ATS CyberChiller User Manual

CyberChiller Series Installation, Operation & Maintenance Manual

(©October, 2006)

CyberChiller Series Installation, Operation & Maintenance Manual

MODEL NOMENCLATURE

CCH-330-D-AR

OHS = Overhead System

CC H = CyberChiller System

VFS = Vertical Floor System

FCS = Floor Console System

GPS = Glycol Pump System

CO S = CyberONE System

MCS = Modular Cyber System

Nominal Capacity in

1,000’s of BTU/Hr

D ( ) = Dual (Two) Circuit System

AR = Air-Cooled Remote (Split)

W/G = Water/Glycol Cooled

(©October, 2006)

CyberChiller Series Installation, Operation & Maintenance Manual

TABLE OF CONTENTS

1.0 Introduction.......................................1-1

1.1 General...................................................... 1-1

1.2 Product Description ................................... 1-1

1.2.1 Capabilities and Features .......................... 1-1

1.2.2 Application Ranges.................................... 1-1

1.2.3 General Design .......................................... 1-2

1.2.4 Safety Features......................................... 1-3

1.3 Product Warranty ...................................... 1-4

1.4 Safety........................................................ 1-6

1.4.1 General...................................................... 1-6

1.4.2 Safety Summary........................................ 1-6

2.0 Installation .........................................2-1

2.1 Receiving the Equipment. .......................... 2-1

2.2 Site Preparation......................................... 2-1

2.3 Rigging ...................................................... 2-1

2.4 Mounting/Placement .................................. 2-1

2.4.1 Indoor Equipment....................................... 2-2

2.4.2 Outdoor Equipment.................................... 2-2

2.4.3 Pump Package Installation (Water - Glycol

Systems.................................................... 2-2

2.4.4 Optional Equipment (Field Installed) .......... 2-2

2.4.4.1 Remote Display ......................................... 2-2

2.4.4.2 Remote Water Detector ............................. 2-2

2.5 Piping Connections.................................... 2-3

2.5.1 Process Supply Fluid Lines ....................... 2-3

2.5.2 Refrigerant ................................................. 2-3

2.5.2.1 Split Air Cooled Systems ........................... 2-3

2.5.2.2 Water/Glycol Fluid Cooled Systems .......... 2-4

2.5.3 Pump Package.......................................... 2-5

2.6 Utility Connections .................................... 2-5

2.6.1 Main Power ............................................... 2-5

2.6.2 Controls..................................................... 2-7

2.6.3 Optional Equipment ................................... 2-7

2.6.3.1 Remote Water Detector ............................. 2-7

2.6.4 Interconnecting Field Wiring....................... 2-7

2.6.4.1 Air-Cooled Split Systems

Remote Condenser .................................... 2-8

2.6.4.2 Glycol Systems with Outdoor Fluid Pump

Package .................................................... 2-8

2.7 System Settings and Adjustments............. 2- 9

2.7.1 Chilled Water Supply Charging

Procedures (Evaporator Side) .................... 2-9

2.7.2 Outdoor Heat Exchanger Glycol Charging

Procedures .............................................. 2-10

2.7.3 R-22 Refrigerant Charging Procedures ......2-11

2.7.4 R-407C Refrigerant Charging Procedures ..2-1 1

2.7.5 Low/High Pressure Limit Switch .............. 2-12

2.7.6 Head Pressure Controls........................... 2-13

2.7.6.1 Air-Cooled Systems................................. 2-13

2.7.6.2 Water/Glycol Cooled Systems................. 2-13

2.7.7 Thermal Expansion V alve......................... 2-13

2.7.8 Hot Gas Bypass ...................................... 2-13

2.8 Refrigerant Characteristics....................... 2-14

2.8.1 Pressure/T emperature Settings................ 2-14

2.8.2 Saturated Refrigerant Pressure T ables ..... 2-14

3.0 Start-Up/Commissioning ..................3-1

3.1 Operation ................................................... 3-1

3.2 Step by S tep S tart-Up Instructions ............. 3- 1

3.2.1 Operational Description.............................. 3-1

3.3 Microprocessor Controller

Programming ............................................. 3-2

4.0 Maintenance/Repairs.......................4-1

4.1 Peri odic Gen eral Mai ntenan ce ................... 4-1

4.1.1 General...................................................... 4-1

4.1.2 Compressor ............................................... 4-1

4.1.3 Outdoor Condenser/Fluid Cooler ................ 4-1

4.2 Troubleshooting ......................................... 4-2

4.3 Fie ld Ser vice.............................................. 4-5

4.3.1 Leak Detection .......................................... 4-5

4.3.2 Leak Repair ............................................... 4-5

4.3.3 Refrigerant Piping ...................................... 4-5

4.3.4 General Common Repairs/

Component Replacement........................... 4-5

4.3.4.1 Compressor Failure ................................... 4-5

5.0 Product Support Group ...................5-1

5.1 T echnical Support ...................................... 5-1

5.2 Obtaining Warranty Parts .......................... 5-1

5.3 Obtaining Spare/Replacement Part s .......... 5-1

(©October, 2006)

i

CyberChiller Series Installation, Operation & Maintenance Manual

List of Figures

Figure 1- Typical Layout ........................................ 1-2

Figure 2- Typical Installation.................................. 2-1

Figure 3- Typical Piping Air Cooled Systems ......... 2- 3

Figure 4- Typical Piping W ater/Glycol Cooled

Systems ................................................ 2-5

Figure 5- Sample Nameplate ................................. 2-6

Figure 6- Electric Box ........................................... 2-7

Figure 7- Interconnecting Field Wiring

Remote Condenser................................. 2-8

Figure 8- Interconnecting Field Wiring

Glycol Systems ...................................... 2-9

Appendix A - Forms

Checklist for Completed Installation .........................A-1

Periodic General Maintenance

Checks and Service Checklist..................................A-2

Appendix B - Glossary

Definition of T erms and Acronyms ............................B-1

ii

(©October, 2006)

CyberChiller Series Installation, Operation & Maintenance Manual

1.0 INTRODUCTION

1.1 General

Congratulations, the CyberChiller™ floor mounted

liquid chiller system covered by this manual is designed and manufactured by Stulz Air Technology

Systems, Inc. (SATS) using the latest, state-of-the-art

control technology . Recognized as a world leader,

SATS provides precision cooling systems with the

highest quality craftsmanship using the finest materials available in the industry . The unit will provide years

of trouble free service if installed and maintained in

accordance with this manual. Damage to the unit from

improper installation, operation or maintenance is not

covered by the warranty .

This manual contains information for installation,

operation, maintenance, troubleshooting and repair .

STUDY the instructions contained in this manual.

They must be followed to avoid difficulties. Sp are part s

are available from Stulz Air T echnology Systems to

insure continuous operation. Using substitute parts or

bypassing electrical or refrigeration components in

order to continue operation is not recommended and

will VOID THE WARRANTY. Due to technological

advancements, components are subject to change

without notice.

CyberChiller systems are designed to precisely control

leaving fluid temperature for fluid cooled equipment

such as server racks, MRI’s, precision cooling units or

other devices. Any use beyond this is deemed to be

not intended. SA TS is not liable for any damage

resulting from improper use. All CyberChiller systems

are designed to be installed indoors unless otherwise

noted on the equipment. Propeller-type condensers

and fluid coolers are designed for outdoor use.

1.2 Product Description

CyberChiller systems are designed to meet the needs

and technical requirements of individual customers.

Each individual module or unit can be supplied with

remote air-cooled condensers (AR) or optional water/

glycol (W/G) cooled heat rejection configurations. The

cooling capacity, in BTU/Hr, will depend on the unit

size, which can range from 120,000 to 330,000 BTU/

Hr. CyberChiller systems are designed to operate with

either R22 or R407C refrigerant. Refer to the unit

nameplate to identify which refrigerant is used with

your unit.

NOTE

The CyberChiller systems are strictly for nonresidential applications.

Refer to the installation drawing supplied with your unit

for layout and dimensions of the cabinet. The

CyberChiller unit is provided with a factory mounted

service disconnect switch with a lockable handle. The

service disconnect switch isolates the unit during

routine maintenance. The system incorporates state of

the art component protection with the use of motor

start protectors and circuit breakers.

An operating manual for the system controller is

provided under separate cover . Refer to that manual for

detailed instructions on operating the system controller provided with your unit.

The standard controller for the CyberChiller unit is the

C6000 microprocessor, which provides the following

features: input/output monitoring status, full integrated

control of cooling, multi-unit control and remote

communication with building management systems.

The controller is typically factory mounted on the front

hinged access door of the unit. As an option the

controller display may be factory supplied for remote

mounting to a wall or control panel.

1.2.1 Capabilities and Features

Dual Refrigeration Circuits

Constant Running Compressor

Vibration Isolation of Compressor

Electronic Hot Gas Bypass

(With control based on the chilled water supply

temperature.)

Heavy Gauge Cabinet Construction

High Density Sound & Thermal Insulation

1.2.2 Application Ranges

The SA TS CCH Modular Line Chiller Units are designed for operation within the following ranges:

Room Temperature Range: 35ºF to 95ºF, non-condensing

environment.

Cold Water Conditions: Between 45ºF and 65ºF.

Voltage Tolerances: 460VAC +/-10%; 208VAC +/-10%.

Frequency: 60 Hz. (as noted on unit nameplate).

Max. Piping Length; Chiller to Air Cooled Condenser:

200 ft equivalent length.

Max. Level Drop; Chiller to Condenser: 20 ft (when

condenser is below the chiller).

Storage Conditions: 35ºF to 95ºF.

NOTE

Damage or malfunctions to the unit due to

storage or operation outside of these ranges

will VOID THE WARRANTY.

(©October, 2006)

1-1

CyberChiller Series Installation, Operation & Maintenance Manual

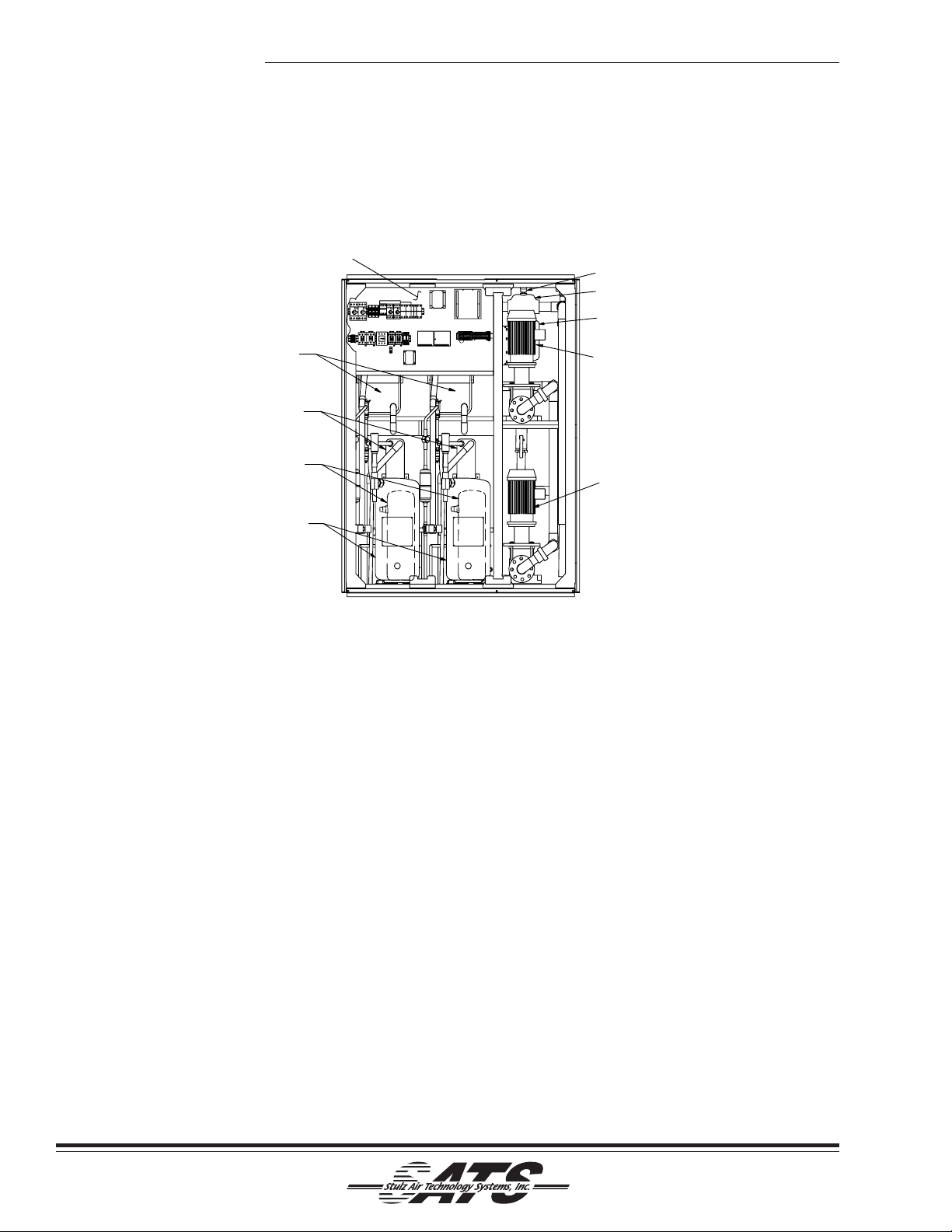

1.2.3 General Design

The CyberChiller is divided into 3 areas; a pump section, a refrigeration section and an electrical section. The

housing is a frame type construction. Figure 1 depicts the internal layout of the unit and the location of the major

components.

ELECTRIC BOX

HEAT EXCHANGERS

(EVAPORATORS)

HEAT EXCHANGERS

(CONDENSERS- NOTE 1)

RECEIVERS

(BEHIND COMPRESSORS)

SCROLL COMPRESSORS

NOTE 1: PROVIDED WITH

WATER/GLYCOL COOLED UNITS.

Figure 1- Typical Layout

1.2.3.1 Electric Box Access

The electrical components are protected behind dual

hinged access doors located on the left side of the

unit. The access doors are safety interlocked with the

service disconnect switch preventing the doors from

opening when the switch in the “On” position. The

switch must be turned “Off” to gain access to the

electrical components.

1.2.3.2 Circuit Breakers/ Motor Start Protectors

Individual overload protection is provided by circuit

breaker(s) and motor start protectors. These switches

must be manually re-set once the overload condition is

cleared.

1.2.3.3 Pumps

Multi-stage centrifugal pumps are located in the right

side of the unit to circulate the coolant through the

system. A hinged access door is located on the right

side of the unit. This door may be opened to gain

access to the pump section.

AIR VENT

AIR SEPARATOR

EXPANSION TANK

(BEHIND PUMP #2)

PUMP #2

(OPTIONAL)

PUMP #1

1.2.3.4 Expansion T ank

An expansion tank has been provided on the chilled

water side of the unit to compensate for thermal

expansion of the coolant. An air vent is mounted on

top of the fluid separator .

1.2.3.5 Heat Exchangers

Constructed of 316 stainless steel with brazed plate fin

construction, the evaporator heat exchangers are for

the exchange of heat from the process water/glycol

coolant to the refrigerant.

1.2.3.6 Receivers

Receivers are provided for each refrigeration circuit for

storage of excess refrigerant in the refrigeration cycle.

1.2.3.7 Compressors

The compressors used in this unit are scroll compressors mounted inside the unit on vibration absorbers to

eliminate noise and vibration during operation. The

scroll compressor is designed around two identical

spirals or scrolls that, when inserted together, form

crescent shaped pockets. During a compression

1-2

(©October, 2006)

CyberChiller Series Installation, Operation & Maintenance Manual

cycle, one scroll remains stationary while the other

scroll orbits around the first. As this motion occurs,

gas is drawn into the scrolls and moved in increasingly

smaller pockets toward the center . At this point, the

gas, now compressed to a high pressure, is discharged from a port in the center if the fixed scroll.

During each orbit, several pockets of gas are compressed simultaneously , creating smooth, nearly

continuous compression.

Due to the design of the scroll compressor, the internal

compression components always start unloaded even

if the system pressures are not balanced. In addition,

since internal compressor pressures are always

balanced at start-up, low voltage starting characteristics are excellent for scroll compressors

With fewer moving parts, the

scroll compressor sets the

industry standard for reliability among one and a half to

twelve horsepower compressors. The compressor’s

simple design and proven

day-to-day performance

means less maintenance

calls for field personnel.

The scroll compressor has

demonstrated superior

durability . Its axial and radial

compliance make the scroll

compressor more tolerant to liquid refrigerant and

debris - two of the most common causes of system

failure.

The scroll compressor is quiet, but not silent. On

average, the compressor is up to five decibels quieter

than standard piston compressors. A scroll compressor, however , has different sound characteristics from

reciprocating compressors. These sounds do not

affect system reliability or performance.

Upon shut-down of a normal run cycle, the compressor

will run backwards for one or two seconds as the

scrolls internal pressures are equalized. A short

reverse rotation “burp” will result. This sound is normal.

A check valve in the discharge tube of the compressor

prevents the compressor from running backwards for

more than a second or two. This normal direction

reversal of the scrolls at shut down has no effect on

compressor reliability .

Each scroll compressor comes equipped with a

crankcase heater, used to evaporate any liquid that

may have migrated to the compressor during extended

periods on non-operation (>12 hours). The crankcase

heaters are equipped with over current protection.

CAUTION

Prior to initial start-up (only when main power

has been disconnected for 12 hours or longer),

allow at least ten (10) minutes (two (2) hours is

recommended) with main power reconnected.

This will allow sufficient time for the crankcase

heaters to evaporate any liquid that may have

migrated to the compressor crankcase. When

this procedure is completed, the CyberChiller is

ready to be run.

Automatic, staged starting of the compressors is

provided to prevent an in rush of current to the

CyberChiller. High and low pressure safety switches

prevent operation of the compressor during high or low

pressure conditions.

1.2.3.8 Strainer

A “Y” strainer is included to remove any debris that

may be circulated to the chiller.

1.2.4 Safety Features

Low and high-pressure switches are provided for each

refrigeration circuit. The pressure switches are nonadjustable encapsulated control switches. If a high

pressure switch is tripped for any reason, it must be

manually reset. The cause for tripping of the high

pressure switch must be determined. The low pressure

switches are reset automatically . These pressure

switches are installed as safety devices and will help

prevent compressor failure or other serious damage to

the system.

A flow switch is provided which will disable the refrigeration circuits if the coolant flow drops below a preset limit.

A blocked flow bypass valve is recommended for field

installation to ensure proper return flow to the chiller at

all times.

Manual reset circuit breakers will open to de-energize

a failed component if electrical overload conditions are

encountered.

(©October, 2006)

1-3

CyberChiller Series Installation, Operation & Maintenance Manual

1.3 Product Warranty

SA TS offers a two year standard limited warranty as st ated below. Additionally an extended warranty may be

purchased on the unit's compressors. Consult the factory to verify if the extended compressor warranty was

purchased for your system. The compressor warranty as stated on the next page will be sent with your unit and

should be retained for future reference.

2-Year S tandard Limited Warranty:

Stulz Air Technology Systems, Inc., warrant s to the original buyer of it s

products that the goods are free from defects in material and workmanship.

Stulz Air Technology Systems, Inc.’s obligation under this warranty is to

repair or replace, at its option, free of charge to the customer , any part or

parts which are determined by S tulz Air Technology Systems Inc. to be

defective. The warranty is in effect for 24 months from date of shipment if a

completed Warranty Registration and S t art Up Form is submitted to S tulz Air

T echnology Systems, Inc. within 90 days from shipment. In the event that a

completed start-up form is not received by S tulz Air Technology Systems, Inc.

within 90 days from shipment, the company’s obligation will be for a period of

12 months from date of shipment. Parts replaced under warranty are warranted for a period of 90 days from shipment or for the remainder of the unit

warranty period, whichever is greater.

Stulz Air Technology Systems, Inc.’s warranty does not cover failures caused

by improper installation, abuse, misuse, misapplication, improper or lack of

maintenance, negligence, accident, normal deterioration including wear and tear,

or the use of improper parts or improper repair as determined by SATS. This

warranty does not include costs for transportation, costs for removal or reinstallation of equipment or labor for repairs or replacement made in the field.

THIS OBLIGA TION AND LIABILITY OF STULZ AIR TECHNOLOGY SYSTEMS, INC. UNDER THIS WARRANTY DOES NOT INCLUDE LOSSES,

DIRECT OR INDIRECT , FOR INCIDENT AL OR CONSEQUENTIAL DAMAGES. THIS WARRANY IS IN LIEU OF ALL OTHER W ARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WARRANTIES OR MERCHANT ABILITY AND FITNESS FOR A P ARTICULAR PURPOSE, AND THERE ARE NO

WARRANTIES THA T EXTEND BEYOND THE DESCRIPTION ON THE F ACE

HEREOF.

1-4

(©October, 2006)

CyberChiller Series Installation, Operation & Maintenance Manual

Optional Limited Extended Warranty (5 Y ears T otal)

Stulz Air Technology Systems, Inc., warrants to the original buyer of its product that

the compressor(s) listed below are warranted for parts replacement (not including

labor) for extended period of 4 years from the date of expiration of the standard

equipment warranty.

Stulz Air Technology Systems' warranty does not cover failures caused by improper

installation, abuse, misuse, misapplication, improper or lack of maintenance, negligence, accident, normal deterioration including normal wear and tear, or the use of

improper parts or improper repair as determined by SA TS.

This warranty does not include costs of transportation, cost for removal or reinstallation

of equipment or labor for repairs or replacement made in the field.

The obligation and liability of Stulz Air Technology Systems under this warranty does

not include losses, direct or indirect, for incidental or consequential damages.

Compressor Serial No.: __________________________________

Unit Model No.: __________________________________

Unit Serial No.: __________________________________

Stulz Air T echnology Systems Job No.: __________________________________

End User: __________________________________

Date: __________________________________

(©October, 2006)

1-5

CyberChiller Series Installation, Operation & Maintenance Manual

1.4 Safety

1.4.1 General

Stulz Air Technology Systems, Inc. uses NOTES

along with CAUTION and WARNING symbols through-

out this manual to draw your attention to important

operational and safety information.

A bold text NOTE marks a short message in the

information to alert you to an important detail.

A bold text CAUTION safety alert appears with

information that is important for protecting your

equipment and performance. Be especially careful to

read and follow all cautions that apply to your application.

A bold text WARNING safety alert appears with

information that is important for protecting you from

harm and the equipment from damage. Pay very

close attention to all warnings that apply to your

application.

A safety alert symbol

WARNING or CAUTION safety statement.

A safety alert symbol accompanies an electrical

shock hazard WARNING or CAUTION safety state-

ment.

accompanies a general

1.4.2 Safety Summary

The following statements are general guidelines

followed by warnings and cautions applicable

throughout the manual.

Prior to performing any installation, operation, maintenance or troubleshooting procedure read and understand all instructions, recommendations and guidelines contained within this manual.

CAUTION

All maintenance and/or repairs must be performed by a journeyman, refrigeration mechanic

or an air conditioning technician.

CAUTION

Never lift any component in excess of 35 pounds

without help. If a lifting device is used to move a

unit ensure it is capable of supporting the unit.

CAUTION

Do not allow the unit to swing while suspended

from a lifting device. Failure to observe this warning may result in injury to personnel and damage to the equipment.

CAUTION

Do not allow anyone under the equipment suspended from a lifting sling.

W ARNING

High voltage is used in the operation of this

equipment. Death on contact may result if

personnel fail to observe safety precautions.

CAUTION

When working on electrical equipment, remove

all jewelry , watches, rings, etc. Keep one hand

away from the equipment to reduce the hazard

of current flowing through vital organs of the body .

CAUTION

Always disconnect the main power supply to

the equipment at the main power disconnect

switch before beginning work on the equipment.

A lock-out tag-out procedure should be followed

to ensure that power is not inadvertently reconnected.

CAUTION

Equipment may contain components subject to

Electrostatic Discharge (ESD). Before attempting to mount or service these electronic devices,

ensure you have no charge built up by touching

a ground source. When possible, use a wristgrounding strap when working on or near electronic devices.

CAUTION

Never work on electrical equipment unless another person who is familiar with the operation

and hazards of the equipment and competent in

administering first aid is nearby .

1-6

(©October, 2006)

CyberChiller Series Installation, Operation & Maintenance Manual

CAUTION

All personnel working on or near equipment

should be familiar with hazards associated with

electrical maintenance. Safety placards/stickers have been placed on the unit to call attention to all personal and equipment damage hazard areas.

CAUTION

Ensure the unit is properly phased. Improper

phasing can cause severe damage to the compressor.

W ARNING

Refrigerant (R-22 or R-407C) is used with this

equipment. Death or serious injury may result if

personnel fail to observe proper safety precautions. Great care must be exercised to prevent

contact of liquid refrigerant or refrigerant gas, discharged under pressure, with any part of the

body . The extremely low temperature resulting

from the rapid expansion of liquid refrigerant or

pressurized gas can cause sudden and irreversible tissue damage.

As a minimum, all personnel should wear thermal protective gloves and face-shield/goggles

when working with refrigerant. Application of excessive heat to any component will cause extreme pressure and may result in a rupture.

Exposure of refrigerant to an open flame or a

very hot surface will cause a chemical reaction

that will form carbonyl chloride (hydrochloric/hydrofluoric acid); a highly poisonous and corrosive gas commonly referred to as PHOSGENE.

In its natural state, refrigerant is a colorless, odorless vapor with no toxic characteristics. It is

heavier than air and will disperse rapidly in a

well-ventilated area. In an unventilated area, it

presents a danger as a suffocant.

Always refer to the manufacturer's MSDS provided with the unit.

W ARNING

Avoid skin contact or inhaling fumes from any

acid formed by burn out of oil and refrigerant.

Wear gas mask if area is not thoroughly ventilated. Wear protective goggles or glasses to

protect eyes. Wear rubber gloves to protect

hands. Use care to avoid spilling compressor

burnout sludge. If sludge is spilled , clean area

thoroughly.

W ARNING

When performing soldering or desoldering operations, make certain the refrigeration system

is fully recovered and purged and dry nitrogen is

flowing through the system at the rate of not

less than 1-2 CFM (.03 - .06 M³/minute).

CAUTION

Certain maintenance or cleaning procedures

may call for the use and handling of chemicals,

solvents, or cleansers. Always refer to the

manufacturer's Material Safety Data Sheet

(MSDS) prior to using these materials. Clean

parts in a well-ventilated area. Avoid inhalation

of solvent fumes and prolonged exposure of skin

to cleaning solvents. Wash exposed skin thoroughly after contact with solvents.

CAUTION

Do not use cleaning solvents near open flame or

excessive heat. Wear eye protection when blowing solvent from parts. The pressure-wash should

not exceed 30 psig. Solvent solutions should be

disposed of in accordance with local and state

regulatory statutes.

CAUTION

Units must be kept in its normal installed position. If the unit is not kept level and vertical,

damage to the unit's compressors will result.

(©October, 2006)

1-7

CyberChiller Series Installation, Operation & Maintenance Manual

2.0 INSTALLATION

2.1 Receiving the Equipment

Your CyberChiller system has been tested and

inspected prior to shipment. T o ensure that your

equipment has been received in excellent condition,

make a visual inspection of the equipment immediately upon delivery . Carefully remove the shipping

container and all protective packaging. Open the

access doors and thoroughly inspect the unit interior

for any signs of transit-incurred damage. If there is

shipping damage, it must be noted on the freight

carrier's delivery forms BEFORE signing for the

equipment. Any freight claims MUST be done through

the freight carrier. SATS ships all equipment FOB

factory . SA TS is not liable for any equipment damage

while in transit. SA TS can assist in the claim filing

process with the freight carrier. Should any such

damage be present, notify the SA TS Product Support

Group prior to attempting any repairs. Refer to section

five of this manual for instructions.

Check the equipment against the packing slip to see if

the shipment is complete. Report all discrepancies to

appropriate authority .

A Data Package has been sent with your unit. It

contains this manual, a supplemental microprocessor

controller manual, system drawings, applicable

MSDS’s, other component manuals, warranty registration and other applicable instructions based on the

configuration and options of your unit. The data

package has been placed in your unit in a clear plastic

envelope. These documents need to be kept with the

unit for future reference.

NOTE

Working clearance requirements need to be established prior to the mounting of the unit. Refer

to local and national electrical codes.

2.3 Rigging

The CyberChiller systems are designed to be kept in

the vertical position. Move the unit with a suitable

device such as a forklift, pallet jack or roller bar and

dollies. Weight tables are provided on the installation

drawings. Units are shipped on a skid to facilitate

moving prior to installation. Units should always be

stored indoors in a dry location prior to installation.

CAUTION

Units must be kept level and in the vertical position when lifting to prevent damage to the unit.

2.4 Mounting/Placement

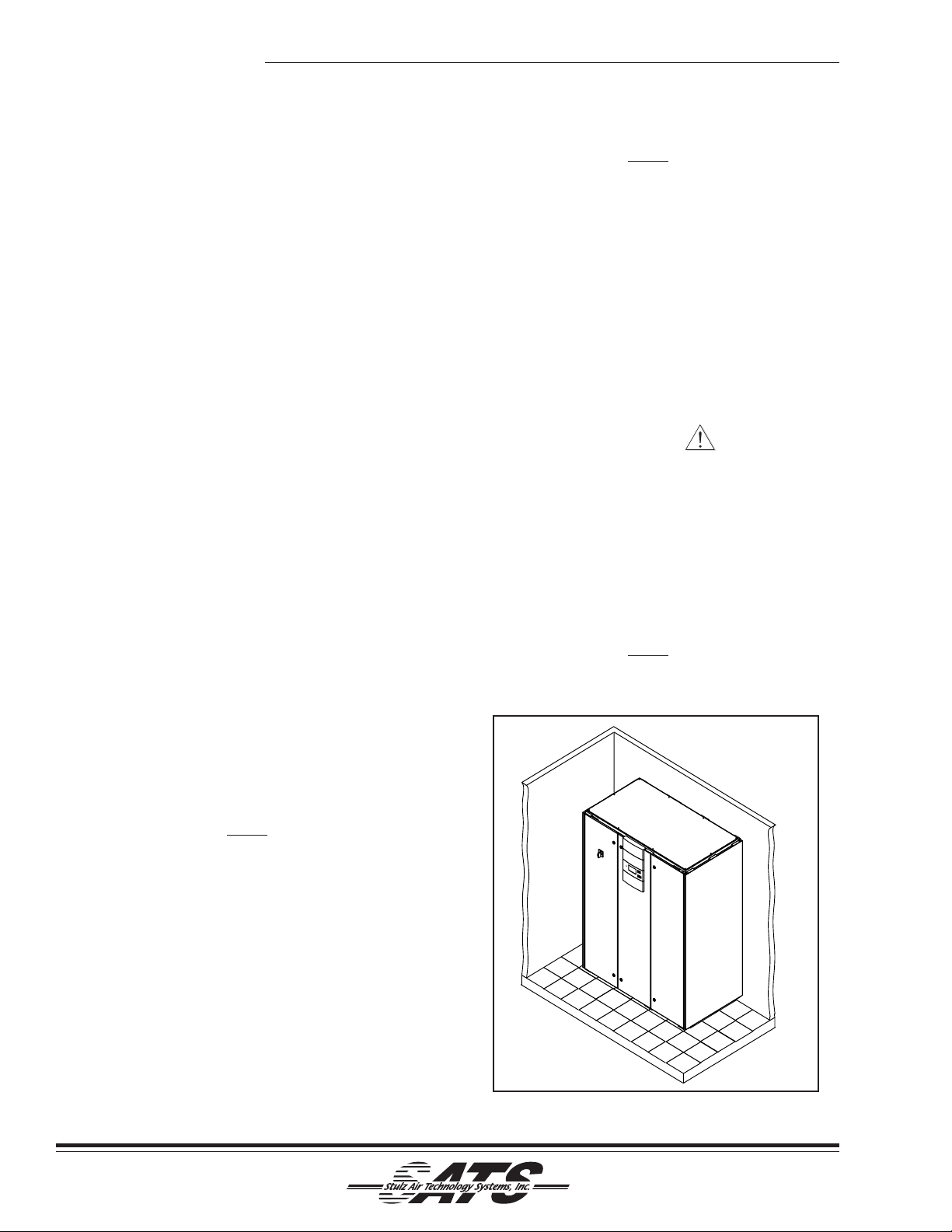

Position unit in the desired location. CyberChiller

systems are 100% front accessible, which allows the

units to be placed in a corner or between cabinetry .

(See Figure 2.)

NOTE

Allow access to the unit for routine operation,

servicing and for necessary maintenance.

NOTE

Items that have been shipped loose, such as

controllers, temperature sensors, water detectors, etc., are shipped inside the air conditioner

unless specified otherwise by the customer.

Unpack and store these items in a safe place

unless you are using them immediately .

2.2 Site Preparation

CyberChiller systems are designed with easy service

access in mind. Component access doors are located

on the front of the unit.

In order to have full service access through the front,

no permanent obstructions should be placed within 40

inches of the front of unit.

2-1

Figure 2- Typical Installation

(©October, 2006)

Loading...

Loading...