Attwood T800 User Manual [en, de, es, fr]

Tsunami Bilge Pump

4606, 4608, 4612, 4613 Series

Installation Instructions

SAVE THESE INSTRUCTIONS

Form Number 69390 Rev. C |

08-08 |

WARNING

WARNING

Read all instructions carefully before installing and using this product. To prevent personal injury, disconnect the power source when installing or servicing this product. Always remove the boat from the water before using 120V AC power tools.

DO NOT use pump to remove gasoline, oil or other flammable liquids. Always use the fuse amperage rating specified for your pump model. Failure to do so could result in serious personal injury or

fire hazards.

Attwood bilge pumps are designed to exhaust STANDING WATER ONLY. They are not intended to prevent rapid accumulation of on-board water due to rough weather, hull damage, and/or other unsafe navigational conditions.

Refer to Specification Chart to be sure you have selected the proper pump:

|

|

|

|

ABYC Specifications |

ISO Specifications |

|||||

|

|

|

|

|

@13.6 VDC |

|

@12 VDC |

|

||

12-VOLT MODELS |

|

|

(GPH = Gal. Per Hour) |

(LPH = Liters Per Hour) |

||||||

|

|

|

|

0 ft. |

|

3.3 ft |

6.7 ft |

0kPa |

10kPa |

Max |

Part |

Outlet |

|

|

Head |

|

Head |

Head |

Head |

Head |

Head |

Num./ |

Hose |

Motor |

Amp |

GPH/ |

|

GPH/ |

GPH/ |

LPH/ |

LPH/ |

(ft.@13.6v/ |

Series |

I.D. |

Cart. |

Fuse |

amps |

|

amps |

amps |

amps |

amps |

kPa@12v) |

4606/500 |

3/4" |

4620 |

3A |

500/1.5 |

|

400/1.5 |

250/1.5 |

1705/1.3 |

1250/1.3 |

8'/27 |

4608/800 |

3/4" |

4622 |

4A |

800/3.0 |

|

660/3.0 |

510/3.0 |

2840/2.5 |

2274/2.5 |

14'/33 |

4612/1200 |

1-1/8" |

4624 |

5A |

1200/3.5 |

|

900/3.5 |

700/3.5 |

4169/3.0 |

3000/3.0 |

11' 7"/28 |

|

|

|

|

ABYC Specifications |

ISO Specifications |

||||||

|

|

|

|

|

@24.0 VDC |

|

@24.0 VDC |

|

|||

24-VOLT MODELS |

|

|

(GPH = Gal. Per Hour) |

(LPH = Liters Per Hour) |

|||||||

|

|

|

|

0 ft. |

|

3.3 ft |

6.7 ft |

0kPa |

|

10kPa |

Max |

Part |

Outlet |

|

|

Head |

|

Head |

Head |

Head |

|

Head |

Head |

Num. |

Hose |

Motor |

Amp |

GPH/ |

|

GPH/ |

GPH/ |

LPH/ |

|

LPH/ |

(ft.@24v/ |

Series |

I.D. |

Cart. |

Fuse |

amps |

|

amps |

amps |

amps |

|

amps |

kPa@24v) |

4609/800 |

3/4" |

4623 |

2A |

800/1.3 |

|

660/1.3 |

500/1.3 |

2842/1.1 |

|

2160/1.1 |

14'/31 |

4613/1200 |

1-1/8" |

4625 |

2A |

1200/1.5 |

|

900/1.5 |

725/1.5 |

4100/1.3 |

|

3100/1.3 |

11'/28 |

MATERIALS REQUIRED

•Three #8 stainless fasteners, suitable length for mounting surface

•Cordless drill and 1/8" (3 mm) bit

•Hose clamps (Attwood # 9185, 2 per connection)

•Mounting pad: marine plywood, fiberglass cloth and resin

•Manual (# 7615A) or automatic float switch (#4201 or 4202)

•Fuel-resistant, reinforced smooth bore outlet hose

INSTALLATION LOCATION

1.Position pump in the lowest accessible part of the bilge. On sailboats, location should be centered over keel. (Figure 1)

2.Do not mount pump directly to hull. Attach base strainer to a marine plywood mounting pad that is fiberglassed to the hull.

HOSE CONNECTION INSTRUCTIONS

IMPORTANT: To prevent airlock, hose must rise continually upward to the thru-hull connector with no dips or sharp bends. Support hose if necessary.

1.Orient pump outlet for a direct, unobstructed hose path.

2.Secure all connections with hose clamps.

3.If no thru-hull connector exists, install at 12" min. (30.5 cm) above water line. Apply marine sealant around thru-hull flanges on interior and exterior of hull.

PUMP MOUNTING INSTRUCTIONS

1.To access mounting holes, remove base strainer. Hold housing with one hand, depress locking tab with other. Twist counter-clockwise and remove pump housing from base. It is not necessary to remove motor cartridge for installation. (Figure 2)

2.Use base as template to mark 3 mounting holes in mounting pad.

CAUTION: Do not drill through hull. Before drilling be sure mounted pump will be correctly positioned with pump nozzle pointing toward thru-hull connector. (Figure 1)

3.Remove base. Drill three 1/8" (3 mm) pilot holes at marked locations.

4.Replace base. Attach with #8 stainless steel fasteners.

5.Re-attach pump to base. Insert into base, twist clockwise until tab snaps in and prevents turning. (Figure 2)

WIRING INSTRUCTIONS

Make all wire connections above the highest water level. Use marine grade wire connectors only. Waterproof all connections with suitable materials. (Figure 3)

NOTE: Failure to make waterproof connections and fuse pump properly will void the product warranty.

1.Connect positive lead (brown) to switch. For automatic operation, use Attwood Automatic Float Switch (#4201 or 4202). Connect negative lead (black) to ground.

2.Install fuse holder within 72" (183 cm) of the positive (+) battery terminal. Use standard automotive (SAE J554) glass tube type electrical fuse.

3.To test system, feed water into the pump. If flow appears low, be sure wires have been connected properly: Brown-to-positive (switch), and black-to-negative. Reversed wiring reduces performance and can cause pump failure.

MAINTENANCE AND TROUBLESHOOTING

Disconnect power to the pump. Regularly inspect and clean to be sure that debris is not blocking the strainer or impeller.

If pump runs but does not pump water:

1.Check for airlock. Be sure that outlet hose runs upward to the thru-hull connector, with no dips. (Figure 1)

2.Remove pump housing from base. Remove debris from chamber and impeller. Be sure impeller is firmly attached to shaft and is not cracked or broken. (Figure 2)

If pump does not run:

1. Check fuse. Be sure electrical connections and fuse are waterproof and haven’t loosened. (Figure 3)

To replace motor cartridge:

1.Hold pump housing, depress motor cartridge tab and twist cartridge counter-clockwise to remove (Figure 2).

2.Check motor cartridge fit: See specification chart for replacement motor cartridge number. Motor must match housing color: 500 Series = RED, 800 = BLUE, 1200 = GRAY.

3.To reinstall cartridge: Coat O-ring with vegetable oil (petroleum-based oils will cause deterioration).

4.Insert cartridge into housing. Twist clockwise until you hear tab snap up into slot. (Figure 2)

ATTWOOD BILGE PUMPS LIMITED WARRANTY

This Attwood Bilge Pump carries a three (3) year warranty. See product catalog or www.attwoodmarine.com for details.

Figure 1 / Figura 1

Abbildung 1 / Figur 1

C

D

A

E

F

B

Figure 1

A.Base Strainer

B.Suitable Mounting Pad

C.Thru-Hull Connector

D.Hose & Clamp

E.12" min. Above Water Line

F.Hose MUST Rise Upward with NO DIP

Figura 1

A.Filtro de base

B.Almohadilla de montaje adecuada

C.Conector de casco pasante

D.Manguera y abrazadera

E.Longitud mínima de 30 cm por encima línea del agua

F.La manguera se DEBE elevar. en dirección ascendente SIN INCLINACIÓN

Figur 1

A.sockelsil

B.lämpligt monteringsunderlag

C.skrovgenomföring

D.slang och klämma

E.minst 12 tum ovanför vattenlinje

F.slangen MÅSTE riktas uppåt UTAN BÖJAR

Figure 1

A.Crépine de base

B.Tampon de fixation convenable

C.Raccord passe-coque

D.Boyau et collier

E.12 po min. au-dessus de la ligne de flottaison

F.Le boyau DOIT s’élever vers le haut SANS DESCENTE

Abbildung 1

A.Geschlitzter Sockel

B.Passende Montagefläche

C.Rumpfdurchführung

D.Schlauch und Klemme

E.Mindestens 12 Zoll über der wasserlinie

F.Der Schlauch MUSS ständigOHNE SENKE aufwärts geführt werden

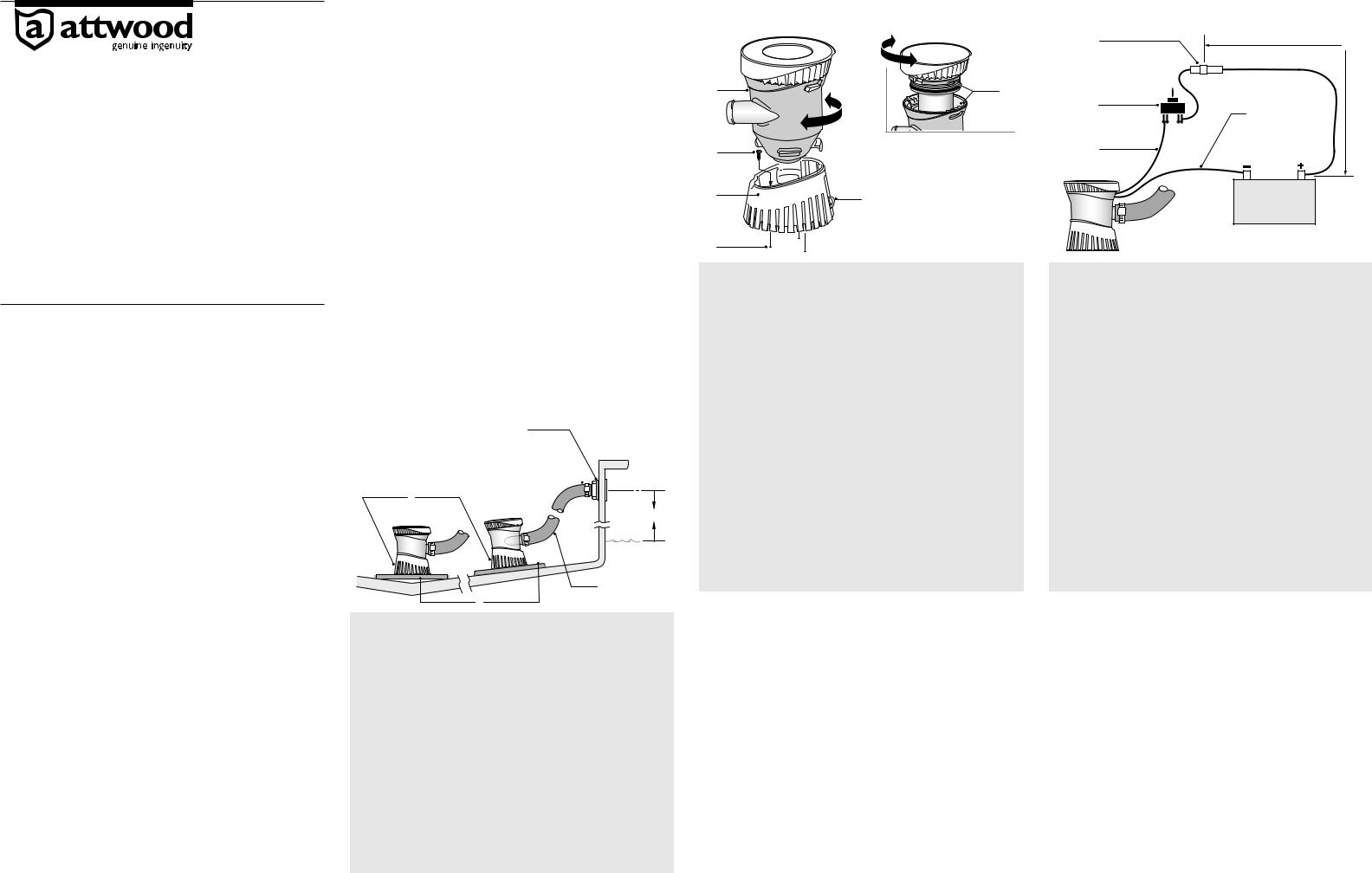

Figure 2 / Figura 2

Abbildung 2 / Figur 2

|

|

|

E |

|

|

|

F |

A |

F |

|

G |

|

E |

|

|

|

|

|

H |

B |

|

|

|

C |

|

I |

|

|

|

|

|

D |

|

|

|

Figure 2 |

Figure 2 |

||

A. Pump Housing |

A. Boîtier de la pompe |

||

B. |

(3) #8 Fasteners |

B. |

(3) attaches N° 8 |

C. |

Base Strainer |

C. Crépine de base |

|

D. |

1/8" Pilot Holes |

D. Orifices de guidage de 1/8 po |

|

E. |

Lock |

E. Verrouillage |

|

F. |

Unlock |

F. |

Déverrouillage |

G. |

Motor Cartridge Tab |

G. Cartouche du moteur Languette |

|

H. |

Motor Cartridge Replacement |

H. Remplacement de la cartouche du moteur |

|

I. |

Press Tab To Unlock |

I. Appuyez sur la languette pour déverrouiller |

|

Figura 2 |

Abbildung 2 |

||

A. Bastidor de la bomba |

A. Pumpengehäuse |

||

B. |

(3) sujetadores N.° 8 |

B. Drei Schrauben Nr. 8 |

|

C. |

Filtro de base |

C. Geschlitzter Sockel |

|

D. |

Agujeros guía de 3 mm |

D. Führungslöcher 3 mm (1/8 Zoll) |

|

E. |

Trabar |

E. Verriegeln |

|

F. |

Destrabar |

F. |

Entriegeln |

G. |

Lengüeta del cartucho del motor |

G. Lasche des Motorgehäuses |

|

H. |

Reemplazo del cartucho del motor |

H. Austauschen des Motorgehäuses |

|

I. |

Presione la lengüeta para destrabar |

I. |

Zum Entriegeln die Laschen hineindrücken |

Figur 2

A.pumphus

B.(3) fästdon (nr 8)

C.sockelsil

D.1/8-tums styrhål

E.lås

F.lossa

G.motorpatronflik

H.Montering av motorpatron

I.tryck på fliken för att lossa

Figure 3 / Figura 3

Abbildung 3 / Figur 3

A |

D |

|

B

E

C

F G

H |

Figure 3

A.Fuse Holder

B.2-Terminal On/Off Switch

C.Brown Wire

D.72" (183cm) Max. Length From

(+) Terminal to Fuse

E.Black Wire

F.(negative)

G.(positive)

H.Power Source

Figura 3

A.Portafusibles

B.2 interruptores de encendido/apagado terminales

C.Cable marrón

D.Longitud máxima de 183 cm desde el terminal (+) al fusible

E.Cable negro

F.(negativo)

G.(positivo)

H.Fuente de energía

Figur 3

A.säkringshållare

B.dubbelpolig till/från-strömställare

C.brun tråd

D.72 tum (183 cm) maxlängd från (+)-pol till säkring

E.svart tråd

F.(negativ)

G.(positiv)

H.strömkälla

Figure 3

A.Porte-fusible

B.Commutateur marche/arrêt à deux bornes

C.Fil brun

D.Longueur maximum de 72 po (183) à partir de la borne (+) jusqu au fusible

E.Fil noir

F.(nég.)

G.(pos.)

H.Source d’alimentation

Abbildung 3

A.Sicherungshalter

B.Ein / Aus-Schalter mit zwei Anschlüssen

C.Brauner Draht

D.Maximale Länge vom Plus-Pol (+) zur Sicherung 183 cm (72 Zoll)

E.Schwarzer Draht

F.(negativ)

G.(positiv)

H.Stromquelle

©2008 Attwood Corporation

1016 N. Monroe Street, Lowell, MI 49331-0260 www.attwoodmarine.com

Loading...

Loading...