Page 1

Global LCD Panel Exchange Center

AU OPTRONICS CORPORATION

www.panelook.com

Spec.No.DDPM-M150XN05-0.1

Version: 5

Total pages: 29

Date: 2003-Apr-25

Product Specifications

15.0” XGA Color TFT-LCD Module

Model Name: M150XN05

V.5

Approved by Prepared by

IDBU Marketing Division / AU Optronics Croporation

Customer Checked & Approved by

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

1/29

www.panelook.com

Page 2

Global LCD Panel Exchange Center

www.panelook.com

Product Specifications

15.0” XGA Color TFT-LCD Module

Model Name:M150XN05

V.5

() Preliminary Specifications

( ) Final Specifications

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

2/29

www.panelook.com

Page 3

Global LCD Panel Exchange Center

i Contents

1.0 Handling Precautions

2.0 General Description

2.1 Display Characteristics

2.2 Functional Block Diagram

3.0 Absolute Maximum Ratings

4.0 Optical Characteristics

4.1 Signal for Lamp connector

4.2 Parameter guideline for CCFL Inverter

5.0 Signal Interface

5.1 Module Interface Connectors

5.2 Module Connector Pin Configuration

5.3 Backlight Connectors

5.4 Backlight Connector Pin Configuration

5.5 Signal Electrical Characteristics

5.6 Interface Timings Characteristics

5.7 Interface Timing Definition

www.panelook.com

6.0 Pixel format image

7.0 Power Consumption

8.0 Power ON/OFF Sequence

9.0 Backlight Characteristics

9.1 Signal for Lamp connector

9.2 Parameter guideline for CCFL Inverter

10.0 Vibration, Shock, and Drop

10.1 Vibration & Shock

10.1.1 Vibration Test Spec

10.1.2 Shock Test Spec

10.2 Drop

11.0 Environment

11.1 Temperature and Humidity

11.1.1 Operating Conditions

11.1.2 Shipping Conditions

11.2 Atmospheric Pressure

11.3 Thermal Shock

12.0 Reliability

12.1 Failure criteria

12.2 Failure rate

12.2.1 Usage

12.2.2 Components de-rating

12.3 CCFL life

12.4 ON/OFF cycle

13.0 Safety

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

3/29

www.panelook.com

Page 4

Global LCD Panel Exchange Center

13.1 Sharp edge requirement

13.2 Material

13.2.1 Toxicity

13.2.2 Flammability

13.3 Capacitors

13.4 Hazardous voltage

14.0 Other requirements

14.1 Smoke free design

14.2 National test lab requirement

15.0 Label

16.0 Mechanical Characteristics

www.panelook.com

ii Record of Revision

Version and Date Page Old description New Description Remark

0.1 2003/4/25

All First Edition for Customer All

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

4/29

www.panelook.com

Page 5

Global LCD Panel Exchange Center

1.0 Handling Precautions

1) Since the upper polarizer can be easily damaged, pay attention not to scratch it.

2) Be sure to turn off power supply when inserting or disconnecting from input connector.

3) Wipe off water drop immediately. Long contact with water may cause discoloration or spots.

4) When the panel surface is soiled, wipe it with absorbent cotton or other soft cloth.

5) Since the panel is made of glass, it may break or crack if dropped or bumped on hard surface.

6) Since CMOS LSI is used in this module, take care of static electricity and insure human earth when

handling.

7) Do not open or modify the Module Assembly.

8) Do not press the reflector sheet at the back of the module to any directions.

9) In case if a Module has to be put back into the packing container slot after once it was taken out from the

container, do not press the center of the CCFL Reflector edge. Instead, press at the far ends of the CCFL

Reflector edge softly. Otherwise the TFT Module may be damaged.

10) At the insertion or removal of the Signal Interface Connector, be sure not to rotate nor tilt the Interface

Connector of the TFT Module.

11) After installation of the TFT Module into an enclosure (LCD monitor housing, for example), do not twist nor

bend the TFT Module even momentarily. At designing the enclosure, it should be taken into consideration

that no bending/twisting forces are applied to the TFT Module from outside. Otherwise the TFT Module

may be damaged.

12) Cold cathode fluorescent lamp in LCD contains a small amount of mercury. Please follow local ordinances or

regulations for disposal.

13) Small amount of materials not reaching flammability grade is used in the LCD module. The LCD module should be

supplied by power complied with requirements of Limited Power Source (2.11, IEC60950 or UL1950), or be

complied exemption.

14) The LCD module is designed for CCFL to be supplied by Limited Current Circuit (2.4, IEC60950 or UL1950). Do not

connect the CCFL in Hazardous Voltage Circuit.

www.panelook.com

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

5/29

www.panelook.com

Page 6

Global LCD Panel Exchange Center

2.0 General Description

This specification applies to the 15.0 inch Color TFT-LCD Module M150XN05.

The display supports the XGA (1024(H) x 768(V)) screen format and 262,144 colors (RGB 6-bits data).

All input signals are 2 Channel TTL interface compatible.

This module does not contain an inverter card for backlight.

Features

-XGA 1024(H) x 768(V) resolution

-2 CCFLs (Cold cathode Fluorescent Lamp)

-High contrast ratio, high aperture ratio

-Wide viewing angle

-High-speed response

-Low power consumption

www.panelook.com

Application

Desktop monitors

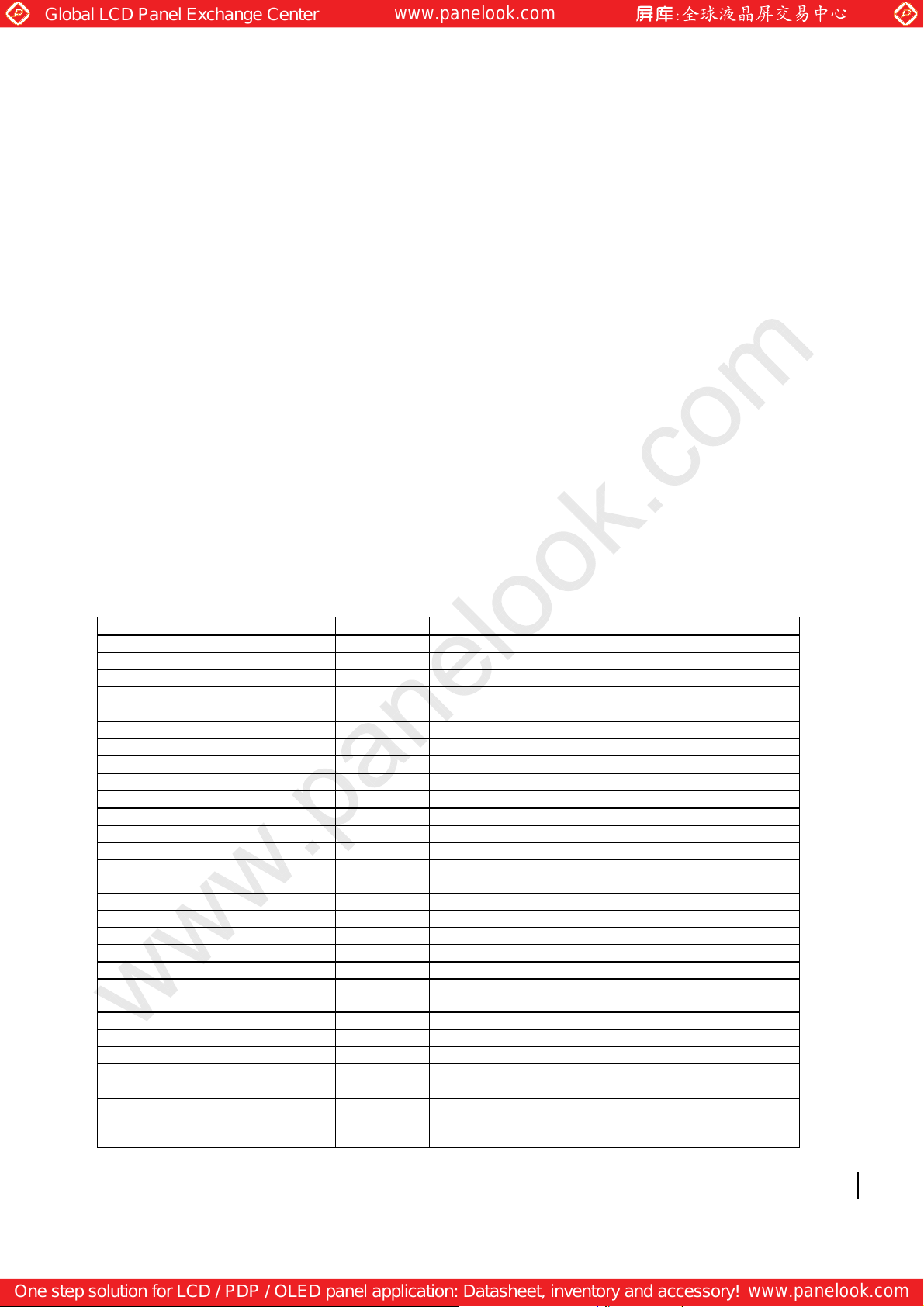

2.1 Display Characteristics

The following items are characteristics summary on the table under 25 condition:

ITEMS Unit SPECIFICATIONS

Screen diagonal [mm] 381 (15”)

Outline dimension [mm] 326 x 249.0 x 12.0 typ.

Display Area [mm] 304.128 (H) x 228.096(38.1cm diagonal)

Resolution 1024(R,G,B x 3) x 768

Pixel Pitch [mm] 0.297 x 0.297

Pixel Arrangement R.G.B. Vertical Stripe

Display Mode TN mode, Normally White

Typical white Luminance. [cd/m2]

Brightness uniformity 80% typ. (note 2)

Luminance uniformity 1.7 max.(Note 3)

Crosstalk (at 60Hz) 1.2% max. (note 4)

Contrast Ratio 400 : 1 typ.

Support Colors 262,144 colors (6-bit for R,G,B)

Chromaticity(CIE1931)

White-x

White-y 0.329

Color Gamut 60% typ., of NTSC coverage

Viewing angle 60(left),60(right),40(up),60(down) CR=10

Response Time [msec] 16ms typ. (Tr +Tf)

Nominal Input Voltage VDD [Volt] +3.3 V

Power Consumption

(VDD line + CCFL line)

Electrical Interface TTL 2 port

Frame rate [Hz] 60Hz typ., 75Hz max.

Weight [Grams] 1100 typ.

Mounting method Side mounting

Surface treatment Anti-glare, hard coating (3H)

Temperature Range

Operating

Storage (Shipping)

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

[Watt] 12.7 (typ.) @8mA (All Black Pattern)

o

[

C]

o

[

C]

250nit (typ) @8mA

0.313

0 to +50

-20 to +60

(note 1)

6/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

256 512

2

1

4

Note 1: Brightness is measured at the center point of brightness value with all pixels displaying white.

90 %

50 %

768

3

192

384

5

576

Unit: pixels

10 %

10 %

50 %

90 %

Unit: percentage of dimension of display area

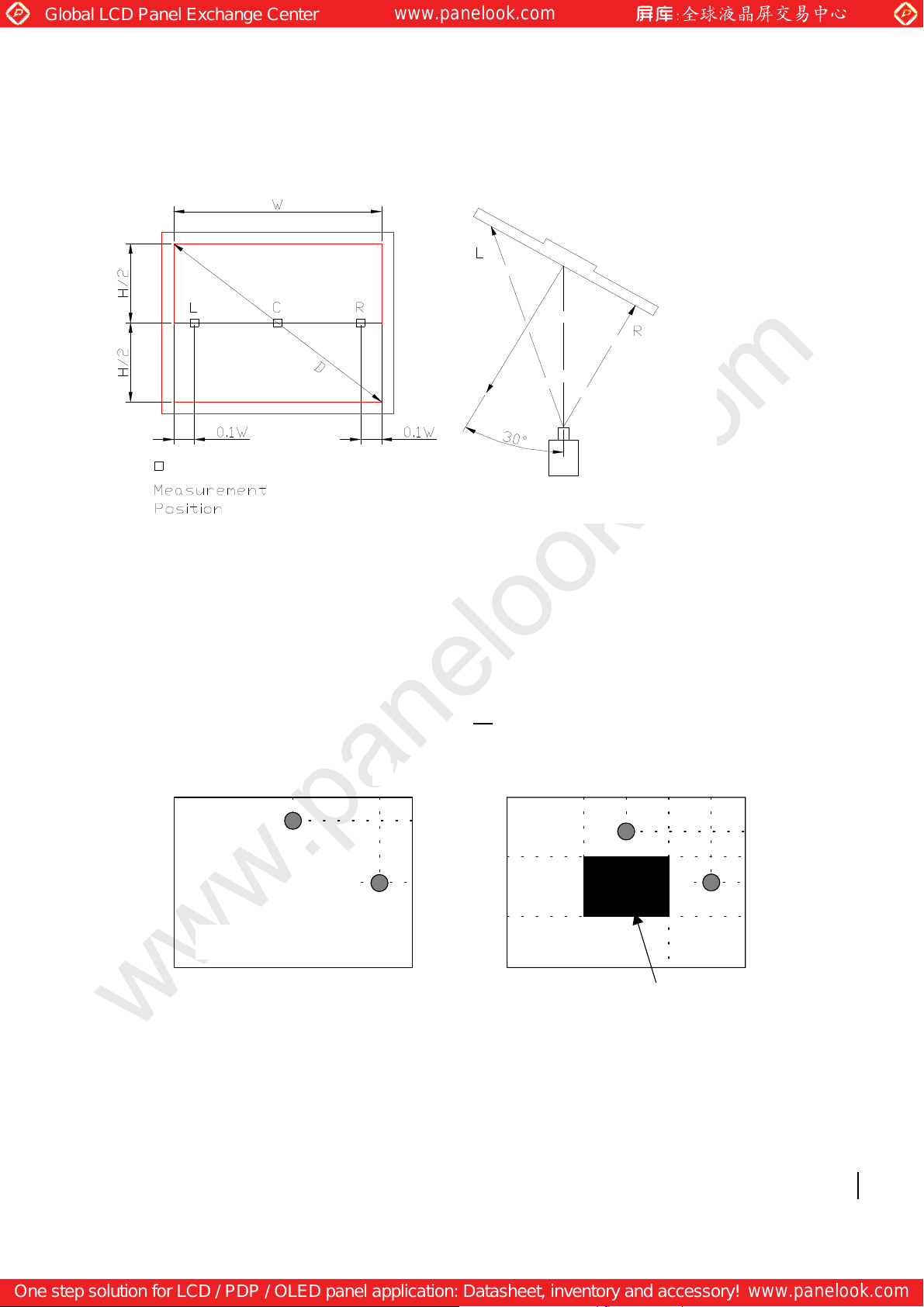

Note 2: Brightness uniformity of these 9 points is defined as below:

(Min. brightness / Max. brightness) x 100%

Note 3: TCO ’99 Certification Requirements and test methods for environmental labeling of Display Report No. 2

defines Luminance uniformity as below:

((Lmax,+30deg. / Lmin,+30deg.) + (Lmax,-30deg. / Lmin,-30deg.)) / 2

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

7/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

A

A

TCO 99 certification requirements and test methods

1) Diagrammatic

www.panelook.com

m

d

Note 4:

Effective areaW×H

2) D is the diagonal of the screen in centimeters. And m

m

(cm)=D×1.5 with a minimum distancemd=50 cm

d

d

L

max+30

is as follow.

and L

min+30

3) The measurement positions shall consist of an active white square of size 4 by 4 cm.

4)Measure L

max+30

and L

degrees and measure L

that are given as points L & R. And then rotated to an azimuth angle of –30

min+30

max-30

and L

again using the same procedure.

min-30

5) The variation in luminance ratio is calculated as the ratio:

L

=(( L

R

max+30

/ L

min+30

1/2

)(L

max-30

1/6

/ L

min-30

1/6

))/21.7

1/2

2/3 1/3

’

1/2

B

184 gray level 184 gray level

B’

1/6

1/6

1/3

1/2

2/3

Unit: percentage of dimension of display area

l / LAx 100%= 1.2% max., LA and LB are brightness at location A and B

l L

A-LA’

l / LBx 100%= 1.2% max., LA’ and LB’ are brightness at location A’ and B’

l L

B-LB’

0 gray level

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

8/29

www.panelook.com

Page 9

Global LCD Panel Exchange Center

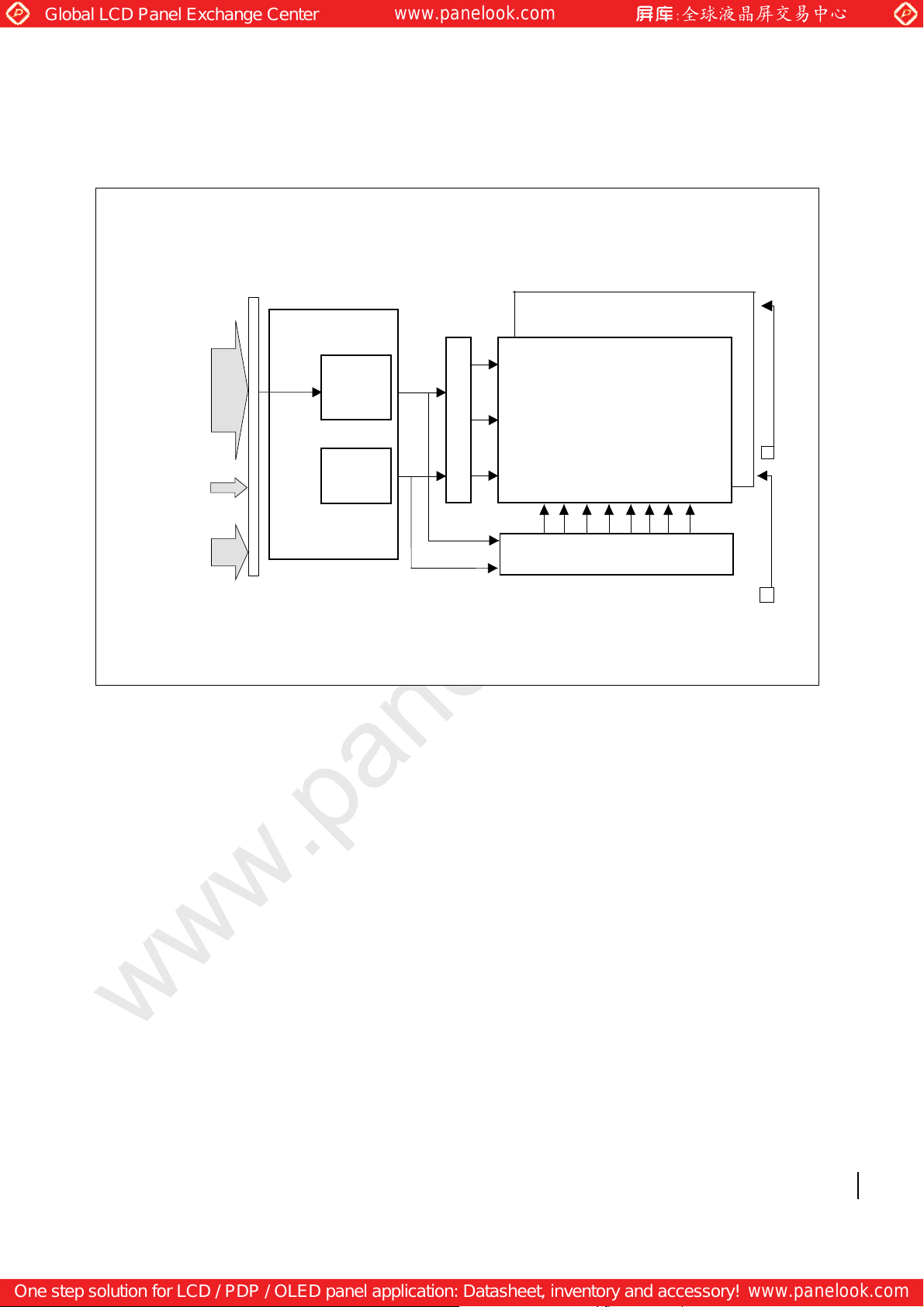

2.2 Functional Block Diagram

The following diagram shows the functional block of 15.0 inches Color TFT-LCD Module:

www.panelook.com

2 Port TTL

6 bits data

for R/G/B

DE

Vsync

Hsync

DCLK

VDD

GND

LCD DRIVE

CARD

LCD

Controller

DC-DC

Converter

Ref circuit

LCD Drive Connector

CN11 : FH-12-30S-0.5SH(Hirose)

CN12 :FH-12-45S-0.5SH(Hirose)

Backlight Unit 2CCFL

TFT ARRAY/CELL

1024(R/G/B) X 768

Y-Driver

X-Driver

Lamp Connector

JST BHR-03VS-1

Mating Type SM02(8.0)B-BHS-1-TB

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

9/29

www.panelook.com

Page 10

Global LCD Panel Exchange Center

g

g

3.0 Absolute Maximum Ratings

Absolute maximum ratings of the module is as following:

Item Symbol Min Max Unit Conditions

Logic/LCD Drive Voltage VDD -0.3 +3.6 [Volt]

Input Voltage of Signal Vin -0.3 VDD+0.3 [Volt]

CCFL Current ICFL -3.0 9.0 [mA] rms

Operating Temperature TOP 0 +50 [oC] Note 2

Operating Humidity HOP 20 85 [%RH] Note 2

Storage Temperature TST -20 +60 [oC] Note 2

Storage Humidity HST 5 95 [%RH] Note 2

Vibration 1.5 / 10-200 [G / Hz]

Shock 50/20 [G / ms] Half sine wave

Assured Torque at Side Mount 2.0 [kgf.cm]

Re-screw 3 [Times]

Note 1: CCFL life time will drop tremendously if exceeding 8.0mA; CCFL will have safety concern if exceeding

9.0mA.

www.panelook.com

Note 1

Note 2 : Maximum Wet-Bulb should be 39

Wet bulb temperature chart

Relative Humidity %

100

95

90

80

70

60

50

Stora

40

e range

Operation range

30

and No condensation.

=39

Twb

T=40,H=95%

T=50,H=55%

T=60,H=39%

T=65,H=29%

20

Stora

e range

10

5

0

-20 0 6050

TemperatureoC

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

10/29

www.panelook.com

Page 11

Global LCD Panel Exchange Center

4.0 Optical Characteristics

The optical characteristics are measured under stable conditions at 25 (Room Temperature):

Item Unit Conditions Min. Typ. Max.

Viewing Angle

CR: Contrast Ratio

Contrast ratio

Response Time( Note 1) [msec]

Color / Chromaticity Red x

Coordinates (CIE) Red y

Color Coordinates (CIE) W hite

Brightness Uniformity [%]

White Luminance at CCFL 8.0mA

White Luminance at CCFL 6.5mA

Crosstalk ( in 60Hz)

www.panelook.com

Horizontal (Right)

[degree]

[degree]

[degree]

[degree]

[msec]

[msec] Raising + Falling

[cd/m2]

[%]

CR = 10 (Left)

Horizontal (Right)

CR =5 (Left)

Vertical (Upper)

CR = 10 (Lower)

Vertical (Upper)

CR = 5 (Lower)

Normal Direction 300 400 -

Raising Time Ton

( 10%-90% )

Falling Time Toff

( 90%-10% )

Green x

Green y

Blue x

Blue y

White x

White y

50

50

60

60

30

50

60

65

-46

-1217

-1623

0.587 0.617 0.647

0.317 0.347 0.377

0.260 0.290 0.320

0.563 0.593 0.623

0.118 0.148 0.178

0.070 0.100 0.130

0.283 0.313 0.343

0.299 0.329 0.359

75 80 -

200

170

60

60

75

75

40

60

70

75

250

200

-

-

1.2

Note 1: Definition of Response time:

The output signals of photodetector are measured when the input signals are changed from “ Black” to “ White”

(falling time), and from “White” to “ Black” (rising time), respectively. The response time interval between the 10% and

90% of amplitudes. Refer to figure as below.

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

11/29

www.panelook.com

Page 12

Global LCD Panel Exchange Center

www.panelook.com

Optical

Response

100

90

10

TrR

%

white

0

black

TrD

white

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

12/29

www.panelook.com

Page 13

Global LCD Panel Exchange Center

q

t

q

t

5.0 Signal Interface

5.1 Module Interface Connectors

Physical interface is described as for the connector on module.

These connectors are capable of accommodating the following signals and components

www.panelook.com

Connector Name

Manufacturer

Type / Part Number

Interface Connector

Hirose or compatible

CN11 : FH-12-30S-0.5SH (Hirose) or

e

uivalen

CN12 : FH-12-45S-0.5SH (Hirose) or

e

uivalen

5.2 Module Connector Pin Configuration

CN11 : FH-12-30S-0.5SH (Hirose) CN12 : FH-12-45S-0.5SH (Hirose)

Pin No. Symbol Description Pin No. Symbol Description

1 GND ground 1 GND ground

2 BE5 Blue even data (MSB) 2 CLK Data clock

3 BE4 Blue even data 3 GND ground

4 BE3 Blue even data 4 DENA Data enable

5 BE2 Blue even data 5 GND ground

6 GND ground 6 VD Vertical sync

7 BE1 Blue even data 7 GND ground

8 BE0 Blue even data (LSB) 8 HD Horizontal sync

9 NC Reserve 9 GND ground

10 NC Reserve 10 GND ground

11 GND ground 11 GND ground

12 GE5 Green even data (MSB) 12 BO5 Blue odd data (MSB)

13 GE4 Green even data 13 BO4 Blue odd data

14 GE3 Green even data 14 BO3 Blue odd data

15 GE2 Green even data 15 BO2 Blue odd data

16 GND ground 16 GND ground

17 GE1 Green even data 17 BO1 Blue odd data

18 GE0 Green even data (LSB) 18 BO0 Blue odd data (LSB)

19 NC Reserve 19 NC Reserve

20 NC Reserve 20 NC Reserve

21 GND ground 21 GND ground

22 RE5 Red even data (MSB) 22 GO5 Green odd data (MSB)

23 RE4 Red even data 23 GO4 Green odd data

24 RE3 Red even data 24 GO3 Green odd data

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

13/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

25 RE2 Red even data 25 GO2 Green odd data

26 GND ground 26 GND ground

27 RE1 Red even data 27 GO1 Green odd data

28 RE0 Red even data (LSB) 28 GO0 Green odd data (LSB)

29 NC Reserve 29 NC Reserve

30 NC Reserve 30 NC Reserve

www.panelook.com

31 GND ground

32 RO5 Red odd data (MSB)

33 RO4 Red odd data

34 RO3 Red odd data

35 RO2 Red odd data

36 GND ground

37 RO1 Red odd data

38 RO0 Red odd data (LSB)

39 NC Reserve

40 NC Reserve

41 VCC Power input +3.3V

42 VCC Power input +3.3V

43 VCC Power input +3.3V

44 NC Reserve

45 NC Reserve

5.3 Backlight Connectors

Connector Name / Designation

Manufacturer

Type / Part Number

Mating Type / Part Number

For Lamp Connector

JST or compatible

BHR-03VS-1 or equivalent

SM02(8.0)B-BHS-1-TB or equivalent

5.4 Backlight Connector Pin Configuration

Pin Symbol Description

1 HV Lamp High Voltage

2 NC No connection

3 LV Ground

Cable length: 150 +- 5 mm

Connector-output position: right side (front view)

Lamp assembly design shall be easy for replacement and repair.

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

14/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

5.5 Signal Electrical Characteristics

Each signal characteristics are as follows;

Item Symbol Min Typ Max Unit

LCD Drive

voltage

“High” input signal

voltage

“Low” input signal

voltage

VDD +3.0 +3.3 +3.6 [V]

Vih 2.0 - - [V]

Vil - - 0.8 [V]

5.6 Interface Timings Characteristics

Signal Item Symbol MIN TYP MAX Unit

DCLK Frequency 1/TDCLK - 32.5 40.0 MHz

Period TDCLK 25 30.8 - ns

High time TCH 0.4 0.5 0.6 TDCLK

Low time TCL 0.4 0.5 0.6 TDCLK

DATA Setup time TDS 3 - - ns

Hold time TDH 1 - - ns

Data Enable Setup time TES 3 - - ns

Hold time TEH 1 ns

Horizontal sync Frequency 1/TH - 48 60 KHz

Pulse width THP 2 68 - TDCLK

Horizontal Back –porch THB 1 80 - TDCLK

Signal Display period THD 512 512 512 TDCLK

Front-porch THF 0 12 - TDCLK

H total TH 600 672

Vertical sync Frequency 1/TV - 60 75 Hz

Pulse width TVP 1 6 - TH

Vertical Back-porch TVB 7 29 64 TH

Signal Display period TVD 768 768 768 TH

Front-porch TVF 1 3 - TH

Vsync period +

Vback-porch

5.7 Interface Timing Definition

www.panelook.com

TVP+TVB 8 64

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

15/29

www.panelook.com

Page 16

Global LCD Panel Exchange Center

K

A

VSYNC

www.panelook.com

TV

TVBTVP

HSYNC

DE

TH

HSYNC

THP

DCLK

THB THF

DE

DATA Valid Data

TCH

0.8V

DCL

DAT

TEH

DE

TES

2.0V

0.8V

TCLK

TCLK

TVD

TVF

THD

TCL

2.0V

0.8V

TDHTDS

2.0V

0.8V

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

16/29

www.panelook.com

Page 17

Global LCD Panel Exchange Center

6.0 Pixel format image

Following figure shows the relationship of the input signals and LCD pixel format.

www.panelook.com

Odd : RO0~RO5,GO0~GO5,BO0~BO5

1st Line

768th Line

Odd Even

1 2 1023 1024

B

G G

R R

B

G

R R

Even: RE0~RE5,GE0~GE5,BE0~BE5

B

B

G G G

B

G G

R

B

R R

R B

B

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

17/29

www.panelook.com

Page 18

Global LCD Panel Exchange Center

7.0 Power Consumption

Input power specifications are as follows;

Symbol Parameter Min Typ Max Units Condition

VDD LCD Drive Voltage 3.0 3.3 3.6 [V]

IDD LCD Drive Current - 1000 1300 [mA] VDD=3.3v, All Black Pattern

www.panelook.com

PDD LCD Drive power

consumption

VDDns Allowable

LCD Drive Ripple

Noise

- 3.3 4.2 [Watt] VDD=3.3v, All Black Pattern

100 [mV]

p-p

8.0 Power ON/OFF Sequence

VDD power and lamp on/off sequence is as follows. Interface signals are also shown in the chart.

1sec

min.

Vin

Signal

0 V

0 V

10%

90% 90%

15ms max.

10%10%

10%

10%

0 min.0 min.

Lamp

On

0 V

250ms

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

18/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

)

9.0 Backlight Characteristics

9.1 Signal for Lamp connector

Pin # signal Name

www.panelook.com

1

2

3

Lamp High Voltage

No connection

Ground

9.2 Parameter guide line for CCFL Inverter

Symble Parameter Min Typ Max Units Condition

IRCFL CCFL operation range 3.0 8.0 8.5 [mA]

rms

ICFL CCFL Inrush current - - 20 [mA]

FCFL CCFL Frequency 40 55 80 [KHz]

ViCFL

(25)

(reference)

ViCFL

(0)

(reference)

VCFL CCFL Discharge Voltage

CCFL Ignition Voltage

CCFL Ignition Voltage

(Reference)

1000

1300

590 650

[Volt]

rms

[Volt]

rms

[Volt]

rms

(Ta=25)

Note 4

(Ta=25)

Note 1

(Ta= 25)

Note 3

(Ta= 0)

Note 3

(Ta=25)

Note 2

PCFL CCFL Power consumption

@ 8mA (excluding

inverter

Note 1: CCFL Frequency should be carefully determined to avoid interference between inverter and TFT LCD

Note 2: Calculator value for reference (IRCFL×VCFLx2=PCFL)

Note 3: CCFL inverter should be able to give out a power that has a generating capacity of over 1300 voltage.

Lamp units need 1300 voltage minimum for ignition

Note 4: CCFL life time 30,000hr at 8mA. It is defined as when reaching 30,000 hr, the brightness may be reduced by

half. CCFL life time will drop tremendously if exceeding 8mA.

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

9.4 10.4

[Watt]

(Ta=25)

Note 2

19/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

10.0 Vibration,Shock,and Drop

10.1 Vibration & Shock

The module shall work error free after following vibration and shock condition. Likewise the module shall not sustain

any damage after vibration and shock test.

10.1.1 Vibration Test Spec:

Frequency:10 - 200Hz

Sweep: 30 Minutes each Axis (X, Y, Z)

Acceleration: 1.5G (10~200Hz P- P)

Test method:

www.panelook.com

Acceleration (G)

Frequency (Hz)

Active time (min)

10.1.2 Shock Test Spec:

Acceleration (G)

Active time (ms)

Wave form

Times

Direction: X , Y, Z

10.2 Drop

Package test: The drop height is defined as 60 cm.

(1 corner,3 edges,6 flat faces)

-- No damage and defect found for panel.

1.5

10~200~10

30

50

20

Half-sin

1

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

20/29

www.panelook.com

Page 21

Global LCD Panel Exchange Center

11.0 Environment

The display module will meet the provision of this specification during operating condition or after storage or

shipment condition specified below. Operation at 10% beyond the specified range will not cause physical

damage to the unit.

11.1 Temperature and Humidity

11.1.1 Operating Conditions

The display module operates error free, when operated under the following conditions;

Temperature 0

Relative Humidity 20% to 85%

Wet Bulb Temperature 39.0

11.1.2 Shipping Conditions

The display module operates error free, after the following conditions;

Temperature -20

Relative Humidity 5% to 95%

Wet Bulb Temperature 39.0

0

C to 50 0C

0

C

0

C to 60 0C

0

C

www.panelook.com

11.2 Atmospheric Pressure

The display assembly is capable of being operated without affecting its operations over the pressure range as

following specified:

Pressure Altitude

Maximum Pressure 1040 hPa 0 m = sea level

Minimum Pressure 601 hPa 3658 m = 12,000 feet

Note: Non-operation altitude limit of this display module = 40,000 feet. = 12193 m.

11.3 Thermal Shock

The display module will not sustain damage after being subjected to 100 cycles of rapid temperature change. A

cycle of rapid temperature change means the temperature varies from -20

Thermal shock cycle

0

-20

C for 30min

0

60

C for 30min

Power is not applied during the test. After temperature cycling, the unit is placed in normal room temperature

environment for at least 4 hours before powering on.

0

C to 600C, and back again.

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

21/29

www.panelook.com

Page 22

Global LCD Panel Exchange Center

12.0 Reliability

This display module and the packaging of that will comply the following standards.

12.1 Failure Criteria

The display assembly will be considered as a failing unit when it no longer meets any of the requirements

stated in this specification. Only as for maximum white luminance, following criteria is applicable.

Maximum white Luminance shall be 75 cd/m

12.2 Failure Rate

The average failure rate of the display module (from first power-on cycle till 1,000 hours later) will not

exceed1.0%. The average failure rate of the display module from 1,000 hours until 10,000 hours will not

exceed 0.70% per 1000 hours.

12.2.1 Usage

The assumed usage for the above criteria is:

220 power-on hours per month

500 power on/off cycles per month

Maximum brightness setting

Operation to be within office environment (25

www.panelook.com

2

or more.

0

C typical)

12.2.2 Component De-rating

All the components used in this device will be checked the load condition to meet the failure rate criteria.

12.3 CCFL Life

The assumed CCFL Life will be longer than 30,000 hours under stable conditi

Standard current at 8.0 0.5 mA

Definition of life: brightness becomes 50% or less than the minimum luminance value of CCFL.

on at 2550C;

12.4 ON/OFF Cycle

The display module will be capable of being operated over the following ON/OFF Cycles.

ON/OFF Value Cycle

+VDD and CCFL power 36,000 10 seconds on / 10 seconds off

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

22/29

www.panelook.com

Page 23

Global LCD Panel Exchange Center

13.0 Safety

13.1 Sharp Edge Requirements

There will be no sharp edges or corners on the display assembly that could cause injury.

13.2 Materials

13.2.1 Toxicity

There will be no carcinogenic materials used anywhere in the display module. If toxic materials are used, they

will be reviewed and approved by the responsible AUO Toxicologist.

13.2.2 Flammability

All components including electrical components that do not meet the flammability grade UL94-V1 in the module

will complete the flammability rating exception approval process. The printed circuit board will be made from

material rated 94-V1 or better. The actual UL flammability rating will be printed on the printed circuit board.

www.panelook.com

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

23/29

www.panelook.com

Page 24

Global LCD Panel Exchange Center

14.0 Other requirements

14.1 Smoke Free Design

Neither smoke nor abnormal odor should be sensed by the operator in any single failure mode.

14.2 National Test Lab Requirement

The display module will satisfy all requirements for compliance to the following requirement:

www.panelook.com

UL 1950, First Edition

CSA C22.2 No.950-M89

IEC 950

EN 60 950

The construction of the display module is designed to suppress EMI. When mounted into a specified host

system, the system will meet the following EMI requirement:

FCC Part 15 Class B

VCCI Class 2

CISPR 22, class B

Taiwan CNS standard

China CCIB standard

U.S.A. Information Technology Equipment

Canada, Information Technology Equipment

International, Information Technology Equipment

International, Information Processing Equipment

(European Norm for IEC950)

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

24/29

www.panelook.com

Page 25

Global LCD Panel Exchange Center

15.0 Label

www.panelook.com

(C) Copyright AU Optronics, Inc.

Sep. 2002 All Rights Reserved. M150XN05-5 Ver0.1

No Reproduction and Redistribution Allowed.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

25/29

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

26/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

) Copyright AU Optronics, Inc.

o Reproduction and Redistribution Allowed.

ep. 2002 All Rights Reserved. M150XN05-1 Ver0.6

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

27/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

) Copyright AU Optronics, Inc.

o Reproduction and Redistribution Allowed.

ep. 2002 All Rights Reserved. M150XN05-1 Ver0.6

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

28/29

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

) Copyright AU Optronics, Inc.

o Reproduction and Redistribution Allowed.

ep. 2002 All Rights Reserved. M150XN05-1 Ver0.6

www.panelook.com

Loading...

Loading...