DC Receiver System

USER’S MANUAL

!!

Prima dell'accensione leggere il manuale d’uso.

Attenersi alle norme di sicurezza.

Togliere l’alimentazione in caso di apertura.

Before switching on please read the user manual.

Adhere to safety rules.

Disconnet power source before opening.

Vor Inbetriebnahme die Gebrauchsanleitung

lesen. Sicherheitsnormen beachten.

Die Speisespannung muss ausgeschaltet

werden, falls der Empfänger geöffnet wird

Avant d’allumer l’engine, lire le manuel de

l’utilisateur.

Respecter le consignes de sécurité.

Couper l’alimentation avant d’ouvrir le boîtier.

Antes de encenderlo leer el manual.

Atenerse a las normas de seguridad.

Desconectar la alimentación antes de abrir.

Follow the indications and warnings given by the machine producer regarding the machine

controlled by the radio remote control.

The information contained in this manual considers a representative configuration of the

radio remote control: please find radio remote control real configuration in the technical data

sheet (attached to the manual).

If this manual is lost or damaged, ask for a copy from AUTEC. Please specify the serial

number of the relative radio remote control.

Contact AUTEC if any of the instructions and/or warnings given in this manual are not clear.

The information contained in this manual is subject to modification without notice and is not

binding.

No parts of this manual may be reproduced by any means without the written permission of

AUTEC (including recording and photocopying).

LIE&LDA0

1

Index & Conventions

1

INDEX & CONVENTIONS

INDEX

Page

1

2

Introduction

3

Receiving units

4

Warnings for installation

5

Warnings for maintenance

6

Light signals

7

Programming

8

Receiving unit diagnostic

2

5

8

10

11

12

14

CONVENTIONS

In this manual, all important information is indicated using the following symbols and

conventions:

!

abcd. . .

abcd. . .

: WARNINGS

: TECHNICAL DATA

abcd. . .

abcd. . .

: INSTRUCTIONS

: IMPORTANT TEXTS

THIS MANUAL REFERS EXCLUSIVELY TO THE RECEIVING UNIT: THE GENERAL

USAGE WARNINGS ARE GIVEN IN THE TRANSMITTING UNIT MANUAL.

BEFORE INSTALLING, STARTING AND USING THE RADIO REMOTE CONTROL, THIS

MANUAL MUST BE READ AND UNDERSTOOD CAREFULLY BY ALL PEOPLE WHO

INSTALL, USE AND CARRY OUT MAINTENANCE ON THE RADIO REMOTE CONTROL.

Page 1

LIE&LDA0

2

INTRODUCTION

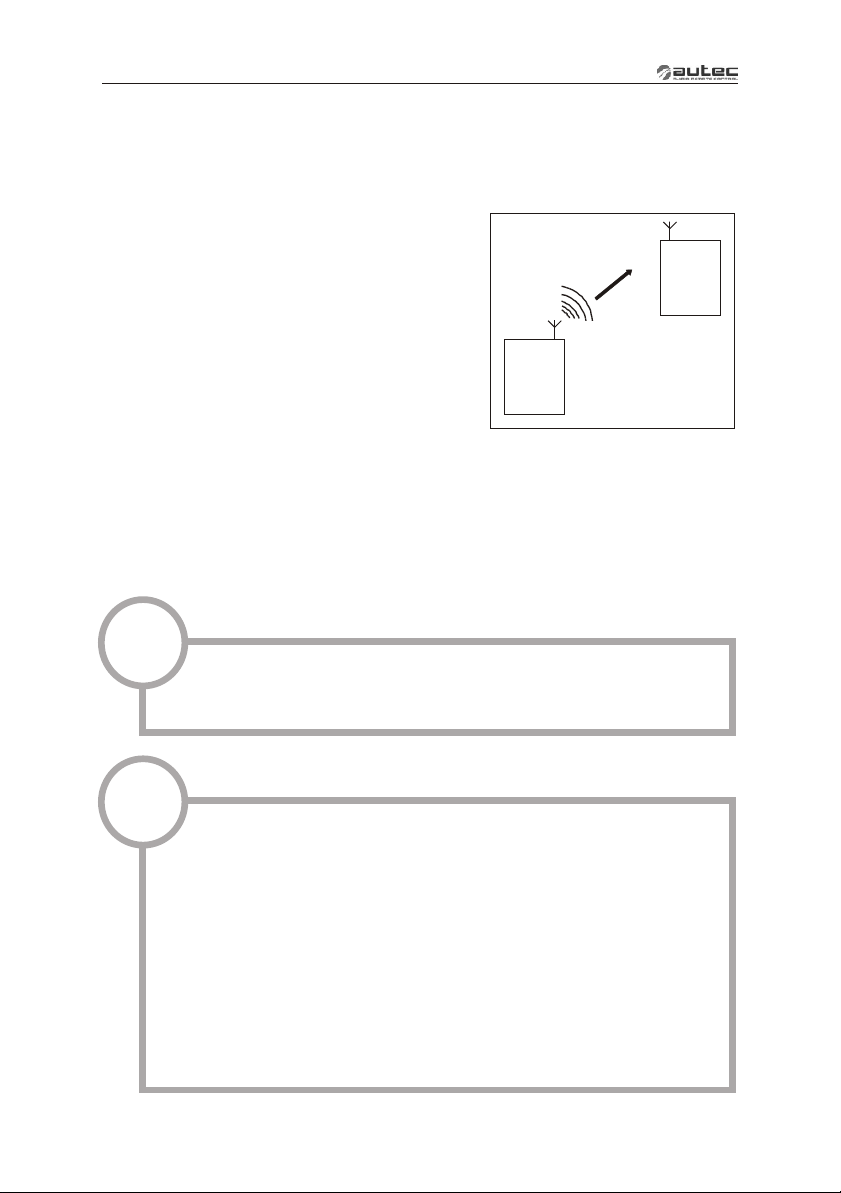

Industrial radio remote controls are used to command

machines from a distance. Each industrial radio

remote control is made up of a portable transmitting

unit, from which the user can remotely control the

machine, and a receiving unit installed on board the

machine itself.

The transmitting unit uses radio frequencies to

transmit a coded message which contains a value

called address. Each receiving unit can only decode

the messages coming from its own transmitting unit

with the same address.

This excludes the possibility of an interference

activating any system function. If the radio frequency

transmission is disturbed, incorrect or interrupted, the

receiving unit autonomously stops the whole system.

Each radio remote control complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

Transmitting

unit

Receiving

unit

!

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate

the equipment.

!

Autec cannot be held responsible if the radio remote control is

installed on applications that are different from those permitted

PERMITTED USES

Material lifting machines (construction cranes, industrial bridge cranes,

machines for moving material in general, . . . )

FORBIDDEN USES

Machines installed in areas where equipment with explosion-proof

characteristics are being used.

Machines for moving, raising and transporting people.

.

:

Page 2

LIE&LDA0

Alll machines must undergo a risk analysis; therefore it is necessary to evaluate, within

the limits of this analysis, if the machine can be radio remote controlled.

The machine producer and/or the person who decides upon radio remote control use

and installation is responsible for this analysis.

Autec cannot be held responsible if the risk analysis is not carried out correctly.

To guarantee correct radio remote control operation, all current regulations regarding

safety at work and accident prevention should be respected. All current user country

national laws regarding the use of both the machine and the radio remote control MUST

ALWAYS be respected.

Autec cannot be held responsible if the radio remote control is used in unlawful

working conditions.

System must be installed by a licensed technician and in accordance with all

relevant local, state/provincial and federal regulations, including but not limited to

NEC, OSHA, CE etc.

!

In any cases of emergencies, faults or damaged parts, ALWAYS stop

the “machine + radio remote control” system until the problem has

been solved.

Any damaged parts can ONLY be replaced by authorised

Autec personnel or service representative, and only using original Autec

spare parts.

ENGLISH

Page 3

LIE&LDA0

INSTRUCTIONS FOR DOCUMENT MANAGEMENT

The following minimum documentation is supplied with each radio remote

control:

- transmitting unit manual

- receiving unit manual

- battery charger manual

- a guarantee certificate

- the radio remote control technical data sheet.

Make sure that the following documents have been supplied: if they are not, request

them from Autec. Please specify the radio remote control serial number.

The conditions of the radio remote control guarantee are given in the “Certificate of

CERTIFICATE OF GUARANTEE

Guarantee”.

TECHNICAL DATA SHEET

The technical data sheet shows the wiring system between the receiving unit and the

machine. It should be compiled and checked by the installer, who has the responsibility

of correct wiring. Once all necessary checks have taken place the installer must sign the

technical data sheet, which must be kept with the user's manual (always keep a copy of

this data sheet in case it is needed for administrative purposes).

IDENTIFICATION PLATES

The radio remote control identification and approval data is given on plates that are on

both the transmitting unit and the receiving unit.

The plates MUST NOT be removed from where they are placed or damaged

otherwise the warranty will be forfeited.

TECHNICAL DATA

Frequency band

Programmable radio channel

Hamming distance

Probability of non-recognition of error

Typical working range

Time of reply to commands

Time of reply to STOP

Passive emergency time

* refer to paragraph “Programming” in the receiving unit manual, DIP nr. 1

settings.

902 - 928 MHz

32

³ 8

<10 exp-11

100 m

<100 ms

<100 ms

* 0,35 / 1 sec.

Page 4

LIE&LDA0

3

RECEIVING UNITS

The receiving unit

unit:

- SERIES LIGHT

- SERIES MODULAR

These receiving units are equipped with a safety function called SAFETY that protects

the “radio remote control + machine” system, when it is in neutral (rest position), from

involuntary movements caused by possible radio remote control faults.

Type R202 and Type R302 can be used with the following transmitting

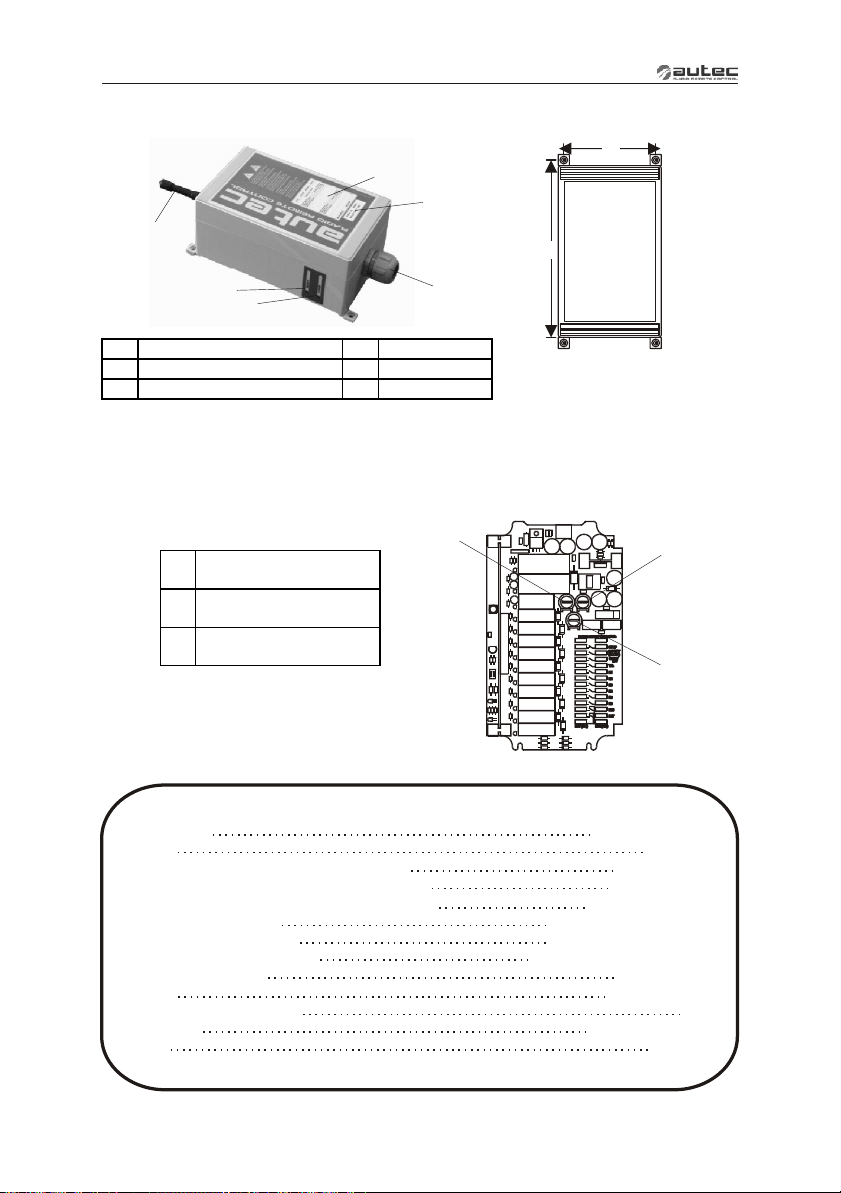

RECEIVING UNIT TYPE R202

C

D

F

Drilling template

A = 150mm

B = 75 mm

C = 357,5mm

D = 118,5mm

E = 167mm

F = 350,5mm

E

D

A

cable holder (opt. plug)

B

data technical plate

C

identification plate

D

POWER light

E

ENABLE light

coaxial cable exit for stylus antenna

F

or for blinker (when present))

B

C

A

B

A

F

E

Page 5

LIE&LDA0

The master board in this type of receiving unit is E16B22DC for configurations of up to 22

commands (plus extension interface card).

E16B22DC

F1

F2

STOP circuit protection

F1

fuse

F2

SAFETY circuit

F3

protection fuse

POWER SUPPLY

F4

protection fuse

F3

F4

Receiving unit Type R202 TECHNICAL DATA

Power supply

Antenna

Max switching capacity of STOP contacts

Max switching capacity of SAFETY contacts

Max switching capacity of command contacts

Fuse F1 (STOP circuit)

Fuse F2 and F3 (SAFETY circuit)

Fuse F4 (POWER SUPPLY)

1A (24Vdc) or 2A (12Vdc)T 250V (5x20 mm)

Working temperature

Housing

Minimum protection grade

Dimensions

Weight

*Capacity only valid if both terminals are used for each contact.

**If the radio remote control output have been cabled by Autec, please see technical data sheet.

12 or 24 Vdc ±25% (~15W)

integrated or dedicated

* 10A (30Vdc)

2 x 5A (30Vdc)

* 10A (30Vdc)**

10A T 250V (5x20 mm)

5A T 250V (5x20 mm)

-4°F - +158°F

nylon (20% fg)

IP65

(202x381x91) mm

max 3,5 kg

Page 6

LIE&LDA0

F

RECEIVING UNIT TYPE R302

A

C

B

B

E

A

D

A

cable holder (opt. plug)

B

identification plate

C

data technical plate

D

POWER light

E

ENABLE light

F

antenna

Drilling template

A=106 mm

B=213,5 mm

The master board in this type of receiving unit is E16B10DC for configurations of up to 10

commands.

E16B10DC

STOP circuit protection

F1

fuse

SAFETY circuit

F2

protection fuse

POWER SUPPLY

F3

protection fuse

F2

F1

F3

Receiving unit Type R302 TECHNICAL DATA

Power supply

Antenna

Max switching capacity of STOP contacts

Max switching capacity of SAFETY contacts

Max switching capacity of command contacts

Fuse F1 (STOP circuit)

Fuse F2 (SAFETY circuit)

Fuse F3 (POWER SUPPLY)

Working temperature

Housing

Minimum protection grade

Dimensions

Weight

*Capacity only valid if both terminals are used for each contact.

**If the radio remote control output have been cabled by Autec, please see technical data sheet.

8 - 30 Vdc (~7W)

dedicated

* 10A (30Vdc)

* 10A (30Vdc)

** max 6A (30Vdc)

10A T 250V (5x20 mm)

10A T 250V (5x20 mm)

3.15A T 250V (5x20 mm)

-4°F - +158°F

Polycarbonate

IP65

(120x200x90) mm

max 2 kg

Page 7

LIE&LDA0

!

4

WARNINGS FOR INSTALLATION

Installation should only be carried out by qualified people and in

accordance with installation country rules.

THE INSTALLER

MUST

PLACE the receiving unit vertically, with the cable holder (or plug)

facing down.

DO NOT MODIFY or TAMPER WITH the radio remote control, the

machine or its electric panel. DO NOT PERFORATE the receiving unit for

any reason whatsoever.

CHECK that the receiving unit power supply is inside the voltage range

given in the “Technical Data”, and that the voltages and currents being

used do not exceed the maximum permitted values.

DO NOT EXCLUDE the radio remote control safety mechanisms and/or

those present inside the machine.

RESPECT all the machines and for hoisting machines

(see corresponding ).

NEVER SUPPLY the receiving unit directly from the mains. A main

switch should always be present to permit power supply removal.

PLACE the receiving unit so that it is not completely screened by metal

parts and that it must be easily reachable.

REMEMBER to carefully wire the SAFETY contacts in series with the

movement commands inside the receiving unit.

After installation and wiring, ALWAYS CHECK that the maneuvers

carried out are exactly the same as the commands given (in particular

check the STOP command).

FAILURE TO COMPLY WITH THE ABOVE WARNINGS MAY RESULT IN

SERIOUS INJURY OR DEATH TO PERSONNEL AND DAMAGE TO

EQUIPMENT.

prescriptions for

EN60204-1 and EN60204-32 prescriptions

Page 8

LIE&LDA0

WARNING: The stylus of dedicated antenna (always present in the receiving unit

Type R302, optional for the receiving unit Type R202), must never come in contact

with metal parts.

If installing on machines that vibrate, it is advisable to fix the receiving unit to the machine

with the appropriate antivibration absorbers.

The receiving unit should also be positioned away from heat sources (for example

motor/exhaust pipes).

!

When welding on the machine, REMOVE POWER SUPPLY by

disconnecting all the electric connections (both during installation and

during normal operation).

If present, the switch that is enable to open the ground (e.g. battery

negative) MUST OPEN also the receiving unit ground as well.

The installer must CHECK and/or COMPLETE the "Technical Data Sheet" indicating the

date of activation of the system, putting his signature and stamp.

Page 9

LIE&LDA0

!

5

WARNINGS FOR MAINTENANCE

ALWAYS ENSURE THAT THE RECEIVING

UNIT HAS BEEN DISCONNECTED FROM THE

POWER SOURCE BEFORE CARRYING OUT

ANY MAINTENANCE WORK.

All the faults should be repaired by authorised

Autec personnel using original Autec spare

parts only.

The receiving unit requires no special

maintenance, but some simple things are

necessary to work with apparatus that is always

reliable and safe:

- check for signs of damage,

- remove dust or any other material that has

deposited on the receiving unit with a cloth that has

been dampened with water (never use solvents or

flammable/corrosive materials to clean, and do not

use high pressure water cleaners or stream

cleaners).

The correct operation of SAFETY function must be checked every six months. The

check can be carried out by inspection of the correct operation of the SAFETY

relay when a movement command is activated.

AUTHORIZED SERVICE CENTER

When it is necessary to carry out special maintenance (radio remote control repair and

replacement of damaged or faulty parts), do not contact anyone other than our

Authorized Service Center. In order to make the intervention faster and more reliable,

please help us identify the radio remote control correctly and completely by giving:

- the serial number

- the purchase date (given on the guarantee)

- description of the problem found

- the address and telephone number of the place where the radio remote control is being

used

- the name of the person to be contacted

- the name of the company that supplied the radio remote control.

!

In order to close the

receiving unit,

tighten the

upper two screws

first and then the

lower two.

SERV

ICE

Before speaking with a service technician, it is advisable to make sure that the

given instructions have been followed correctly.

Entrust the radio remote control and the its battery to the separate scrap collecting

services in the user country.

DISPOSAL

Page 10

LIE&LDA0

6

LIGHT SIGNALS

On each receiving unit

there are:

a POWER lamp

indicates the presence of power

supply in the receiving unit

an ENABLE lamp

which indicates radio link on

between the transmitting unit

and receiving unit

a LED

for each relay

on the master board,

which indicates

the activation of that relay

On the receiver module there are three LEDs, which indicate:

1. power supply

2. radio connection

3. frequency scanning search.

1 2 3

Page 11

LIE&LDA0

!

7

PROGRAMMING

The dip switches must be programmed when the receiving unit is not

powered and can be done only by authorised personnel.

DIP SWITCHES ON E16SRXUS1 RADIO RECEIVING MODULE

The group of eight dip switches found in

the module permits the programming of

different operating mode and the setting

of operating frequency.

The programming set in the other group

of four dip switches must never be

modified.

Group of 8 dip switches

DIP POS.

1 (*)

2 (**)

3

3 - 7 ON/OFF

8

(*) With the MK12 transmitting unit the dip switch should be at ON.

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Deactivated of low battery warning from horn on machine

Activation of low battery warning from horn on machine

With DIP 8 OFF automatic scan mode of the freque ncies

With DIP 8 OFF automatic scan mode of the frequencies

With DIP 8 ON see “Appendix: Frequency Table”

DIP 3 - DIP 7 (see “Appendix: Frequency Tab le”)

Automatic scan mode of frequencies in the band selected with DIP 3

Group of 8

dip switches

DESCRIPTION

Passive emergency at 0,35 second

Passive emergency at 1 second

in the 915 - 928 MHz

in the 902 - 915 MHz

Manual selection of frequencies with

(DIP 4 – DIP 7 not relevant)

Group of 4

dip switches

!

These eight dip switches must be programmed in the same manner

as the group of 8 dip switches (excluding DIP 1) present in the radio

module of the transmitting unit (see manual).

Page 12

LIE&LDA0

DIP SWITCHES ON MASTER BOARDS

There are a number of dip switches on the E16B22DC and E16B10DC master boards for

programming various functions of the radio remote control, as explained in the following

tables:

DIP SWITCHES ON E16B22DC MASTER BOARD

DIP

SWITCH

1 ON E9 and E10 excite FLOW

1 OFF function disabled

2 ON E11 and E12 excite FLOW

2 OFF function disabled

3 ON E16 activated also E15

3 OFF function disabled

4 ON E18 activated also E17

4 OFF function disabled

POS.

SEL.

DESCRIPTION

DIP SWITCHES ON E16B10DC MASTER BOARD

DIP

SWITCH

1 ON E5 and E6 excite SAFETY / FLOW

1 OFF function disabled

2 ON E15 and E17 excite SAFETY / FLOW

2 OFF function disabled

POS.

SEL.

DESCRIPTION

Page 13

LIE&LDA0

8

RECEIVING UNIT DIAGNOSTIC

If the “machine+radio remote control” system does not start, check if the problem is caused

by the radio remote control or the machine. Before carrying out any verifications, check the

functioning of the machine with the cable control panel: if it does not switch on, the problem

lies with the machine itself.

If, on the other hand, the machine can only be switched on using the cable control panel, the

problem lies with the radio remote control. In this case, follow diagnostics procedure for the

transmitter unit and then proceed as follows:

Is the “POWER”

light lit?

YES YES

Is the “ENABLE”

light lit?

NO

Carry out the

frequency

change procedure

(see transmitting

unit manual)

Does the

machine start?

YES

Is the connecting

plug between the radio

NO

remote control and the

machine correctly

connected?

Remove power

from the receiving

unit and open it.

Check fuses.

Are they blown?

NO

CALL TECHNICAL

ASSISTANCE

YES

Correctly insert

NO

NO

NO

the connecting plug

and start the radio

remote control.

the power supply

connections.

blown fuses. Connect

to power source

and switch on

radio remote control.

machine start?

Check

Replace

Does the

Page 14

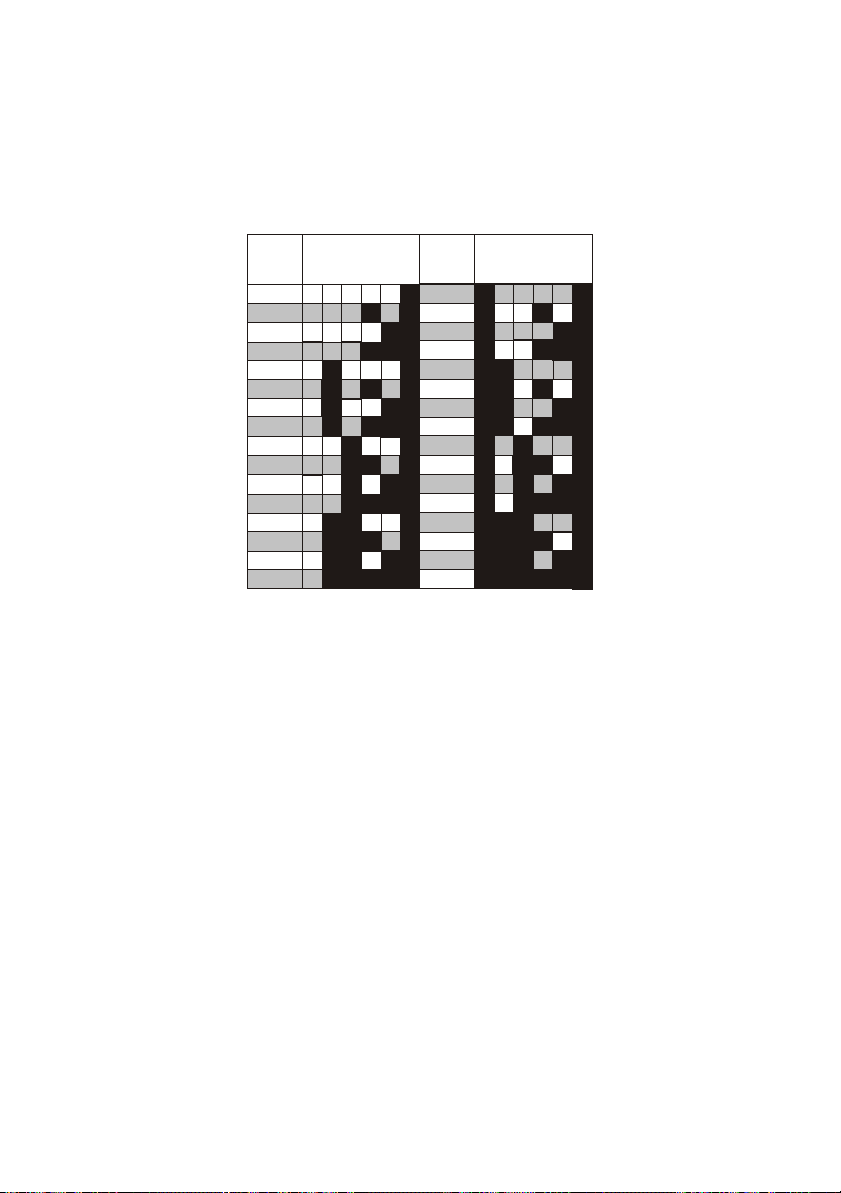

Appendix: FREQUENCY TABLE

E16SRXUS1

DIP SWITCH DIP SWITCH

MHz MHz

4

3

OFF OFF OFF

OFF

902.150

903.050

903.850

904.650

905.525

906.325

907.175

907.975

908.850

909.650

910.450

911.250

912.125

912.925

913.775

914.525

OFF OFF

OFF

OFF OFF

OFF

OFF OFF OFF

OFF OFFONOFF

OFF

OFF OFF

OFF

ON

OFFONOFF

OFF

OFFOFF

ON

ON

OFF

ON

OFF

OFF

ON

OFF

OFF

OFF

OFF

ON

OFF OFF

OFF

ONON

OFF

ON

ON

OFF

8

7

ON

OFF OFF OFF OFF

ON

ON

OFF

ON

ON

OFF

ON

ON

ON

ON

ONON

ON

ON

ON

ONON

ON

ON

OFFOFF

OFF

ON

ON

OFF

ON

ON

OFF

ONONON

ON

ONON

OFF

ON

OFF

OFF

ON

ON ON

ON

ONONON ON

915.350

916.250

917.050

917.850

918.675

919.525

920.375

921.175

922.050

922.850

923.650

924.450

925.325

926.175

926.925

927.725

3

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

4

OFF OFF

OFF OFF

OFF OFF

ON

ON

ON

OFF

OFF

OFF

ON

ON

5566

OFF OFFONOFF

OFF OFF

OFFONOFF

OFF

ON

ON

ON

ON

ONON

ON

ONON ON

7

8

ON

OFF

ON

ON

OFF

ON

ON

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ONON

ON

OFFOFF

OFF

ON

ON

OFF

ON

ON

OFF

ONON

ON

ON

ON

OFF

OFF

OFF

ON

ONON

ON

OFF

ON

ON

ON

Via Pomaroli, 65

36030 Caldogno (VI) ITALY

Tel : ++39 - 0444/901000 r.a.

Fax: ++39 - 0444/901011

email: info@autec.it

http://www.autec.it

Loading...

Loading...