S

.

.

U

U

D

D

D

D

RA

RA

P

P

E

E

I

I

P

O

P

O

G

G

N

N

L

L

R

R

Y

Y

M

G

M

G

.

.

E

E

.

.

E

E

O

O

.

.

E

E

.

.

.

.

.

.

D

D

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

ULE

.

.

ULE

.

.

.

.

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

T

T

.

.

..

.

43

.

43

.

.

.

1

.

.

1

.

.

e

e

.

.

.

.

0

.

.

0

.

.

3.

.

3.

.

.

.

ch

ch

÷

.

÷

.

.

.

.

.

.

.

0

.

0

.

.

.

3

.

3

.

.

.

5

5

.

.

.

.

0

.

0

.

.

.

0

n

n

0

.

.

.

.

.

.

.

.

÷

÷

.

.

.

.

.

.

.

a

a

.I

.I

c

c

P

P

/

/

dc

2

dc

2

0

0

9

9

7

7

0

0

W

W

M

M

R

H

R

H

X

Z

X

Z

E

E

U1

U1

E1

.

V

V

.

i

i

.

.

.

c

c

4

4

.

.

.

.

34.

34.

.

.

a

a

.

.

6

6

.

.

.

.

l

l

.

.

U

U

7

7

.

.

.

.

.

D

D

.

R

R

.

.

E

E

a

a

1

1

Q

Q

6

6

t

t

a

a

M

M

O

O

D

D

E

E

L

L

16A

16A

C

C

A

A

EI

EI

V

V

E

E

R

RR

R

E

E

C

C

c

p

p

l

n

si

l

n

si

f

f

d

d

e

e

u

u

v

v

ri

ri

t

t

é

é

f

f

f

f

n

n

c

c

h

h

i

i

n

n

G

G

h

a

h

a

e

e

g

g

a

a

ll

e

ll

e

e

e

e

e

i

i

n

n

v

v

s

s

s

s

rh

rh

b

b

a

a

e

l

e

l

e

e

d

d

’

’

D

r

D

r

n

u

n

u

s

s

s

e

s

e

a

a

t

t

t

t

e

e

i

p

i

p

it

d

it

d

i

i

u

u

sc

sc

l

l

d

d

r

r

i

i

a

e

a

sn

e

A

sn

A

c

sa

c

sa

’

’

E

E

n

o

n

o

h

d

h

d

o

s

o

s

m

m

o

n

o

n

te

te

é

s

é

s

h

h

n

n

R

R

u

r

u

r

c

a

c

a

p

e

p

u

e

u

n

n

m

m

e

u

u

g

g

e

e

ö

ö

g

g

e

e

s

s

e

e

n

n

r

r

a

a

.

.

e

n

n

n

n

r

r

fä

r

r

fä

e

e

a

.

a

.

g

g

e

e

l

e

e

l

t

e

t

e

d

T

d

T

n

n

n

n

m

t

m

i

t

o

p

i

p

o

g

g

t

t

o

o

t

t

b

b

u

g

g

u

o

o

h

h

u

e

u

e

A

A

e

n

l

e

s

n

l

s

w

w

e

r

e

s

r

s

i

i

t

s

s

o

o

p

p

r

r

t

t

u

u

t

e

e

a

a

a

a

g

g

t

s

t

s

e

e

u

e

u

e

r

r

c

c

f

f

au

au

t

t

e

e

n

n

.

.

f

o

o

r

r

e

e

p

p

e

e

L

L

e

r

l

e

r

l

e

e

n

n

s

s

h

h

e

e

e

e

l

l

t

s

t

s

e

e

e

e

s

g

g

s

y

y

’a

’a

ou

ou

r

r

r

r

e

e

g

g

s

s

r

r

l

l

n

n

m

m

e

e

i

i

i

i

u

u

m

r

m

r

.

.

r

r

a

a

l

l

c

c

a

a

e

e

e

e

l

l

e

e

e

e

n

l

n

l

s

s

e

e

i

i

nt

nt

l

l

u

u

b

.

b

.

n

m

n

m

a

a

a

a

e

e

o

o

z

z

l

l

a

a

f

.

.

r

r

i

i

n

n

o

o

m

m

u

u

n

n

e

e

a

a

e

e

l

l

d

d

e

e

i

i

n

n

i

i

d

d

!!

s

s

c

c

’

i

’

i

c

u

a

c

u

a

u

u

s

s

s

s

o

o

o

r

o

r

e

e

.

.

d

d

z

z

i

z

i

z

a

a

a.

a.

.

Address key (see B.6)

F0CHAB00E14D0

Programming interface

card (see B.4)

F0CHAB02E07A0

Receiving module (see B.3)

R0RXDE06E08A0

i

i

e

n

s

e

n

c

s

d

a

c

d

a

e

e

o

o

Si

o

u

o

Si

n

t

u

n

t

S

S

e

e

i

i

o

n

el

o

n

.

el

.

,

,

s

s

r

r

ff

ff

c

c

p

p

n

s

n

s

f

f

G

G

h

a

h

a

i

d

i

d

e

e

gn

gn

a

a

l

e

l

e

e

e

e

e

is

is

l

l

v

v

s

s

r

r

b

b

a

a

e

l’

e

l’

h

e

h

e

d

d

Di

r

Di

r

n

u

n

u

s

s

s

e

s

e

au

au

t

t

t

t

e

e

p

p

i

d

i

d

i

i

s

s

t

l

t

l

d

d

r

r

i

i

an

e

an

s

e

A

s

A

c

s

c

s

c

’

’

o

o

u

u

ö

ö

e

e

s

s

ni

ni

a

a

.

.

c

Emp

Emp

n

n

a

a

h

d

h

d

o

s

o

s

o

n

o

n

t

t

éc

s

éc

s

he

he

n

n

R

e

R

e

u

r

u

r

an

an

u

u

ne

ne

m

m

e

e

n

n

r

r

fän

r

r

fän

.

.

r

r

g

g

e

e

u

u

s

s

g

g

o

o

p

p

e

e

r

r

t

t

u

u

r

r

a

a

g

g

e

e

le

e

e

le

t

t

d

d

T

T

n

n

mu

t

mu

i

t

og

p

i

p

og

g

g

t

t

o

o

t

t

b

b

u

u

o

o

he

he

e

e

A

A

e

n

e

l

s

n

l

s

w

w

s

s

i

i

t

t

e

e

a

a

a

a

g

g

t

t

s

s

e

e

us

e

us

e

r

r

c

c

f

f

a

a

h

h

t

t

e

e

n

n

n

n

.

.

.

.

e

e

f

f

o

o

r

r

e

e

d

d

i

i

a

a

p

p

e

e

L

L

e

r

l

e

r

l

e

e

ne

ne

e

e

e

e

t

s

t

s

e

e

l

l

g

s

g

s

y

y

’

’

o

o

r

r

r

a

r

a

e

e

g

g

s

s

r

r

u

u

l

l

m

m

er

er

i

i

i

i

ul

ul

m

rc

m

rc

a

a

a

a

e

e

e

e

l

l

e

e

e

e

n

l

n

l

s

s

e

e

i

i

n

n

l

l

u

u

n

b

n

.

b

.

t

t

m

m

a

a

a

a

or

or

z

z

l

l

a

a

.

.

i

i

n

n

one

one

m

m

uale

uale

e

e

d

d

i

i

n

n

i

i

d

d

s

s

c

c

’

i

’

i

c

u

a

c

u

a

u

u

s

s

s

s

o

o

o

r

o

r

e

e

.

.

z

z

z

z

a

a

.

.

Receiving

case extension

(see B.5)

R0CASS01P01A0

Receiving

case and base

(see B.5)

F0BASE00E54A0

Receiving

case and base

extension

(see B.5)

F0ESBA00E34A0

Antenna (see page 7)

F0ANTE00E34A0

LIKTCNA0 Page 17

A.2 Diagnostic flow chart

In the event that the system or the machine activated by the Kit Transmission Commands doesn't function

properly carry out the following procedure:

Check the

transmitting unit.

Is the POWER

signal on?

YES

Is the state

of the unit

signal light on?

Is the power supply

NO NO

terminal block

connected

correctly?

YES

Is the power

supply with the

correct

parameters?

NO

YES

No voltage.

Is the fuse

FUSE burnt?

NO

YES

Change the

transmitting case

and base

YES

with a steady light?

Is the state

of the unit

signal light on

NO

Correctly connect

the power supply

to the terminal

connector.

Power the

transmitting unit

correctly

Replace FUSE

Is the state

of the unit light

signal flashing

quickly?

NO

The state

of the unit light

signal is

flashing slowly?

NO

The START

of the unit light

signal is on?

YES

CALL

TECHNICAL

ASSISTANCE

inserted commands

RL1÷ RL6 and

NO

YES

Switch off the

RL11÷RL16

Activate

the START

command.

YES

Power

the transmitting

unit correctly

When each com-

mand is switched

on does the

appropriate RL_

signal go on?

NO

Are the

COM and CSZ

receiving power?

NO

Change the

transmitting case

and base

The transmitting

YES

YES

unit is working.

the receiving unit

It's a system or

machine problem,

a KTC problem.

Check

(see page 17).

not

LIKTCNA0Page 18

Check the

receiving unit.

Is the POWER

signal on?

Is the power supply

terminal block

connected

correctly?

YES

NONONO

Correctly connect

the power supply

to the terminal

connector.

YES

Is the ENABLE

signal on?

YES

No voltage.

Is the fuse

F2 burnt?

NO

Is the power

supply with the

correct

parameters?

YES

No voltage.

Is the fuse

F1 burnt?

YES

Change the

receiving case

and base

NO

Replace F2

NO

NO

Power the

receiving unit

correctly

Replace F1

Is the antenna

installed

correctly?

YES

Change

the operational

frequency

NO

does not switch on,

CALL TECHNICAL

Install

the antenna

correctly

If the KTC

ASSISTANCE

YES

No voltage.

Is the fuse

F3 burnt?

YES

When the

transmitting unit

RL_ signal goes on

does the RL_

signal in the

receiving unit

go on?

YES

It's a system

or equipment

problem, not

a KTC problem.

NO

NO

Replace F3

CALL

TECHNICAL

ASSISTANCE

LIKTCNA0 Page 19

B.1 Opening and closing the unit

Opening

Remove the antenna cable from

the connector.

Remove the cable and power

connectors.

Closing

Insert the antenna cable in the

connector.

Insert the power and cable

connectors

Cut the strip which locks the unit

with pliers.

Open the cover and carry out the

necessary operations.

Opening Closing

Lock the cover by inserting a

strip in the hole provided.

Close the cover.

LIKTCNA0Page 20

B.2 Replacement of the transmitting module and/ or interface card

Disassembly

Carry out the opening described

in procedure B.1.

Extract the transmitting module interface card sandwich.

Extract the antenna cable from

the transmitting module.

Assembly

Carry out the closure described

in procedure B.1.

Insert the transmitting module

interface card in the appropriate

fissure so that it fits correctly into

the connector.

Insert the antenna cable in the

transmitting module.

Unscrew the four screws and

separate the transmitting

module from the interface card.

Replace the transmitting module and/or the

interface card.

If you replace the transmitting module you

have to:

- remove the address key from the module to

be substituted and put it in the new one (see

procedure B.6)

- programme the dip switches of the new

module in the same way as those on the old

model.

Put the transmitting module and

the interface card together and

tighten the four screws.

LIKTCNA0 Page 21

B.3 Replacement of the receiving module

Disassembly

Carry out the opening described

in procedure B.1.

Extract the receiving module

from the receiving unit.

Replace the receiving module.

If you replace the transmitting module you

have to:

- remove the address key from the module

to be substituted and put it in the new one

(see procedure B.6)

- programme the dip switches of the new

module in the same way as those on the old

model.

Assembly

Carry out the closure described

in procedure B.1.

Put the receiving module in the

appropriate fissure so that it fits

correctly into the connector.

B.4 Replacement of the programming interface card

Disassembly Assembly

Carry out the disassembly

described in procedure B.3.

Remove the programming

interface card from the receiving

unit and substitute it.

Follow the assembly

instructions in procedure B.3

Put the programming interface

card in the appropriate fissure

so that it fits correctly into the

connector.

LIKTCNA0Page 22

B.5 Replacement of the case or/and base

Disassembly Assembly

Carry out the opening described

in procedure B.1.

Remove the module and the

card from the unit to be replaced

(see relevant replacement).

Replacement

of the case

and base

Replacement of the only

case

With the help of a screwdriver

move the two catches on the

bottom of the case, as shown in

the figure.

Carry out the closure described

in procedure B.1.

Insert the modules and cards

removed from the old unit, in the

replacement unit.

Raise (A) and remove (B) the

case bottom, starting from the

side from which the catches

have been moved.

Extract the base, widening the

lower edge (E) slightly.

BB

CC

EE

DD

AA

Reposition (C) first one side of

the case bottom, then lightly

push the other side (D) into its

correct position.

Insert the base firstly into the

upper and then into the lower

part, slightly widening the lower

edge (E) in order to pass the

connector.

LIKTCNA0 Page 23

B.6 Replacement of the address key

IN THE EVENT THAT ONE ADDRESS KEY DOES NOT FUNCTION, BOTH HAVE TO BE REPLACED

(ONE IS TO BE FOUND ON THE TRANSMITTING MODULE AND ONE ON THE RECEIVING MODULE)

Disassembly

Carry out the disassembly

described in the procedures B.2

and B.3.

Unscrew the screws and remove

both the address keys from the

modules.

Assembly

Carry out the assembly

described in procedures B.2

and B.3.

Place the address keys in the

appropriate modules fix the

screws.

Example using

the transmitting module

Page 24

LIKTCNA0

B.7 Replacement of the transmitting unit fuse

Disassembly

After removing the cable

connectors, use a screwdriver to

remove the cover to the bottom

right of the transmitting unit.

Remove the fuse.

The replacement fuse has to

have the indicated technical

characteristics:

Assembly

Close the cover to the bottom

right and insert the cable

connectors.

Put in a new fuse.

Fuse Function Technical

characteristics

FUSE POWER SUPPLY 0.4A T 250V 5x20 mm

B.8 Replacement of the receiving unit fuses

Disassembly

After removing the cable

connectors, push the fuse to be

replaced with a screwdriver and

turn it in the indicated direction.

Remove the fuse.

The replacement fuse has to have

the technical characteristics

indicated in the following table:

Assembly

Push the fuse rolling it in the

opposite direction to that

indicated. Insert the cable

connectors.

Put in a new fuse.

Fuse Function

F1 POWER SUPPLY 1A T 250V 5x20 mm

F2 SAFETY 4A T 250V 5x20 mm

F3 STOP 4A T 250V 5x20 mm

F4 SAFETY 4A T 250V 5x20 mm

Technical

characteristics

LIKTCNA0 Page 25

C Programming

There are eight dip switches for programming in the transmitting and receiving modules.

Operational functions and working frequencies may be programmed.

The group of eight dip switches found in the module is necessary for programming some operations (see

C.1)and setting the operating frequency (see C.2).

The other group of four dip switches must be set as indicated in C.1.

Group of 4

dip switches

Group of 8

dip switches

The dip switches must be programmed by qualified personnel. During these operations the

unit which is being used must not be connected to the power supply.

Before programming the dip switch remove:

- the transmitting module- interface card sandwich in the transmitting unit (see procedure B.2)

-the receiving module in the receiving unit (see procedure B. 3)

The group of 8 dip switches present in the radio module of the transmitting unit must be set

in the same manner as the group of 8 dip switches (excluding DIP 1) present in the radio

module of the receiving unit, when any kind of programming is carried out.

LIKTCNA0Page 26

C.1 Programming functions

The dip switches 1 and 2 programme the same functions in 433 MHZ and in 870 MHZ modules.

DIP SWITCH Functional description

Group of 8

dip switches

in the

transmitting

module

E16STXEU_

Group of 8

dip switches

in the

receiving

module

E16SRXEU_

ON

OFF

182 7

ON

OFF

182 7

ON

OFF

182 7

ON

OFF

182 7

5

4

3 6

5

4

3 6

5

4

3 6

5

4

3 6

DIP SWITCH Functional Description

ON

OFF

182 7

ON

OFF

182 7

ON

OFF

182 7

ON

OFF

182 7

5

4

3 6

5

4

3 6

5

4

3 6

5

4

3 6

* passive emergency: the receiving unit decides autonomously to switch the system off when

the radio signal is incorrect, interrupted or there is interference

Dip switch 1 OFF enables the automatic off switch: if the

transmitting unit is on but none of the commands is operational,

after about 3,5 minutes the unit switches itself off automatically.

Dip switch 1 ON disables the automatic switch off function: if the

transmitting unit is on but no commands are activated for about 3,5

minutes, automatic switch off does not occur.

Dip switch 2 OFF activates the insufficient power acoustic signal.

When the power supply to the transmitting unit goes below a

certain value, the relay in the receiving unit is activated.

Dip switch 2 ON switches off the insufficient power acoustic

signal.

Dip switch 1 in the ON position fixes passive emergency* at 1

second.

Dip switch 1 in the ON position fixes passive emergency* at 0.35

seconds. **

Dip switch 2 OFF activates the insufficient power acoustic signal.

When the power supply to the transmitting unit goes below a

certain value, the relay in the receiving unit is activated.

Dip switch 2 ON switches off the insufficient power acoustic

signal.

** Following from the status of dip switch no.1 or possibly due to a failure (of the dip

switch itself), a delay up to max 1 second may occasionally occur between command

release and actual deactivation of outputs. This is due to the characteristics of radio

propagation (i.e.: EM interferences, near out-of-range condition). Care must be taken to

ensure that this could never lead to.

Group of 4

dip switches

in the

transmitting

module

DIP SWITCH

ON

OFF

1 2

4

3

E16STXEU_

Group of 4

dip switches

in the

receiving

module

DIP SWITCH

ON

OFF

1 2

4

3

E16SRXEU_

LIKTCNA0 Page 27

C.2 Programming the operational frequency

A kit Transmission Commands has two operational modes:

- manual frequency (programming with DIP8=ON)

- automatic scan (programming with DIP 3- DIP 8= OFF).

AUTEC PROGRAMMES THE OPERATIONAL MODE TO MANUAL FREQUENCY.

MANUAL SELECTION: DIP 8 = ON