查询TK5552 供应商

Read/Write Transponder

Description

The TK5552 is a complete programmable R/W

transponder which implements all important functions

for identification systems. It allows the contactless

reading (uplink) and writing (downlink) of data which are

transmitted bidirectionally between a read/ write

basestation and the transponder. It is a plastic-cube device

which accomodates the IDIC *) T ransponder IC and also

the antenna realized as an LC-circuit. No additional

external power supply is necessary for the transponder

because it receives power from the RF field generated by

Features

D Contactless read/write data transmission

TK5552

the base station. Data are transmitted by modulating the

amplitude of the RF field (uplink mode). The TK5552 can

be used to adjust and modify the ID-code or any other

stored data, e.g. rolling code systems. The on-chip

1056-Bit EEPROM (32 blocks, 33 bits per block) can be

read (uplink) and written (downlink) blockwise from the

base station. The blocks can be protected against

overwriting. One block is reserved for setting the

operation modes of the IC.

D Write protection by lock bits

D 992-bit EEPROM user programmable in 31 blocks

32 bits

D Inductive coupled power supply at 125 kHz

D Basic component: R/W IDIC

D Built-in coil and capacitor for circuit antenna

D Starts with cyclical data read out

D Typical < 50 ms to write and verify a block

D Modulation defeat (for EAS)

D Direct access to each block

D Configurable POR delay

Transponder IC

RF field

Power

Data

D Malprogramming protection

D Configurable options:

Bitrate [bit/s]: RF/16 and RF/32

Modulation: Manchester

POR delay: 1 ms / 65 ms

Max. block: 0, 1, 1 to 2, 1 to 3,

1 to 4, .... 1 to 31

Application

D Industrial asset management

D Process control and automation

D Installation and medical equipment

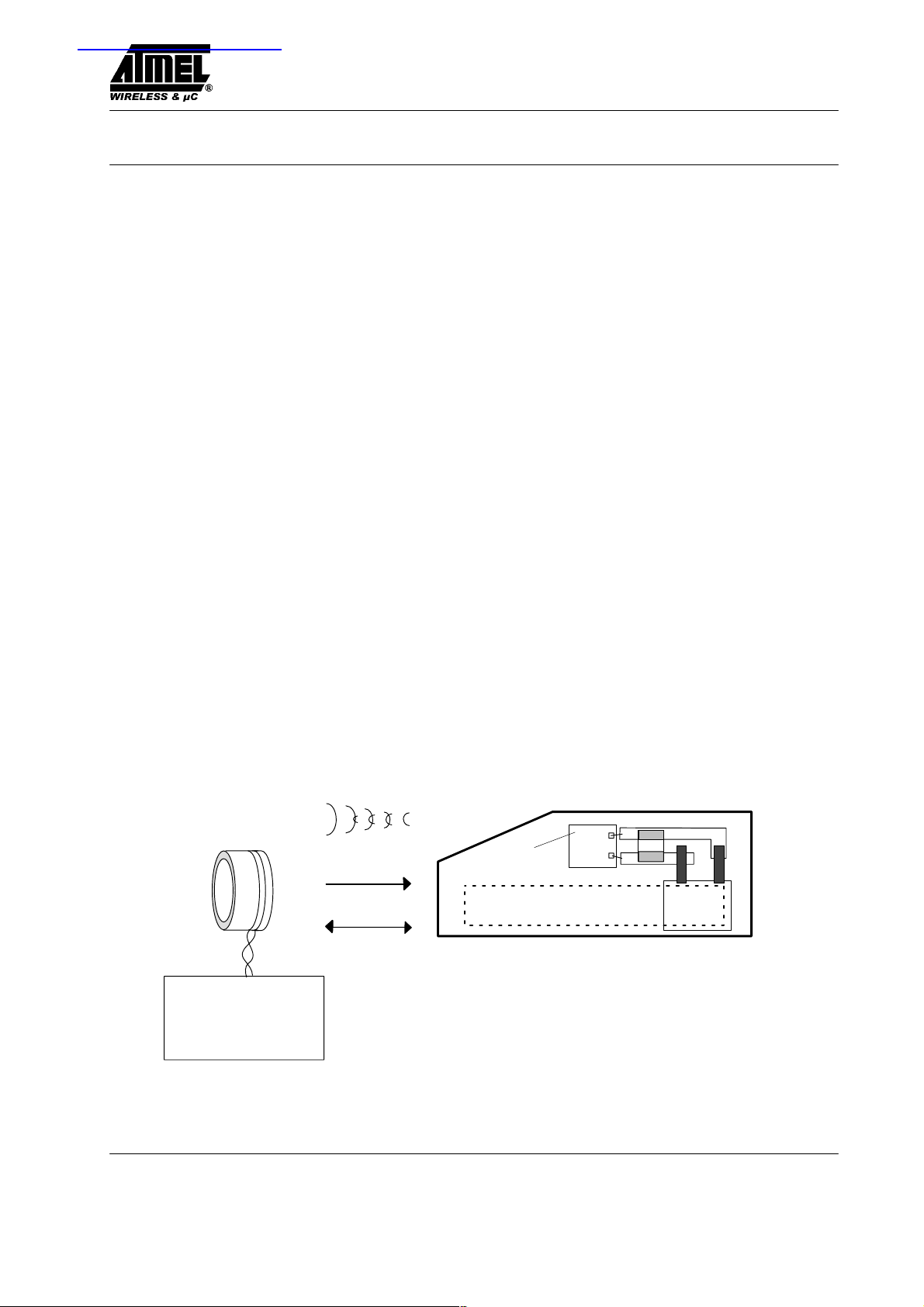

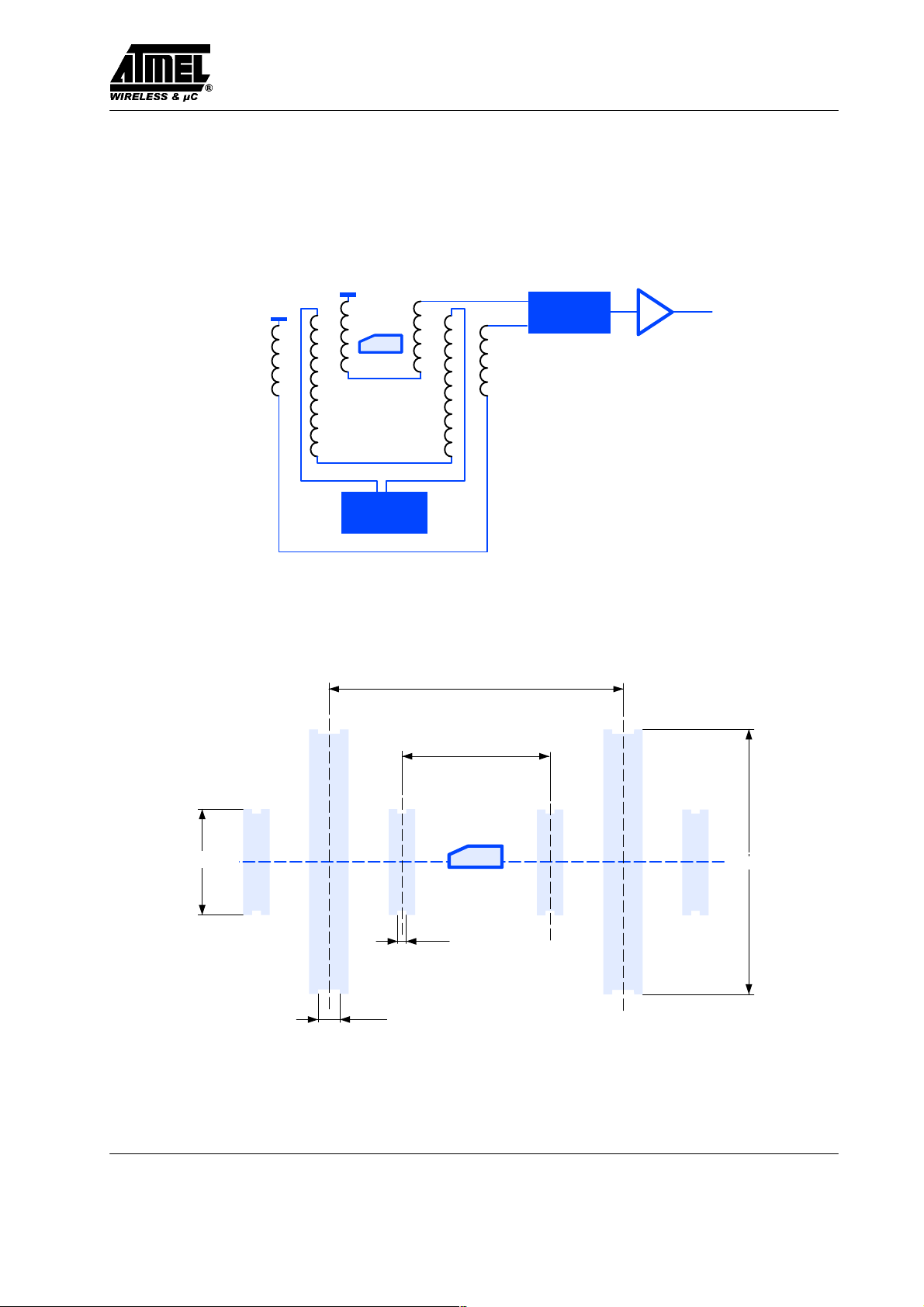

T ransponder TK5552

Transponder IC + coil + C in plastic cube

C

Transponder IC

Coil

Base station

*)

IDIC stands for IDentification Integrated Circuit and is a trademark of Atmel Wireless & Microcontrollers.

Rev. A5, 04-Oct-00 1 (20)

**)

**) for short distance U2270 B read/ write IC with MARC4 (see figure 12)

Figure 1. Transponder and base station

Preliminary Information

TK5552

Ordering Information

Extended Type Number Package Remarks

TK5552A–PP Plastic cube All kind of modulation; RF/16 and RF/32 *)

Default programmed: Manchester Modulation, RF/16,

MAXBLK = 1 to 31

*) see data sheet Transponder IC in the appendix

General

The transponder is the mobile part of the closed coupled

identification system (see figure 1), whereas the

read/ write base station is basing on the U2270B or other

solutions, and the read/ write transponder is basing on the

IDIC Transponder IC.

The transponder is a plastic-cube device consisting of

following parts:

D The transponder antenna, realized as tuned LC-circuit

D Read/ write IDIC (Transponder IC) with EEPROM

The Transponder Antenna

The antenna consists of a coil and a capacitor for tuning

the circuit to the nominal carrier frequency of 125 kHz.

The coil has a ferrite core for improving the distance of

read (uplink) and write (downlink) operations.

The Read/ Write IDIC

The read/ write IDIC Transponder IC is part of the transponder TK5552. The data are transmitted bidirectionally

between the base station and the transponder. The transponder receives power via a single coil from the RF signal

generated by the base station. The single coil is connected

to the chip and also serves as the IC’s bidirectional communication interface.

Data are transmitted by modulating the amplitude of the

RF signal. Reading (uplink) occurs by damping the coil

by an internal load. Writing (downlink) occurs by

interrupting the RF field in a specific way. The TK5552

transponder operates at a nominal frequency of 125 kHz.

There are different bit rates and encoding schemes.

The on-chip 1056-bit EEPROM (32 block, 33 bits each)

can be read (uplink) and written (downlink) blockwise

from the base station. The blocks can be protected against

overwriting by using lock bits. One block is reserved for

setting the operation modes of the IC.

See Transponder IC data sheet in the appendix for more

detailed information of IDIC .

2 (20)

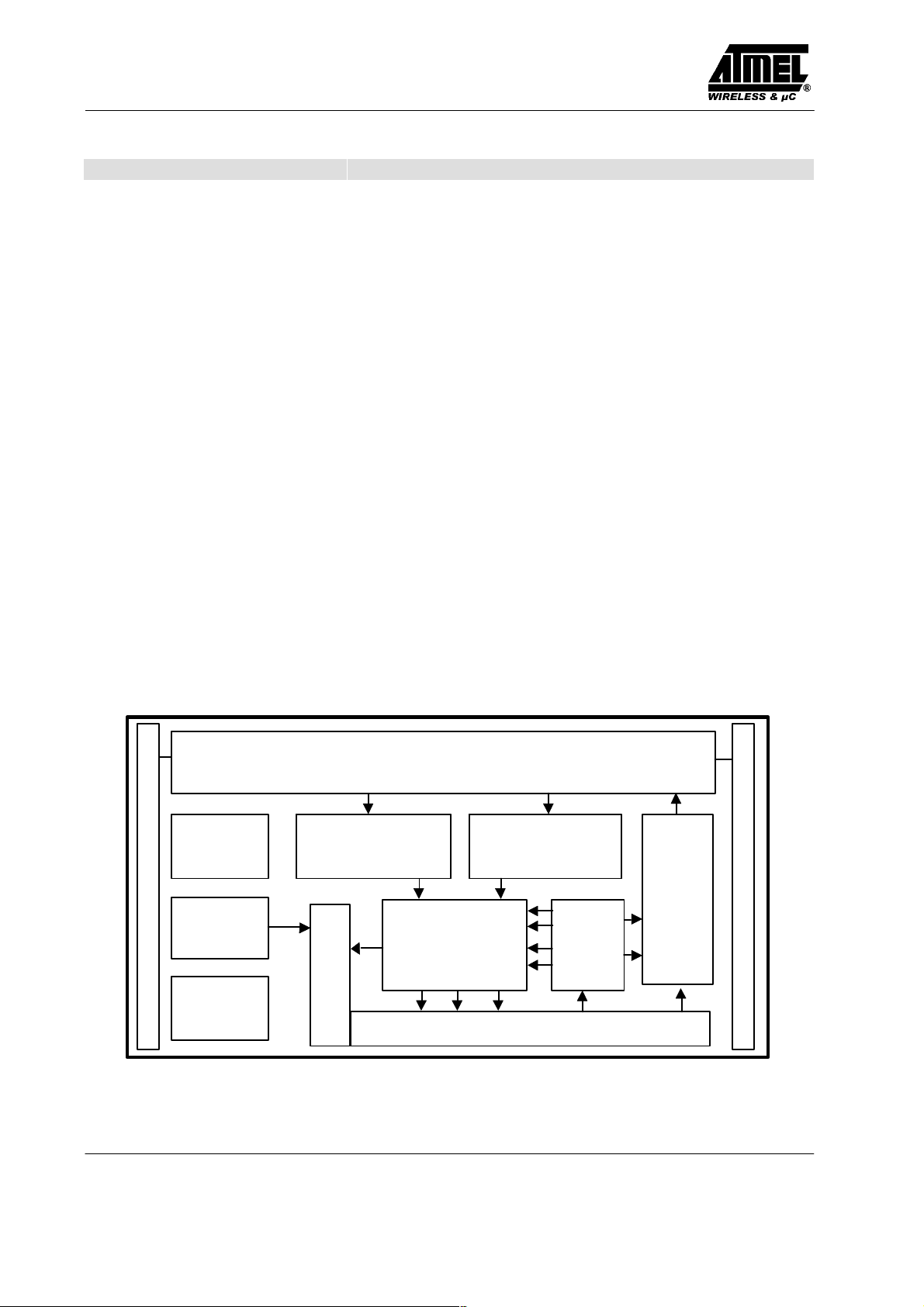

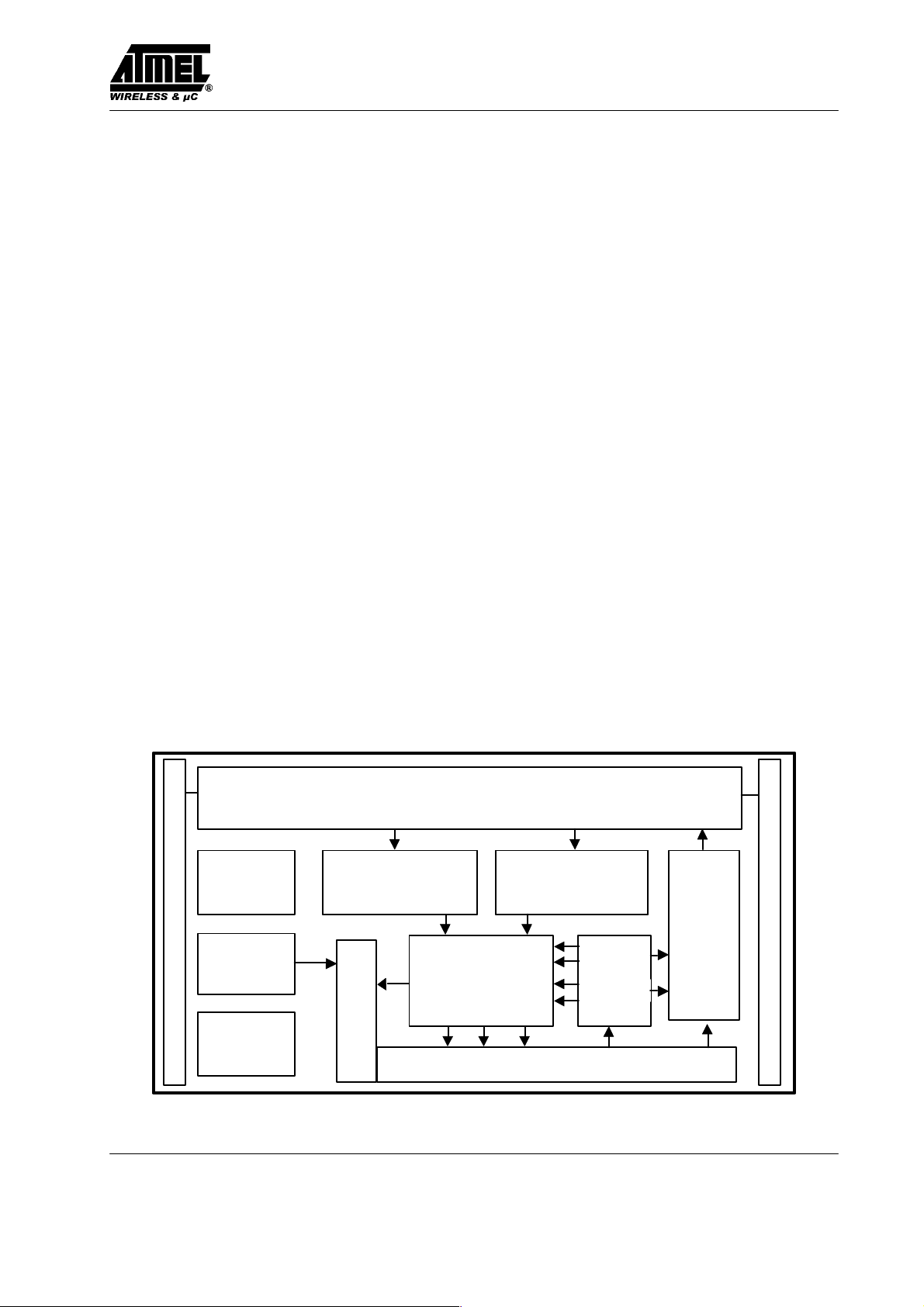

POR Bit decoderBit rate generator

Charge

Clock-A

pump

Start-up

delay

Analog front end

(rectifier, regulator, clock extractor, ESD protection)

Mode

Controller

Input register

Figure 2. Block diagram Transponder IC

EEPROM memory

register

Modulator

Rev. A5, 04-Oct-00

Clock-B

Preliminary Information

TK5552

Absolute Maximum Ratings

Parameters Symbol Value Unit

Operating temperature range T

Storage temperature range T

Maximum assembly temperature, t < 5 min. T

Magnetic field strength at 125 kHz H

amb

stg

ass

pp

Operating Characteristics Transponder

T

=

amb

25°C, f = 125 kHz Rf/32 and Manchester if not otherwise noted

Parameters Test Conditions Symbol Min. Typ. Max. Unit

Inductance L 4 mH

Resonance frequency LC circuit, HPP = 12 A/m f

Magnetic field strength (H)

Parameters Test Conditions Symbol Min. Typ. Max. Unit

Max. field strength where

tag does not modulate

Minimum field strength

Uplink/ downlink mode H

Programming mode H

Data retention EEPROM t

Programming cycles

EEPROM

Maximum field strength H

No influence to other tags

in the field

r

H

pp not

pp 25

pp 25

retention

pp max

119 125 131 kHz

100,000

–25 to +75 °C

–40 to +125 °C

170 °C

1000 A/m

4 A/m

12 A/m

18 A/m

10 Years

600 A/m

Rev. A5, 04-Oct-00 3 (20)

Preliminary Information

TK5552

4

3

2

1

0

–1

–2

–3

TK of resonance frequency ( % )

–4

–30–20 –100 1020304050607080

Temperature ( °C )

V2V1

V1 * V2

m +

V1 ) V2

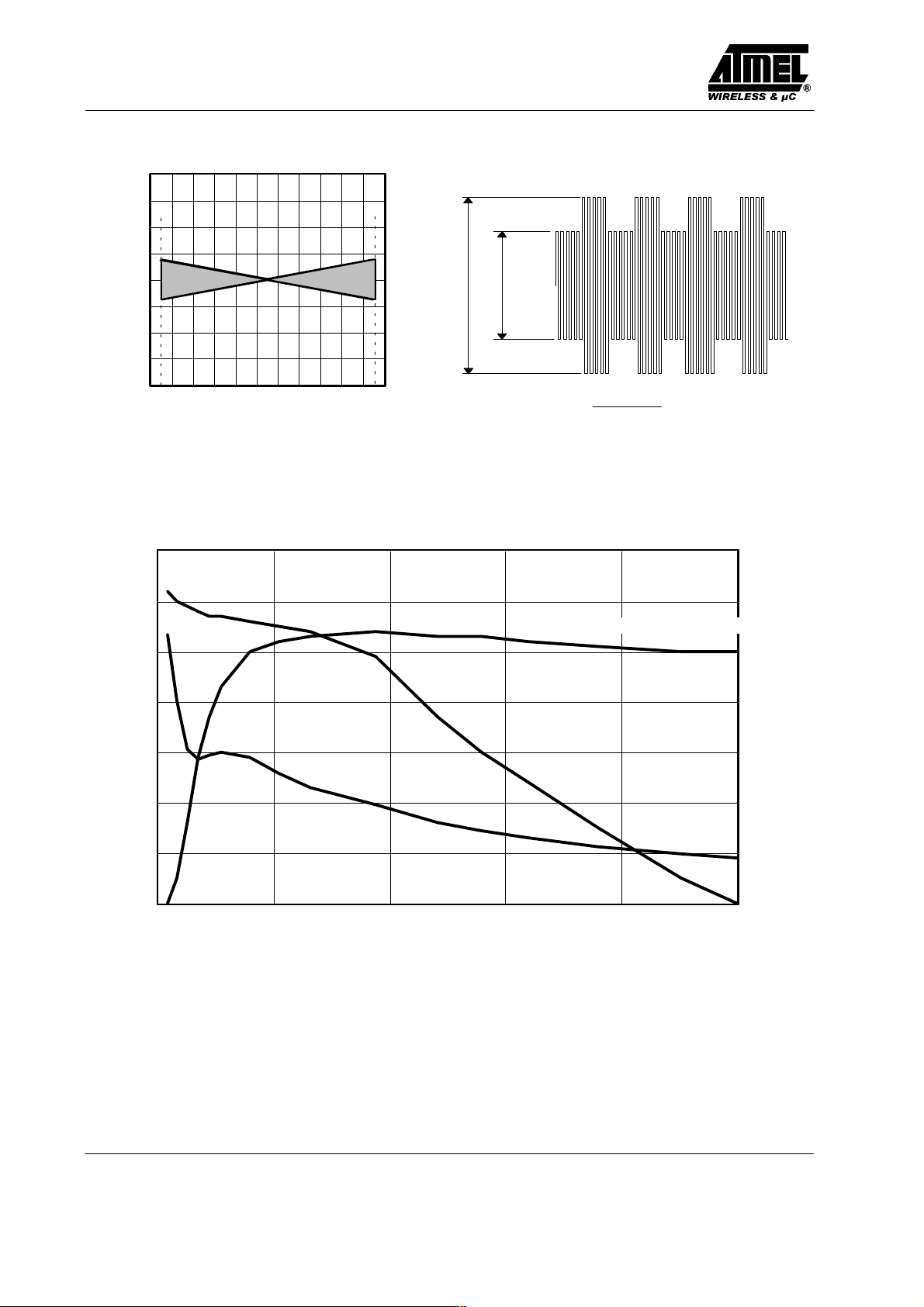

Figure 3. Typical TK-range of resonance frequency

0.7

0.6

0.5

0.4

m ( 1 )

0.3

0.2

0.1

0.0

0 25 50 75 100 125

Quality factor (Q)

Hpp ( A/m)

Figure 4. Degree of modulation measurement

Degree of modulation (m)

Resonant frequency

127

126

125

124

123

122

121

120

35

30

25

20

Q ( 1 )

fres (kHz)

15

10

5

0

4 (20)

Figure 5. Typical behaviour of resonant frequency, degree of modulation and quality factor versus field strength

(by Rf/ 32, Manchester )

Rev. A5, 04-Oct-00

Preliminary Information

Measurement Assembly

All parameters are measured in a Helmholtz-arrangement, which generates a homogenous magnetic field (see

figure 6 and 7). A function generator drives the field

SENSING COILS ( IN PHASE )

TK5552

REFERENCE COIL

( IN PHASE )

FIELD GENERATING

COILS ( IN PHASE )

FUNCTION

GENERATOR

TK5552

generating coils, so the magnetic field can be varied in

frequency and field strength.

SUBTRACTOR

REFERENCE COIL ( IN PHASE )

AMPLIFIER

1:10

OUTPUT

VOLTAGE

24mm

REFERENCE COIL

Figure 6. Testing application

SENSING COIL

5mm

FIELD GENERATING COIL

TK5552

2mm

30mm

15mm

60mm

REFERENCE COIL

SENSING COIL

FIELD GENERATING COIL

Figure 7. Testing geometry

Rev. A5, 04-Oct-00 5 (20)

Preliminary Information

TK5552

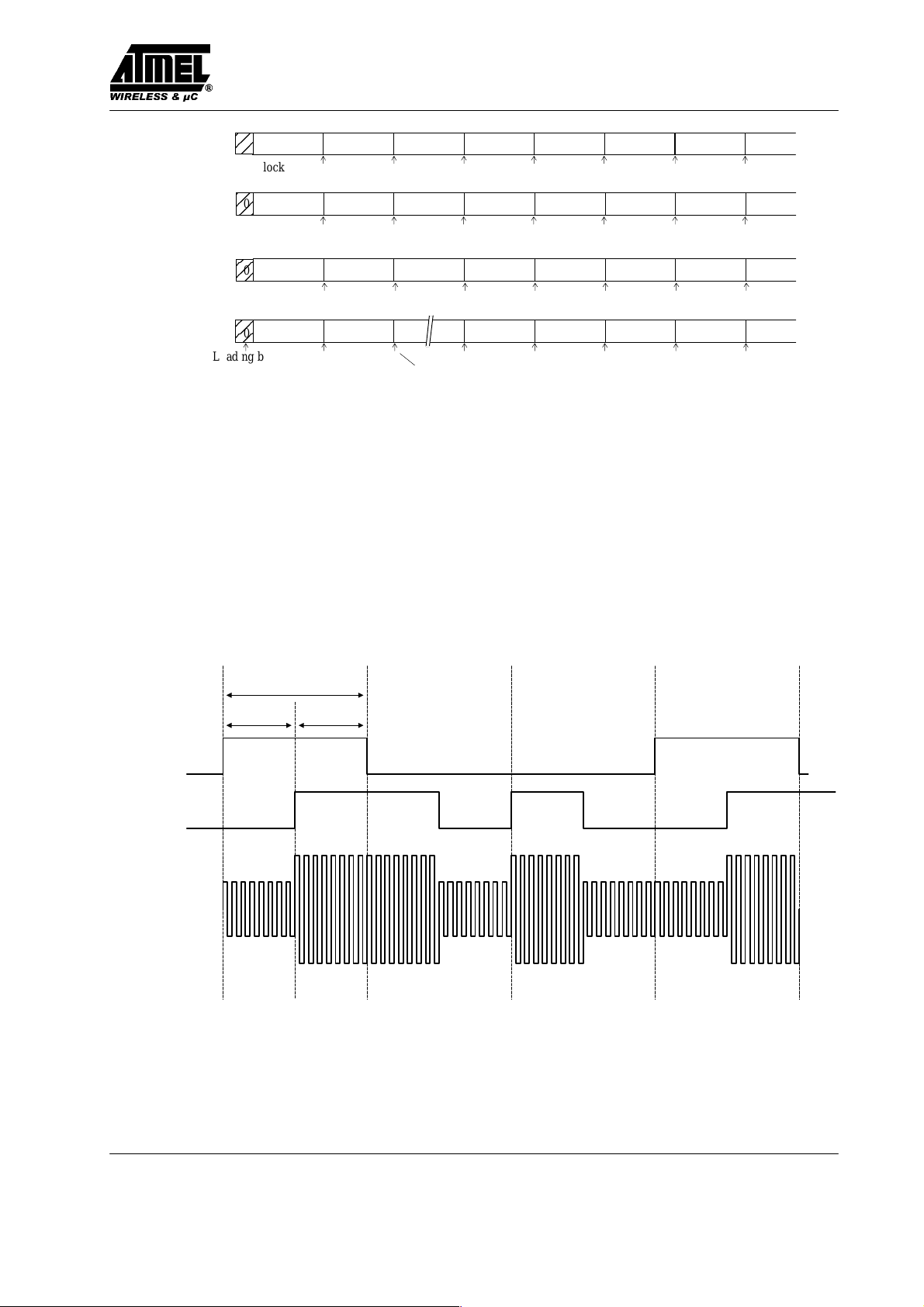

Downlink Operation

The write sequence (downlink mode) of the TK5552 is

shown below. Writing data into the transponder occurs by

interrupting the RF field with short gaps. After the start

gap the standard OP-code (11) is followed by the lockbit.

The next 32 bits contain the actual data. The last 5 bits

denote the destination block address. If the correct

number of bits have been received, the actual data is

programmed into the specified memory block.

RF field

Uplink mode Downlink mode

Standard OP–code

Start gap

Lock

bit

32 bit

01

Figure 8. Downlink protocol

Address bits (e.g. block 16)

01

0

0

> 64 clocks1 0

6 (20)

Figure 9. Explanation of the programming cycle

Rev. A5, 04-Oct-00

Preliminary Information

Downlink Data Decoding

The time elapsing between two detected gaps is used to

encode the information. As soon as a gap is detected, a

counter starts counting the number of field clock cycles

until the next gap will be detected. Depending on how

many field clocks elapse, the data is regarded as ’0’ or ’1’.

The required number of field clocks is shown in figure 10.

TK5552

A valid ’0’ is assumed if the number of counted clock

periods is between 16 and 32, for a valid ’1’ it is 48 or 64

respectively. If the data transmission was correct, programming is started and in case of success the written

block is cycling his data back to the base station until

POR.

Field clock cycles

Downlink data decoder

1 16324864

Fail 0 Fail 1 Downlink done

Figure 10. Downlink data decoding scheme

Behavior of the Real Device

The TK5552 detects a gap if the voltage across the coils

decreases below a threshold value of an internal MOS

transistor. Until then, the clock pulses are counted. The

number given for a valid ’0’ or ’1’ (see figure 10) refers

to the actual clock pulses counted by the device. However, there are always more clock pulses being counted

than were applied by the base station. The reason for this

is the fact that an RF field cannot be switched off immediately. The coil voltage decreases exponentially. So

although the RF field coming from the base station is

switched off, it takes some time until the voltage across

the coils reaches the threshold value of an internal MOS

transistor and the device detects the gap.

t

Coil

voltage

t

1

gap

t

0

01

1

12445

Referring to the following diagram (figure 11), this

means that the device uses the times t

0 internal

and t1

internal

The exact times for t0 and t1 are dependent on the application (e.g., field strength, etc.)

Typical time frames are:

t0 = 70 to 150 ms

t1 = 300 to 400 ms

t

= 180 to 400 ms

gap

Antennas with a high Q-factor require longer times for

t

and shorter time values for t0 and t1.

gap

t

Coil

t

1

gap

t

0

voltage

1 0

1

.

t

0 internal

12446

Gap detect

Ideal behavior

RF level reduces to zero immediately

Figure 11. Ideal and real behavior signals

Gap detect

t

1 internal

Real behavior

RF level decreases exponentially

Operating Distance

The maximum distance between the base station and the

TK5552 depends mainly on the base station, the coil

geometries and the modulation options chosen (see

U2270B Antenna Design Hints and the U2270B data

sheet). When using the Atmel Wireless & Microcontrollers U2270B demo board, the typical distances in the

range of 0 to 5 cm can be achieved. Maximum distance

Rev. A5, 04-Oct-00 7 (20)

values which are generally valid can not be given in this

data sheet. The exact measuring of the maximum distance

should be carried out with the TK5552 being integrated

into the specific application.

For longer distance used in industrial applications, please

use specific solutions like two or more reader coils.

Preliminary Information

TK5552

Application

V

31

470 kW

47 nF

1.5 nF

Power

Transponder IC

Transponder

22 mF

4.7 kW

1N4148

1.35 mH

TK5552

680 pF

1.2 nF

R

Data

V

V

Batt

DV

S

Input

COIL2

COIL1

DGND GND

EXTVS

U2270B

Standby

Read/write

circuit

f

Output

res

RF

MS

CFE

OE

Gain

+

100 nF

1

Ǹ

2p LC

110 kW

+

BP00

BP01

BP02

BP03

BP10

125 kHz

5 V

V

DD

M44C260

osc OUT

Micro-

controller

V

SS

osc IN

32 kHz

12456

Figure 12. Complete transponder system with the read/write base station IC U2270B

(only Manchester code, short distance)

8 (20)

Rev. A5, 04-Oct-00

Preliminary Information

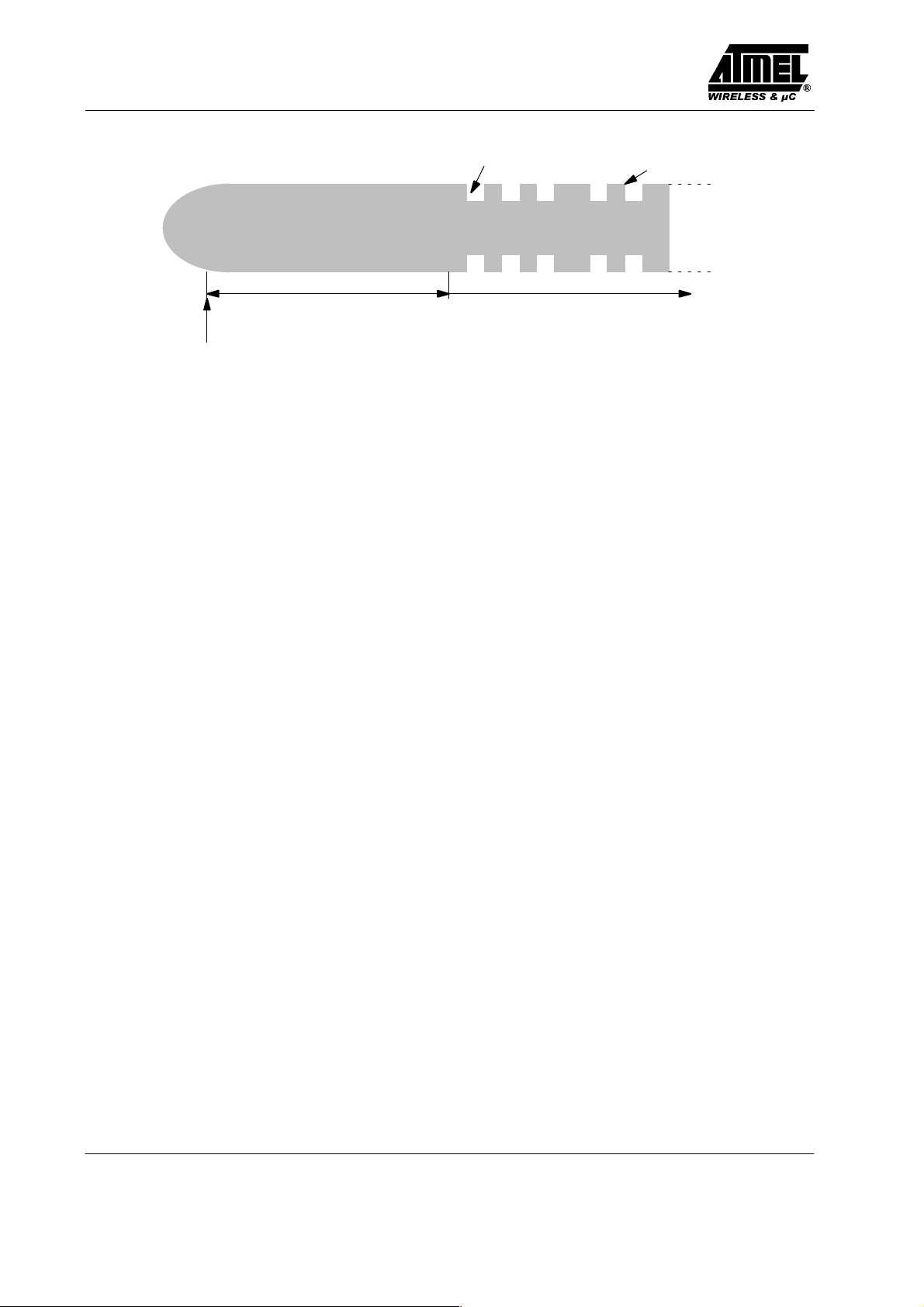

Package Information

Dimensions in mm

TK5552

Rev. A5, 04-Oct-00 9 (20)

Preliminary Information

TK5552

Appendix: Transponder IC Read/Write Identification IC with 1 kbit Memory

Functional Description

The Transponder IC is a two-terminal, contactless

R/W-IDentification IC (IDIC

the 125 kHz (± 25 kHz) range. The IC uses the external

RF signal to generate its own power supply and internal

clock reference.

The IC contains a total of 1056 bits of EEPROM memory

grouped into 32 individually addressable data blocks.

Each block is made up of 32 bits of data plus an associated

lock bit for block write protection. Blocks 1 to 31 are

provided for user related data and block 0 for system

configuration.

)* for tag applications in

Features

D Low power, low voltage operation

D ESD protection: > 8 kV (HBM)

D Optimized for flipchip die attach processes

D Contactless power supply

D Contactless read/write data transmission

D Radio Frequency (RF): 100 kHz to 150 kHz

D 1056 bits of EEPROM memory

D 992 bits (31 x 32 bits) of user memory

Data is transmitted from the IC (uplink) using reflective

load (backscatter) modulation. This is achieved by

damping the external RF field by switching a resistive

load between the two terminals Clock–A/Clock–B as

shown in figure 14 (downlink). The IC receives and

decodes amplitude modulated data from the base station.

As soon as the tag including the Transponder IC is

exposed to an RF field and the field is strong enough to

derive enough energy to operate, the tag will respond by

continuously transmitting stored data (uplink mode). The

base station can at any time switch the tag into downlink

mode to write new user or configuration data. Generally,

the tag will automatically return to the default uplink

mode when the downlink transfer is complete, interrupted

or an error condition occurs.

D Auto-verify after EEPROM programming

D Block write protection for each block

D Configurable options include:

– Modulation type: PSK | Manchester

– Bit rate [bit/s]: RF/16 | RF/32

– Number of readable blocks

– Modulation defeat

D Defined start of data transmission

Power

Power

Base station

Base station

Figure Appendix 1. Transponder system example using Transponder IC

* IDICstands for IDentification Integrated Circuit and is a trademark of Atmel Wireless & Microcontrollers

10 (20)

Data

downlink

Data

uplink

– POR start-up delay: ≈ 1 ms | ≈ 65 ms

Transponder

Transponder

Memory

Memory

Controller

Coil interface

Analog frontend

Controller

Transponder IC

Rev. A5, 04-Oct-00

Preliminary Information

Functional Modules

TK5552

Analog Front End (AFE)

The analog front end (AFE) includes all circuits which are

directly connected to the coil. It generates the IC’s power

supply and handles the bidirectional data communication

with the basestation. It consists of the following blocks:

D Rectifier to generate a DC supply voltage from the AC

coil voltage.

D ESD protection

D Clock extractor

D Switchable load between Clock-A/ Clock-B for data

transmission from the IC to the reader electronics

(uplink mode).

D Field gap detector for data transmission from the base

station to the IC (downlink mode).

Controller

The control logic is responsible for the following:

D Initializing and refresh configuration register from

EEPROM block 0.

D Controlling read and write memory accesses.

D Handling data transmission and opcode decoding.

D Error detection and error handling.

Clock Extraction

The clock extraction circuit generates the internal clock

source out of the external RF signal.

Data Rate Generator

The data rate in uplink mode can be selected to operate

at either RF/16 (nominally 7.81 kHz, default) or RF/32

(nominally 3.91 kHz).

Bit Decoder

This function block decodes the field gaps and verifies the

validity of the incoming data stream.

Charge Pump

This circuit generates the high voltage required for programming the EEPROM.

Power-On Reset (POR)

This circuit delays the IC’s functionality until an acceptable voltage threshold has been reached.

Mode Register

This register holds the configuration data bits stored in

EEPROM block 0. It is refreshed at the start of every

block read operation.

Modulator

The modulator encodes the serial data stream shifted out

of the selected EEPROM data block and controls the

damping circuit in the AFE. The Transponder IC frontend

supports PSK and Manchester encoding.

Analog front end

(rectifier, regulator, clock extractor, ESD protection)

POR Bit decoderBit rate generator

Charge

Clock-A

pump

Controller

Mode

register

Modulator

Clock-B

Start-up

delay

Rev. A5, 04-Oct-00 11 (20)

Input register

Figure Appendix 2. Functional block diagram

EEPROM memory

Preliminary Information

TK5552

Operating the Transponder IC

Damping on

Damping off

Loading block 0 (114 FC [ 1 ms),

start-up delay inactive

Power-on reset

Figure Appendix 3. Voltage at Clock-A/ Clock-B after power on

General

The basic functions of the Transponder IC are to supply

the IC from the RF field, read data out of the EEPROM

and shift them to the modulator, receive data and program

these data bits into the EEPROM. An error detecting circuit prevents the EEPROM from being written with

wrong data.

Power Supply

The IC is supplied via a tuned LC circuit which is connected to the Clock-A/Clock-B pads. The incoming RF

induces a current in the coil. The on-chip rectifier generates the DC supply voltage. Overvoltage protection

prevents the IC from damage due to high field strengths.

Depending on the coil, the open-circuit voltage across the

LC circuit can reach more than 100 V.

Initialization

The occurrence of a RF field triggers a power–on reset

pulse, ensuring a defined start-up. The Power-On-Reset

circuit (POR) remains active until an adequate voltage

threshold has been reached. This in turn triggers the default start-up delay sequence. During this period of 114

field clock cycles (FC) the Transponder IC is initialized

with the configuration data stored in EEPROM block 0.

This is followed by an additional delay time which is defined by the ”Start-up Delay” bit.

Read data with selected

modulation and bitrate

Any field gap occuring during initialization will restart

the complete sequence.

T

= (114 + 8,192*delay bit)/125 kHz ≈ 65 ms

INIT

After this initialization time the Transponder IC enters

uplink mode and modulation starts automatically using

the parameters defined in the configuration block.

Uplink Operation

All transmissions from the IC to the base station utilizes

amplitude modulation (ASK) of the RF carrier. This takes

place by switching a resistive load between the coil pads

(Clock-A and Clock-B) which in turn modulates the RF

field generated by the base station (reflective backscatter

modulation).

MaxBlock

Data from the memory is serially transmitted, starting

with block 1, bit 1, up to the last block (MAXBLK), bit

32. The last block which will be transmitted is defined by

the mode parameter field MAXBLK is stored in EEPROM block 0. When the MAXBLK address has been

reached, data transmission restarts with block 1.

The user defines the cyclic datastream by setting the

MAXBLK between 0 and 31 (representing each of the 32

data blocks). If set to 1, only block 1 is transmitted. If set

to 31, blocks 1 to 31 will be sequentially transmitted. If

set to 0, only the contents of the configuration block (normally not accessible) will be transmitted (see figure 4).

If the ”Start-up Delay” bit is set the Transponder IC remains inactive until 8192 RF clock cycles have occured.

If this option is deactivated, no delay is observed after the

configuration period of 114 RF clock cycles (≈ 1 ms).

12 (20)

Preliminary Information

On the other hand it is also possible to access a single data

block selectively, independant of the MAXBLK value,

with the direct access command (Opcode ‘11’). The thus

addressed data block is transmitted repeatedly.

Rev. A5, 04-Oct-00

TK5552

0

MAXBLK = 0

MAXBLK = 1

MAXBLK = 2

Loading block 0

Loading block 0

Loading block 0

Loading block 0

(not transmitted)

Block 0 Block 0 Block 0 Block 0 Block 0

0

Block 1 Block 1 Block 1 Block 1 Block 1

0

Block 1 Block 2 Block 1 Block 2 Block 1

Block 1 Block 2 Block 30 Block 31MAXBLK = 31

0

Refreshing configuration register

Figure Appendix 4. Datastream pattern depending on MAXBLK

Data Encoding

Everytime when entering uplink mode, the data stream is

preceeded by a single start bit (always ‘0’). Then the data

stream continues with block 1, bit 1, and continues

through MAXBLK, bit 32. This data stream pattern

cycles continuously.

The modulator is configurable for

Block 0

Block 1

Block 2

Block 1

Block 0

Block 1

Block 1

Block 2

....

....

....

....

16546

D MANCHESTER

Manchester encoded data represent a logical ‘1’ with a

rising edge and a logical ‘0’ with a falling edge.

D PSK using sub-carrier frequency RF/2

The PSK modulator changes phase with each change of

data. The first phase shift represents a data change from

‘0’ ––> ‘1’.

Datastream

Manchester

encoded

RF-field

Data rate =

16 Field Clocks (FC)

21

1001

8 FC8 FC

9

Figure Appendix 5. Example of Manchester encoding with data rate RF/16

16818 18 9 16

16 1 8916

16552

Rev. A5, 04-Oct-00 13 (20)

Preliminary Information

TK5552

Data rate =

16 Field Clocks (FC)

Datastream

Inverted

modulator

signal

subcarrier RF/2

21891618 1618 161 8

RF-field

1001

8 FC8 FC

Figure Appendix 6. Example of PSK encoding with data rate RF/16

Downlink Operation

Data is transmitted from the base station by amplitude

modulation of the field (m = 1) using a series of so called

gaps. With the exception of the initial synchronisation

gap (start gap), all field gaps have the same duration, the

logical data being encoded in the length of the unmodulated phases (see figure A 7)

A valid data stream is always preceeded by a start gap

which is approximately twice as long as a normal field

gap. Detection of this first gap causes the Transponder IC

to switch immediately into the downlink mode where it

can receive and decode the following data stream. This

stream consists of two opcode bits, followed by (0 or 33)

data bits (including the lock bit) and finally (0, 3 or 5) address bits. In downlink mode the transponder damping is

permanently enabled. This loads the resonant transponder

coil circuit so that it comes quickly to rest when field gaps

occur – thus allowing fast gap detection.

Read mode Receive mode

RF

Damping ON

Damping OFF

Figure Appendix 7. Entering the downlink mode

Field gap + data ’0‘

Field gap + data ’1‘

Start gap + data ’0‘

16559

A start gap will be accepted at any time after start–up initialization has been finished (RF field ON plus ≈ 1 ms,

startup delay inactive) and the IC is not in downlink operation.

Downlink Data Coding

The duration of a field gap is typically between 80 and

250 µs. After the start gap the data bits are transmitted by

the base station whereby each bit is separated by a field

gap. The bit decoder interprets 16 to 32 internal field

clocks as a logical ‘0’ and 48 to 64 internal field clocks

as a logical ‘1’ (see figure A 8). Therefore the time between two gaps is typically 24 field clocks for a ‘0’ and

56 field clocks for a ‘1’.

Whenever the bit decoder detects more than 64 field

clocks, the Transponder IC will abort the downlink mode.

The incoming data stream is checked continuously and

should an error be detected the corresponding error handling is initiated.

The control logic initiates an EEPROM programming

cycle if the correct number of bits had been received (see

figure A 9).

14 (20)

Rev. A5, 04-Oct-00

Preliminary Information

TK5552

Uplink mode

start gap detected ?

YES

Downlink mode

count field clocks FC

FC count > 64 ?

NO

gap detected ?

YES

16 <= FC <= 32 ?

NO

48 <= FC <= 64 ?

NO

YES

Data stream check

NO

YES

’0’ into shift register

YES

’1’ into shift register

Data stream check

OPCODE ’11’ ?

NO

OPCODE ’10 ’ ?

YES

bitcount = 38 ? bitcount = 40 ?

NO

enter error handler

–> ”Frame error”

YES

NO

Execute command

’00’ or ’01’

YES YES

Programming

NO

bitcount = 7 ?

NO

YES

NO

enter error handler

–> ”Bit Error”

Uplink mode

Figure Appendix 8. Operation of bit decoder – data stream

decoder

Opcode definitions

The first two bits of the data stream are decoded by the

controller as the opcode bits (see figure A 10):

‘11’: Opcode for a 5-bit address data stream

D To initiate a standard block write cycle the 2 opcode

bits are followed by the lock bit, the 32 data bits and

the 5-bit block address (40 bits total).

D The direct access command consists of the opcode

‘11’ followed by the 5-bit block address and is a read–

only command (7 bits total).

enter uplink mode

–>block 1...MAXBLK

Direct access mode

enter uplink mode

–> selected block

Figure Appendix 9. Data stream checking

‘10’: Opcode for a 3-bit address data stream

D e5550 receive mode compatible

To initiate a block write cycle, the opcode ‘10’ is followed by the lock bit, the 32 data bits and the 3-bit

block address (38 bits total).

‘01’: reserved for production test commands.

‘00’: Opcode for an internal reset command.

Rev. A5, 04-Oct-00 15 (20)

Preliminary Information

TK5552

Standard block write

Short block write

Direct access command

Reset command

OP

11

OP

10

L 321

OP

11

40

Addr

OP

00

Figure Appendix 10. Transponder IC opcode format definition

Data bitsL 321

Data bits

Addr20

4

Addr

0

enter error handler

–> ”Verification error”

PROGRAMMING

turn off transponder

damping

addressed block

locked ?

NO

generate high

programming voltage

erase block

NO

erase successful ?

YES

program ’1’s

NO

programming ’1’s

successful ?

YES

enter uplink mode

–> read selected block

YES

Programming

If the bit decoder and controller detect a valid data stream,

the Transponder IC will start an erase and programming

cycle if a data write command was decoded (see figure

A 11).

During the erase and programming cycle downlink damping is turned off. The programming cycle includes a data

verification read to check the integrity of the data. After

EEPROM programming and verification has been finished successfully, the Transponder IC enters uplink

mode transmitting the block just programmed.

The typical programming time is ≈ 18 ms.

Error Handling

Several error conditions are detected by the Transponder

IC to ensure that only valid information is programmed

into the EEPROM.

Errors During EEPROM Programming

There are two error types which will lead to different actions.

D Verification error

If one of the data verification cycles fails, the

Transponder IC will inhibit modulation and not return

to the uplink mode. This ”modulation defeat” state is

terminated by re-entering the downlink mode with a

start gap.

D Block write protection

enter

”Modulation Defeat”

Figure Appendix 11. Programming cycle flow chart

16 (20)

Preliminary Information

16551

If the lock bit of the addressed block is set, programming is disabled. In this case, the programming cycle

is not initiated and the Transponder IC reverts to

uplink mode, transmitting the currently addressed

(and unmodified) block continuously.

Rev. A5, 04-Oct-00

TK5552

Errors During Data Transmission

The following errors are detected by the decoder:

D Bit error

Wrong number of field clocks between two gaps (i.e.

not a valid ‘0’ or ‘1’ pulse stream).

D Frame error

The number of data bits received is incorrect:

– valid bit count for 3-bit address write is 38 bits

– valid bit count for 5-bit address write is 40 bits or

– 7 bits for a direct access command.

If any of these conditions is detected, the Transponder IC

enters uplink mode starting with block 1.

EEPROM Memory Organisation

The memory array of the Transponder IC consists of

1,056 bits of EEPROM, arranged in 32 individually addressable blocks of 33 bits each, consisting of one lock bit

and 32 data bits. All 33 bits, including the lock bit, are

programmed simultaneously.

The programming voltage is generated on-chip.

Lock bit

Each block has an associated write lock bit with which the

entire block can be protected. By default all lock bits L

are reset (‘0’).

Note: Once set, the lock bit – and the content of the asso-

ciated block – cannot be altered.

1320

L

L

L

L

L

L

Not transmitted

Configuration data block

User data bits

User data bits

User data bits

User data bits

User data bits

33 bits total (incl. one lock bit)

Figure Appendix 12. Memory map

Block 0

Block 1

Block 2

Block 29

Block 30

Block 31

16549

Configuration Data Block

This data block contains 9 configuration bits.

The remaining bits of block 0 are reserved for future en-

hancements and should be set to ‘0’.

D Start-up Delay bit (SD, default: NO delay)

When set, an additional delay time of 64 ms is added

after any internal reset.

D Data Rate bit (DR, default: RF/16)

Selects data rate of RF/16 or RF/32.

D Modulation Select bit (MS, default is PSK)

Selects type of data encoding which is either

MANCHESTER or PSK.

D Modulation Defeat bit (MD, default is OFF)

When set (to ‘1’) the modulation output is deactivated, hence no data will be transmitted. The

”modulation defeat” state does not impact the transponder damping function.

Memory Map

The configuration data of the Transponder IC is stored in

block 0 of the EEPROM.

The remaining thirty-one data blocks (1 .. 31) each consist

of one lock bit and 32 user data bits.

Rev. A5, 04-Oct-00 17 (20)

D MAXBLK address bits (MAXBLK, default is 31)

This 5-bit block address is used to define the upper

limit of cyclic block reads.

Note: The configuration is changed by re-programming

block 0 as long as the corresponding lock bit is not set.

The default settings can be lost due to the die cut.

Preliminary Information

TK5552

Transponder IC Configuration Block 0

L 1 2 3 456789 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

reserved, to be ’0‘

Lockbit

Data rate DR

Start-up delay SD

0 = Unlocked 0 = PSK

1 = Locked 1 = MANCHESTER

NO delay =

Delay of 8,192 field clocks =0101

= RF/16

= RF/32

MAXBLOCK

00000 = Block 0

00001 = Block 1

00010 = Block 1...2

00011 = Block 1...3

MD

11111 = Block 1...31

Modul. select MS

Modulation Defeat

0 = Normal function

1 = Modulation off

reserved

Figure Appendix 13. Transponder IC configuration block 0 bit mapping

1.5k

Clock-A

Clock-B

Figure Appendix 14. Simplified damping circuit

1.5k

~ 2 V

~ 2 V

Mod

16580

18 (20)

Rev. A5, 04-Oct-00

Preliminary Information

TK5552

Absolute Maximum Ratings

Parameters Symbol Value Unit

Maximum DC current into Clock-A/Clock-B Icoil 10 mA

Maximum AC current into Clock-A/Clock-B,

f = 125 kHz

Power dissipation (dice)

Electrostatic discharge voltage according to MIL-Stan-

dard 883D method 3015 (HBM)

Operation ambient temperature range Tamb –25 to +75 °C

Storage temperature range

Maximum assembly temperature for less than 5 min

Notes: 1) Free–air condition, time of application: 1s

2) Data retention reduced

3) Assembly temperature of 150°C for less than 5 minutes does not affect the data retention

Stresses above those listed under ”Absolute Maximum Ratings” may cause permanent damage to the device.

1)

2)

3)

Icoil PP 20 mA

Ptot 100 mW

Vmax 8000 V

Tstg –40 to +125 °C

Tsld +150 °C

Operating Charateristics

T

= 25°C; fRF = 125 kHz reference terminal is VSS

amb

Parameters Test Conditions / Pins Symbol Min. Typ. Max. Unit

RF frequency range fRF 100 125 150 kHz

Supply current Uplink & downlink mode –

full temperature range

Programming – full tem-

perature range

Clamp voltage 10 mA current into Clock-

A/B

Programming time Per block tP 18 ms

Startup time 2) t startup 1 65 ms

Data retention 1) t retention 10 Years

Programming cycles 1) ncycles 100,000

Clock-A/B voltage Uplink & downlink mode VclockPP 6 V

Clock-A/B voltage Programming, RF field w/o

damping

Damping resistor Each at Clock-A and

Clock-B

IDD 5 7.5 µA

IDD 14 28 µA

Vclamp 7 11 V

VclockPP 12 V

RD 1.5 kΩ

Note: 1) Since EEPROM performance is influenced by assembly and packaging, Atmel Wireless & Microcontrollers

confirms the parameters for DOW (= tested dice on wafer) and ICs assembled in standard package.

2) Depends on start-up delay bit in configuration register

Rev. A5, 04-Oct-00 19 (20)

Preliminary Information

TK5552

Ozone Depleting Substances Policy Statement

It is the policy of Atmel Germany GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and operating systems

with respect to their impact on the health and safety of our employees and the public, as well as their impact on

the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are known as

ozone depleting substances (ODSs).

The Montreal Protocol (1987) and its London Amendments (1990) intend to severely restrict the use of ODSs and forbid

their use within the next ten years. Various national and international initiatives are pressing for an earlier ban on these

substances.

Atmel Germany GmbH has been able to use its policy of continuous improvements to eliminate the use of ODSs listed

in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments respectively

2. Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency (EPA) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C (transitional substances) respectively.

Atmel Germany GmbH can certify that our semiconductors are not manufactured with ozone depleting substances

and do not contain such substances.

6.

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each customer

application by the customer. Should the buyer use Atmel Wireless & Microcontrollers products for any unintended

or unauthorized application, the buyer shall indemnify Atmel Wireless & Microcontrollers against all claims,

costs, damages, and expenses, arising out of, directly or indirectly, any claim of personal damage, injury or death

associated with such unintended or unauthorized use.

20 (20)

Data sheets can also be retrieved from the Internet: http://www.atmel–wm.com

Atmel Germany GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Telephone: 49 (0)7131 67 2594, Fax number: 49 (0)7131 67 2423

Rev. A5, 04-Oct-00

Preliminary Information

Loading...

Loading...