STK500

..............................................................................................

User Guide

Table of Contents

Section 1

Introduction ........................................................................................... 1-1

1.1 Starter Kit Features ...................................................................................1-1

1.2 Device Support .........................................................................................1-2

Section 2

Getting Started......................................................................................2-1

2.1 Unpacking the System ..............................................................................2-1

2.2 System Requirements...............................................................................2-1

2.3 Quick Start ................................................................................................2-2

2.3.1 Connecting the Hardware ...................................................................2-3

2.3.2 Programming the Target AVR Device ................................................2-3

Section 3

Hardware Description ...........................................................................3-1

3.1 Description of User LEDs ..........................................................................3-1

3.2 Description of User Switches ....................................................................3-2

3.3 Connection of LEDs and Switches............................................................3-3

3.4 Port Connectors ........................................................................................3-3

3.5 Description of User RS-232 Interface .......................................................3-5

3.6 Description of DataFlash Pins...................................................................3-6

3.7 Target Socket Section...............................................................................3-8

3.7.1 ISP Programming ...............................................................................3-9

3.7.2 High-voltage Programming...............................................................3-11

3.8 Jumper Settings ......................................................................................3-15

3.8.1 Target V

3.8.2 Analog Reference Voltage, AREF ....................................................3-17

3.8.3 Reset Settings, RESET ....................................................................3-18

3.8.4 Clock Settings, XTAL1 and OSCSEL ...............................................3-20

3.8.5 BSEL2 Jumper .................................................................................3-22

3.8.6 PJUMP Jumpers...............................................................................3-22

3.9 Expansion Connectors ............................................................................3-23

3.9.1 Signal Descriptions ...........................................................................3-25

3.10 Prog Ctrl and Prog Data Headers ...........................................................3-25

3.11 Miscellaneous .........................................................................................3-26

3.11.1 RESET Push Button .........................................................................3-26

3.11.2 PROGRAM Push Button ..................................................................3-27

AVR STK500 User Guide i

Settings, VTARGET .......................................................3-16

CC

1925C–AVR–3/03

Table of Contents

3.11.3 Main Power LED...............................................................................3-27

3.11.4 Target Power LED ............................................................................3-27

3.11.5 Status LED .......................................................................................3-27

Section 4

Installing AVR Studio............................................................................4-1

Section 5

Using AVR Studio................................................................................. 5-1

5.1 Windows Software ....................................................................................5-1

5.2 Starting the Windows Software.................................................................5-1

5.2.1 Starting STK500 .................................................................................5-1

5.3 STK500 User Interface .............................................................................5-2

5.3.1 “Program” Settings .............................................................................5-2

5.3.2 “Fuses” Settings .................................................................................5-3

5.3.3 “LockBits” Settings..............................................................................5-4

5.3.4 “Advanced” Settings ...........................................................................5-4

5.3.5 “Board” Settings..................................................................................5-5

5.3.6 “Auto” Settings ....................................................................................5-7

5.3.7 History Window...................................................................................5-8

5.4 Command Line Software ..........................................................................5-9

5.5 Parameters ...............................................................................................5-9

Section 6

In-System Programming of an External Target System ....................... 6-1

Section 7

Troubleshooting Guide ......................................................................... 7-1

Section 8

Technical Support.................................................................................8-1

Section 9

Example Applications ........................................................................... 9-1

9.1 Using LEDs and Switches.........................................................................9-1

Section 10

Appendix A .........................................................................................10-1

ii AVR STK500 User Guide

1925C–AVR–3/03

Section 1

Introduction

Congratulations on your purchase of the AVR® STK500 Flash Microcontroller Starter

Kit. The STK500 is a complete starter kit and development system for the AVR Flash

Microcontroller from Atmel Corporation. It is designed to give designers a quick start to

develop code on the AVR and for prototyping and testing of new designs.

1.1 Starter Kit Features

n AVR S tudio

n RS-232 Interface to PC for Programming and Control

n Regulated Power Supply for 10 - 15V DC Power

n Sockets for 8-pin, 20-pin, 28-pin, and 40-pin AVR Devices

n Parallel and Serial High-voltage Programming of AVR Devices

n Serial In-System Programming (ISP) of AVR Devices

n In-System Programmer for Programming AVR Devices in External Target System

n Reprogramming of AVR Devices

n 8 Push Buttons for General Use

n 8 LEDs for General Use

n All AVR I/O Ports Easily Accessible through Pin Header Connectors

n Additional RS-232 Port for General Use

n Expansion Connectors for Plug-in Modules and Prototyping Area

n (NB! No longer valid: "On-board 2-Mbit DataFlash

The STK500 is supported by AVR Studio, version 3.2 or higher. For up-to-date information on this and other AVR tool products, please read the document “avrtools.pdf”. The

newest version of AVR Studio, “avrtools.pdf” and this user guide can be found in the

AVR section of the Atmel web site, www.atmel.com.

®

Compatible

®

for Nonvolatile Data Storage")

AVR STK500 User Guide 1-1

Rev. 1925C–AVR–3/03

Introduction

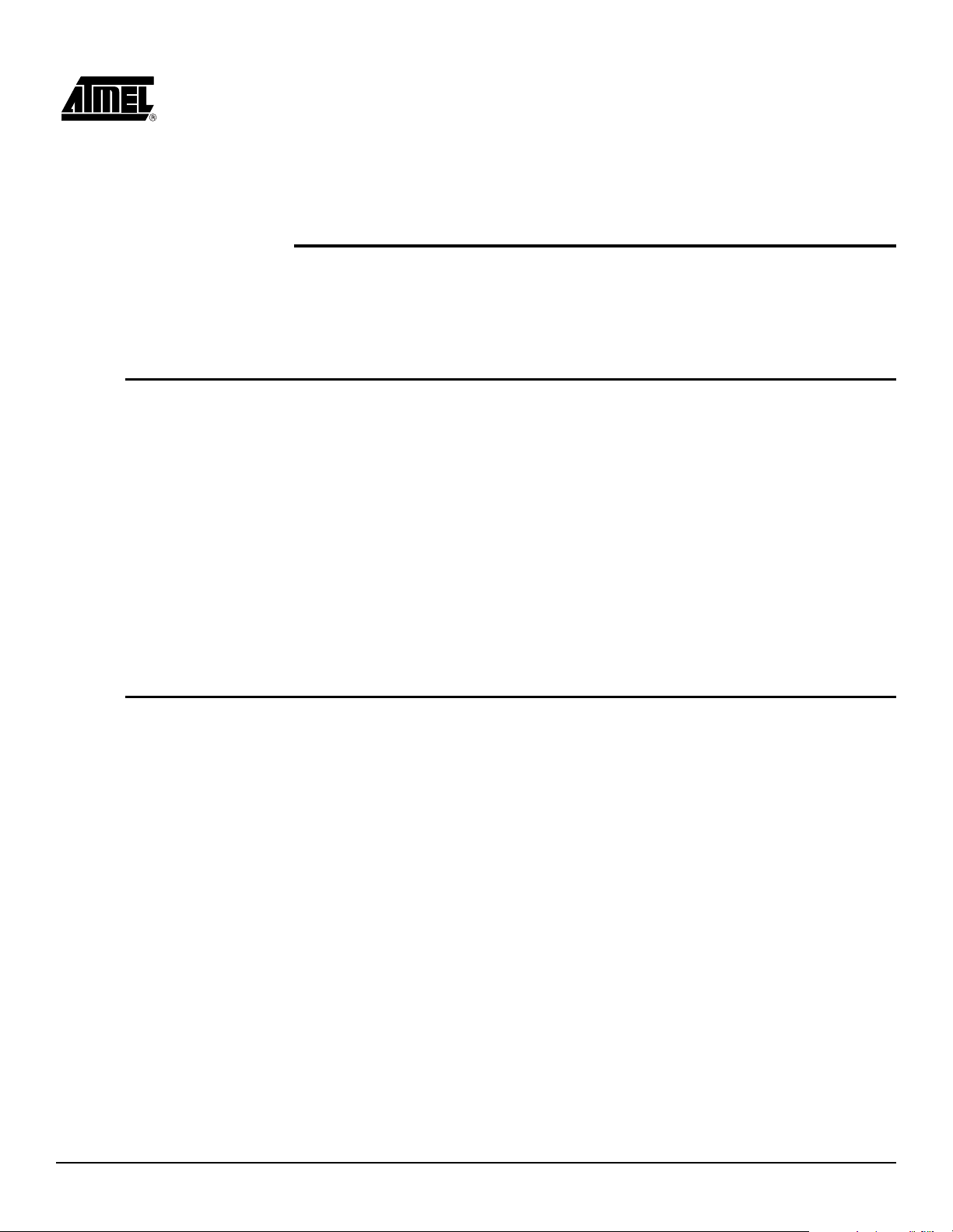

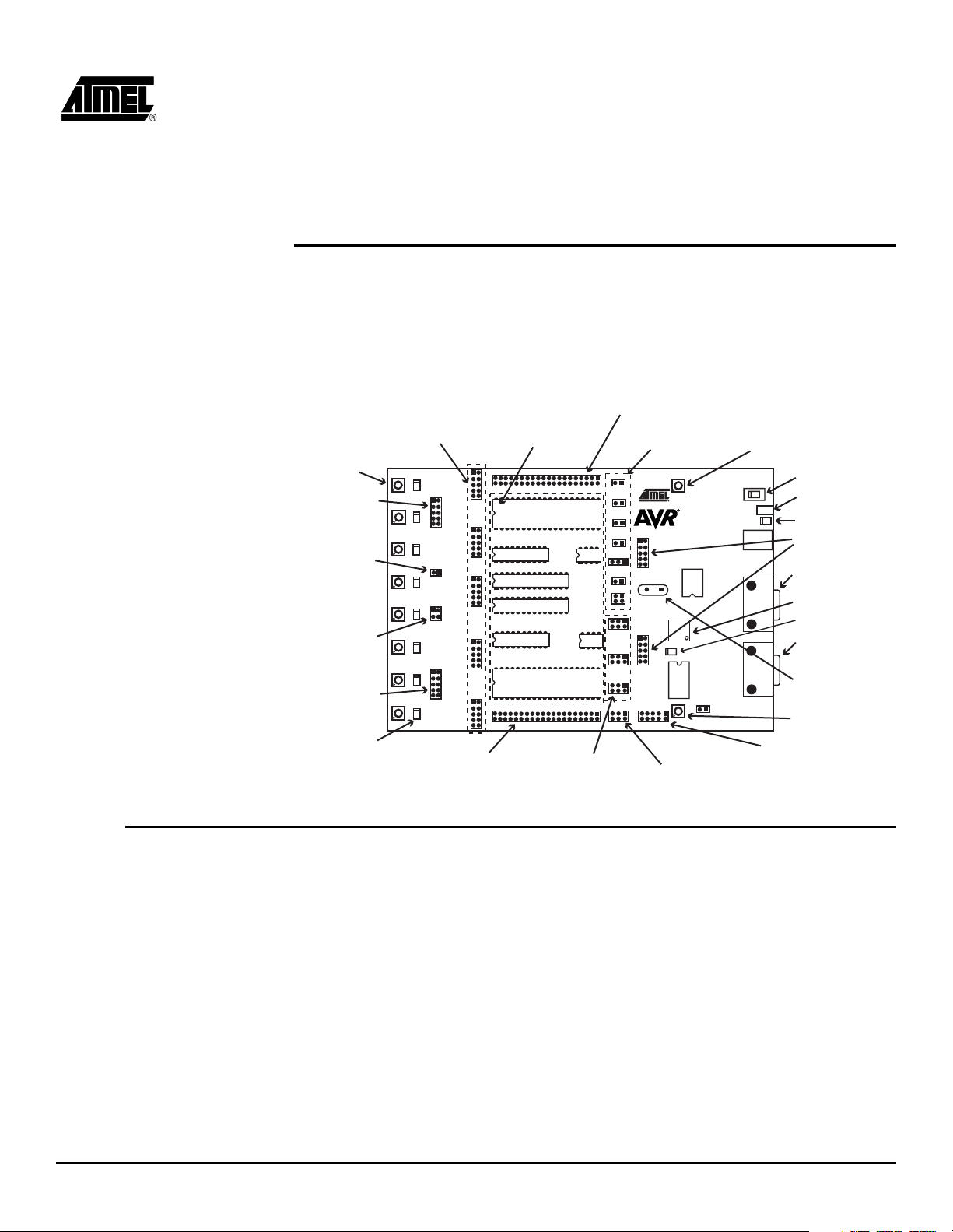

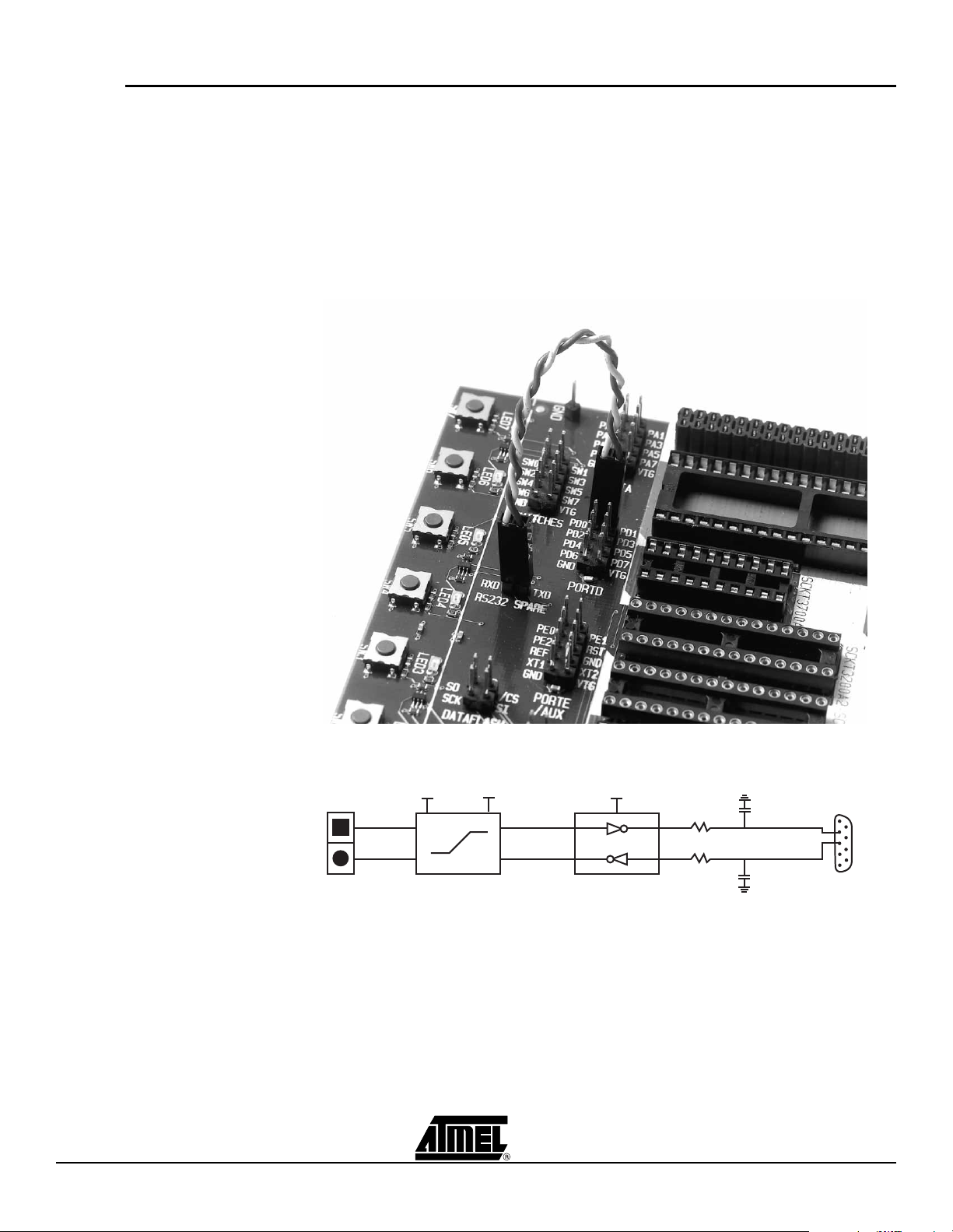

Figure 1-1. STK500

1.2 Device Support The system software currently supports the following devices in all speed grades:

n AT t in y 11 n AT90S4433

n AT t in y 12 n AT90S4434

n AT t in y 15 n AT90S8515

n AT t in y 22 n AT90S8535

n AT t in y 28 n ATmega8

n AT90S1200 n ATmega16

n AT90S2313 n ATmega161

n AT90S2323 n ATmega163

n AT90S2333 n ATmega323

n AT90S2343 n ATmega103

n AT90S4414 n ATmega128

Note: 1. In external target or in STK501, devices do not fit into the sockets of

STK500.

(1)

(1)

Support for new AVR devices may be added in new versions of AVR Studio. The latest

version of AVR Studio is always available from www.atmel.com.

1-2 AVR STK500 User Guide

1925C–AVR–3/03

Section 2

Getting Started

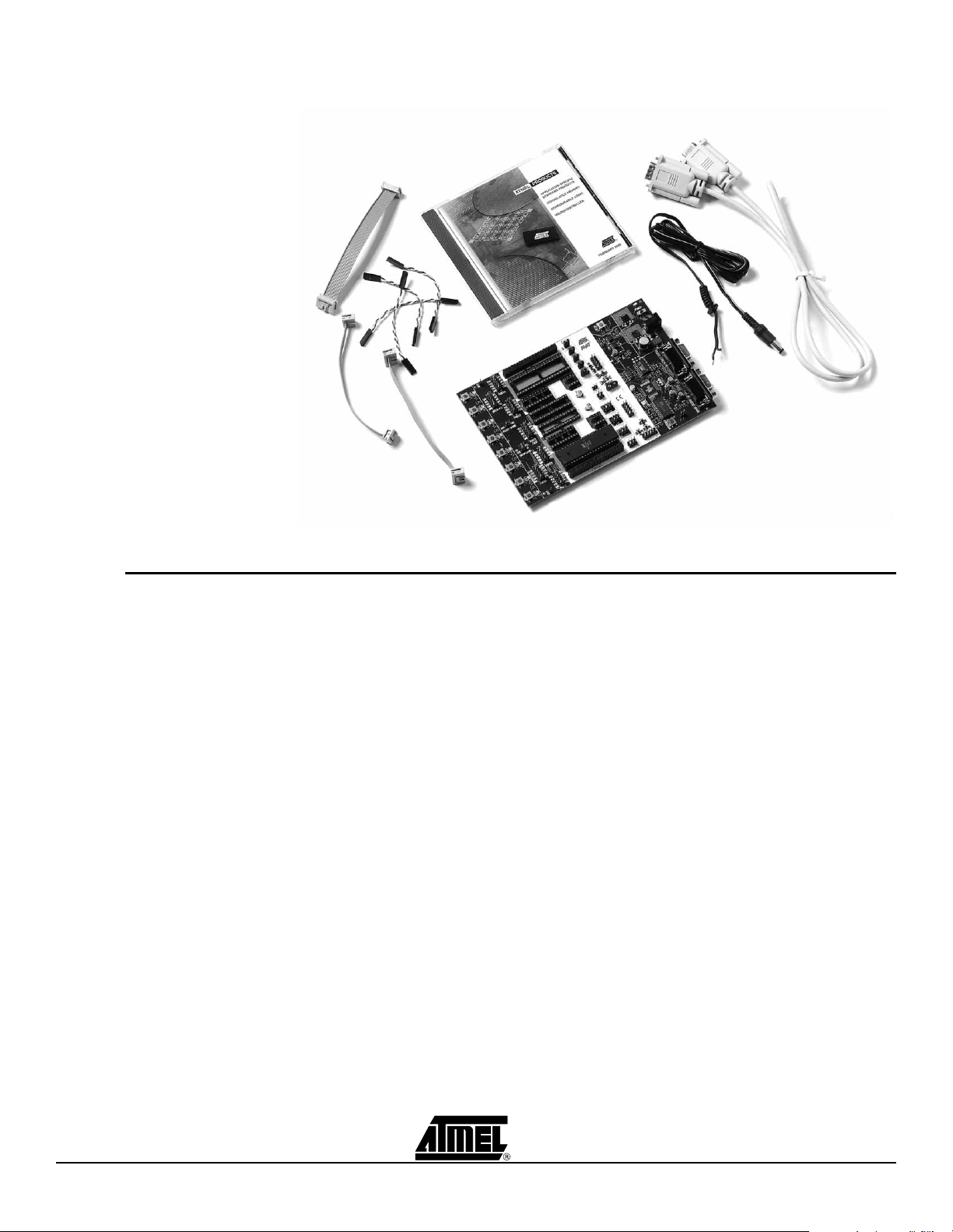

2.1 Unpacking the System

2.2 System Requirements

Kit contents:

n STK500 starter kit evaluation board

n Cables for STK500:

– (2 pcs) 10-wire cables for I/O ports and parallel mode programming

– (1 pc) 6-wire cable for In-System Programming

– (4 pcs) 2-wire cable for UART and DataFlash connections

n 9-pin RS-232 cable

n DC power cable

n Atmel CD-ROM with datasheets and software

n AT90S8515-8PC sample microcontroller

The minimum hardware and software requirements are:

n 486 processor (Pentium

n 16 MB RAM

n 12 MB free hard disk space (AVR Studio)

n Windows

®

95/98/2000/ME and Windows NT® 4.0 or higher

®

is recommended)

n 115200 baud RS-232 port (COM port)

n 10 - 15V DC power supply, 500 mA min.

AVR STK500 User Guide 2-1

Rev. 1925C–AVR–3/03

Getting Started

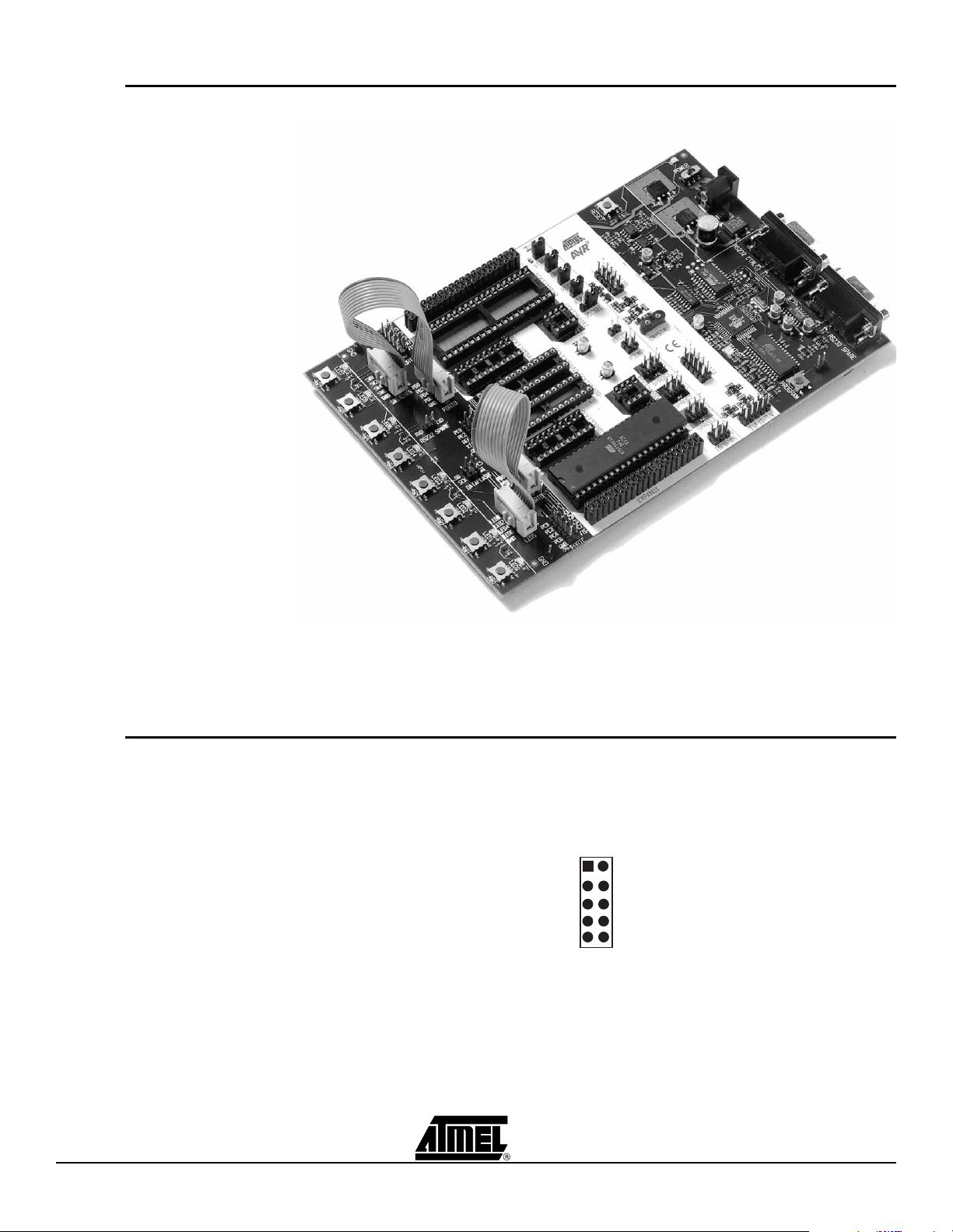

2.3 Quick Start The STK500 starter kit is shipped with an AT90S8515-8PC microcontroller in the socket

marked SCKT3000D3. The default jumper settings will allow the microcontroller to execute from the clock source and voltage regulator on the STK500 board.

The microcontroller is programmed with a test program that toggles the LEDs. The test

program in the AT90S8515 is similar to the example application code described in Section 9. Connect the LEDs and switches and power up the STK500 to run the test

program in the AT90S8515.

Use the supplied 10-pin cables to connect the header marked “PORTB” with the header

marked “LEDS”, and connect the header marked “PORTD” with the header marked

“SWITCHES”. The connections are shown in Figure 2-1.

An external 10 - 15V DC power supply is required. The input circuit is a full bridge rectifier, and the STK500 automatically handles both positive or negative center connectors.

If a positive center connector is used, it can be impossible to turn the STK500 off since

the power switch disconnects the GND terminal. In this case, GND can be supplied

through the RS-232 cable shield if connected or through alternative GND connections.

Connect the power cable between a power supply and the STK500. Apply 10 - 15V DC

to the power connector. The power switch turns the STK500 main power on and off. The

red LED is lit when power is on, and the status LEDs will go from red, via yellow, to

green. The green LED indicates that the target V

ning in the AT90S8515 will respond to pressed switches by toggling the LEDs.

is present. The program now run-

CC

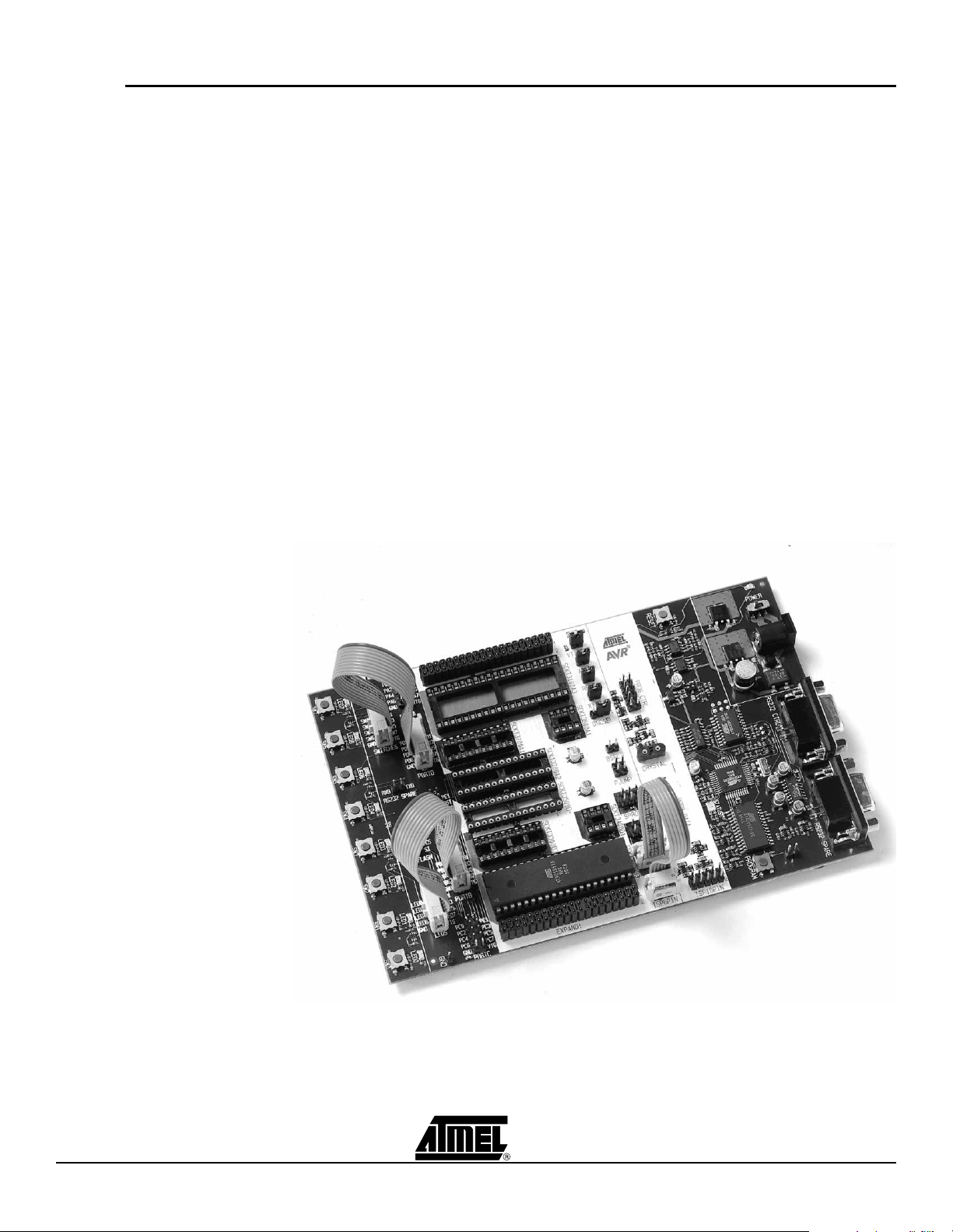

Figure 2-1. Default Setup of STK500

The starter kit can be configured for various clock and power sources. A complete

description of the jumper settings is explained in paragraph 3.8 on page 3-15 and on the

reverse side of the starter kit.

2-2 AVR STK500 User Guide

1925C–AVR–3/03

Getting Started

2.3.1 Connecting the Hardware

2.3.2 Programming the Target AVR Device

Figure 2-2. Connection to STK500

10 - 15V DC

To Computer (RS-232)

To program the AT90S8515, connect the supplied 6-wire cable between the ISP6PIN

header and the SPROG3 target ISP header as shown in Figure 2-1. Section 3.7.1 on

page 3-9 describes the programming cable connections.

Connect a serial cable to the connector marked “RS232 CTRL” on the evaluation board

to a COM port on the PC as shown in Figure 2-2. Install AVR Studio software on the PC.

Instructions on how to install and use AVR Studio are given in Section 5 on page 5-1.

When AVR Studio is started, the program will automatically detect to which COM port

the STK500 is connected.

The STK500 is controlled from AVR Studio, version 3.2 and higher. AVR Studio is an

integrated development environment (IDE) for developing and debugging AVR applications. AVR Studio provides a project management tool, source file editor, simulator, incircuit emulator interface and programming interface for STK500.

To program a hex file into the target AVR device, select “STK500” from the “Tools”

menu in AVR Studio.

Select the AVR target device from the pull-down menu on the “Program” tab and locate

the intel-hex file to download.

Press the “Erase” button, followed by the “Program” button. The status LED will now

turn yellow while the part is programmed, and when programming succeeds, the LED

will turn green. If programming fails, the LED will turn red after programming. See the

troubleshooting guide in Section 7 on page 7-1.

AVR STK500 User Guide 2-3

1925C–AVR–3/03

Getting Started

Figure 2-3. AVR Studio STK500 Programming Menu

Complete descriptions of using the STK500 interface in AVR Studio are given in Section

5 on page 5-1.

2-4 AVR STK500 User Guide

1925C–AVR–3/03

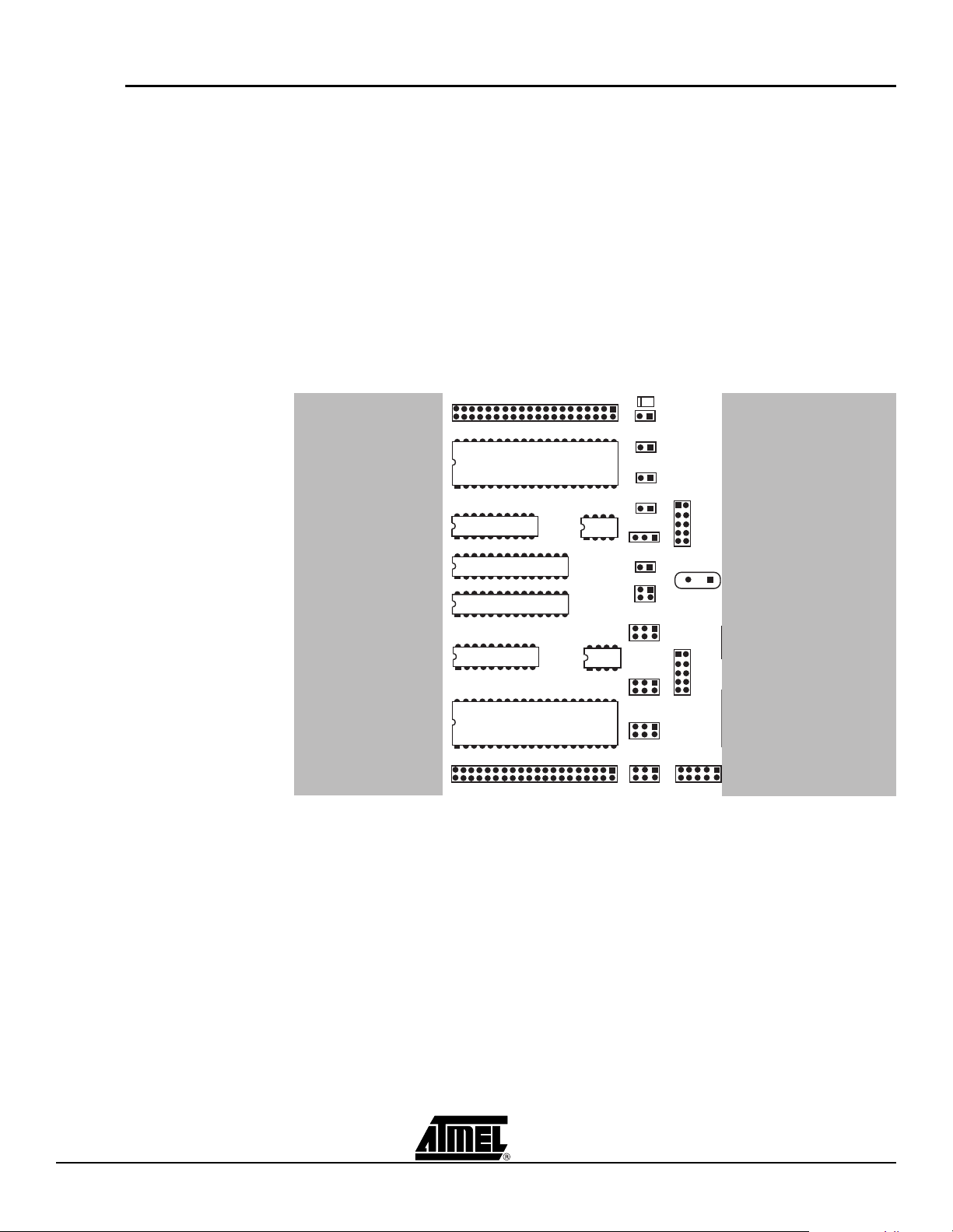

Figure 3-1. STK500 Components

Headers

for I/O Ports

Switches

Header for

Switches

RS-232 Interface

Header

DataFlash Interface

Header

Header for LEDs

Section 3

Hardware Description

Header for

Sockets for

Target AVR

Expansion Boards

Options Setting

Jumpers

Target Reset

Push Button

Power Switch

Power Connector

Parallel Programming

Headers

RS-232 Port

for Programming

Power LED

Master MCU

Status LED

RS-232 Port

for Communication

Socket for

Crystal

Program Button

10-pin ISP Header

(for External Target Only)

3.1 Description of User LEDs

LEDs

Header for

Expansion Boards

Target ISP Headers

6-pin ISP Header

The STK500 starter kit includes 8 yellow LEDs and 8 push-button switches. The LEDs

and switches are connected to debug headers that are separated from the rest of the

board. They can be connected to the AVR devices with the supplied 10-wire cable to the

pin header of the AVR I/O ports. Figure 3-4 shows how the LEDs and switches can be

connected to the I/O port headers. The cables should be connected directly from the

port header to the LED or switch header. The cable should not be twisted. A red wire on

the cable indicates pin 1. Confirm that this is connected to pin 1 on each of the headers.

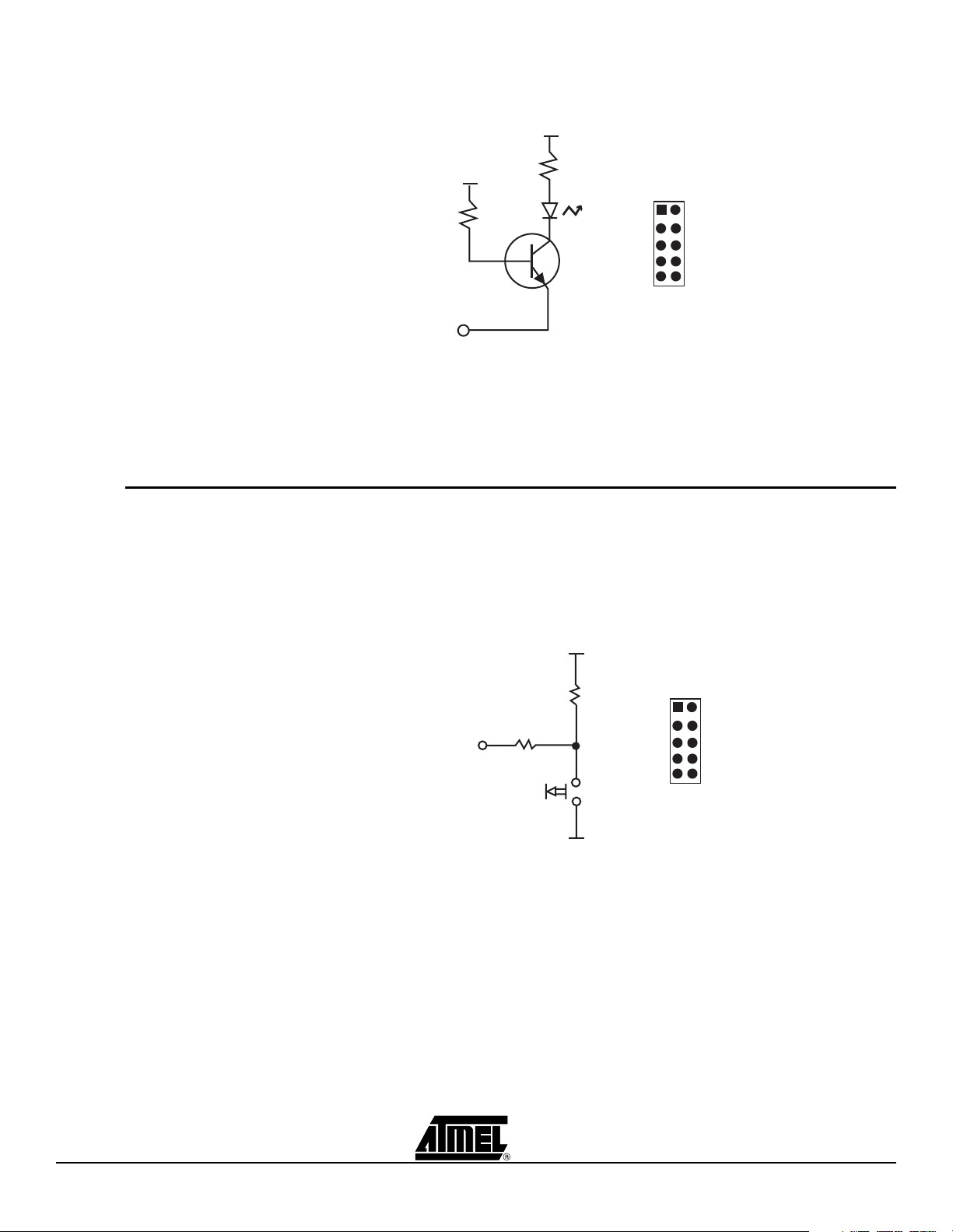

Figure 3-2 shows how the LED control is implemented. This solution will give the same

amount of light from the LED for all target voltages from 1.8V to 6.0V.

AVR STK500 User Guide 3-1

Rev. 1925C–AVR–3/03

Hardware Description

Figure 3-2. Implementation of LEDs and LED Headers

+5V

3.2 Description of User Switches

VTG

10K

LEDn

150R

LED0

LED2

LED4

LED6

GND

1 2

LED1

LED3

LED5

LED7

VTG

Note: The AVR can source or sink enough current to drive a LED directly. In the

STK500 design, a transistor with two resistors is used to give the same amount

of light from the LED, whatever the target voltage (VTG) may be and to turn off

the LEDs when VTG is missing.

The switches connected to the debug headers are implemented as shown in Figure 3-3.

Pushing a switch causes the corresponding SWx to be pulled low, while releasing it will

result in VTG on the appropriate switch header connector. Valid target voltage range is

1.8V < VTG < 6.0V.

Figure 3-3. Implementation of Switches and Switch Headers

VTG

SW0

SW2

SW4

SW6

GND

1 2

SW1

SW3

SW5

SW7

VTG

SW

10K

150R

n

SW

n

Note: In the AVR, the user can enable internal pull-ups on the input pins, removing the

need for an external pull-up on the push-button. In the STK500 design, we have

added an external 10K pull-up to give all users a logical “1” on SWn when the

push-button is not pressed. The 150R resistor limits the current going into the

AVR.

3-2 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

3.3 Connection of LEDs and Switches

Figure 3-4. Connection of LEDs and Switches to I/O Port Headers

Any I/O port of the AVR can be connected to the LEDs and switches using the 10-wire

cables. The headers are supplied with VTG (target V

) and GND lines in addition to the

CC

signal lines.

3.4 Port Connectors The pinout for the I/O port headers is explained in Figure 3-5. The square marking indi-

cates pin 1.

Figure 3-5. General Pinout of I/O Port Headers

1 2

Px0

Px2

Px4

Px6

GND

PORTx

The PORTE/AUX header has some special signals and functions in addition to the

PORTE pins. The pinout of this header is shown in Figure 3-6.

Px1

Px3

Px5

Px7

VTG

AVR STK500 User Guide 3-3

1925C–AVR–3/03

Hardware Description

Figure 3-6. Pinout of PORTE Header

1 2

PE0

PE2

REF

XT1

GND

PE1

RST

GND

XT2

VTG

PORTE/AUX

The special functions of this port are:

n PE0 - PE2:

Table 3-1. PORTE Connection

ATmega161 AT90S4414/AT90S8515

PE0 PE0/ICP/INT2 ICP

PE1 PE1/ALE ALE

PE2 PE2/OC1B OC1B

n REF: Analog reference voltage. This pin is connected to the AREF pin on devices

having a separate analog reference pin.

n XT1: XTAL 1 pin. The internal main clock signal to all sockets. If the XTAL1 jumper is

disconnected, this pin can be used as external clock signal.

n XT2: XTAL 2 pin. If the XTAL1 jumper is disconnected, this pin can be used for

external crystal with the XT1 pin.

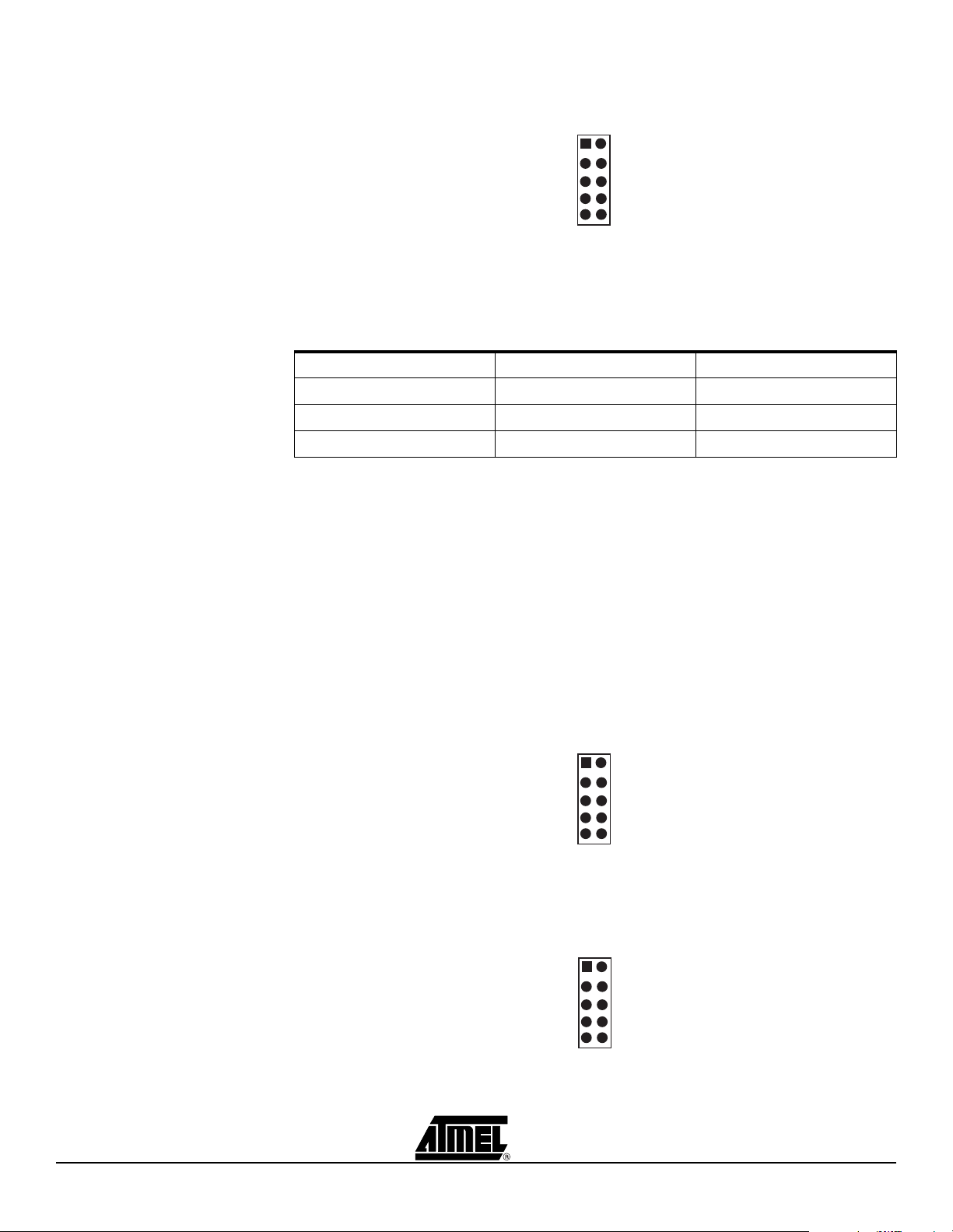

The headers for the LEDs and switches use the same pinout as the I/O port headers.

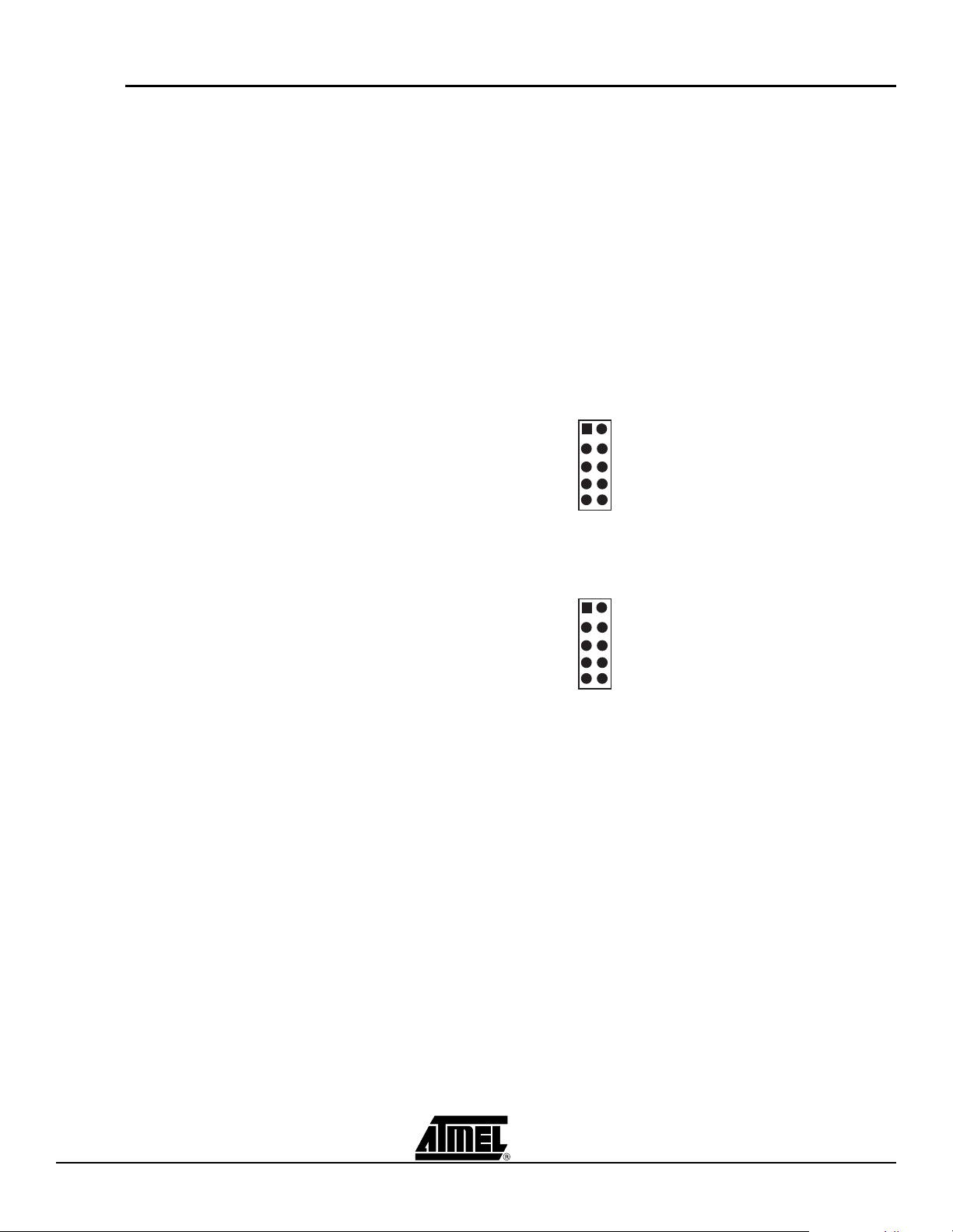

The pinout of the switch header is explained in Figure 3-7 and the pinout for the LED

header is explained in Figure 3-8. The square marking indicates pin 1.

Figure 3-7. Pinout of the Switch Header

1 2

SW0

SW2

SW4

SW6

GND

SW1

SW3

SW5

SW7

VTG

SWITCHES

Figure 3-8. Pinout of the LED Header

1 2

LED0

LED2

LED4

LED6

GND

LED1

LED3

LED5

LED7

VTG

LEDS

3-4 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

3.5 Description of User RS-232 Interface

The STK500 includes two RS-232 ports. One RS-232 port is used for communicating

with AVR Studio. The other RS-232 can be used for communicating between the target

AVR microcontroller in the socket and a PC serial port connected to the RS-232. To use

the RS-232, the UART pins of the AVR need to be physically connected to the RS-232.

The 2-pin header marked “RS232 SPARE” can be used for connecting the RS-232 converter to the UART pins on the target AVR microcontroller in the socket. Use the 2-wire

cable to connect the UART pins to the RS-232. The connection is shown in Figure 3-9.

The block schematic of the RS-232 connection is shown in Figure 3-10.

Figure 3-9. Connection of I/O Pins to UART

Figure 3-10. Schematic of UART Pin Connections

TXD

RXD

VTG 5V

Voltage

5V

MAX202CSE

470R

470R

1n2

1n2

2

3

RS-232

Converter

AVR STK500 User Guide 3-5

1925C–AVR–3/03

Hardware Description

3.6 Description of DataFlash Pins

NB! Not valid: AT45D021 2-Mbit DataFlash is included on the STK500 for data storage.

A DataFlash is a high-density Flash memory with SPI serial interface. A detailed

datasheet of the DataFlash can be obtained from the Flash memory section of the Atmel

CD-ROM or from the Atmel web site.

The DataFlash can be connected to the I/O pins of the microcontroller sockets. The

4-pin header marked “DATAFLASH” can be used for connecting the SPI interface of the

DataFlash to the I/O pins on the target AVR microcontroller in the socket. 2-wire cables

are included with STK500 for connecting the DataFlash to the I/O pins. The supplied

10-wire cables can also be used if the DataFlash is connected to the hardware SPI interface on PORTB of the AVR microcontroller. The connection of the I/O pins is shown in

Figure 3-13. The block schematic of the DataFlash connection is shown in Figure 3-14,

for connection of the DataFlash to the AVR hardware SPI interface. The SPI interface

pinout is shown in Figure 3-11 and Figure 3-12.

Figure 3-11. PORTB SPI Pinout (40-pin Parts)

1 2

PB0

PB2

(SS)PB4

(MISO)PB6

GND

PB1

PB3

PB5(MOSI)

PB7(SCK)

VTG

Figure 3-12. PORTB SPI Pinout (28-pin Analog Parts)

PB0

(SS)PB2

(MISO)PB4

PB6

GND

1 2

PB1

PB3(MOSI)

PB5(SCK)

PB7

VTG

3-6 AVR STK500 User Guide

1925C–AVR–3/03

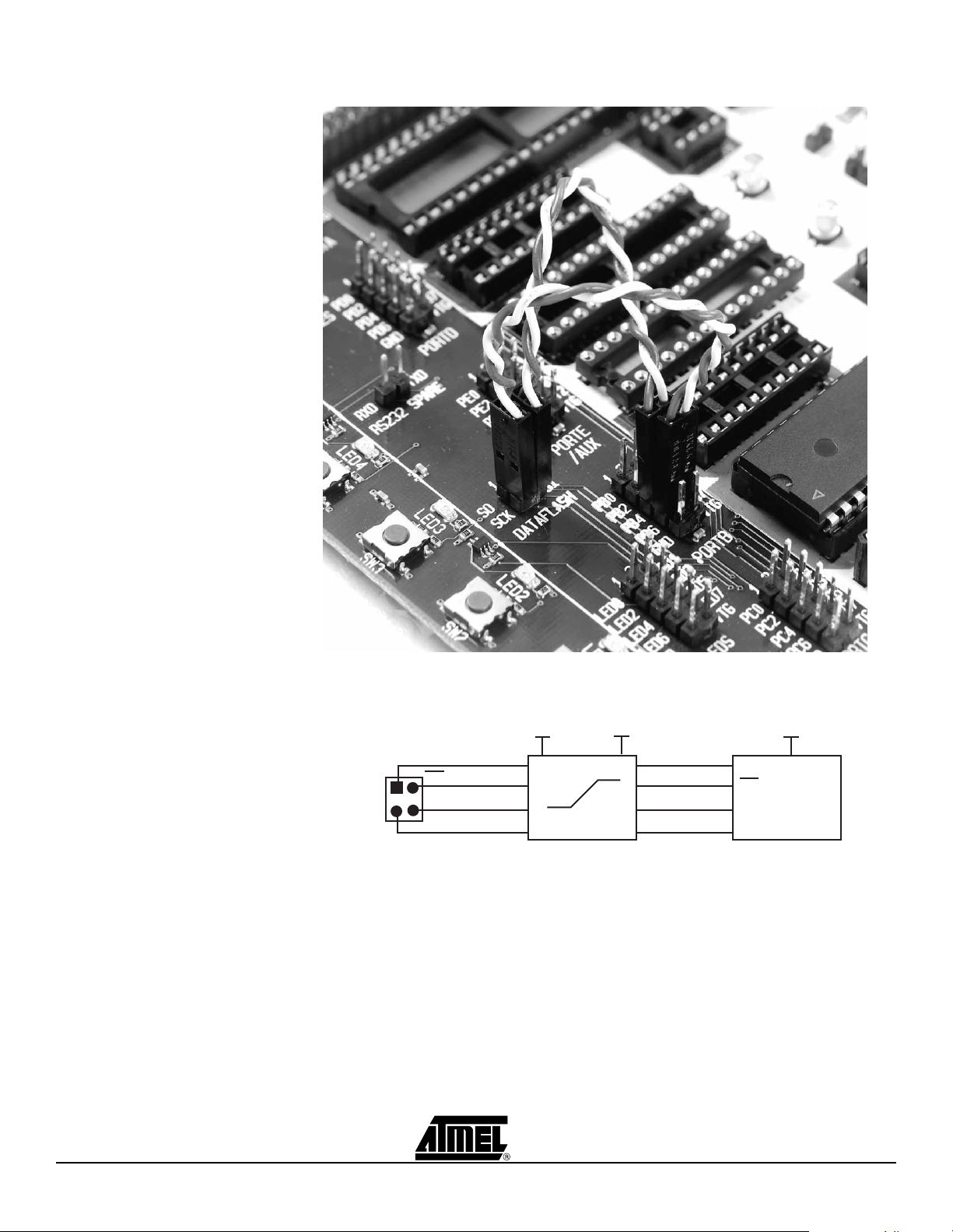

Figure 3-13. Connection of I/O Pins to DataFlash for AT90S8515

Hardware Description

Figure 3-14. Schematic of DataFlash Connections

VTG 5V

S0

SCK

CS

SI

Voltage

Converter

5V

S0

CS

SI

SCK

AT45D021

DataFlash

AVR STK500 User Guide 3-7

1925C–AVR–3/03

Hardware Description

3.7 Target Socket Section

The programming module consists of the eight sockets in the white area in the middle of

the starter kit. In these sockets, the target AVR devices can be inserted for programming

and are used in the application.

Note: Only one AVR device should be inserted in the sockets at a time.

The AVR Flash memory is guaranteed to be correct after 1,000 programming operations; the typical lifetime of the Flash memory is much longer.

Note: When inserting a device in the socket, notice the orientation of the device.

The notch on the short side of the part must match the notch on the socket. If the device

is inserted the wrong way, it may damage the part and the starter kit.

The socket section is used for both running applications and target device programming.

Figure 3-15. The STK500 Programming Module

The part inserted in the socket can be programmed in the system from AVR Studio with

two different methods:

1. AVR In-System Programming (ISP) running at the parts normal supply voltage.

2. High-voltage Programming, where the supply voltage is always 5 volts.

Four general nets (VTARGET, RESET, XTAL1 and AREF) can be connected to the

socket section.

The following sections describe how to use both programming methods. For instructions

on using the AVR Studio programming software, see Section 5, “Using AVR Studio” on

page 5-1.

3-8 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

3.7.1 ISP Programming In-System Programming uses the AVR internal SPI (Serial Peripheral Interface) to

download code into the Flash and EEPROM memory of the AVR. ISP programming

requires only V

, GND, RESET and three signal lines for programming. All AVR

CC

devices except AT90C8534, ATtiny11 and ATtiny28 can be ISP programmed. The AVR

can be programmed at the normal operating voltage, normally 2.7 - 6.0V. No high-voltage signals are required. The ISP programmer can program both the internal Flash and

EEPROM. It also programs fuse bits for selecting clock options, start-up time and internal Brown-out Detector (BOD) for most devices.

High-voltage programming can also program devices that are not supported by ISP programming. Some devices require High-voltage Programming for programming certain

fuse bits. See the High-voltage Programming section on page 3-11 for instructions on

how to use High-voltage Programming.

Because the programming interface is placed on different pins from part to part, three

programming headers are used to route the programming signals to the correct pins. A

6-wire cable is supplied for connecting the ISP signals to the target ISP header. A color

coding system and a number system are used to explain which target ISP header is

used for each socket.

During ISP programming, the 6-wire cable must always be connected to the header

marked “ISP6PIN”. When programming parts in the blue sockets, connect the other end

of the cable to the blue SPROG1 target ISP header. When programming parts in the

green socket, use the green SPROG2 target ISP header. And when programming parts

in the red sockets, use the red SPROG3 target ISP header.Table 3-2 shows which

socket suits which AVR device, and which SPROG target ISP header to use for ISP

programming.

The 6-wire cables should be connected directly from the ISP6PIN header to the correct

SPROG target ISP header. The cable should not be twisted. A colored wire on the cable

indicates pin 1. Confirm that this is connected to pin 1 on each of the headers.

When programming 8-pin devices, note the following: Pin 1 is used both as RESET and

as PB5 on some devices (ATtiny11, ATtiny12 and ATtiny15). Pin 1 on the 8-pin sockets

SCKT3400D1 and SCKT3400D1 are connected to PB5. The RESET signal used during

ISP programming is therefore not connected to pin 1 on these sockets. This signal must

be connected by placing a wire between RST and the PORTE header and PB5 on the

PORTB header.

AVR STK500 User Guide 3-9

1925C–AVR–3/03

Hardware Description

Table 3-2. AVR Sockets

AVR Devices STK500 Socket Color Number Target ISP Header

AT90S1200

AT90S2313

SCKT3300D3 Red 3 SPROG3

AT90S2323

AT90S2343

AT ti ny 1 2

AT ti ny 2 2

SCKT3400D1 Blue 1 SPROG1. Connect RST on

PORTE to PB5 on PORTB.

Connect XTI on PORTE to PB3

(XTAL1 on 2323) on PORTB.

ATtiny11 SCKT3400D1 Blue 1 High-voltage Programming only

ATtiny28 SCKT3500D- None – High-voltage Programming only

AT90S4414

SCKT3000D3 Red 3 SPROG3

AT90S8515

ATmega161

AT90S4434

SCKT3100A3 Red 3 SPROG3

AT90S8535

ATmega16

ATmega163

ATmega323

AT90S2333

SCKT3200A2 Green 2 SPROG2

AT90S4433

AT me ga 8

ATtiny15 SCKT3600A1 Blue 1 SPROG1. Connect RST on

PORTE to PB5 on PORTB.

N/A SCKT3700A1 Blue 1 Socket is not in use in this version

of STK500

ATmega103

Use the STK501 Top Module

ATmega128

Figure 3-16 shows an example of how AT90S2313 can be In-System Programmed. The

6-wire cable is connected from the ISP6PIN header to the red SPROG3 target ISP

header, and the AT90S2313 part is inserted in the red socket marked “SCKT3100D3”.

Figure 3-16. Example Connection for Programming AT90S2313

SPROG1

AVR

SCKT3300D3

SPROG2

SPROG3

ISP6PIN

3-10 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

It is not necessary to remove the 6-wire cable from its ISP position while running a program in the AVR. The port pins used for ISP programming can be used for other

purposes in your program.

3.7.2 High-voltage Programming

For High-voltage Programming, a 12V programming voltage is applied to the RESET pin

of the AVR device. All AVR devices can be programmed with High-voltage Programming, and the target device can be programmed while it is mounted in its socket.

Two different methods are used for High-voltage Programming: 8-pin parts use a serial

programming interface, while other parts use a parallel programming interface. The programming signals are routed to the correct pins of the target device using the cables

supplied with STK500.

Table 3-3 summarizes the programming method and special considerations when using

High-voltage Programming.

Table 3-3. High-voltage Programming Settings

AVR

Devices

AT90S1200

AT90S2313

AT90S4414

AT90S8515

AT90S4434

AT90S8535

ATtiny28 SCKT3500D- None –

ATmega161 SCKT3000D3 Red 3 Parallel programming as above; mount

ATmega16

ATmega163

ATmega323

AT90S2333

AT90S4433

STK500

Socket Color Number High-voltage Programming Method

SCKT3300D3 Red 3 Parallel High-voltage Programming.

Connect PROG CTRL header to

SCKT3000D3 Red 3

SCKT3100A3 Red 3

SCKT3100A3 Red 3

SCKT3200A2 Green 2 Parallel programming as above; mount

PORTD and PROG DATA to PORTB,

as shown in Figure 3-17 on page 3-12.

BSEL2 jumper. See Section 3.8.

PJUMP jumpers. See Section 3.8.

ATmega103

ATmega128

ATmega8 SCKT3200A2 Green 2 Parallel programming as above; Mount

AT90S2323

AT90S2343

AT ti ny 1 1

AT ti ny 1 2

AT ti ny 2 2

ATtiny15 SCKT3600A1 Blue 1

N/A SCKT3700A1 Blue 1 Socket not in use in this version of

AVR STK500 User Guide 3-11

Use the

STK501 Top

Module

SCKT3400D1 Blue 1 Serial High-voltage Programming

– – Parallel programming as above; mount

BSEL2 jumper. See Section 3.8.

PJUMP jumpers and mount BSEL2

terminal to PC2. See Section 3.8.5 and

Section 3.8.6.

STK500

1925C–AVR–3/03

Hardware Description

3.7.2.1 Parallel High-voltage Programming

To use High-voltage Programming, the programming signal must be routed to the AVR

I/O pins. The two 10-wire cables supplied with the STK500 can be used to connect the

PROG DATA header to the PORTB header and the PROG CTRL header to the PORTD

header, as shown in Figure 3-17.

Figure 3-17. Connection for Parallel High-voltage Programming

Some of the jumper settings on STK500 must be changed when using High-voltage Programming. Figure 3-18 explains these jumper settings.

3-12 AVR STK500 User Guide

1925C–AVR–3/03

Figure 3-18. Jumper Settings for High-voltage Programming

J

VTARGET

AREF

Hardware Description

umpers

must be

Mounted

Devicedependent

Jumpers

(See Below)

RESET

XTAL1

OSCSEL

BSEL2

PJUMP

Hardware setup for parallel High-voltage Programming:

1. Switch power off.

2. Place the device to program in its socket according to Table 3-3 on page 3-11.

3. Connect the headers PROGDATA and PORTB with the 10-wire cable.

4. Connect the headers PROGCTRL and PORTD with the 10-wire cable.

5. Mount jumper OSCSEL on pins 1 and 2 to select software-controlled clock.

6. Mount jumper XTAL1 to route the oscillator signal to the device.

7. Mount jumpers VTARGET and RESET.

8. When programming AT90S2333, AT90S4433, or ATmega8, mount both PJUMP

jumpers. The 2-wire cables can be used instead of jumpers.

9. When programming ATmega16, ATmega163, ATmega161, ATmega128, or

ATmega323, mount the BSEL2 jumper. When programming ATmega8, connect

BSEL2 terminal to PC2. A 2-wire cable can be used instead of jumpers.

10. Disconnect target system.

11. Switch power on.

12. Ensure that VTARGET is between 4.5V and 5.5V before programming. See Sec-

tion 5.3.5.1.

For a complete description of jumper settings, see Section 3.8, “Jumper Settings”.

Note: Remove the hardware setup for High-voltage Programming before starting a

debug session.

AVR STK500 User Guide 3-13

1925C–AVR–3/03

Hardware Description

3.7.2.2 Serial High-voltage Programming

The 8-pin AVRs have too few pins to use parallel communication during High-voltage

Programming. They use serial communication instead.

This means that fewer signals have to be routed. Hardware setup for serial High-voltage

Programming is as follows:

1. Switch power off.

2. Place the device to program in its socket according to Table 3-3 on page 3-11.

3. Mount jumper OSCSEL on pins 1 and 2 to select software-controlled clock.

4. Mount jumper XTAL1 to route the oscillator signal to the device.

5. Mount jumpers VTARGET and RESET.

6. Use one 2-wire cable to connect the PB3 pin (pin 4) on the PORTB header to the

XT1 pin (pin 7) on the PORTE/AUX header. This will connect the clock system to

the AVR device.

7. Use another 2-wire cable to connect the PB5 pin (pin 6) on the PORTB header to

the RST pin (pin 4) on the PORTE/AUX header. This will connect the reset system to the AVR device.

8. Use a third 2-wire cable to connect the PB0 and PB2 pins (pins 4 and 3) on the

SPROG1 header to the DATA0 and DATA2 pins (pins 1 and 3) on the PROG

DATA header.

9. Use the last 2-wire cable to connect the PB1 pin (pin 1) on the SPROG1 header

to the DATA1 pin (pin 2) on the PROG DATA header.

10. Switch power on and you are ready to program.

All connections are shown in Figure 3-19.

Figure 3-19. Connection for Serial High-voltage Programming

3-14 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

3.8 Jumper Settings A master microcontroller and the eight jumpers control the hardware settings of the

starter kit. During normal operation these jumpers should be mounted in the default

position. To configure the starter kit for advanced use, the jumpers can be removed or

set to new positions. The jumper settings and usage are explained in the following section. The default setting of the jumpers are shown in Figure 3-20.

Figure 3-20. Default Jumper Setting

VTARGET

AREF

RESET

XTAL1

OSCSEL

BSEL2

PJUMP

Table 3-4. Description of Jumpers

Jumper Description of Default Setting

VTARGET On-board VTARGET supply connected

AREF On-board Analog Voltage Reference connected

RESET On-board Reset System connected

XTAL1 On-board Clock System connected

OSCSEL On-board Oscillator selected

BSEL2 Unmounted. Used for High-voltage Programming of ATmega8,

ATmega16, ATmega161, ATmega163, ATmega128, and ATmega323

PJUMP Unmounted. Used for High-voltage Programming of AT90S2333,

AT90S4433, and ATmega8

AVR STK500 User Guide 3-15

1925C–AVR–3/03

Hardware Description

3.8.1 Target VCC Settings, VTARGET

VTARGET controls the supply voltage to the target AVR microcontroller sockets. It can

either be controlled from AVR Studio or supplied from an external source. If the VTARGET jumper is mounted, the on-board supply voltage is connected. The on-board

supply voltage can be adjusted to 0 - 6V from AVR Studio. Always verify the respective

datasheet for the AVR device operating voltage before adjusting VTARGET voltage.

Using the on-board supply voltage, approximately 0.5A can be delivered to the target

section. See “Appendix A” in Section 10.

If the VTARGET jumper is disconnected, target V

must be supplied from an external

CC

source at one of the VTG pins on the PORT headers. Figure 3-21 explains VTARGET

jumper options.

When using an external source for VTARGET, the user must control that VTARGET is

at a higher voltage level than AREF (analog reference voltage). Always connect common ground (GND) when using an external VTARGET voltage.

Figure 3-21. VTARGET Jumper Options

Jumper Mounted

VTARGET

AREF

On-board VTARGET supply connected (default)

Jumper not Mounted

VTARGET

AREF

On-board VTARGET supply disconnected

The STK500 master microcontroller controls the target voltage using the internal PWM.

Figure 3-22 shows the internal connection of the VTARGET signal.

Figure 3-22. VTARGET Connection

VTARGET

0 - 6V

Jumper

VTG NET

Green LED

Master

MCU

Rd

Wr

ADC

PWM

10 - 15V

VIN

Voltage

Regulator

Note: The green LED will light when there is a voltage available on the VTG NET. It’s

impossible to use the debug or programming area of STK500 without VTG.

3-16 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

The internal VTARGET has a short circuit protection. If VTARGET is set to be higher

than 0.3V and the master microcontroller measures it to be below 0.3V for a duration of

80 ms, the master microcontroller will shut off the VTARGET and the Internal AREF.

When this happens, the status LED will blink quickly.

If an external VTARGET is used and the external VTARGET is turned off, this will also

be detected by the STK500 as a (false) short circuit. The latter case can be avoided by

lowering the internal VTARGET below 0.3V.

3.8.2 Analog Reference Voltage, AREF

The analog reference voltage (AREF) can supply the reference voltage to the on-chip

A/D Converter on the AVR. If the AREF jumper is mounted, the on-board analog reference voltage is connected to the AVR’s AREF. The on-board analog reference voltage

can be adjusted from AVR Studio to 0 - 6.0V, but not above VTARGET.

When the AREF jumper is disconnected, AREF voltage must be supplied from an external source at the AREF pin on the PORTE/AUX header (Figure 3-6). Figure 3-23

explains AREF jumper options.

When using an external source for AREF, the user must control VTARGET at a higher

voltage level than AREF. This can be controlled easily by reading the VTG value from

AVR Studio before setting AREF.

Figure 3-23. AREF Jumper Options

Jumper Mounted

VTARGET

AREF

RESET

On-board AREF voltage connected (default)

Jumper not Mounted

VTARGET

AREF

RESET

On-board AREF voltage disconnected

The STK500 master microcontroller controls the analog reference voltage using the

internal PWM. The AVR’s AREF signal is also accessible on the PORTE header; this

pin can also be used for external AREF signal. Figure 3-24 shows the internal connection of the AREF signal.

AVR STK500 User Guide 3-17

1925C–AVR–3/03

Hardware Description

Figure 3-24. Internal AREF Connection

3.8.3 Reset Settings, RESET

AREF

Jumper

AREF

1 2

PE0

PE2

REF

XT1

GND

PORTE/AUX

PE1

RST

GND

XT2

VTG

Master

MCU

Rd

Wr

ADC

PWM

10 - 15V

VIN

Voltage

regulator

0 - 6V

The AVR Studio-controlled analog reference voltage can also be used as an input to the

analog comparator or for ADC measurements on the AVR. AVR’s AREF signal can then

be connected to VTG.

The internal AREF has a short circuit protection. If an AREF value is set up to be higher

than 0.3V and the master microcontroller measures it to be below 0.3V for a duration of

80 ms, the master microcontroller will shut off the AREF. When this happens, the status

LED will blink slowly.

The AREF will also be shut down by the master microcontroller if a short circuit is

detected on VTARGET (in addition to shutting down VTARGET). In this case, the status

LED will blink quickly.

The RESET jumper controls the RESET signal to the STK500. When ISP programming

the target device in the socket, the master microcontroller programs the AVR device

without interfering with the application. When the RESET jumper is mounted, the master

microcontroller controls the RESET signal of the AVR. When the RESET jumper is not

mounted, the RESET signal is disconnected. This is useful for prototype applications

with an external reset system.

The RESET jumper must always be mounted when High-voltage Programming an AVR

device. When using an external reset system, it must allow the reset line to be controlled

by the master microcontroller reset system during programming. The RESET button is

disconnected if the RESET jumper is not mounted. Figure 3-25 explains the RESET

jumper options.

3-18 AVR STK500 User Guide

1925C–AVR–3/03

Figure 3-25. RESET Jumper Options

Jumper Mounted

AREF

RESET

XTAL1

On-board RESET Signal Connected (default)

Jumper not Mounted

AREF

RESET

XTAL1

Hardware Description

On-board RESET Signal Disconnected

The STK500 master microcontroller controls the RESET signal to the target AVR. The

RESET signal is accessible on the PORTE/AUX header; this pin can also be used for

external RESET signal. Figure 3-26 shows the internal connection of the RESET signal.

Figure 3-26. Internal RESET Connection

Master

MCU

RESET

RESET

CIRCUIT

0V - VTG - 12V

1 2

PE0

PE2

REF

XT1

GND

RESET

RESET NET

Jumper

PE1

RST

GND

XT2

VTG

PORTE/AUX

Note: During High-voltage Programming, STK500 applies 12V to the AVR’s RESET

line. Thus, an external reset circuit not capable of handling this must be disconnected before High-voltage Programming the AVR.

AVR STK500 User Guide 3-19

1925C–AVR–3/03

Hardware Description

When connected to an external system, there is often an external pull-up resistor connected to the reset line. A typical reset connection is shown in Figure 3-27.

Figure 3-27. External Reset Connection

R (4.7 kohm)

RESET

C (10 nF)

If the external pull-up resistor is too low (<4.7 kΩ), STK500 will not be able to pull the

RESET line low.

3.8.4 Clock Settings, XTAL1 and OSCSEL

STK500 includes several clock options for the target AVR. Setting the jumpers XTAL1

and OSCSEL controls the clock selections. OSCSEL determines what signal to route to

the XTAL1 pin of the AVR.

When the XTAL1 jumper is connected, the STK500 internal clock system is used as

main clock to the target AVR. When XTAL1 jumper is not mounted, the internal clock

system is disconnected. This allows external clock signals or crystals to be used as target clock source for the AVR. Figure 3-28 illustrates the XTAL1 jumper option.

Figure 3-28. XTAL1 Jumper Options

Jumper Mounted

AREF

RESET

XTAL1

OSCSEL

On-board XTAL1 Signal Connected (Default)

Jumper not Mounted

AREF

RESET

XTAL1

OSCSEL

On-board XTAL1 Signal Disconnected

When the XTAL1 jumper is not mounted, an external clock source or crystal can be connected to the PORTE header. This is shown in Figure 3-30.

3-20 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

When the XTAL1 jumper is mounted, the STK500 internal clock system is used as main

clock to the target AVR. The internal clock system can either use a crystal in the

on-board crystal socket or a software-generated clock from the master microcontroller.

The frequency of the software-generated clock can be set from 0 to 3.68 MHz. The

default value is 3.68 MHz. Section 5.3.5.3 on page 5-7 explains how to set the clock frequency from AVR Studio.

When using the STK500 software-generated clock system as main clock, the target

AVR microcontroller fuses should be configured for “external clock” as clock source.

This gives shortest start-up time for the microcontroller. For details of start-up time, see

the datasheet for the AVR microcontroller. For an explanation of clock source fuses configuration, see Section 5.3.2 on page 5-3. Not all AVR devices have fuses for selection

between using a crystal or oscillator as clock source.

The internal clock system is selected with the OSCSEL jumper. Figure 3-29 shows the

jumper options for OSCSEL.

The on-board oscillator will work with ceramic resonators or crystals between

2 - 20 MHz (AT-cut, fundamental and parallel resonant crystals).

Figure 3-29. OSCSEL Jumper Options

Jumper mounted on pins 1 and 2

XTAL1

OSCSEL

On-board software clock signal connected (default)

Jumper mounted on pins 2 and 3

XTAL1

OSCSEL

On-board crystal signal connected

Jumper not mounted

XTAL1

OSCSEL

On-board XTAL1 signal disconnected

When programming AVR in High-voltage Programming mode, OSCSEL should be

mounted on pins 1 and 2 to give the master microcontroller control of the target clock.

This is explained in detail in Section 3.7.2 on page 3-11.

Note: In a real application with only one AVR connected to the crystal, there is no

need for an external oscillator circuit. The STK500 has eight different AVR

sockets connected to the same clock system. The long signal lines in this

system makes it difficult to drive a crystal with the On-chip Oscillators on the

AVR. The oscillator on STK500 is designed to operate on all target voltages

from 1.8 to 6.0V.

AVR STK500 User Guide 3-21

1925C–AVR–3/03

Hardware Description

Figure 3-30. XTAL1 and OSCSEL Connections

CRYSTAL

AVR

Studio

Oscillator

OSCSEL

3

2

1

Jumper

MASTER

MCU

VTG5V

Voltage

converter

XTAL1

Jumper

XTAL1 NET

PE0

PE2

REF

XT1

GND

1 2

PE1

RST

GND

XT2

VTG

PORTE

3.8.5 BSEL2 Jumper The BSEL2 jumper connects the Byte Select 2 signal for High-voltage Programming of

ATmega8, ATmega16, ATmega161, ATmega163, ATmega128, and ATmega323. The

BSEL2 jumper should only be mounted when High-voltage Programming ATmega16,

ATmega161, ATmega163, ATmega128, or ATmega323. When using ATmega8, connect the right BSEL2 pin to PC2 in the target area. See Figure 3-31. For descriptions of

the Byte Select 2 signal, see the programming section of the corresponding parts

datasheet.

Figure 3-31. BSEL2 Connection for ATmega8

Cable to PC2

BSEL2

PJUMP

3.8.6 PJUMP Jumpers The PJUMP jumpers route the programming pin of AT90S2333, AT90S4433, and

ATmega8 to the programming lines when using High-voltage Programming. The

PJUMP jumpers should only be mounted when using High-voltage Programming on

AT90S2333, AT90S4433, or ATmega8. During debugging, High-voltage Programming

of other parts and ISP programming, these jumpers should not be mounted.

Figure 3-32. PJUMP Jumpers Placement

Correct

Jumper

Placement

Not

Correct

3-22 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

3.9 Expansion Connectors

STK500 has two expansion connectors, one on each side of the programming module.

All AVR I/O ports, programming signals and control signals are routed to the expansion

connectors. The expansion connectors allow easy prototyping of applications

with STK500. The pinout of the expansion connectors is shown in Figure 3-34 and Figure 3-35.

Figure 3-33. Expansion Headers

Expansion Header 0

Pin 1

Prog Ctrl

Expansion Header 1

Pin 1

Prog Data

AVR STK500 User Guide 3-23

1925C–AVR–3/03

Hardware Description

Figure 3-34. Expansion Connector 0 Pinout

CT7

CT5

CT3

CT1

NC

RST

PE1

VTG

PC7

PC5

PC3

PC1

PA7

PA5

PA3

PA1

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

GND

AUXI0

GND

GND

Figure 3-35. Expansion Connector 1 Pinout

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

2

4

6

8

GND

AUXO0

CT6

CT4

CT2

BSEL2

REF

PE2

PE0

GND

VTG

PC6

PC4

PC2

PC0

PA6

PA4

PA2

PA0

GND

GND

AUXI1

DATA7

DATA5

DATA3

DATA1

SCK

XT1

VTG

GND

PB7

PB5

PB3

PB1

PD7

PD5

PD3

PD1

GND

1

3

5

7

9

11

13

SI

15

17

19

21

23

25

27

29

31

33

35

37

39

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

2

4

6

8

GND

AUXO1

DATA6

DATA4

DATA2

DATA0

SO

CS

XT2

VTG

GND

PB6

PB4

PB2

PB0

PD6

PD4

PD2

PD0

GND

3-24 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

3.9.1 Signal Descriptions The signals AUXI1, AUXI0, AUXO1, and AUXO0 are intended for future use. Do not connect these signals to your application.

The DATA[7:0] and CT[7:1] signals are also found on the Prog Data and Prog Ctrl connectors. These signals and connectors are explained in Section 3.10 on page 3-25.

The BSEL2 signal is the same as that found on the BSEL2 jumper. This jumper is

explained in Section 3.8.5 on page 3-22.

3.10 Prog Ctrl and

Prog Data

Headers

The SI, SO, SCK, and CS

signals are connected to the DataFlash. Use of the DataFlash

is described in Section 3.6 on page 3-6.

NC means that this pin is not connected.

The remaining signals are equal to those found on the PORT connectors, explained in

Section 3.4 on page 3-3.

Note: DATA, CT, and AUX signals are based on 5V CMOS logic. No voltage conver-

sion to adapt to VTG is done on these signals.

The Prog Ctrl and Prog Data headers are used for High-voltage Programming of the target AVR device. The placement of the headers is shown in Figure 3-33. During parallel

High-voltage Programming, the Prog Ctrl signals are routed to PORTD of the target

device. The Prog Data signals are routed to PORTB. See Section 3.7.2 on page 3-11 for

a complete description of High-voltage Programming. The pinouts of the Prog Ctrl and

Prog Data headers are shown in Figure 3-36 and Figure 3-37. For more information

about High-voltage Programming of AVR devices, see the programming section of each

AVR datasheet.

Note: Prog Ctrl and Data connectors are connected directly to the master microcon-

troller without level converters. This means that these signals are always 5V

logic.

Figure 3-36. Prog Ctrl Header Pinout

1 2

NC

(OE)CT2

(BS1)CT4

(XA1)CT6

GND

CT1(RDY/BSY)

CT3(/WR)

CT5(XA0)

CT7(PAGEL)

NC

The Prog Ctrl signals are normally used for the control signals when parallel Highvoltage Programming an AVR device.

Note: All Prog Ctrl signals are based on 5V CMOS logic. No voltage conversion to

adapt to VTG is done on these signals.

AVR STK500 User Guide 3-25

1925C–AVR–3/03

Hardware Description

Figure 3-37. Prog Data Header Pinout

1 2

DATA0

DATA2

DATA4

DATA6

GND

DATA1

DATA3

DATA5

DATA7

NC

The Prog Data signals are used for the data bus when parallel High-voltage Programming an AVR device. During ISP programming, DATA5 is used as MOSI, DATA6 is

used as MISO, and DATA7 is used for SCK.

Note: All Prog Data signals are based on 5V CMOS logic. No voltage conversion to

adapt to VTG is done on these signals.

3.11 Miscellaneous STK500 has 2 push buttons and 3 LEDs for special functions and status indication. The

following section explains these features. Figure 3-38 shows the placement of these

functions.

Figure 3-38. Special Functions and Status Indication LEDs

Target Power LED

RESET Push Button

Main Power LED

Status LED

Program Push Button

3.11.1 RESET Push Button The RESET push button resets the target AVR device when pushed. The master microcontroller is not controlled by the RESET push button. When the RESET jumper is not

mounted, the RESET push button is disabled.

3-26 AVR STK500 User Guide

1925C–AVR–3/03

Hardware Description

3.11.2 PROGRAM Push

Button

Future versions of AVR Studio may upgrade the master microcontroller on STK500.

AVR Studio will then detect old software versions of STK500 and update the Flash program memory of the master microcontroller. To do this, the user is required to push the

PROGRAM button when powering on STK500. AVR Studio issues instructions on how

to perform the upgrade during the upgrade process.

3.11.3 Main Power LED The red power LED is directly connected to the STK500 main power supply. The power LED is always lit when power is applied to STK500.

3.11.4 Target Power LED The target power LED is connected to VCC lines (VTG) on the target AVR devices in the sockets. The target power LED is lit when power is applied to the target AVR device.

3.11.5 Status LED The PROGRAM LED is a 3-color LED. During programming, the LED is yellow. When the target AVR device is successfully programmed, the LED will turn green. If programming fails, the LED will turn red to indicate that programming failed. When programming fails, check the troubleshooting guide in Section 7 on page 7-1. During start-up, the status LED will shift from red, through yellow, to green to indicate that the master microcontroller is ready.

AVR STK500 User Guide 3-27

1925C–AVR–3/03

Hardware Description

3-28 AVR STK500 User Guide

1925C–AVR–3/03

Section 4

Installing AVR Studio

AVR Studio, with its Integrated Development Environment (IDE), is the ideal software

for all AVR development. It has an editor, an assembler and a debugger and is front-end

for all AVR emulators and the STK500 starter kit.

To install AVR Studio, insert the supplied Atmel CD-ROM databook in the computer and

navigate to “Products → AVR 8-bit RISC → Software”. Right-click with the mouse on the

“AVRstudio.exe” file and select “save link as”. Select an empty directory and save the

file.

Execute the “AVRstudio.exe” file; this is a self-extracting file that will extract all required

files to the current directory. Execute the “Setup.exe” file; this will guide you through the

setup process.

Note: AVR Studio, version 3.2 or higher, is required for STK500 support.

AVR STK500 User Guide 4-1

Rev. 1925C–AVR–3/03

Installing AVR Studio

4-2 AVR STK500 User Guide

1925C–AVR–3/03

Section 5

Using AVR Studio

5.1 Windows

Software

5.2 Starting the

Windows Software

5.2.1 Starting STK500 Pressing the “AVR” button on the AVR Studio toolbar will start the STK500 user inter-

In this section, the supporting software for STK500 will be presented and an in-depth

description of the available programming options is given.

The software used for communicating with the STK500 development board is included

in AVR Studio, version 3.2 and higher. For information on how to install this software,

please see Section 4 on page 4-1. Once installed, AVR Studio can be started by doubleclicking on the AVR Studio icon. If default install options are used, the program is

located in the Windows “Start menu → Programs → Atmel AVR Tools” folder.

face as shown in Figure 5-1.

Figure 5-1. AVR Studio with STK500 User Interface

AVR STK500 User Guide 5-1

Rev. 1925C–AVR–3/03

Using AVR Studio

5.3 STK500 User

Interface

The STK500 user interface includes powerful features for the STK500 development

board. The available settings are divided into six groups, each selectable by clicking

on the appropriate tab. Since different devices have different features, the available

options and selections will depend on which device is selected. Unavailable features are

grayed out.

5.3.1 “Program” Settings The program settings are divided into four different subgroups.

5.3.1.1 Device A device is selected by selecting the correct device from the pull-down menu. This

group also includes a button that performs a chip erase on the selected device, erasing

both the Flash and EEPROM memories.

5.3.1.2 Programming Mode This group selects programming mode. For devices only supporting High-voltage Programming, the ISP option will be grayed out. If both modes are available, select a mode by clicking on the correct method. Checking “Erase Device Before Programming” will force STK500 to perform a chip erase before programming code to the program memory (Flash). Checking “Verify Device After Programming” will force STK500 to perform a verification of the memory after programming it (both Flash and EEPROM).

5.3.1.3 Flash If the STK500 user interface is opened without a project loaded in AVR Studio, the “Use Current Simulator/Emulator FLASH Memory” option will be grayed out. When a project is open, this option allows programming of the Flash memory content currently present in the Flash Memory view of AVR Studio. For more information about AVR Studio memory views, please take a look in the AVR Studio Help file.

If no project is running, or the source code is stored in a separate hex file, select the

“Input HEX File” option. Browse to the correct file by pressing the button or type the

complete path and filename in the text field. The selected file must be in “Intel-hex” format or “extended Intel-hex” format.

Figure 5-2. Program

5-2 AVR STK500 User Guide

1925C–AVR–3/03

Using AVR Studio

5.3.1.4 EEPROM If the STK500 user interface is opened without a project loaded in AVR Studio, the “Use Current Simulator/Emulator EEPROM Memory” option will be grayed out. When a project is open, this option allows programming of the EEPROM memory content currently present in the EEPROM Memory view. For more information about AVR Studio memory views, please take a look in the AVR Studio Help file.

If no project is running, or the source code is stored in a separate hex file, select the

“Input HEX File” option. Browse to the correct file by pressing the button or type the

complete path and filename in the text field. The selected file must be in “Intel-hex” format or “extended Intel-hex” format.

5.3.2 “Fuses” Settings In the “Fuses” tab an overview of accessible fuses are presented. Some fuses are only available during High-voltage Programming. These will be displayed but not accessible if operating in ISP programming mode. Press the “Read” button to read the current value of the fuses, and the “Write” button to write the current fuse setting to the device. Checking one of these check boxes indicates that this fuse should be enabled/programmed, which means writing a “0” to the fuse location in the actual device. Note that the selected fuse setting is not affected by erasing the device with a chip-erase cycle (i.e., pressing “Chip Erase” button in the “Program” settings).

Detailed information on what fuses are available in the different programming modes

and their functions can be found in the appropriate device datasheet.

Figure 5-3. Fuses

AVR STK500 User Guide 5-3

1925C–AVR–3/03

Using AVR Studio

5.3.3 “LockBits” Settings Similar to the “Fuses” tab, the “LockBits” tab shows which lock modes are applicable to the selected device. All lock bits are accessible in both ISP and High-voltage Programming. A lock mode may consist of a combination of setting multiple Lock bits. This is handled by the STK500 user interface, and the correct lock bits are programmed automatically for the selected lock mode. Once a Lock mode protection level is enabled, it is not possible to lower the protection level by selecting a “lower” degree of protection or by setting a different Lock mode. The only way to remove a programmed Lock bit is to perform a complete chip erase, erasing both program and data memories. One exception exists: If the target device has a programmed “EESAVE” fuse, the contents of the EEPROM will be saved even though a complete chip erase on the device is performed.

Figure 5-4. LockBits

5.3.4 “Advanced”

The “Advanced” tab is currently divided into two subgroups.

Settings

5.3.4.1 Signature Bytes By pressing the “Read Signature” button, the signature bytes are read from the target

device. The signature bytes act like an identifier for the part. After reading the signature,

the software will check if it is the correct signature according to the chosen device.

Please refer to the AVR datasheets to read more about signature bytes.

5-4 AVR STK500 User Guide

1925C–AVR–3/03

Figure 5-5. Advanced

Using AVR Studio

5.3.4.2 Oscillator

Calibration Byte

The oscillator calibration byte is written to the device during manufacturing, and cannot

be erased or altered by the user. The calibration byte is a tuning value that should be

written to the OSCCAL register in order to tune the internal RC oscillator.

5.3.4.3 Reading Oscillator

Calibration Byte

By pressing the “Read Cal. Byte” button, the calibration value is read from the device

and is shown in the “Value” text box. Note that the calibration byte is not directly accessible during program execution and must be written to a memory location during

programming if it shall be used by the program. If this option is grayed out, the selected

device does not have a tunable internal RC oscillator.

5.3.4.4 Writing Oscillator

Calibration Byte

Since the calibration byte is not directly accessible during program execution, the user

should write the calibration byte into a known location in Flash or EEPROM memory. Do

this by writing the desired memory address in the “Write Address” text box and then

press the “Write to Memory” button. The calibration byte is then written to the memory

indicated by the “Flash” and “Eeprom” radio buttons.

5.3.5 “Board” Settings The “Board” tab allows the changing of operating conditions on the STK500 development board. The following properties can be modified: VTARGET, AREF and oscillator frequency.

The interface is very flexible and it is possible to force the operating conditions beyond

the recommended specifications for the device. Doing this is not recommended, and

may damage the target device. The recommended operating conditions for the part are

stated in the device datasheet.

AVR STK500 User Guide 5-5

1925C–AVR–3/03

Using AVR Studio

Figure 5-6. Board

5.3.5.1 VTARGET VTARGET controls the operating voltage for the target board. Through the use of the slide bar or the text box, this voltage can be regulated between 0 and 6.0V in 0.1V increments. Please refer to the device datasheet to find the specified voltage range for the selected device. Both voltages are read by pressing the “Read Voltages” button, and written by pressing the “Write Voltages” button.

The physical connection of the VTARGET voltage is shown in Figure 3-22 on page 3-16.

5.3.5.2 AREF AREF controls the analog reference voltage for the ADC converter. This setting only apply to devices with AD converter. Through the use of the slide bar or the text box, this voltage can be regulated between 0 and 6.0V in 0.1V increments. Please refer to the device datasheet to find the valid voltage range for the selected device. Both VTARGET and AREF are read by pressing the “Read Voltages” button, and written by pressing the “Write Voltages” button.

It is not possible to set AREF to a higher voltage than VTARGET because this will permanently damage the AVR.

The physical connection of the AREF voltage is shown in Figure 3-24 on page 3-18.

5-6 AVR STK500 User Guide

1925C–AVR–3/03

Using AVR Studio

5.3.5.3 Oscillator The STK500 development board uses a programmable oscillator circuit that offers a wide range of frequencies for the target device.

Since it is not possible to generate an unlimited number of frequencies, the STK500

user interface will calculate the value closest to the value written to the oscillator text

box. The calculated value is then presented in the oscillator text box, overwriting the

previously written number.

5.3.6 “Auto” Settings When programming multiple devices with the same code, the “Auto” tab offers a powerful method of automatically going through a user-defined sequence of commands. The commands are listed in the order they are executed (if selected). To enable a command, the appropriate check box should be checked. For example, if only “Program FLASH” is checked when the “Start” button is pressed, the Flash memory will be programmed with the hex file specified in the “Program” settings. All commands depend on and use the settings given in the STK500 user interface.

Figure 5-7. Auto

It is possible to log the command execution to a text file by checking the “Log to file”

check box.

AVR STK500 User Guide 5-7

1925C–AVR–3/03

Using AVR Studio

5.3.6.1 Setting Up the

System for

Auto-programming

Click on the check boxes for the commands that you want the STK500 user interface to

perform. A typical sequence where the device is erased and then programmed is shown

in Figure 5-7. The chip is erased, both memories programmed and verified, and finally,

fuses and lock bits are programmed.

Once configured, the same programming sequence is executed every time the “Start”

button is pressed. This reduces both work and possibilities for errors due to operational

errors.

5.3.6.2 Logging the

Auto-programming

to a File

By clicking on the “Log to file” check box, all output from the commands are written to a

text file. Select or create the file by pressing the “Browse” button and navigate to the

location where the file is placed or should be created. The output is directed to this file,

and can be viewed and edited using a text editor.

5.3.7 History Window The History window is located at the bottom of the STK500 view. In this window the dialog between AVR Studio and STK500 is shown. For every new command performed,

the old dialog is replaced with the new one.

Figure 5-8. History Window

5-8 AVR STK500 User Guide

1925C–AVR–3/03

Using AVR Studio

5.4 Command Line

Software

The DOS command line version of the STK500 software is useful for programming

STK500 from external editors or for use in production programmers. Simple batch files

can be made for automatic programming. Type “STK500 -?” for help.

The program returns ERRORCODE 0 if the operation was successful, and ERRORCODE 1 if the operation failed.

Command Line Switches:

[-d device name] [-m s|p] [-if infile] [-ie infile] [-of outfile]

[-oe outfile] [-s] [-O] [-Sf addr] [-Seaddr] [-e] [-p f|e|b]

[-r f|e|b] [-v f|e|b] [-l value] [-L value] [-y] [-f value] [-E value]

[-F value] [-G value] [-q] [-x value] [-af start,stop] [-ae start,stop]

[-c port] [-ut value] [-ua value] [-wt] [-wa] [-b h|s] [-! freq] [-t]

[-g] [-z] [-h|?]

5.5 Parameters d Device name. Must be applied when programming the device. See list below.

m Select programming mode; serial (s) or parallel/High-voltage (p).

Serial programming mode is the default, and is used if this parameter not

applied.

if Name of FLASH input file. Required for programming or verification of the FLASH

memory. The file format is Intel Extended HEX.

ie Name of EEPROM input file. Required for programming or verification of the

EEPROM memory. The file format is Intel Extended HEX.

of Name of flash output file. Required for readout of the FLASH memory. The file

format is Intel Extended HEX.

oe Name of EEPROM output file. Required for readout of the EEPROM memory. The

file format is Intel Extended HEX.

s Read signature bytes.

O Read oscillator calibration byte.

Sf Write oscillator call. byte to FLASH memory. “addr” is byte address

Se Write oscillator call. byte to EEPROM memory. “addr” is byte address

e Erase device. If applied with another programming parameter, the device will be

erased before any other programming takes place.

p Program device; FLASH (f), EEPROM (e) or both (b). Corresponding input files

are required.

r Read out device; FLASH (f), EEPROM (e) or both (b). Corresponding output files

are required

v Verify device; FLASH (f), EEPROM (e) or both (b). Can be used with -p or stand

alone. Corresponding input files are required.

l Set lock byte. “value' is an 8-bit hex. value.

L Verify lock byte. “value” is an 8-bit hex. value to verify against.

y Read back lock byte.

AVR STK500 User Guide 5-9

1925C–AVR–3/03

Using AVR Studio

f Set fuse bytes. “value” is a 16-bit hex. value describing the settings for the upper

and lower fuse.

E Set extended fuse byte. “value” is an 8-bit hex. value describing the extend fuse

settings.

F Verify fuse bytes. “value” is a 16-bit hex. value to verify against.

G Verify extended fuse byte. “value” is an 8-bit hex. value describing the extend fuse

settings.

q Read back fuse bytes.

x Fill unspecified locations with a value (0x00-0xff). The default is to not program

locations not specified in the input files.

af FLASH address range. Specifies the address range of operations. The default is

the entire FLASH. Byte addresses.

ae EEPROM address range. Specifies the address range of operations. The default

is the entire EEPROM. Byte addresses.

c Select communication port; “com1” to “com8”. If this parameter is omitted the

program will scan the comm. ports for the STK500

ut Set target voltage VTARGET in Volts. “value” is a floating point value between 0.0

and 6.0, describing the new voltage.

ua Set adjustable voltage AREF in Volts. “value” is a floating point value between 0.0

and 6.0, describing the new voltage.

wt Get current target voltage VTARGET.

wa Get current adjustable voltage AREF.

b Get revisions; hardware revision (h) and software revision (s).

! Set oscillator frequency; “freq” is the frequency in Hz.

t Get oscillator frequency.

g Silent operation.

z No progress indicator. For example, if piping to a file for log purposes, use this

option to avoid the non-ascii characters used for the indicator.

h|? Help information (overrides all other settings)

Figure 5-9. Sample Usage

Erase before Program

stk500 -dAT90S8515 -ms -e -pf -vf -iftest.hex

Select Device Number

Serial Programming Mode

Program Flash

Name of hex File

Verify Device

5-10 AVR STK500 User Guide

1925C–AVR–3/03

Section 6

In-System Programming of an

External Target System

The STK500 can be used as a programmer to program AVR devices in other applications. There are two different ISP connector pinouts available: a 6-pin and a 10-pin

version. Both are supported by STK500.

Figure 6-1. 6-pin ISP Connector Pinout

1 2

MISO

SCK

RST

ISP6PIN

Figure 6-2. 10-pin ISP Connector Pinout

VTG

MOSI

GND

1 2

MOSI

NC

RST

SCK

MISO

VTG

GND

GND

GND

GND

ISP10PIN

Select the device to be programmed in the same way as programming a device on the

STK500. The V

verted into voltage levels suitable for the target system.

Note: If the other application has its own power supply to VTG, the jumper VTARGET

must be removed before connecting STK500 to the other application. STK500

may be damaged if the VTARGET jumper is not removed.

AVR STK500 User Guide 6-1

of the target application is detected by STK500 and signals are con-

CC

Rev. 1925C–AVR–3/03

In-System Programming of an External Target System

6-2 AVR STK500 User Guide

1925C–AVR–3/03

Troubleshooting Guide

Table 7-1. Troubleshooting Guide

Problem Reason Solution

Section 7

The red power LED is not on. The DC power cable is not

connected.

Wrong power supply is used. Check that the power supply

The power switch is off. Turn on the power switch.

The preprogrammed

example code does not

toggle the LEDs.

The AVR device cannot be

programmed.

There is no AVR device in the

socket.

The LEDs are not connected

to the I/O ports.

The Flash memory is erased. Connect STK500 to a PC

The PC serial cable is not

connected.

The AVR device is inserted in

wrong socket.

The AVR device is inserted

with wrong orientation.

Connect the DC power cable

to the DC jack (page 2-3).

is of DC type 10 - 15V, min.

500 mA (page 2-3).

Plug the AVR device into the

right socket (page 2-3).

Connect the LEDS header to

the PORTD header, and the

SWITCHES header to the

PORTB header (page 3-3).

and reprogram the AVR

device (page 2-3).

Connect the serial cable to

the PC COM port and the

RS232 PROG port.

Check that the correct socket

is used (page 3-10).

Check that the notch on the

AVR socket matches the

notch on the AVR device.

The target ISP header is not

connected.

The jumpers settings are

wrong.

The memory lock bits are

programmed.

AVR STK500 User Guide 7-1

Connect the 6-pin flexible

cable from ISP6PIN header

to the correct SPROG target

ISP header (page 3-10).

Set jumper to default setup

(page 3-15).

Erase the memory before

programming.

Rev. 1925C–AVR–3/03

Troubleshooting Guide

Table 7-1. Troubleshooting Guide (Continued)

Problem Reason Solution

The AVR device cannot be

programmed (continued).

AVR Studio does not detect

STK500.

STK500 cannot be switched

off.

The status LED is blinking

slowly

The status LED is blinking

quickly.

Reset disable fuse is set. Check reset disable fuse.

Programming too fast Check oscillator settings and

make sure it is not set higher

than actual clock.

External pull-up resistor on

reset line too low.

Serial cable is not connected,

or power is off.

Ensure that external pull-up

resistor is ≥ 4.7 kΩ.

Connect serial cable to

RS232 PROG and check

power connections.

PC COM port is in use. Disable other programs that

are using PC COM port.

Change PC COM port.

AVR Studio does not detect

COM port.

Disable COM port autodetection in AVR Studio file

menu. Force COM por t to

correct COM port.

Positive center power

connector is used.

Use negative center power

connector.

Turn off STK500 by removing

power connector.

There is a short circuit on

Resolve the short circuit.

AREF

There is a short circuit on

Resolve the short circuit.

VTARGET.

The LEDs don’t work

(running from external

VTARGET).

An external VTARGET is

being used and has been

turned off.

STK500 must be powered for

LEDs to work.

Set VTARGET to a value

below 0.3V in AVR Studio.

Supply poser to STK500 and

turn it on.

7-2 AVR STK500 User Guide

1925C–AVR–3/03

Section 8

Technical Support

For technical support, please contact avr@atmel.com. When requesting technical sup-

port for STK500, please include the following information:

n Version number of AVR Studio. This can be found in the AVR Studio menu,

“Help → About”.

n PC processor type and speed

n PC operating system and version

n What target AVR device is used (complete part number)

n Programming voltage

n Jumper settings

n A detailed description of the problem

AVR STK500 User Guide 8-1

Rev. 1925C–AVR–3/03

Technical Support

8-2 AVR STK500 User Guide

1925C–AVR–3/03

Section 9

Example Applications

9.1 Using LEDs and Switches

Connect PORTB to LEDS and PORTD to SWITCHES.

LEDs will operate differently depending on what switch is pressed.

Tip: Copy the code from this document into AVR Studio.

;***** STK500 LEDS and SWITCH demonstration

.include “8515def.inc”

.def Temp =r16 ; Temporary register