DEFINITY

®

Enterprise Communication Server

Release 8. 2

Installation and Test for Multi-Carrier Cabinets

555-233-114

Comcode 108678327

Issue 1

April 2000

Copyright 2000, Lucent Technologies

All Rights Reserved

Printed in U.S.A.

Notice

Every effort was made to ensu re that th e in for mation in this book was

complete and accu ra te at the time o f printing. However , information is

subject to change.

Your Responsibility for Your System’s Security

Toll fraud is the unauthorized use of you r te lecommunications system

by an unauthorized party, for example, persons other than your com-

pany’s employees, agents, subcontractors, or persons working on your

company’s behalf. Note that there may be a risk of toll fraud associated

with your telecommunications system and, if toll fraud occurs, it can

result in substantial additional charges for your telecommunications

services.

This equipment returns answer-supe rvi sion signals on all DID calls

forwarded back to the public sw i tc he d te le phone network. Permissible

exceptions are:

• A call is unanswered

• A busy tone is received

• A reorder tone is received

Canadian Department of Communications (DOC)

Interference Information

This digital apparatus does no t exceed the Class A limits for radio

noise emissions set out in the radi o int er f erence regulations of the

Canadian Department of Com m unications.

Le Présent Appareil Nom

dépassant les limites applicables aux appareils numériques de la class

A préscrites dans le reglement sur le brouillage radioélectrique édicté

par le ministére des Communications du Canada.

érique n’é

met pas de bruits radioélectriques

You and your system manager are responsible for the security of your

system, such as programming and configur ing your e qui pm ent to prevent unauthorized use. The system manager is also responsibl e for

reading all installation, instruc tion, and system administration doc uments provided with this produc t i n orde r to fully understand the features that can introduce risk of toll fraud and the steps that can be taken

to reduce that risk. Lucent Technologies does not warrant that this

product is immune from or will prevent unauthorized use of common-carr ier telecommunication services or facilities accessed through

or connected to it. Lucent Technologies will not be responsible for any

charges that result from such unauthorized use.

Lucent Technologies Fraud In te rven tion

If you suspect that you are being victimized by toll fraud and you need

technical support or assistan ce , c al l Technical Service Cen ter Toll

Fraud Intervention Hotlin e at 1 800 643-2353 or contact your loca l

Lucent repr esentative.

Federal Communications Commission Statement

Part 15: Class A S t atement. This equipment has been tested and

found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate rad io- fre quency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to corre c t th e in te rference at his own expense.

Part 68: Network Registration Number. This equipment is registered

with the FCC in accordan ce with Part 68 of th e FCC Rules. It is identified by FCC registration number AS593M-13283-MF-E.

Trademarks

See the preface of this document.

Ordering Info rm a tion

Call: Lucent Technologies BCS Publications Center

Voice 1 800 457-1235 International Voice 317 322-6416

Fax 1 800 457-1764 International Fax 317 322-6699

Write: Lucent Technologies BCS Publications Center

2855 N. Franklin Road

Indianapolis, IN 46219

Order: Document No. 555-233-114

Comcode 10867832 7

Issue 1, April 2000

For additional documents, refer to the section in “About This Document” entitled “Related Resources.”

Y ou can be placed on a standing order list for this and other documents

you may need. Standing order will enable you to automatically receive

updated versions of individual documents or doc um en t set s , billed to

account information that you provide. For more information on standing orders, or to be put on a list to receive future issues of this do cument, contact the Lucent Technologies Publications Ce nt er.

European Union Declaration of Conformity

The “CE” mark affixed to the DEFINITY® equip ment described in

this book indicates that the e quipment conforms to the foll owing European Union (EU) Directives:

• Electromagne tic Compatibility (89/336/EEC)

• Low Voltage (73/23/EEC)

• T elecommunicat ions T er m inal Equipment (TTE) i-CTR3 BRI

and i-CTR4 PRI

For more information on standards compliance, contact your l oc al distributor.

Part 68: Answer-Supervision Signaling. Allowin g th is eq ui p men t to

be operated in a manner that does not provide proper answer-supervi sion signaling is in violation of Part 68 Rules. This equipment returns

answer-supervision signals to the public switched network when:

• Answered by the called station

• Answered by the attendant

• Routed to a recorded announcement that can be administered by

the CPE user

Comments

T o co mmen t on this document, return the co mme nt card at the front of

the document.

Acknowledgment

This document was prepared by Product Documentation Development,

Lucent Technologies, Denver, CO.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

Contents

Contents

Contents iii

About This Book ix

■ Organization x

■ How to Comment on This Book x

■ Related Books xi

■ Conventions Used in This Book xi

■ How to Order Books xii

■ Trademarks xiii

■ Standards Compliance xiv

■ LASER Product xv

■ Electromagnetic Compatibility Standards xv

■ Where to Call for Technical Support xvii

Issue 1

April 2000

iii

■ Anti-Static Protection xvii

■ Remove/Install Circuit Packs xviii

■ Security Issues xviii

■ Federal Communications Commission Statement xviii

1 Install and Connect Cabinets 1-1

■ Unpack and Inspect Cabinets 1-1

■ Check Customer’s Order 1-2

■ Correcting Shipping Errors 1-2

■ Install System Cabinets 1-3

■ Connect AC Power and Ground 1-6

■ Connect DC Power and Ground 1-16

■ Approved Grounds 1-22

■ Connect Remote Power Off Cable and

External Alarm Cable 1-24

■ Connect External Alarm Cable 1-25

■ Connect AC Power to Stratum 3 Clock Cabinet 1-26

■ Connect DC Power and Ground to

Stratum 3 Clock Cabinet 1-26

■ Fiber Optic Duplication Interface Cabling (R8si only) 1-27

■ Fiber Optic Interconnect Cabling 1-28

■ Earthquake Protection Installation 1-33

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

Contents

2 Install Telecommunications Cabling 2-1

■ Equipment Room Hardware 2-1

■ Main Distribution Frame 2-4

■ Installation Requirements 2-5

■ Install Equipment and Cables 2-6

■ Install Cable Slack Managers 2-11

■ Off-Premises Circuit Protection 2-12

■ Install Sneak Fuse Panels 2-13

■ Cable Installation 2-16

■ Install Coupled Bonding Conductor 2-26

■ Station Wiring Design 2-28

■ Station Circuit Distribution from Equipment Room 2-33

■ Layout 2-39

■ Voice and Data Terminals 2-41

Issue 1

April 2000

iv

■ Label the Main Distribution Frame 2-44

■ Patch Cord/Jumper Installation and Administration 2-45

■ Create a Provisioning Plan 2-49

3 Accessing and Activating the System 3-1

■ Access the System 3-2

■ Activate the System 3-12

■ Screens and Commands 3-15

■ System Administration 3-16

■ Set Country Options 3-17

■ Circuit Pack Administration 3-24

■ Set System Maintenance Parameters 3-24

■ Administer System Confi gurations (Release 8r) 3-25

■ Administer Fiber Links (Release 8r Only) 3-30

■ Reboot High Reliability System 3-48

■ Administer Attendant Consol e 3-48

■ Save Translations 3-49

■ Add Translations 3-49

■ Installation Completion 3-50

■ DEFINITY AUDIX Power Procedures 3-50

4 Test the System 4-1

■ Check System Status for Each Cabinet 4-2

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

Contents

■ Check Circuit Pack Configuration 4-2

■ Test TDM Bus in PPN 4-3

■ Test Tone-Clock Circuit Packs 4-4

■ Test SPE Duplication Memory Shadowing Link 4-5

■ Test Duplicated Switch Processing

Element Interchange 4-6

■ Test Expansion Interface Circuit Packs 4-7

■ Test TDM for each EPN 4-8

■ Test Tone-Clock for each EPN 4-8

■ Test Tone-Clock Interchange for each EPN 4-9

■ Test Expansion Interface Exchange for Each EPN 4-9

■ Check Circuit Pack Configuration Again 4-10

■ System Test Completion 4-10

■ LED Indicators 4-11

Issue 1

April 2000

v

5 Install and Wire Telephones and

Other Equipment 5-1

■ Analog Station or 2-Wire Digital Station Example 5-5

■ Analog Tie Trunk Example 5-6

■ Digital Tie Trunk Example 5-7

■ DS1 Tie Trunk Example 5-7

■ Auxiliary Connector Outputs 5-10

■ Three-Pair and Four-Pair Modularity 5-12

■ Adjunct Power Connections 5-13

■ Attendant Console 5-16

■ 26B1 Selector Console 5-16

■ Connect External Alarm Indicators 5-17

■ Connect Power Distribution Unit External Alarm Wires 5-18

■ Remote Network Interface 5-20

■ TN1654 DS1 Converter (R8r Only) 5-21

■ Off-Premises Station Wiring 5-32

■ Off-Premises or Out-of-Building Stations 5-32

■ Emergency Transfer Units and

Associated Telepho nes 5-38

■ External Ringing 5-45

■ Queue Warning Indicator 5-46

■ 1145B Power Supply 5-46

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

Contents

■ 1151A1 Power Supply 5-55

■ BRI Terminat ing Resistor 5-58

■ Multi-point Adapters 5-62

■ Add Circuit Packs 5-65

■ List of Circuit Packs 5-65

■ Add CO, FX, WATS, and PCOL 5-71

■ Add DID Trunks 5-71

■ Add Tie Trunks 5-72

■ Add DS1 Tie and OPS 5-74

■ Add Speech Synthesis 5-78

■ Add Code Calling Access 5-78

■ Add Pooled Modem 5-79

■ Add External Modem to EPN 5-80

■ Add External Modem to PPN 5-81

■ Add External Modem to TN1648B 5-82

Issue 1

April 2000

vi

■ Add DCS Interface 5-91

■ Add Multiple Announcement 5-93

■ Add ISDN — PRI 5-97

■ Add Packet Bus Support 5-99

■ Add CallVisor ASAI 5-105

■ Add ISDN—BRI 5-106

■ CAMA/E911 Installation 5-108

■ Add IP Interface 5-118

■ Installing an Integrated Channel

Service Unit (ICSU) Module 5-146

■ Installing a 3150/3170 Channel Service Unit 5-150

■ Connector and Cable Diagrams (Pinout Charts) 5-152

6 Test Telephones and Other Equipment 6-1

■ Make Test Calls 6-2

■ Test 302C Attendant Console 6-2

■ Test External Ringing 6-3

■ Test Queue Warning Indicator 6-3

■ Test Integrated Announcement 6-3

■ Test Music-on-Hold 6-4

■ Test Emergency Transfer 6-4

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

Contents

■ Test Remote Access Interface 6-4

■ Test Basic Rate Interface 6-5

■ Test Duplication Option Processing

Element Interchange 6-5

■ Test Terminating Trunk Transmission 6-6

■ Test Stratum 3 Clock 6-6

■ Perform Complete System Test 6-8

■ Activate and Test Alarm Origination Feature 6-8

A Connecting Fiber Optic Cables A-1

■ LASER Product A-2

■ Fiber Optic Requirements A-2

■ Optical Cross-Connect Hardware A-6

■ Cleaning Fiber Optic Cables A-16

■ Labels for Fiber Optic Cables A-16

Issue 1

April 2000

vii

■ Making Changes at an LIU or Shelf A-17

■ Routing Fiber Optic Cables A-18

B Option Switc h Settings B-1

■ External Modem Option Settings B-1

■ Printer Option Settings B-4

■ Call Detail Recording Option Settings B-7

■ TN760D Tie Trunk Option Settings B-9

■ TN464E/F Option Settings B-11

C Cable Ductwork C-1

D Connector and Cable Diagrams D-1

E Access Security Gateway E-1

■ Using the ASG Mobile E-1

GL Glossary and Abbreviations GL-1

IN Index IN-1

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Contents

555-233-114

Issue 1

April 2000

viii

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

555-233-114

About This Book

Issue 1

April 2000

ix

This book provides procedures and information for installing and initially testing

the DEFINITY

®

Enterprise Communications Server Multicarrier Cabinets.

This document covers information related to DEFINITY ECS Release 8.2. For

details about changes for Release 8, refer to DEFINITY Enterprise

Communications Server Release 8.2, Change Description.

The following conventions describe the systems referred to in this book.

■ The word system, is a general term and includes references to the

DEFINITY Enterprise Communications Server

■ DEFINITY Systems are called: Release 5, Release 5r, Release 6,

Release 6r, Release 8, and Release 8r

■ All occurrences of Release 5r and Release 6r are called Release 6r unless

a specific configuration is required to differentiate between product

offerings

■ Information in this book is applicable for Release 8 unless otherwise

specified

■ DEFINITY Enterprise Communications Server is abbreviated DEFINITY

ECS

This book describes installation and wiring including:

1. Placing and interconnecting the various cabinets and adjuncts.

2. Wiring from the telephone network interface to and including the 25-pair

cables that connect directly to the system.

3. The main equipment room main distribution frame and the associated

cabling to the system and/or 8-pin information outlets (modular wall jacks).

4. Testing of the completed installation.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

This issue replaces all previous issues of DEFINITY Communications System

Generic 1 and Generic 3 Installation and Test, 555-204-104.

NOTE:

This book is being modified for international translation. This means some

illustrations contain numbers instead of descriptive text. In the future, all

illustrations will contain numbers.

555-233-114

Organization

This book contains the following chapters:

Issue 1

April 2000

xOrganization

Chapter 1, ‘‘

connect power, and connect the cabinets together.

Chapter 2, ‘‘

between the system and the Main Distribution Frame.

Chapter 3, ‘‘

management terminal and how to activate and initialize the system.

Chapter 4, ‘‘

Chapter 5, ‘‘

and wire telephones and other equipment to the system.

Chapter 6, ‘‘

equipment installed in Chapter 5.

Install and Connect Cabinets’’ — How to install the cabinets,

Install Telecommunications Cabling’’ — How to install cabling

Accessing and Activating the System’’ — How to install the

Test the System’’ — How to initially test the system.

Install and Wire Telephones and Other Equipment’’— How to install

Test Telephones and Other Equipment’’ — How to test the

How to Comment on This Book

Lucent Technologies welcomes your feedback. Please fill out the reader

comment card at the front of this book and return it. Your comments are of great

value and help improve our documentation.

If the reader comment card is missing, fax your comments to 1-303-538-1741 or

to your Lucent Technologies representative, and mention this document’s name

and number, DEFINIT Y E nterprise Communication Server Release 8.2 Installation

and Test for Multi-Carrier Cabinets, 555-233-114.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

About This Book

Related Books

The following books are useful for system-related information:

■ DEFINITY Enterprise Communications Server Release 8 Administration for

Network Connectivity

■ DEFINITY Enterprise Communications Server Release 8 System

Description

■ DEFINITY Enterprise Communications Server Release 8 Maintenance for

R8r

■ DEFINITY Enterprise Communications Server Release 8 Maintenance for

R8si

■ AT&T Network and Data Connectivity Reference

■ BCS Products Security Handbook

■ DEFINITY Wireless Business System Users Guide

■ DEFINITY Wireless Business System Installation and Test Guide

Issue 1

April 2000

xiRelated Books

■ DEFINITY Wireless Business Systems System Interface

■ DEFINITY Enterprise Communications Server Release 8 Installation and

Test for Single-Carrier Cabinets

■ DEFINITY Enterprise Communications Server Release 8 Administrator’s

Guide

■ DEFINITY Enterprise Communications Server Release 8 Upgrades and

Additions for R8si

■ DEFINITY Enterprise Communications Server Release 8 Upgrades and

Additions for R8r

■ Switch Administration for DEFINITY AUDIX

Conventions Used in This Book

This book uses the following conventions:

■ Keyboard keys are shown as: Enter.

■ Information you type is shown as:

command you typed, press the

keyboard, not the

■ Information displayed on the screen is shown as:

Enter/Return key in the letters section.

save announcements.

Enter key in the numbers section of the

To submit the

login:

■ Circuit pack codes (for example, TN772 or TN754B) are shown with the

minimum acceptable alphabetic suffix (like the ‘‘B” in the code ‘‘TN754B”).

Generally, an alphabetic suffix higher than the 1 shown is also acceptable.

However, not every vintage of either the minimum suffix or a higher suffix

code is necessarily acceptable.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

555-233-114

NOTE:

Refer to Technical Monthly: Reference Guide for Circuit Pack

Vintages and Change Notices, for current information about the

usable vintages of specific circuit pack codes (including the suffix)

in a DEFINITY ECS Release 8 system.

The following conventions are used to describe the systems referred to in this

book.

■ The word system, is a general term encompassing Release 8 and

includes references to the DEFINITY Enterprise Communications Server

■ Systems in this book are called: G3V4, Release 5, Release 6, Release 7,

and Release 8

■ Older DEFINITY Communications Systems Generic 3vs, Generic 3s, and

Generic 3i are referred to as G3vs, G3s, and G3i

■ All occurrences of G3s, G3i, G3siV4, G3siV 4+m, Release 5si, Release 5si

+ memory, and Release 6si are called Release 6si unless a specific

configuration is required to differentiate between product offerings

Issue 1

April 2000

xiiHow to Order Books

■ Information in this book is applicable for G3V4 through Release 8, unless

otherwise specified

■ DEFINITY Enterprise Communications Server is abbreviated as

DEFINITY ECS

How to Order Books

In addition to this book, other description, installation and test, maintenance, and

administration books are available. A complete list of DEFINITY books is

provided in the Business Communication s System Publications Catalog,

555-000-010.

This book and any other DEFINITY books can be ordered directly from the

Luc ent Technologies Bus i ness Communic a tion s System Publications Fulfillment

Center at 1-317-322-6791 or toll free at 1-800-457-1235.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

About This Book

Trademarks

This document contains references to the following Lucent Technologies

trad em arke d prod ucts:

■ ACCUNET

■ AUDIX

■ Callmaster

■ CallVisor

■ CONVERSANT

■ DEFINITY

■ FORUM

■ LGX

■ MEGACOM

■ SYSTIMAX

■ TRANSTALK

®

®

®

®

®

®

™

®

®

®

™

Issue 1

April 2000

xiiiTrademarks

The following products are trademarked by their appropriate vendor:

■ Audichron

■ Music Mate

■ PagePac

®

is a registered trademark of Audichron Company

®

is a registered trademark of Harris Corporation

®

is a registered trademark of Harris Corporation, Dracon

Division

■ SHOCKWATCH

®

is a registered trademark of Media Recovery,

Incorporated

■ Styrofoam

■ TILTWATCH

■ VELCRO

■ Zone Mate

®

is a registered trademark of Styrofoam Corporation

®

is a registered trademark of Media Recovery, Incorporated

®

is a registered trademark of VELCRO U.S.A. Incorporated

®

is a registered trademark of Harris Corporation

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

About This Book

Standards Compliance

The equipment presented in this book complies with the following standards (as

appropriate):

■ ITU-T (Formerly CCITT)

■ ECMA

■ ETSI

■ IPNS

■ DPNSS

■ National ISDN-1

■ National ISDN-2

■ ISO-9000

■ ANSI

■ FCC Part 15 and Part 68

Issue 1

April 2000

xivStandards Compliance

■ EN55022

■ EN50081

■ EN50082

■ CISPR22

■ Australia AS3548 (AS/NZ3548)

■ Australia TS 001 (AS/NZS 3260)

■ IEC 825

■ IEC 950

■ UL 1459

■ UL 1950

■ CSA C22.2 Number 225

Contact your Lucent Technologies representative for more information.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

555-233-114

LASER Product

The DEFINITY ECS may contain a Class 1 LASER device if single-mode fiber

optic cable is connected to a remote Expansion Port Network (EPN). The LASER

device operates within the following parameters:

Power Output: -5 dBm

Wavelength: 1310 nm

Mode Field Diameter: 8.8 microns

CLASS 1 LASER PRODUCT

IEC 825 1993

!

CAUTION:

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Contact your Lucent Technologies representative for more information.

Issue 1

April 2000

xvLASER Product

Electromagnetic Compatibility Standards

This product complies with and conforms to the following EMC standards (as

appropriate):

■ Limits and Methods of Measurements of Radio Interference

Characteristics of Information Technology Equipment, EN55022

(CISPR22), 1993

■ EN50082-1, E uropean Generic Immunity Standard

■ FCC Part 15

■ Australia AS3548

NOTE:

The system conforms to Class A (industrial) equipment. Voice terminals

meet Class B requirements.

■ Electrostatic Discharge (ESD) IEC 1000-4-2

■ Radiated radio frequency field IEC 1000-4-3

■ Electrical Fast Transient IEC 1000-4-4

■ Lightning effects IEC 1000-4-5

■ Conducted radio frequency IEC 1000-4-6

■ Mains frequency magnetic field IEC 1000-4-8

■ Low frequency mains disturbance IEC 1000-4-11

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

555-233-114

About This Book

European Union Standards

Lucent Technologies Business Communications Systems declares that the

DEFINITY equipment specified in this book bearing the Conformité Europeénne

(CE) mark conforms to the European Union Electromagnetic Compatibility

Directives.

The CE mark indicates conformance to the European Union Electromagnetic

Compatibility Directive (89/336/EEC) Low Voltage Directive (73/23/EEC) and

Telecommunication Terminal Equipment (TTE) Directive (91/263/EEC) and with

i-CTR3 Basic Rate Interface (BRI) and i-CTR4 Primary Rate Interface (PRI) as

applicable. The CE mark is applied to the following Release 8 products:

■ Global AC powered Multicarrier Cabinet (MCC)

■ DC powered Multi-Carrier Cabinet (MCC) with 25 Hz ring generator

■ AC powered Single-Carrier Cabinet (SCC) with 25 Hz ring generator

■ AC powered Compact Single-Carrier Cabinet (CSCC) with 25 Hz ring

generator

Issue 1

April 2000

xviElectromagnetic Compatibility Standards

■ Enhanced DC Power System

■ Compact Modular Cabinet (CMC) with 25 Hz ring generator

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

555-233-114

Where to Call for Technical Support

Use the following telephone numbers for the region in which the system is being

installed:

Issue 1

April 2000

xviiWhere to Call for Technical Support

Tel ep ho ne N u m be r

DEFINITY Helpline (feature administration and system

applications)

Luc ent Tec hnologies Toll Fraud Intervention 1-800-643-2353

Lucent Technologies National Customer Care Center 1-800-242-2121

Lucent Technologies Corporate Security 1-800-822-9009

Streamlined Implementation (for missing equipment) 1-800-772-5409

USA/Canada Technical Service Center 1-800-248-1234

ITAC 1-303-804-3777

Luc ent Tec hnol ogies Centers of Exc elle nce

Asia/Pacific Regional Support Center 65-872-8686

Western Europe/Middle East/South Africa 44-1252-77-4800

Central/Eastern Europe 361-345-4334

Central/Latin America Caribbean 1-303-804-3778

Australia 61-2-9352-9090

North America (INADS Database Administration) 1-800-248-1111

1-800-225-7585

Anti-Static Protection

!

CAUTION:

When handling circuit packs or any components of a DEFINITY System,

always wear an authorized wrist ground strap. Connect the strap to an

approved ground such as an unpainted metal surface on the DEFINITY

System.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

555-233-114

Remove/Install Circuit Packs

!

CAUTION:

The control circuit packs with white labels cannot be removed or installed

when the power is on. The port circuit packs with gray labels (older version

circuit packs had purple labels) can be removed or installed w hen the

power is on.

Security Issues

To ensure the greatest security possible for customers, Lucent Technologies

offers services that can reduce toll-fraud liabilities. Contact your Lucent

Technologies representative for more security information.

Login security is an attribute of the DEFINITY ECS software. Existing passwords

expire 24 hours after installation.

Issue 1

April 2000

xviiiRemove/Install Circuit Packs

Federal Communications Commission Statement

Part 68: Statement

Part 68: Answer-Supervision S ignaling. Allowing this equipment to be operated in

a manner that does not provide proper answer-supervision signaling is in

violation of Part 68 rules. This equipment returns answer-supervision signals to

the public switched network when:

■ Answered by the called station

■ Answered by the attendant

■ Routed to a recorded announcement that can be administered by the CPE

user

This equipment returns answer-supervision signals on all DID calls forwarded

back to the public switched telephone network. Permissible exceptions are:

■ A call is unanswered

■ A busy tone is received

■ A reorder tone is received

Lucent Technologies attests that this registered equipment is capable of

providing users access to interstate providers of operator services through the

use of access codes. Modification of this equipment by call aggregators to block

access dialing codes is a violation of the Telephone Operator Consumers Act of

1990.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

555-233-114

This equipment complies with Part 68 of the FCC Rules. On the rear of this

equipment is a label that contains, among other information, the FCC registration

number and ringer equivalence number (REN) for this equipment. If requested,

this information must be provided to the telephone company.

The REN is used to determine the quantity of devices which may be connected

to the telephone line. Excessive RE Ns on the telephone line may result in devices

not ringing in response to an incoming call. In most, but not all areas, the sum of

RENs should not exceed 5.0. To be certain of the number of devices that may be

connected to a line, as determined by the total RENs, contact the local telephone

company.

NOTE:

REN is not required for some types of analog or digital facilities.

Means of Connection

Connection of this equipment to the telephone network is shown in the following

table (U.S. only).

Issue 1

April 2000

xixFederal Communications Commission Statement

SOC/REN/

Manufacturer’s Port Identifier FIC Code

Off/On Premises Station OL13C 9.0F RJ2GX, RJ21X,

DID Trunk 02RV2-T 0.0B RJ2GX, RJ21X

CO Trunk 02GS2 0.3A RJ21X

CO Trunk 02LS2 0.3A RJ21X

Tie Trunk TL31M 9.0F RJ2GX

1.544 Digital Interface 04DU9-B,C 6.0P RJ48C, RJ48M

1.544 Digital Interface 04DU9-BN,KN 6.0P RJ48C, RJ48M

120A2 Channel Service Unit 04DU9-DN 6.0P RJ48C

A.S. Code Network Jacks

RJ11C

If the terminal equipment (DEFINITY® System) causes harm to the telephone

network, the telephone company will notify you in advance that temporary

discontinuance of service may be required. But if advance notice is not practical,

the telephone company will notify the customer as soon as possible. Also, you

will be advised of your right to file a complaint with the FCC if you believe it is

necessary.

The telephone company may make changes in its facilities, equipment,

operations or procedures that could affect the operation of the equipment. If this

happens, the telephone company will provide advance notice in order for you to

make necessary modifications to maintain uninterrupted service.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

About This Book

555-233-114

If trouble is experienced with this equipment, for repair or warranty information,

please contact the Technical Service Center at 1-800-242-2121. If the equipment

is causing harm to the telephone network, the telephone company may request

that you disconnect the equipment until the problem is resolved.

It is recommended that repairs be performed by Lucent Technologies certified

technicians.

The equipment cannot be used on public coin phone service provided by the

telephone company. Connection to party line service is subject to state tariffs.

Contact the state public utility commission, public service commission or

corporation commission for information.

This equipment, if it uses a telephone receiver, is hearing aid compatible.

Issue 1

April 2000

xxFederal Communications Commission Statement

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Install and Connect Cabinets

This chapter discusses installation of Multicarrier Cabinets only. For information

on Single-Carrier Cabinets, refer to DEFINITY Enterprise Communications Server

Release 8 Installation and Test for Single-Carrier Cabinets.

Issue 1

April 2000

1-1Unpack and Inspect Cabinets

1

Floor plans and equipment layouts for typical system installations are provided in

DEFINITY Enterprise Communications Server Release 8 S ystem Description.

Unpack and Inspect Cabinets

Perform these steps for all cabinets.

!

DANGER:

A cabinet may weigh as much as 800 lb (363 kg) and may be top heavy.

Use extreme caution.

1. Check the status of the SHOCKWATCH and/or TILTWATCH indicators on

the container. If the container has been shaken or tilted beyond

specifications, the indicators are red, indicating potential damage. Report

any damage according to local shipping instructions.

!

DANGER:

Take care to avoid injury while cutting and removing the 2 metal bands.

2. Unpack the cabinet and remove all packing material.

3. Move the cabinets into their proper positions.

4. Do not adjust the leveling ft at this time.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Unpack and Inspect Auxiliary Cabinet

The Auxiliary cabinet is normally positioned adjacent to the PPN cabinet or the

EPN cabinet, if provided.

1. Unpack the cabinets as outlined on the previous page.

2. Remove the lower rear panel from the Auxiliary cabinet. Install the lower

rear panel when the installation is completed.

Unpack and Inspect Stratum 3 Clock Cabinet

1. Check the status of the SHOCKWATCH and/or TILTWATCH indicators on

the cardboard container. If the container has been jarred or tilted beyond

specifications, the indicato rs are red, indicating possible damage.

2. Remove all packing material.

3. Remove front door and rear screw-on panels from the cabinet.

4. Inspect the cabinet for damage. Report any damage per local

instructions.

Issue 1

April 2000

1-2Check Customer’s Order

Check Customer’s Order

1. Check the customer’s order and the shipping packing lists to confirm all

equipment is present. If any equipment is missing, report the information

to your Lucent Technologies representative.

2. Ensure all circuit packs are fully inserted into the proper slots according to

the Customer Service Document (CSD). Report any discrepancies in

circuit pack type or quantity to your Lucent Technologies representative.

3. Check the system adjuncts for damage and report all damage according

to local shipping instructions.

Correcting Shipping Errors

1. Red-tag all defective equipment and over-shipped equipment and return

per the nearest Material Stocking Location (MSL) instructions. For

international customers, contact your order service agent.

2. Direct all short-shipped reports to the nearest MSL. Contact the

appropriate location for specific instructions. For Streamlined

Implementation in the United States, call 1-800-772-5409.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Install System Cabinets

Check the location of the AC power receptacles in the equipment room. The

receptacles must be on a separately fused circuit not controlled by a wall switch.

They must be located within 10 ft (3 m) of the cabinet and outside the Main

Distribution Frame (MDF) area.

Position the PPN Cabinet

1. If the system is supplied with cable ductwork, space the cabinets on 32 in.

(81.3 cm) centers +-1/8 in. (0.3 cm), they must be level, and must be

square with respect to each other.

2. I f t h e s y ste m i s s u pplied wit h ca bl e s l a ck ma n a ge r s , place t h e ca bi n e ts far

enough from the connection field to lay down the 32 in. (81.3 cm) slack

managers and to provide a little extra room for the cables to access the

cable slack managers.

Issue 1

April 2000

1-3Install System Cabinets

3. If earthquake protection is required, skip to ‘‘

Installation’’ on page 1-33.

4. If earthquake protection is not required, level the cabinets and adjust and

lock the cabinet stabilizing bolts to keep the cabinet from moving.

5. At the bottom of the cabinet, install hole plugs (provided with cabinet) in

the holes previously occupied by the 4 carriage bolts.

Position the EPN Cabinets

Each EP N cabinet is normally positioned adjacent to the PP N cabinet but may be

located remotely in a different room or a different building.

1. The procedure for installing an EPN cabinet is the same as for the PPN

cabinet.

2. If earthquake protection is required, skip to ‘‘

Installation’’ on page 1-33.

3. If earthquake protection is not required, level the cabinets and adjust and

lock the cabinet stabilizing bolts to keep the cabinets from moving.

NOTE:

To install a new EPN cabinet to an existing system, refer to DEFINTY

Enterprise Communications Server Release 8 Upgrades and

Additions for R8r.

Earthquake Protection

Earthquake Protection

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Position the Auxiliary Cabinet (Optional)

1. Position the Auxiliary cabinet next to the PPN cabinet (or EPN cabinet, if

installed). The location of equipment inside the Auxiliary cabinet is

specified in the Customer Service Document (CSD).

Issue 1

April 2000

1-4Install System Cabinets

2. If earthquake protection is required, skip to ‘‘

Installation’’ on page 1-33. Return to this section when finished.

3. If earthquake protection is not required, level the cabinets and adjust and

lock the cabinet stabilizing bolts to keep the cabinet from moving.

Install Auxiliary Cabinet Equipment

The Auxiliary cabinet allows for carrier, 23-in. (58.4 cm) rack, or panel mounting

of hardware. The following equipment is furnished with the cabinet.

■ Fuse panel — Distributes -48 VDC power to fused cabinet circuits

■ Power receptacle strip — Provides switched and unswitched 120

VAC receptacles

■ DC connector block — Required when Auxiliary cabinet is

powered by an external DC source

■ AC to DC power supply — Converts AC power provided by the AC

power strip switched outlet to the required DC voltage

1. Install equipment inside the cabinet as specified in the CSD. T he following

optional equipment can be installed:

■ Audichron H9040 Wake-Up Announcement System

■ 909A/B Universal Coupler

Earthquake Protection

■ 7400 Series Data Modules

■ Z77A Multiple Data Mounting

■ Fan Assembly — Requires 120 volt AC power

■ COMSPH ERE 3000 -seri es modems

■ External Channel Service Unit (CSU) — 1 is required for each T1

car r ie r li nk

■ PagePac Paging System — 3 models are available. All PagePac

models require 120 VAC power.

■ Model 15A Announcement System — See Tab le 1-1 for PEC

codes.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Table 1-1. Model 15A Announcement Equipment

PEC Code Description

PEC 63240 1 chassis and 1 BLD1 circuit pack

PEC 63241 1 BLD1 circuit pack

PEC 63242 1 chassis and 1 BLD2 circuit pack

PEC 63243 1 BLD2 circuit pack

PEC 63246 1 remote record module

The BLD1 circuit pack provides 8 channels with up to 20 seconds of

recording time on each channel. The BLD2 circuit pack provides 8

channels with up to 40 seconds of recording time on each channel. Each

chassis can be populated with any combination of 2 BLD circuit packs.

The Model 15A Announcement System is FCC registered and does not

require a voice coupler.

Issue 1

April 2000

1-5Install System Cabinets

2. If earthquake protection is required, skip to ‘‘

Installation’’ on page 1-33.

Install and Position Stratum 3 Clock Cabinet

Check the location of the AC power receptacle. The receptacle must be on a

separately fused circuit that is not controlled by a wall switch. It must be located

within 10 ft (3 m) of the cabinet and should be located outside the MDF area.

1. Position the clock cabinet in the designated location.

2. If earthquake protection is required, skip to ‘‘

Installation’’ on page 1-33.

3. If earthquake protection is not required, level the cabinets and adjust and

lock the cabinet stabilizing bolts to keep the cabinet from moving.

Earthquake Protection

Earthquake Protection

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Connect AC Power and Ground

Power Requirements

Table 1-2 shows the power requirements.

Table 1-2. DEFINITY System Power Requirements

Maximum DEFINITY UL Rating Label Power Capacity

Issue 1

April 2000

1-6Connect AC Power and Ground

Vac InIac

I

nMax W InBTU/Hr

208 24 3245 11071.26

240 21 3276 11177.71

120 40 3120 10645.44

J58890CE-1, J58890CE-2, and J58890CH-1

The following procedures apply to the AC-powered PPN and EPN cabinets.

Either of the following power sources can supply 60 Hz power to the AC load in

Release 5 and later systems:

■ Single-phase, 4-wire, 120/240 VAC supplying 240 VAC. This source has 2

hot wires, 1 ground wire, and 1 neutral wire (J58890CE).

■ Single-phase, 4-wire, 120/208 VAC supplying 208 VAC. This source has 2

hot wires, 1 ground wire, and 1 neutral wire (J58890CE).

■ Single-phase, 3-wire, 208 or 240 VAC. This source has 2 hot wires and 1

ground wire (J58890CH).

Either of the following power sources can supply 50 Hz power to the AC load in

Release 5 and later systems:

■ Non-United States 5-wire, Y, 220/380 VAC. This source has 3 hot wires, 1

neutral wire, and 1 ground wire.

■ Non-United States Delta, 4-wire, 220 or 240 VAC. This source has 3 hot

wires and 1 ground wire.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

Table 1-3 describes the power s ources and required AC input power.

Table 1-3. AC Power Sources and Plug Type

Power Distribution

Unit Power Sources Power Input

555-233-114

Issue 1

April 2000

1-7Connect AC Power and Ground

AC po w er di s t r ibu t i o n

(J58890CE-1 and

J58890CE-2)

Multicarrier Cabinet

AC po w er di s t r ibu t i o n

(J58890CH-1)

Multicarrier Cabinet

NOTE:

The type of power required is shown on the cabinet’s rear door.

!

CAUTION:

The equipment room AC power and ground wiring must be performed by a

qualified electrician. Refer to DEFINITY Enterprise Communications Server

Release 8 System Description Pocket Reference, for site requirement

information.

Single phase 120 VAC

with neutral

Single phase 240 VAC

with neutral, or single

phase of 3-phase, 208

VAC with neutral

Single Phase 176-264

VAC

120 VAC, 60 Hz NEMA

5-50R

208/240 VAC, 60 Hz NEMA

L14-30R

200-240 Volts, 50-60 Hz

NEMA L6-30R. Installations

outside the United States

require a receptacle

suitable for use in the

country of installation.

!

CAUTION:

The power circuit must be dedicated to the system and must not be shared

with other equipment and must not be controlled by a wall switch. The AC

receptacle should not be located under the MDF.

!

CAUTION:

System grounding must comply with the general rules for grounding

contained in Article 250 of the National Electrical Code (NEC), National Fire

Protection Agency (NFPA) 70, or the applicable electric code in the country

containing the equipment. For more information, refer to ‘‘

Grounds’’ on page 1-22.

Approved

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Connect Ground to AC-Powered System (J58890CE)

Grounding is relatively simple for an AC-powered system. Basically , the cabinets

connect to the single-point ground terminal block located at either the AC load

center or to a separate single-point ground block wired to the AC load center (or

optional AC protector cabinet).

Issue 1

April 2000

1-8Connect AC Power and Ground

■ The approved ground wire must be a green (or green with yellow stripe), 6

AWG (#40) (16 mm

■ Bond all approved grounds at the single-point ground to form a single

2

), copper, stranded wire.

grounding electrode system.

AC Load Center is 50 ft (15.2 m) or Less from

Cabinet

1. At the bottom rear of the PPN cabinet, connect a 6 AWG (#40) (16 mm2)

CABINET GROUND wire to the cabinet ground terminal block. See

Figure 1-1

2. Route the CABINET GROUND wire to the single-point ground block at the

AC load center and connect.

3. At the bottom rear of the first EPN cabinet (if provided), connect a 6 AWG

(#40) (16 mm

block.

4. Route the CABINET GROUND wire to the single-point ground block at the

AC load center and connect.

.

2

) CABINET GROUND wire to the cabinet ground terminal

NOTE:

If the EPN cabinet is located remote from the PPN cabinet (in a

separate room or building), connect the CABINET GROUND wire to

an approved ground.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

1 2 2

Issue 1

April 2000

1-9Connect AC Power and Ground

7

33 3

5

6

4 4 4

widmgrnd LJK 092697

Figure Notes

1. PPN Cabinet

2. EPN Cabinet (if Installed)

3. 6 AWG (#40) (16 mm

2

) CABINET GROUND

Wire

4. Cabinet Ground Terminal Block

5. AC Load Center

Single-Point Ground

6. Less than 50 Wire ft

(15.2 m)

7. 10 AWG (#25) (6 mm

Ground Wire to CBC

Figure 1-1. Typical Cabinet Ground Location

5. Repeat connecting each EPN cabinet to the single-point ground block.

2

6. At the AC load center, connect a 10 AWG (#25) (6 mm

) wire to the

single-point ground block. This ground wire will later be tie-wrapped to the

trunk cables and connected to the Coupled Bonding Conductor (CBC)

ground block at the MDF.

2

)

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

AC Load Center is More Than 50 ft (15.2 m) from

Cabinet

1. Mount the single-point ground block to any surface between the MCC

cabinets and the AC load center single-point ground. The single-point

ground block must be mounted to a non-metallic surface.

2. At the bottom rear of the PPN cabinet, connect a 6 AWG (#40) (16 mm

CABINET GROUND wire to the cabinet ground block. See Figur e 1-2

3. Route the wire to the single-point ground block and connect.

4. At the first EPN cabinet (if provided), connect a 6 AWG (#40) (16 mm

CABINET GROUND wire to the cabinet ground terminal block.

5. Route the CABINET GROUND wire to the single-point ground block and

connect.

NOTE:

If the EPN cabinet is located remote from the PPN cabinet (in a

separate room or building), route the EPN CABINET GROUND wire

to an approved ground.

Issue 1

April 2000

1-10Connect AC Power and Ground

2

)

.

2

)

6. Repeat connecting each EPN cabinet to the single-point ground block.

7. Connect a 6 AWG (#40) (16 mm

2

) ground wire to an unused terminal on

the single-point ground block.

8. Route the ground wire to the AC load center ground and connect.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Issue 1

April 2000

1-11Connect AC Power and Ground

5

3 3 3

1 2 2

8 8 8

widfspgb KLC 100297

Figure Notes

1. PPN Cabinet

2. EPN Cabinet (if Installed)

3. 6 AWG (#40) (16 mm

2

GROUND Wire

4. Single-Point Ground Block

) CABINET

4

5. 6 AWG (#40) (16 mm

6

7

2

) Ground Wire

6. AC Load Center Single-Point Ground

7. Over 50 ft (15.2 m)

8. Cabinet Ground Ter m ina l Blo ck

Figure 1-2. Typical Cabinet Grounding Wiring Diagram

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Connect Battery Leads (J58890CH-1)

Figure 1-3 shows a typical optional small battery holdover assembly. These

assemblies may ship with the battery leads disconnected to prevent the batteries

from disc har ging.

1. Plug the battery connector into the -48 VDC Batteries connector on the

rear of the J58890CH-1 Power Distribution Unit.

Issue 1

April 2000

1-12Connect AC Power and Ground

Battery

connector

psdfbatb RPY 061797

Figure 1-3. Typical Small Battery Assembly

!

CAUTION:

Power is present in the cabinet even if the AC power cable is unplugged.

When procedures require ALL Power to be removed from the cabinet and

to prevent unnecessary discharging of the battery, always power down the

cabinet using the main circuit breaker located on the front of the power

distribution unit.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

External Alarms

1

tte

a

B

C

D

V

8

-4

te

o

r

m

e

R

Powe

Issue 1

April 2000

1-13Connect AC Power and Ground

2

3

A

r

ie

rr

a

C

s

ie

r

/G

F

E

D

C

B

C

D

V

n

8

r

-4

tu

e

R

7

4

5

pcdf010 KLC 020599

6

Figure Notes

1. Connect small battery holdover

cable (or temperature sensor cable

from large battery cabinet) to J20

2. Carrier Circuit Breakers

3. Ground Terminal Block

4. Connect -48 VDC Return - 1 AWG

(50 mm

2

) red cable here.

5. Connect -48 VDC - 1 AWG

(50 mm

2

) black cable

Figure 1-4. Power Distribution Unit (J58890CH)

6. 1 AWG (50 mm

2

) 50 ft (15.2

m) cable to large battery

cabinet. For cables greater

than 50 ft

(15.2 m), contact your

Lucent Technologies

representative.

7. Ground Terminal Block

8. To AC load center or

approved single-point

ground block

8

2. Be sure the main power to the power distribution unit is OFF.

3. At the power distribution unit, set all carrier circuit breakers OFF.

Small Battery Holdover

1. Connect the small battery holdover cable to J20. See Figure 1-4.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Large Battery Holdover

When using large battery holdover, 1 battery cabinet is required for every system

cabinet requiring holdover. The 24-cell battery cabinet must have a float voltage

of 54.2 VDC.

Issue 1

April 2000

1-14Connect AC Power and Ground

1. Connect the -48 VDC cable to the large battery connector. See Figure 1-4

2. Connect the -48 VDC RETURN cable to the ground terminal block.

3. Connect the temperature sensor cable, from the battery cabinet, to J20.

NOTE:

An adapter cable may be required when connecting the temperature

sensor cable to the J58890CH unit. See Tab le 1-4

Table 1-4. Temperature Sensor Cable Adapter Cables

H600-476 Adapter Cable Usage

Group 1 (G1) 24-cell customer-provided battery

Group 3 (G3) (included

24-cell Lucent Technologies battery

with battery cabinet)

Connect Shorting Cable to J58890CE-2

!

CAUTION:

For a cabinet with a battery charger, read the caution label on the 397C

battery charger before disconnecting batteries.

.

.

Some cabinets contain a J58890CE -2 AC Power Distribution Unit without an

optional battery charger. Install the shorting cable only when a battery charger is

not installed. If you do not install the shorting cable or a battery charger, then an

alarm app ear s.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Issue 1

April 2000

1-15Connect AC Power and Ground

Figure Notes

1. Shorting Cable (H600-442-G1) (If

Battery Charger is Not Installed)

Figure 1-5. Shorting Cable Installation

1. Set the circuit breakers on the power distribution unit OFF. See Figure 1-5

2. At the rear of the cabinet, insert the shorting cable (H600-442-G1) into

J11. The cable is keyed so it can fit only 1 way.

Connect AC Power

1. Set the main circuit breakers on the power distribution unit OFF.

2. Connect cabinet AC line cords to the AC power receptacles.

3. Do not power up the system at this time.

2. J11

.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Connect DC Power and Ground

Power Distribution Unit (J58890CH-1 Only)

Rectifier Modules and Battery Interface Unit

Each rectifier module operates as an integral part of a complete power system

with battery backup. The modules operate in a redundant, high reliability mode to

provide -48 VDC at 850 Watts to a common power bus.

The Battery Interface Unit (BIU) controls the rectifier modules, manages the

batteries, and reports the status of system power. The BIU provides the Remote

Power Off (RPO) option and battery alarm interfaces for internal and external

alarms.

Issue 1

April 2000

1-16Connect DC Power and Ground

Figure Notes

1. Install Battery Interface Unit into Slot 1

2. Install Rectifier Modules into Slots 2-5

3. Rectifier Module 3 (in Slot 4)

Figure 1-6. Rectifier Module Installation

4. Test Points

5. Main Circuit Breakers

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

1. Install the BU3200A Battery Interface Unit (comcode 107781502) in the

first slot of the power distribution unit. See Figure 1-6

NOTE:

The BIU and the rectifier modules are keyed and can only install 1

way.

2. Install the first 2 RM0850HA100 Rectifier Modules (comcode 107793796)

into the second and third slots of the power distribution unit.

3. If 2 to 3 carriers are installed in the system, install a third rectifier module

(N+1).

4. If 4 to 5 carriers are installed in the system, install a fourth rectifier module.

5. The fifth rectifier module slot is reserved for future system growth.

Connect Power

1. Have a qualified electrician connect and route wires from the AC load

center to the dedicated electrical outlet for the power distribution unit.

Issue 1

April 2000

1-17Connect DC Power and Ground

.

Connect PPN Cabinet Ground

1. Connect 1 end of a 6 AWG (#40) (16 mm2) wire to the ground terminal

block on the rear of the cab i net. See Figure 1-4

2. Route the CABINET GROUND wire to the AC load center single-point

ground block and connect.

Connect EPN Cabinet Ground(s)

1. Connect 1 end of a 6 AWG (#40) (16 mm2) CABINET GROUND wir e to the

ground terminal block at the bottom rear of the EPN cabinet. See Figure

1-2.

2. Route the CABINET GROUND wire to the AC load center single-point

ground and c onn ect.

3. Connect each remaining EPN cabinet to the AC load center single-point

ground.

.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

DC Power and Ground (J58890CF Only)

Figure 1-7 shows a typical power and ground layout for a DC-powered cabinet.

The size of the wire required for the -48 volt DC and -48 volt return must ensure

the voltage supplied by the battery plant is maintained between -42.5 and -54.2

volts DC at all times for proper operation and to prevent hardware damage. The

wire must be sized for a maximum voltage drop of 0.5 VDC in each leg of the DC

distribution. This procedure applies to both PPN and EPN cabinets.

1 AWG

ground wire

3

Approved

ground

DC power cabinet

Issue 1

April 2000

1-18Connect DC Power and Ground

10 AWG

To

CBC ground terminal

bar at the MDF

Ground

connection

terminal

+

circuit

breaker

1

+

DC battery

cabinet

Battery

-

-

Frame ground

Single point

ground

block

Main AC

supply

(AC m a in s )

4

6 AWG

Ground

discharge

bar

System

single point

2

ground

-48V

8

DC power

from rectifiers

DC

LVD

Rectifiers

5

5

DC output

1 AWG

75A

1 AWG

distribution bus

75A

1 AWG

-48V DC

75A

75A

RTN

1 AWG

1 AWG

1 AWG

-48V RTN

PPN cabinet

7

-48V

-48V RTN

7

EPN cabinet 1

-48V

-48V RTN

7

EPN cabinet n

-48V

To next

cabinet

5

5

5

6 AWG

6 AWG

6 AWG

cydf_dc KLC 032999

Figure 1-7. Typical Power and Ground for a DC-Powered Cabinet

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Connect DC Power and Ground

The grounding methods for the DC-powered system are more complex than that

of an AC-powered system. The following installation procedures refer to Figure

1-7. The numbers 1-8 in Figure 1-7 match the following subsections 1-8. Other

figures may be referenced as required.

!

CAUTION:

Grounding of the system shall comply with the general rules for grounding

contained in Article 250 of the National Electrical Code, NFPA 70. For more

information, refer to ‘‘

Approved Grounds’’ on page 1-22.

1. Install Coupled Bonding Conductor Wires

This is a conductor that connects to the single-point ground block and run

adjacent to pairs in an associated cable. The mutual coupling between the CBC

and the pairs reduces potential differences in terminating equipment. The

conductor consists of a 10 AWG (#25) (6 mm

ground terminal bar at the Main Distribution Frame (MDF).

1. At the DC Power Cabinet, connect a 10 AWG (#25) (6 mm

the Ground Discharge Bar. See Figure 1-7

2. Route the 10 AWG (#25) (6 mm

bar at the MDF. Be sure a minimum of 12 in. (30.5 cm) spacing is

maintained between the CBC and other power and ground leads.

Issue 1

April 2000

1-19Connect DC Power and Ground

2

) wire terminated at the CBC

2

) grou n d w ire t o

.

2

) ground wire to the CBC ground terminal

3. Tie wrap the ground wire to the inside wiring cable.

NOTE:

The ground wires are connected to the CBC as instructed in Chapter 2,

‘‘Install Telecommunications Cabling’’.

2. Connect DC Battery and Power Cabinet

Grounds

NOTE:

The wire in the next step must be sized for a maximum voltage drop of 0.5

VDC in each leg of the DC distribution. In this example 1 AWG is used.

1. Measure and cut a minimum of a 1 AW G (#70 ) ( 44 m m

to reach between the

Cabinet and the Ground Discharge Bar in the DC Power Cabinet. See

Figure 1-7

.

2. Crimp terminal lugs on each end of the wire. Terminal lugs are furnished

as part of D-181895, Kit of Parts (comcode 105434559).

ground connection t

2

) wire long enough

erminal in the DC Battery

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

3. At the DC Power Cabinet, connect the wire to the Ground Discharge Bar.

4. Route the wire through 1 of the holes in the side of the cabinets and

terminate it on the Ground Connection Terminal in the DC Battery Cabinet.

3. DC Power Cabinet Approved Ground

NOTE:

The wire must be at least as large as the largest distribution wire in the

system (required by UL). In this example 1 AWG is used.

Issue 1

April 2000

1-20Connect DC Power and Ground

1. At the DC Power Cabinet, connect a 1 AWG (#70) (44 mm

the Ground Discharge Bar. See Figure 1-7

2. Route the ground wire out of the cabinet and terminate it on the approved

ground. The approved ground must be identified with a grounding tag

(FORM 15657NR or equivalent). See ‘‘

4. Connect Main AC Supply to DC Power Cabinet

1. Ensure the associated circuit breakers at the AC power panel are

2. Have a qualified electrician connect AC power leads to the rectifiers in the

DC Power Cabinet. Each rectifier should have its own branch circuit.

Terminate the leads on the AC INPUT terminal block of each rectifier.

5. Connect Ground Wires for DC-Powered

Systems

!

CAUTION:

Do not connect any ground wires from an EPN cabinet to another EPN

cabinet or to a PPN cabinet. All ground wires must be terminated at the

single-point ground block at the main AC supply (AC mains).

1. Connect a 6 AW G (#40) (16 mm

block.

2

) wire to the PPN cabinet ground terminal

2

) grou n d w ire t o

.

Approved Grounds’’ on page 1-22.

OFF

.

2. Route the wire to the AC mains single-point ground block and connect.

3. Connect a 6 AWG (#40) (16 mm

2

) wire to each EPN’s cabinet ground

terminal block.

4. Route the wire(s) to the AC mains single-point ground block and connect.

5. Connect a 6 AWG (#40) wire to the DC battery cabinet and DC power

cabinet.

6. Route wires to the AC mains single point ground block and connect them.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

6. Turn Circuit Breakers Off

The main circuit breaker on a DC-powered PPN/EPN cabinet is located on the

front of the power distribution unit. The circuit breakers on the rear of the power

distribution unit control the individual carriers. See Figure 1-4

the carrier breakers.

1. Set the main circuit breaker to OFF.

2. Set the carrier circuit breakers to OFF.

7. Connect DC Power to PPN and EPN Cabinets

1. Be sure the main circuit breaker is OFF.

2. Measure and cut 2 pieces of 1 AWG (#70) (44 mm

reach from the DC Power Cabinet to the PPN cabinet.

3. At the DC Power Cabinet, connect the -48 volt DC wire to the DC OUTPUT

circuit breaker. See Figure 1-7

the grou nd discharge bar.

4. Route the wires out of the cabinet, through the hole in the lower rear cover,

and to the PPN cabinet.

. Connect the -48 volt RTN (return) wire to

Issue 1

April 2000

for the location of

2

) wire long enough to

1-21Connect DC Power and Ground

5. Connect the -48 volt DC wire to the -48VDC terminal on the J58890CF

Power Distribution Unit.

6. Connect the -48 volt RTN wire to the -48RTN terminal on the J58890CF

Power Distribution Unit terminal block.

7. Repeat Steps 2 through 6 for each EPN and Auxiliary cabinet in the

system.

8. Connect DC Battery Cabinet to DC Power

Cabinet

NOTE:

The wire in the next step must be sized for a maximum voltage drop of 0.5

VDC in each leg of the DC distribution. In this example 1 AWG is used.

1. Turn off the main circuit breaker on the DC Battery Cabinet.

2. Turn off the main circuit breaker on the DC Power Cabinet.

3. Measure and cut a 6 AWG (#40) (16 mm

the DC Battery Cabinet’s -48 Volt DC terminal to a

distribution bus on the DC Power Cabinet.

4. At the DC Battery Cabinet, connect the -48 volt DC wire to the -48 VDC

connector.

2

) wire long enough to reach from

DC OUTPUT

5. Route the wire out of the cabinet through the hole in the lower rear cover

and to the DC Power Cabinet.

6. At the DC Power Cabinet, terminate the -48 volt DC wire on a

DC OUTPUT

distribution bus.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Mixed AC/DC Power and Ground

Figure 1-8 shows a power and ground layout for a mixed AC/DC-powered

cabinet configuration in the same equipment room with the PPN being DC

powered and the EPN being AC powered. If a second EPN is part of the system,

use the same basic connections shown in Figure 1-8

1 AWG (44 mm2) up to

50 feet (15.2 m) or engineered for

less than 0.5 volt drop per conductor

Approved

ground

Issue 1

April 2000

1-22Approved Grounds

.

To AC

power source

Ground

discharge

bar

System

single-point

ground

Coupled

bonding conductor

75A

-48V

DC power

supply

-48V

To CBC terminal

block at MDF

-48V RTN

PPN

cabinet

AC po wer cord

AC power-

distribution unit

Cabinet

ground block

cydfacdc KLC 032999

Figure 1-8. Typical Power and Ground for a Mixed AC/DC-Powered Cabinet

Approved Grounds

An approved ground is the closest acceptable medium for grounding the

building entrance protector, entrance cable shield, or single-point ground of

electronic telephony equipment. If more than 1 type of approved ground is

available on the premises, the grounds must be bonded together as required in

Section 250-81 of the National Electrical Code.

EPN

cabinet

Grounded Building Steel

— The metal frame of the building where it is

effectively grounded by 1 of the following grounds: acceptable metallic water

pipe, concrete encased ground, or a ground ring.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Issue 1

April 2000

1-23Approved Grounds

Acceptable Water Pipe

— A metal underground water pipe, at least 1/2-in. (1.3

cm) in diameter, in direct contact with the earth for at least 10 ft (3 m). The pipe

must be electrically continuous (or made electrically continuous by bonding

around insulated joints, plastic pipe, or plastic water meters) to the point where

the protector ground wire connects. A metallic underground water pipe must be

supplemented by the metal frame of the building, a concrete encased ground, or

a ground ring. If these grounds are not available, the water pipe ground can be

supplemented by 1 of the following types of grounds:

■ Other local metal underground systems or structures — Local

underground structures such as tanks and piping systems

■ Rod and pipe electrodes — A 5/8-in. (1.6 cm) solid rod or 3/4-in. (2 cm)

conduit or pipe electrode driven to a minimum depth of 8 ft (2.4 m).

■ Plate electrodes — Must have a minimum of 2 square ft (0.185 square m)

of metallic surface exposed to the exterior soil

Concrete Encased Ground

— An electrode encased by at least 2 in. (5.1 cm)

of concrete and located within and near the bottom of a concrete foundation or

footing in direct contact with the earth. The electrode must be at least 20 ft (6.1

m) of 1 or more steel reinforcing bars or rods 1/2-in. (1.3 cm) in diameter, or at

least 20 ft (6.1 m) of bare, solid copper, 4 AWG (26 mm

Ground Ring

— A buried ground that encircles a building or structure at a depth

2

) wire.

of at least 2.5 ft (0.76 m) below the earth’s surface. The ground ring must be at

least 20 ft (6.1 m) of 2 AWG (35 mm

2

), bare, copper wire.

Approved Floor Grounds

Approved floor grounds are those grounds on each floor of a high-rise building

suitable for connection to the ground terminal in the riser closet and to the

cabinet equipment single-point ground terminal. Approved floor grounds may

include the following:

■ Building steel

■ The grounding conductor for the secondary side of the power transformer

feeding the floor

■ Metallic water pipes

■ Power feed metallic conduit supplying panel boards on the floor

■ A grounding point specifically provided in the building for the purpose

!

WARNING:

If the approved ground or approved floor ground can only be accessed

inside a dedicated power equipment room, then connections to this ground

should be made by a licensed electrician.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

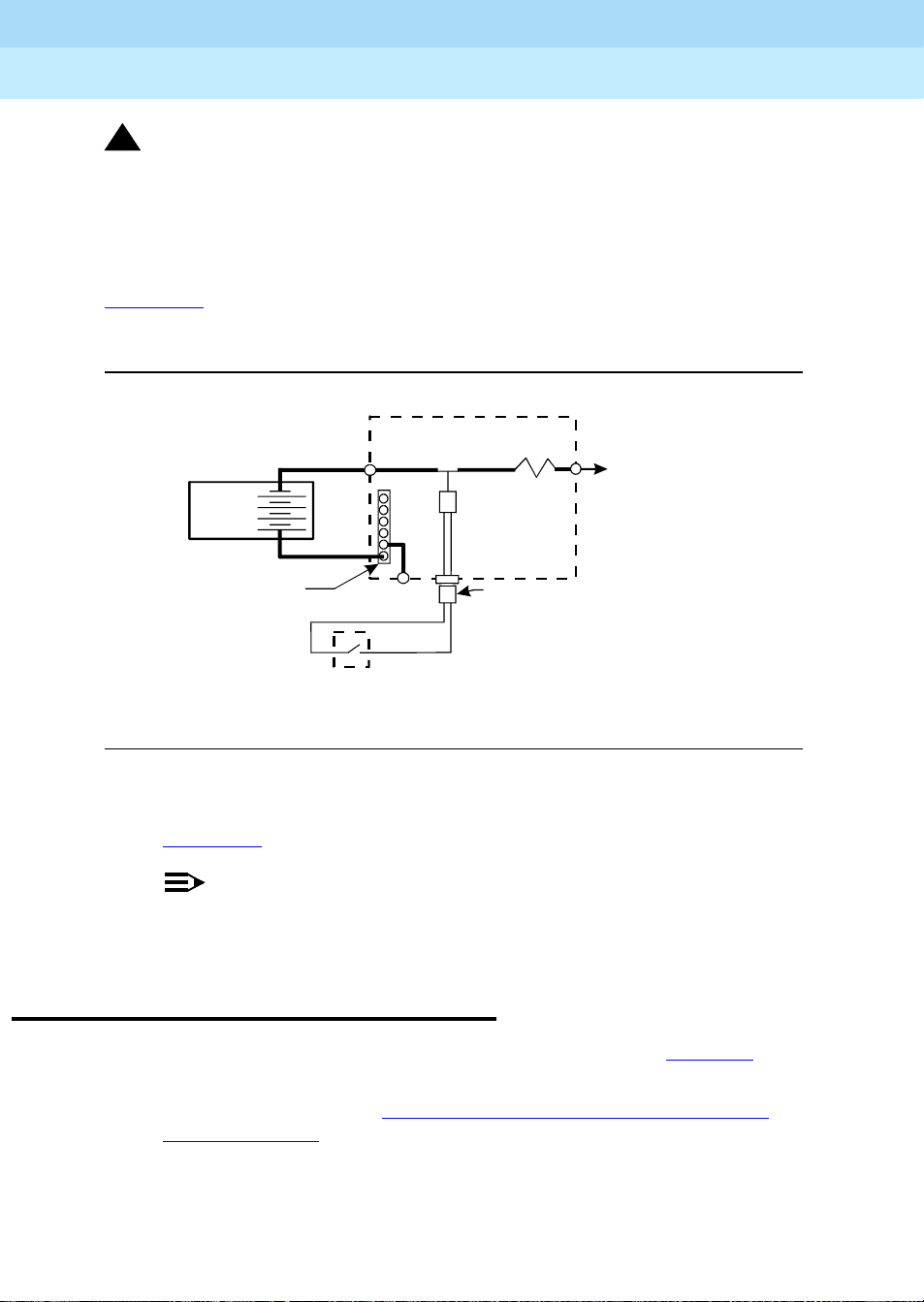

Connect Remote Power Off Cable and External Alarm Cable

Figure 1-9 shows the location of the Remote Power Off (RPO) cable. The

opposite end of the cable connects to the Emergency Power Off (EPO) switch

located outside of the equipment room.

Connect RPO

cablehere(J21)

Issue 1

April 2000

1-24Connect Remote Power Off Cable and External Alarm Cable

Carrier

circuit

breakers

Connect external

alarm cable here

(J18)

psdf002 CJL 081596

alarm cable

Figure 1-9. Remote Power Off Cable Connections — Part 1

Even though the equipment room EPO switch disconnects main AC power to the

equipment room, it cannot disconnect the battery power from the J58890CH. An

auxiliary set of contacts inside the EPO are used for this function.

1. Plug the RPO cable into the connector shown in Figure 1-9

2. Route the opposite end of the wires to the EPO switch. The opposite end

of the RPO cable connects to the internal relay.

NOTE:

The EPO switch and the auxiliary contacts (inside the EPO switch

assembly) are customer-provided.

Pin 6 (-RPO)

Pin 2 (+RPO)

External

.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

!

CAUTION:

555-233-114

The auxiliary contacts inside the EP O switch assembly must

switch is pressed. This contact closure energizes the relay inside the power

distribution unit, causing the connection to the battery holdover assembly to

open.

close

Issue 1

April 2000

1-25Connect External Alarm Cable

when the

Figure 1-10

shows the cabling from the auxiliary contacts inside the EPO switch

assembly and how they connect to the internal relay.

Power Distribution Unit

Battery

Cabinet

Ground

Terminal

Bar

Auxiliary Contacts

TB3

TB1

in EPO Switch

2

Relay

(K1)

RPO Cable

6

Shunt

To Carriers

AtoE

0026_3 RBP080196

Figure 1-10. Remote Power Off Cable Connections — Part 2

1. Connect the RPO wires to the auxiliary contacts on the EPO switch. See

Figure 1-10

.

NOTE:

The EPO switch and the auxiliary contacts for the RPO connection

are customer-supplied.

Connect External Alarm Cable

1. Plug the external alarm cable into the connector shown in Figure 1-9.

2. Route the opposite end of the cable to the MDF. The alarm cable is

connected to the MDF in Chapter 5, ‘‘

Other Equipment’’.

Install and Wire Telephones and

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Connect AC Power to Stratum 3 Clock Cabinet

The clock cabinet requires a 120 VAC, 15 Amp receptacle. The green wire

ground provided by the receptacle is sufficient. The clock cabinet does not

require a ground connection back to the single-point ground.

Check Commercial Power and Connect AC Power

Before powering up the system, check the AC power using a KS-20599 digital

voltmeter (DVM) (or equivalent).

1. Set the DVM to the 250 volt range.

2. Carefully measure the voltage between the hot and neutral side of the

receptacle. The neutral wire is white, the hot wire is black.

3. Verify the meter reads 106 to 128 VAC. If not, have a qualified electrician

correct the problem.

Issue 1

April 2000

1-26Connect AC Power to Stratum 3 Clock Cabinet

4. Measure the voltage between the neutral and ground side of the

receptacle. The ground wire is green.

5. Verify the meter reads 0 VAC. If not, have a qualified electrician correct the

problem.

6. Set all cabinet power modules OFF. Plug the AC power cable into the

receptacle.

Connect DC Power and Ground to Stratum 3 Clock Cabinet

1. Provide power for the clock cabinet from the same DC power plant as the

DEFINITY System.

2. Ground the clock cabinet to the DC power plant.

Connect Clock Cabinet Grounding

1. Measure and cut a 6 AWG (#40) (16 mm2) wire long enough to reach from

the clock cabinet to the ground discharge bar in the DC power plant.

2. Insert 1 end of the wire into the ground lug on the clock cabinet and

tighten the screw.

3. Attach the lug to the receptacle cover. Be sure the lug and cabinet ground

wires are connected to separate screws on the receptacle cover.

4. Route the ground wire to the DC power plant and connect to DISCH GRD

inside the cabinet.

DEFINITY ECS Release 8.2 Installation and Test

for Multi-Carrier Cabinets

Install and Connect Cabinets

1

555-233-114

Connect Stratum 3 Clock DC Power

1. Set the clock cabinet circuit breaker at the DC power plant OFF.

2. At the clock cabinet, connect a 6 AWG (#40) (16 mm

-48V terminal on the terminal strip.

3. At the clock cabinet, connect a 6 AWG (#40) (16 mm

-48VRTN terminal on the terminal strip.

4. Route the wires out of the cabinet and to the DC power plant.

5. At the DC power plant, connect the -48V wire to the DC OUTPUT circuit

breaker.

6. At the DC power plant, connect the -48VRTN wire to the DISCH GRD bar.

Fiber Optic Duplication Interface Cabling (R8si only)

If not already installed, interconnect the A and B port networks (TN792) with the

14-in. fiber optic cable (comcode 848204434—see Figure 1-11

Issue 1

April 2000

1-27Fiber Optic Duplication Interface Cabling (R8si only)

2

) ground wire to the

2

) wire to the

).

EMERTR

C

Lucent

S

P

E

B

O