Autec RX97RC52 Users Manual

C26PRO SERIES

PRO-M

C26PRO SERIES

PRO-M

Carefully read the instructions and warnings about the system or the equipment in which the KTC is installed.

Should the manual be damaged or lost, ask AUTEC for a copy of the manual Specifying the KTC serial number.

Contact AUTEC if any of the instructions and/or warnings given in this manual are not clear.

The information contained in this manual is subject to modification without notice and is not binding.

No parts of this manual may be produced by any means without the written permission of AUTEC (including recording

and photocopying).

1

CONVENTIONS

Any pieces of text written in bold should be read very carefully.

This symbol highlights extremely important indications and information

which, if not observed, can create seriously dangerous situations for people,

equipment or property.

This symbol highlights all important indications and information that deal

with operation.

2

CONFORMITY

The C26 PRO series PRO-M radio remote control is in conformity with FCC

Rules (Part 90 for the transmitting unit and Part 15 for the receiving unit).

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference

that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate

the equipment.

In Technical Data (see chapter 15) there are the characteristics of safety functions

according with EN 954-1.

All machines must undergo a risk analysis; therefore it is necessary to evaluate, within the limits of this analysis, if the machine can be radio remote controlled.

The machine producer and/or the person who decides upon radio remote control use

and installation is responsible for this analysis.

Autec, or its distributors, cannot be held responsible if the risk analysis is not

carried out correctly and if the radio remote control is installed on applications that are different from those permitted:

PERMITTED APPLICATIONS:

Hoisting and moving machines installed exclusively on vehicles that

use a battery as electrical power supply source (for example: hydraulic cranes, concrete pumps…)

LIPROMA3-00

FORBIDDEN APPLICATIONS

- machines installed in areas where equipment with explosionproof characteristics are being used

- AC supplied machines

- machines using a DC supply that does not come from a battery

- machines where risk analysis regarding verification of radio remote control conformity to the application is not possible or has

given a negative or uncertain result.

To guarantee correct radio remote control operation, all current regulations regarding

safety at work and accident prevention should be respected. All applicable standards

and regulations valid in the user country regarding the use of both the machine and

the radio remote control MUST ALWAYS be respected.

Autec cannot be held responsible if the radio remote control is used in unlawful working conditions.

System must be installed by a licensed technician and in accordance with all

relevant local, state/provincial and federal regulations, including but not

limited to NEC, OSHA, CE etc.

- 1 Conventions -

- 1 -

3

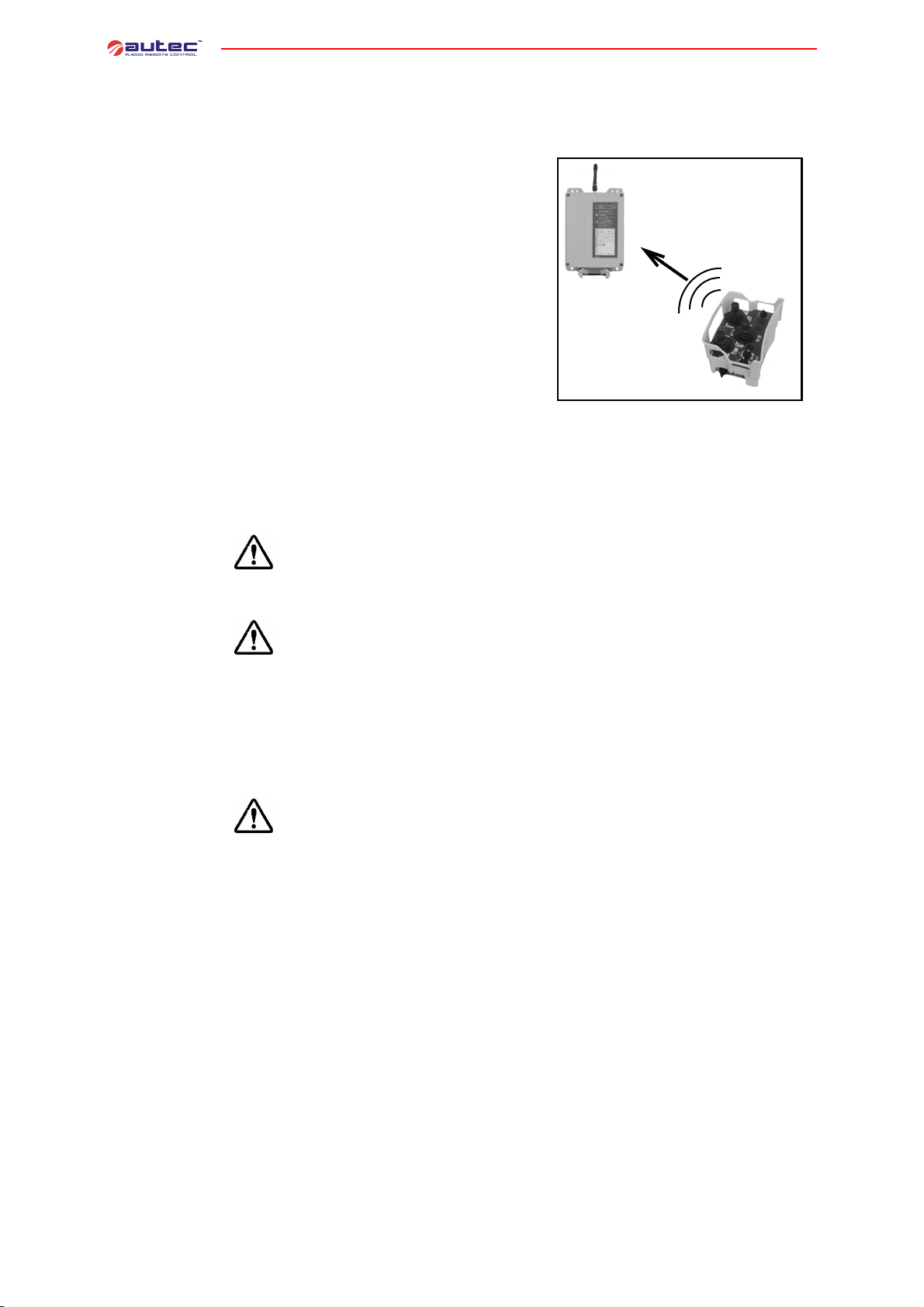

RADIO REMOTE CONTROL DESCRIPTION

Industrial radio remote controls are used to

command machines from a distance. Each industrial radio remote control is made up of a

portable transmitting unit, from which the

user can remotely control the machine, and a

receiving unit installed on board the machine

itself. The transmitting unit sends a coded

message over radio frequency transmission.

This message contains a value called “address”, which lets the receiving unit decode

only the messages coming from its own

transmitting unit (the one that has the same

address).

This ensures that no interference can activate

any command. If the radio frequency transmission is disturbed, incorrect or interrupted,

the receiving unit autonomously stops the

whole system.

Receiving

unit

Transmitting

unit

4

General

indications

Installation

WARNINGS REGARDING INSTALLATION

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS MAY RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE

TO EQUIPMENT.

Installation must only be carried out by qualified people and in accordance with the standards and regulations in the country in which

the system is to be installed. Only a correct installation can ensure

the necessary level of safety during subsequent radio remote control use.

Respect the machine operational characteristics when connecting the Radio remote

control. The safety circuits on the radio remote control and/or present on the

machine should not be bypassed (or excluded).

The receiving unit wiring can be configured very easily, therefore it can be installed

without having to modify the machine. Do not modify the machine electric panel without the machine manufacturer authorization.

Disconnect the receiving unit by detaching all the electrical connections each time some welding operation is performed on the machine.

The receiving unit must be placed in a position that favours reception of the

signals issued by the transmitting unit.

It should therefore be assembled vertically (antenna upwards). The receiving unit

should also be easily accessible to permit operation under safe conditions.

If the receiving unit is covered by metal structures or installed inside metal panels,

use the appropriate extension kit for external antennas.

The antenna must never come into contact with metal parts.

It is forbidden to pierce the receiving unit casing. Doing so compromises the

protection degree against external agents (level IP65).

The vehicle creates vibrations, therefore antivibration blocks must always be used to

reduce the effect that these vibrations have on the receiving unit.

The receiving unit must be positioned away from heat sources (exhaust pipes, alternators, radiators etc.)

Wiring

Most machines are connected to the receiving unit by multiple-pole plugs which permit quick disconnection of the radio remote control for replacement with a hard wired

- 3 Radio remote control description -

- 2 -

LIPROMA3-00

Proportional

output

setting

Testing

(cabled) control. This connecting technique is advisable even if the machine is not

originally equipped for it.

The reliability of the installation is largely dependent on the quality of the wiring, and

connections should therefore be made to the highest standards using multi-core or

single-core cables of suitable cross-sectional area for the current to be carried.

should also be flame retardant

Oil resistant cables should be used for connections external to the receiving unit.

The receiving unit power supply must pass through an isolation

switch to permit power disconnection during installation, wiring

and/or maintenance operations.

To improve radio remote control operation, connect the receiving

unit immediately downstream of the machine main switch.

It is always advisable to check the supply voltage even under maximum load; in this

way the maximum variations can be verified (the limit values of tolerated deviation

are given both in the Technical Data and on the technical data sheet of the Radio remote control).

Receiving unit supply voltage fluctuations that exceed the limit values can compromise regular radio remote control operation.

The C26-PRO series radio remote controls are equipped with circuits to protect

against unintended movements from standstill of the actuators if the wiring indications indicated in the technical data sheet are respected.

Autec supplies the radio remote control with the proportional output values

already set depending on the valve type(s). During installation, these values

must be verified and, if necessary, modified according to machine function

and operator preference (see chapter 12).

When installation and wiring have been completed, always do the following:

- make sure that when the radio remote control STOP pushbutton is pressed

the machine goes into a situation of safety (through direct action on the

general solenoid valve of the main circuit), the motor possibly switches

off and, if present, the main line contactor opens to remove voltage.

- make sure that the manoeuvres carried out by the machine and which

have been commanded by the transmitting unit correspond exactly

(this correspondence is given in the technical data sheet)

-check safety circuit operation (a simple way of doing this is to remove

fuse F3, housed on the main board of the Receiving Unit. Make sure that

in these conditions no movement command can be carried out, then insert

the F3 fuse again and check correct operation)

(for further information refer to IEC 60204 - 1).

Cables

5

LIPROMA3-00

The installer must also compile and/or verify the two copies of the technical

data sheet, where the wiring layout between the receiving unit and the machine is given. The first copy of the technical data sheet is inside the receiving unit, the second is annexed to the user's manual. The installer must put

the date of installation, sign and stamp both copies.

WARNINGS REGARDING USE

FAILURE TO COMPLY WITH THE FOLLOWING WARNINGS MAY RESULT IN SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE

TO EQUIPMENT.

The radio remote control can only be used by operators who:

- have read and understood this manual,

- are qualified and trained,

- know the “radio remote control + machine” system well.

The radio remote control can only be used by operators who:

- have read and understood this manual,

- 5 Warnings regarding use -

- 3 -

Loading...

Loading...