Page 1

STK525

.............................................................................................

Hardware User Guide

Page 2

Section 1

Introduction...........................................................................................1-3

1.1 Overview...................................................................................................1-3

1.2 STK525 Starter Kit Features.....................................................................1-4

Section 2

Using the STK525.................................................................................2-6

2.1 Overview...................................................................................................2-6

2.2 Power Supply............................................................................................2- 7

2.3 RESET....................................................................................................2-10

2.4 AT90USBxxx AVR Microcontroller..........................................................2-11

2.5 Serial Links .............................................................................................2-11

2.6 On-board Resources...............................................................................2-14

2.7 STK500 Resources.................................................................................2-19

2.8 In-System Programming.........................................................................2-20

2.10 Test Points..............................................................................................2-23

2.11 Configuration Pads .................................................................................2-24

2.12 Solder Pads ............................................................................................2-25

Section 3

Troubleshooting Guide.......................................................................3-26

Section 4

Technical Specifications................... ......... .......... ......... ......... .......... ...4-27

Section 5

Technical Support............................. ......... .......... ......... ......... .......... ...5-28

Section 6

Complete Schematics.......................................... ......... ......... .......... ...6-29

STK525 Hardware User Guide User Guide 1

7608A–AVR–04/06

Page 3

1.1 Overview

Section 1

Introduction

Congratulation for acquiring the A VR® STK525 Starter Kit. This ki t is designed to give

designers a quick start to develop code on the AT90USBxxx and for prototyping and

testing of new designs.

This document describes the STK525 dedicated to the AT90USBxxx AVR

microcontroller. This board is des ig ned to al low an eas y ev alu ation of t he product using

demonstration software.

To complement the evaluation and enable additional development capability, the

STK525 can be plu gged into the Atmel STK500 Start er Kit Board in order to use the

AT90USBxxx with advanced features such as variable VCC, variable VRef, variable

XTAL, etc. and supports all AVR development tools.

To increase its demonstrative capabilities, this stand alone board has numerous onboard resources (USB, RS232, joystick, data-flash, microphone and temperature

sensor).

This user guide acts as a general getting started guide as well as a comple te technical

reference for advanced users.

STK525 Hardware User Guide 1-3

7608A–AVR–04/06

Page 4

Introduction

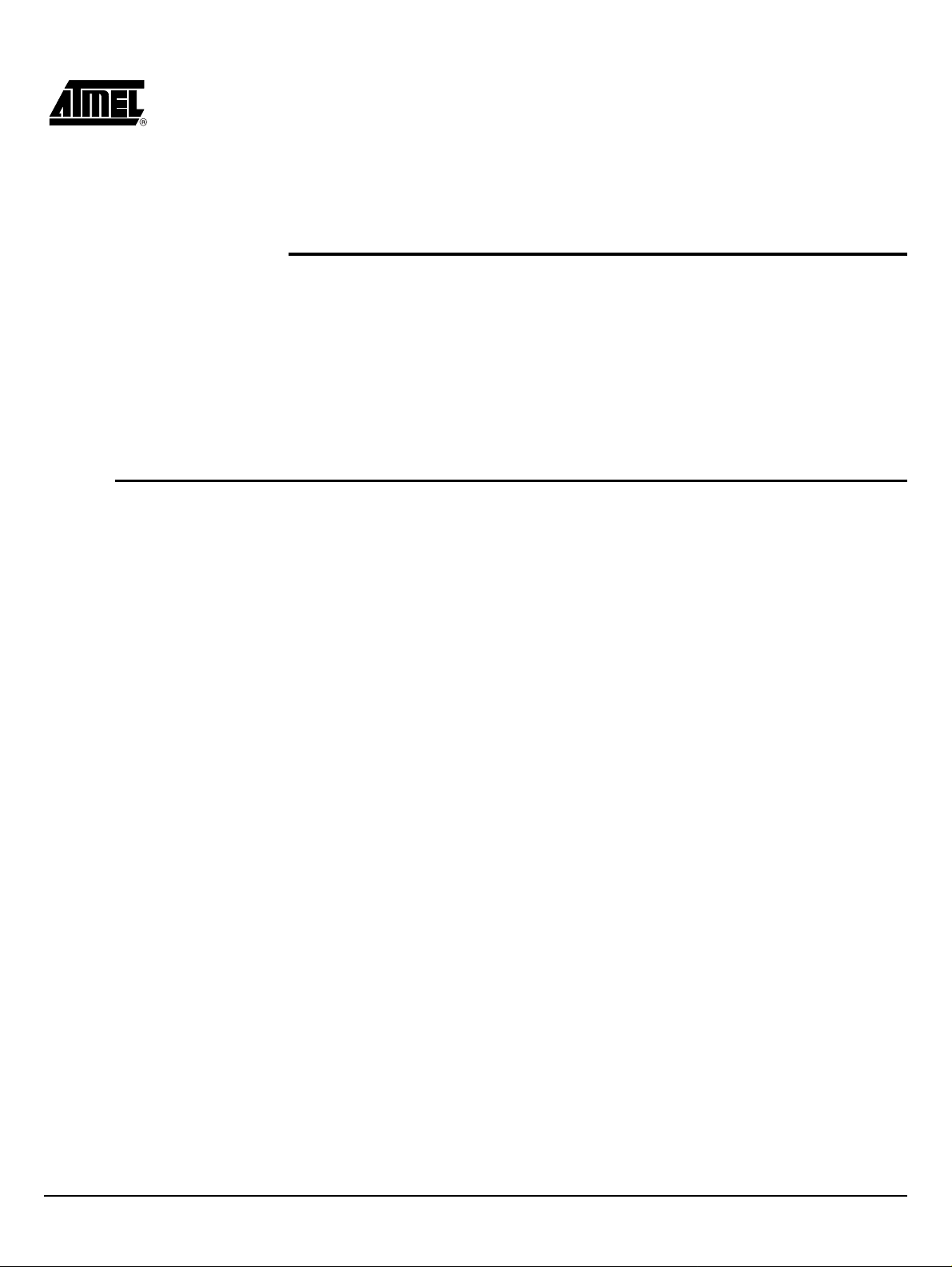

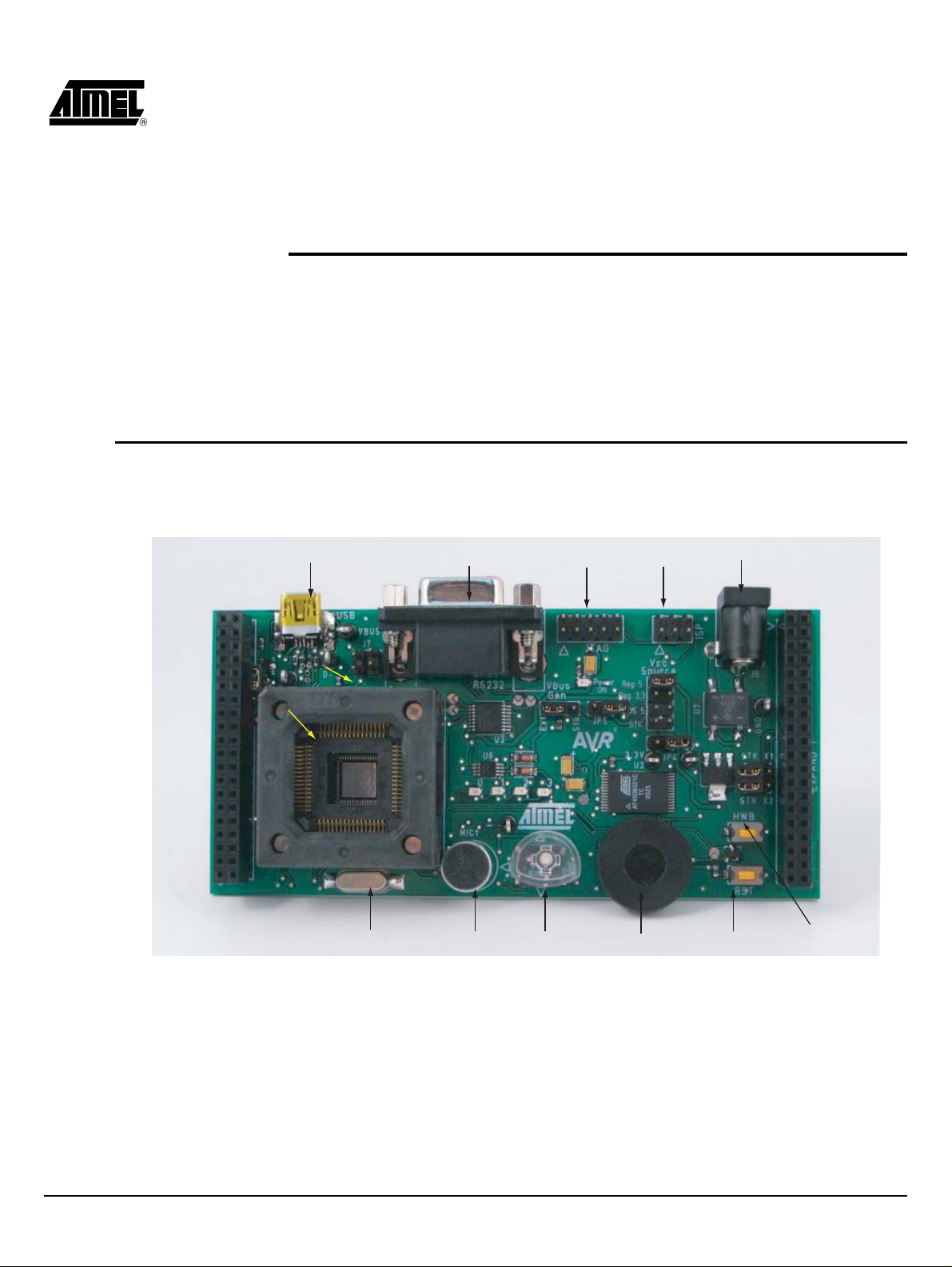

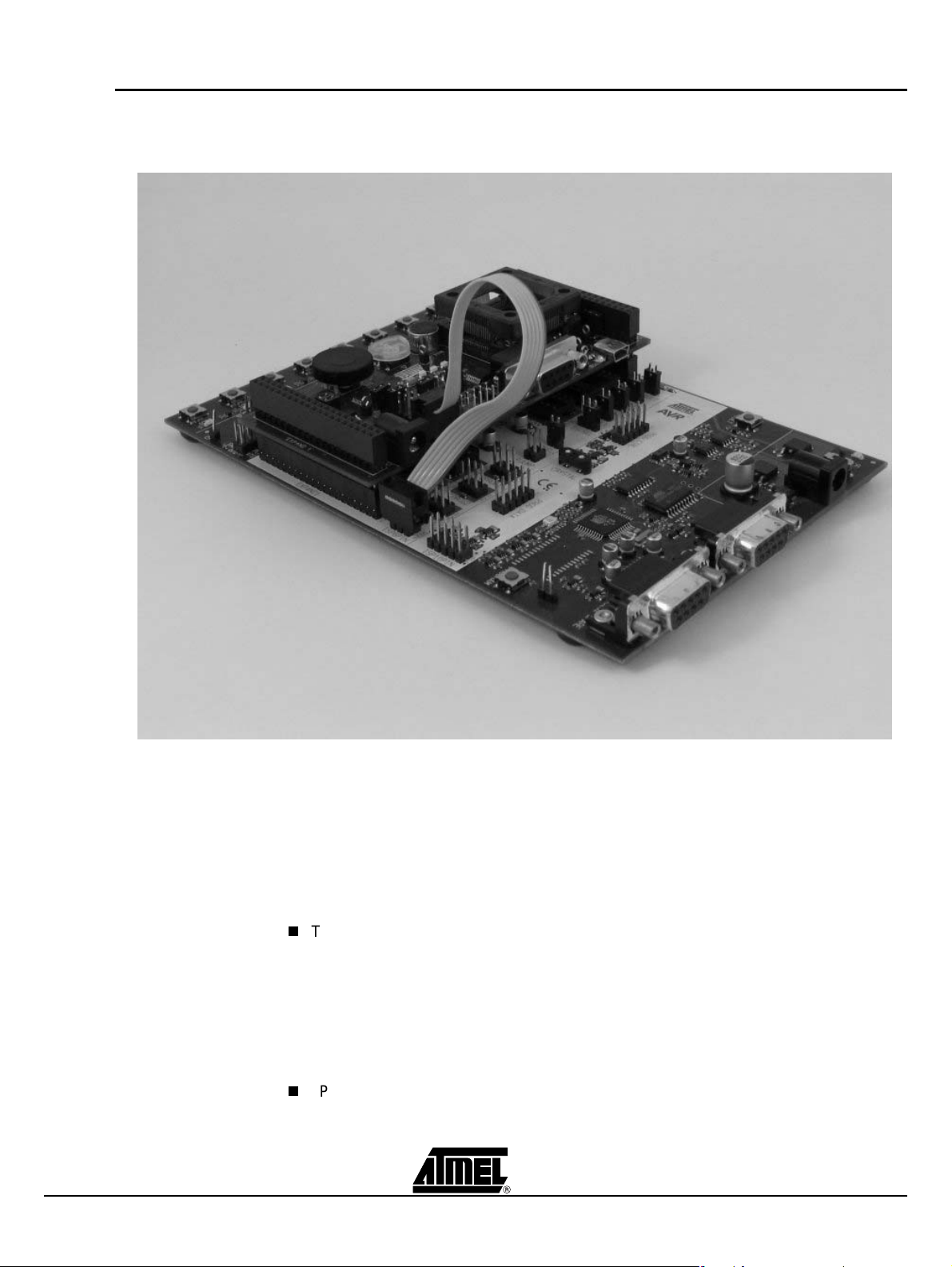

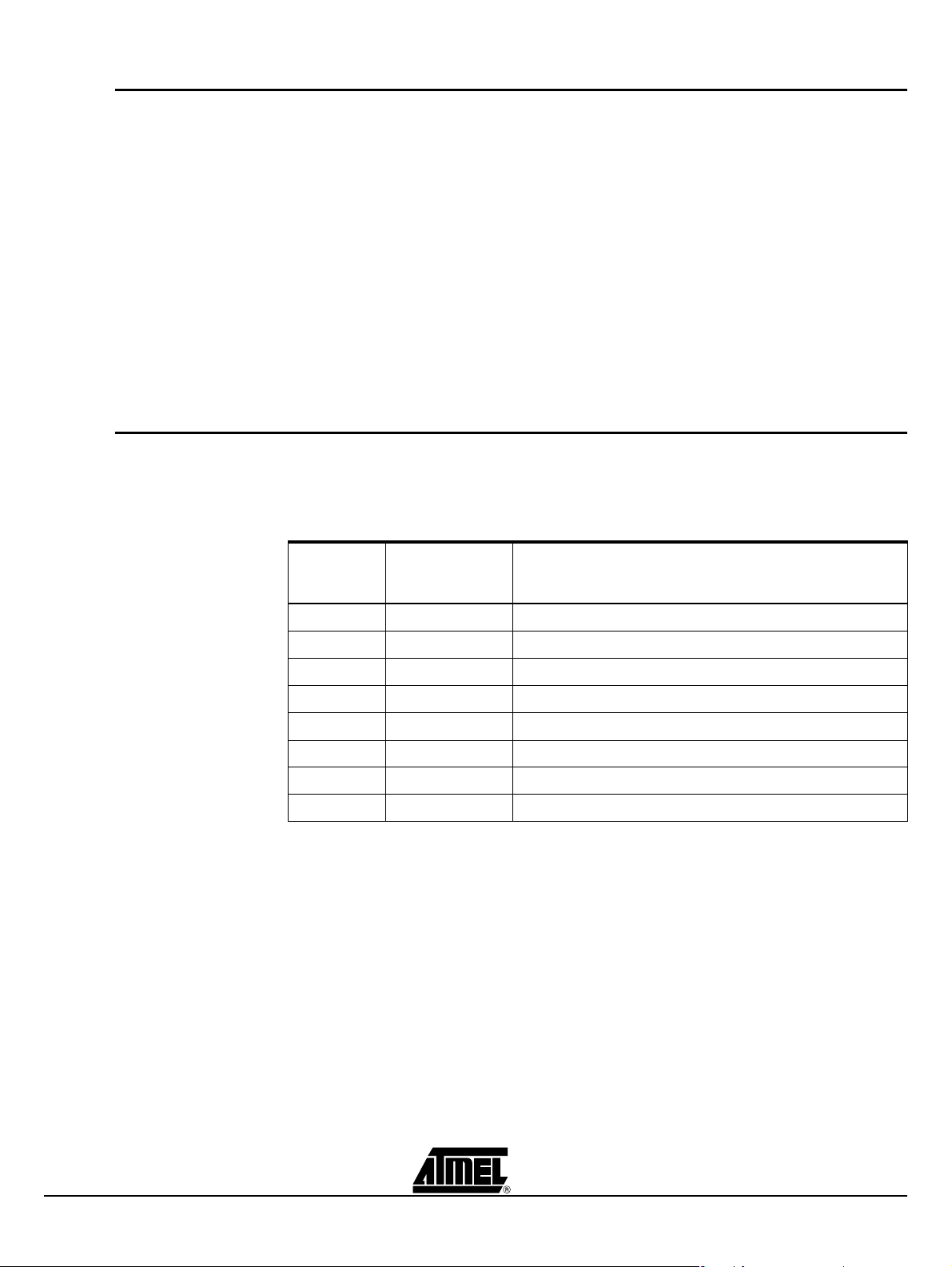

Figure 1-1 . STK525 Board

1.2 STK525 Starter Kit Feature s

The STK525 provides the following features:

AT90USBxxx TQFP device (2.7V<Vcc<5.5V),

AVR Studio® software interface

USB software interface for Device Firmware Upgrade (DFU bootloader)

STK500 compatible

Power supply flagged by “VCC-ON” LED:

– regulated 3 or 5V,

– from an external power connector,

– from the USB interface (USB device bus powered application),

– from STK5 0 0

ISP connector for on-chip ISP,

JT AG connector:

– for on-chip ISP,

– for on-chip debugging using JTAG ICE,

Serial interfaces:

– 1 USB full/low speed device/host interface

– RS-232C ports with RTS/CTS handshake lines,

On-board resources:

– 4+1-ways joystick,

–4 LEDs,

– temperature sensor,

– microphone,

– serial dataflash memory,

(2)

(1)

,

(2)

,

1-4 STK525 Hardware User Guide

7608A–AVR–04/06

Page 5

Introduction

On-board RESET button,

On-board HWB button for force bootloader section execution at reset.

System clock:

– external clock from STK500 expand connectors

– 8 MHz crystal,

Numerous access points for test.

Notes: 1. The STK525 is suppor ted by A VR S tudi o®, ver sion 4.12SP2 or higher . For up-to-date

information on this and other AVR tool products, please consult our web site. The

newest version of AVR Studio®, AVR tools and this User Guide can be found in the

AVR section of the Atmel web site, http://www.atmel.com.

2. ATMEL Flip®, In System Programming Version 3 or Higher shall be used for Device

Firmware Upgrade . Please consult Atmel web site to retrieve the latest version of Flip

and the DFU bootloader Hex file if needed.

STK525 Hardware User Guide 1-5

7608A–AVR–04/06

Page 6

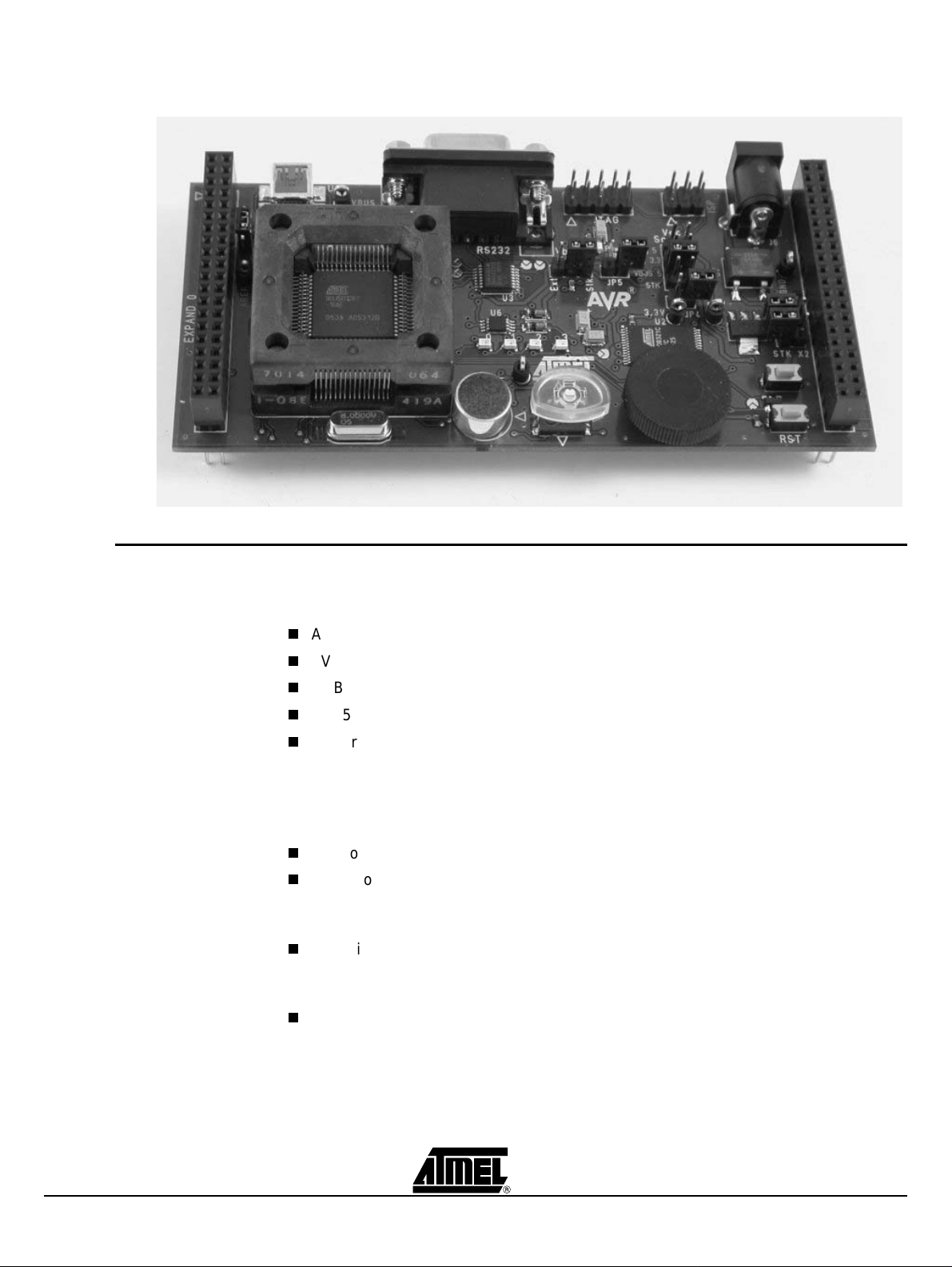

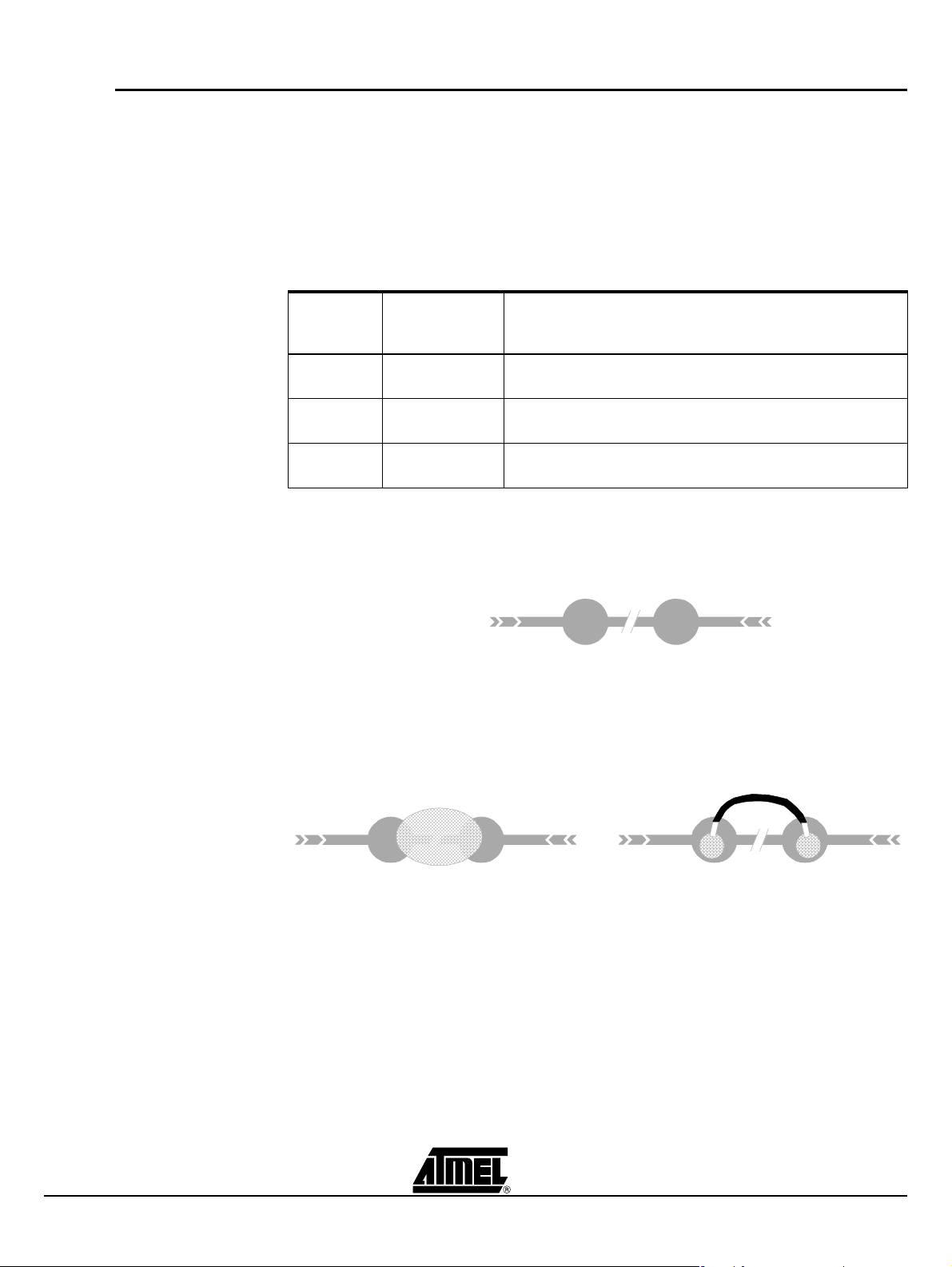

2.1 Overview

Section 2

Using the STK525

This chapter describes the board and all its features.

Figure 2-1 . STK525 Overview

USB MiniAB RS232 JTAG ISP External Power

C Sensor

Pin1

STK500 Expand0

TQFP64 Socket

LEDS

Microphone

Vbus Gen.

Setting

Joystick Potentiometer ResetCrystal

Vcc Src.

Setting

Data Flash

STK500 Expand1

Bootloader

Activation

STK525 Hardware User Guide 2-6

7608A–AVR–04/06

Page 7

2.2 Power Supply

2.2.1 Power Supply Sources

Using the STK525

The on-board power supply circuitry allows various power supply configurations.

The power supply source can come from three different

USB connector,

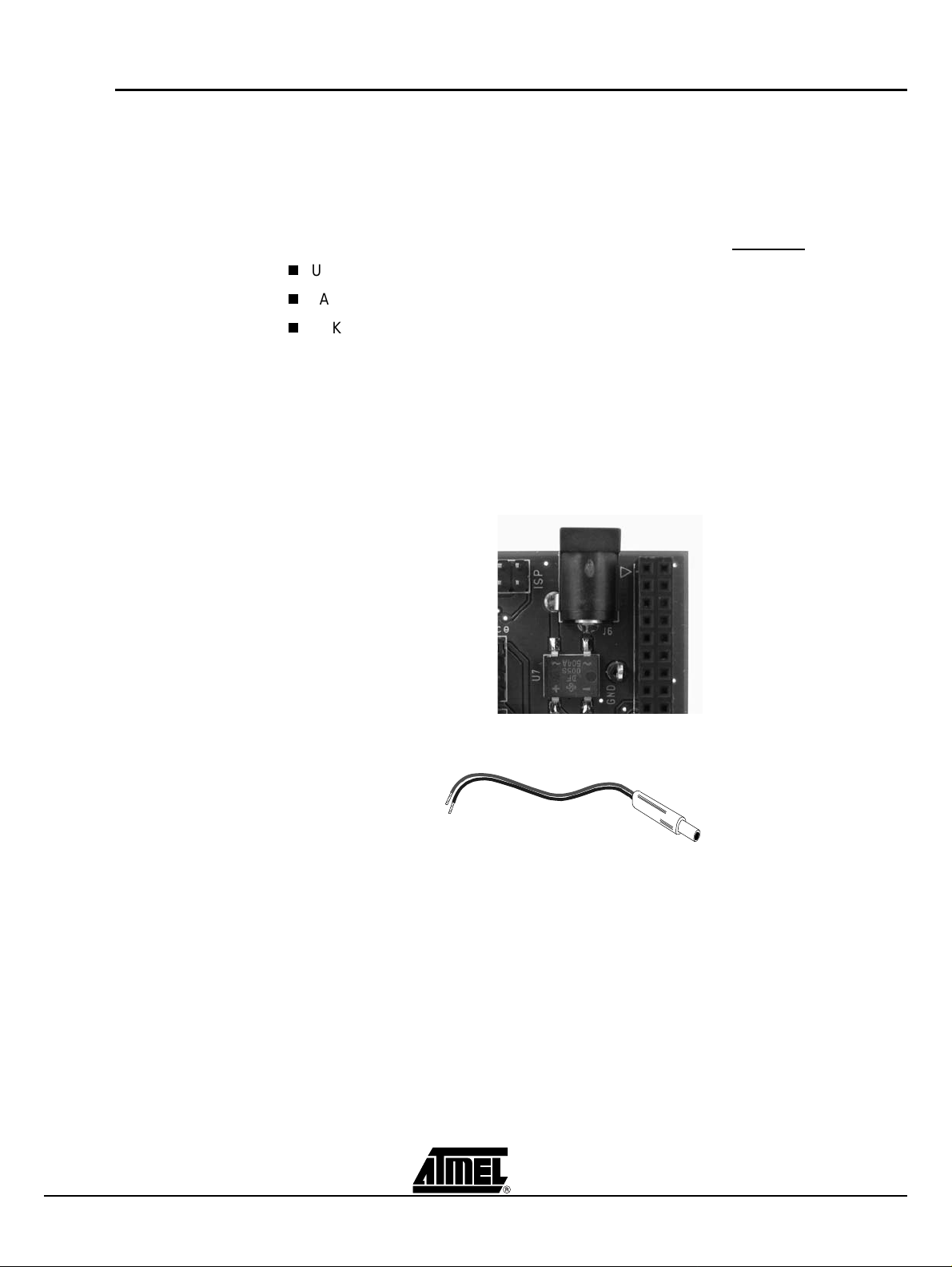

JACK PWR connector (J6, See Figure 2-2),

STK500

USB powered: When used as a USB devi ce bus powered application, the STK525 can be powered via

the USB VBUS power supply line.

JACK PWR connector: – Need of a male JACK outlet,

– Input supply from 9 up to 15V

– No specific polarization

(2)

is required.

Figure 2-2 . JACK PWR Connector (J6)

(1)

DC,

(3)

and exclusive sources:

Figure 2-3 . M ale JACK Outlet and Wires

+

-

STK500 Powered: (c.f.

STK525 Hardware User Guide 2-7

“STK500 Resour ces” on page 19).

Notes: 1. 15V is the maxim um level limitation of an unidirectional transit diode.

2. There is a diode (bridge) voltage level between the negative output of the power

supply and the STK525 “GND”. This could introduce some gap of voltage during

measurement and instrumentation.

3. Caution: Do not mount more than one power supply sour ce on STK525.

7608A–AVR–04/06

Page 8

Using the STK525

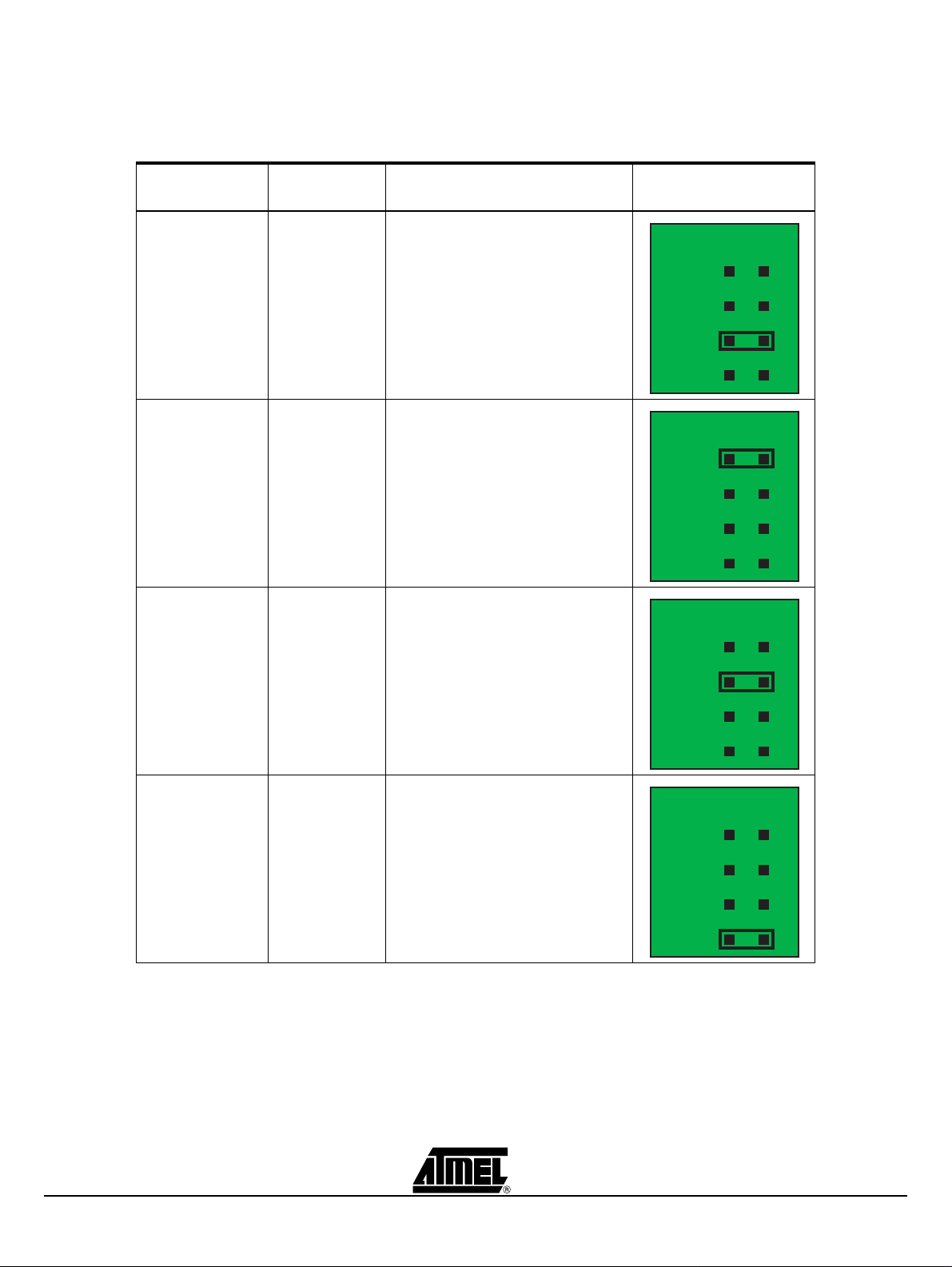

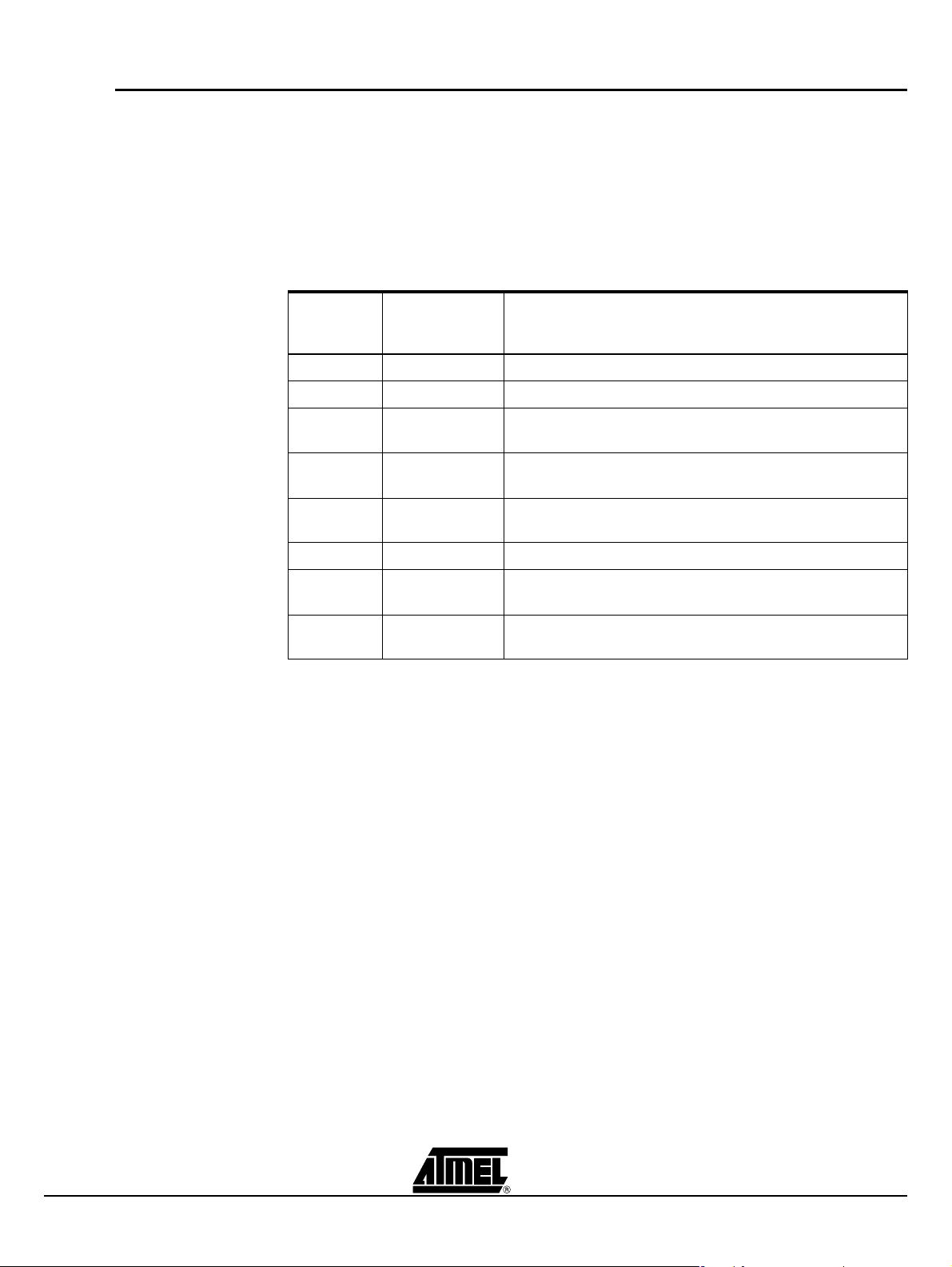

2.2.2 Pow er S upp l y Sett in g

Vcc Source

Jumper position

VBUS 5

REG 5 5V

Table 2-1 . Power Supply

VCC power

supply value

This is the default confi guration.

This should be used for a typical USB

VBUS

(4,7V to 5. 0V)

device “bus powered” application.

In this mod e, the STK525 is powered

directly from th e USB bus, and no

other external power supply is

required.

This configuration can be used for a

USB “self powered” device

application” or when operating has a

USB host.

To use this conf iguration an exter nal

power supply must be connected to

J6 connector.

(1)

Setting

Comments View

Source

Reg 5

Reg 3.3

VBUS 5

STK

Source

Reg 5

Reg 3.3

VBUS 5

STK

VCC

VCC

REG 3.3 3.3V

Depends on

STK

STK500 VTG

setting

Notes: 1. Caution: The STK500 has its own “ON/OFF” switch

This configuration allows the STK525

to be used in a 3V range applicat ion.

This configuration can be used with

both device or host mode USB

applications.

To use this conf iguration an exter nal

power supply must be connected to

J6 connector.

This configuration allows the STK525

to be used with an STK500 board.

In this mode, the STK525 power

supply is generat ed and configured

accord i ng to th e “VT G ” par ameter of

the STK500 (1).

VCC

Source

Reg 5

Reg 3.3

VBUS 5

STK

VCC

Source

Reg 5

Reg 3.3

VBUS 5

STK

2-8 STK525 Hardware User Guide

7608A–AVR–04/06

Page 9

2.2.3 VBUS Generator Setting

Using the STK525

When using the A T90USBxxx microcontroller in USB ho st mode. The STK5 25 should

provide a 5V power supply over the VBUS pin of its USB mini AB connector.

A couple of transistors on the STK525 allows the UVCON pin of the AT90USBxxx to

control the VBUS gene ration (See Figure 2 -4). In this mode the S TK525 is powe red by

external power supply source (J6 or STK500 expand0/1 connectors). JP7 allows to

select the 5V source used by the VBUS generator.

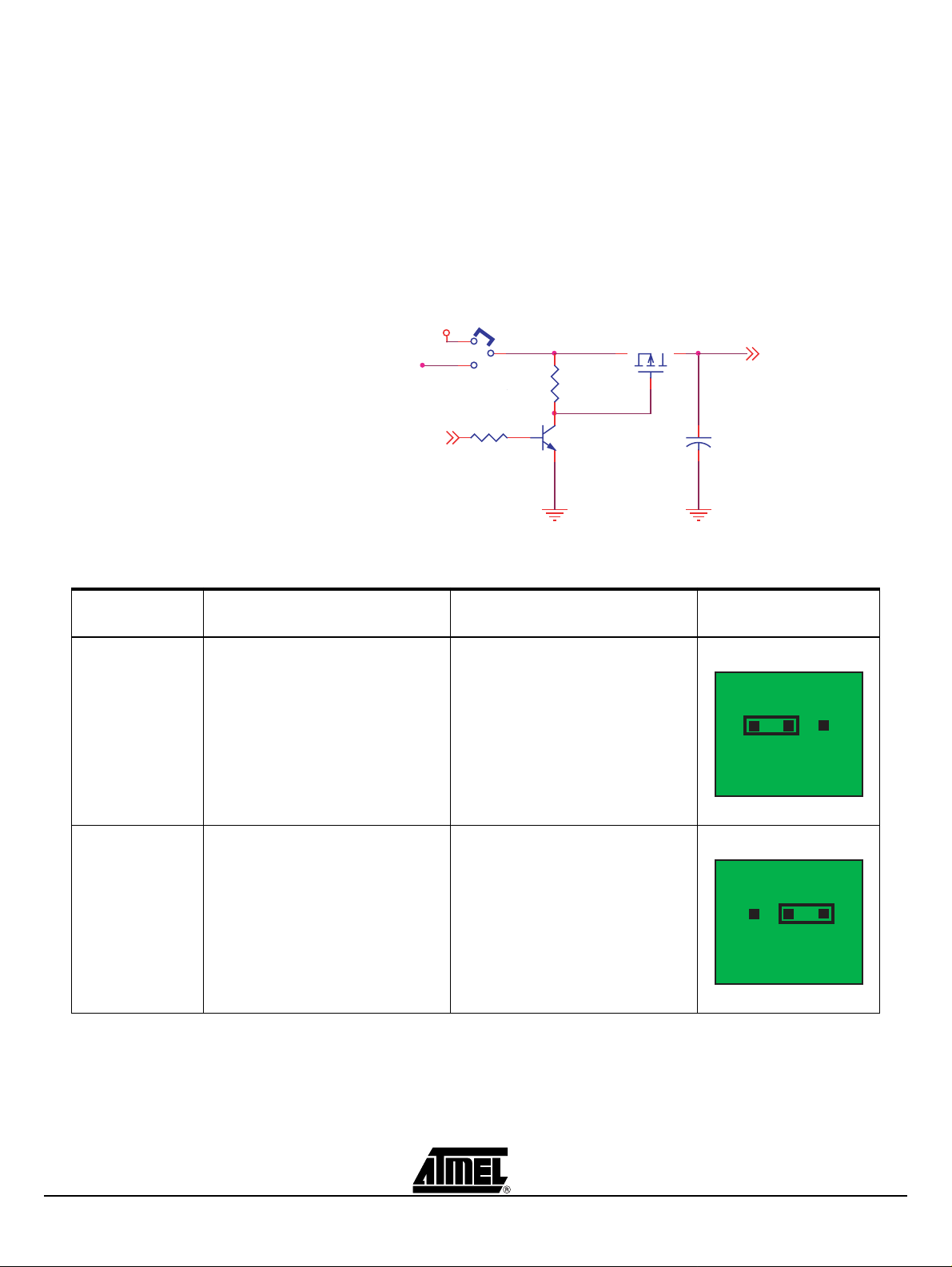

Figure 2-4 . VBUS generator schematic

JP7

VTG

STK

Ext

UVCON

1

3

VBUS ge n

R33

100k

2

R32

10k

Q2

BC847B

FDV304P/FAI

M1

VBUS

C34

4.7uF

-

Table 2-2 . VBUS Generator Setting

“Vbus Gen”

Jumper position

“Ext” Ext e rnal po w er su pp ly from J6

“Stk”

STK525 power supply Comments View

Exte r n a l po w er su pp ly from

Expand0/1 (connected to a STK500)

This is the default configuration.

The VBUS generator source is the

on-board 5V regulator.

The VBUS generator source is the

STK500.

Note:

The “Vtarget” setting of STK500

should be set to “5V”.

Ext

Ext

Vbus

Gen

Stk

Vbus

Gen

Stk

STK525 Hardware User Guide 2-9

7608A–AVR–04/06

Page 10

Using the STK525

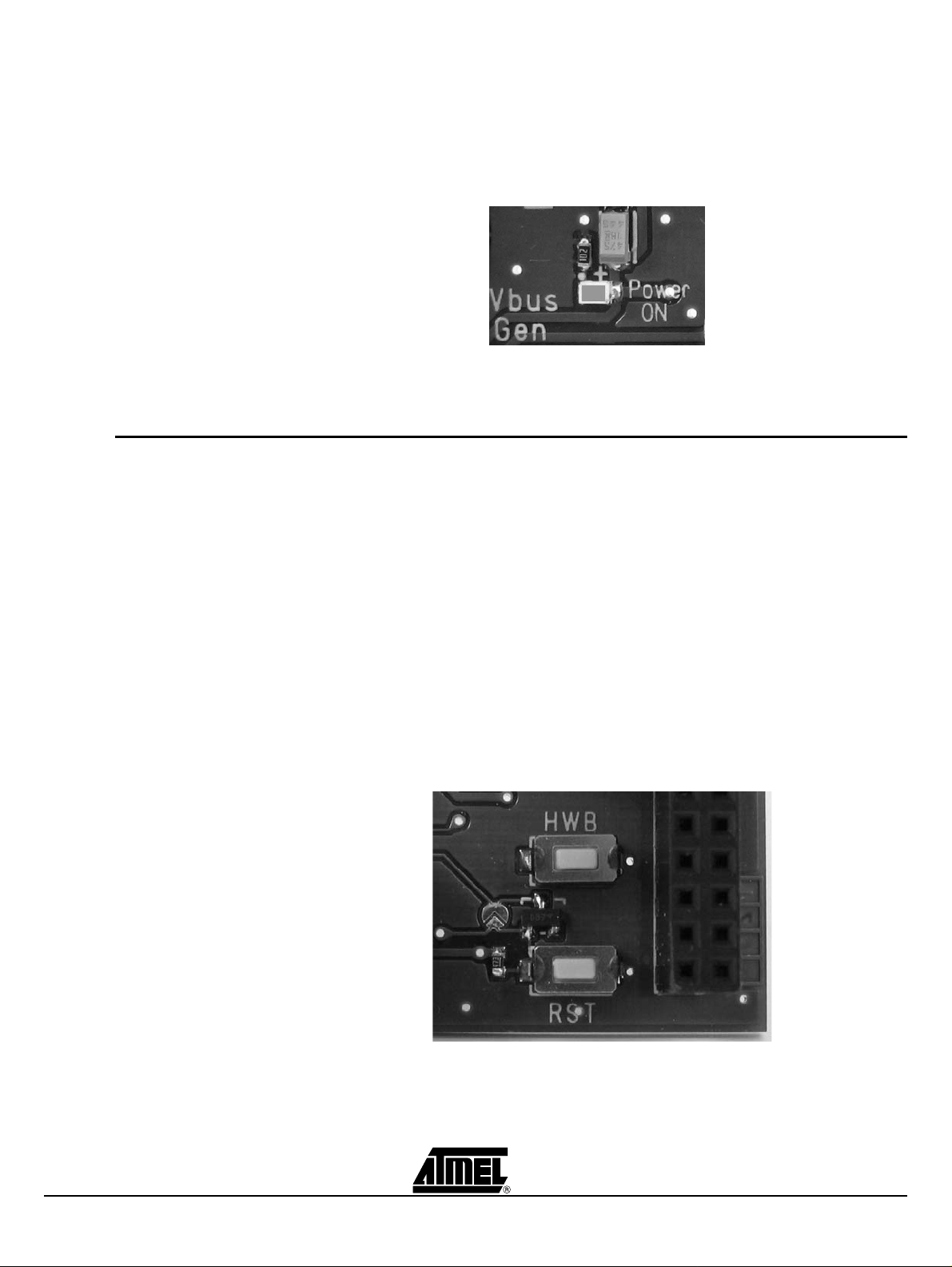

2.2.4 “POWER-ON“ LED

2.3 RESET

The POWER-ON LED is always lit when power is applied to STK525 regardless of

power supply source and the regulation.

Figure 2-5 . “VCC-ON” LED

Although the AT90USBxxx has its on-chip RESET circuitry (c.f. AT90USBxxx

Datasheet, section “System Control and Reset), the STK525 provides the AT90USBxxx

a RESET signal which can come from 3 different sources:

2.3.1 Power-on RESET

2.3.2 RESET Push Button

The on-board RC network acts as power-on RESET.

By pressing the RESET push button on the STK525, a warm RESET of the

AT90USBxxx is performed.

Figure 2-6 . RESET Push Button (RST) Implementation

2-10 STK525 Hardware User Guide

7608A–AVR–04/06

Page 11

2.3.3 STK500 RESET

(c.f.

“RESET from STK500” on page 20)

2.4 AT90USBxxx AVR Microcontroller

2.4.1 Main Clock XTAL

To use the USB i nterface of the AT90USBxxx, the clock source should always be a

crystal or external clock oscillator (the internal 8 MHz RC oscillator cannot be used to

operate with the USB interface). Only the following crystal frequency allows proper USB

operations: 2MHz, 4MHz, 6MHz, 8MHz, 12MHz, 16MHz. The STK525 comes with a

default 8MHz crystal oscillator.

When closing ST KX1 and STKX2 s witches, and STK525 is connected to an STK500,

the STK525 can operate with the “STK500 Osc” frequency parameter.

2.4.2 Anal og P ower Supply

Using the STK525

ANA REF By default, AREF is an output of AT90USBxxx.

2.5 Serial Links

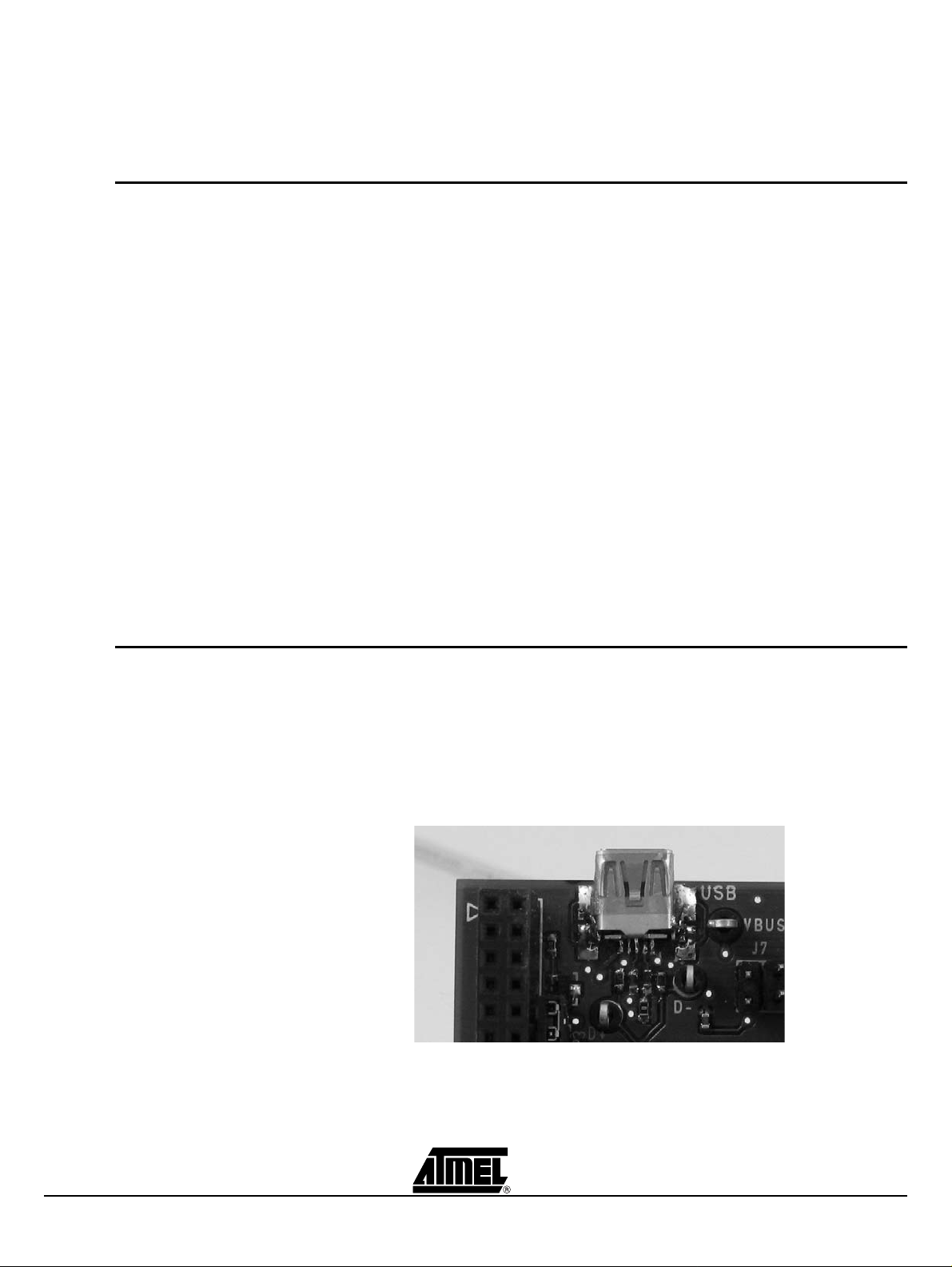

2.5.1 USB

AVCC By default, AVCC is equivalent to VCC.

An external AREF source can be chosen (c.f.

The STK525 is supplied with a standard USB mini A-B receptacle. The mini AB

receptacle allows to connect both a mini A plug or a mini B plug connectors.

Figure 2-7 . USB mini A-B Receptacle

“STK500 Resour ces” on page 19).

When connected to a m ini B plug, the AT90USBxxx opera tes as an “USB device” (the

ID pin of the plug is unconnected) and when connected to a mini A plug, the

AT90USBxxx operates as a “USB host” (the ID pin of the plug is tied to ground).

STK525 Hardware User Guide 2-11

7608A–AVR–04/06

Page 12

Using the STK525

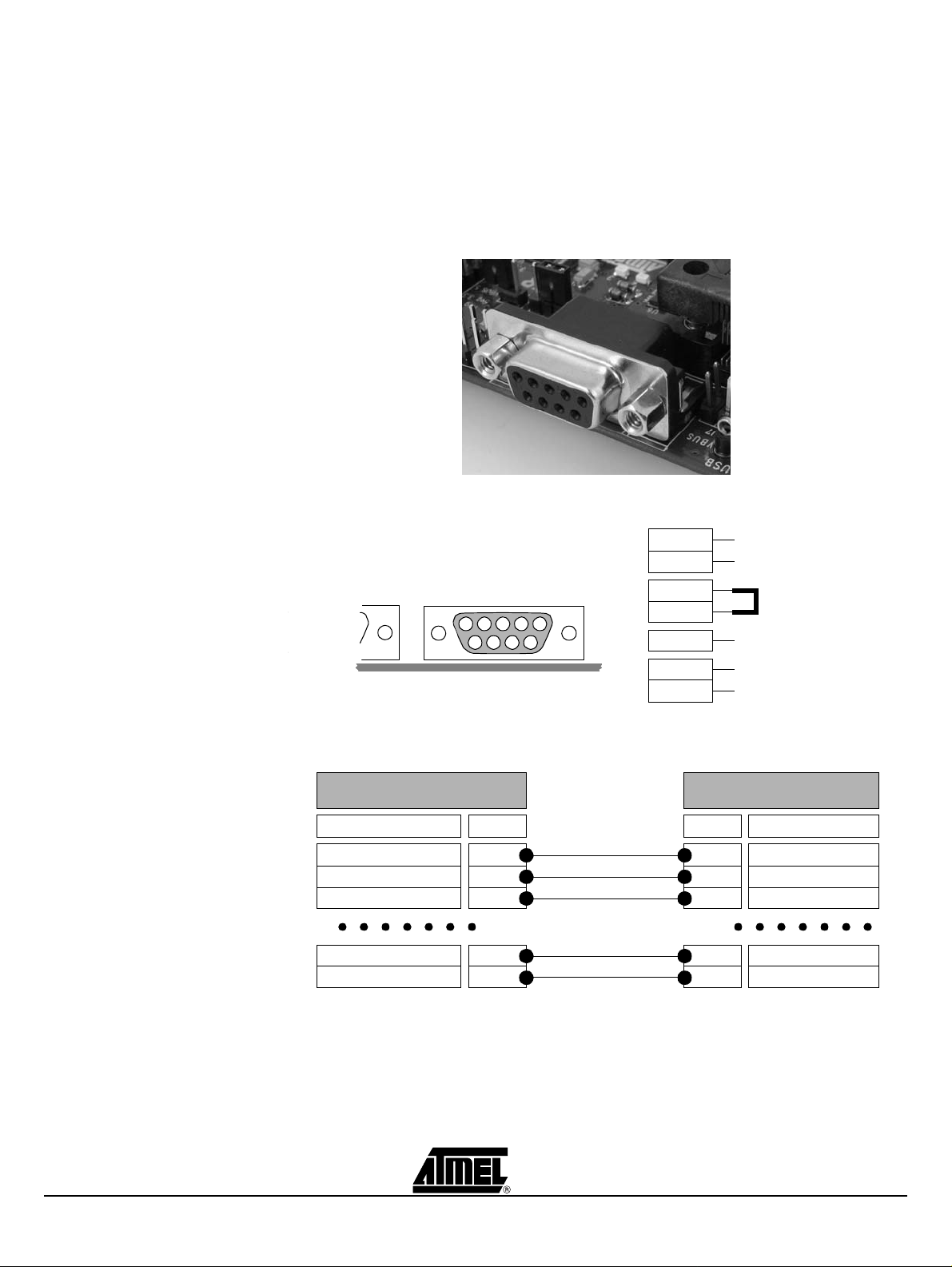

2.5.2 RS-232C

The AT90USBxxx is a microcontroller with an on-chip USART peripheral (USART1).

Only the asynchronous mode is supported by the STK525.

The STK525 is supplied with a RS-232 driver/receiver. One female DB9 connector

assumes the RS-232 connections.

Figure 2-8 . RS -232 DB9 Connector

Figure 2-9 . RS -232 DB9 Connections

RS-232 D B 9 fron t view

5

1

234

69

78

Figure 2-10 . Typical PC Connection Layout

STK525 / RS-232 DB9

Function Pin No Function

RTS (

AT90USBxxx

Pin No

2TxD (AT90USBxxx)

5GND

If Hardware Data Flow Control

7CTS (AT90USBxxx) 7

)

pin 2

RS-TxD

pin 3 RS-RxD

pin 4

pin 6

pin 5 GND

pin 7 RS-CTS

pin 8 RS-RTS

PC / DB9 serial port

(COM1 o r C OM x )

2

3

RxD (PC)

TxD (PC)3RxD (AT90USBxx x)

5 GND

RTS (PC)

8

CTS (PC)8

2-12 STK525 Hardware User Guide

7608A–AVR–04/06

Page 13

Using the STK525

The STK525 USART implement ation allows an optional hardware flow control that can

be enabled thanks to SP4, SP5, SP7, SP8 solder pads (See Figure 2-11).

Figure 2-11 . USART Schematic

VCC

RS232 Interface

U3

16

.

VCC

C1+1V+

C1-

C2+

C2-

RS 232TTL

.

.

.

.

.

GND

15

2

100nF

6

V-

C19

100nF

RS-RxD

13

.

14

.

RS-TxDRS-TxDRS-TxDRS-TxDRS-TxDRS-TxDRS-TxDRS-TxD

RS-CTS

7

.

RS-RTS

8

.

MAX3232

RS232 BUFFER

C18

SP7

SP8

P1

1

6

2

7

3

8

4

9

5

11

10

SUB-D 9 F EMALE

RS232

PD[7..0]

C16

100nF

C17

100nF

RxDPD2

PD3 TXD

SP4

PD1

PD0

CTS

RTS

SP5

3

4

5

12

11

10

9

Table 2-3 . UART Settings

Mode

Software Data Flow

Control

(default configuration)

Optional

Hardwa re Fl ow Control

Note: 1. Tx reference: STK525 source, Rx reference: STK525 destinati on

Solder Pads

Configuration

SP4: open

SP5: open

SP7: open

SP8: open

SP4: close

SP5: close

SP7: close

SP8: close

DB9

Connection

TxRxPin 2

Pin 3

Tx

Pin 2

Rx

Pin 3

CTS

Pin 7

Pin 8

RTS

(1)

STK525 Hardware User Guide 2-13

7608A–AVR–04/06

Page 14

Using the STK525

2.6 On-board Resources

2.6.1 Joystick

The 4+1 way joystick offers an easy user interface implementation for a USB application

(it can emulate mouse movements, keyboard inputs, etc.).

Pushing a push-button causes the corresponding signal to be pulled low, while releasing

(not pressed) causes an H.Z stat e on the s igna l. The user m us t enable i nternal pul l-ups

on the input pins, removing the need for an external pull-up resistors on the push-button.

Figure 2-12 . Joystick Schemati c

SW3

SW3

SW3

1

1

1

2

2

2

TPA511G

TPA511G

TPA511G

Com1

Com1

Com1

Com2

Com2

Com2

Select

Select

Select

Left

Left

Left

Up

Up

Up

Right

Right

Right

Down

Down

Down

PB[7..0]

PB[7..0]

PB[7..0]

PB5

PB5

PB5

5

5

5

PB6

PB6

PB6

7

7

7

PB7

PB7

PB7

3

3

3

PE4

PE4

PE4

6

6

6

PE5

PE5

PE5

4

4

4

PE[7..0]

PE[7..0]

PE[7..0]

2.6.2 LEDs

Figure 2-13 . Joystick Implementation

The STK525 include s 4 green LEDs implemented on one line. They are connected to

the high nibble of “Port D” of AT90USBxxx (PORTD[4..7]).

To light On a LED, the correspo nding port pin must drive to high level. To light Off a

LED, the corresponding port pin must drive a low level. It is the opposite method used in

STK500.

2-14 STK525 Hardware User Guide

7608A–AVR–04/06

Page 15

Figure 2-14 . LEDs Implementation Schematic

In-line Grouped LED s

Using the STK525

R121k

R131k

R141k

R151k

LED 0 (green)

LED 1 (green)

LED 2 (green)

LED 3 (green)

PD4

D2TOPLED LP M676

PD5

D3TOPLED LP M676

PD6

D4TOPLED LP M676

PD7

D5TOPLED LP M676

PD[7..0]

STK525 Hardware User Guide 2-15

7608A–AVR–04/06

Page 16

Using the STK525

2.6.3 Temperature Sensor

The temperature sensor uses a thermistor (R18), or temperature-sensitive resistor. This

thermistor has a ne gative temperature c oefficient (NTC), mea ning the resistance goes

up as temperature goes down. Of all passive temperature measurement sensors,

thermistors have the highest sensitivity (resistance cha nge per degree of temperat ure

change). Thermistors do not have a linear temperature/resistance curve.

The voltage over the NTC can be found using the A/D converter (connected to channel

0). See the AT90USBxxx datasheet for how to use the ADC. The thermistor value (R

T)

is calculated with the following expression:

R

RHV

T

Where: RT = Thermistor value (Ω) at T temperature (°Kelvin)

⋅()VCC V

ADC0

H = Second resistor of the bridge -100 KΩ ±10% at 25°C

R

ADC0 = Volt age value on ADC-0 input (V)

V

VCC = Board power supply

–

()⁄=

ADC0

The NTC thermistor used in STK525 has a resistance of 100 KΩ ±5% at 25° C (T0) and a

beta-value of 4250 ±3%. By the use of the following equation, the temperature (T) can

be calculated:

T

Where: RT = Thermistor value (Ω) at T temperature (°Kelvin)

R

T

⎛⎞

ln

⎝⎠

-------

R

------+

T

0

β

0

β

-------------------------------=

ß = 4250 ±3%

0 = 100 KΩ ±5% at 25°C

R

T

0 = 298 °K (273 °K + 25 °K)

The following cross table also can be used. It is based on the above equation.

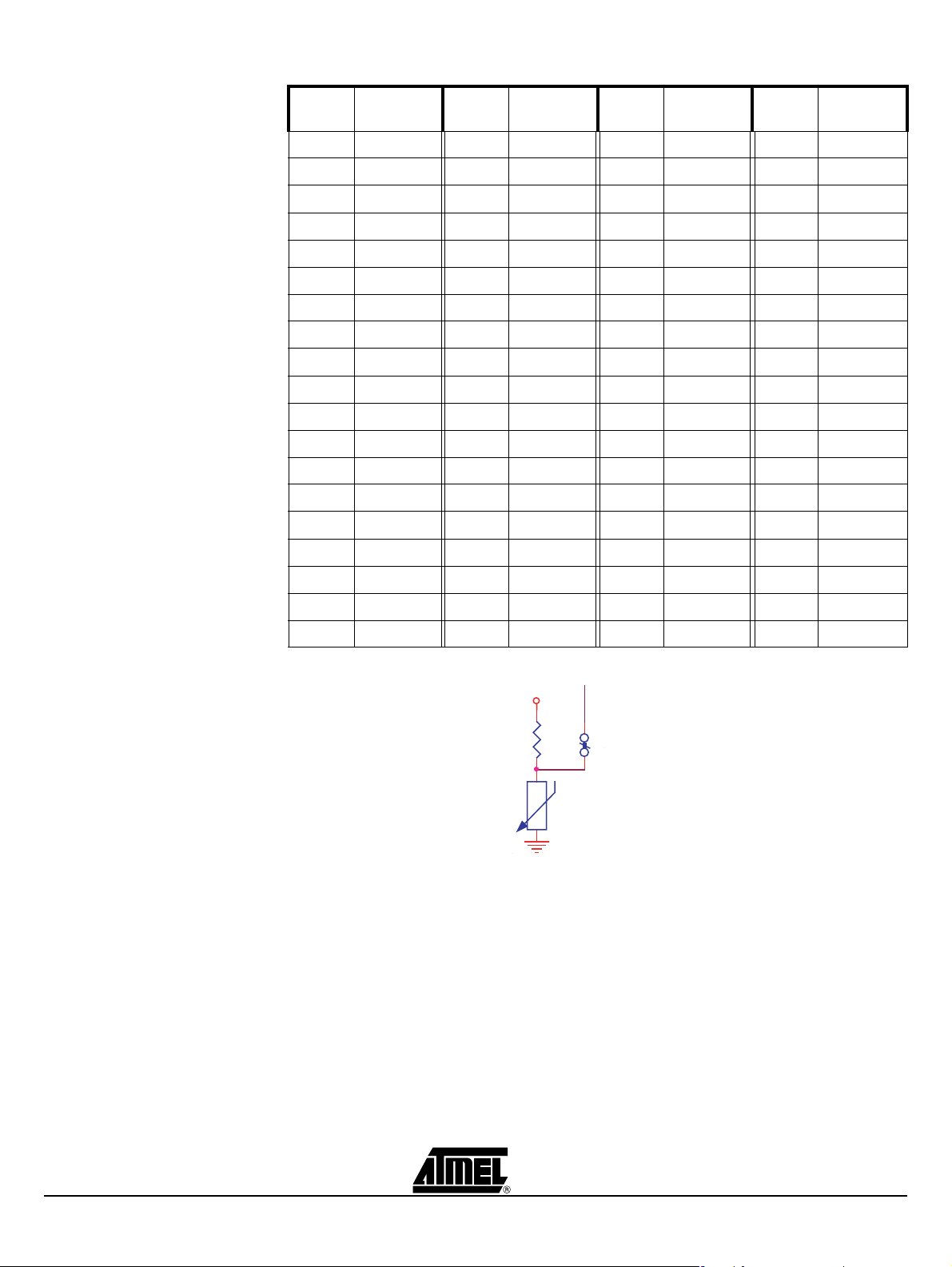

Table 2-4 . Thermistor Values versus Temperature

Temp.

(°C)

-20 1263,757 10 212,958 40 50,486 70 15,396

-19 1182,881 11 201,989 41 48,350 71 14,851

-18 1107,756 12 191,657 42 46,316 72 14,329

-17 1037,934 13 181,920 43 44,380 73 13,828

-16 973,006 14 172,740 44 42,537 74 13,347

-15 912,596 15 164,083 45 40,781 75 12,885

-14 856,361 16 155,914 46 39,107 76 12,442

RT

(KΩ)

Temp.

(°C)

T

R

(KΩ)

Temp.

(°C)

T

R

(KΩ)

Temp.

(°C)

T

R

(KΩ)

-13 803,984 17 148,205 47 37,513 77 12,017

-12 755,175 18 140,926 48 35,992 78 11,608

-11 709,669 19 134,051 49 34,542 79 11,215

-10 667,221 20 127,555 50 33,159 80 10,838

2-16 STK525 Hardware User Guide

7608A–AVR–04/06

Page 17

Using the STK525

Temp.

(°C)

R

T

(KΩ)

Temp.

(°C)

T

R

(KΩ)

Temp.

(°C)

T

R

(KΩ)

Temp.

(°C)

-9 627,604 21 121,414 51 31,840 81 10,476

-8 590,613 22 115,608 52 30,580 82 10,128

-7 556,056 23 110,116 53 29,378 83 9,793

-6 523,757 24 104,919 54 28,229 84 9,471

-5 493,555 25 100,000 55 27,133 85 9,161

-4 465,300 26 95,342 56 26,085 86 8,863

-3 438,854 27 90,930 57 25,084 87 8,576

-2 414,089 28 86,750 58 24,126 88 8,300

-1 390,890 29 82,787 59 23,211 89 8,035

0 369,145 30 79,030 60 22,336 90 7,779

1 348,757 31 75,466 61 21,498 91 7,533

2 329,630 32 72,085 62 20,697 92 7,296

3 311,680 33 68,876 63 19,930 93 7,067

4 294,826 34 65,830 64 19,196 94 6,847

5 278,995 35 62,937 65 18,493 95 6,635

6 264,119 36 60,188 66 17,820 96 6,430

T

R

(KΩ)

2.6.4 Microphone

7 250,134 37 57,576 67 17,174 97 6,233

8 236,981 38 55,093 68 16,556 98 6,043

9 224,606 39 52,732 69 15,964 99 5,860

Figure 2-15 . Thermistor Schematic

VCC

PF0

R16

100k

CP1

R18

Temperature

Sensor

The STK525 provides an electret microph one associated with its required preamplifier

(See Figure 2-16), the interface is connected to ADC channel 2 of the AT90USBxxx

microcontroller.

STK525 Hardware User Guide 2-17

7608A–AVR–04/06

Page 18

Using the STK525

Figure 2-16 . Microphone interface schematic

3.3V

R20

2.2k

MIC1

MICROPHONE

2.6.5 Data Flash Memory

R23 100k

3.3V

R24 100k

-

6

+

5

8 4

U4B

LMV358

7

R27 0

C24 4.7uF

+

R21

100k

R25 10k

R28

100k

+

1uF

C25

2

3

3.3V

C22 220pF

U4A

LMV358

-

1

+

8 4

R22

100k

R26 22k

For mass-storage class demonstration purposes, the STK525 provides an on-chip serial

Flash memory (AT45DB321x) connected to the AT90USBxxx Serial Port Interface

(SPI).

TP4

1

Mic

2.6.6 Potentiometer

The data-flash chip select signal is connected to PortB bit 4 of the AT90USBxxx (See

Figure 2-17).

Figure 2-17 . On-board data flash schematic

PB[7..0]

3.3V

R10

100k

PB4

PB1

PB2

PB3

R11

100k

RESET

U2

1

BUSY

2

RESET

3

WP

11

CS

12

SCK

13

SI

14

SO

AT45DB321C TSOP28

VCC

GND

3.3V

6

C15

7

100nF

The cursor of a potentiometer is connected to ADC channel 1 of the AT90USBxxx.

2-18 STK525 Hardware User Guide

7608A–AVR–04/06

Page 19

2.7 STK500 Resources

Using the STK525

Figure 2-18 . Connecting STK525 to the STK500 Board

Note: Caution: Do not mount an AVR microcontroller on the STK500 board when STK525 is

plugged on STK500.

2.7.1 Supply Voltage from STK500

The AVR supply voltage coming from STK500 (VT G) can also be controlled from AVR

Studio®.

The supply voltage coming from STK500 is controlled by power supply circuitry of

the STK525. Refer to

Table 2-1 on page 8 to configure “Vcc Source” jumper.

2.7.2 Analog Reference Voltage from STK50 0

The AVR Analog Reference V oltage com ing from ST K500 (RE F) can also be cont rolled

from AVR Studio®.

JP3 should be closed

STK525 Hardware User Guide 2-19

7608A–AVR–04/06

Page 20

Using the STK525

2.7.3 EXP.CON 0 & EXP.CON 1 Connectors

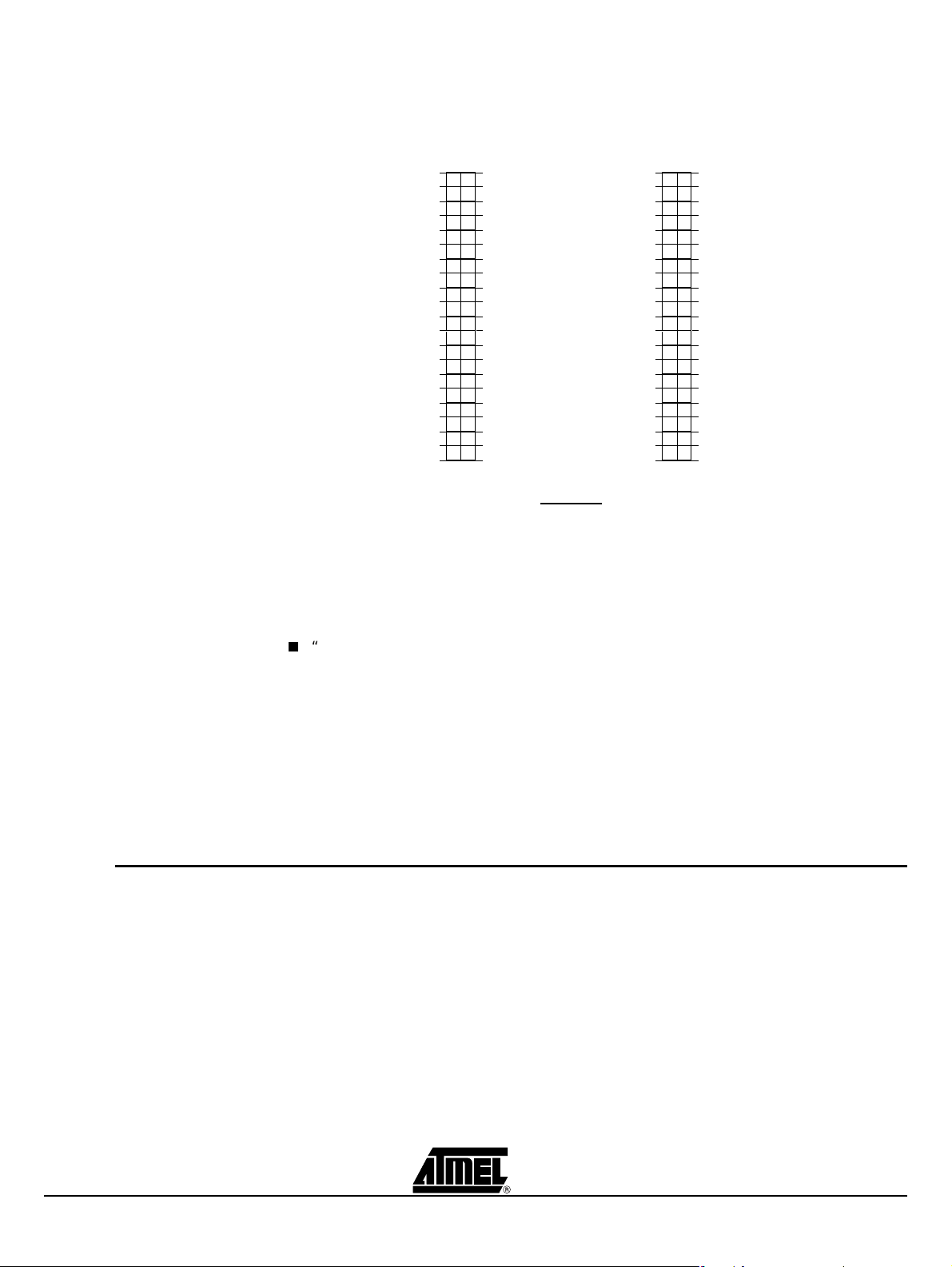

Figure 2-19 . EXP.CON 0 and EXP.CON 1 Connectors

2.7.4 Main Clock from STK500

The AVR clock frequency (external) coming from STK500 (XT1/XT2) can also be

controlled from AVR Studio®.

GND GND1 2

n.c. (AUXI0) n.c. (AUXO0)3 4

n.c. (CT7) n.c. (CT6)5 6

n.c. (CT5) n.c. (CT4)7 8

n.c. (CT3) n.c. (CT2)9 10

n.c. (CT1) n.c. (BSEL2)11 12

n.c. REF13 14

NRST PG215 16

PG1 PG017 18

GND GND19 20

VTG VTG21 22

PC7 PC623 24

PC5 PC425 26

PC3 PC227 28

PC1 PC029 30

PA7 PA631 32

PA5 PA433 34

PA3 PA235 36

PA1 PA037 38

GND GND39 40

EXP. CON 0

GND GND1 2

n.c. (AUXI1) n.c. (AUXO1)3 4

n.c. (DATA7) n.c. (DATA6)5 6

n.c. (DATA5) n.c. (DATA4)7 8

n.c. (DATA3) n.c. (DATA2)9 10

n.c. (DATA1) n.c. (DATA0)11 12

n.c. (SI) n.c. (SO)13 14

n.c. (SCK) n.c. (CS)15 16

XT1 XT21718

VTG VTG1920

GND GND2122

PB7 PB623 24

PB5 PB425 26

PB3 PB227 28

PB1 PB029 30

PD7 PD63132

PD5 PD43334

PD3 PD23536

PD1 PD03738

GND GND3940

EXP. CON 1

T op View

“STKX1” and ”STKX2” jumpers should be closed

2.7.5 RESET from STK500

The AVR RESET coming from STK500 (NRST - EXP.CON 0) can also control the

STK525. STK525 is protected against +12V RESET pulse (parallel programing not

allowed for AT90USBxxx on STK525) coming from STK500.

2.8 In-System Programming

2.8.1 Programming with USB bootloader: DFU (Devi ce Firmware Upgrade)

AT90USBxxx part comes with a default factory pre-programmed USB bootloader

located in the on-chip boot section of the AT90USBxxx. This is the easiest and fastest

way to reprogram the device directly over the USB interface. The “Flip” PC side

application available for free on Atmel website offers a flexible and user friendly

interface to reprogram the application over the USB bus.

2-20 STK525 Hardware User Guide

7608A–AVR–04/06

Page 21

The HWB pin of the A T90USB xx x allows to forc e the boot load er sec tion exec ution after

reset. (Refer to AT90USBxxx datasheet section “boot loader support”). To force

bootloader execution, operate as follows:

Press both “RST” and “HWB” push buttons

First release the “RST” push button

Release the “HWB” push button

For more information about the USB bootloader and FLIP software, please refer to the

‘USB bootloader datasheet’ document and ‘FLIP User Manual’.

2.8.2 P rogramming with AVR ISP mkII Programmer

The AT90USBxxx can be programmed using specific SPI serial links. This sub section

will explain how to connect the programmer.

The Flash, EEPROM and all Fuses and Lock Bits options ISP-programm able can be

programmed individually or with the sequential automatic programming option.

The AVR ISP mkII progra mmer is a com pact an d easy-to-use In-System P rogramming

tool for developing applications with AT90USBxxx. Due to the small size, it is also an

excellent tool for field upgrades of existing applications.

Using the STK525

The AVR ISP programming interface is integrated in AVR Studio®.

To program the device using AVR ISP programmer, connect the 6-wire cable on the ISP

connector of the STK525 as shown in Figure 2-20.

Note: See AVR Studio® on-line Help for informati on.

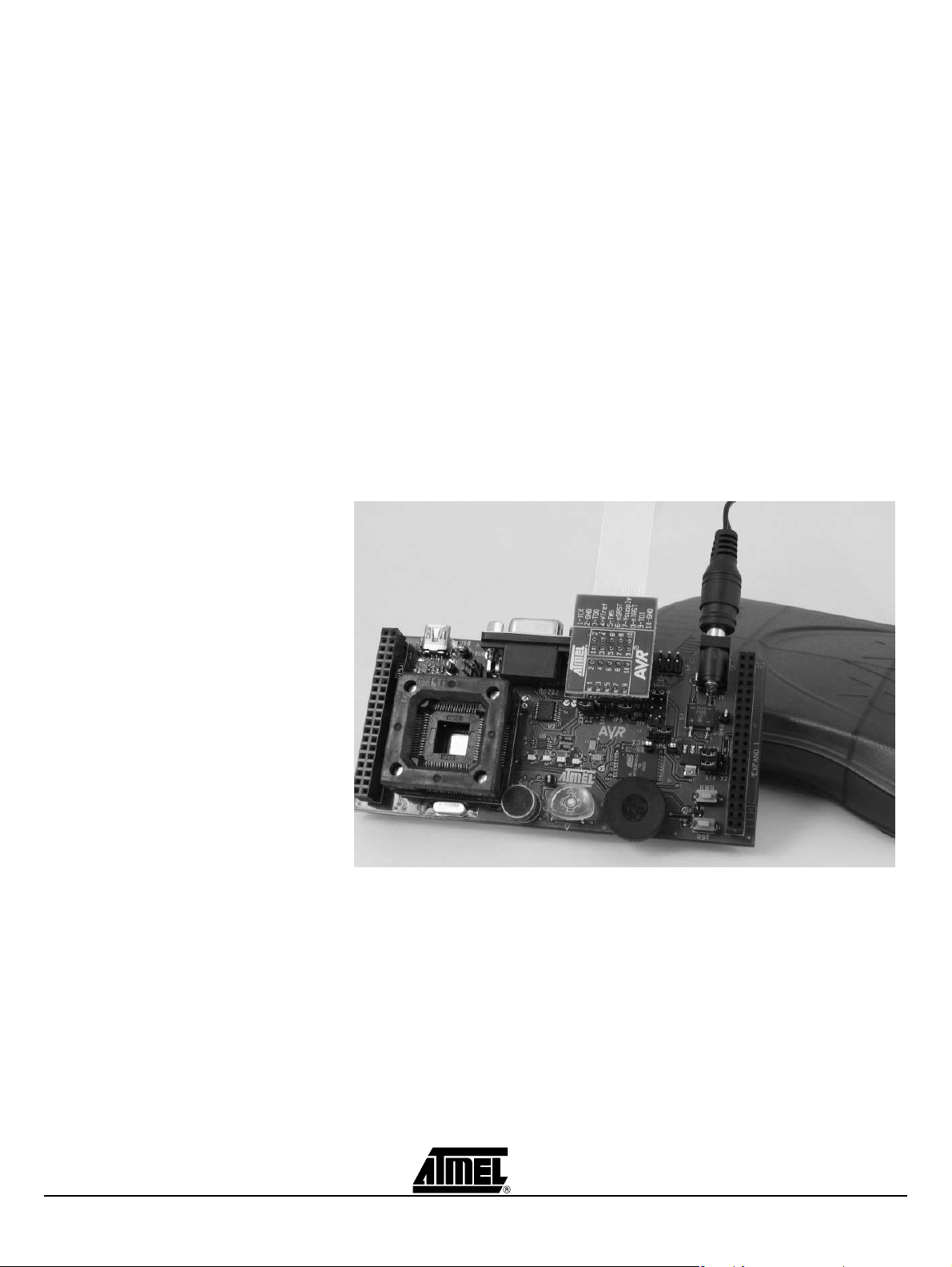

Figure 2-20 . Programming from AVR ISP mkII programmer

2.8.3 Programmin g with STK500

The AT90USBxxx can be programm ed using the serial program ming mode in the A VR

Studio STK500 software. The software interface (In-System Programming of an external

target system) is integrated in AVR S tud i o ®.

STK525 Hardware User Guide 2-21

7608A–AVR–04/06

Page 22

Using the STK525

To program the dev ice using ISP f rom STK500, conne ct the 6-wire cable between the

ISP6PIN connector of the STK500 board and the ISP connector of the STK525 as

shown in Figure 2-18.

Note: See AVR Studio® on-line Help for informati on.

Note: The high voltage parallel programming mode with STK500 is not available for an

STK525. To reprogram an AT90USBxxx part in parallel mode, use an STK501 extension

board (AT90USBxxx product pinout is compatible with the STK501 parallel programing

mode).

2.8.4 Programming with A VR JTAG ICE

The AT90USBxxx can be programmed using specific JTAG link. This sub-section will

explain how to connect and use the AVR JTAG ICE.

Note: When the JTAGEN Fuse is unprogrammed, the four TAP pins are normal port pins, and

the TAP controller is in reset. When programmed, the input TAP signals are internally

pulled high and the JTAG is enabled for Boundary-scan and programming. The

AT90USBxxx device is shipped wit h this fuse programmed.

Figure 2-21 . Connecting AVR JTAG ICE to STK525

The Flash, EEPROM and all Fuse and Lock Bit options ISP-programmable can be

programmed individually or with the sequential automatic programming option.

Note: See AVR Studio® on-line Help for informati on.

2-22 STK525 Hardware User Guide

7608A–AVR–04/06

Page 23

2.9 Debugging

2.9.1 Debugging with AVR JTAG ICE mkII

Every STK525 can be used for debugging with JTAG ICE MK II.

Connect the JTAG ICE mkII as shown in Figure 2-21, for debugging help, please refer to

AVR Studio® Help information.

When using JTAG ICE MK II for debugging, and as AT90USBxxx parts are factory

configured with the higher security level set, a chip erase operation will be performed on

the part before debugging. Thus the on-ch ip flash bootloader will be erased. It can be

restored after the debug session using the bootloader hex file available from ATM EL

website.

2.10 Test Points

There are 8 test points implemented, these test points are referred in the full schematics

section.

Using the STK525

Config.

Pads

Reference

T1 D+ USB D+ data line

T2 D- USB D- data line

T3 Aref Analog reference

T4 Mic Microphone preamplifier output

T5 3.3V 3.3V internal power supply

T6 5V 5V inter nal power supply

T7 Gnd Ground

T8 Vbus USB Vbus power supply

Related Signals Function

STK525 Hardware User Guide 2-23

7608A–AVR–04/06

Page 24

Using the STK525

2.11 Configuration Pads

Configuration pads are used to disconnect/connect on-board peripherals or elements, their

default configuration is: connect.

2.11.1 Confi guration P ads Listing

Table 2-5 . Configuration Pads

Config.

Pads

Reference

CP1 °c sensor (PF0)

CP2 pot. (PF1)

CP3 Mic.(PF2)

2.11.2 Configuration Pads - Disconnection

Figure 1. Configuration Pad - Disconnection

2.11.3 Confi guration P ads - Co nn e ct i on

Related

Signals

Function

This configuration pad is used to disconnect/connect the

CTN sensor from STK525.

This configuration pad is used to disconnect/connect the

potentiomet er from STK525.

This configuration pad is used to disconnect/connect the

microphone preamplifier output from STK525.

Cut Connection

Figure 2. Configuration Pad - Re-connection

WireDroplet of So lder

2-24 STK525 Hardware User Guide

7608A–AVR–04/06

Page 25

2.12 Solder Pads

2.12.1 Solder Pads Listing

Using the STK525

Solder pads are used to disconnect/connect on-board peripherals or elements, their default

configuration is: disconnect.

Table 2-6 . Solder Pads

Solder.

Pads

Reference

SP1 AVCC/VCC This solder pad can be used to bypass L1.

SP2 NRST/RESET This solder pad can be used to bypass D1.

SP3 3.3V

SP4 PD1/CTS

SP5 PD0/RTS

SP6 VBUS This solder pad allows to bypass U5 VBUS current limit er.

SP7 RS-CTS

SP8 RS-RTS

Related

Signals

Function

This solder p ad is reserved to connect 3.3V power supply to

the N.C pin of Expand0/1

This solder pa d all ows to enable the logical CTS signal for

hardware contro l flow on RS232 interface.

This solder pa d all ows to enable the logical R TS signal for

hardware contro l flow on RS232 interface.

This solder pa d all ows to enable the physical CTS signal for

hardware contro l flow on RS232 interface.

This solder pa d all ows to enable the physical R TS signal for

hardware contro l flow on RS232 interface.

STK525 Hardware User Guide 2-25

7608A–AVR–04/06

Page 26

Troubleshooting Guide

Figure 3-1 . Troubleshooting Guide

Problem Reason Solution

Section 3

The Green “VCC-ON”

LED is not on

STK525 does not work

The A T90USBxxx cannot

be programmed

AVR Studi o does not

detect the AVR tool used

No power supply

The

STK500 ISP header

is not connected.

The A VR ISP probe is

not connected

The A V R JTAG ICE

probe is not

connected

The memory lock bits

are programmed

The fuse bits are

wrongly programmed

Programming too fast

with ISP SPI

Serial/USB cable is

not connected, or

power is off

PC COM port is in

use

Verify the power supply source

Verify the power supply source

Connect the DC power supply source, o r

USB interface or STK500.

Connect a 6-pin flexible cable from

STK500 ISP 6-PIN header to the correct

STK525 ISP header (page 21)

Connect the AVR ISP 6-PIN header to

the correct STK525 ISP header (page

21)

Connect the JTAG ICE 10-PIN header to

the correct STK525 JTAG header (page

22)

Erase the memory before programming

Check the fuse bits

Check oscillator settings and make sure

it is not set higher than SPI clock

Connect seri al cable to RS232 (STK5 00 AVR ISP) and check power connect ions

Connect serial cable to USB (JATG ICE

MKII, AVR ISPmkIIl) and chec k power

connections

Disable other programs that are using

PC COM port.

Change PC COM port

AVR Studio does not

detect COM port.

STK525 Hardware User Guide 3-26

Disable COM port auto-detection in AVR

St udio file menu. Force COM port to

correct COM port

7608A–AVR–04/06

Page 27

Troubleshooting Guide

STK525 Hardware User Guide 3-27

7608A–AVR–04/06

Page 28

Section 4

Technical Specifications

System Unit

– Physical Dimensions ................................................. L=119 x W=56 x H=27 mm

– Weight...........................................................................................................70 g

Operating Conditions

– Internal Voltage Supply .............. ........................ ...............................2.7V - 5.5V

– External Voltage Supply ..........................................................9V -15V (100mA)

Connections

– USB Connector......................................................................Mini AB receptacle

– USB Communications .......................................................Full speed/low speed

– RS 232C Connector.............................................................9-pin D-SUB female

– RS 232C Communications Maximum Speed........................................250 kbps

STK525 Hardware User Guide 4-28

7608A–AVR–04/06

Page 29

Section 5

Technical Support

For Technical support, please contact avr@atmel.com. When requesting technical

support, please include the following information:

Which target AVR device is used (complete part number)

Target voltage and speed

Clock source and fuse setting of the AVR

Programming method (ISP, JTAG or specific Boot-Loader)

Hardware revisions of the AVR tools, found on the PCB

Version number of AVR Studio. This can be found in the AVR Studio help menu.

PC operating system and version/build

PC processor type and speed

A detailed description of the problem

STK525 Hardware User Guide 5-29

7608A–AVR–04/06

Page 30

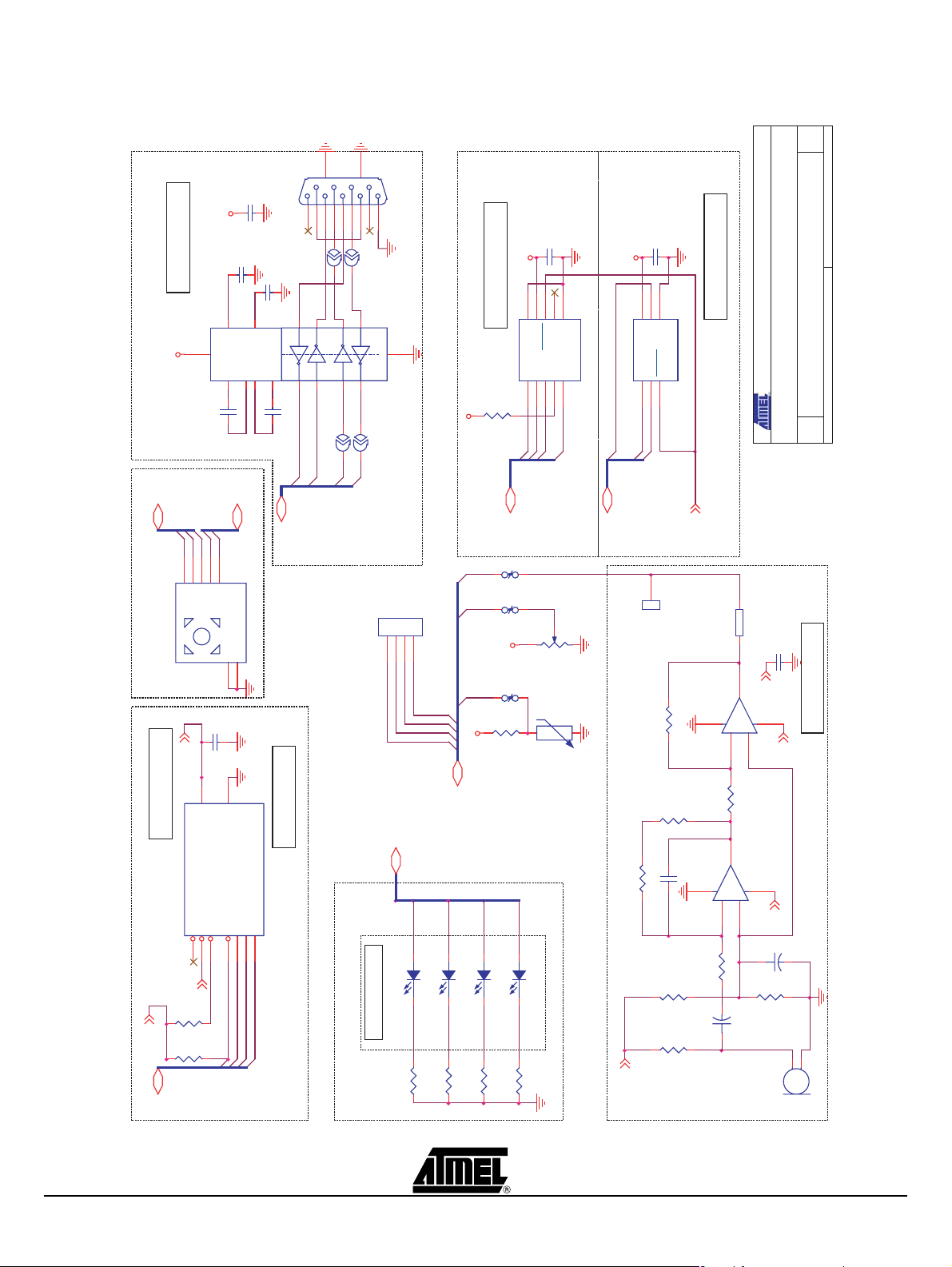

Section 6

Complete Schematics

On the next pages, the following documents of STK525 revision 4381A are shown:

Complete schematics,

Asse m bly drawing,

Bill of mater ials .

Default configuration summary

STK525 Hardware User Guide 6-30

7608A–AVR–04/06

Page 31

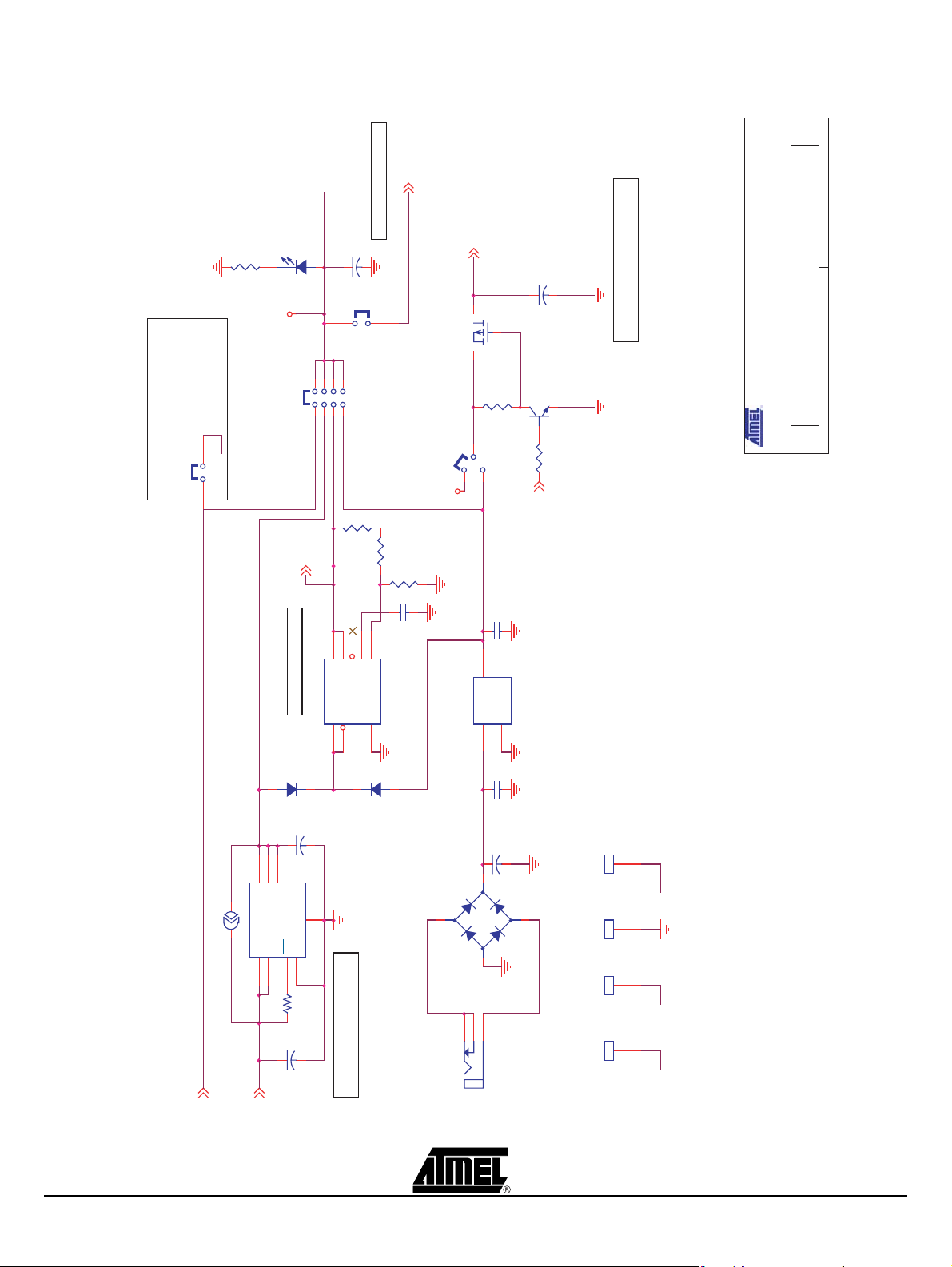

Figure 6-1 . Schematics, 1 of 5

Complete Schematics

PE2

C8

220nF

C1

100nF

VCC

C6

100nF

VCC

C5

100nF

VCC

R3

47k

SW1

HWB

VCC

VCC

Force Bootloader Execution

DECOUPLING CAPACITORS

CLOSED TO THE DEVI C E

DECOUPLING CAPACITORS

CLOSED TO THE DEVI C E

MCU Pin52

DECOUPLING CAPACITORS

CLOSED TO THE DEVI C E

MCU Pin21

MCU Pin3

PC[7..0]

Reset Circuit

PC1

PB3

CR2

CR1

PC0

PC035PC136PC237PC338PC439PC540PC641PC7

PB4

PC[7..0]

PE1

PE0

34

PE033PE1

PD7

PD6

PD5

PD4

PD3

PD2

PD1

PD0

XTAL1

XTAL2

GND

VCC

RESET

PE5

PE4

PB7

16

PB5

PB6

R4 0

PGB0010603

PGB0010603

PD[7..0]

U1

UGND

UCAP C apac it or

PD[7..0]

32

PD7

31

PD6

30

PD5

29

PD4

28

PD3

27

PD2

26

PD1

25

PD0

24

XTAL1

23

XTAL2

22

21

20

19

18

17

PB7

Closed t o t he MCU

PE5

PE4

PB[7..0]PB[7..0]

VCC

RESET

PE7

PE3

PE2

PE1

PE0

PB[7..0]

PE[7..0]

PA[7..0]

PA3

PA4

PA5

PA6

PA7

PE2

PC7

PC6

PC5

PC4

PC3

PC2

PA[7..0]PA[7..0]PA[7..0]

PA[7..0]PA[7..0]PA[7..0]

PA2

PA1

PA0

VCC

AREF

PF[7..0]

C3

100nF

SP1

L1

BLM -21A 102S

VCC AVCC

C2

100nF

Ferrite & c apac it ors

closed t o t he MCU

PF7

PF6

PF5

PF4

PF3

PF2

PF1

PF0

AGND

AVCC

C4

100nF

AREF

48

PA2

49

PA1

50

PA0

51

VCC

52

GND

53

PF7

54

PF6

55

PF5

56

PF4

57

PF3

58

PF2

59

PF1

60

PF0

61

AREF

62

GND

63

AVCC

64

1

UVCON

D+ D- R ESI STORS

Closed t o t he MCU

42

43

PE2

PA744PA645PA546PA447PA3

AT90USB128

PE72UVcc3D-4D+5UGND6UCAP7VBUS8PE39PB010PB111PB212PB313PB414PB515PB6

PE6

PB0

PB1

PB2

UVCON PE7

VCC

J1

VBUS

D+

D-

UID PE3

UCAP

UVCC

VBUS

C7

1uF

UCAP

R2 22

R1 22

VBUS

VBUS

2-D-

1-V_BUS

UGND UGNDUGNDUGNDUGND

4-ID

3-D+

SHIELDSHIELDSHIELDSHIELD

5-GND

USB_MiniABF

RESET

of

RESET

C9

220nF

Close Solder Pad

To use parallel prog mode

BAT54/SOT

SP2

(12V on Reset Pin)

STK525 MEZZANINE FOR STK500

Title

AREF

1

TP3

AREF

D-

1

TP2

D-D+

D+

1

TP1

R7 0

R6 0

RESISTORS

UGND

AGND

SW2

R5

D1

XTAL1

XTAL2

Ext Reset

47k

NCKA

INT 0/2

NRST

15pF

8MHz C11

Y1

C10

15pF

Important Note:

U1 is mounted through a TQFP64 ZIF socket

14Wednesday , February 15, 2006

11.0

CPU

A4

Size Docum ent N um ber Rev

Date: Sheet

CLOSED TO THE DEVI C E

STK525 Hardware User Guide 6-31

7608A–AVR–04/06

Page 32

Complete Schematics

R8

Figure 6-2 . Schematics, 2 of 5

of

24Tuesday , J anuary 17, 2006

C12

1nF

PE[2..0]

PC[7..0]

PB[7..0]

VTG

AREF

PD[7..0]

2k

Q1

BC847B

PD[7..0]

JP3

STK AREF

1 2

R9

10k

C14

100nF

PE[2..0]

PA[7..0]

STK525 MEZZANINE FOR STK500

<Doc> 1.0

PC[7..0]

PA[7..0]

PB[7..0]

STK500 Expand connect ors

A4

Title

Size Docum ent N um ber Rev

Date: Sheet

PE0

PE2

PC6

PC4PC5

PC2

REF

VTG

6

8

10

16

18

12

14

4

2

CT6

CT4

CT2

PE2

PE0

GND

NRST

J3

GND

1

3

VTGVTG

REF

BSEL2

AUXO0

AUXI0

CT7

CT5

CT3

CT1

(n.c.)

NRST

PE1

5

7

9

11

13

15

17

STKNC

PE1

PC0PC1

PA0

PA4

PA2

32

34

36

22

24

26

28

20

VTG

PC6

PC4

GND

GND

VTG

PC7

PC5

19

21

23

25

27

PC3

PC7

38

30

PC2

PC3

29

40

PA6

PA4

PA2

PA0

PC0

PC1

31

PA7 PA6

PA7

33

PA5

PA5

35

PA3

PA3

37

PA1

PA1

GND

CON 2x20

EXP. CON 0

GND

39

XTAL2

XT2XT1

PB6

PB2

PB4

PB0

PD6

PD2

PD4

PD0

JP2

STK X2

1 2

XTAL1

6

8

10

12

2

4

GND

DATA6

DATA4

DATA0

AUXO1

J2

GND

AUXI1

DATA7

DATA5

DATA3

1

3

5

7

9

22

14

16

18

24

26

28

30

20

SO

CS

XT2

PB6

PB4

PB2

VTG

GND

DATA9

DATA1

SI

SCK

XT1

VTG

GND

PB7

PB5

PB3

11

13

15

17

19

21

23

25

27

29

PB0

PB1

40

32

34

36

38

PD6

PD4

PD2

PD0

GND

CON 2x20

PD7

PD5

PD3

31

33

35

37

EXP. CON 1

PD1

GND

39

PD5

PD7

PD1

VTG

JP1

STK X1

1 2

100nF

C13

PB7

PB5

PB3

PB1

PD3

SP3

STKNC

3.3V

Important:

Def ault c onf iguration: open

reserv ed f or f ut ure m as s s t orage ex t ens ion

6-32 STK525 Hardware User Guide

7608A–AVR–04/06

Page 33

VCC

DECOUPLING CAPACITOR

CLOSE TO THE DEVIC E

VCC

C18

2

V+

.

16

VCC

C1+

U3

1

C16

RS232 Interface

Figure 6-3 . Schematics, 3 of 5

10

11

C20

100nF

100nF

6

C1-3C2+4C2-

100nF

P1

SP7

RS-CTS

RS-TxDRS-TxDRS-TxDRS-TxDRS-TxDRS-TxDRS-TxDRS-TxD

RS-RxD

C19

100nF

.13.

V-

RS 232TTL

5

12

RxDPD2

C17

100nF

RS-RTS

7

14

.11.

.10.

CTS

SP4

PD1

PD3 TXD

SUB-D9 F EMALE

RS232

594837261

SP8

SP5

RS232 BUFFER

MAX3232

.

15

GND

.8.

9

RTS

PD0

JTAG Interface

VCC

6

2

4

DECOUPLING CAPACITOR

CLOSE TO THE CONN EC TOR

VCC

GND

J4

TCK

TDO

1

3

R17

VCC

5

0

PF4PF4

PF6

PF5PF5

C21

8

RESET

TMS

7

100nF

10

n.c.

VCC

9

PF7

GND

CON 2x5

TDI

Serial ISP

Interface

VCC

2

J5

JTAG CON

1

PB2

PB3

Complete Schematics

of

34Tuesday , J anuary 17, 2006

C23

100nF

DECOUPLING CAPACITOR

6

4

PDI

VCC

GND

CON 2x3

PDO

SCK

RESET

5

3

RESET

PB1

CLOSE TO THE CONN EC TOR

ISP CON

STK525 MEZZANINE FOR STK500

<Doc> 1.0

Interfaces

A4

Title

Size Document N um ber Rev

Date: Sheet

PB[7..0]

PB5

PB6

5

7

Select

SW3

PE[7..0]

PB7

PE4

PE5

3

6

4

Up

Left

Right

Down

Com11Com2

TPA511G

2

Joystick Interface

C15

100nF

3.3V

7

6

VCC

BUSY1RESET2WP

3

GND

CS11SCK12SI13SO

14

DECOUPLING CAPACITOR

CLOSE TO THE DEVIC E

U2

Data Flash

R11

100k

RESET

PB1

PB2

3.3V

R10

100k

PB[7..0]

PB4

PB3

PD[7..0]

Caution D at aF las h

AT45DB321C TSOP28

Fix 3V Power supply Only

LEDs

PF[7..0]

PF2

CP3

PF1

J7

123

4

PF0

PF1

PF2

PF3

PF Spare (Not m ount ed)

PD[7..0]

PD4

PD5

D2TOPLED LP M676

LED 0 (green)

In-line Grouped LEDs

LED 1 (green)

R121k

R131k

CP2

VCC

R19

CP1

PF0

VCC

PF[7..0]

R18

R16

100k

Temp Sensor

PD7

PD6

D3TOPLED LP M676

D4TOPLED LP M676

D5TOPLED LP M676

LED 2 (green)

LED 3 (green)

R141k

R151k

POT 100k

PB[7..0]

1

TP4

NCP18WF104J03RB

Microphone Preamplifier Interface

R23 100k

3.3V

R24 100k

Mic

R22

100k

C22 220pF

R21

R20

2.2k

100k

RESET

U4A

U4B

LMV358

-

R25 10k

C24 4.7uF

LMV358

R26 22k

2

+

R27 0

-

6

1

+

C26

100nF

7

3.3V

+

8 4

5

3.3V

8 4

3

3.3V

C25

+

R28

100k

MIC1

1uF

DECOUPLING CAPACITOR

CLOSE TO THE DEVIC E

MICROPHONE

STK525 Hardware User Guide 6-33

7608A–AVR–04/06

Page 34

Complete Schematics

Figure 6-4 . Schematics, 4 of 5

UCAP

JP Clos ed f or 3.0<Vcc <3.3

C30

1 2

STK

VCC

3 4

VBUS

5 6

3.3V

3.3V

7 8

Ext

4.7uF

-

JP5

12

VCC Source

R35

100k 1%

R30100k 1%

R31

124k 1%

D8

TOPLED LP M676

R34

1k

3.3V

JP not m ount ed,

JP4

reserv ed f or f uture mas s s t orage ex t ens ion

in stand alone m ode

1 2

POWER LED(RED)

VCC

JP6

3.3V

VBUS

C34

4.7uF

-

VBUS generator f or OTG/HOST mode

FDV304P/FAI

M1

Q2

10k

BC847B

R33

VBUS g e n

100k

UVCON

R32

2

JP7

1

3

VTG

STK

Ext

5V5V

1F <Cap Vbus < 6F OTG Specif ic at ion

STK525 MEZZANINE FOR STK500

Title

of

44Tuesday , J anuary 17, 2006

<Doc> 1.0

POWER

A4

Size Document N um ber Rev

Date: Sheet

4

CC

SET

OUT

OUT

FAULT

U6out=1.25*(1+R28/R29)

U6

IN2GND

SHDN

7

D6

LL4148

C28

4.7uF

6

OUT18OUT27OUT3

GND

SP6

U5

IN12IN23EN4OC

VTG

VBUS

1

TPS2041A

5

R29

10k

C27

100nF

TPS2041A Vbus Icc limiter optionnal

3

D7

LL4148

When Not Mounted C los e Solder Pad

LP3982

U7

3

J6

C33

100nF

OUT

U8

IN

GND

LM340

C32

220nF

4.7uF

C31

-

1

4

-+

2

321

Ext Power Supply

CONNECTOR JACK PWR

DF005S

VBUS

1

TP8

VBUS

GND

1

TP7

5V

1

TP6

TP5

5V

3.3V

1

3.3V

C29

33nF

8

6

5

1

6-34 STK525 Hardware User Guide

7608A–AVR–04/06

Page 35

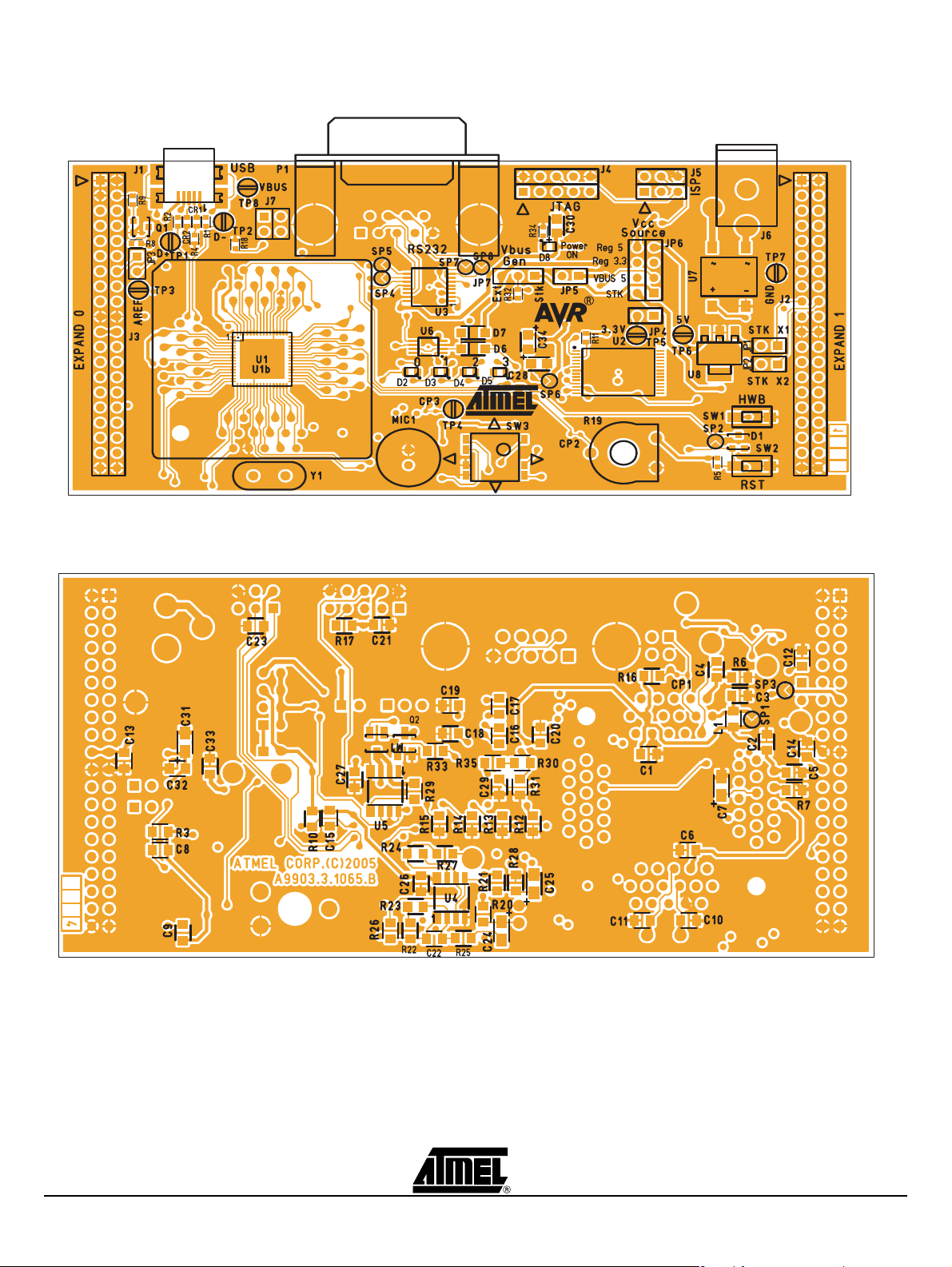

Figure 6-5 . Assembly Drawing, 1 of 2 (component side)

Complete Schematics

Figure 6-6 . Assembly Drawing, 2 of 2 (solder side)

STK525 Hardware User Guide 6-35

7608A–AVR–04/06

Page 36

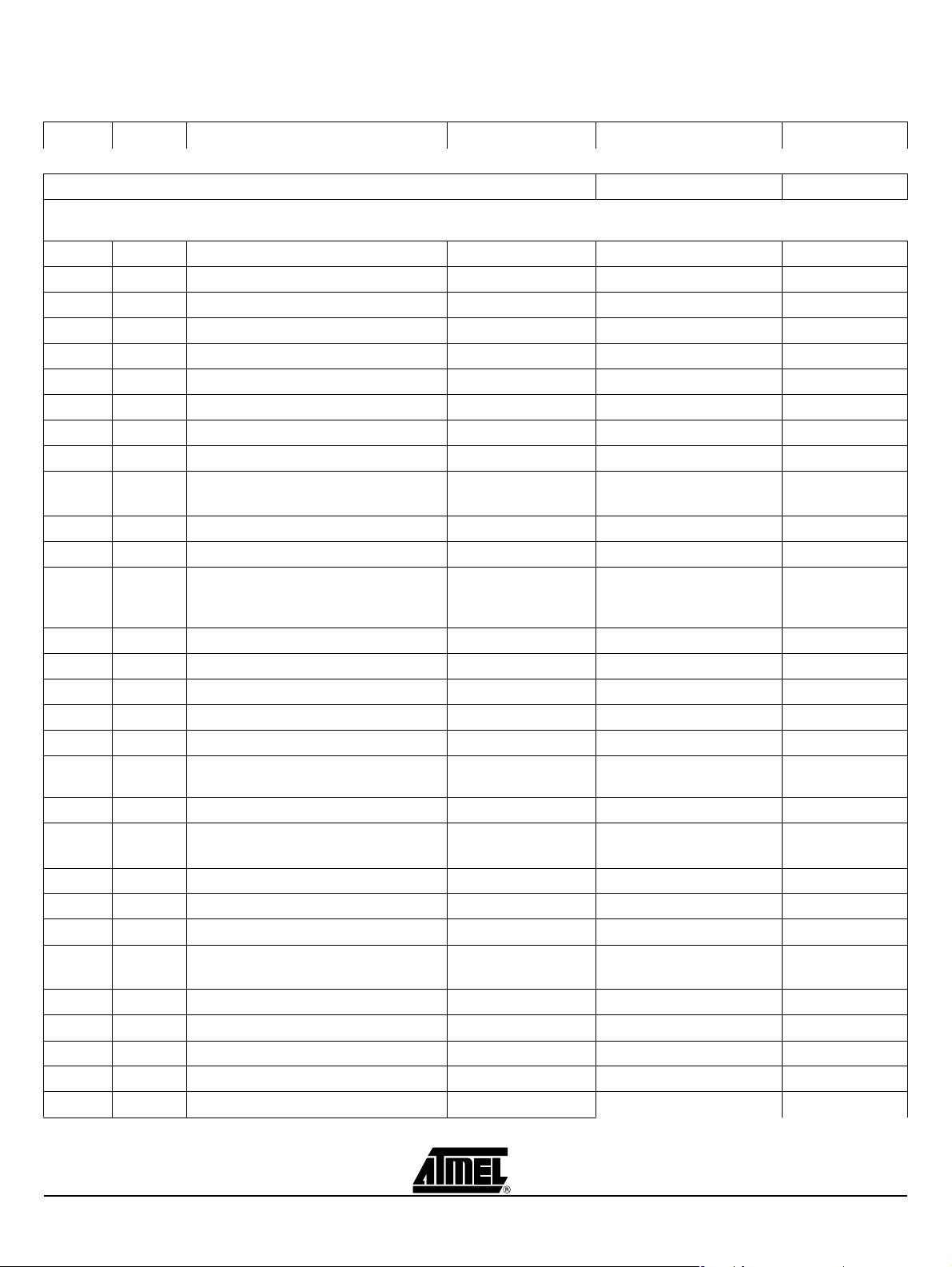

Complete Schematics

Table 6-1 . Bill of material

Item Q.ty Reference Part Tech. Characteristics Package

1 2 CR1,CR2 PGB0010603 ESD protection CASE 0805

219

3 2 C7,C25 1uF 10Vmin ±10% EIA/IECQ 3216

4 3 C8,C9,C32 220nF 50V-10% Ceramic CASE 0805

5 2 C10,C11 15pF 50V-5% Ceramic CASE 08 05

6 1 C12 1nF 50V-5% Ceramic C ASE 0805

7 1 C22 220pF 50V-5% Ceramic CASE 0805

8 5 C24,C28,C30,C31,C34 4.7uF 10Vmin ±10% EIA/IECQ 3216

9 1 C29 33nF 50V-5% Ceramic CASE 08 05

10 3 CP1, CP2, CP3 Config uration Pad

11 1 D1 BAT54/SOT Vf=0.3V SOT23

12 5 D2,D3,D4,D5,D8 TOPLED LP M676

13 2 D6,D7 LL4148 i=200mA max LL-34

14 5 JP1,JP2,JP3,JP4,JP5 JUMPER 1x2 Need 1 shunt 0,1" pitch

15 1 J1 USB_MiniABF

C1,C2,C3,C4,C5,C6,C13,C14,C15,C16,C

17,C18,C19,C20,C21,C23,C26,C27,C33

100nF 50V-10% Ceramic CASE 0805

Green

I=10 mA_

USB mini AB receptacle

Surfa c e mount

PLCC-2

16 2 J2,J3 CON 2x20

17 1 J4 CON 2x5

18 1 J5 CON 2x3

19 1 J7 CON 2x2 Not Mounted

20 1 JP6 JUMPER 2x4 Need 1 shunt 0,1" pitch

21 1 J6

22 1 JP7 JUMPER 3x1

23 1 L1 BLM-21A102S

24 1 MIC1 MICROPHONE Electret Cap Mic

25 1 M1 FDV304P/FAI MOSFET P SOT23

26 1 P1 SUB-D9 FEMALE 90° with harpoons

27 2 Q1,Q2 BC847B

28 2 R1,R2 22 1/16W-5% SMD CASE 0602

29 2 R3,R5 47k 1/16W-5% SMD CASE 0603

30 5 R4,R6,R7,R1 7, R27 0 CASE 0603

31 1 R8 2k CASE 0604

32 4 R9,R25,R29,R32 10k 1/16W-5% SMD CASE 0603

CONNECTOR JACK

PWR

Int.Diam=2.1mm PCB Embase

FERRITE BEAD

1 KOhms at 100 MHz

NPN

IC peak=200mA

CASE 0805

SOT23

6-36 STK525 Hardware User Guide

7608A–AVR–04/06

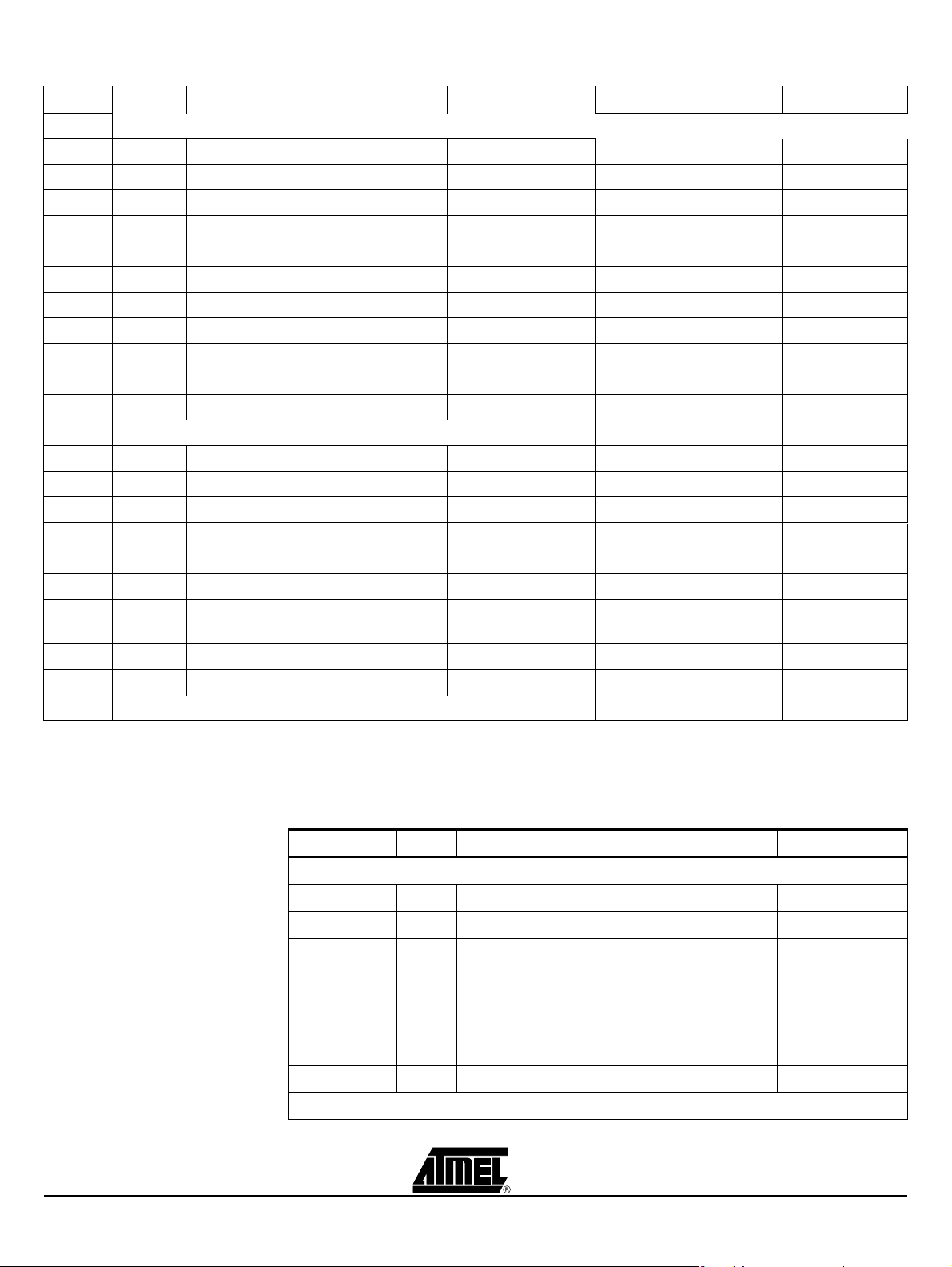

Page 37

Complete Schematics

Item Q.ty Reference Part Tech. Characteristics Package

33 9 R10,R11,R16,R21,R22,R23,R24,R28,R33 100k 1/16W-5% SMD CASE 0603

34 5 R12,R13,R14,R15,R34 1k 1/16W-5% SMD CASE 0603

35 1 R18 NCP18WF104J03RB 100K - ß=4250 CASE 0603

36 1 R19 POT 100k PT10MH104ME

37 1 R19 Button Pot Button

38 1 R20 2.2k 1/16W-5% SMD CASE 0603

39 1 R26 22k 1/16W-5% SMD CASE 0603

40 1 R30, R35 100k 1% 1/16W-1% SMD CASE 0603

41 1 R31 120k 1% 1/16W-1% SMD CASE 0603

42 6 SP1,SP2,SP3,SP4,SP5,SP6 SolderPad (NA) (NA)

43 2 SW1,SW2 PUSH-BUTTON 6x3.5mm - 1.6N

44 1 SW3 TPA511G 4+1 w ay s joysti ck CM S

45 8 TP1,TP2,TP3,TP4,TP5,TP6, TP7, TP8 TEST POINT Diam.=1.32mm

46 1 U1 A T90USBxxx TQFP64

47 1 U1 Soc k et TQFP64 ZIF

48 1 U2 AT45DB321C TSOP28

49 1 U3 MAX3232ECAE+ SSOP16

50 1 U4 LMV358 SO8

51 1 U5 TPS2041A SOIC8

52 1 U6 LP3982

53 1 U7 DF005S Bridge rectifier See DS

54 1 U8 LM340 Reg 5V CMS SOT22 3

55 1 Y1 8MHz CRYSTAL H=4mm HC49/4H

Low Drop Out

Vin Max 6V, 300mA

MSOP8

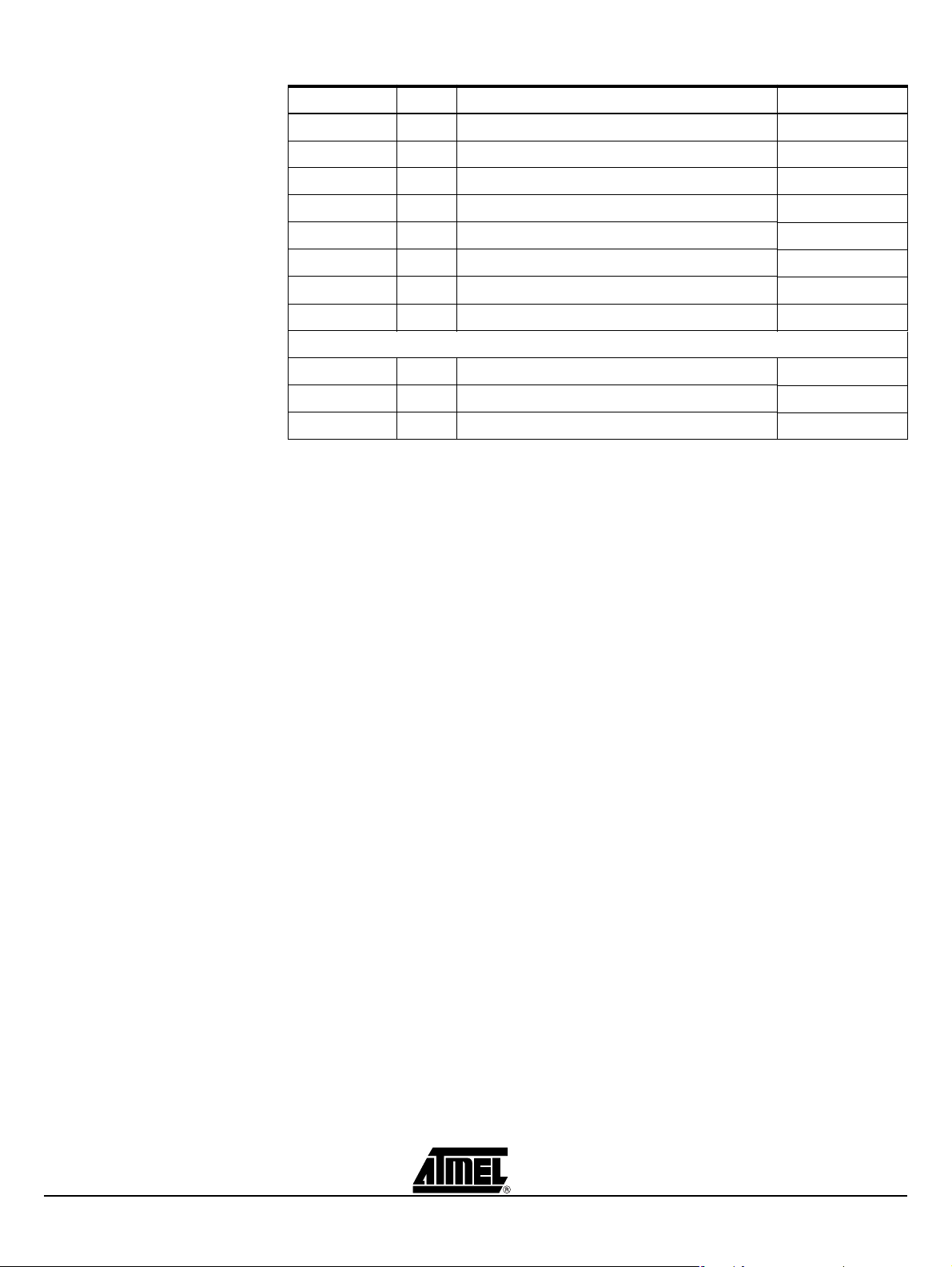

6.0.1 Default Configuration - Summary

Table 6-2 . Default Configuration summary

Name Ref. Function State

Jumpers

STKX1 JP1 XTAL Configuratio n OFF

STKX2 JP2 XTAL Configuratio n OFF

Aref JP3 STK500 Analog Ref OFF

VTG33 JP4 Short 3.3V to VTG (Mass stor age extension

board)

UCAP JP5 Short UCAP with Uvcc OFF

Vcc Src JP6 Vcc Selection 3.4 shorted

Vbus Gen JP7 VBUS generation selec ti on (host mode) 2.3 shorted

Solder PADS

STK525 Hardware User Guide 6-37

OFF

7608A–AVR–04/06

Page 38

Complete Schematics

Name Ref. Function State

SP1 Bypass L1 OPEN

SP2 OPEN

SP3 3.3V on Expand 0 NC pin OPEN

SP4 CTS OPEN

SP5 RTS OPEN

SP6 Bypass limiter OPEN

SP7 RS232 hardware control enable OPEN

SP8 RS232 hardware control enable OPEN

Configuration PADS

CP1 Bypass CTN in on PF0 CLOSE

CP2 Bypass Potentiometer ADC in on PF1 CLOSE

CP3 Bypass Mic In on PF2 CLOSE

6-38 STK525 Hardware User Guide

7608A–AVR–04/06

Page 39

Atmel Corporation Atmel Operations

2325 Orchard Park way

San Jose, CA 95131, USA

Tel: 1(408) 4 41-0311

Fax: 1(408) 487-260 0

Regional Headquarters

Europe

Atmel Sa rl

Route des Ars enau x 41

Case Postale 8 0

CH-1705 Fri bourg

Switzerland

Tel: (41) 26-4 26-55 55

Fax: (41) 26 -426-550 0

Asia

Room 121 9

Chinachem Gold en Plaza

77 Mody Ro ad Tsims hatsu i

East Kowloon

Hong Kong

Tel: (852) 27 21-9778

Fax: (852) 2 722-136 9

Japan

9F, Tonetsu Sh inkaw a Bl dg.

1-24-8 Shi nkawa

Chuo-ku, Tok yo 10 4-0033

Japan

Tel: (81) 3-35 23-35 51

Fax: (81) 3-3 523-758 1

Memory

2325 Orch ard Parkw ay

San Jose, C A 95131 , USA

Tel: 1(408 ) 441-031 1

Fax: 1(408) 43 6-43 14

Microcontrollers

2325 Orch ard Parkw ay

San Jose, C A 95131 , USA

Tel: 1(408 ) 441-031 1

Fax: 1(408) 43 6-43 14

La Chantrer ie

BP 70602

44306 Na ntes Cede x 3, Fra nce

Tel: (33) 2-4 0-18 -18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone In dustrielle

13106 Rousse t Ced ex, France

Tel: (33) 4-4 2-53 -60-00

Fax: (33) 4-42-53-60-01

1150 East C heyenn e Mtn. Blvd.

Colorado Sp rings, CO 8 0906, USA

Tel: 1(719 ) 576-330 0

Fax: 1(719) 54 0-17 59

Scottish Enterprise Technology Park

Maxwell Building

East Kilbrid e G7 5 0QR, S cotlan d

Tel: (44) 13 55-803- 000

Fax: (44) 1355 -242 -743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbr onn, Ge rmany

Tel: (49) 71-31-67-0

Fax: (49) 71 -31-67- 2340

1150 East Ch eyenne M tn. B lvd.

Colorado Spr ings, CO 80 906, USA

Tel: 1(719) 57 6-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de R ocheplei ne

BP 123

38521 Saint- Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-7 6-58-3 4-80

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise,to anyintellectualproperty right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-TIONS OF

SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORYWARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULARPURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL

OR INCIDEN-TAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUTOF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes nor epresentationsor warranties with respect to the accuracy or completeness of the contents of this docum ent and reserves the right to make

changes to specificationsand product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein.

Unless specifically provided otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended,

authorized, or warranted for useas components in applications intended to support or sustainlife.

© Atmel Co rpora tion 20 06. All rights reserved. Atmel®, logo and combinations thereof, are registered trademarks, and Everywhere You Are

are the t ra demarks of At m el Corporation or i ts s u bs idiarie s. O the r t er m s an d pr o du c t names m a y be trade m ar k s of others.

Printed on recy cled paper.

7608A–AVR–04/06

/xM

®

Loading...

Loading...