atwood HE-0601, HE-0801 User Manual

LITERATURE NUMBER MPD 4003333

RV REFRIGERATOR LP-GAS & ELECTRIC

HE-0601, HE-0801

PROTECTED BY US PATENTS PENDING

SAFETY ALERT SYMBOLS

Safety Symbols alerting you to potential personal safety hazards.

Obey all safety messages following these symbols

avoid possible |

avoid possible injury and/or |

injury or death |

property damage |

|

|

FOR YOUR SAFETY

READ ALL INSTRUCTIONS BEFORE OPERATING APPLIANCE

Installer: Provide these instructions to the consumer

Consumer: Keep these documents for future reference

FIRE OR EXPLOSION

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

*Open windows

*DO NOT TOUCH any electrical switch or use any phone or radio in vehicle

*Extinguish any open flame

*Evacuate ALL persons from vehicle

*Shut off gas supply at gas container or source

*DO NO START vehicle's engine or electric generator

*Contact nearest gas supplier or qualified Service Technician for repairs

*If you cannot reach a gas supplier or qualified technician, contact the nearest

. fire department |

* |

DO NOT turn on gas supply until gas leak(s) have been repaired |

|

FOR YOUR SAFETY

*DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

*Improper installation, adjustment, service or maintenance can cause injury, property damage or death. Refer to this manual. For assistance or additional information, consult a qualified installer, service agency, manufacturer or the gas supplier.

EXPLOSION OR FIRE

•Shut off all gas appliances and pilot lights when refueling gasoline tanks or LP tanks

•Atwood refrigerators are for use with LP gas only and for installation in recreation vehicles only (e.g. travel trailers, motor homes, tent campers, etc. )

CARBON MONOXIDE POISONING

•Shut off all gas appliances and pilot lights when refueling gasoline tanks or LP tanks

•Atwood refrigerators are for use with LP gas only and for installation in recreation vehicles only (e.g. travel trailers, motor homes, tent campers, etc. )

Installation * Operation * Maintenance

Effective 1/15/2011

NOTE TO CONSUMER:

Have the installer or dealer show you where the main gas shut off valve is located so that you will know how and where to turn off the gas supply when necessary.

Table of Contents

Safety Information……………………………………………..………1 Installation……………………………………………………….…...1-3 Ventilation………………………………………………………….…2-3 Doors ………………………………………………………………...4-5 Operation…………………………………………………………….6-7 Maintenance………………………………………………….……..8-9 Storage…………………………………………………………….……8 Warranty…………………………………………………….………….9 Wiring Diagram…………………………………………….…………..10

INSTALLATION

GENERAL INSTRUCTION

This appliance is designed for storage of foods and frozen foods and is certified under ANSI Z21.19 – CSA 1.4 Refrigerators using gas fuel.

This installation must conform with local codes, or in the absence of local codes, the following standards as applicable.

The US installation codes include:

1.National Fuel Gas Code, ANSI Z223.1/NFPA 54

2.Recreational Vehicles Code, ANSI A119.2

3.Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 280.

A manufactured home (mobile home) installation must conform with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 [formerly the Federal Standard for Mobile Home Construction and Safety, Title 24 (Part 280) and current CSA Z240.4, Gas-equipped Recreational Vehicles and Mobile Home Housing.

If an external electrical source is utilized, the installed refrigerator must be electrically grounded in accordance with local codes including the edition of National Electrical Code, ANSI/ NFPA 70.

The Canadian installation codes include:

1.Natural Gas and Propane Installation Code, CSA B149.1

2.CSA Z240 RV Series, Recreational Vehicles

3.Current CSA Z240.4, Gas-equipped Recreational Vehicles and Mobile Housing.

If an external electrical source is utilized, the installed refrigerator must be electrically grounded in accordance with local codes including the latest edition of the Canadian Electrical Code, CSA C22.1, Parts I and II.

1

INSTALLING THE REFRIGERATOR INTO THE ENCLOSURE

1. Make sure that the height of the enclosure is between 59.875 and 60.125 inches for HE-08xx models or between 52.875 and 53.125 inches for HE-06xx models. The width of the enclosure must be between 23.50 and 23.65 inches. The depth of the enclosure should be at least 24.00 inches.

2.The floor must be solid and level and must be able to support the weight of the refrigerator and contents. Never install the refrigerator directly on carpeting.

3.When installing the refrigerator into the enclosure recess, all areas within the recess must be sealed to prevent exhaust fumes from entering the living space. Insure that the combustion seal is compressed between the front mounting flange of the refrigerator and all sides including the top and bottom of the enclosure. The bottom trim must be installed so that the mounting holes line up with the two holes in the bottom flange (Fig 12).

4.The refrigerator must be secured in place with four wood screws. Two screws secure the bottom flange and the bottom trim to the bottom of the enclosure and 2 screws secure the top flange to the top of the enclosure.

FIG 12

5. The refrigerator is certified to operate in an enclosure with zero clearance to combustible materials refrigerator as illustrated in Fig. 7 for the top (G), sides (K), bottom

(L) and back (M) of the refrigerator.

FIG 7

VENTILATION

Proper installation requires one lower fresh air intake vent and one upper exhaust vent. The ventilation kits for this refrigerator are certified for use with these models and must be installed exactly as written in this manual without modification. Any other installation method voids both the certification and the factory warranty of the refrigerator.

VENT CUTOUT DIMENSIONS (Rough Opening)

Upper Roof Vent Base |

24” x 5 ¼ “ |

Side Vent Cutout Dims |

13 ¾ “ x 21 ½ “ |

INSTALLATION OF LOWER VENT

The bottom of the opening of the lower fresh air intake should be even with floor of the enclosure. With the lower vent in this position, it can provide a path for any leaking propane fumes to escape and not collect at the

floor level. The center of the lower vent should be directly behind the center of the refrigerator as illustrated in Fig. 8.

FIG 8

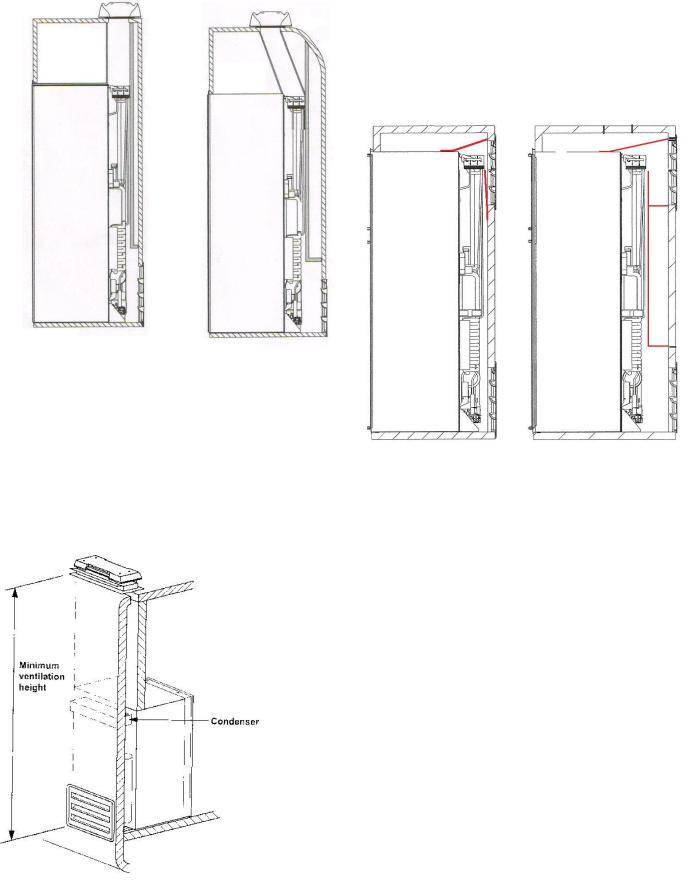

INSTALLATION OF UPPER ROOF VENT

The upper roof vent should be aligned directly above the refrigerator with a free and unobstructed path for the air flow rising up from the refrigerator’s condenser.

Ideally the roof vent is installed directly above the condenser of the refrigerator as shown in Fig. 9. Other installations require the roof vent to be positioned more in the center of the vehicle which requires the construction of a special baffle to angle the air back to the roof vent as shown in Fig 10.

2

FIG 9 |

FIG 10 |

|

|

For installations where the depth of the enclosure is greater than 26 inches, additional baffling may be required to direct the airflow thru the absorber and condenser section of the refrigerator as shown in Fig 10.

The refrigerator must be positioned with respect to the upper roof vent so that a minimum ventilation height is achieved as illustrated in Fig 11. The minimum

ventilation heights are: |

|

Refrigerator |

Min Ventilation Height |

HE-06xx |

57.75 in |

HE-08xx |

63.75 in |

|

FIG 11 |

Slide-Out |

Applications |

There are some vehicle applications, such as in slide-out configurations, where a roof vent is not practical. For those applications, the roof vent is replaced with an upper side vent as shown in Fig 14 and Fig 15 below. It is important to note that for these installations with restricted air flow, Atwood offers refrigerator models with a built-in external fan to insure that adequate ventilation is provided and to insure optimal cooling performance.

FIG 14 |

FIG 15 |

For installations with an enclosure depth of between 24” and 26”, the installation is given in Fig 14. It is important to install the two baffle sections highlighted in red in the diagram. These baffles can be pieces of sheet metal which extend the entire width of the refrigerator cabinet. The main objective of these baffles is to force the ventilation air through the condenser fin section and to prevent hot air from collecting above the condenser and directing it out the upper side vent.

For installations with an enclosure depth greater than 26”, the installation is given in Fig 15. Both baffle sections must be the entire width of the refrigerator cabinet. The lower box baffle (highlighted in red) forces the air from the lower side vent up through the absorber coils. It is very important that the top section of the lower box baffle extend up to within an inch of the lower corner of the condenser fin to insure that air is directed thru condenser section as well. The top baffle section can be made of sheet metal and must also extend the entire width of the cabinet. It’s purpose is to prevent hot air from collecting above the condenser and directing it out the upper side vent.

Minimum height from bottom of the enclosure to the top of upper side vent is:

HE-06xx is 55 inch HE-08xx is 62 inch

3

Loading...

Loading...