Attwood Deck fills for Carbon Canister Systems User Manual

CARBON CANISTER SYSTEM DECK FILL

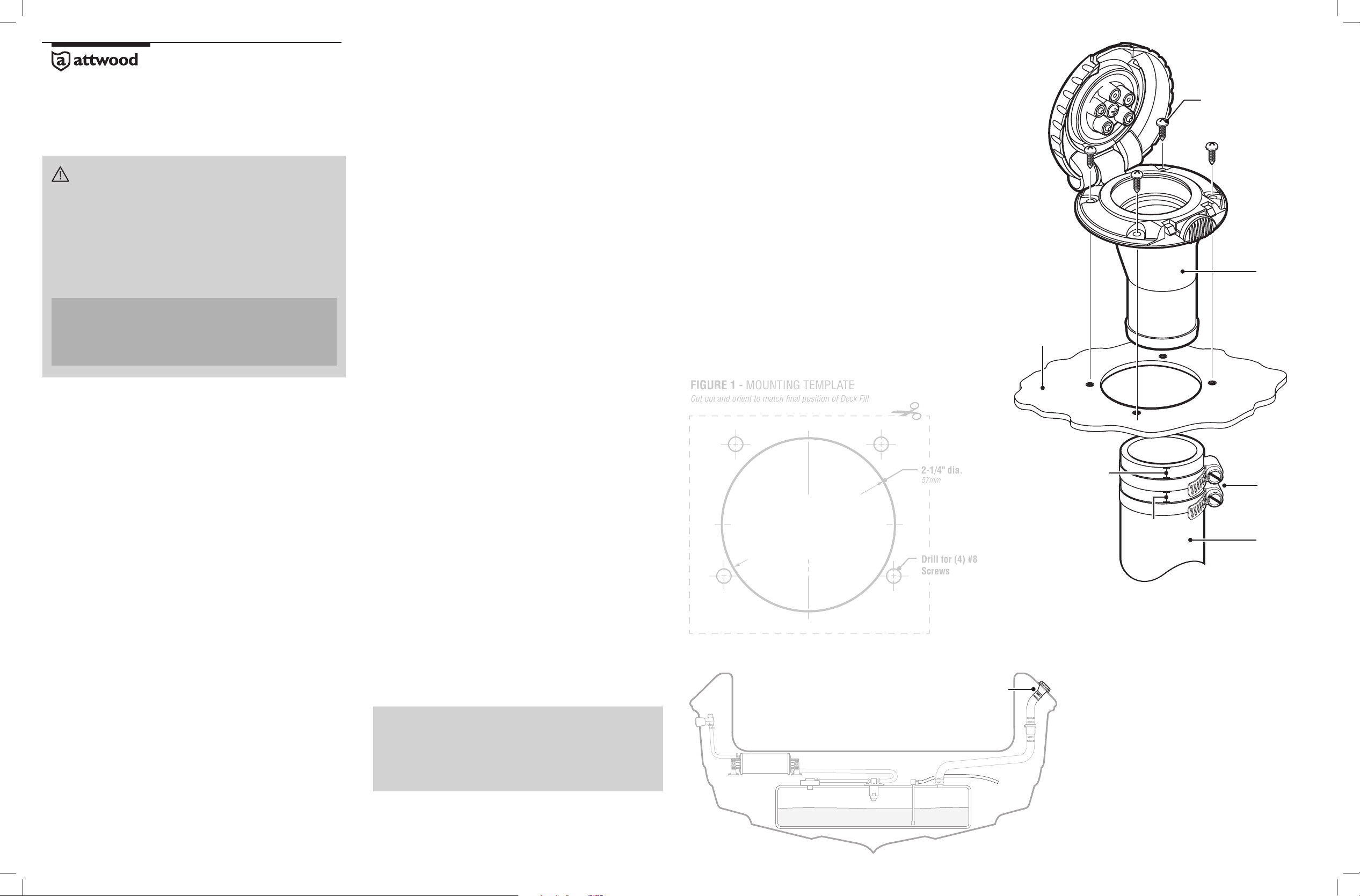

FIGURE 1 - MOUNTING TEMPLATE

Cut out and orient to match final position of Deck Fill

2-1/4" dia.

57mm

Drill for (4) #8

Screws

99DFCC Series

INSTALLATION INSTRUCTIONS 11/04 69484 Rev. C

SAVE THESE INSTRUCTIONS

CAUTION:

The vessel manufacturer must comply with the

requirements of CFR 40 1060.202. Any questions can be

directed to www.attwoodmarine.com

Failure to follow these instructions may result in accidental

fuel system over-pressurization. Users must follow these

instructions to ensure vessel function and operation

EMISSION-RELATED INSTALLATION INSTRUCTIONS

Failing to follow these instructions when installing the Attwood

Carbon Canister System Deck Fills in a piece of nonroad equipment

violates federal law (40 CFR 1068.105(b)), subject to fines or other

penalties as described in the Clean Air Act.

2. Mark and drill pilot hole positions for large and small holes.

3. Remove template. Drill 2-1/4" dia. (57mm) hole.

4. “Dry Fit” the Deck Fill neck into hole. (Figure 2)

5. Mark position and drill small pilot holes for deck fasteners (fasteners not provided).

6. Remove Deck Fill Neck. Apply a thin bead of marine-grade, urethane-based sealant

(Attwood #30106-6 recommended) to underside of the Deck Fill.

7. Press Deck Fill neck into hole.

8. Fasten Deck Fill with #8 screws appropriate for the deck material (fasteners not provided).

Torque to 30+/- 3 in-lb. Do not overtorque.

9. Clean any sealant spilled around Deck Fill edges.

10. Attach and clamp 1-1/2" (38mm) fill hose using two (2) clamps. Use corrosionresistant metallic clamps with nominal band width of at least 1/2" (12mm). The first

clamp should be 1/4" (6mm) from the end of the hose. The second hose clamp

should be located above the barb leaving a small gap (maximum 1/4") between the

clamps. Torque hose clamps to 36+/- 4 in-lb.

11. Attach and clamp 5/8" vent hose using at least one (1) clamp. Torque hose clamp to

36+/- 4 in-lb. Ensure 5/8" vent hose connects with 5/8" port on 99FL Series vent valves.

12. Leak test installed deck fill per USCG CFR 33 183.580 at pressure of 3 psi for no less

than 10 minutes. Inspect all connections for leaks by a method other than

pressure decay.

Important safety instructions

(for all Attwood 99FL/99GV/99CC/99ICV/99DF components):

When a fuel system is configured with Attwood 99DFCC Series Deck Fills, the following

safety precautions must be taken;

1. Use an Attwood 99ICV series Inlet Control valve between the liquid reservoir and the

deckfill to prevent the accidental wellback of fuel. Use only an Attwood 99ICV series

Inlet Control Valve in-line with the fuel fill hose. No other fill hose valves should be

installed in order to ensure the safety of the fuel system and vessel. The Attwood 99ICV

series inlet control valves includes features to allow vapor and liquid to pass the valve in

order to ensure the system does not become accidentally over pressurized.

TWO-YEAR WARRANTY & LIABILITY

Generally: Attwood Carbon Canister System Deck Fills are covered by a two (2) year

limited warranty from the date of a Vessel’s first retail sale.

Pre-requisites to Warranty Eligibility: For the warranty coverage described herein to

apply, the following conditions must be met:

• Component must have been properly installed per Attwood installation instructions; and

• The component cannot have been altered or abused by Boat Company or its customers.

Warranty Terms for Components:

Attwood warrants that any Attwood Carbon Canister System Deck Fills are free from

defects in materials and workmanship and are designed, built, and equipped to conform

at the time of sale to Boat Company with the 40CFR.1060 requirements. For two (2)

years from the date of the vessel’s first retail sale, Attwood will, at its sole option,

repair or replace any components that fail due to a defect in material or workmanship.

ATTWOOD PROVIDES NO WARRANTIES WITH RESPECT TO ANY PART OR COMPONENT

NOT MANUFACTURED BY ATTWOOD, INCLUDING FUEL TANKS. Boat Company is

responsible for the installation of all Systems, whether installed by Boat Company or

under its direction.

A.B.Y.C.

American Boat & Yacht Council

3069 Solomon’s Island Road

Edgewater, Maryland 21037

www.abycinc.org

U.S. Coast Guard

Washington, DC 20460

www.uscgboating.org

E.P.A.

401 “M” Street, SW

Washington, DC 20593 www.

www.epa.gov

ISO

iso.org

National Marine

Manufacturers Association

(NMMA)

231 S. LaSalle Street

Suite 2050

Chicago, IL 60604

www.NMMA.org

FIGURE 2

Stainless Steel Screws

#8 pan head fasteners appropriate

for specific deck material

(not included)

Deck Fill

Do not install

straight Deck

Fill on a vertical

surface.

Deck

FEATURES:

Attwood Carbon Canister System Deck Fills are sturdy, non-corrosive plastic. Bonding

and grounding are not required because they are non-metallic. When latched, Deck

Fills are water-resistant. They meet all requirements for ISO 10080, ABYC, and USCG.

The 99DFCC Series Deck Fills are not certified for diurnal emission control. The use

of a certified Carbon Canister for proper diurnal emission control is required to meet

EPA diurnal emission control requirements. The Attwood 99DFCC Series Deck Fills

are equipped with dual over pressure relief valves. These valves are intended only to

prevent the accidental over pressurization of a fuel system and are safety devices only

not for use as diurnal emission control devices.

REQUIRED FOR INSTALLATION

• Pencil

• Drill

• 2-1/4" (57mm) dia. hole saw (see Figure 1)

• Drill bit for fastener pilot holes — 3/32" (2.4mm)

• (4) #8 pan head stainless steel fasteners appropriate for specific deck material

• File for smoothing holes

• Screwdriver

• Marine-grade urethane-based sealant (Attwood #30106-6 recommended, DO NOT

USE A SILICONE-BASED SEALANT)

• 1-1/2" (38mm) I.D. fill hose

• Stainless Steel clamps to match hose diameters

MOUNTING LOCATION AND REGULATIONS

Select location that meets these conditions:

1. Conforms to all ABYC, U.S. Coast Guard, and EPA regulations. (See end of this

document for information availability.)

2. Surface must be flat, in an area where spilled fuel cannot enter the boat.

3. Below-deck area must allow adequate clearance to install and route hose(s)

to the tank and should also all for predominantly vertical orientation of the fill hose.

4. Fill and vent hose installation must meet regulations — A.B.Y.C and U.S. Coast

Guard Safety Standards for Small Boat Fuel Systems (33 CFR 183).

5. Deck thickness must be 1/2” (13mm) or less.

6. Straight Deck Fills cannot be mounted on a vertical surface +/- 30˚. A ngled Deck

Fills can be mounted on a vertical surface right side up with hinge on top +/-15˚.

CARE AND MAINTENANCE

Care should be taken, when cleaning the boat, to prevent contaminating the valves and

deckfill. Cleaning with only mild soapy water is recommended. All connections should be

checked annually.

MANUFACTURER REQUIREMENTS

The information below applies only to EPA CFR 40 1060.135. The vessel manufacturer

is responsible to meet all additional regulatory labeling requirements including EPA,

CARB, USCG and others as necessary. The below information is for reference only.

The vessel manufacturer should refer to CFR 40 for complete labeling guidelines.

In order to meet the requirements of CFR 40 1060.135, the vessel must be labeled

with respect to evaporative emissions in the following manner when installing certified

components;

Excerpt from CFR 40 1060.135

(a) You must affix a permanent and legible label identifying each engine or piece of equipment before

introducing it into U.S. commerce. The label must be—

(1) Attached in one piece so it is not removable without being destroyed or defaced.

(2) Secured to a part of the engine or equipment needed for normal operation and not normally

requiring replacement.

(3) Durable and readable for the equipment’s entire life.

(4) Written in English.

(5) Readily visible in the final installation. It may be under a hinged door or other readily opened

cover. It may not be hidden by any cover attached with screws or any similar designs. Labels on

marine vessels must be visible from the helm.

(c) If you produce equipment without certifying with respect to evaporative emissions, the equipment

label specified in paragraph (a) of this section must—

(1) State: ‘‘MEETS U.S. EPA EVAP STANDARDS USING CERTIFIED COMPONENTS.’’

(2) Include your corporate name.

Below is an example of a label specified by CFR40 1060.135 for use with certified

components;

MEETS U.S. EPA EVAP STANDARDS USING

CERTIFIED COMPONENTS

CORPORATE NAME

DO NOT USE

Template may not be to scale.

Refer to separate template sheet

included in product carton.

FIGURE 3

Full Carbon Canister System

Deck Fill

1/4" Max

6mm

1/4" Max

6mm

Clamps (2)

(not included)

Fill Hose

INSTALLATION INSTRUCTIONS

1. Cut out and orient mounting template (Figure 1) to match final position of Deck

Fill. Attach template to deck.

Note: Deck Fill should be oriented to allow for standard fuel nozzles to be correctly

inserted at the pump.

Please refer to CFR 40 1060.135 to review EPA vessel labeling requirements.

The NMMA has a program to supply OEM builders with labels. Please refer to the NMMA

website below for further information regarding the NMMA label program;

www.nmma.org/certification/products/labelsanddecals.aspx

©2011 Attwood Corporation

1016 North Monroe Lowell, MI 49331

www.attwoodmarine.com

Loading...

Loading...